Patents

Literature

1284results about How to "Improve project quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

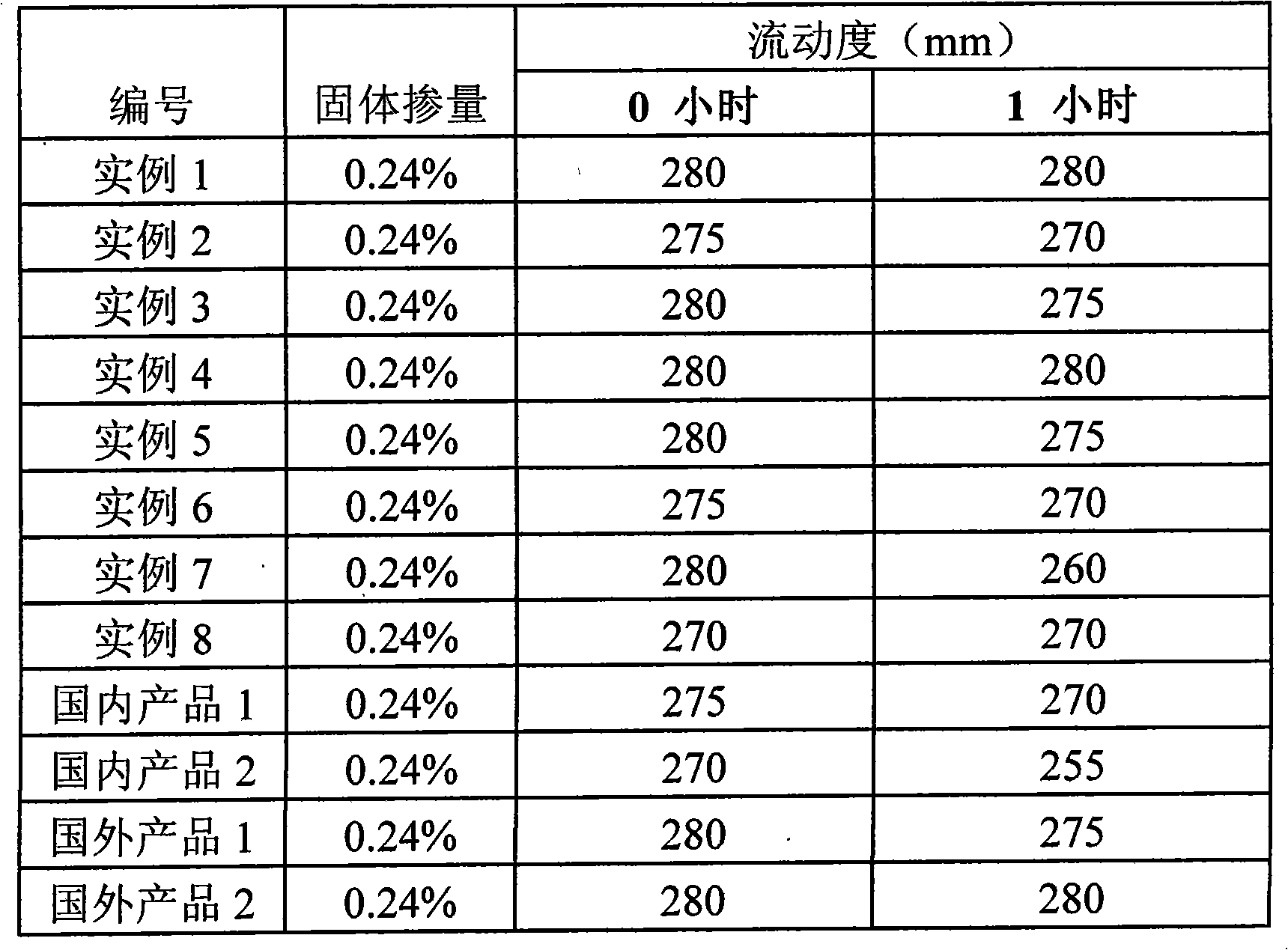

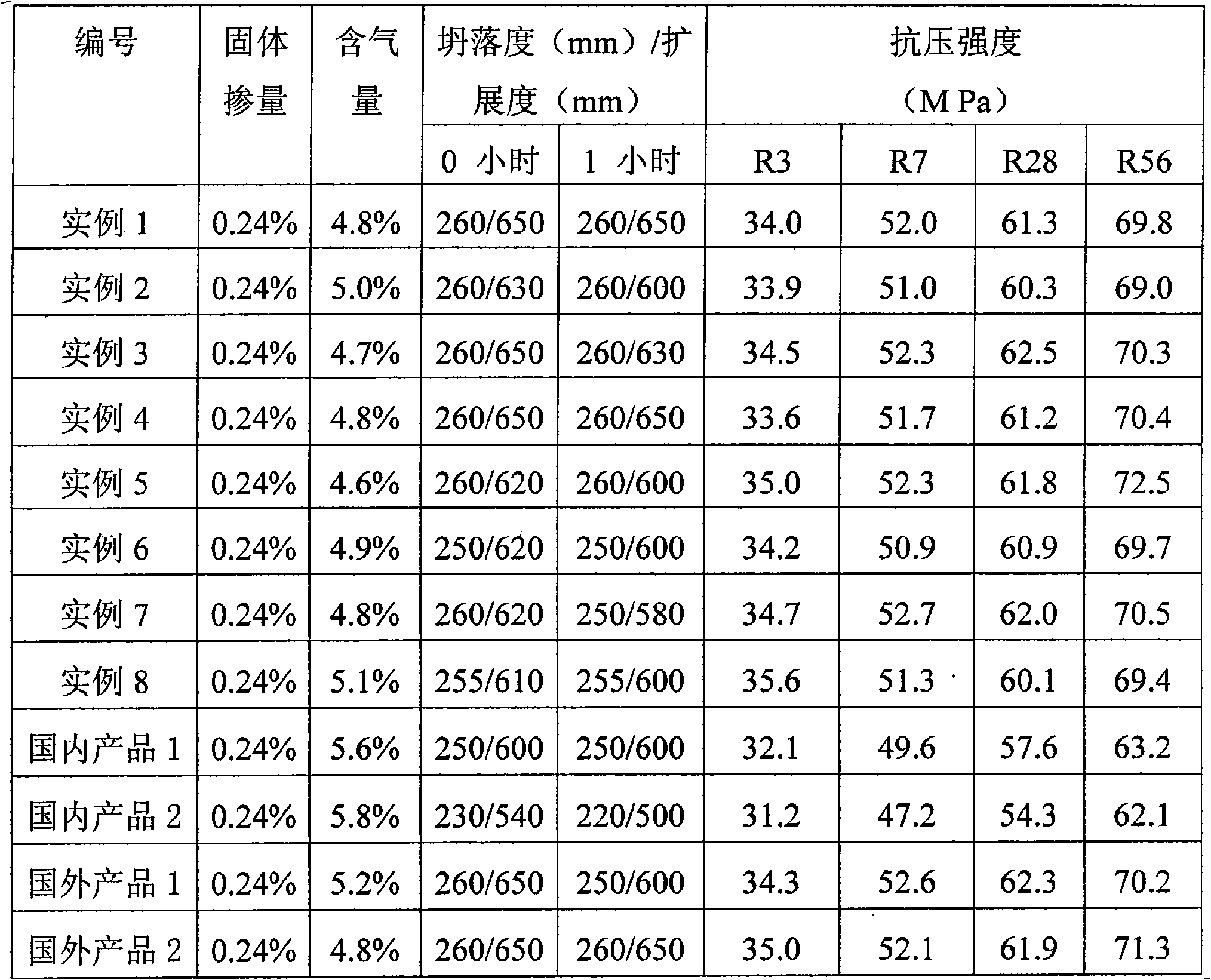

Polyether class polycarboxylic acid high-efficiency water reducing agent and preparation method thereof

The invention relates to a polyether class polycarboxylic acid high-efficiency water reducing agent and a preparation method thereof, belonging to the field of concrete materials, structures and engineering of building materials. The polyether class polycarboxylic acid high-efficiency water reducing agent raises the temperature of water solutions of 15-55 mass percent of allyl polyethenoxy ether and 0-6 mass percent of chain transfer agent is raised to 50-90 DEG C, one side is dropwise added with a water solution of 0.01-0.9 mass percent of an evocating agent, one side is dripwise added with miscible liquids of 3-15 mass percent of unsaturated acids and one or more than one derivative thereof, the temperature is kept unchanged, and the water solution and the miscible liquids are completely dropped within 2-6 hours, the temperature is preserved for 1-6 hours and naturally cooled to room temperature, and the mixed solution is neutralized by sig water till a PH value reaches 6.8-7.2 so as to obtain the polyether class polycarboxylic acid high-efficiency water reducing agent. The polyether class polycarboxylic acid high-efficiency water reducing agent and the preparation method thereof have simple technique, low cost and good property, can effectively reduce the water-cement ratio of concrete, improves the compaction rate of a pore structure of the concrete, enhances the strength and the durability of the concrete and has great significance on enhancing the engineering quality, prolonging the service life, reducing the engineering cost, reducing the environment pollution, and the like.

Owner:大连华健科技有限公司

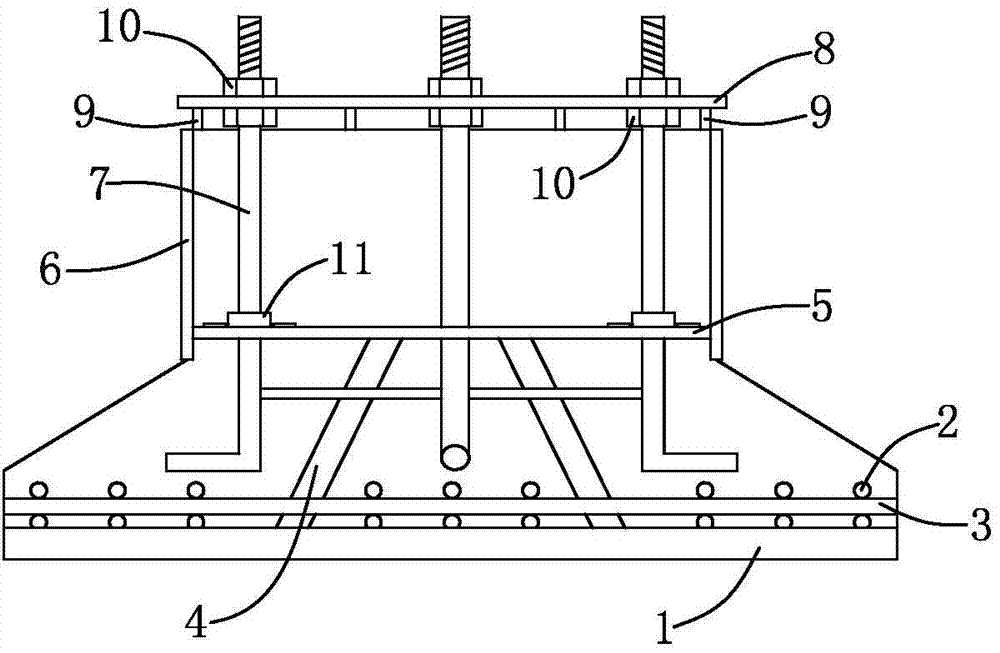

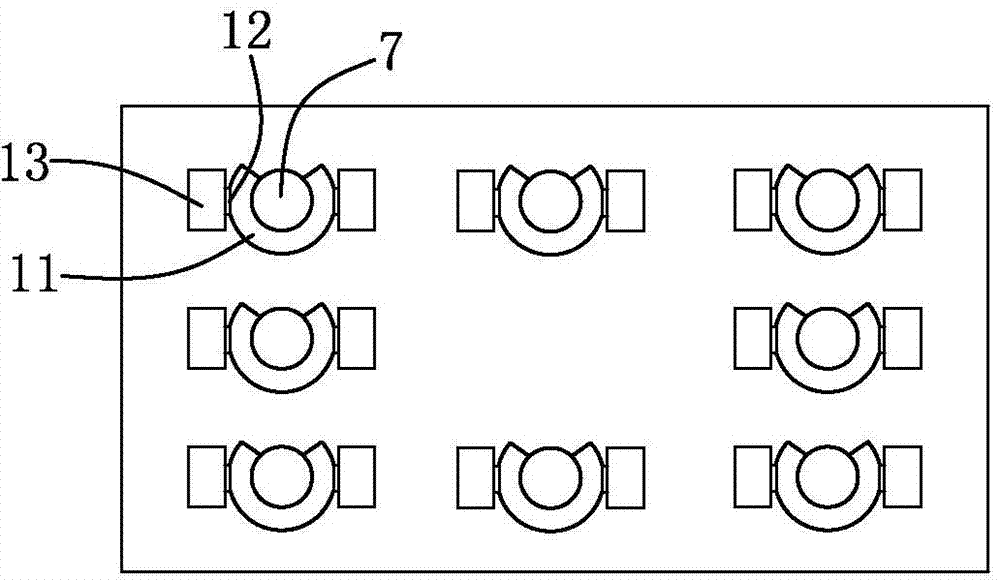

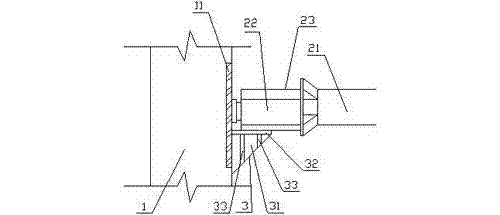

Pre-buried construction method for high-precision foundation bolts

The invention discloses a pre-buried construction method for high-precision foundation bolts. The method includes the following steps that (a), construction preparation is performed; (b), a control net is established; (c), a positioning clamp and a positioning control plate are manufactured; (d), foundation steel bars are buried in advance; (e), the positioning clamp is installed; (f), the foundation bolts are installed; (g), the foundation bolts are reinforced and protected; (h), concrete pouring is performed; (i), the clamp is dismantled; (j) acceptance inspection and handover are performed to finish the pre-buried construction. The manufactured high-precision positioning clamp is adopted for performing clustering control over the pre-buried foundation bolts of each set of equipment foundations, elastic clamping tools are arranged on the outer sides of the foundation bolts, supporting legs of the elastic clamping tools are embedded into clamping holes in the positioning clamp, and the elastic clamping tools are clamped on the positioning clamp of the foundation bolts, so that the foundation bolts are further reinforced and prevented from loosening. The pre-buried construction method has the effects of being reliable in technology, high in construction precision, easy to understand and master and convenient to operate, and meanwhile is short in construction period and low in cost.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

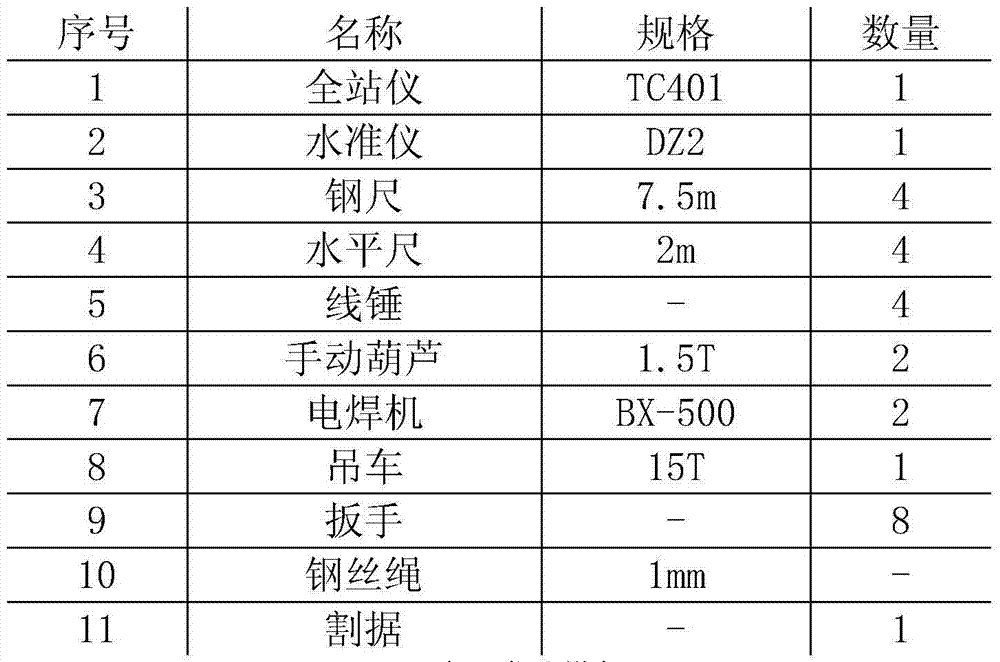

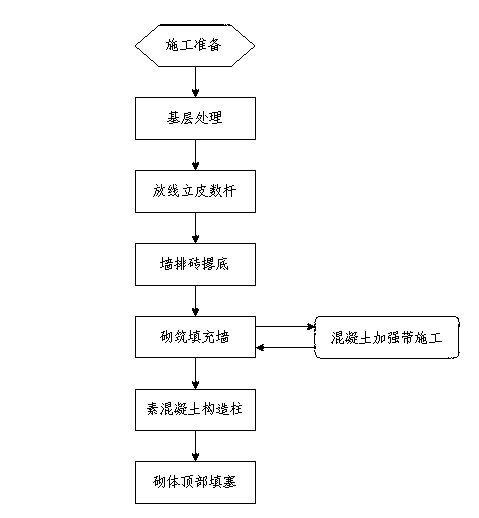

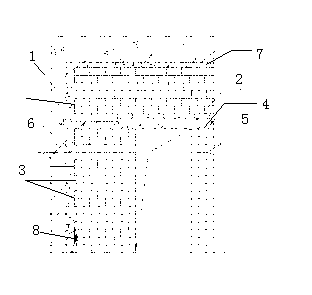

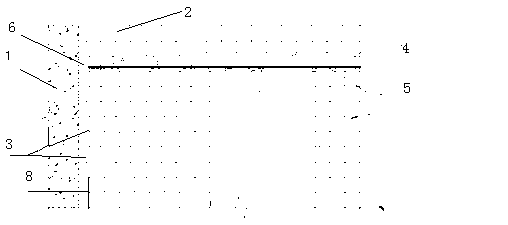

Construction method for preventing and treating cracks between concrete structure and filler wall

The invention discloses a construction method for preventing and treating cracks between a concrete structure and a filler wall. The construction method particularly comprises the following operation steps of step one, preparing construction; step two, treating a basic layer; step three, conducting paying off wire and setting up height pole; step four, conducting brick laying and putting down the bottom row of bricks; step five, masoning the filler wall; step six, constructing plain concrete constructional columns; step seven, filling the top of masonry. The construction method for preventing and treating the cracks between the concrete structure and the filler wall has the advantages of being wide in application range, and applicable to masonry construction of the filler wall with hollow bricks, autoclaved aerated concrete blocks and the like of the industrial and civil construction concrete structure; when the method compared with traditional processes, being capable of saving cost due to the fact that the main difference in procedure is that the plain concrete constructional columns, concrete reinforcing bands, wall crown filled with hard concrete and other portions replace the masonry; fundamentally solving the problem that cracks of a plaster layer and a coating layer caused by the cracks of the contact surface of the concrete structure and the filler wall, improving a project impression level and project quality, eradicating leakage risks of outer wall surfaces, reducing reworking cost and maintenance cost, saving materials, reducing production of construction waste, lowering a complaint rate of users, and being capable of setting up a corporate image in society and considerable in social benefit.

Owner:CHINA AEROSPACE CONSTR GROUP +1

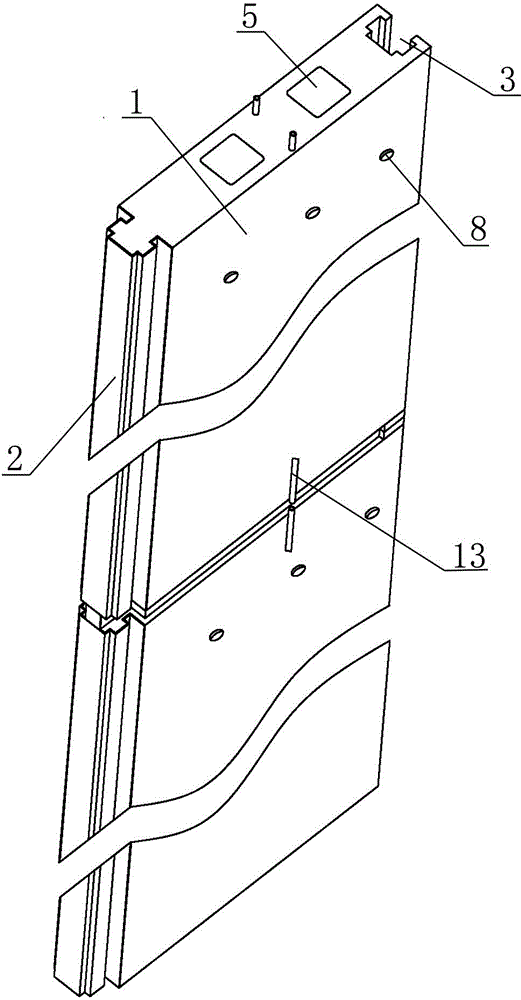

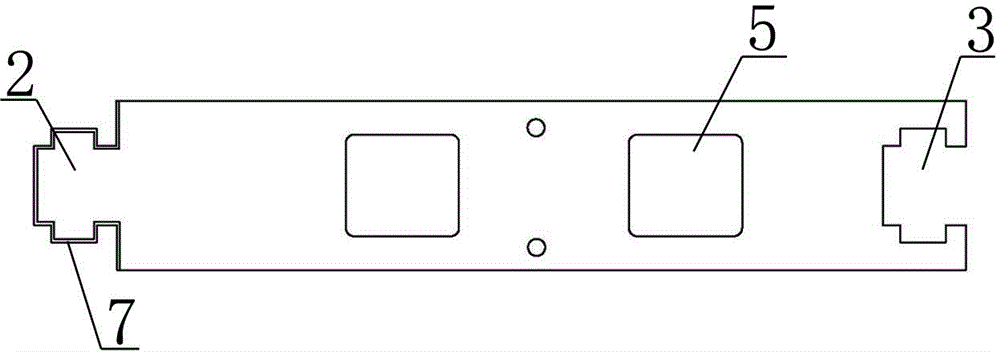

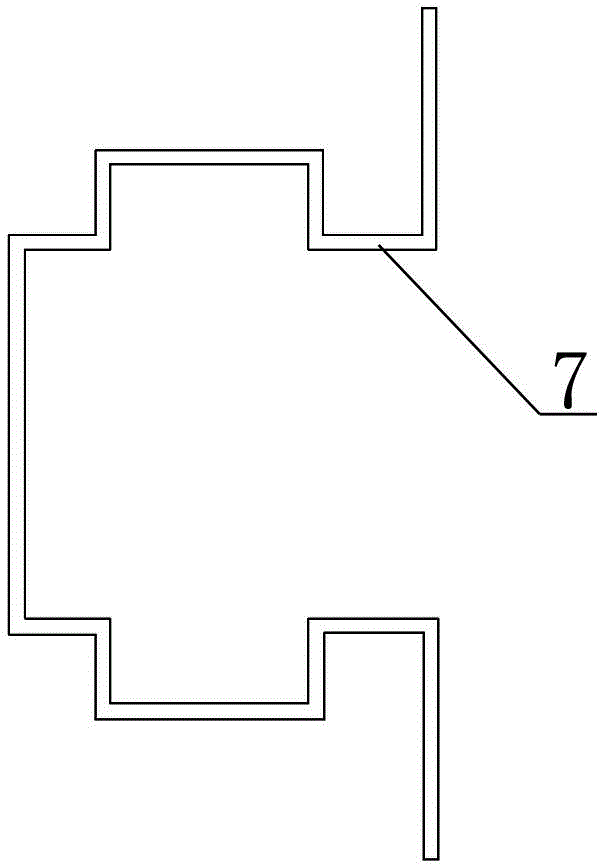

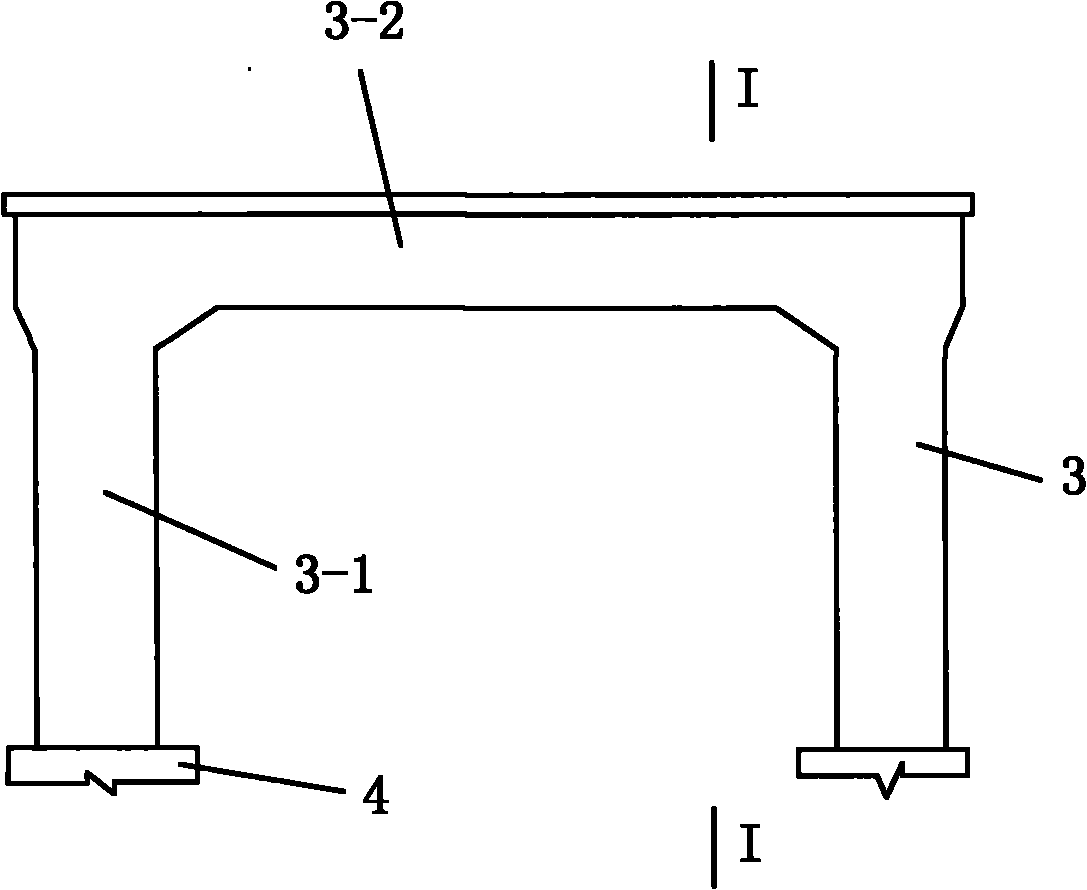

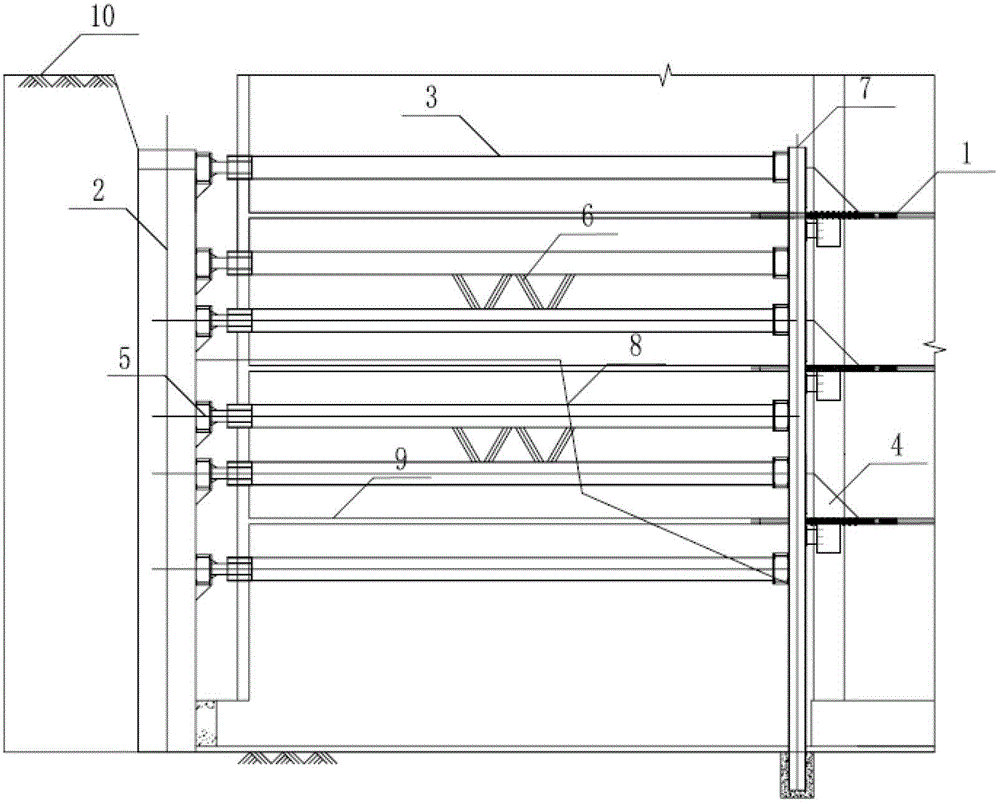

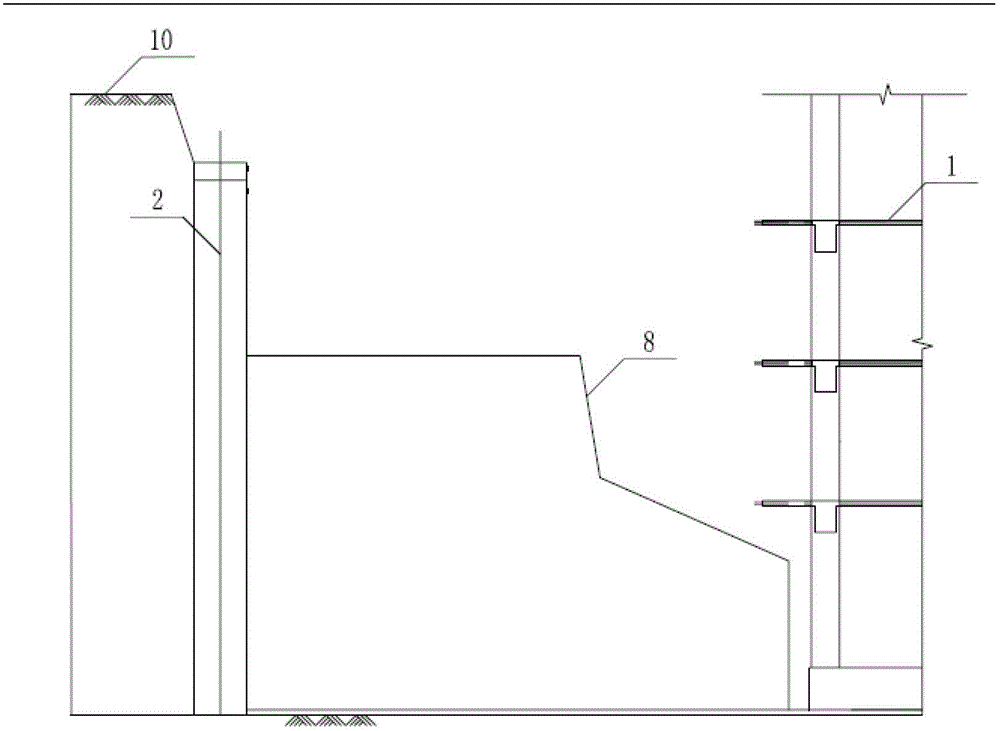

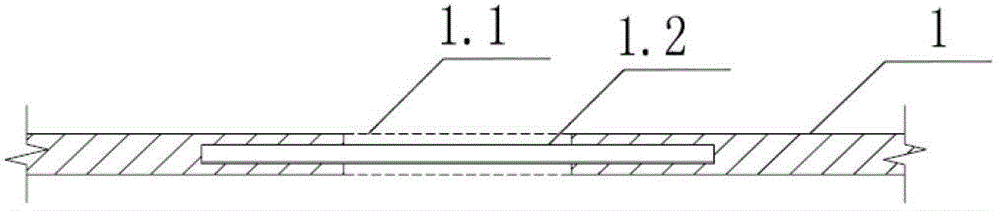

Assembled embedded type prefabricated hollow underground continuous wall and construction method thereof

InactiveCN103334422AEnsure safetyGuaranteed reliabilityArtificial islandsUnderwater structuresConvex sideHollow core

The invention relates to an assembled embedded type prefabricated hollow underground continuous wall. The assembled embedded type prefabricated hollow underground continuous wall is formed by splicing a plurality of wall body units; each wall body unit comprises a wall body unit body, an upper connecting assembly and a lower connecting assembly; the wall body unit body is a hollow block body; the left side face of the wall body unit body is provided with a tenon; the transverse end surface of the tenon is a rectangle provided with an externally convex side wall, and the right side face of the tenon is a groove; the upper connecting assembly is formed by a right side opening groove body which is the same as the transverse end surface of the wall body unit body, a base plate and two L-type connecting blocks; the opening groove body is encircled by a connecting steel plate with a keyhole; an opening of the opening groove body is in inserting connection with the two L-type connecting blocks; the height of each L-type connecting block is half that of the connecting steel plate; the base plate is arranged at the top surface of the connecting steel plate, and is projected out of the outer edge of the connecting steel plate; wall body main ribs are welded on the base plate; the structures and shapes of the upper connecting assembly and the lower connecting assembly are completely the same; and the up-and-down splicing of the wall body unit is realized through bolts after the upper connecting assembly and the lower connecting assembly are in inserting connection. The assembled embedded type prefabricated hollow underground continuous wall has the advantages of shortening the construction period, improving the construction quality, reducing the probability of construction accidents, and the like.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

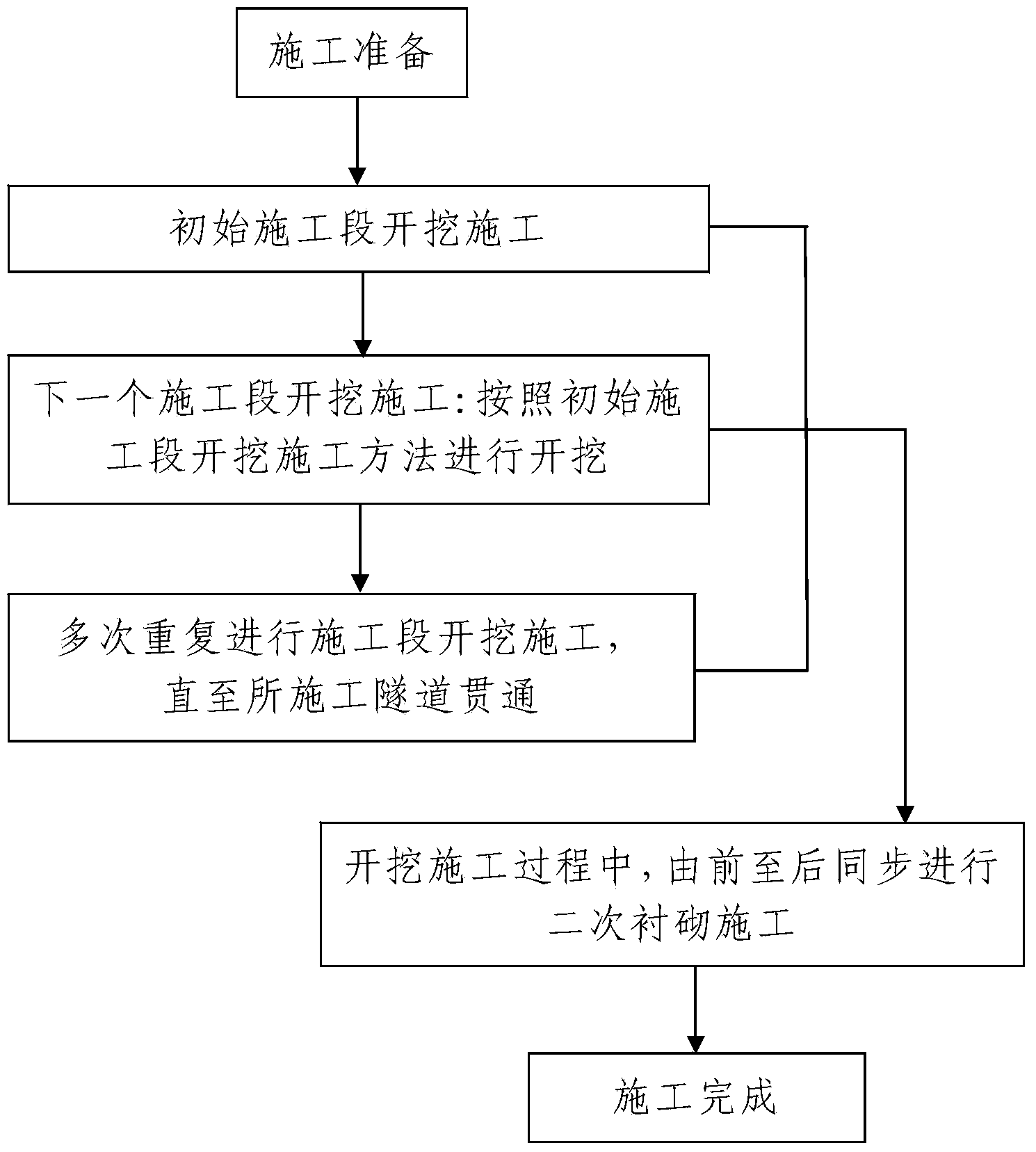

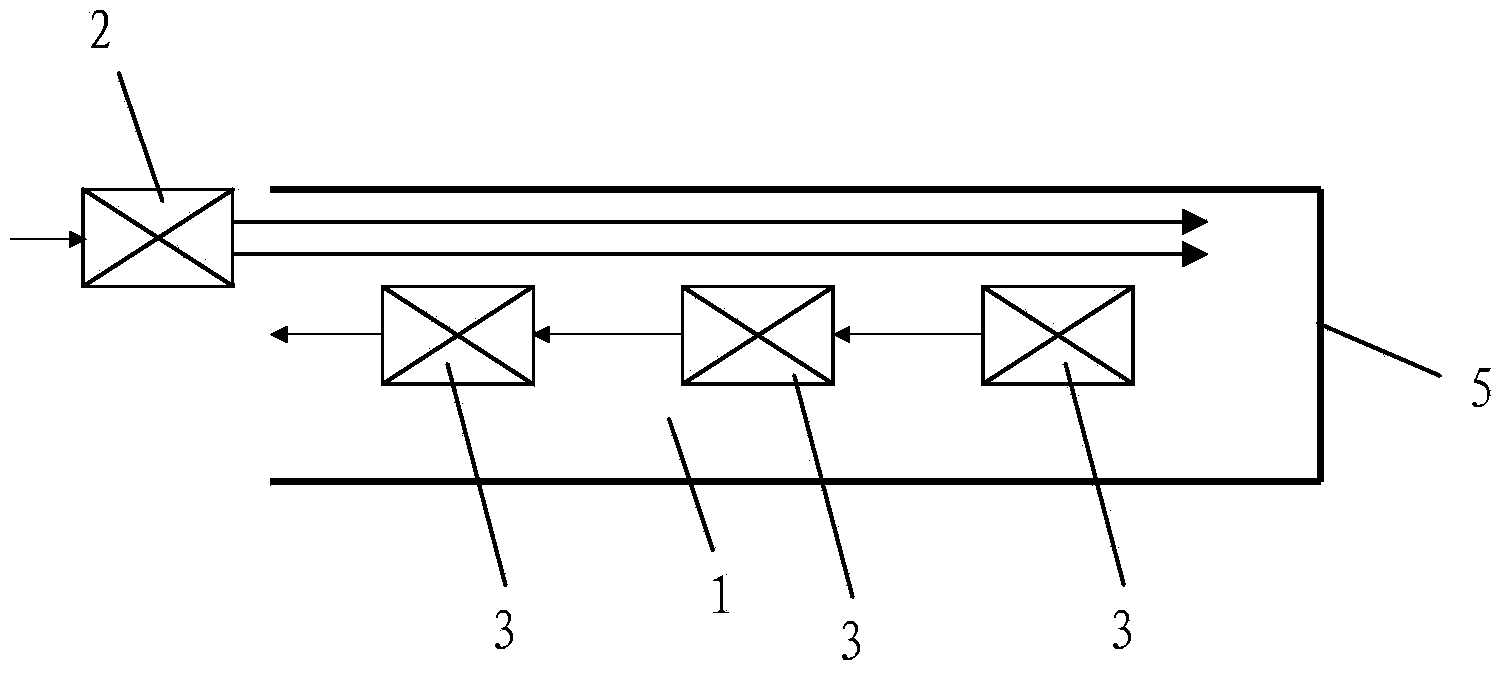

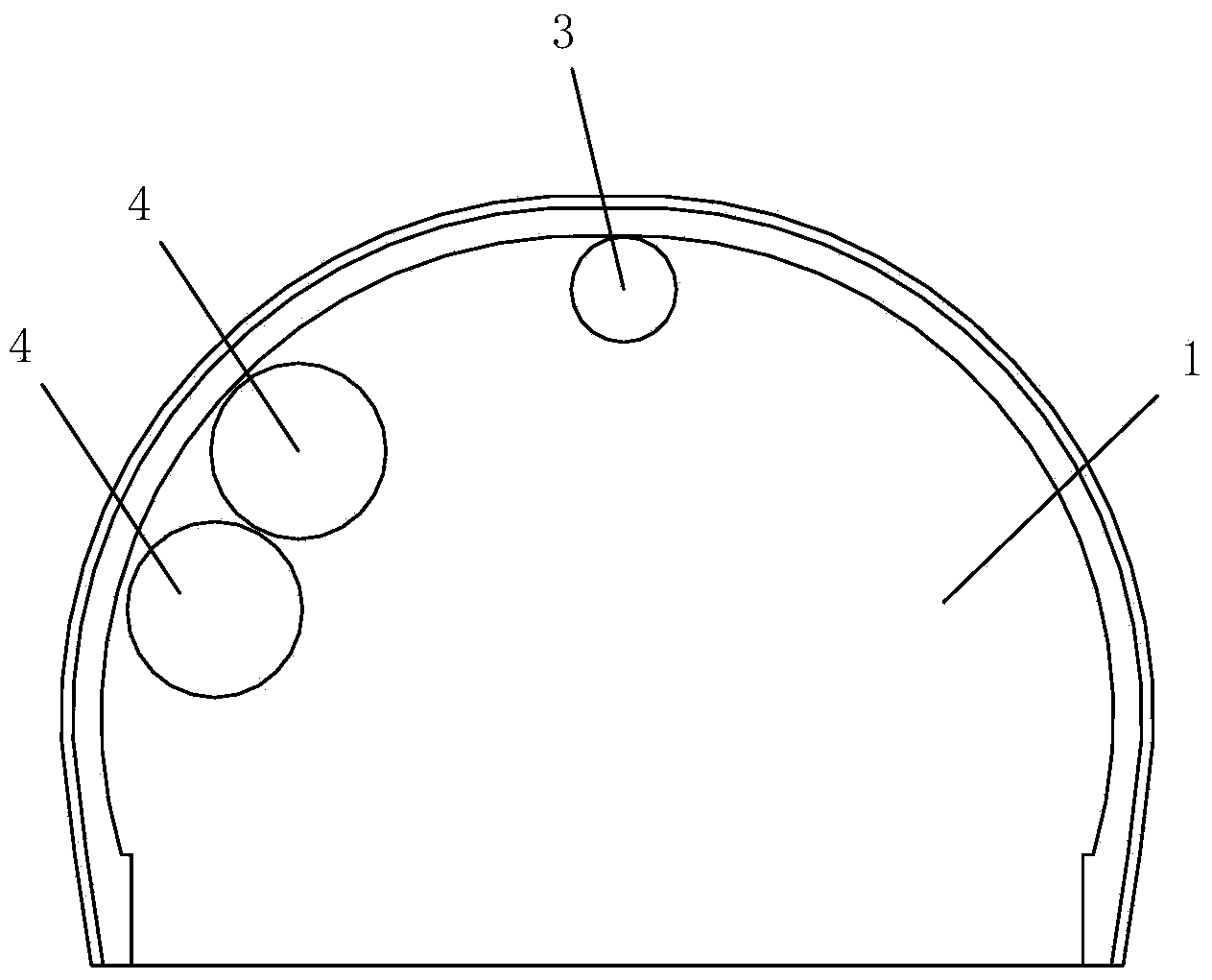

Long tunnel fast construction process

ActiveCN103470267AReasonable designSimplify construction stepsUnderground chambersTunnel/mines ventillationTunnel constructionWater seepage

The invention discloses a long tunnel fast construction process. The tunnel construction method in the direction from the entrance to the exit and the tunnel construction method in the direction from the exit to the entrance are the same and each construction section is respectively constructed from back to front. The construction process is as follows: 1, excavating construction at an initial construction section, the process is as follows: performing advance geology forecast, determining the excavating construction method for the current construction section, excavating and primary supporting; 2, excavating construction at the next construction section; 3, repeating the step 2 for multiple times until the construction tunnel is through, wherein in the tunnel construction process, found water seepage areas are timely subjected to draining treatment, and the secondary lining construction is synchronously performed on the tunnel holes formed by excavating from front to back. The long tunnel fast construction method is reasonable in design, simple and convenient in construction, safe in the construction process, short in construction process and fast in construction progress, thus effectively solving the defects and shortcomings such as large equipment investment, long construction period and slow construction progress of the existing long tunnel construction.

Owner:中铁二十局集团第二工程有限公司

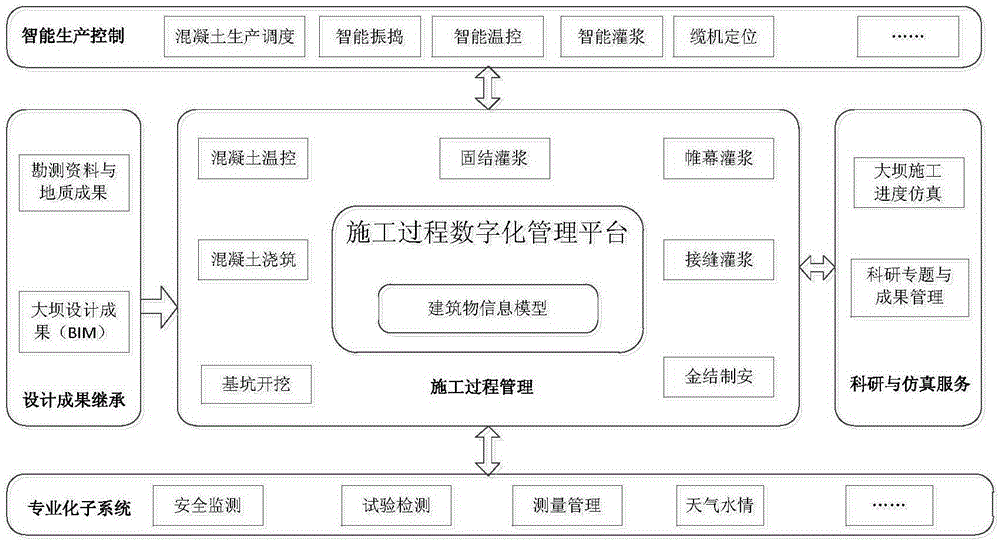

Digital management method and system used for water conservancy and hydropower engineering construction process

InactiveCN105184505AService life cycle managementEnsure dynamic securityResourcesConstruction engineeringData acquisition

The present invention relates to a digital management method and system used for a water conservancy and hydropower engineering construction process. The method comprises the steps of establishing a construction process integrated data acquisition and analysis platform; establishing a building information model (BIM) management platform by taking a three dimensional platform as the basis; integrating the simulation and analysis services to realize the dynamic evaluation and the analysis prediction; realizing the process management facing a construction technology by taking the integrated data acquisition and analysis platform as the basis; integrating the specialized sub-systems to realize the comprehensive analysis and evaluation; integrating the digital construction equipment to realize the on-site digital monitoring and the intelligent control. According to the present invention, by taking a building information model as the basis, taking a digital construction cooperative working platform as the core, and facing a concrete construction specialty, an integrated, digital and intelligent management platform covering the engineering on-site construction full process is realized, the refinement construction is realized, the engineering progress and the quality management level are improved, the dynamic safety of the engineering structures is guaranteed, and the full life circle management of an engineering is served.

Owner:武汉英思工程科技股份有限公司

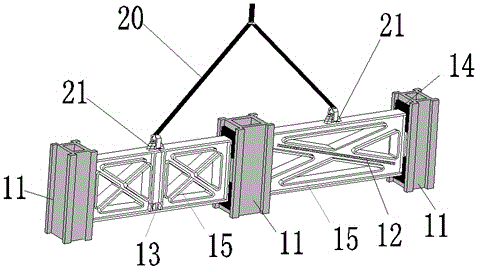

Steel structure integral hoisting method based on BIM

ActiveCN104866659AHigh precisionImprove securityBuilding material handlingSpecial data processing applicationsCompletion timePre stress

According to the present invention, a steel structure integral hoisting method based on BIM comprises: calculating member deflection by using BIM software, determining an arching degree of a single truss, checking member deflection in construction, comparing the member deflection in construction with a pre-arching degree, and comparing a deflection degree after loading that follows completion of construction with designed control deflection degree requirements; using an MIDAS finite element analysis plug-in to set hoisting points at intersection of an upper chord and a diagonal web member on the truss and on each truss, performing design calculations of lifting lugs, and analyzing displacement of structurally critical nodes; performing manual or automatic layout on the integral steel truss, steel tubes and steel cables in a venue model, performing integral analysis on the steel truss of the steel structure, calculating pre-stress of each node of the integral structure by using the BIM software; finally, virtually adding an environment and roads of a construction site by using the BIM software, completing stimulation of a whole erection process, determining the installation time and the situation of occupying construction roads of each steel truss, and estimating construction completion time. The present invention solves the construction problem of limited space, reduces the construction cost and shorten the construction period.

Owner:JIANGSU NEW BLUE SKY STEEL STRUCTURE

Double track bridge construction process crossing existing railway operational lines

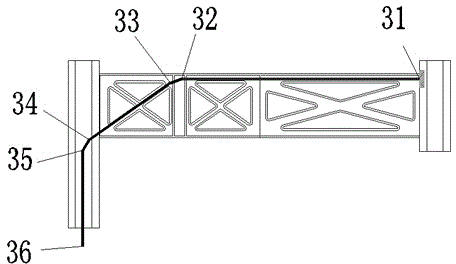

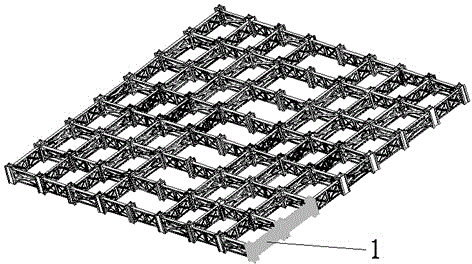

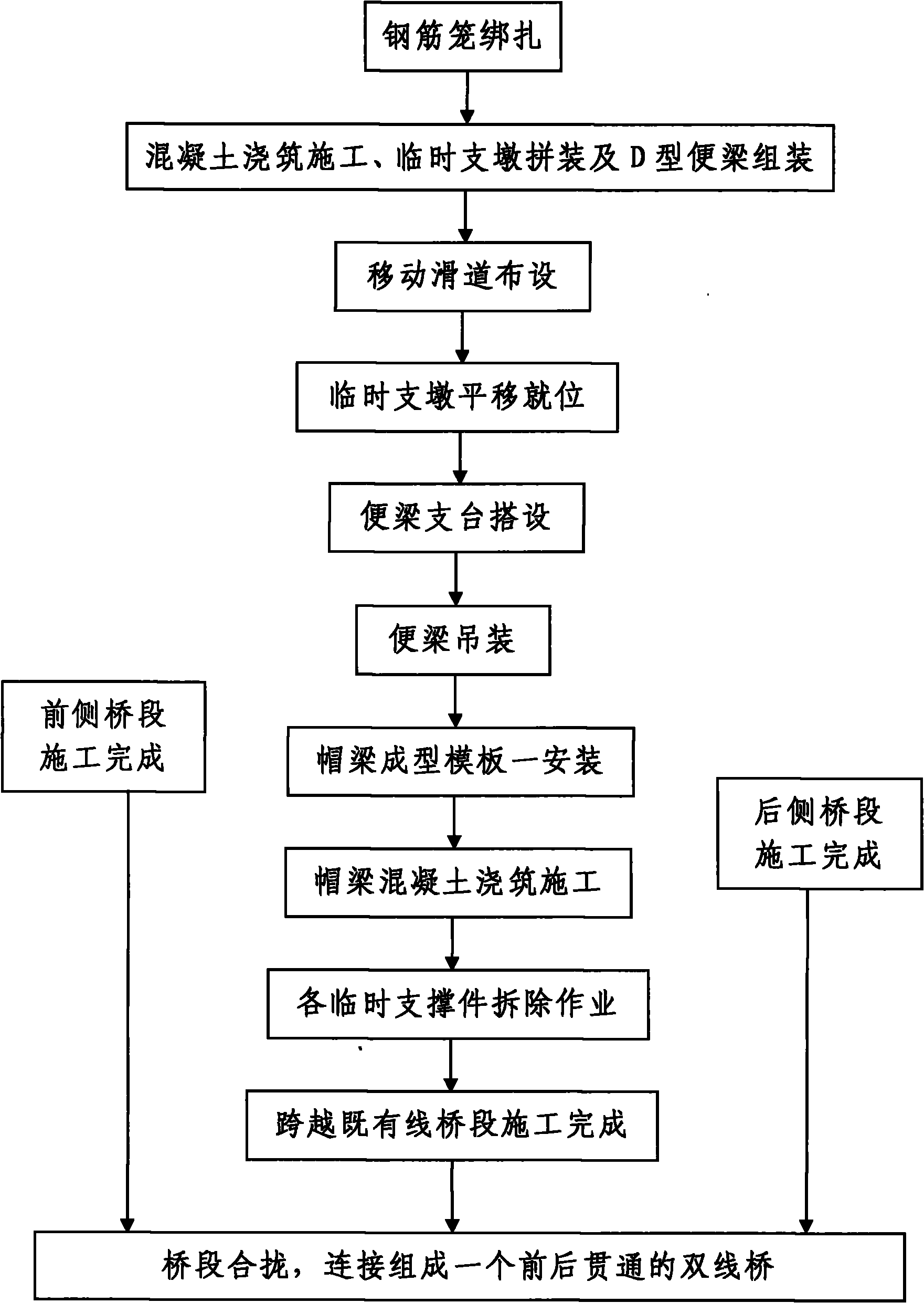

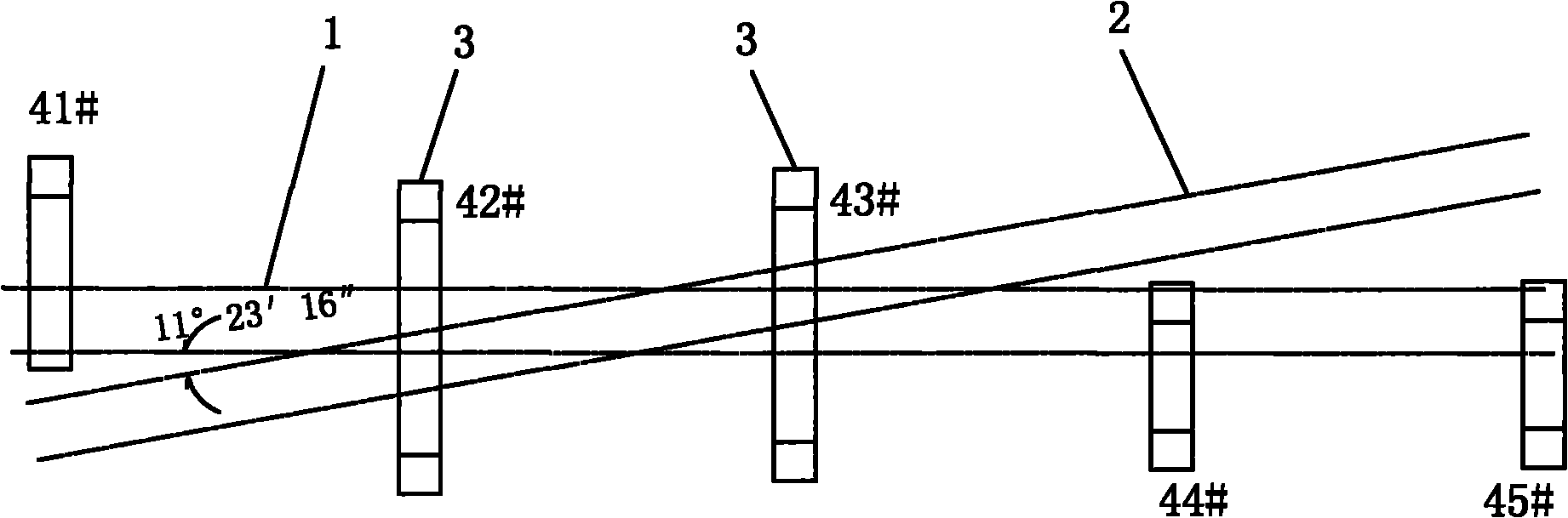

ActiveCN101838968AReduce distractionsImprove construction progressBridge erection/assemblyButtressSafety risk

The invention discloses a double track bridge construction process crossing existing railway operational lines, and the constructed double track bridge comprises a front side bridge section, a crossed existing line bridge section with mutually connected front and rear ends and a rear side bridge section. The process comprises the following steps: 1) synchronously constructing the front side bridge section, the crossed existing line bridge section and the rear side bridge section, wherein the crossed existing line bridge section is constructed as follows: binding reinforcement cages, concreting, assembling temporary buttresses and D-shaped temporary beams, arranging movable slide rails, carrying out translation insertion on the temporary buttresses, setting up temporary beam supporters, hoisting the temporary beams, installing cap beam forming templates, concreting cap beams and removing all temporary strut members; and 2) folding the bridge sections. The invention has the advantages of reasonable design, convenient construction, low investment cost, good use effect, high construction efficiency, short construction period and low safety risk, and can effectively solve the actual problems such as large construction difficulty, long construction period, high investment cost, high safety risk and the like in the construction process of the crossed existing line gate piers.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

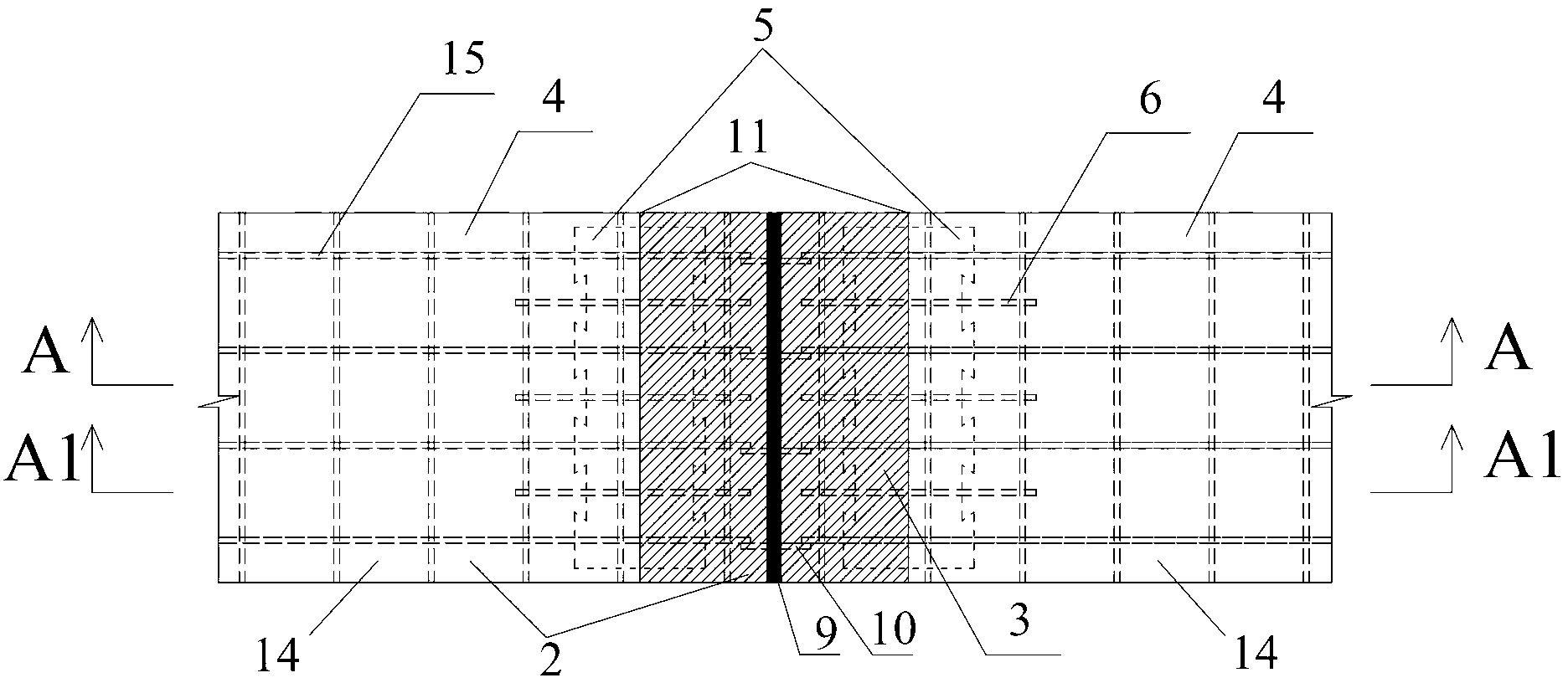

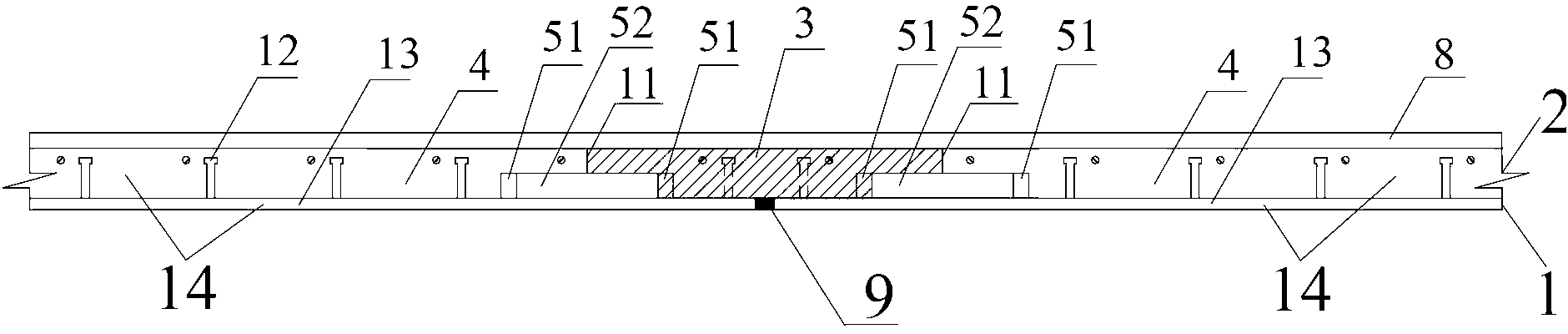

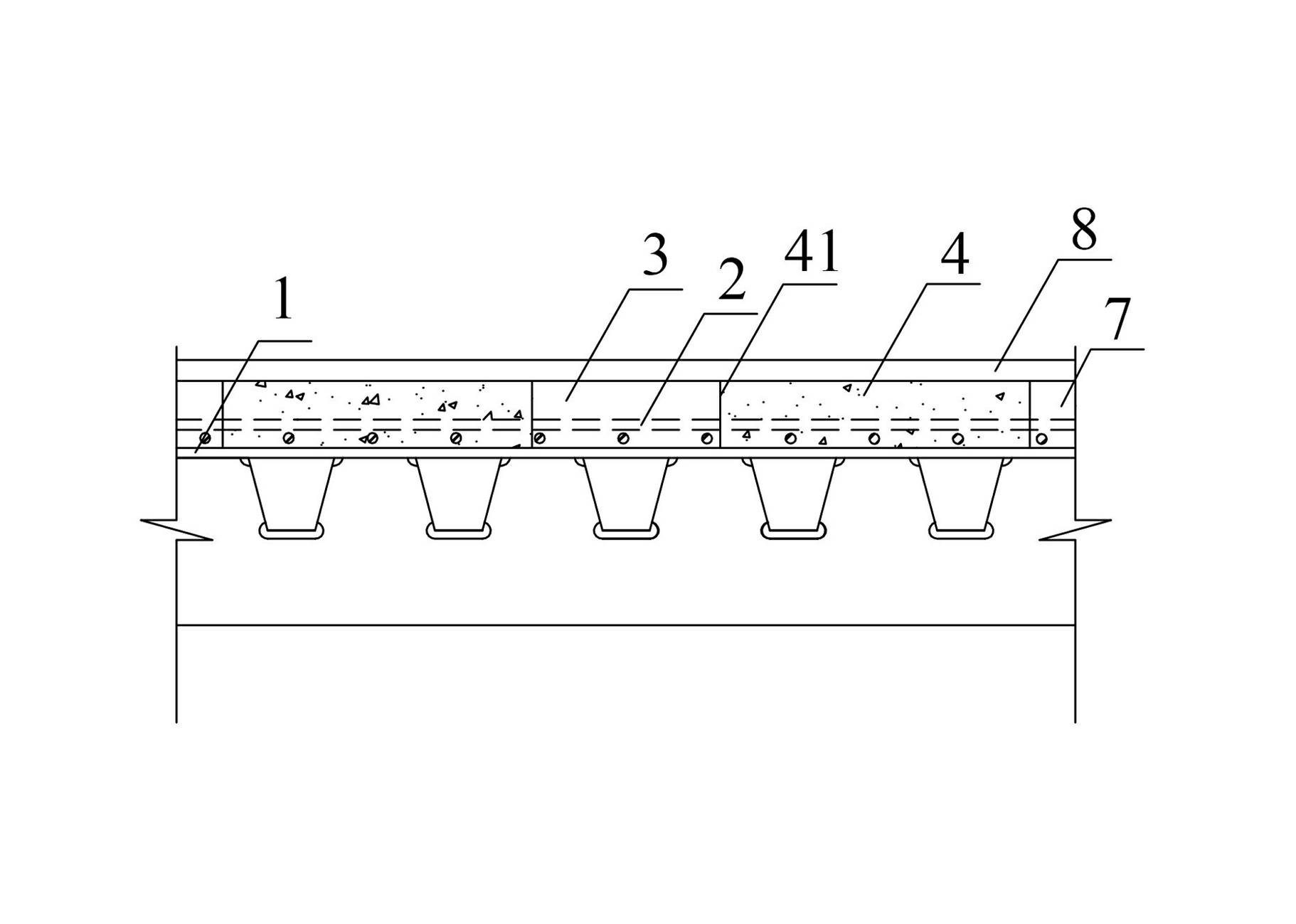

Steel-fiber concrete combined bridge deck structure with reinforced joints and construction method of steel-fiber concrete combined bridge deck structure

ActiveCN102704394AReduce adverse effectsEasy constructionBridge structural detailsBridge erection/assemblyButt jointArchitectural engineering

The invention discloses a steel-fiber concrete combined bridge deck structure with reinforced joints. The steel-fiber concrete combined bridge deck structure is mainly formed by assembling a plurality of steel plate-fiber concrete combined components, each component comprises a steel bridge deck plate and a prefabricated fiber concrete element cast on the steel bridge deck plate, reinforced joint structures are arranged in butt joint regions of two adjacent components and comprise cast-in-situ concrete elements and steel plate reinforcing components, the steel plate reinforcing components are covered by prefabricated fiber concrete elements and cast-in-situ fiber concrete elements, the steel plate reinforcing components and the prefabricated concrete elements are connected in a tongue-and-groove engaging mode for forming an integral fiber concrete layer, and the adjacent steel bridge deck plates are welded into an integral steel bridge deck plate layer. A construction method provided by the invention comprises the following steps that the steel-fiber concrete combined components are firstly manufactured, then, the combination and split joint is carried out, and next, the repeated sequential assembly is carried out. The steel-fiber concrete combined bridge deck structure and the construction method have the advantages that the tensile strength and the rigidity of local parts of the combined bridge deck structure can be improved, the joint seam stress is reduced, and the generation of cracks of paving layers is prevented.

Owner:HUNAN UNIV

Support change construction building method implemented by using main structure of building

ActiveCN102720201AGuaranteed not to be brokenEnsure safetyArtificial islandsExcavationsRebarBuilding construction

The invention relates to a support change construction building method implemented by using a main structure of a building, which is characterized in that a foundation pit support is respectively supported on a foundation pit support pile and a beam slab of the main structure of the building by using the two ends of a steel supporting member, one end of the steel supporting member is connected with the structure beam slab through a steel waling and a steel soldier pile, and parts of a post-cast strip, a tunnel opening and a ramp are respectively provided with a steel-structure load-transfer member, thereby achieving a supporting effect on foundation pits; and under the action of supporting, the main structure between the foundation pit support pile and a finished structure is constructed. According to the method disclosed by the invention, the appropriate parts of the post-cast strip, the tunnel opening and the ramp of the structure are respectively provided with a reliable load-transfer member, so that a situation that in the process of support change construction, the main structure of the building is not damaged is ensured, wherein, the post-cast strip is provided with a rebar as the load-transfer member, and the tunnel opening and the ramp are respectively provided with a temporary floor; by using the building method, the safety of the foundation pit support can be effectively ensured, the deformation of the ground and the supporting pile can be effectively controlled, and the difficulty of engineering construction can be reduced; and the building method is rapid in construction progress, low in construction cost and high in engineering quality.

Owner:THE SECOND CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU +3

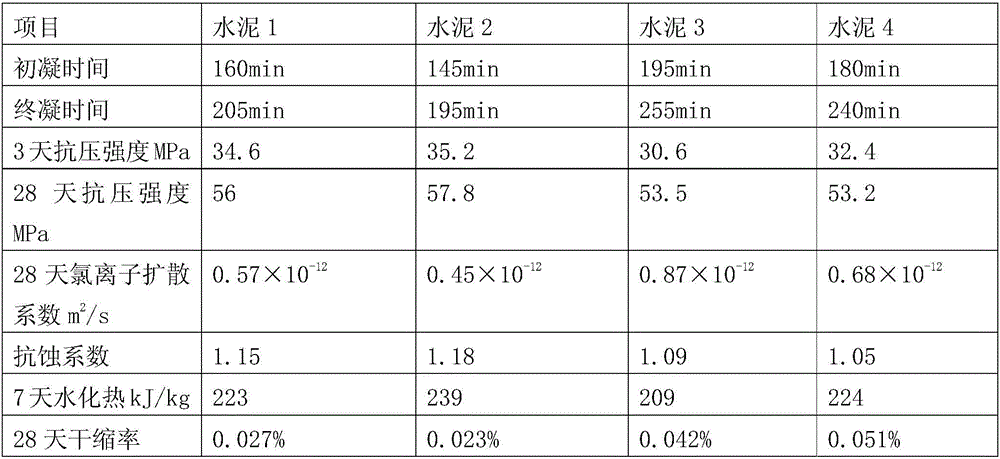

High early strength and high corrosion resistant Portland cement and preparation method thereof

ActiveCN106082724AReduce tricalcium contentExtended service lifeClinker productionMass ratioPortland cement

Belonging to the field of cement production and also relating to the field of building materials, the invention provides a high early strength and high corrosion resistant Portland cement and a preparation method thereof. The high early strength and high corrosion resistant Portland cement is mainly applied to engineering projects in complex marine environments and the west harsh environments. The high early strength and high corrosion resistant Portland cement is characterized by containing, by weight percentage, 60%-90% of a high iron and low calcium cement clinker mineral component, 2%-10% of an auxiliary functional component, 5%-25% of an auxiliary cementitious component, and 3%-7% of industrial gypsum. The high iron and low calcium cement clinker mineral component is mainly prepared from high iron and low calcium Portland cement clinker and high iron and low calcium Q phase cement clinker in a mass ratio of 5-15:1. The cement not only has strong seawater erosion resistance and high early strength, but also has the characteristics of low shrinkage and low hydration heat.

Owner:WUHAN UNIV OF TECH

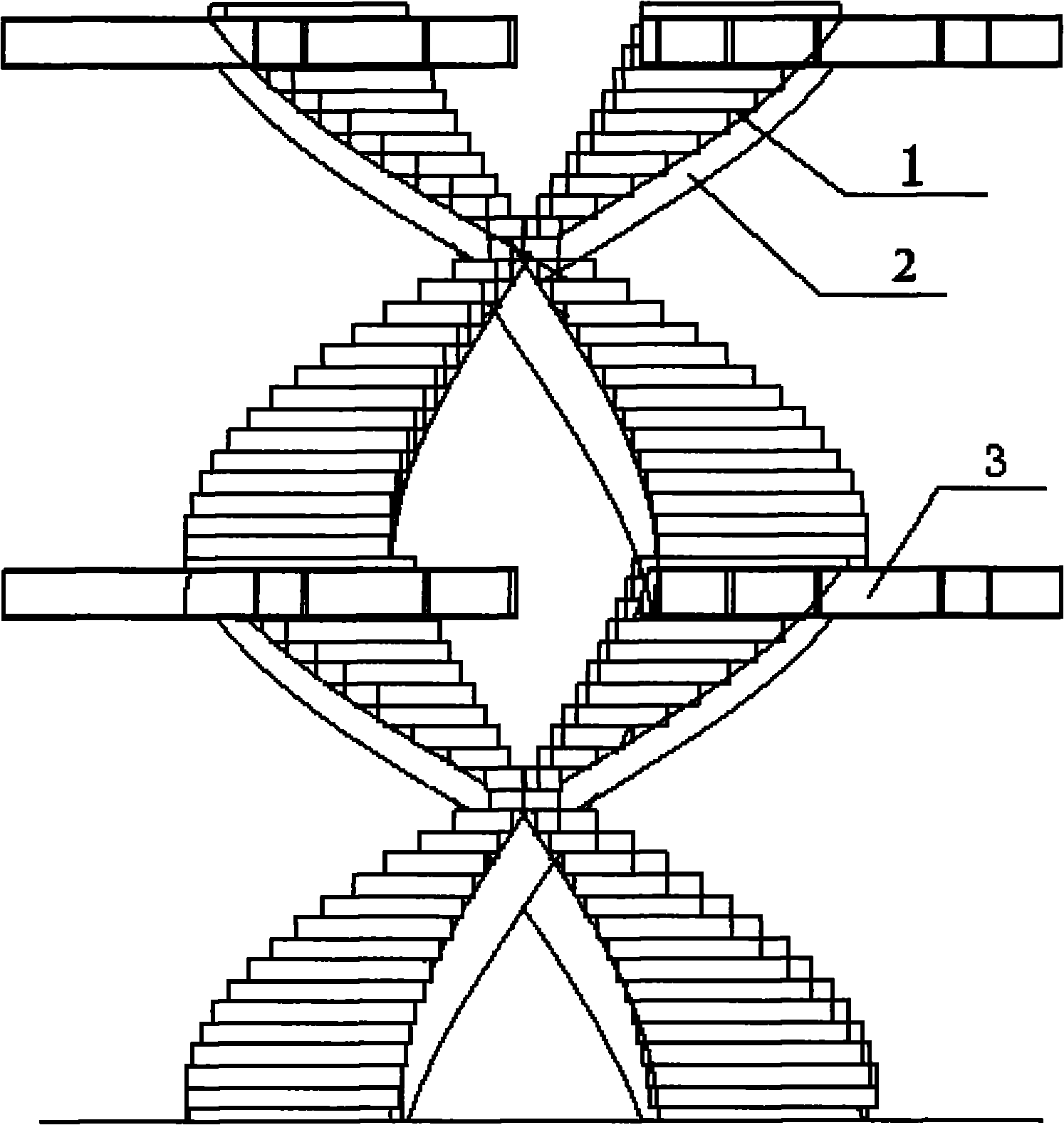

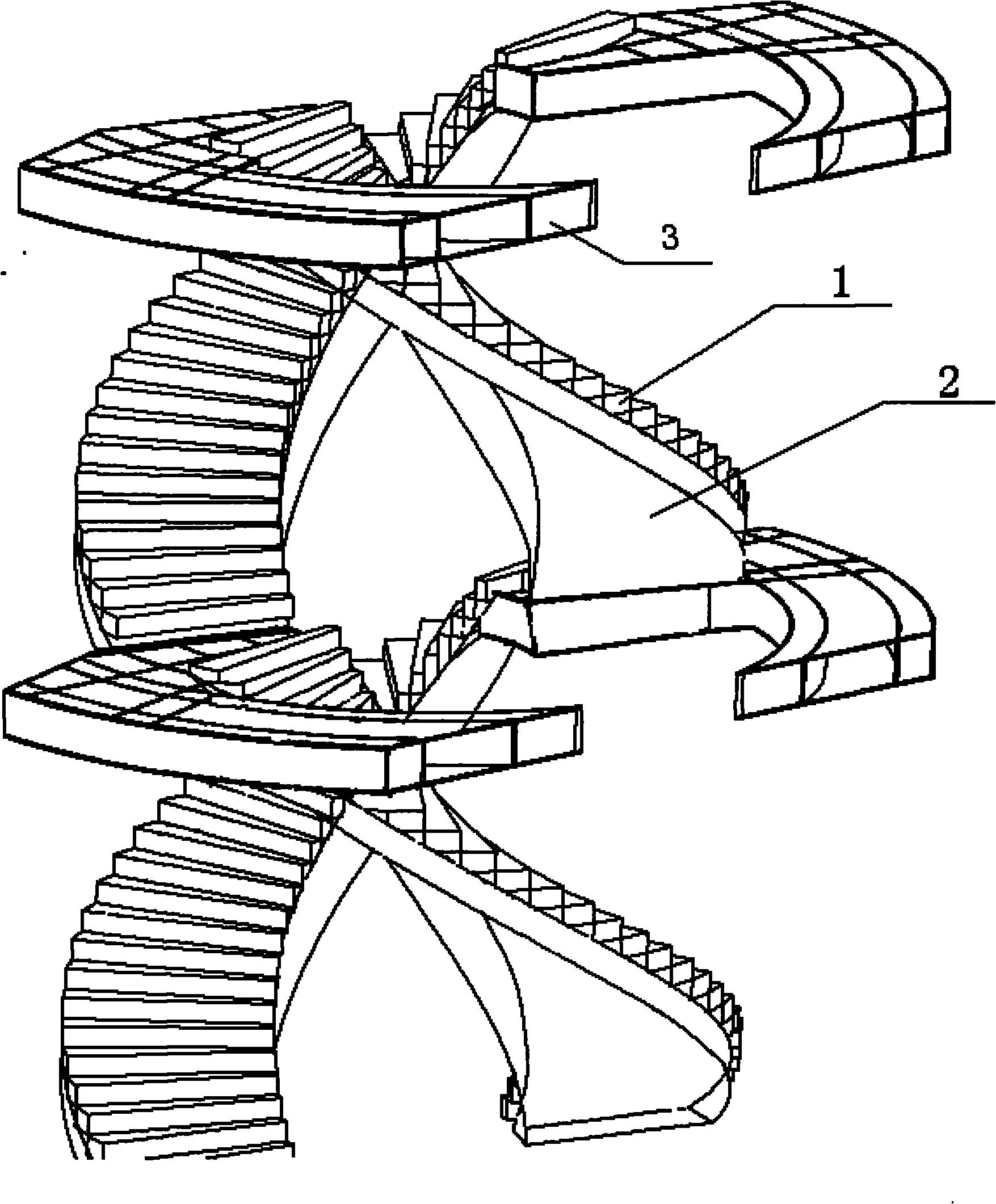

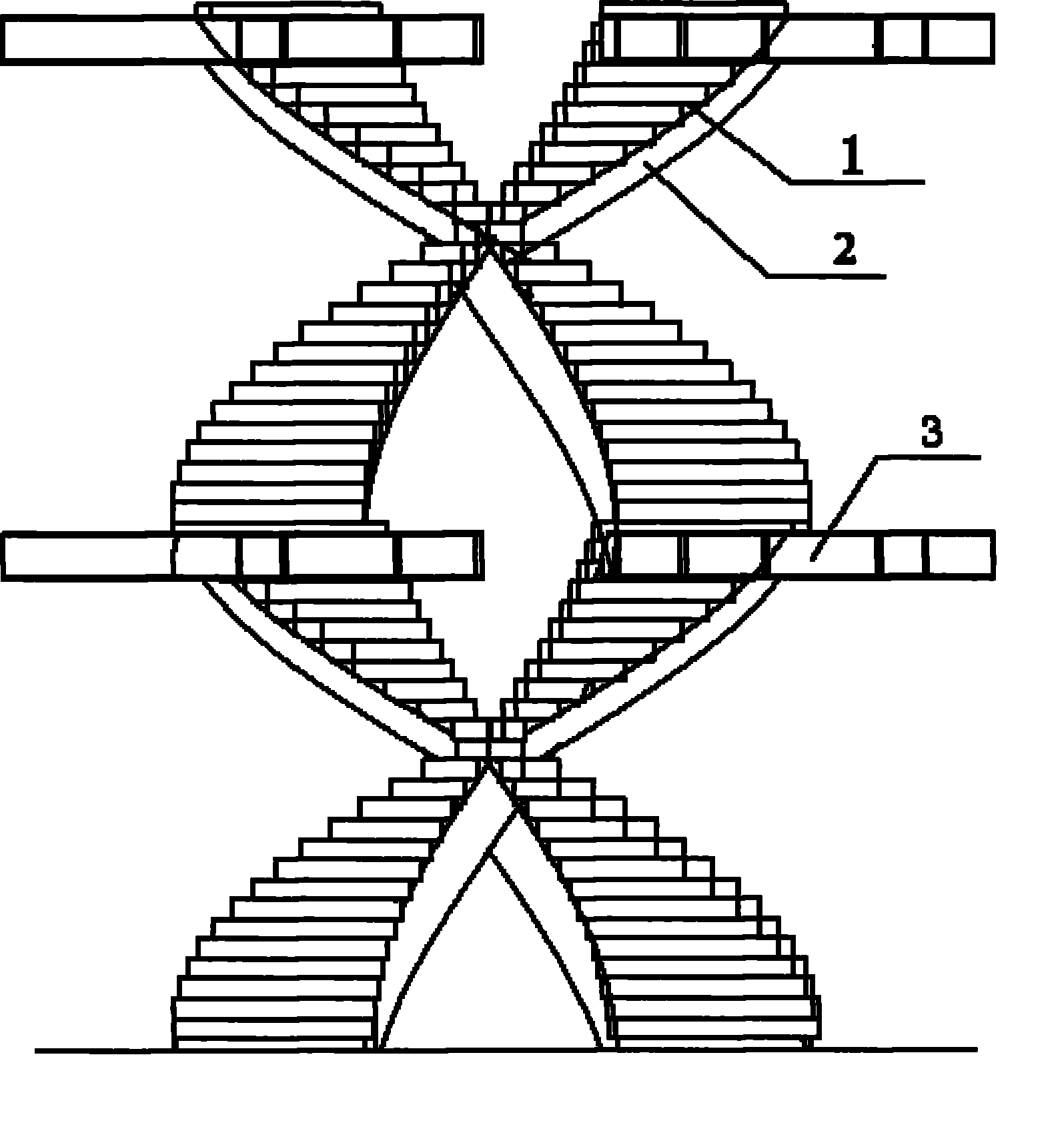

Method for manufacturing double-spiral steel staircase without middle standing pillar

The invention discloses a method for manufacturing a double-spiral steel staircase without a middle standing pillar. The staircase is formed by welding stairs, stair fixing layers and a staircase platform. The method comprises the following steps: carrying out the three-dimensional lofting by using a computer, so as to decompose the staircase into bent plate components; calculating the length, width, bending radius and planar cutting line position of each bent plate component; feeding and cutting materials by a numerical-control cutting machine; manufacturing the bent plate components; checking the bent plate components; manufacturing a jig; lifting the bent plate components onto the assembly jig, to check and locate the bent plate components, and welding the bent plate components into box-type components; lifting the stair fixing layers onto the assembly jig, so as to locate the stair fixing layers, then, lifting the staircase platform onto the stair fixing layers to mount and fix the staircase platform, and carrying out the integrity acceptance; numbering the stairs, the stair fixing layers and the staircase platform, then lifting the stairs, the stair fixing layers and the staircase platform off the assembly rig, sand-washing and coating; and carrying out the integral installation. By using the method for 'breaking up the whole into parts', the invention increases the accuracy of the single component, ensures the integrity of the double-spiral steel staircase and guarantees the overall quality.

Owner:JIANGSU HUNING STEEL MECHANISM

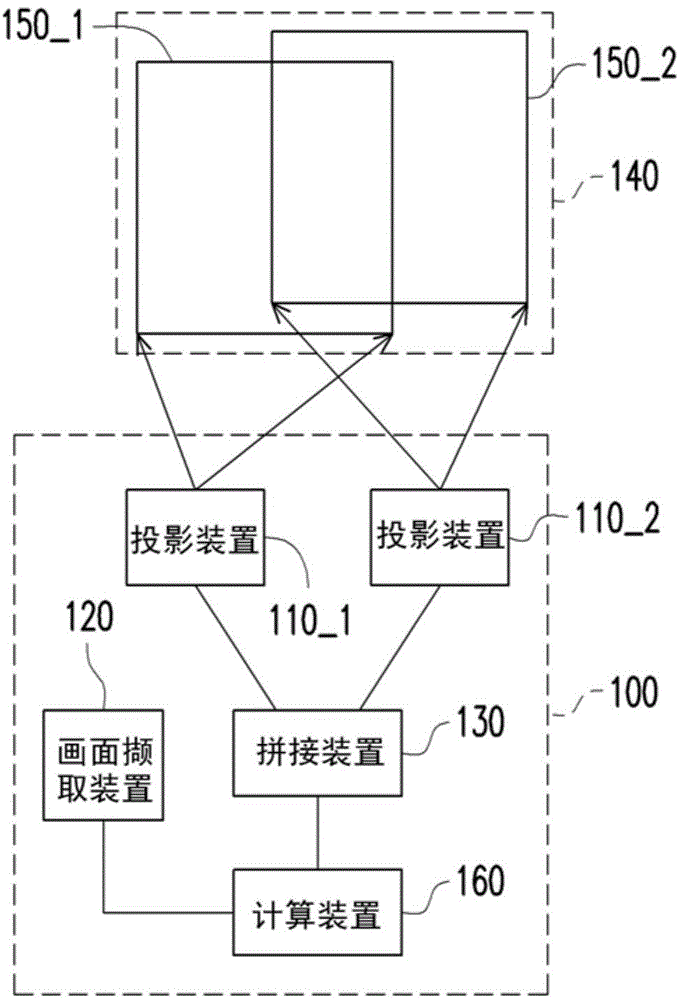

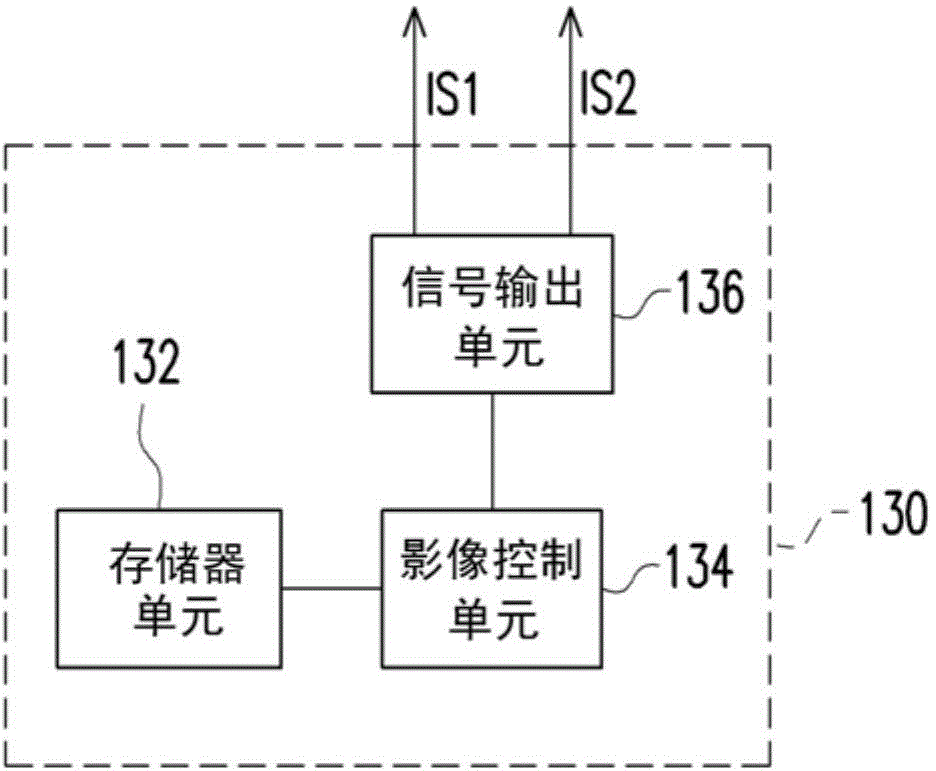

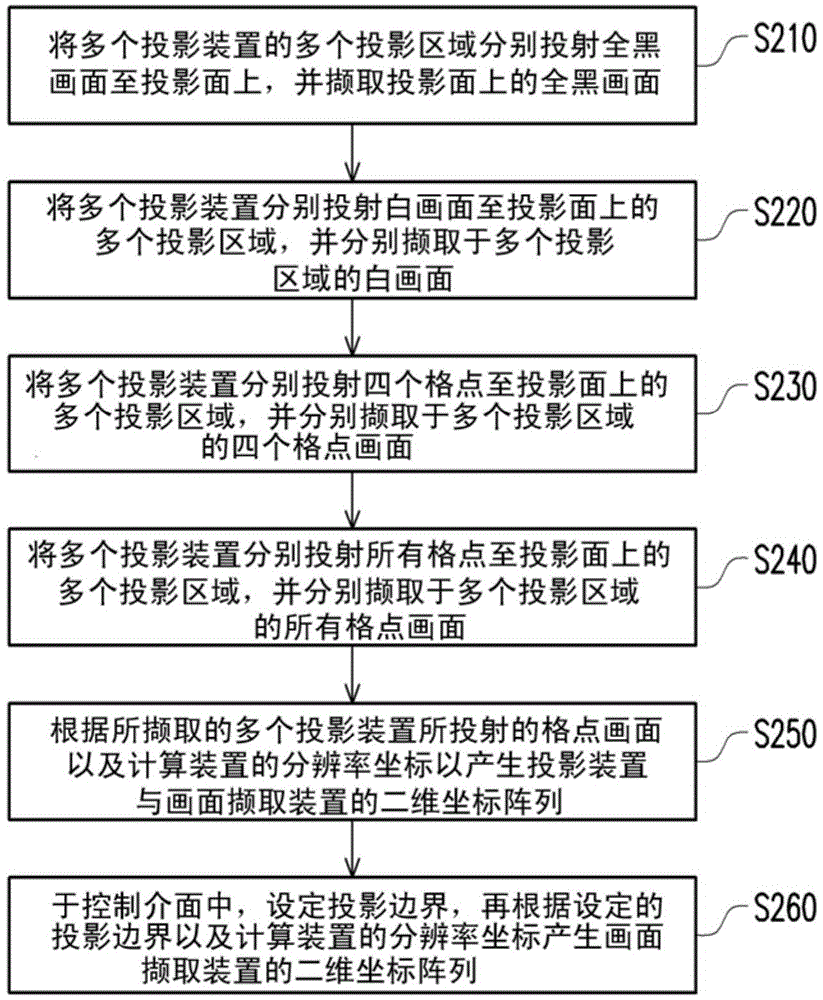

Projection display system and correction method of projection area

InactiveCN105376540AImprove projection qualityImprove project qualityTelevision system detailsProjectorsCorrection methodImage capture

The invention provides a projection display system and a correction method of a projection area. A projection display device comprises a multiple protection devices, an image capturing device, a splicing device and a computing device. The projection devices are used for projecting multiple projection areas in a projection plane. The image capturing device is used for capturing the imaging image on the projection plane. The coumputing device judges the positions of the projection areas through the imaging image captured by the image capturing device. The display screen of the computing device is used for displaying a control interface which is corresponding to the display image area of the projection areas according to a ratio. The computing device dynamically adjusts the projection ratio of the images displayed in the projection areas through adjusting the positions of the control points in the display image area and the distance between control points.

Owner:CORETRONIC

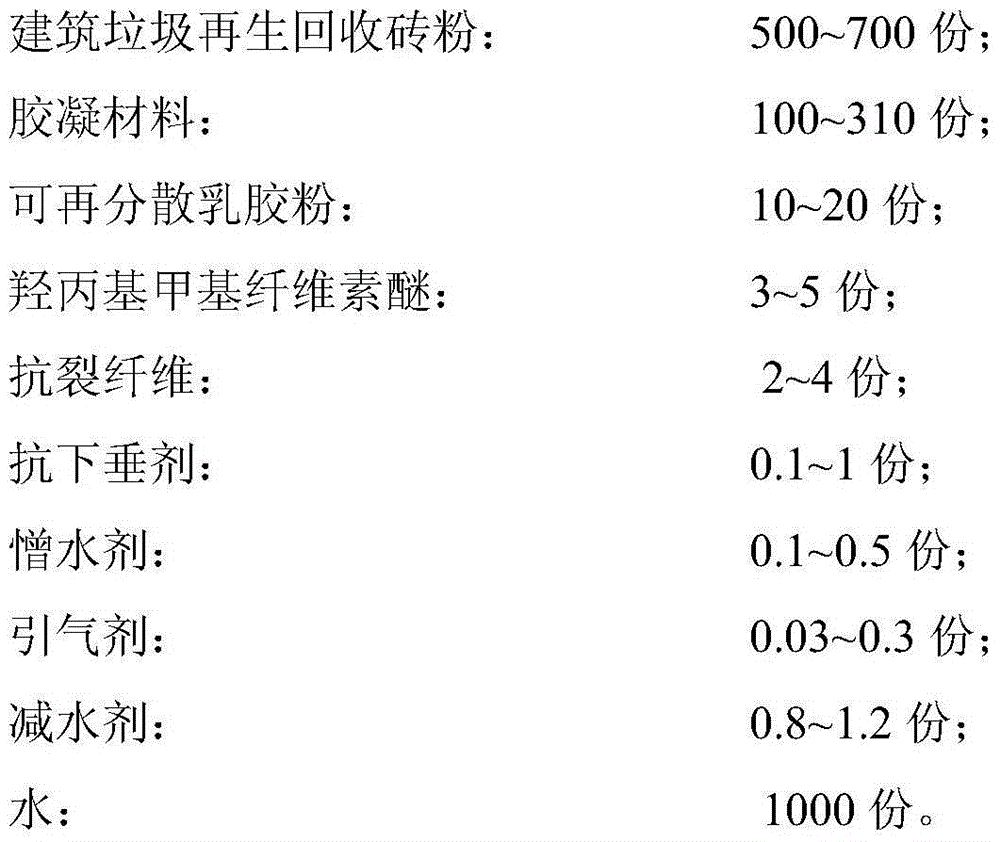

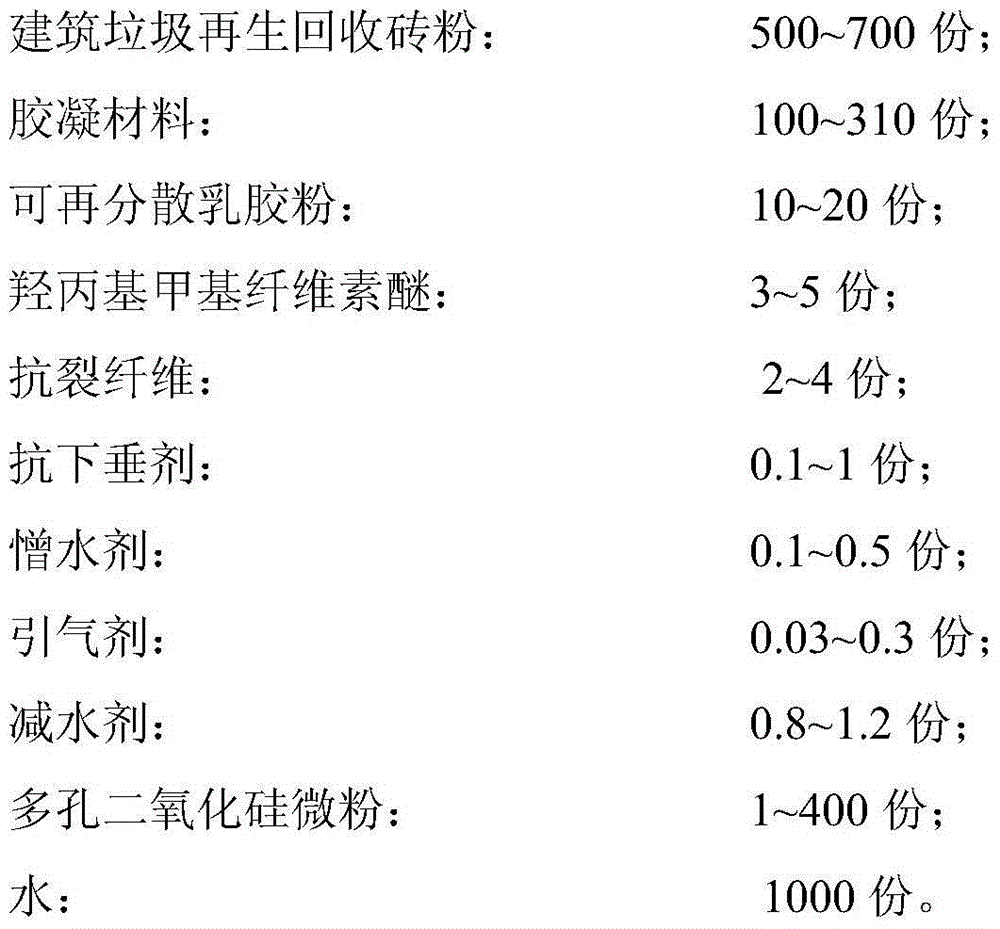

Construction waste reclaimed brick powder-containing spray construction heat insulation mortar

The invention discloses a construction waste reclaimed brick powder-containing spray construction heat insulation mortar. The mortar is prepared from, by weight, 500-700 parts of construction waste reclaimed brick powder, 100-310 parts of a gelling material, 10-20 parts of redispersible powder, 3-5 parts of hydroxypropyl methyl cellulose ether, 2-4 parts of a crack resistant fiber, 0.1-1 part of an anti-sagging agent, 0.1-0.5 parts of a water repellent, 0.03-0.3 parts of an air entraining agent, 0.8-1.2 parts of a water reducer and 1000 parts of water. The mortar has the characteristics of A grade flame retardation, good heat insulation performance, high compression and tensile strength, long life, environmental protection, waste recycling, easy mechanical spraying construction, construction energy consumption reduction, suitableness for internal and external wall heat insulation construction, simplicity, feasibility and low cost.

Owner:TONGJI UNIV

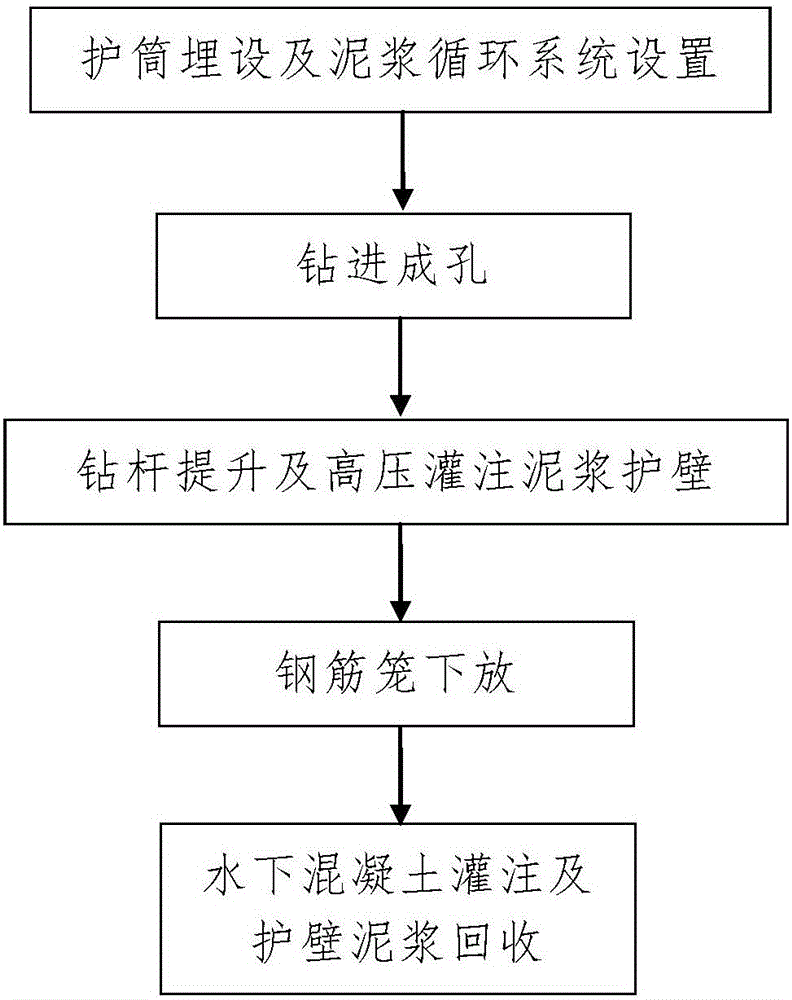

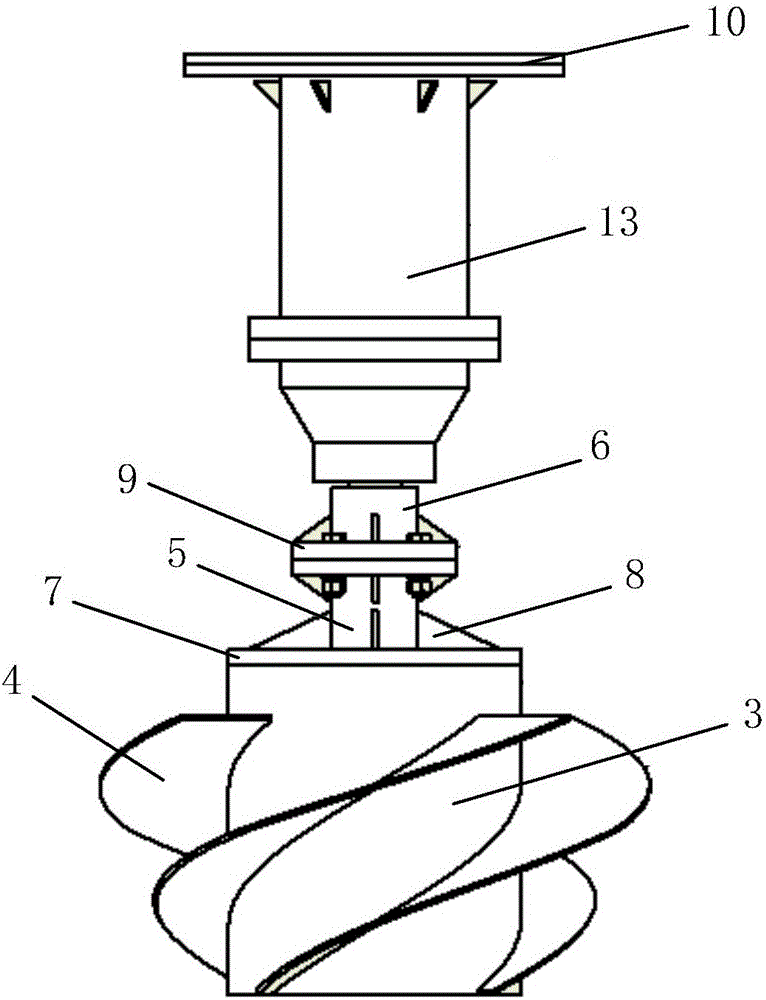

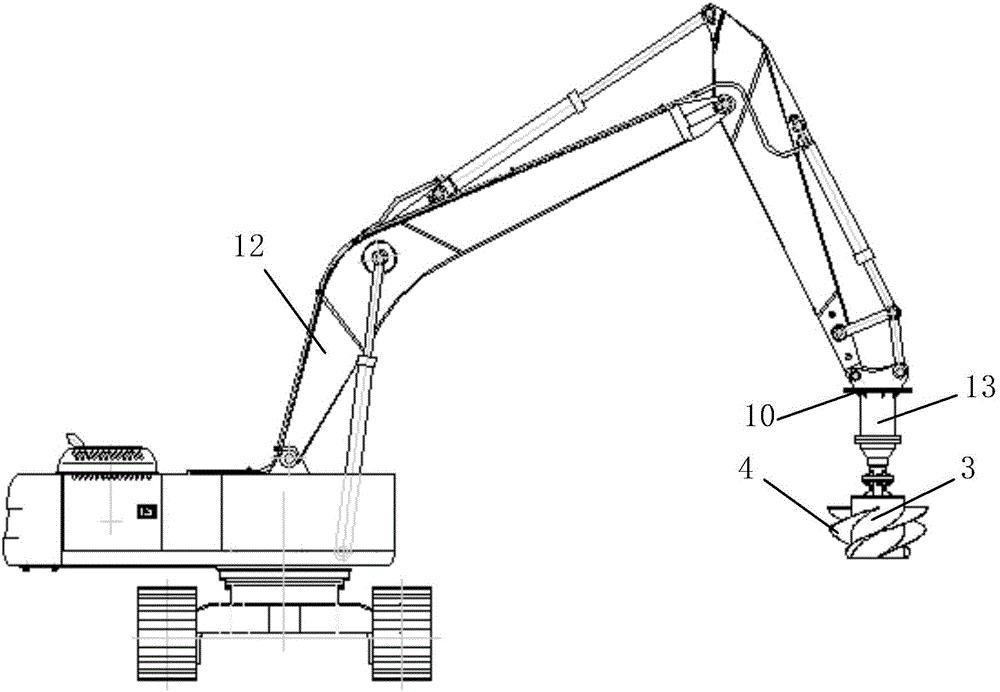

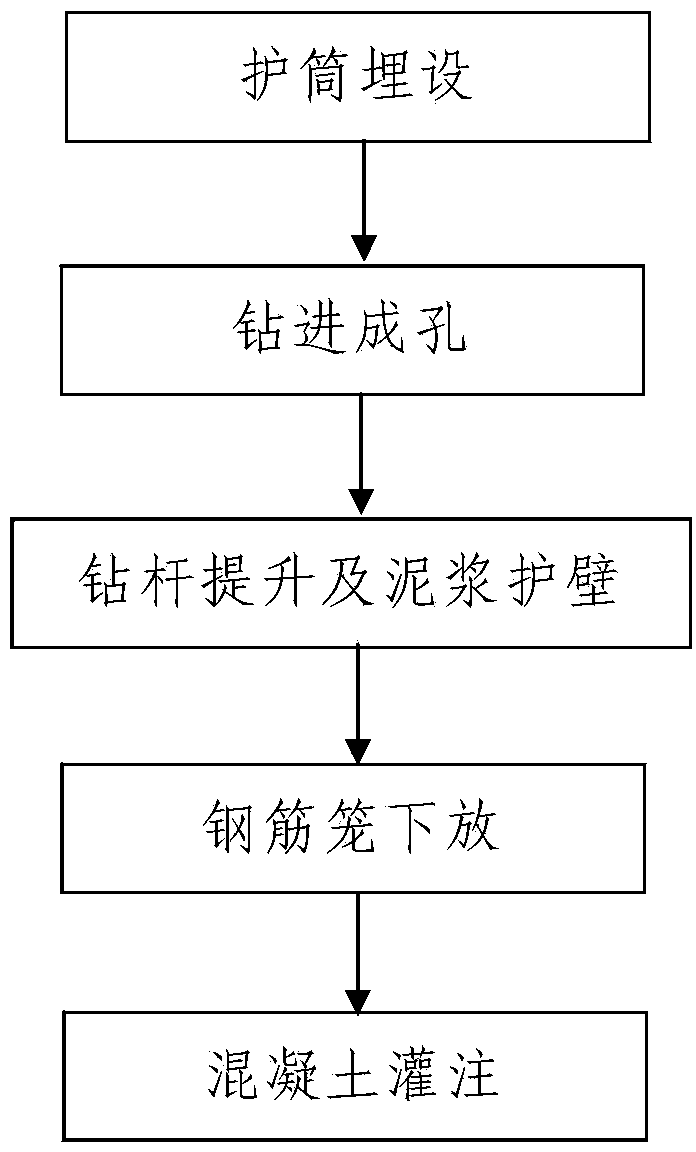

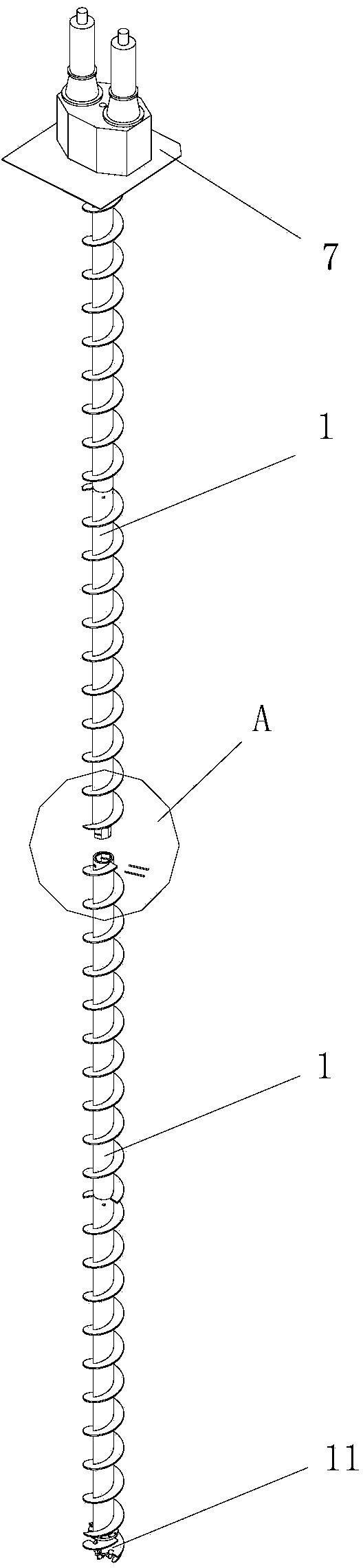

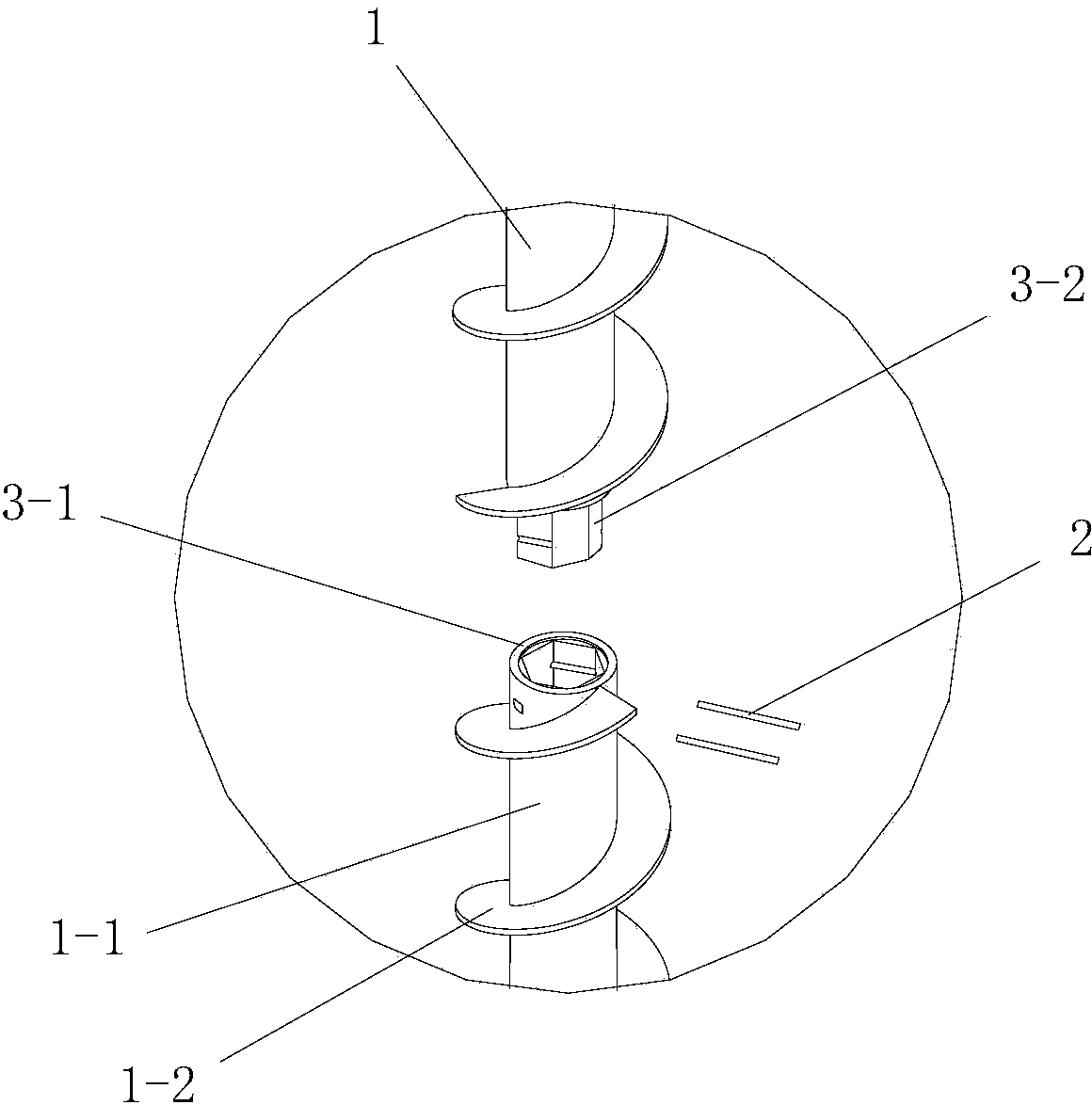

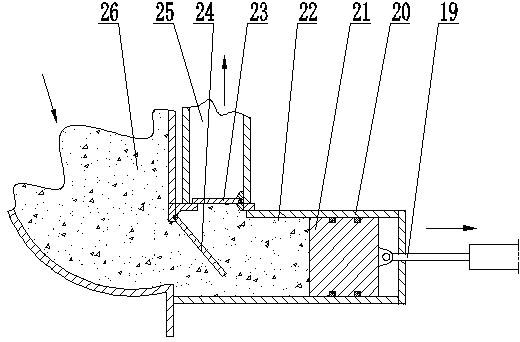

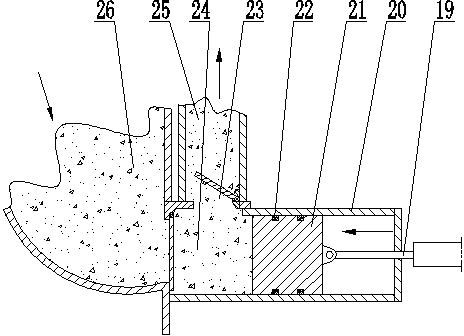

Long screw extrusion-socketed cast-in-place pile construction method based on circulating slurry breast wall

ActiveCN106284313AReasonable structural designEasy to operateBulkheads/pilesDrilling machines and methodsUnderwaterHigh pressure

The invention discloses a long screw extrusion-socketed cast-in-place pile construction method based on circulating slurry breast wall, comprising the steps of first, burying a protective barrel and setting a slurry circulating system that comprises a slurry storage tank and a slurry pumping device, with the upper portion of the protective barrel provided with an overflow hole; second, drilling to form a borehole; third, lifting a drill pipe, and casting a slurry breast wall under high pressure: lifting up the drill pipe, and continuously casting wall supporting slurry from bottom to top from the borehole bottom through the drill pipe by using the slurry pumping device; fourth, lowering a reinforcement cage; fifth, casting concrete underwater and recycling the wall supporting slurry, and recycling the wall supporting slurry discharged through the overflow hole to the slurry storage tank for backup. The method has simple steps, is easy to implement, has high hole-forming quality and good construction effect, and enables the construction of a long screw extrusion-socketed cast-in-place pile to be finished simply and quickly, and by casting the wall supporting slurry from bottom to top from the borehole bottom in a high-pressure casting manner, it is possible to effectively protect the wall and keep the borehole bottom clean with no deposit; the wall supporting slurry is reusable.

Owner:SHAANXI ZHUANGXIN CONSTR ENG +4

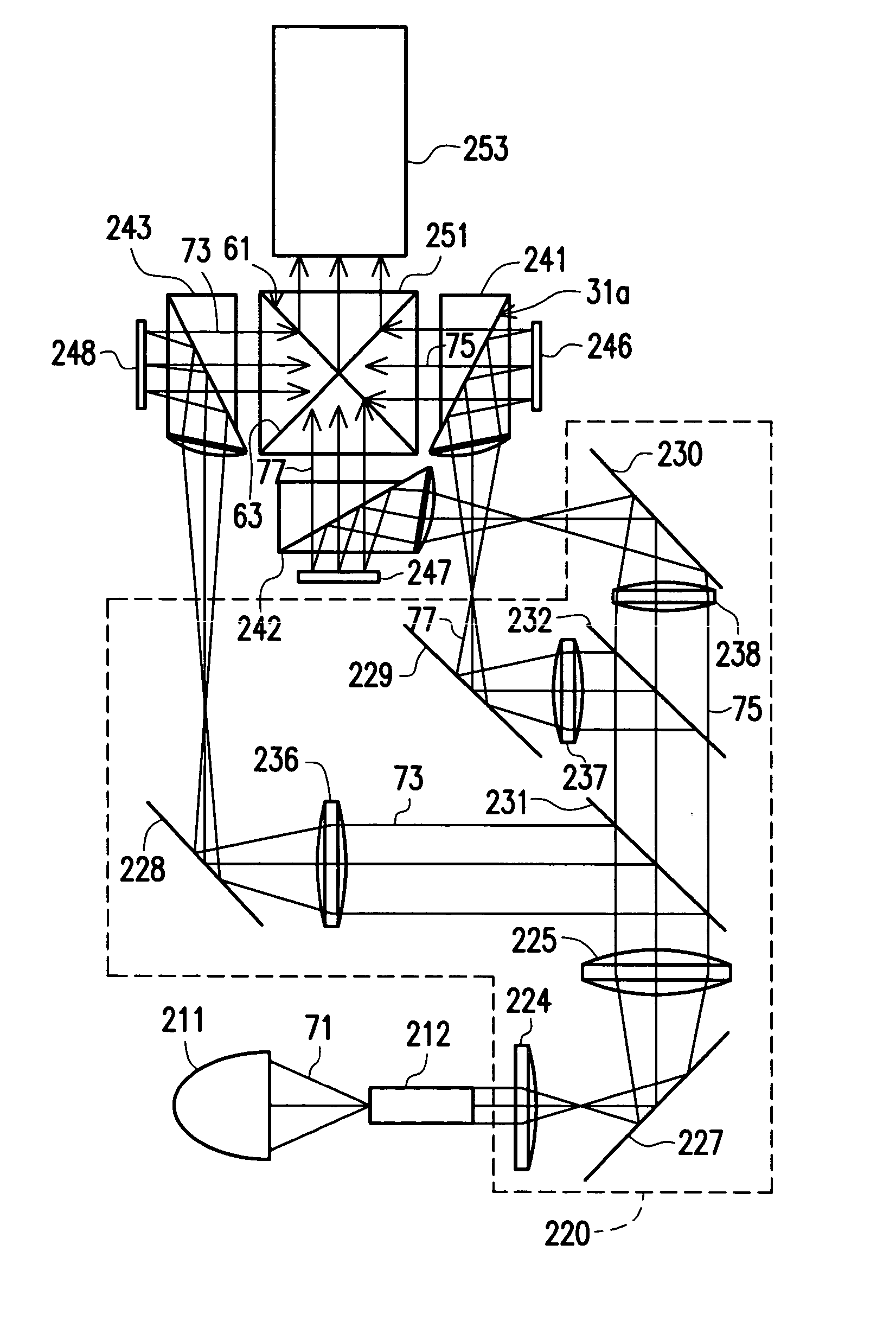

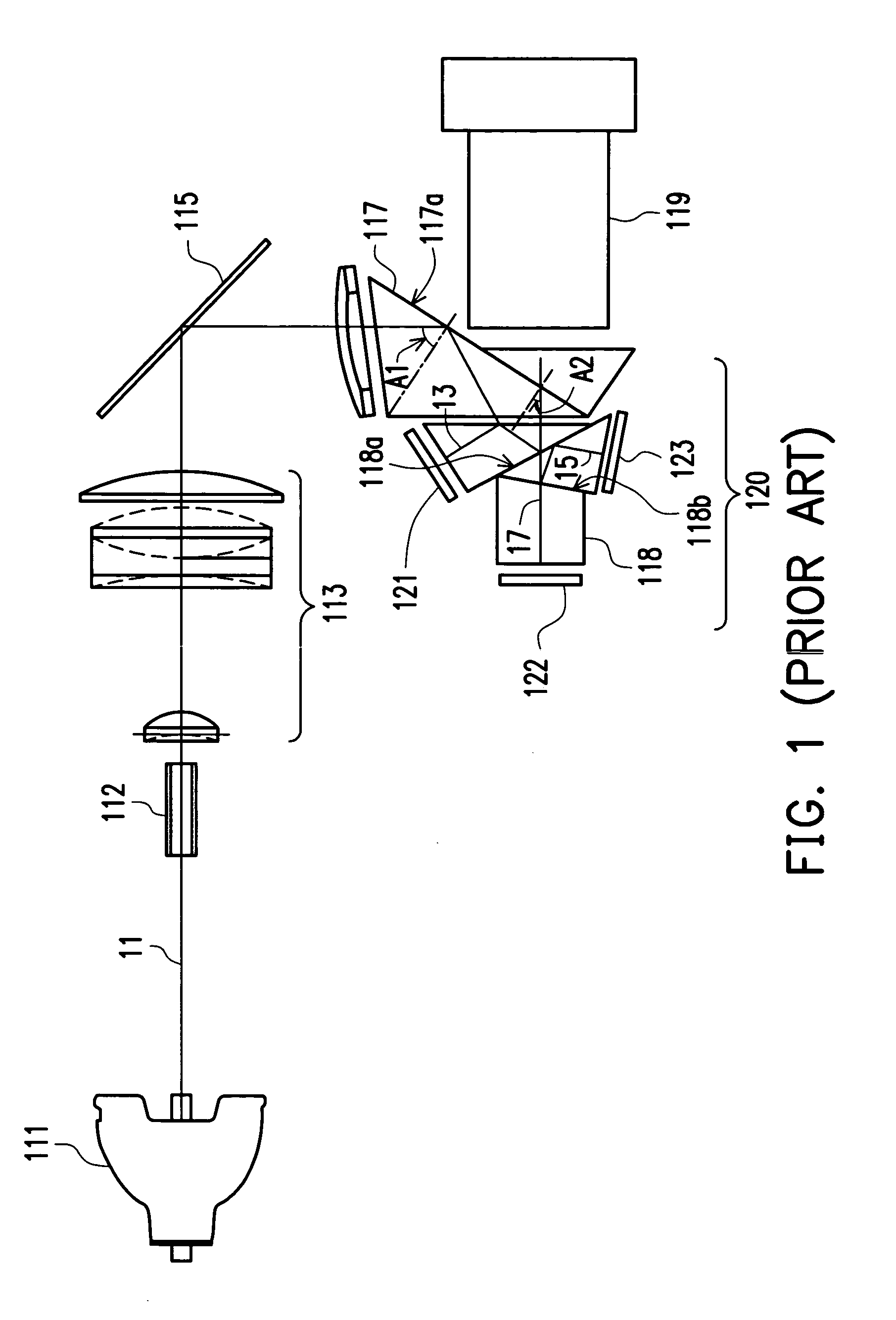

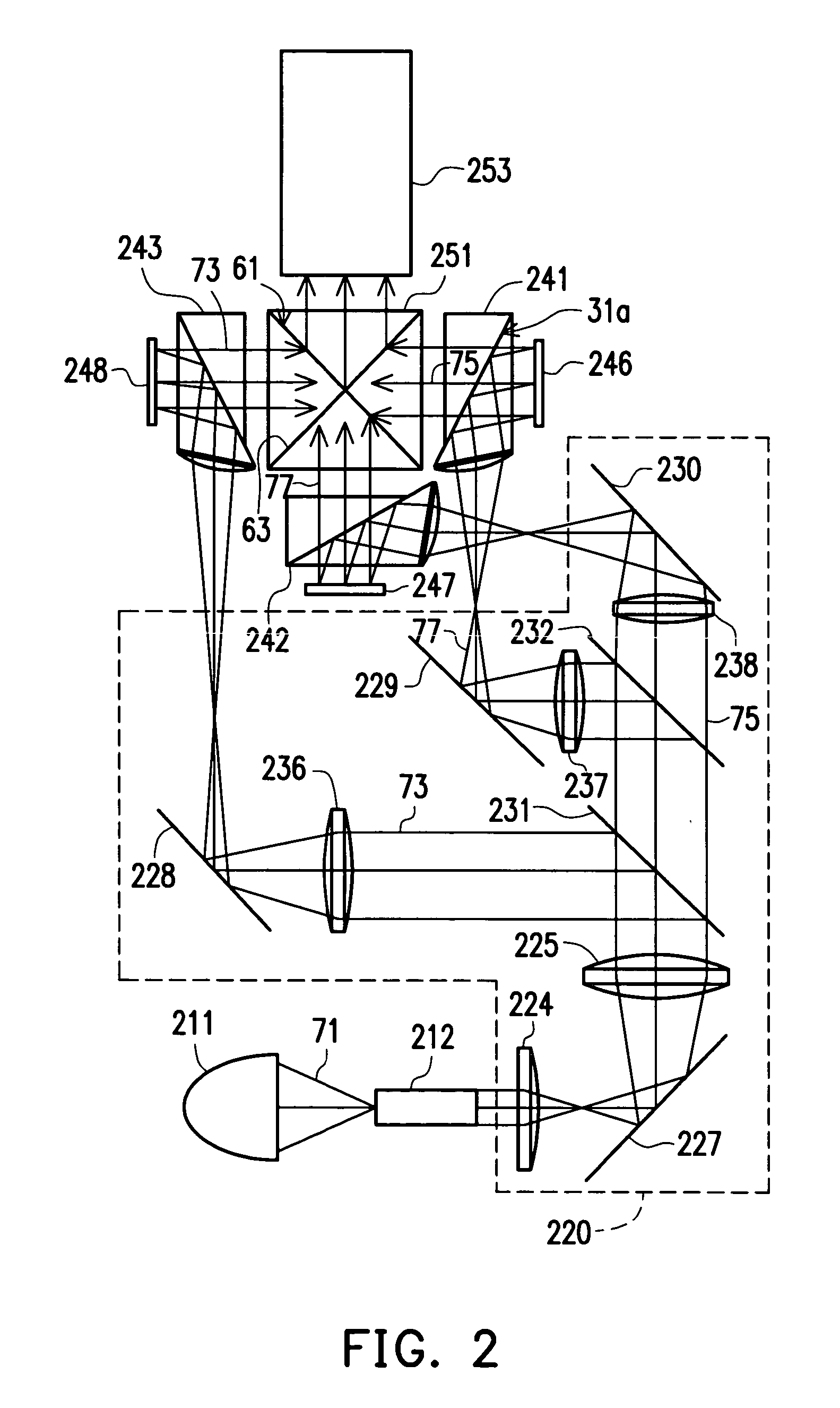

Digital light processing projector

ActiveUS20050057729A1Small sizeProjection quality is not alteredProjectorsOptical elementsTotal internal reflectionPrism

A digital light processing projector comprising a light source, a splitter module, a plurality of total internal reflection (TIR) prisms and digital mirror devices (DMDs), a combiner and a projection lens is provided. The splitter module is disposed in the light path of the light after the light source to split the light into a plurality of color lights. Each color light is incident to the total reflection plane of the TIR prism with an incident angle larger than the critical angle, and then is totally reflected to the DMD. Thereafter, each color light is reflected by the DMD being incident to the total reflection plane of the TIR prism with an incident angle smaller than the critical angle, and then passes through the TIR prism directly. The color lights passing through the TIR prisms are combined by the combiner and then projected by the projection lens.

Owner:DELTA ELECTRONICS INC

Construction technology for long-spiral cast-in-place pile extruded into rock

ActiveCN103850249AReasonable structural designEasy to operateDrilling rodsRotary drillingSlurryEngineering

The invention discloses a construction technology for a long-spiral cast-in-place pile extruded into rock. The construction technology comprises the following steps: 1) embedding a pile casing: embedding the pile casing in a pile position acquired by surveying and setting out; 2) drilling a hole: downward drilling by a long-spiral pile machine and acquiring a constructed and formed hole after drilling in place; 3) lifting a drill rod and protecting a wall with slurry: upward lifting the drill rod after drilling in place till taking the drill rod out of the formed hole, adopting a grouting device and pumping the wall-protecting slurry through the drill rod during the process of upward lifting the drill rod, and protecting the wall with the slurry for the formed hole; 4) putting down a reinforced bar cage; 5) grouting concrete: performing concrete grouting construction on the constructed long-spiral cast-in-place pile extruded into rock through a concrete pumping device and a grouting guide tube. The construction technology provided by the invention has the advantages of simple steps, convenience in realization, high hole quality, good construction effect and capability of effectively solving the problems of the present construction for the long-spiral cast-in-place pile extruded into rock that the hole wall is easy to collapse, the hole is repeatedly cleaned, the construction efficiency is low, and the like.

Owner:SHAANXI ZHUANGXIN CONSTR ENG

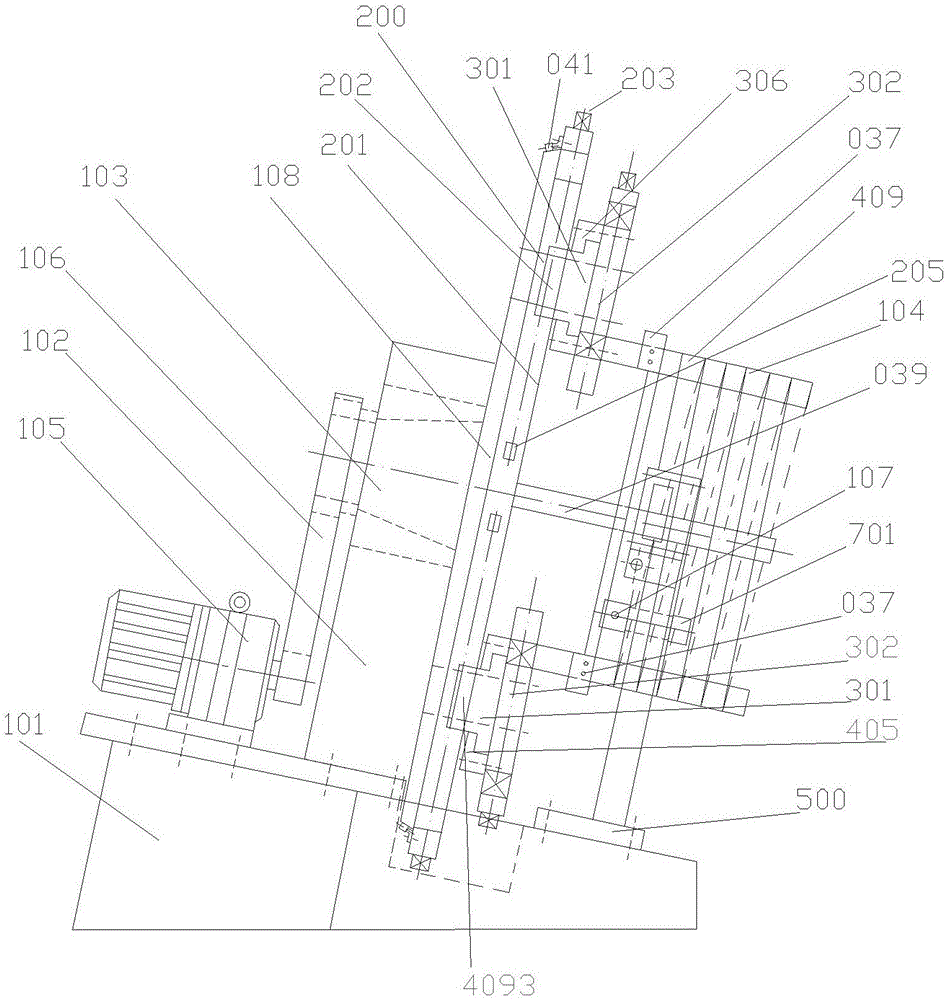

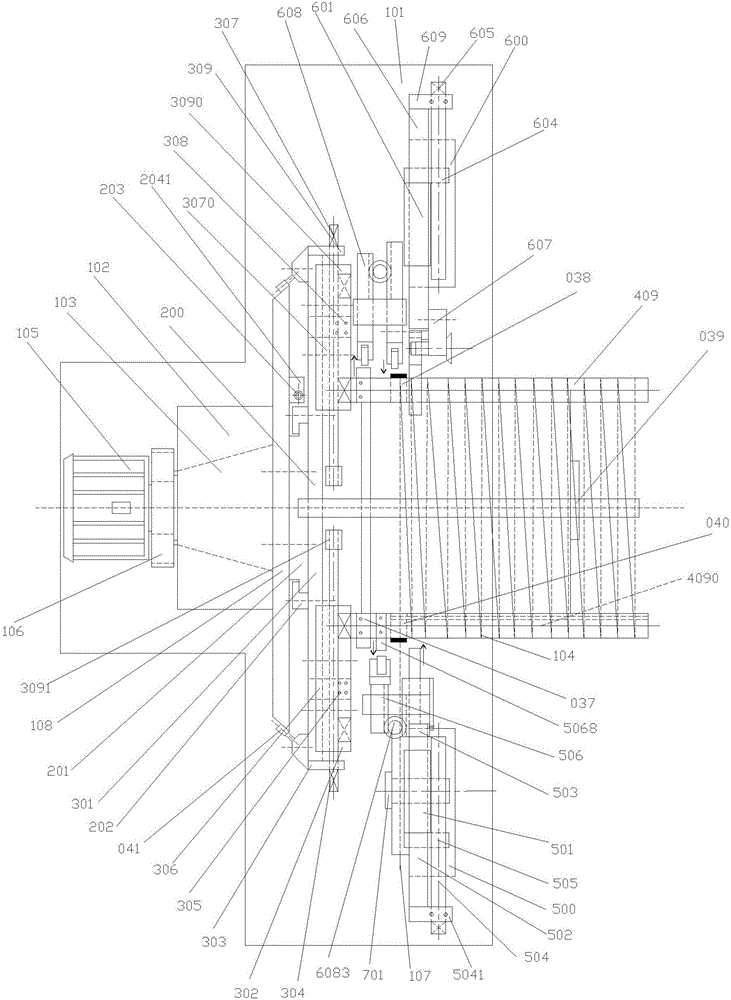

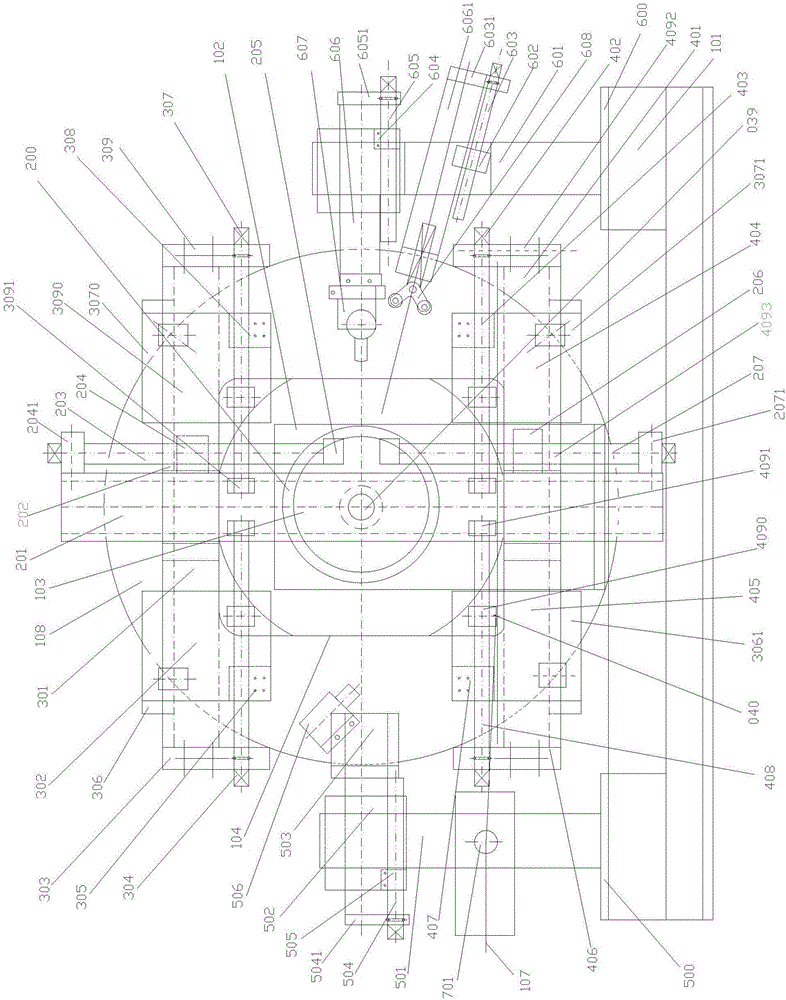

Spiral stirrup continuously and synchronously machining machine and machining method

The invention discloses a spiral stirrup continuously and synchronously machining machine and a machining method. The machining machine comprises a machine body seat, a spiral stirrup machining device and a monitoring device. The spiral stirrup machining device comprises a rotary workbench, a stirrup winding mechanism, a feeding mechanism and a cutting mechanism. The stirrup winding mechanism comprises a stirrup twining frame, a rolling type bending mechanism and a screw pitch axial feed mechanism. The monitoring device comprises a control device, a counting unit and a rotating speed measuring unit. The machining method comprises the first step of determining the number of winding shafts and the installation position, the second step of adjusting the positions of the winding shafts, the third step of feeding and positioning stirrup material, the fourth step of forming spiral stirrups and the fifth step of cutting spiral stirrups. The machining machine is simple in structure, continuous machining of spiral stirrups is achieved, and the production efficiency is high; meanwhile, the concrete constraining force of beam columns of buildings can be improved through the produced spiral stirrups, and therefore the seismic capacity of the buildings is improved. Practicality is high, and the machining machine and the machining method are low in carbon, environmentally friendly and efficient and save energy.

Owner:刘国政 +1

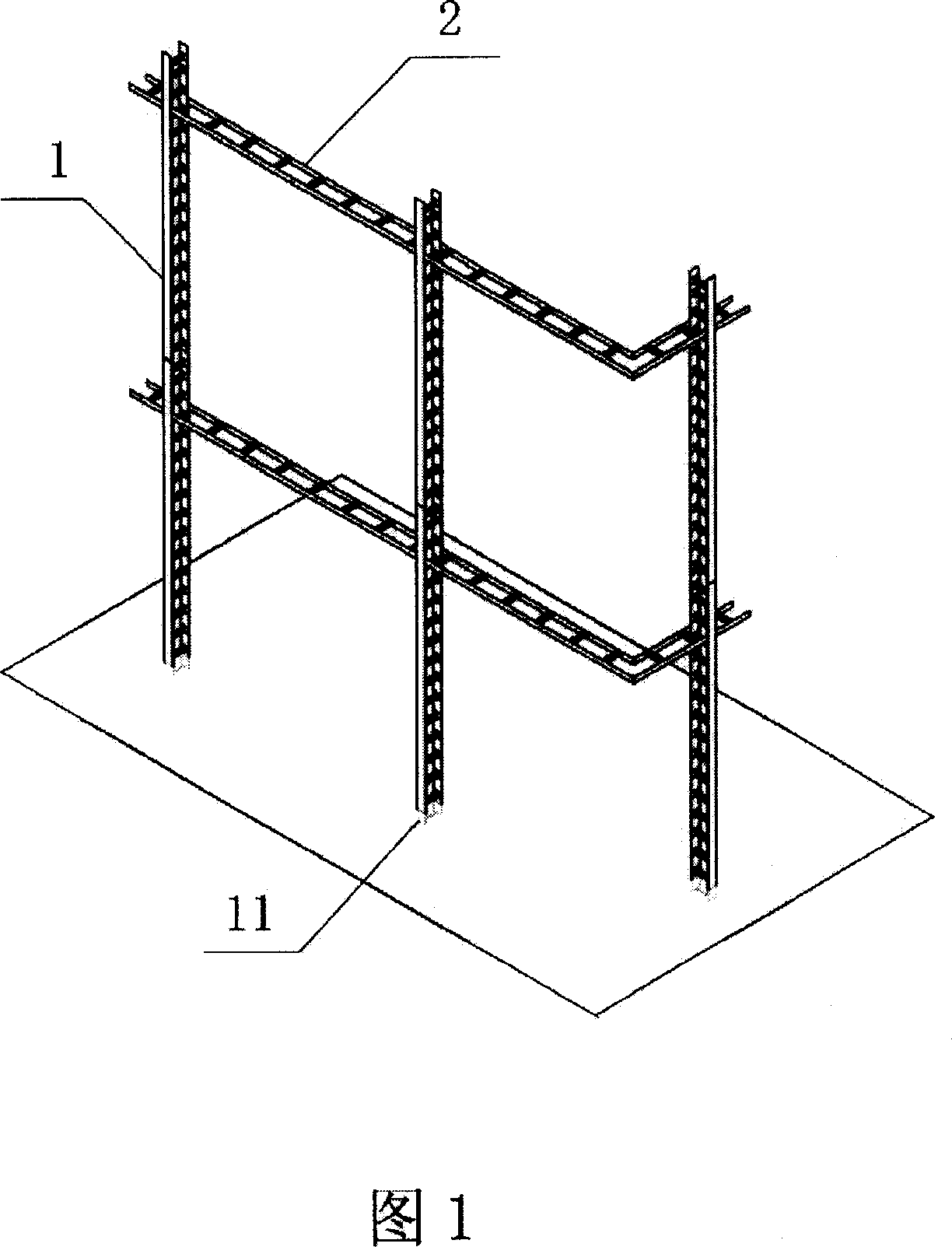

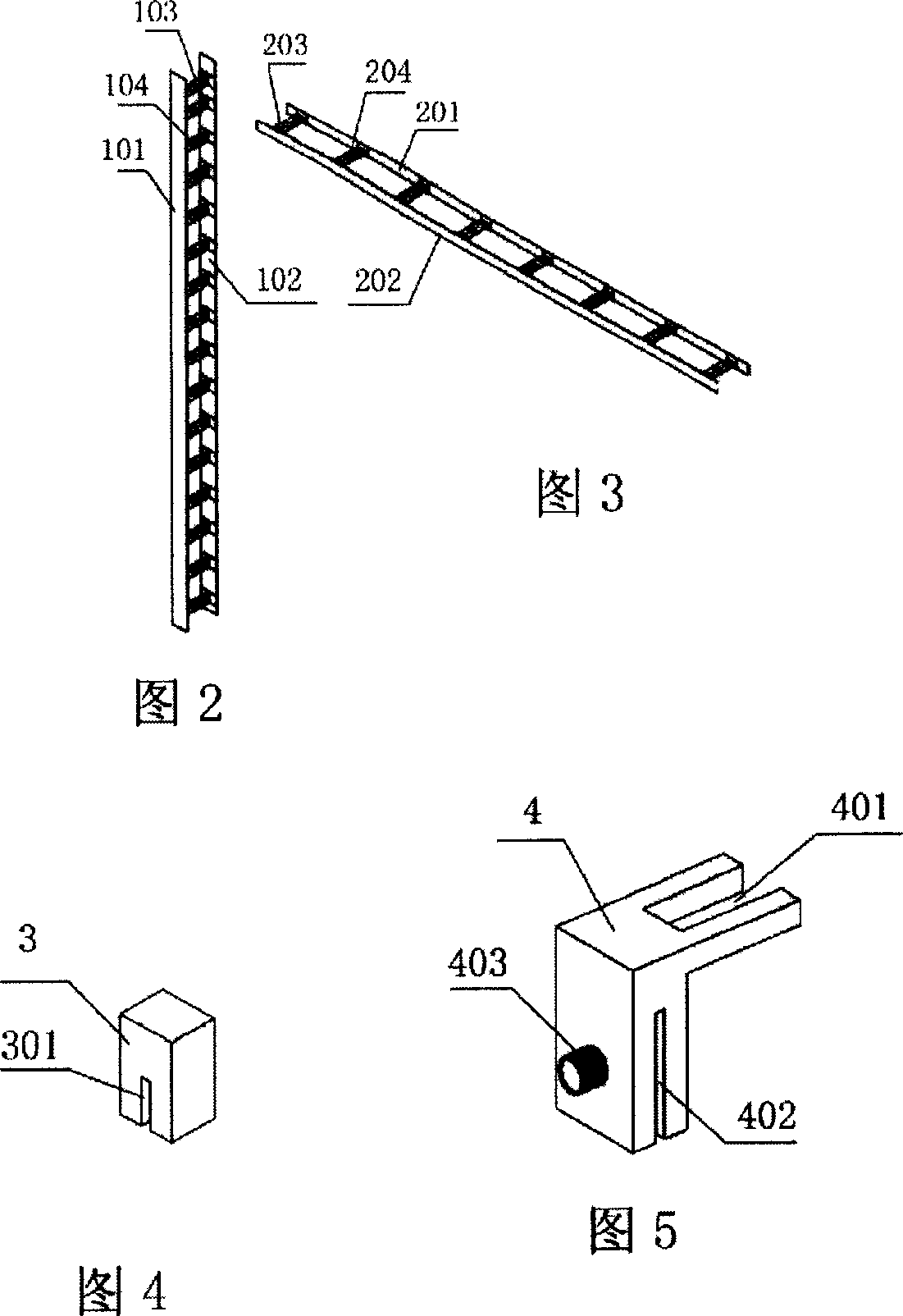

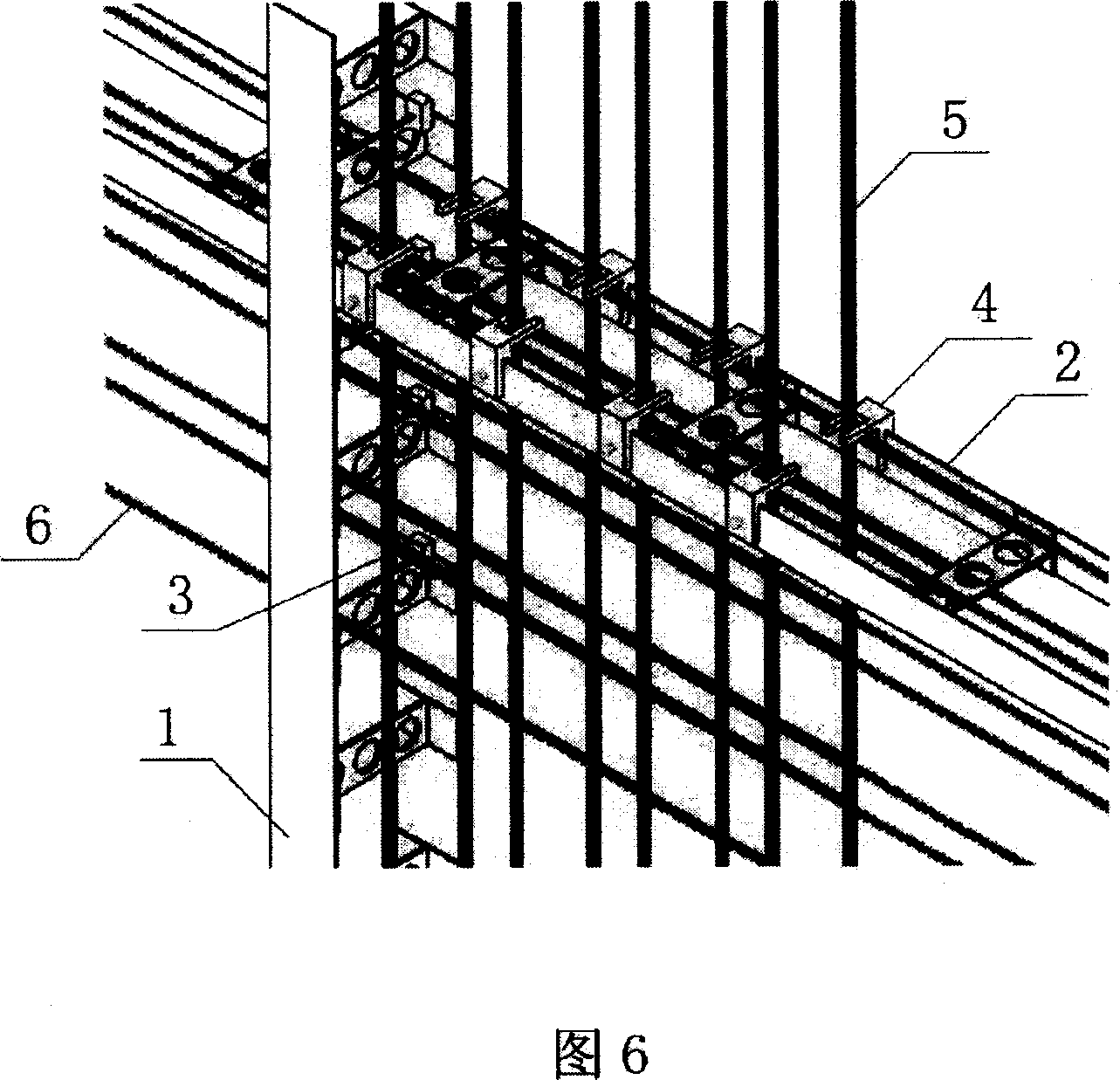

Concrete building reinforcing-bar precision positioning system and its construction method

InactiveCN1936228ANo displacementAvoid corrosionBuilding reinforcementsBuilding material handlingRebarPositioning system

The invention relates to a concrete construction reinforcing steel bar accurate locating system and the constructing method. It includes vertical localizer, horizontal positioning, vertical reinforcing steel bar locating block component, horizontal reinforcing steel bar locating block component, and pre-buried steel component. The vertical localizer is made up of inner board, external board, crosspiece fixation stairway stringer that is plumbed to vertical reinforcing steel bar and paralleled to horizontal reinforcing steel bar, and has the same thickness with wall and the same width with cavity of it. The invention could improve constructing speed and increase the constructing accuracy and entire rigidity of the reinforcing steel bar construction.

Owner:朱秦江

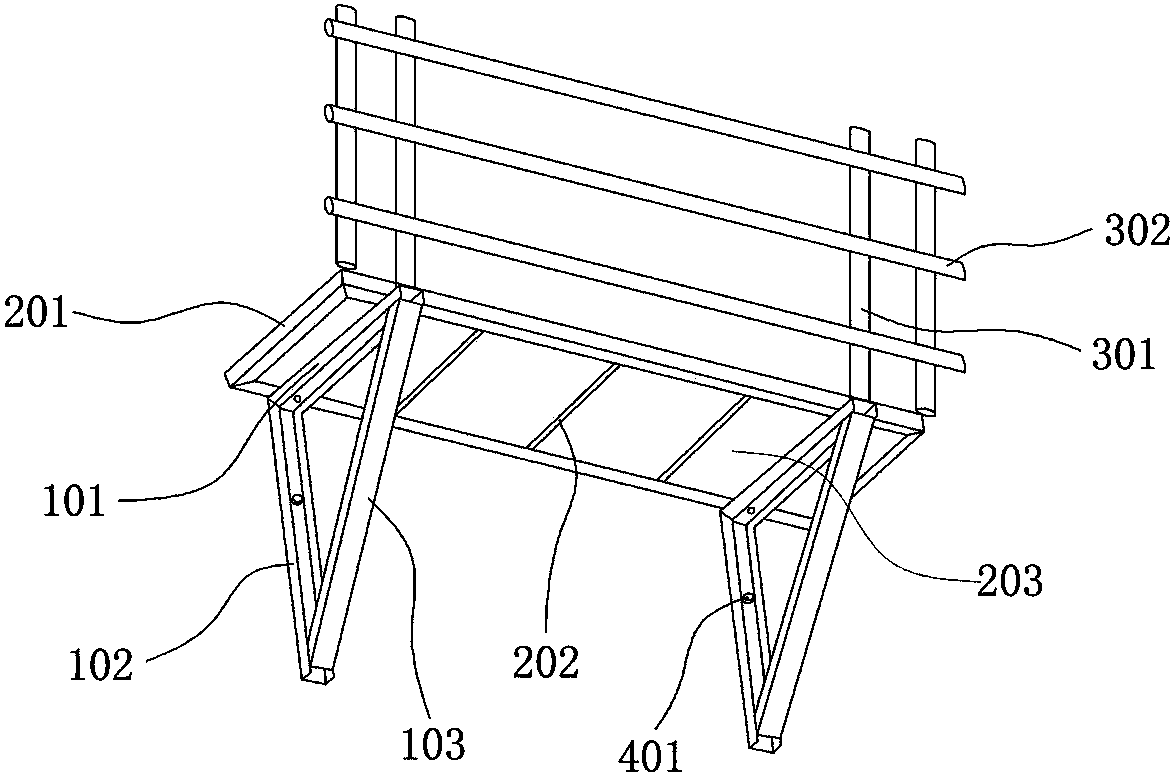

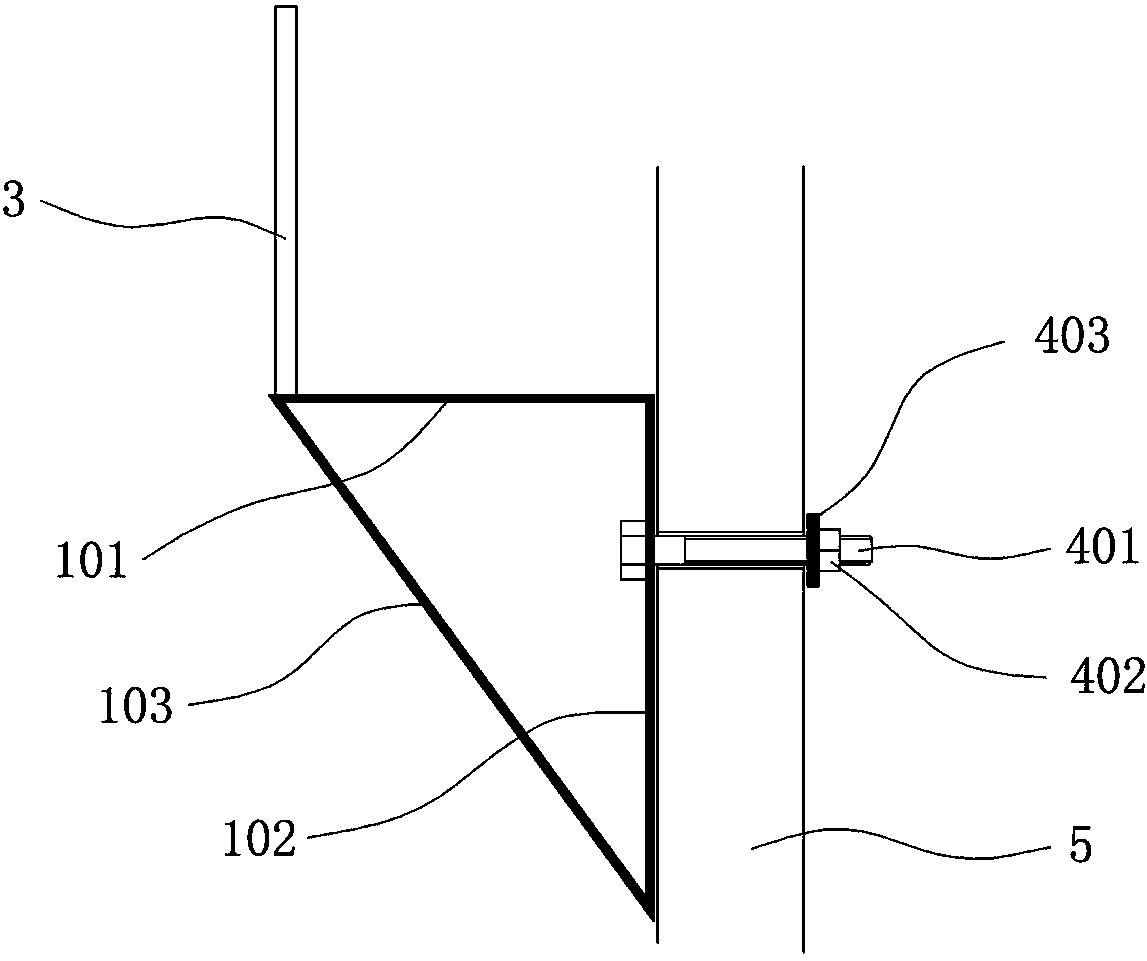

Construction method of prefabricated assembled building

ActiveCN104074358AFast constructionSimple structureBuilding material handlingScaffold accessoriesEngineeringSlurry

The invention discloses a construction method of a prefabricated assembled building. The construction method comprises the following steps of designing and manufacturing of prefabricated components, acceptance inspection and field entering of the prefabricated components, measurement, paying-off, installation of the prefabricated components, and the like. In the process of installing the prefabricated components, the building is built and constructed through installing two layers of outer wall protection frames and adopting a method of using double-layer frame bodies in an exchange way. The construction method has the advantages that the construction work procedures of installing, correcting and fixing outer wall plates, casting concrete slurry and the like are completed in modes of forming wall connecting preserved holes in the prefabricated outer wall plates and installing the outer wall protection frame; the arrangement of a great number of embedded parts and suspended holes on an outer wall is avoided; the engineering quality is improved; and the damage rate of the outer wall engineering is reduced.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

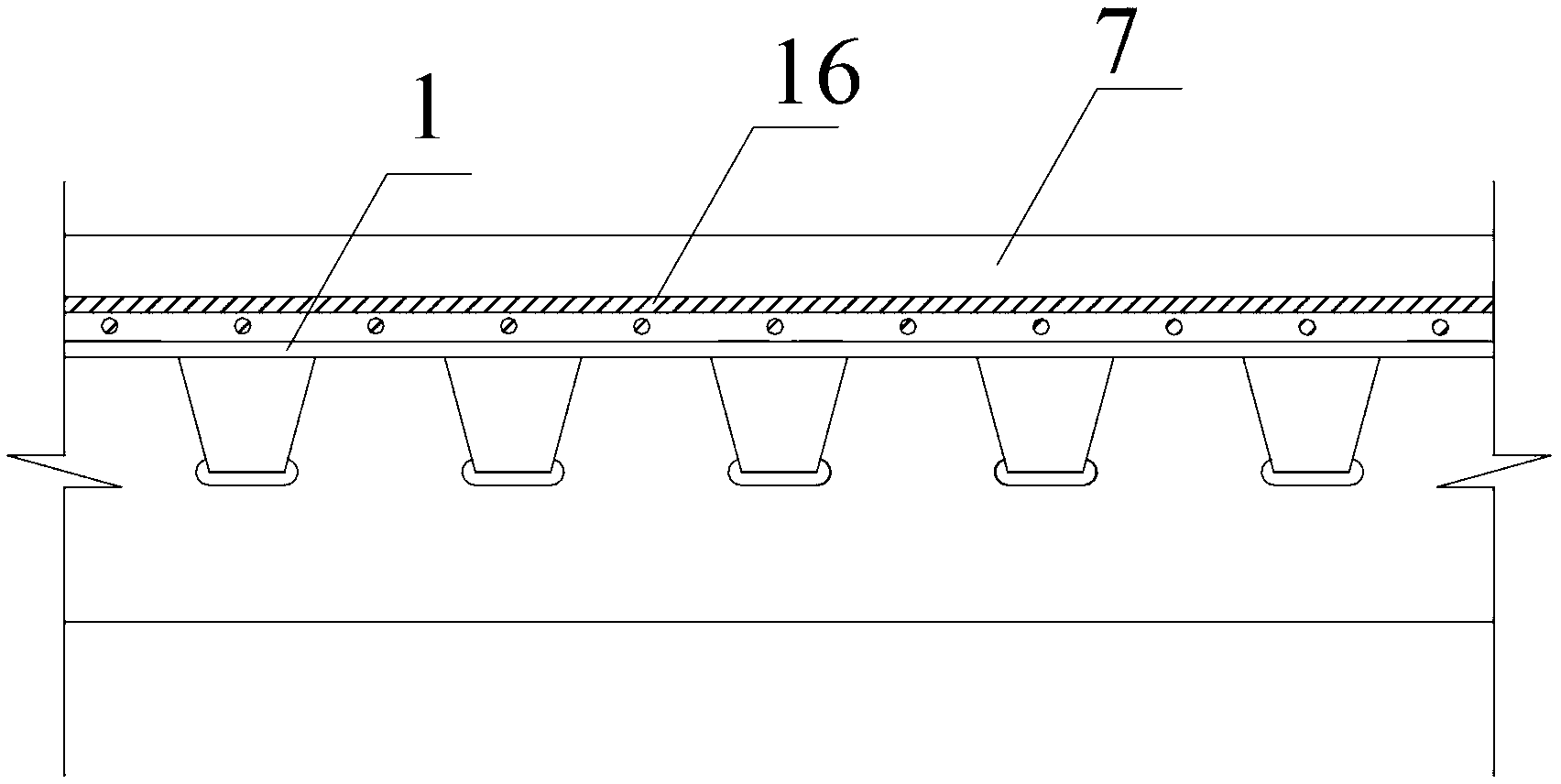

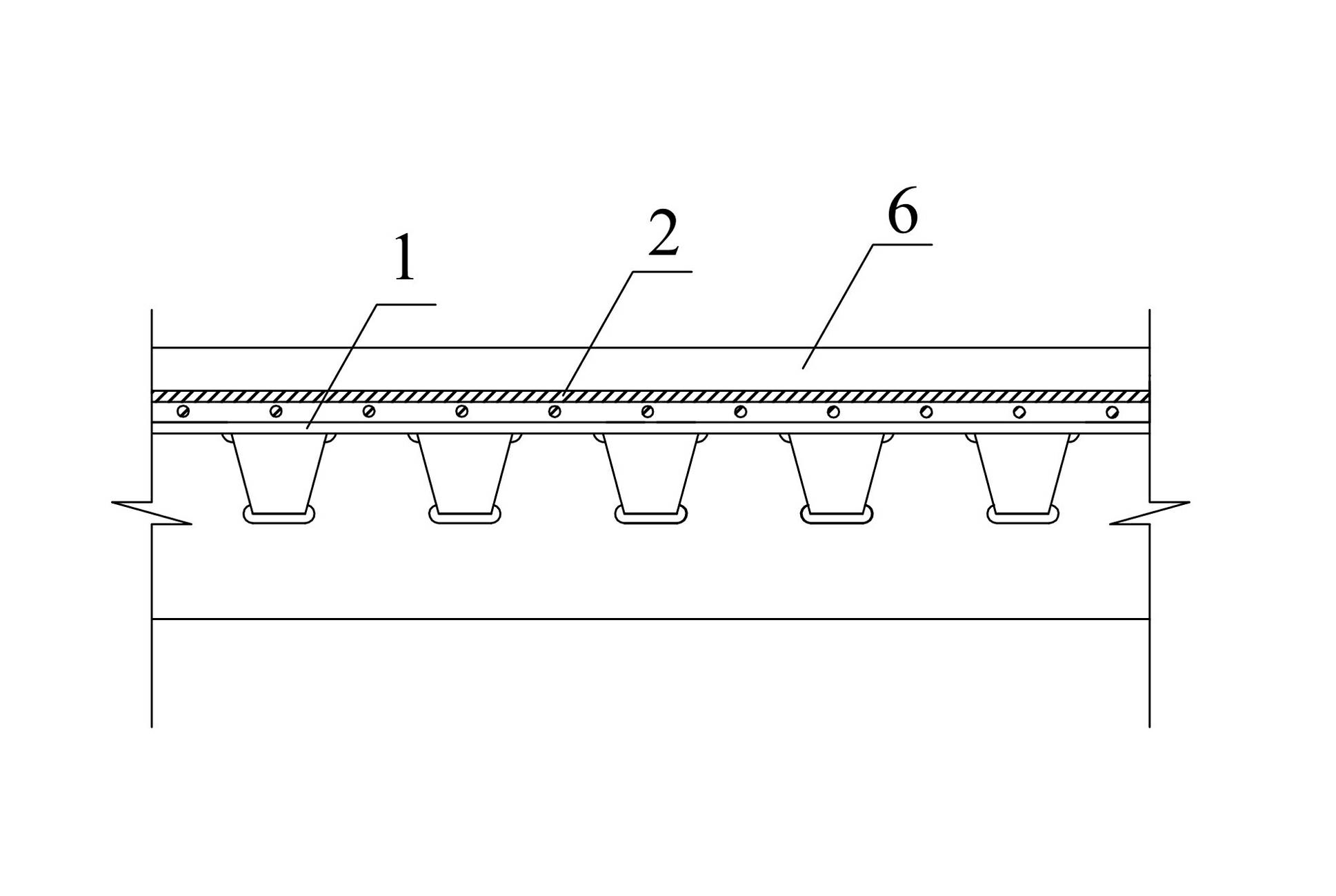

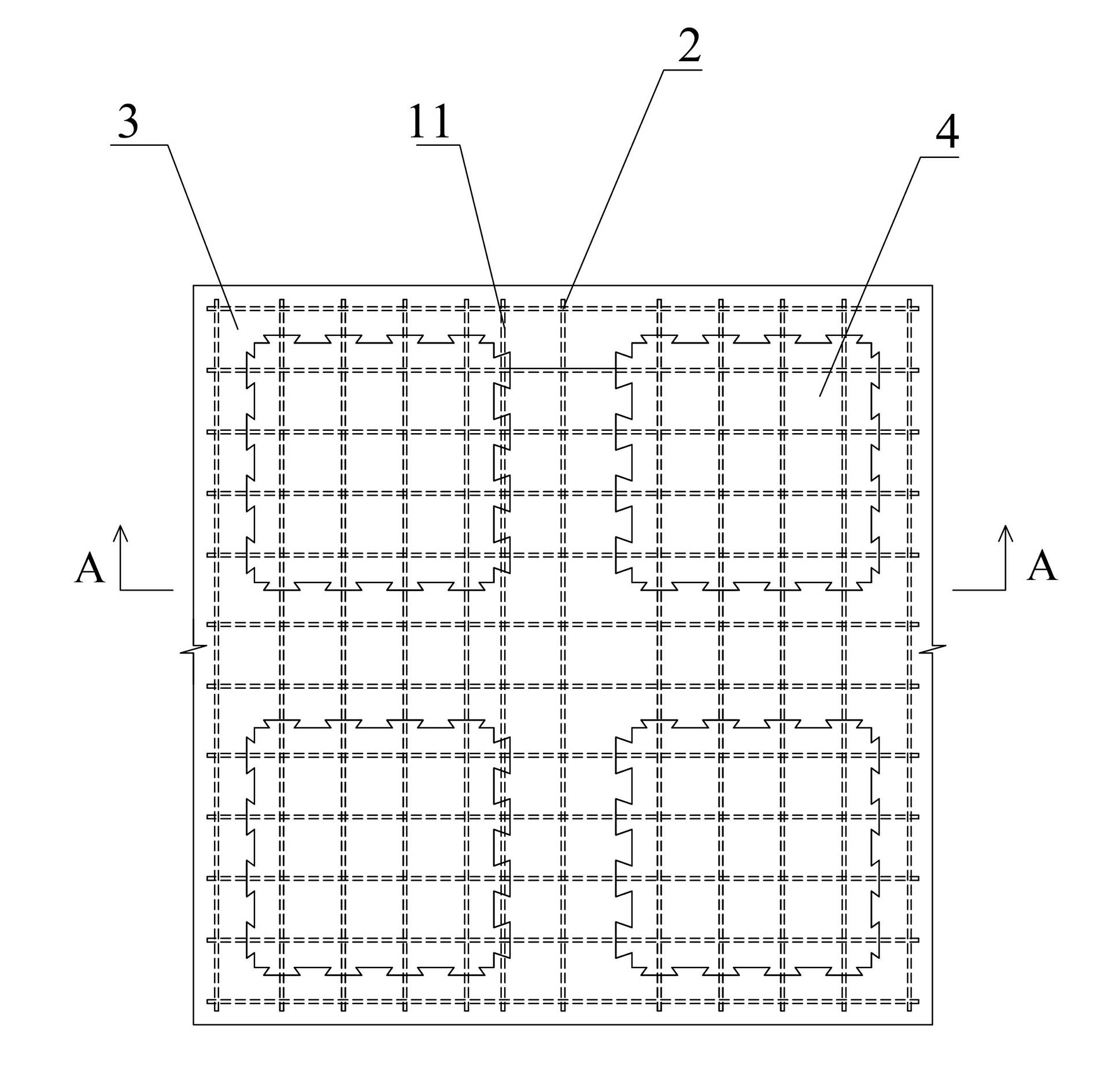

Fabricated fibrous concrete combined deck structure and construction method thereof

ActiveCN102383374AChange structureChange work statusBridge structural detailsBridge erection/assemblyArchitectural engineeringBridge deck

The invention discloses a fabricated fibrous concrete combined deck structure and a construction method thereof. The combined deck structure comprises a steel bridge deck layer, wherein a fabricated fibrous concrete layer covers the upper surface of the steel bridge deck layer; the main body of the fabricated fibrous concrete layer is a cast-in-situ fibrous concrete layer; a plurality of prefabricated fibrous concrete plates are in embedded connection with the cast-in-situ fibrous concrete layer; tongue-and-groove joints articulated with the cast-in-situ fibrous concrete layer are arranged at the periphery of each prefabricated fibrous concrete plate; and the fabricated fibrous concrete layer is equipped with steel bars. The construction method comprises the following steps: the steel bridge deck layer is manufactured at first, and then the prefabricated fibrous concrete plates are manufactured and laid, or steel bridge deck blocks are prefabricated at first, and steel beams are erected and assembled; after that, the construction of the cast-in-situ fibrous concrete layer and the surface treatment are carried out in sequence; and the construction is completed finally. The combined deck structure disclosed by the invention can improve the tensile strength limit of concrete slabs and effectively prevent a pavement layer from cracks, and has good service durability, good fatigue resistance; and the construction process is simple and efficient.

Owner:HUNAN UNIV

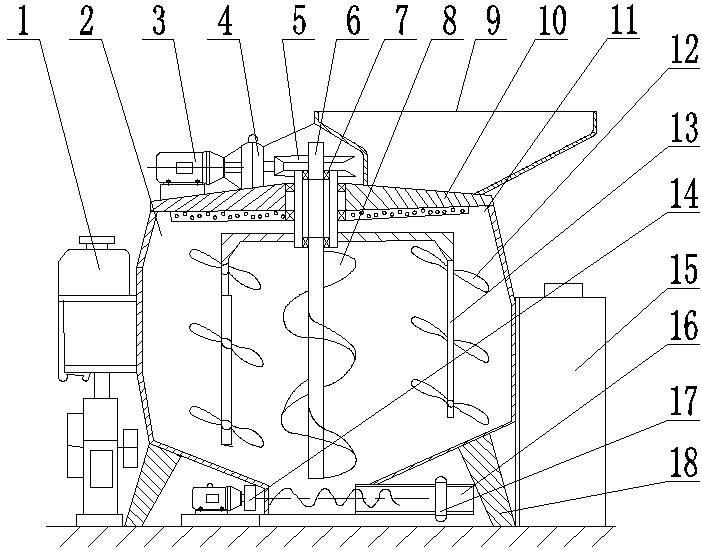

Concrete mixing grout transporting equipment

The invention discloses concrete mixing grout transporting equipment. The concrete mixing grout transporting equipment comprises a power system, a mixing cabin, a feed hopper and a mixing mechanism, wherein the power system and the mixing cabin are fixed on the ground; the power of the mixing mechanism is supplied by the power system. The concrete mixing grout transporting equipment is characterized in that: a mixing cabin door capable of opening and closing the mixing cabin is arranged at the connection position of the mixing cabin of the feed hopper; a cleaning mechanism used for cleaning the mixing cabin is arranged on the mixing cabin door; a way of combining a mixing main shaft and a plurality of mixing countershafts is adopted by the mixing mechanism; a propeller is arranged on the mixing main shaft; mixing blades are arranged on the mixing countershafts; a thruster and a discharge tube which are used for delivering a finished concrete product according to a ration are arranged on a discharge hole of the mixing cabin; and valves are arranged in a feed inlet of the thruster and in the discharge tube. The concrete mixing grout transporting equipment has the characteristics of simple structure and wide applicability.

Owner:贵港市新梅农业科技有限公司

Whole-high valent titanium slag concrete

ActiveCN1880258AReduce total usageLow costSolid waste managementNational standardMechanical property

The invention discloses a concrete of high-titanium slag, including cement, high-titanium slag rubble, high-titanium slag sand, mineral admixture, matching designing according to national standard, the quantity of high-titanium slag sand matched in the concrete increases 3%-6% in the base of design, in which the content of ground-slag is 10%-18%, watering high-titanium slag rubble and high-titanium slag sand before agitating, then adding the compositions to the agitator according to the priority of block aggregate, cement, admixture, fine aggregate and agitating for the time that extends 10-30 seconds than normal concrete, the concrete not only makes use of waste resource effectively and also protects the environment and has good mechanical property.

Owner:攀枝花环业冶金渣开发有限责任公司

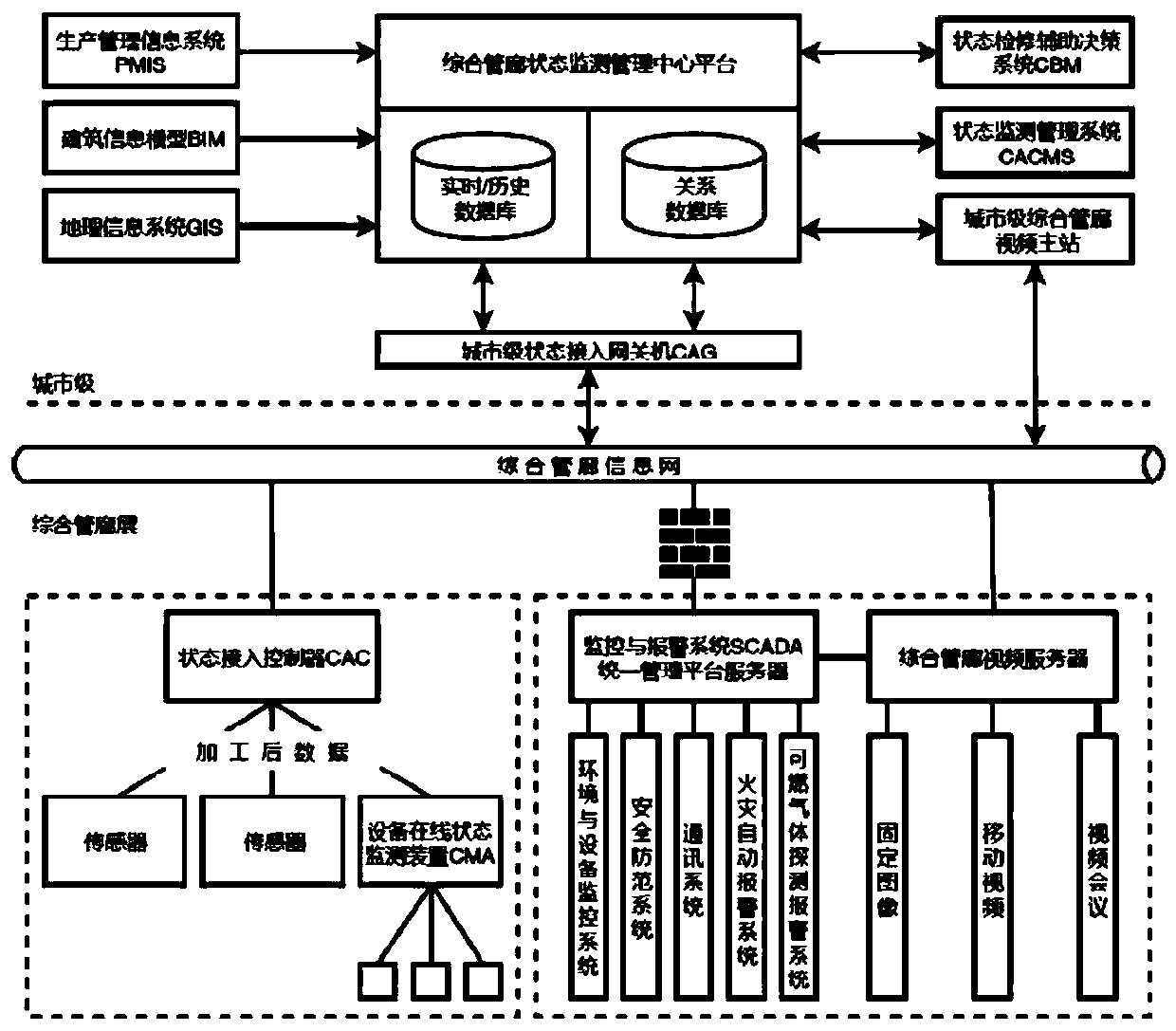

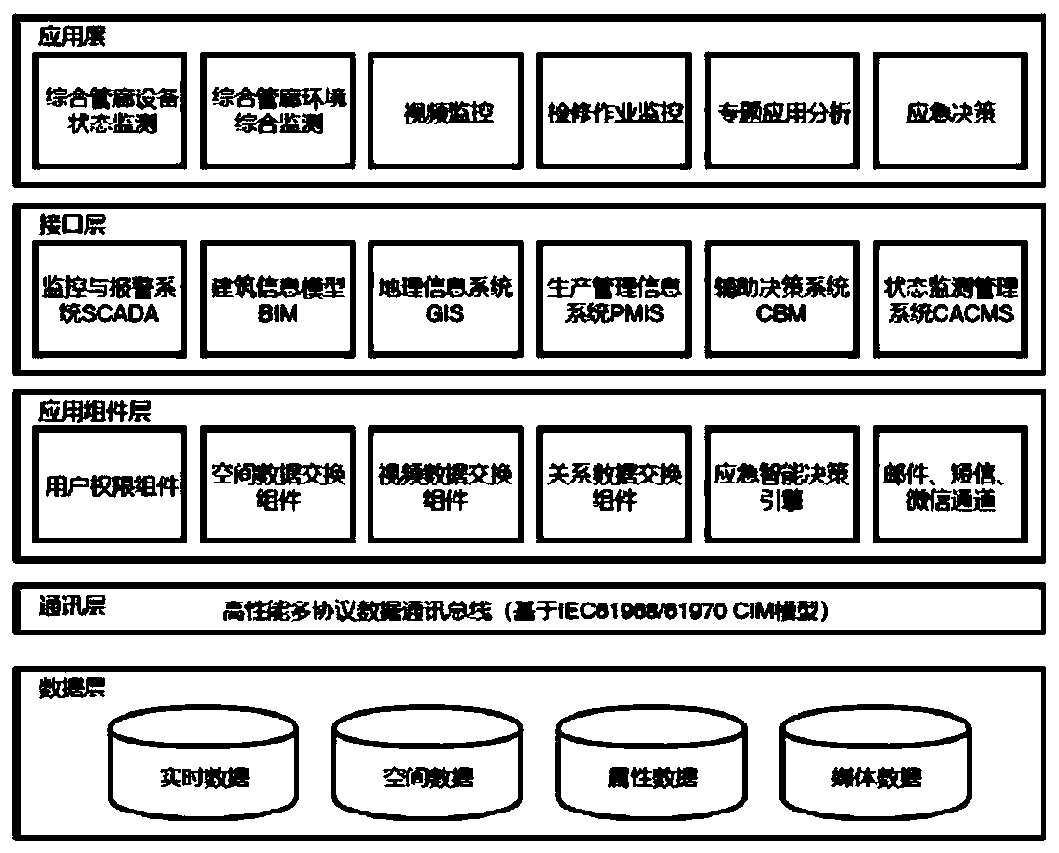

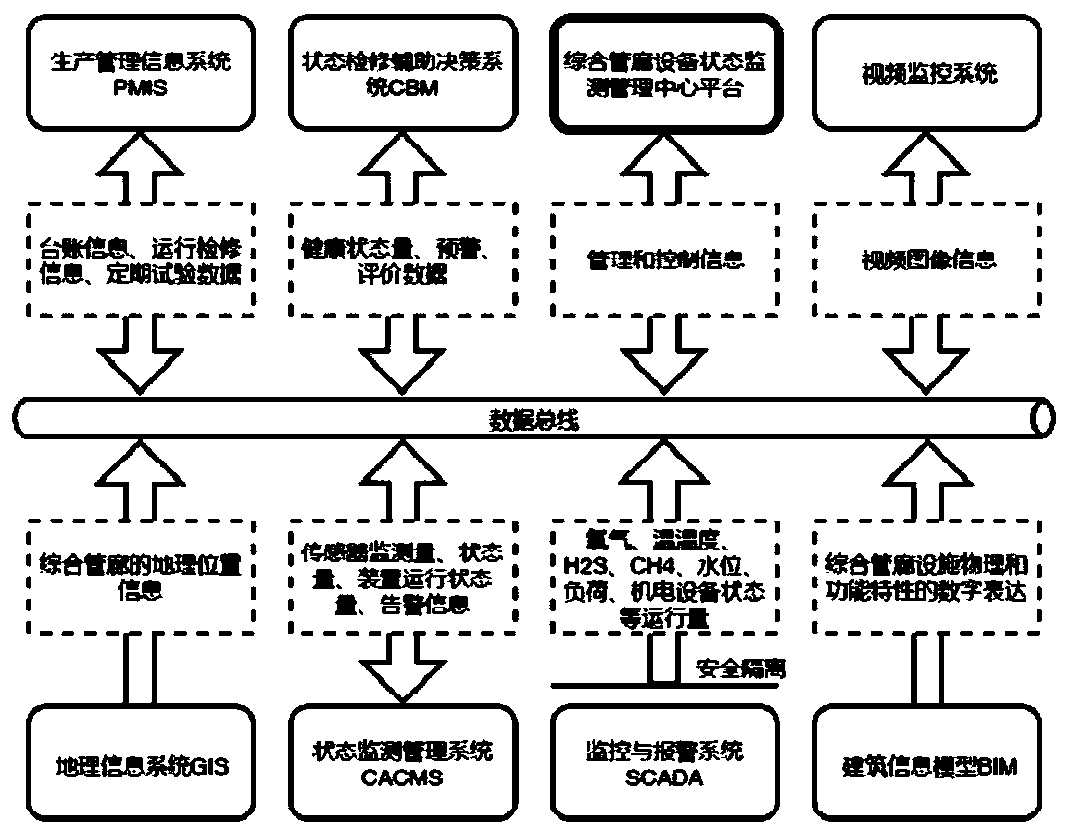

Comprehensive pipe gallery equipment state monitoring and management system

PendingCN110428135AComprehensive and timely information serviceImprove operational efficiencyRegistering/indicating working of machinesHardware monitoringTime informationData warehouse

The invention discloses a comprehensive pipe gallery equipment state monitoring and management system which is characterized by comprising a comprehensive pipe gallery layer system and a city-level system. According to the invention, a real-time database, a data warehouse and an intelligent platform tool are used as key technical means; a centralized and unified integration and sharing platform isprovided for various real-time information and production management information; a comprehensive pipe gallery equipment state unified centralized monitoring system is established; real-time information and business information based on manual work are effectively collected, converted, integrated, loaded and displayed, and more comprehensive and timely information services are better provided forvarious business fields such as comprehensive pipe gallery production operation commanding, emergency disposal, gallery entry professional pipeline operation management and state maintenance.

Owner:SHANGHAI ELECTRICAL APPLIANCES RES INSTGROUP +1

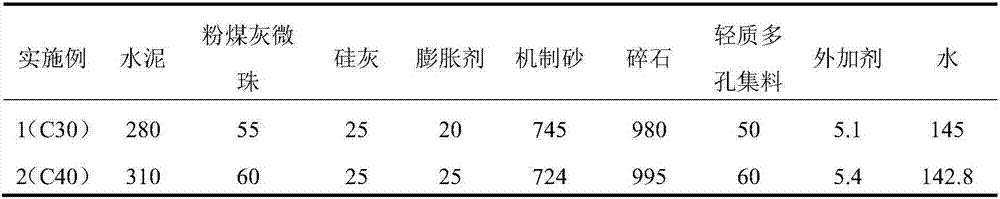

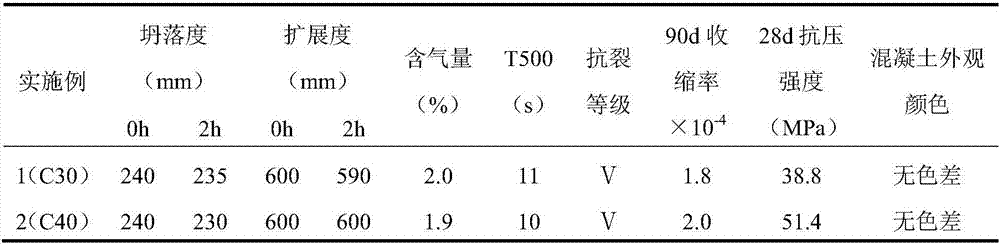

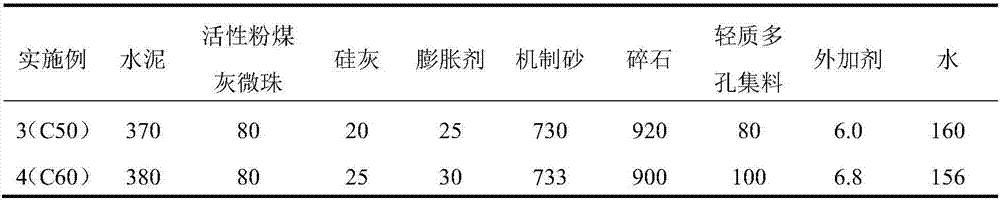

Bridge self-compaction anti-crack bare concrete prepared by utilizing high fine powder content machine-made sand

The invention discloses a bridge self-compaction anti-crack bare concrete prepared by utilizing high fine powder content machine-made sand. The bridge self-compaction anti-crack bare concrete is prepared from cement, activated fly ash microbeads, silica fume, an expanding agent, machine-made sand, gravel, a light-weight porous aggregate, a high-performance additive and water. The bridge self-compaction anti-crack bare concrete provided by the invention adopts the high fine powder content machine-made sand to replace common natural river sand, utilizes the activated fly ash microbeads and the silica fume for adjusting the viscosity and the fluidity of the concrete so as to improve the homogeneity of a concrete slurry, and further additive is used for reducing the gas content of the concrete, so that a working performance and a fluidity keeping performance of the concrete are improved; meanwhile, the expanding agent and the light-weight porous aggregate are combined, so that the volume stability and an anti-early-age cracking behavior of the bare concrete can be effectively improved. The self-compaction anti-crack bare concrete obtained through the invention has wide adaptability on different fine powder content machine-made sand, excellent working performance, mechanical property, volume stability performance and anti-cracking ability, uniform appearance and color, and better mirror surface effect.

Owner:WUHAN UNIV OF TECH +2

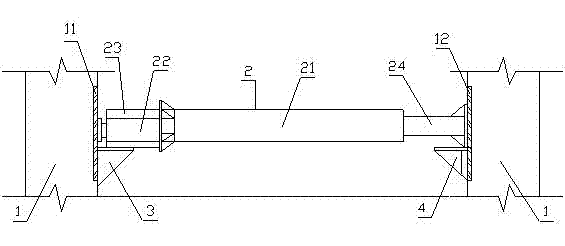

Pit supporting system and installation method

ActiveCN102345295AFast constructionEffective control of deformationArtificial islandsExcavationsSupporting systemEngineering

The invention provides a pit supporting system and an installation method. The pit supporting system comprises a diaphragm wall which is arranged on the surface of a pit body, wherein a first steel plate is longitudinally arranged on one side of the diaphragm wall, a second steel plate is arranged on the diaphragm wall on the side opposite to the side of the first steel plate, a first support is installed on the first steel plate, a second support is installed on the second steel plate, and the first support and the second support are arranged at the same height of a pit; and the two ends of a retractable steel support are respectively arranged on the first support and the second support, and the first steel plate is abutted against the second steel plate. By arranging the supports on the diaphragm wall in the pit to lift the retractable steel support, the effects of reducing construction cost, improving engineering quality, accelerating pit construction and effectively controlling pit deformation are achieved.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD

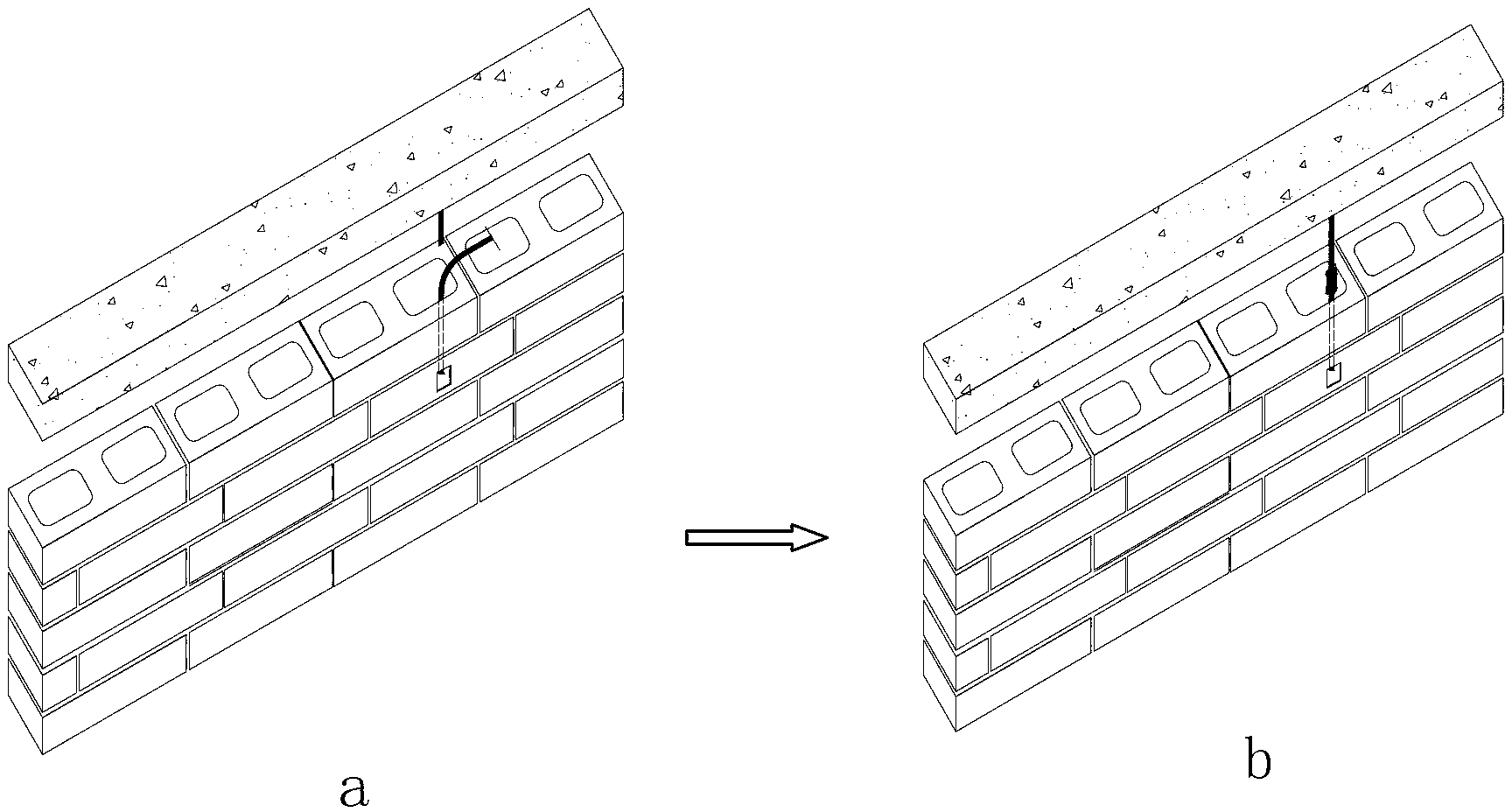

Method for perforating and pre-burying polyvinyl chloride (PVC) wiring tubes in concrete hollow block filled walls

ActiveCN103061515AAvoid destructionImprove project qualityBuilding material handlingEngineeringBuilding construction

The invention discloses a method for perforating and pre-burying polyvinyl chloride (PVC) wiring tubes in concrete hollow block filled walls. PVC wiring tubes are hidden in the hollow block filled walls for one step through cavity characteristics of hollow blocks and the flexibility of PVC wiring tubes. A distribution case is mounted through a method of mounting a case body after reserving a hole on the wall, and a wire box is mounted after a hole is opened on the wall. The method aims to use masonry structure characteristics and reasonable construction processes, the completeness of the wall structure is guaranteed, and the efficiency and the quality of wiring tube, case / box mounting are improved.

Owner:陕西建工第三建设集团有限公司

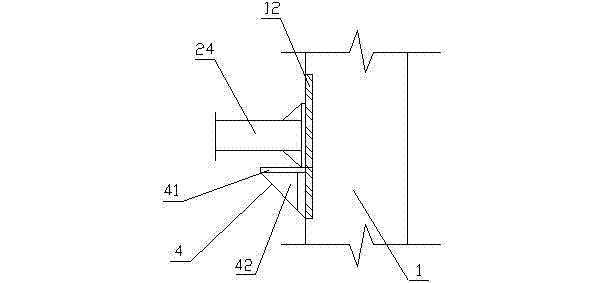

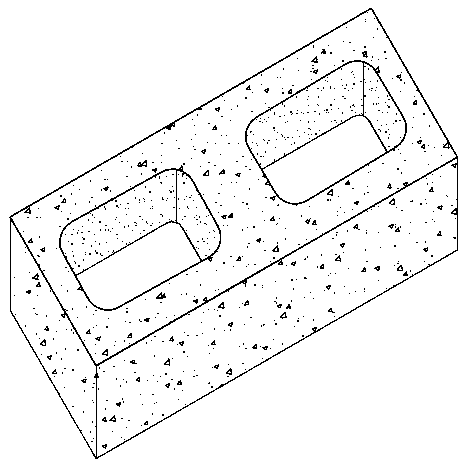

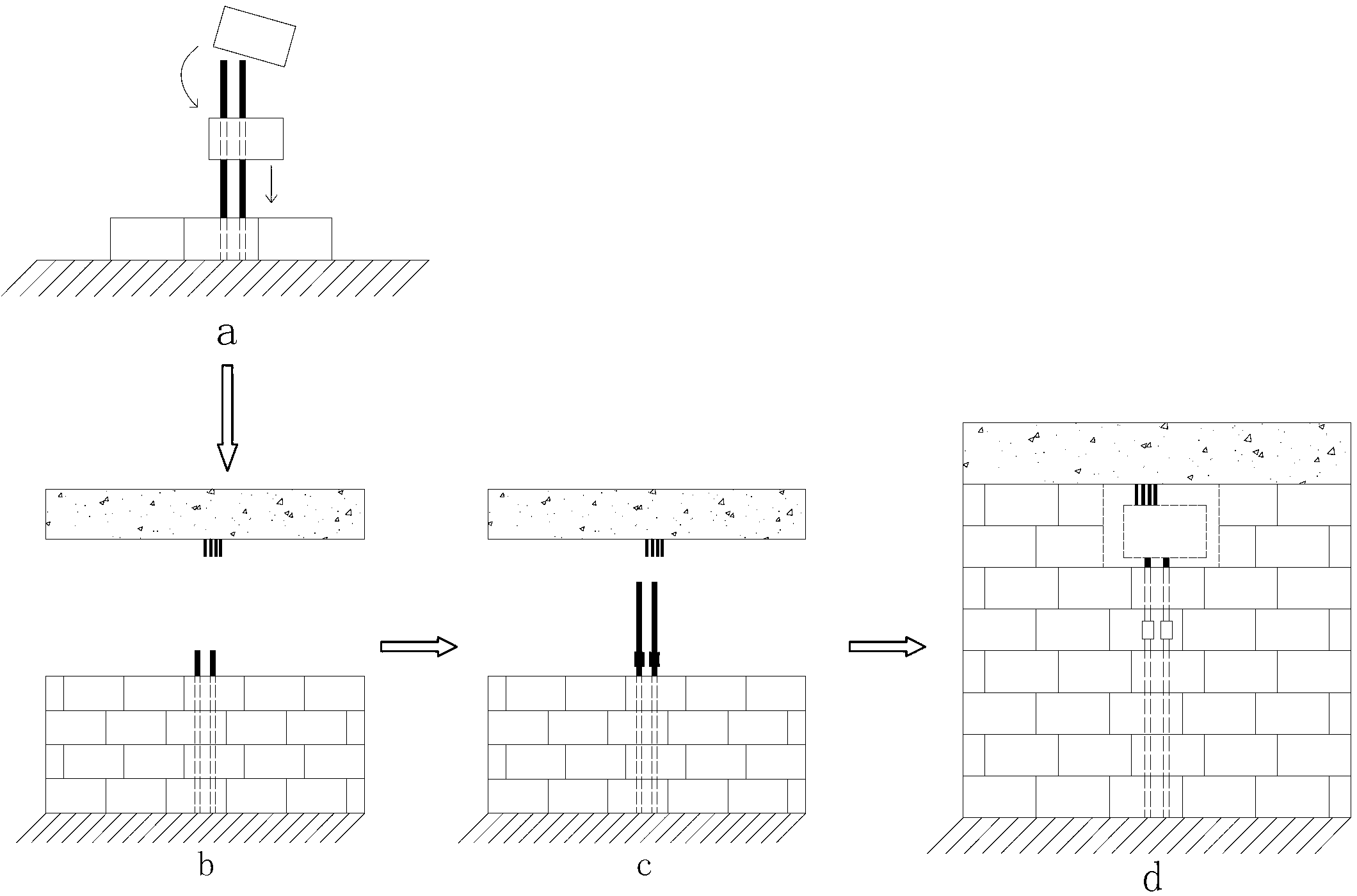

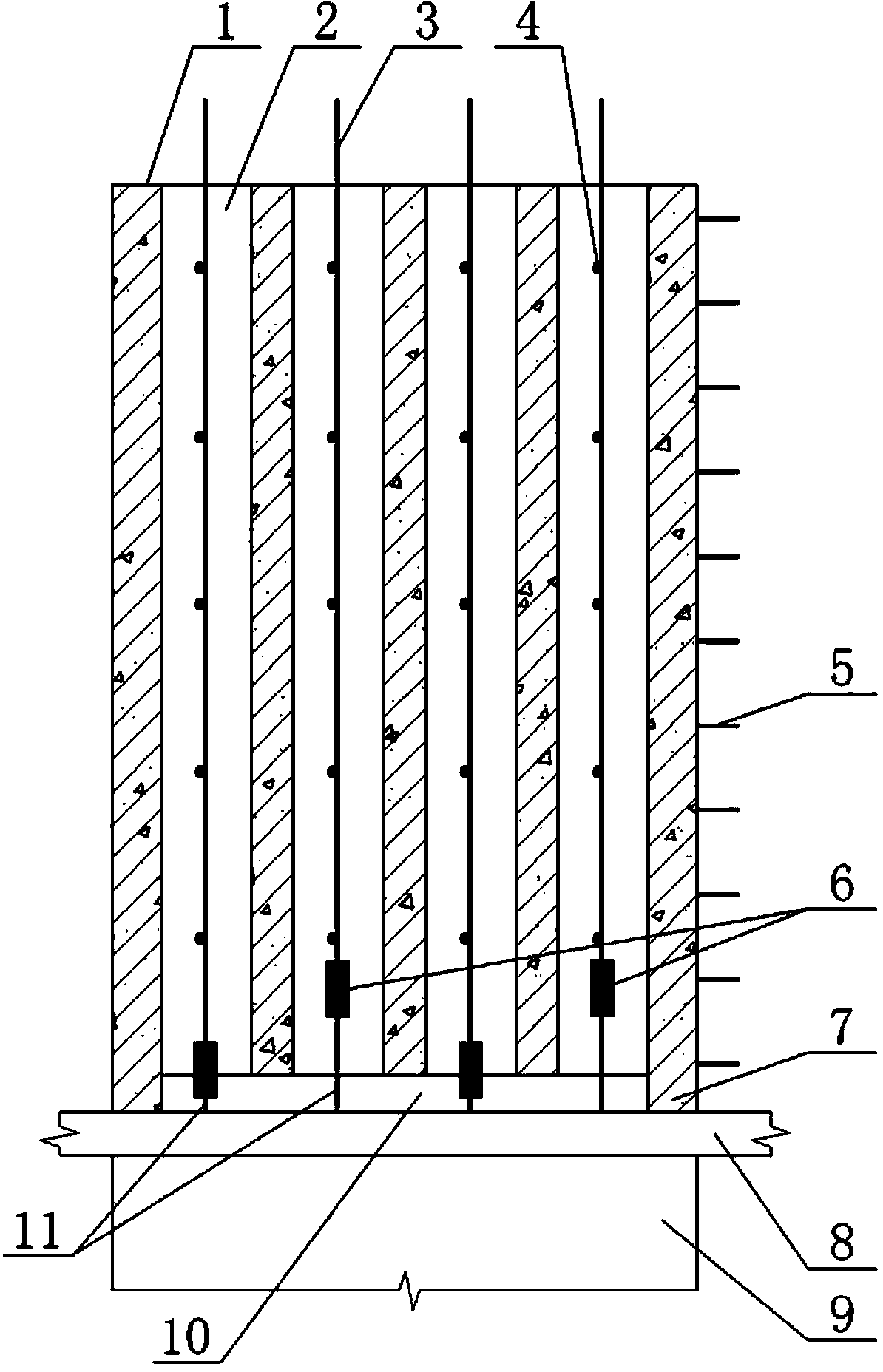

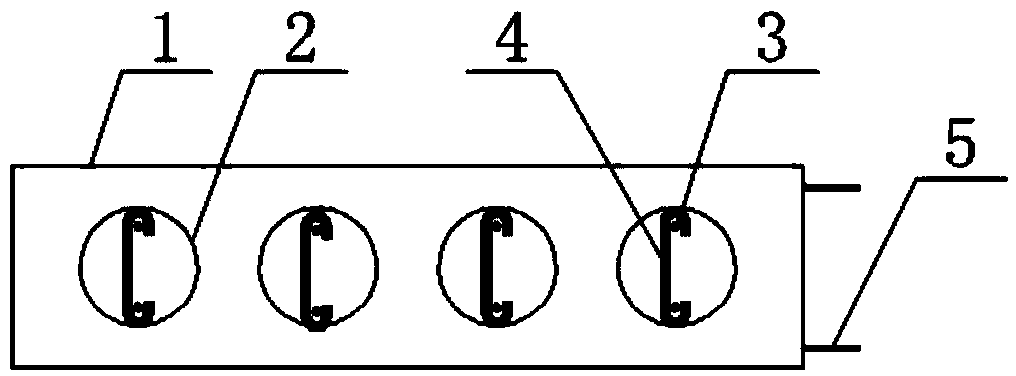

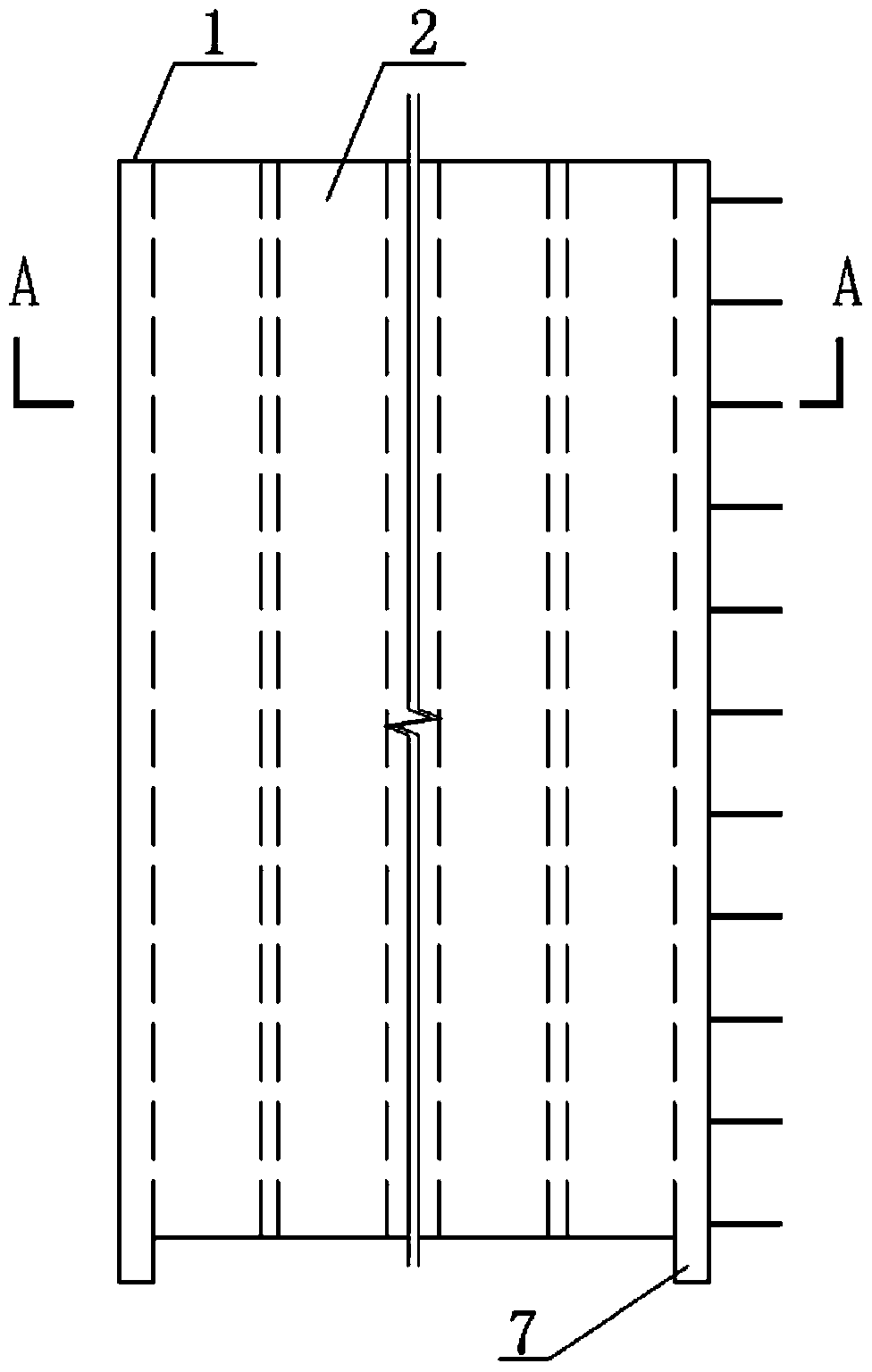

Prefabricated through hole assembly type reinforced concrete shear wall and construction method of prefabricated through hole assembly type reinforced concrete shear wall

ActiveCN103850363AGuaranteed to stagger each otherReduce construction difficultyWallsBuilding material handlingReinforced concreteRebar

The invention provides a prefabricated through hole assembly type reinforced concrete shear wall and a construction method of the prefabricated through hole assembly type reinforced concrete shear wall. A plurality of vertical through holes are formed in a wall body, a plurality of movably connected vertical steel bars are respectively arranged in each through hole, the upper ends of the vertical steel bars are higher than the wall body, the lower ends of the vertical steel bars are connected with the steel bars of the lower layer shear wall, and the bottom end of the wall body is provided with support feet. The vertical steel bars are movably connected in the through holes of the shear wall, and when the steel bars of the upper and lower layers of shear wall are connected, the joint position is adjustable in the vertical direction, so the mutual staggering of the adjacent vertical steel bar joints can be conveniently ensured, the installation quality is enabled to conform to national relevant standards, the concrete casting and the steel bar connection in the through holes can be constructed according to the traditional cast-in-plate reinforced concrete process, the construction difficulty is reduced, and the engineering quality is improved.

Owner:吉林森煌建筑材料集团有限公司

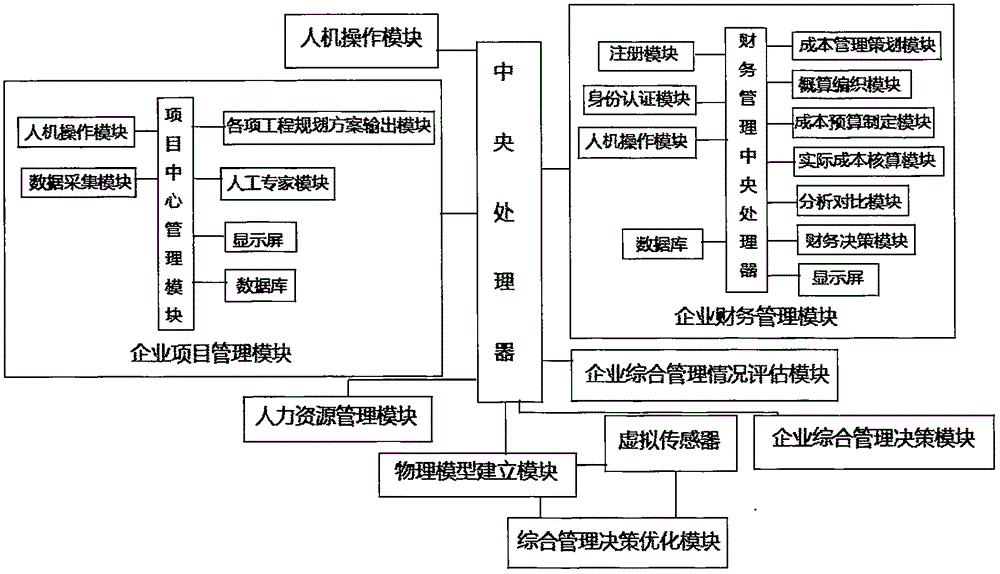

Enterprise management comprehensive evaluation system

InactiveCN106203940AImprove targetingImprove project quality and work efficiencyOffice automationEnterprise project managementPhysical model

The invention discloses an enterprise management comprehensive evaluation system, which comprises an enterprise project management module, a human resource management module, an enterprise financial management module, a physical model building module, an enterprise comprehensive management condition evaluation module, an enterprise comprehensive management decision making module, a comprehensive management decision simulation optimization module, a virtual sensor, a human-machine operation module and a central processor. Automatic transfer of service processes between different departments and automatic statistics of cross-department data can be realized; according to different conditions, different processing decisions are made, and demands on enterprise management by related people are ensured; each decision can be simulated and analyzed, the pertinence of management decision making is greatly improved; and the financial data are subjected to double encryption processing, thereby ensuring data security.

Owner:LESHAN NORMAL UNIV

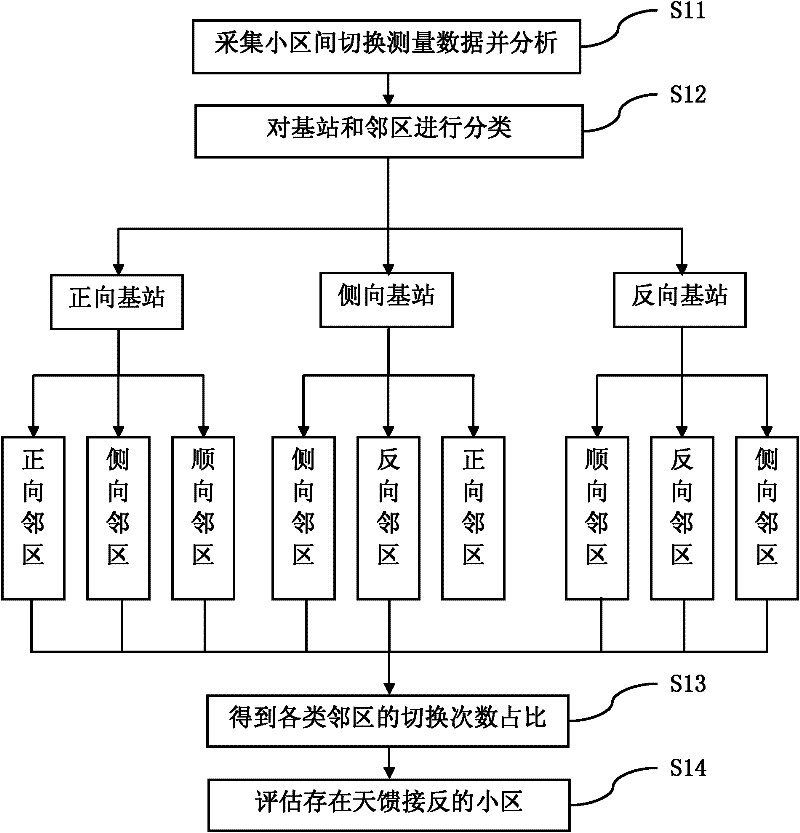

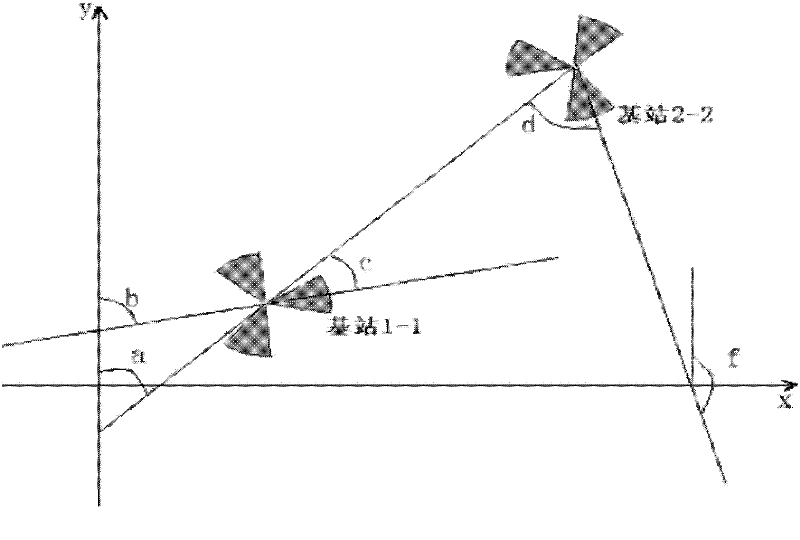

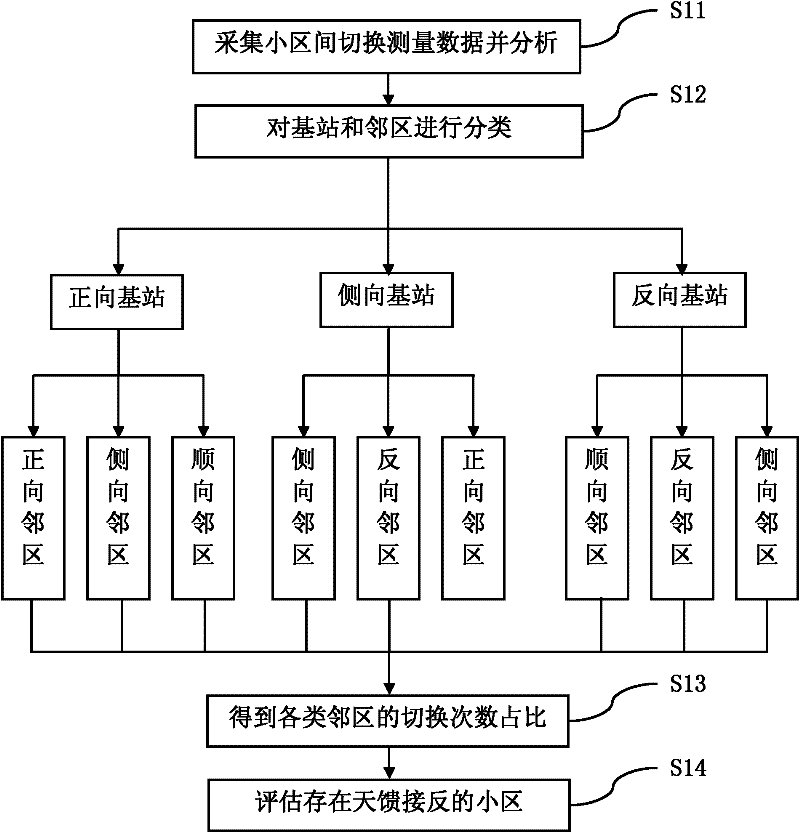

Method for assessing reverse antenna feeder between cells of base stations

ActiveCN102355690AImprove project qualityQuality improvementWireless communicationLongitudeEngineering

The invention discloses a method for assessing reverse antenna feeder between cells of a base stations. The method is characterized by: firstly, collecting switching measurement data in telephone traffic statistics and analyzing; then, according to an azimuthal angle of the cell, the azimuthal angle of the neighbor cell, an included angle formed by a line between the cell base station and the neighbor cell base station and a cell covering direction, and the included angle formed by the line between the cell base station and the neighbor cell base station and a neighbor cell covering direction, classifying the base stations and the neighbor cell; finally, assessing the cells with the reverse antenna feeder according to a relationship between various neighbor cell switching time ratios and a setting value. In the method of the invention, through using the switching measurement data in the GSM telephone traffic statistics and according to the various neighbor cell switching time ratios, whether there is the reverse antenna feeder in the cells can be determined, simultaneously, correctness of engineering parameters (latitude and longitude, the azimuthal angle and the like) can be determined. Checking efficiency of whole network engineering quality can be effectively raised. Network quality can be improved and assessment costs can be reduced at a certain degree.

Owner:BEIJING TUOMING COMM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com