Bridge self-compaction anti-crack bare concrete prepared by utilizing high fine powder content machine-made sand

A fair-faced concrete and self-compacting technology, applied in the field of building materials, can solve the problems of increasing the cost of concrete raw materials and engineering costs, poor concrete work performance and homogeneity, and the concrete is prone to bottoming and bleeding, etc., so as to improve resistance to external erosion. ability to improve strength and corrosion resistance, reduce harmful capillary effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2

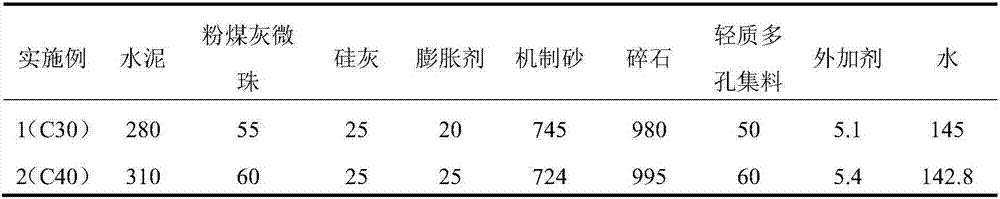

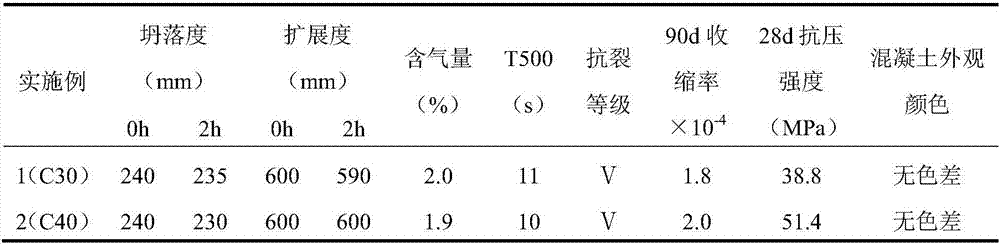

[0037] A self-compacting anti-cracking concrete (C30-C40) for bridges prepared by machine-made sand with high fine powder content, the preparation method comprising the following steps:

[0038] 1) Weigh each raw material according to the ratio in Table 1-1; pre-saturate the lightweight porous aggregate, and then dry the saturated lightweight porous aggregate to a saturated surface dry state before use. spare;

[0039] 2) Pour the weighed machine-made sand, crushed stone and light porous aggregate into the mixing pot according to the ratio and dry mix for 1 minute, then add cement, fly ash microbeads, silica fume, and expansion agent to continue dry mixing for 1.5 minutes Mix evenly, then mix the admixture with water, slowly pour it into the mixing pot, and start stirring at the same time, the duration is 3 minutes, to obtain a uniform mixture, and finally pour it into the mold. Bridge self-compacting anti-cracking fair-faced concrete prepared by machine-made sand with high f...

Embodiment 3~4

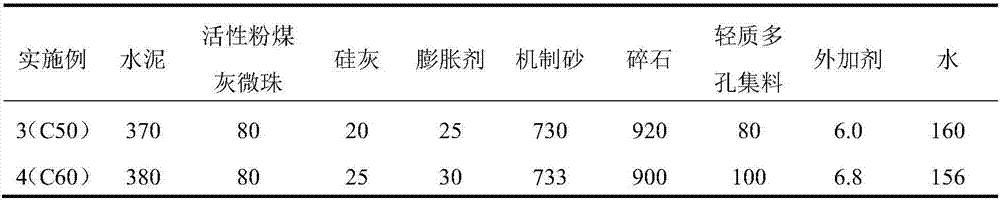

[0047] A self-compacting anti-cracking concrete (C50-C60) for bridges prepared by machine-made sand with high fine powder content, the preparation method comprising the following steps:

[0048] 1) Weigh each raw material according to the ratio in Table 2-1; saturate the lightweight porous aggregate in advance, and then dry the lightweight porous aggregate to a saturated surface-dry state before use, and set aside;

[0049] 2) Pour the weighed machine-made sand, crushed stone and saturated pre-wet shale ceramsite into the mixing pot according to the ratio and dry mix for 1 minute, then add the weighed cement, fly ash microbeads, silica fume, expansion Continue dry mixing for 1 minute to mix the admixture evenly, then mix the admixture with water, slowly pour it into the mixing pot, and start stirring at the same time, the duration is 3 minutes, to obtain a uniform concrete mixture, and finally pour it into the mold, 1d after demolition Standard curing, that is, the self-compac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com