Patents

Literature

35 results about "Saturated-surface-dry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Saturated surface dry (SSD) is defined as the condition of an aggregate in which the surfaces of the particles are "dry" (i.e., surface adsorption would no longer take place), but the inter-particle voids are saturated with water. In this condition aggregates will not affect the free water content of a composite material. The water adsorption by mass (Aₘ)) is defined in terms of the mass of saturated-surface-dry (Mssd) sample and the mass of oven dried test sample (Mdry) by A=(Mₛₛd-Mdᵣy)/Mdᵣy

Full-lightweight ceramsite concrete and preparation method thereof

The invention relates to full-lightweight ceramsite concrete and a preparation method thereof. The full-lightweight ceramsite concrete is prepared from, by weight, 278-339 parts of cement, 318-344 parts of ceramsite, 334-382 parts of pottery sand, 50-55 parts of coal ash, 35-42 parts of silica fume, 0.001-3 parts of triisopropanolamine, 0.5-3 parts of a water reducing agent and 0.001-3 parts of athickening agent. The method includes steps: subjecting ceramsite and pottery sand to surface pretreatment through alkyl alkoxy silane, prewetting ceramsite and pottery sand to achieve a saturated surface dry state, then sequentially feeding lightweight aggregates, cement, silica fume and coal ash into a forced mixer, and well mixing to obtain the full-lightweight ceramsite concrete. The full-lightweight ceramsite concrete prepared according to the method has advantages of light weight, high peaceability and effectiveness in inhibition of ceramsite floating and has a promising application prospect in the field of energy-saving construction engineering.

Owner:CHINA THREE GORGES UNIV

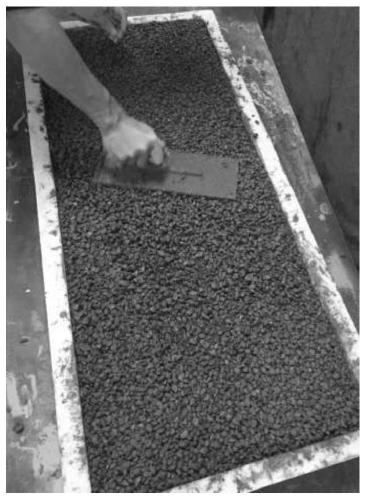

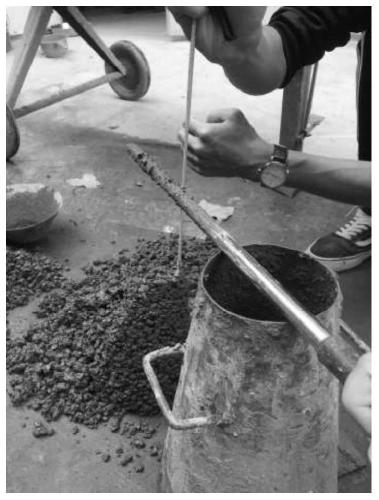

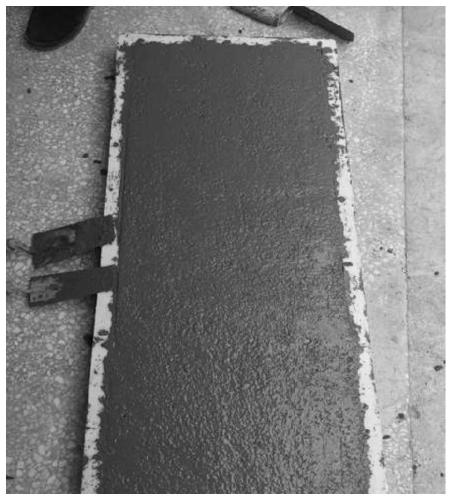

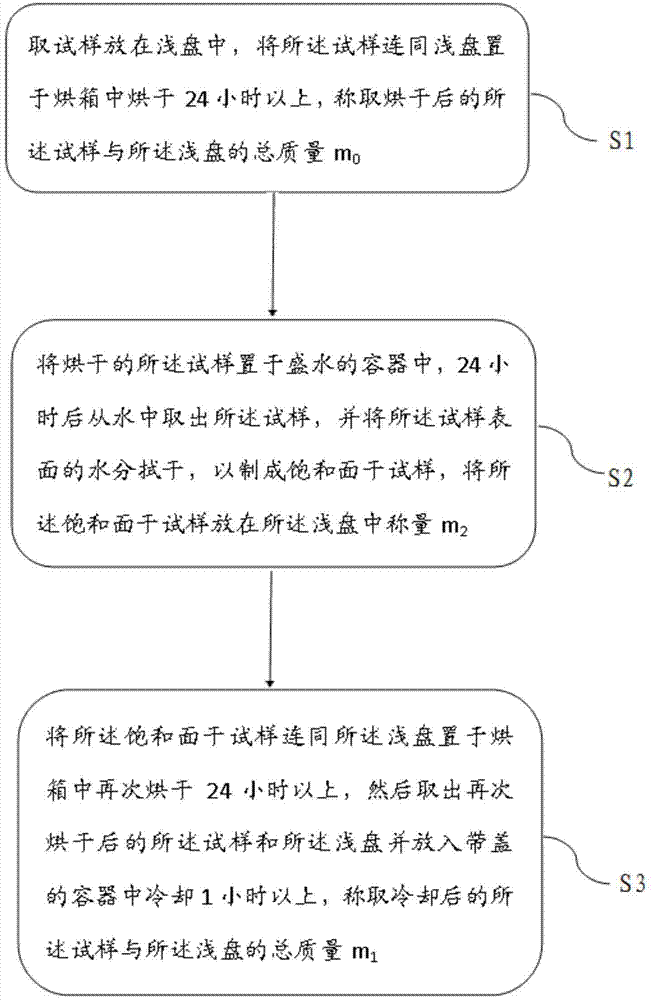

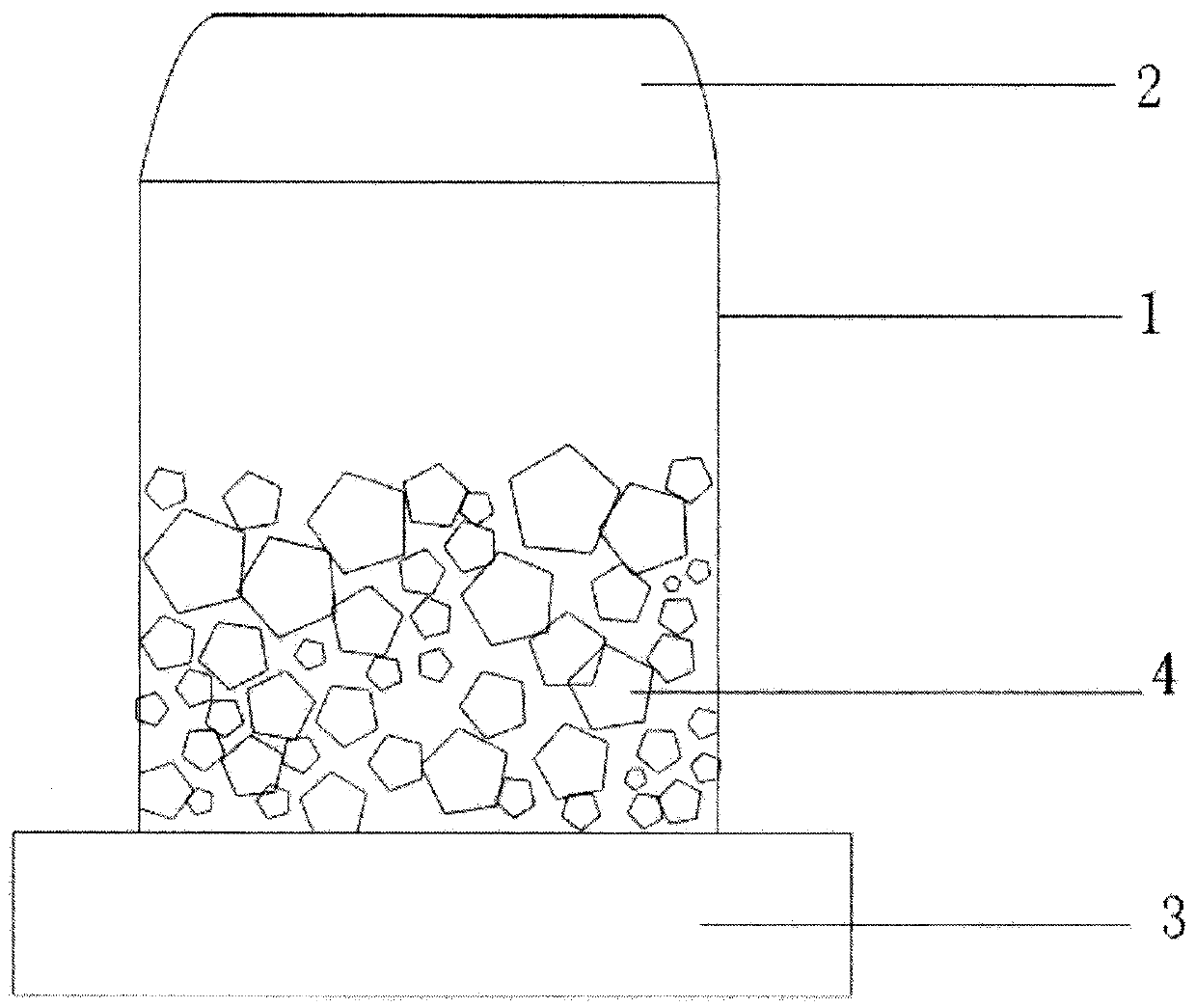

Measurement method of water absorption of regenerative coarse aggregates

The invention provides a measurement method of water absorption of regenerative coarse aggregates. The measurement method includes the following steps: S1 taking a sample and placing it in a tray, drying the sample and the tray in a drying oven for more than 24h, and weighing the total mass of the dried sample and the tray as m0; S2 placing the dried sample in a container with water, taking the sample out after 24h, wiping away water on the surface of the sample to make a saturated surface dried sample, and weighing the total weight of the saturated surface dried sample and the tray where the saturated surface dried sample is located as m2; S3 drying the saturated surface dried sample and the tray in the drying oven again for more than 24h, taking out the redried sample and tray and cooling them in a container with a cover for more than 1h, and weighing the total mass of the cooled sample and tray as m1; wherein the water absorption wx is calculated with the formula in the patent claim, and m4 is the mass of the tray. The measurement method of the water absorption of the regenerative coarse aggregates can reduce the influence of crystal water loss in cement mortar of the regenerative coarse aggregates on tests as much as possible.

Owner:湖南省交通科学研究院有限公司

Method for rapid measurement of material water content and water absorption

The invention discloses a method for rapid measurement of material water content and water absorption. Precise weighing and measurement of the gas content A% are carried out on a test material, and then the material water content and water absorption are calculated according to a formula as the following: the material water content and water absorption=(V-VW-A%*V-(Mtest / rho0) / [Mtest*(1 / rhoW-1 / rho0)]. Specifically, V is the volume of a sealed container, VW is the water volume under a finally water filled state, VW=(M2-M1) / rhoW, A% is the measured gas content, M is the mass of the sealed container, M1 is the mass of the material-loaded sealed container, M2 is the mass of the material-loaded sealed container filled with water, Mtest is the mass of the test material, Mtest=M1-M, rho0 is the density of the material under a saturated surface dry condition, and rhoW is the density of water. If the calculated data is a positive value, the data refers to the water, and if the calculated data is a negative value, the data refers to the water absorption of the test material.

Owner:BEIJING NELD INSTR

Concrete hollow building block with junked tire rubber granules and preparation method thereof

InactiveCN104058661AImprove insulation effectImprove insulation performanceSolid waste managementSaturated-surface-dryPolymer science

The invention discloses a concrete hollow building block with junked tire rubber granules and a preparation method thereof. The concrete hollow building block is prepared from the following raw materials in parts by weight: 302-375 parts of cement, 565.7-607.2 parts of medium river sand, 1180-1300 parts of gravel and / or rubble, 21.8-59.3 parts of rubber granule, 2.385 parts of water reducing agent and 106-134 parts of water. The preparation method comprises the following steps: immersing the rubber granules in a 20% KOH solution for 20 minutes, cleaning with clear water, and airing to the saturated-surface dry condition; adding the medium river sand, cement, water reducing agent and rubber granules into a stirrer, and stirring; and adding the gravel and / or rubble, adding water, stirring to obtain mixed concrete grout, forming the mixed concrete grout in a forming machine, curing, stripping, and naturally curing. The granularity of the rubber granules is 0.1-5mm, and the size distribution is reasonable. The hollow building block prepared by the method has favorable thermal insulation property, heat insulation property, sound insulation property, light weight and other comprehensive properties, and is suitable to be used as a building load-bearing building block for different load-bearing strength demands.

Owner:SHANDONG UNIV OF SCI & TECH

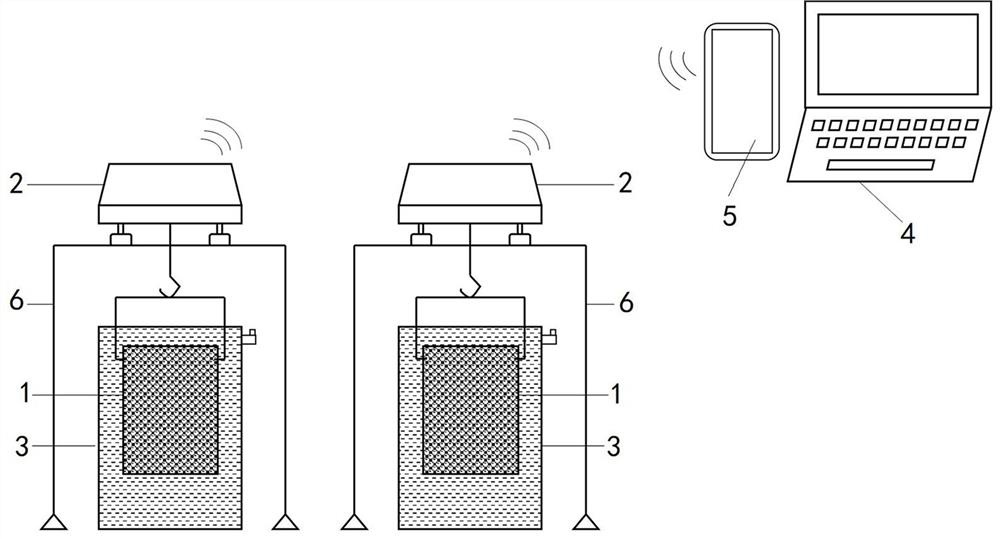

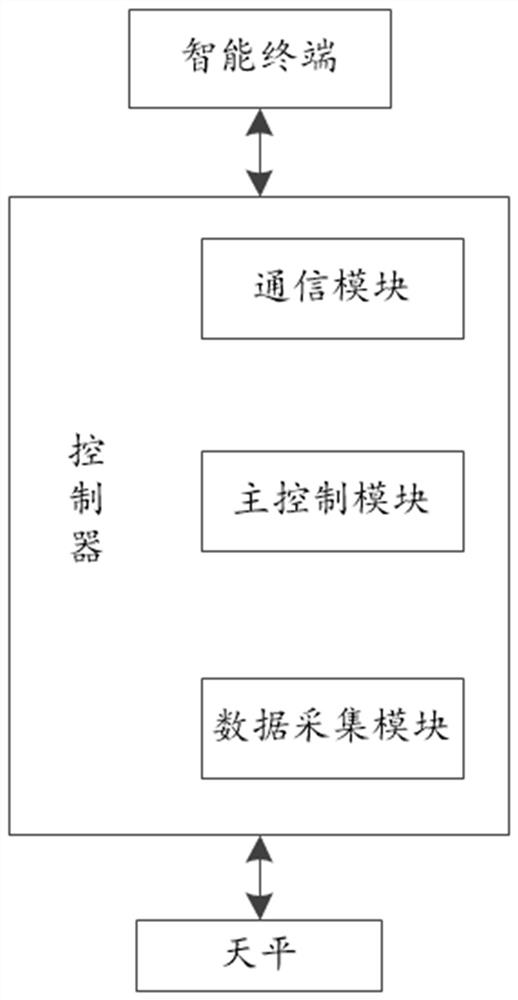

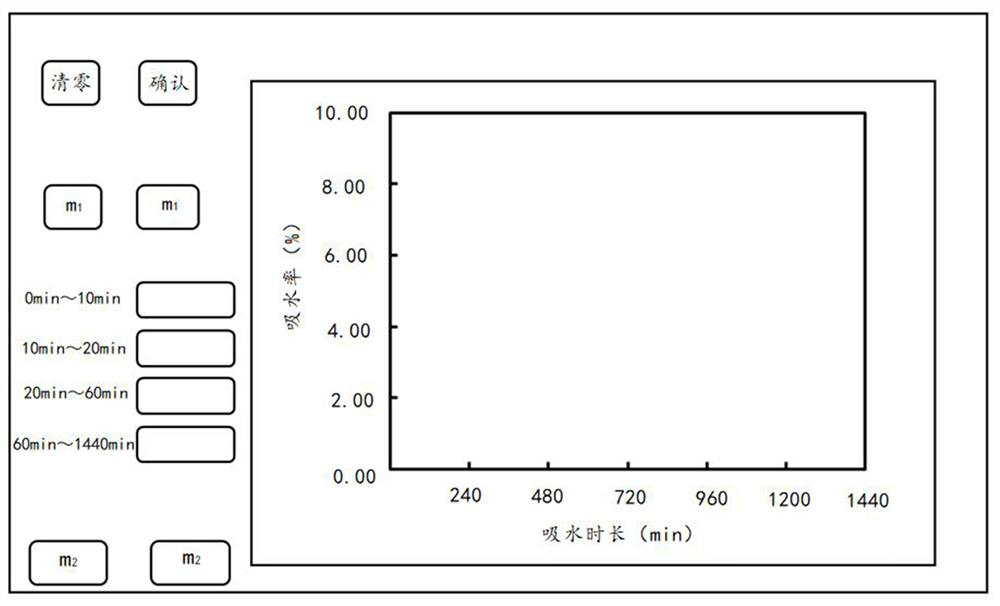

Recycled coarse aggregate water absorption testing method and system

ActiveCN112697635AEase of estimating the effect of slumpTest accurateWeighing by absorbing componentSaturated-surface-dryProcess engineering

The invention relates to the technical field of recycled coarse aggregate measurement, and discloses a recycled coarse aggregate water absorption testing method and system, and the method comprises the following steps: measuring the mass m1 of dried recycled coarse aggregate; putting the mesh basket containing the recycled coarse aggregate into water at a preset temperature to enable the recycled coarse aggregate to stand in the water for 1440 minutes, and respectively collecting the water mass MT and M1 of the recycled coarse aggregate when the water absorption duration is T and 1440 minutes; taking out the recycled coarse aggregate, wiping to a saturated surface dry state, and measuring the mass m2 of the recycled coarse aggregate in the saturated surface dry state; and calculating the water absorption rate WT of the regenerated coarse aggregate when the water absorption duration is T, wherein WT=(MT+m2-m1-M1) / m1*100%. By setting T, the water absorption rate of the recycled coarse aggregate at any moment within 0-1440 min can be obtained, the early water absorption rate of the recycled coarse aggregate is tested, especially the water absorption rate of the recycled coarse aggregate in the first 10 min, and the influence of the recycled coarse aggregate on the slump of cement concrete can be conveniently estimated.

Owner:北京新桥技术发展有限公司 +2

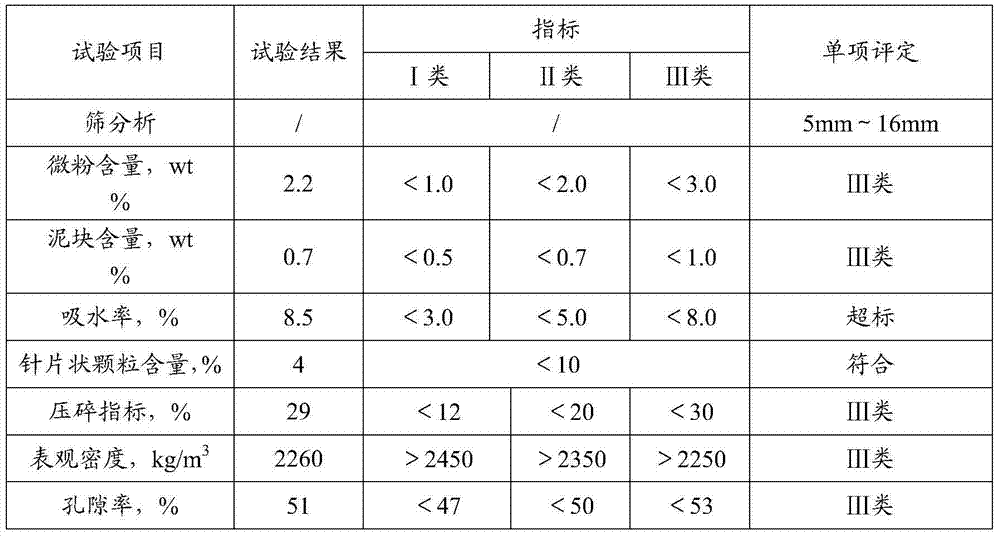

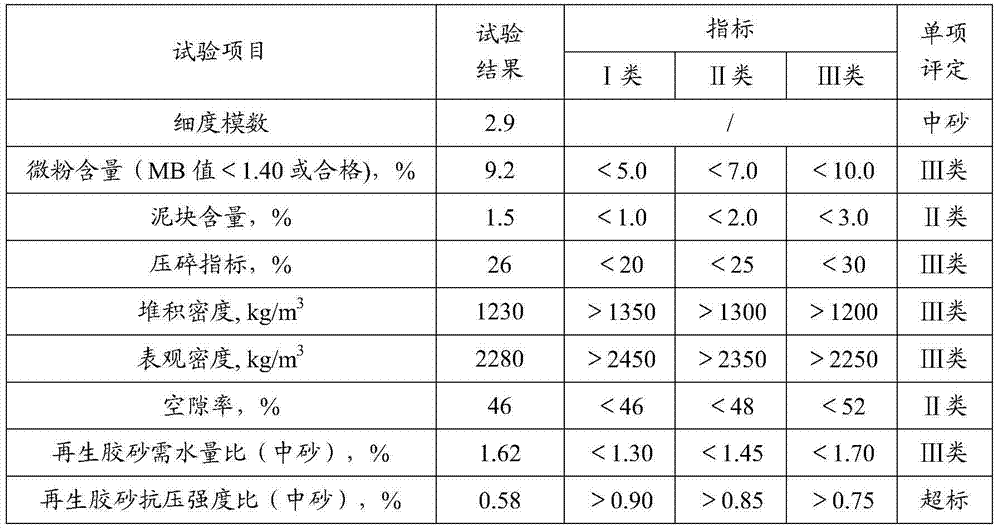

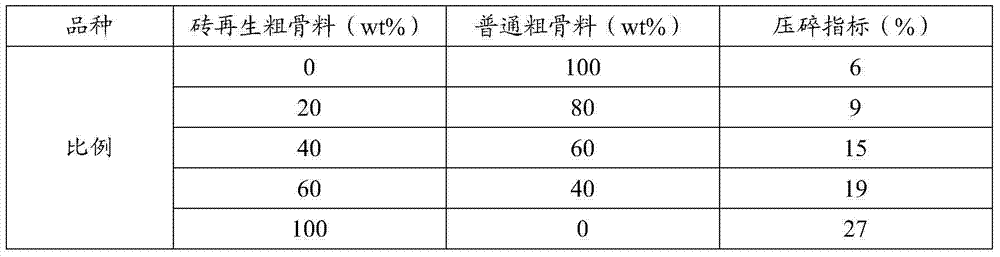

Grading evaluation system of low-quality recycled aggregates

ActiveCN104276775AEfficient recyclingSmall sturdinessSolid waste managementSaturated-surface-dryBrick

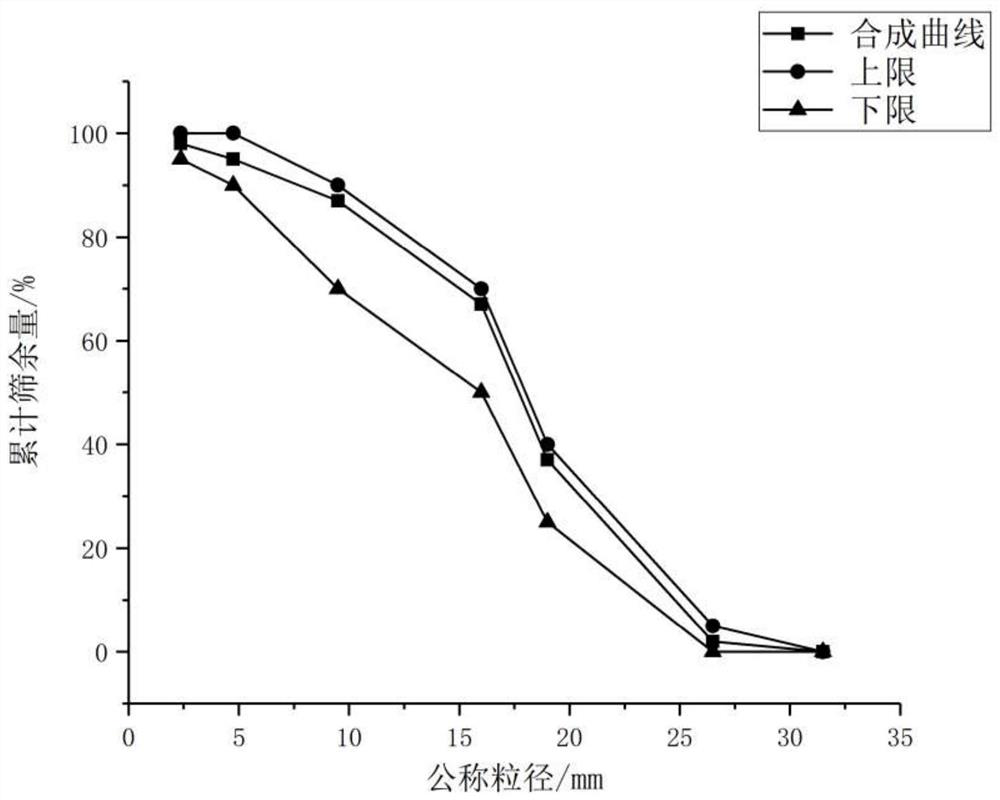

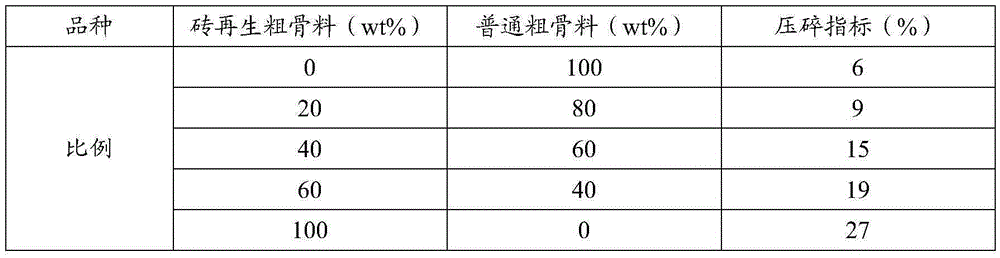

The invention discloses a grading evaluation system of low-quality recycled aggregates. The grading evaluation system comprises the following steps: (1) carrying out grading evaluation on low-quality recycled aggregates; (2) carrying out grading evaluation on ordinary aggregates; (3) carrying out grading evaluation on mixed aggregates, wherein mixed coarse aggregates are composed of low-quality coarse recycled aggregates and ordinary coarse aggregates; the performance indexes of the mixed coarse aggregates meet the requirements as follows: the crushing value index is less than 30%, the sturdiness is less than 12%, and the water absorption of an hour is less than 3%; mixed fine aggregates are composed of low-quality fine recycled aggregates and ordinary fine aggregates; and the performance indexes of the mixed fine aggregates meet the requirements as follows: the compressive strength rate of 28 days is greater than or equal to 85%, the sturdiness is less than 10%, and the saturated-surface-dried moisture retention is less than 5%. When the low-quality brick recycled aggregates of meeting the grading evaluation indexes disclosed by the invention are applied to recycled aggregate concrete, the recycled aggregate concrete has the advantages of high compressive strength, stable performance and the like, and the problem of recycling of the low-quality recycled aggregates can be effectively solved.

Owner:北京东方建宇混凝土科学技术研究院有限公司

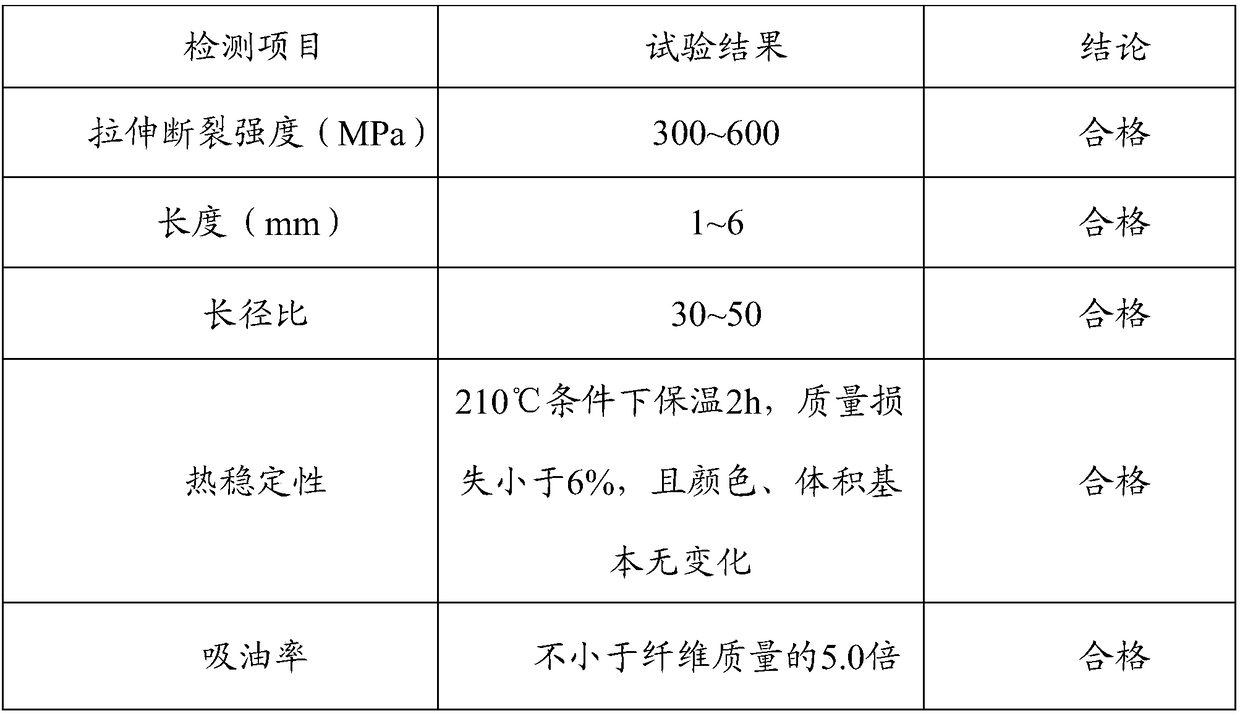

Preparation method of bagasse fiber for asphalt pavement reinforcement

The invention discloses a preparation method of bagasse fiber for asphalt pavement reinforcement. The method comprises the steps as follows: purifying a bagasse material, removing impurities, adding alkali liquor for soaking, taking out bagasse, and adjusting pH to obtain saturated bagasse; adding enzyme to the saturated bagasse for hydrolysis, taking the bagasse to obtain saturated surface dry bagasse; adding a chemical dispersant and an expanded perlite micropowder to the saturated surface dry bagasse, and performing mixing to obtain a mixture; adding water to the mixture and performing mechanical dispersion to obtain a mechanical dispersed substance; drying and screening the mechanical dispersed substance to obtain the bagasse fiber. The bagasse prepared with the preparation method hasthe length of 1-6 mm, the length-diameter ratio of 30-50 and the tensile and breaking strength of 300-600 MPa, and the thermal stability and oil absorbency of the bagasse fiber are good; the bagasse fiber is mixed in an asphalt mixture, the high-temperature stability, low-temperature crack resistance and fatigue crack resistance of the asphalt mixture can be remarkably improved, and the asphalt mixture is low in raw material cost, low-carbon and environmentally friendly.

Owner:CHANGAN UNIV +1

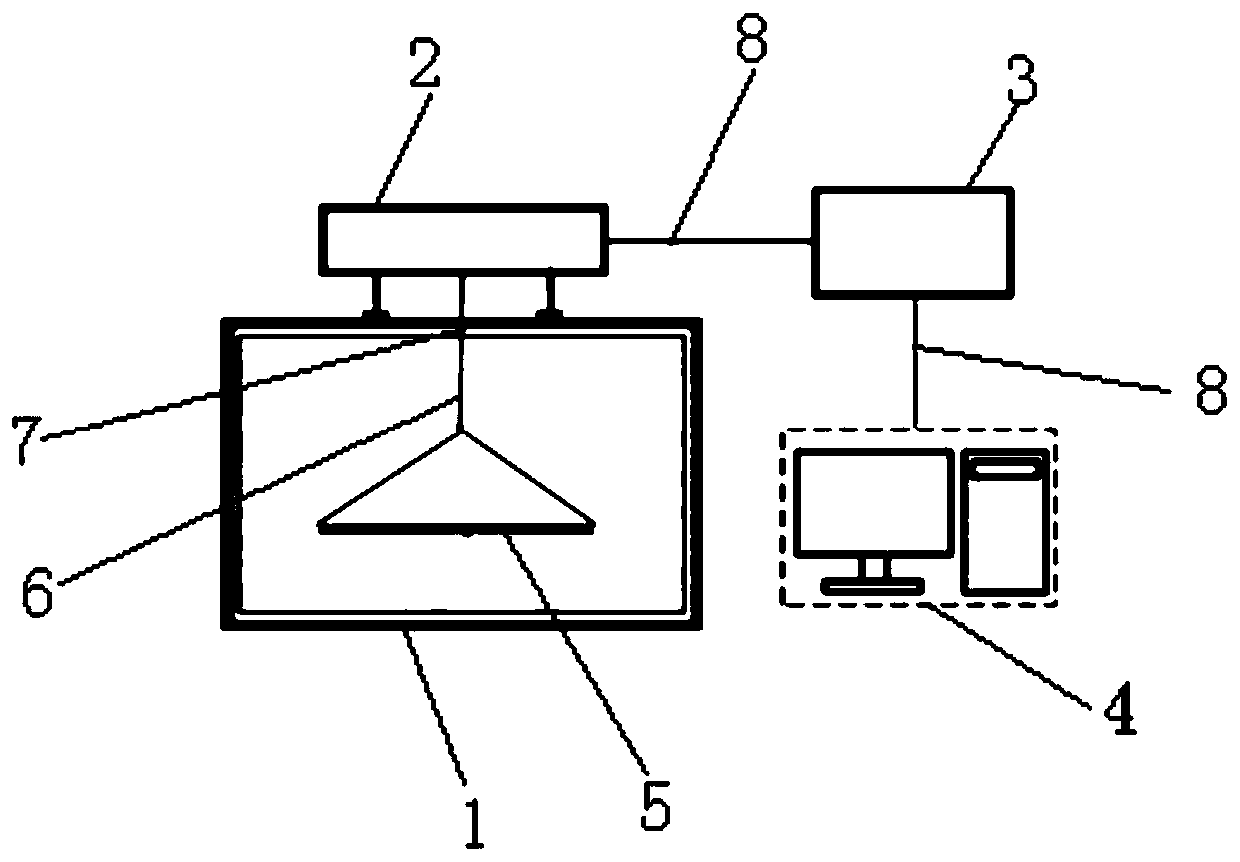

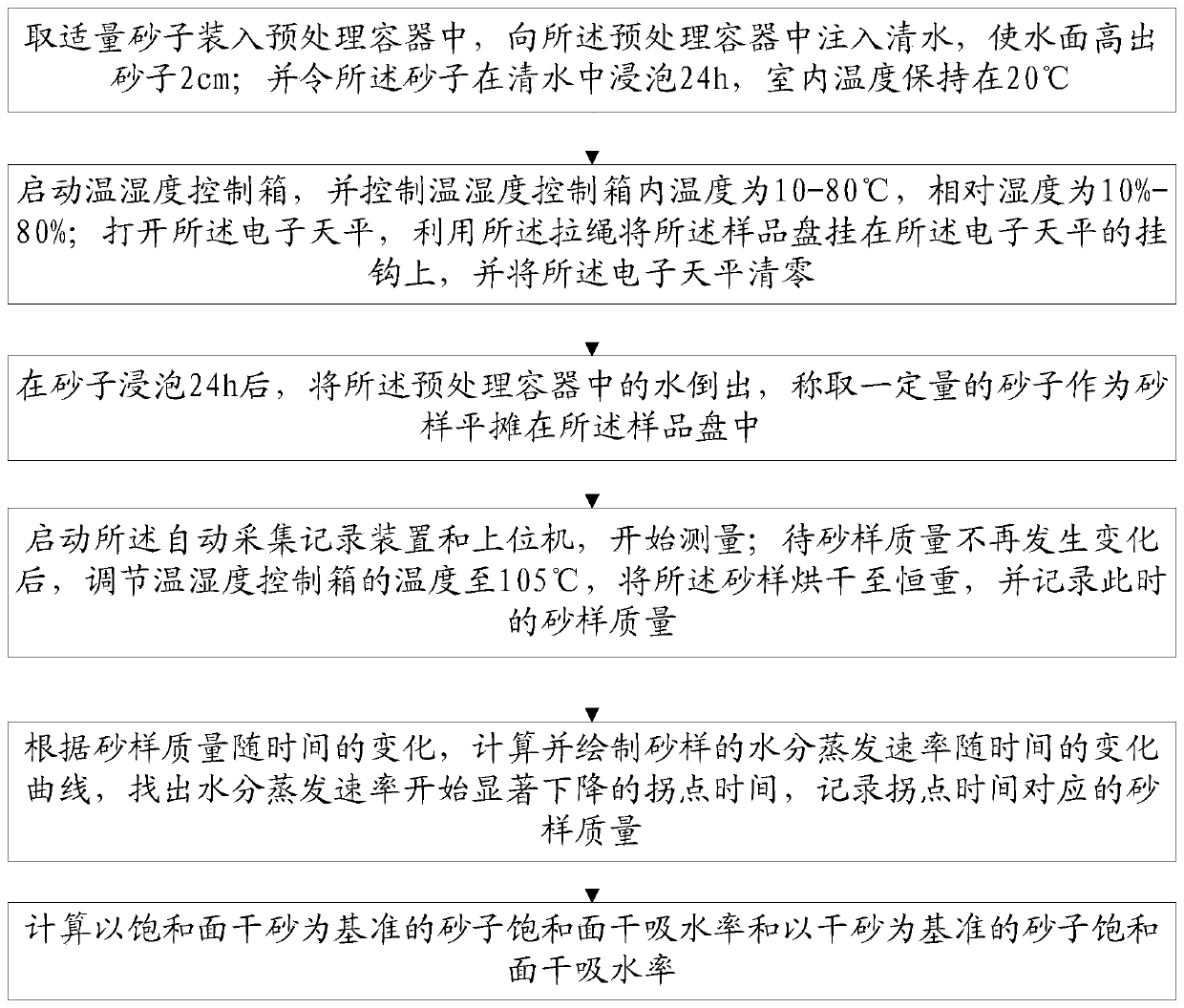

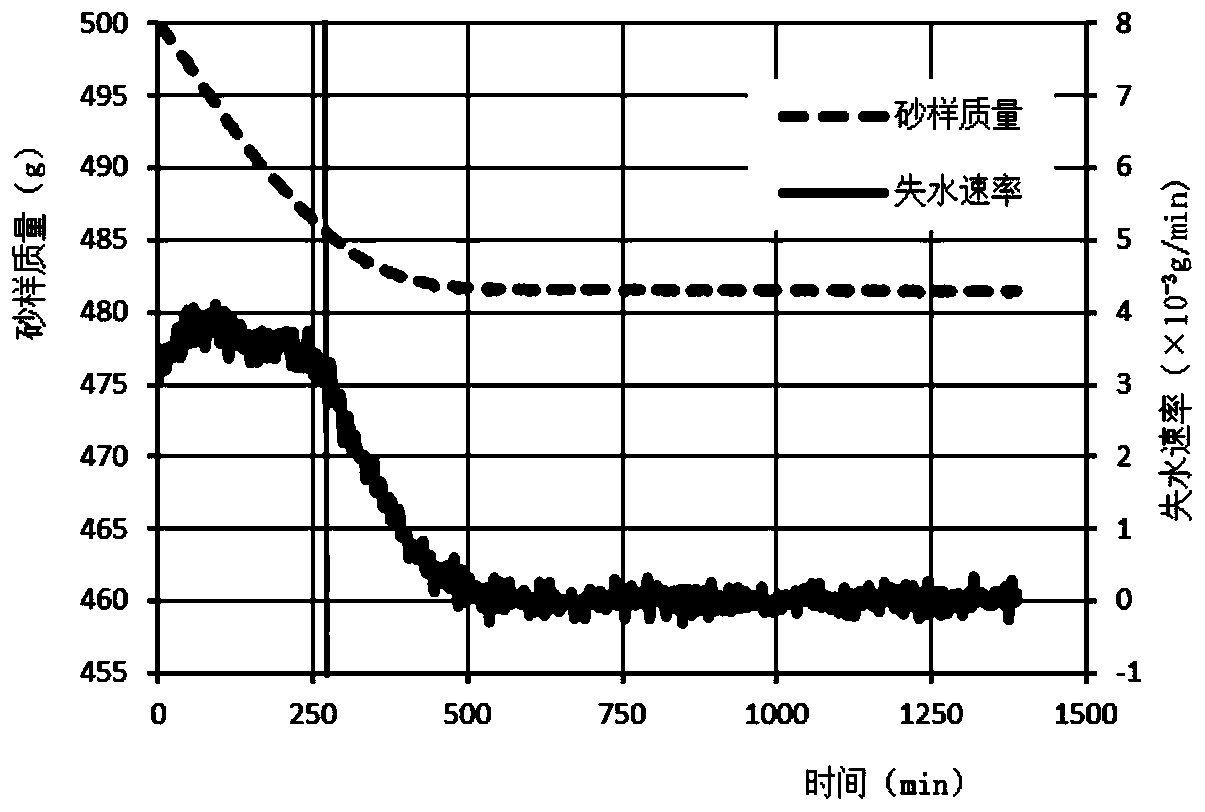

Measuring device and method for saturated surface dry water absorption of sandstone aggregate

PendingCN110736675AHigh precisionNot affectedWeighing by absorbing componentSaturated-surface-dryEngineering

The invention discloses a measuring device and method for saturated surface dry water absorption of sandstone aggregate. The measuring device comprises a temperature and humidity control box, an automatic collecting and recording device, an upper computer, an electronic balance and a sample disc. A through hole for communicating the interior of the temperature and humidity control box with the outside is formed in the top of the temperature and humidity control box, the sample disc is connected with the electronic balance through a pull rope, the pull rope penetrates through the through hole to hang the sample disc in the temperature and humidity control box, the electronic balance is connected with the automatic collecting and recording device, and the automatic collecting and recording device is connected with the upper computer. The measuring device and method have the advantages that the sand saturated surface dry state can be accurately determined, the automation degree is high, the influence of operators is avoided, and the test result accuracy is high.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

Lightweight aggregate concrete containing low-quality recycled aggregate and preparing method thereof

ActiveCN104058673AWith retarding effectHigh strengthSolid waste managementStable stateSaturated-surface-dry

The invention discloses lightweight aggregate concrete containing low-quality recycled aggregate. The raw materials of the lightweight aggregate concrete are comprised of cement, coal ash, mineral powder, water, low-quality recycled light-fine aggregate, low-quality recycled light-coarse aggregate, inorganic salt and polrvinyl benzene sulphonate. The raw materials of the lightweight aggregate concrete further comprise additional water consumption. The additional water consumption is represented through the formula of delta W=msr*wsr + mgr*wgr, wherein the msr means consumption of the low-quality recycled light-fine aggregate, the wsr means the saturated-surface-dried water absorption rate of the low-quality recycled light-fine aggregate, the mgr means consumption of the low-quality recycled light-coarse aggregate and wgr means the 1h water absorption rate of the low-quality recycled light-coarse aggregate. According to the lightweight aggregate concrete and the preparing method of the lightweight aggregate concrete, when the low-quality recycled aggregate is applied to preparing of the lightweight aggregate concrete, through adjustment to the raw materials and matching with specific additionally added agents, the additional water consumption targeted to the low-quality recycled aggregate is adopted, so that the mixture state can meet the use requirements, the stable state of the mixture is maintained, cement slurry can be helped to be evenly coated around the aggregate, workability of the concrete mixture is good, and no bleeding and segregation phenomena exist.

Owner:北京东方建宇混凝土科学技术研究院有限公司

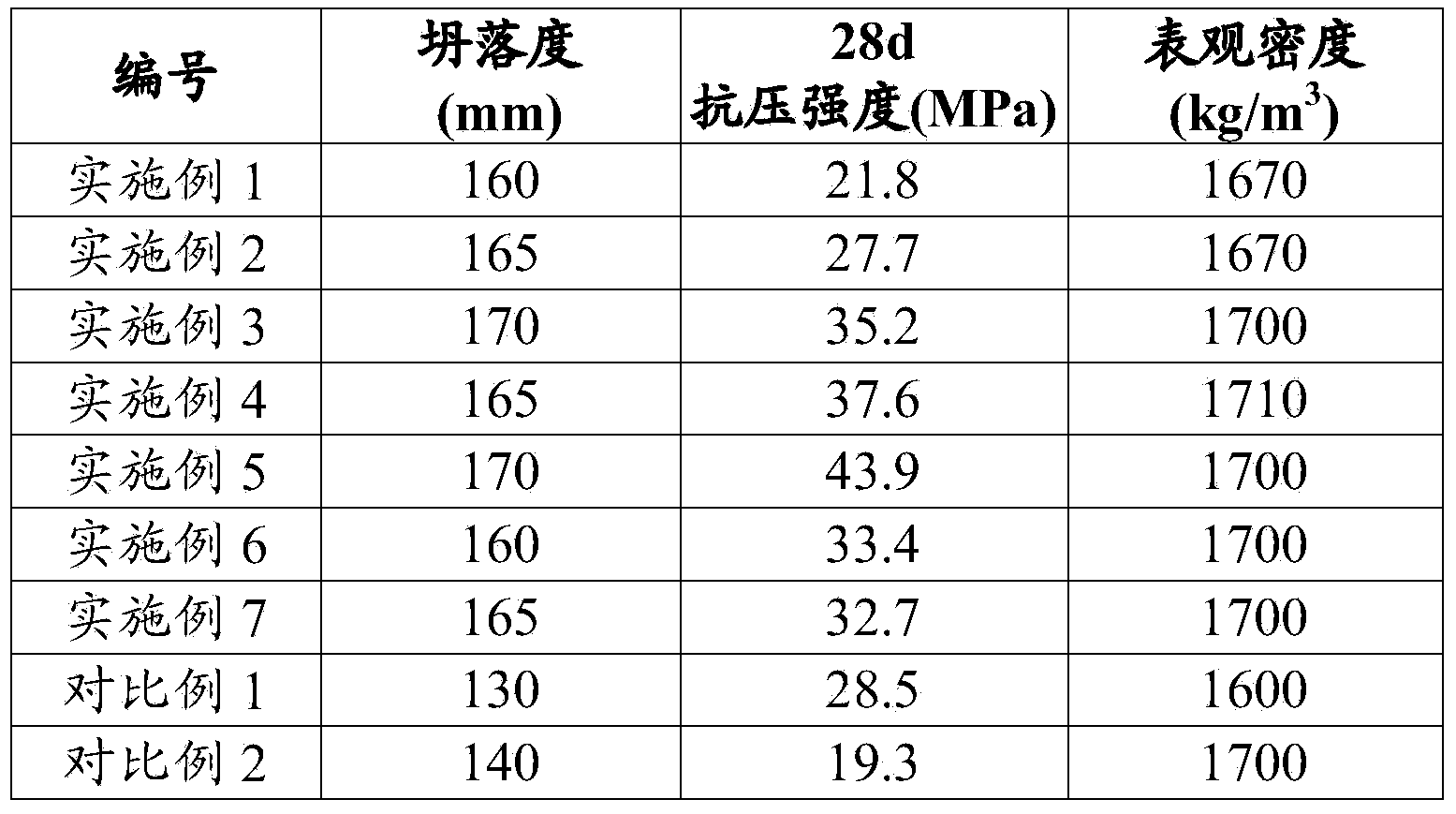

Determination method for compression strength ratio of low-quality recycled fine aggregate mixed mortar

InactiveCN104266907AMeet the measurement requirementsReduce varianceMaterial strength using tensile/compressive forcesSaturated-surface-dryCompressive strength

The invention discloses a determination method for compression strength ratio of low-quality recycled fine aggregate mixed mortar. The determination method comprises the steps of firstly determining saturated-surface-dry water adsorption of the low-quality recycled fine aggregate and common sand; drying to a constant weight; weighing dried common sand and cement; mixing the dried common sand with the cement; adding water with stirring to obtain mortar until the fluidity of the mortar is (130+ / -5) mm; making a benchmark mortar test specimen from the mortar; testing after 28 days of standard curing; recording a strength being f[0] MPa; then mixing the low-quality recycled fine aggregate and the common sand to obtain mixed mortar; weighing the mixed mortar and the cement; mixing the mixed mortar with the cement; adding water in the mixture to prepare a contrast mortar specimen; testing after 28 days of standard curing; and recording a strength being f MPa. The mortar compression strength ratio (delta) after 28 days of standard curing is equal to f / f[0]. The determination method takes additional water consumption while determining the mixed mortar strength ratio, and can actually reflect the performances of the mixed recycled fine aggregate.

Owner:北京东方建宇混凝土科学技术研究院有限公司

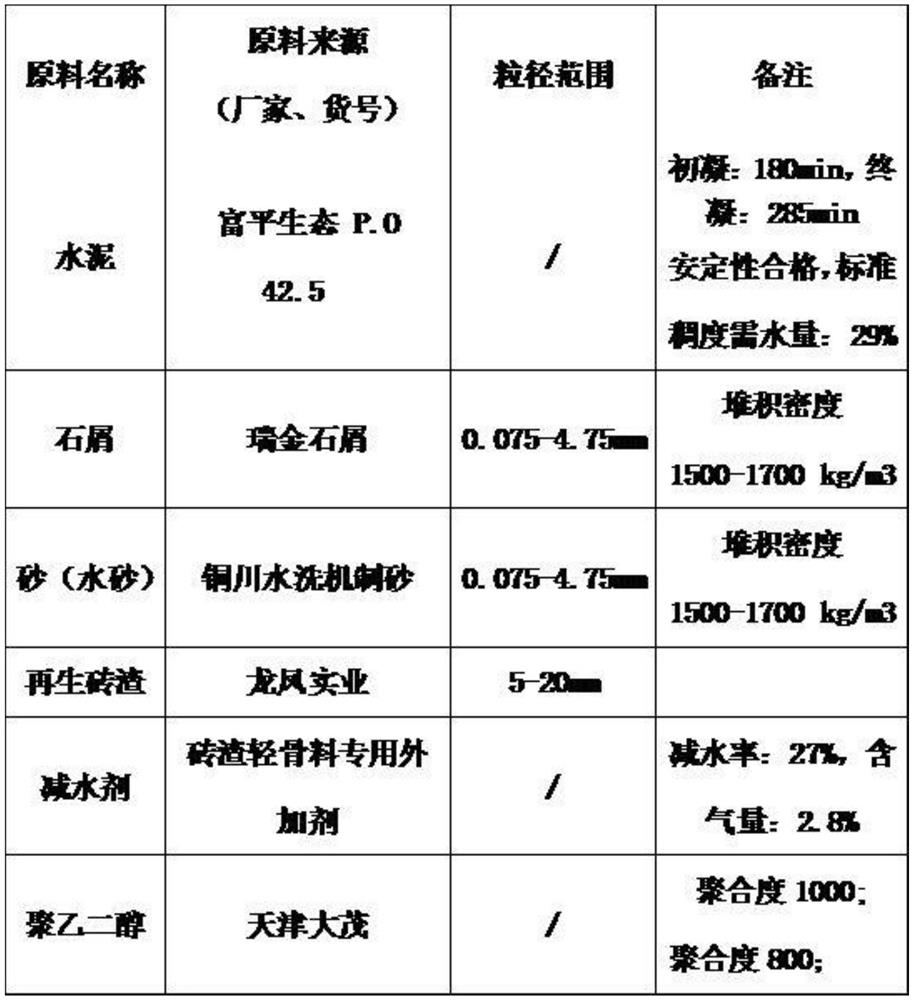

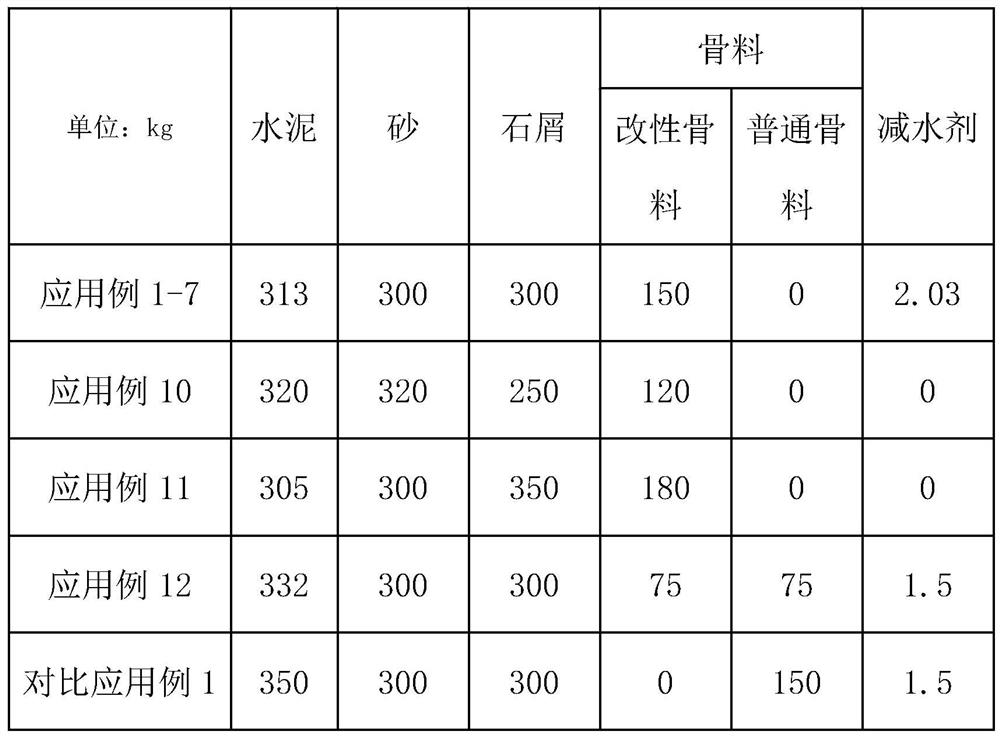

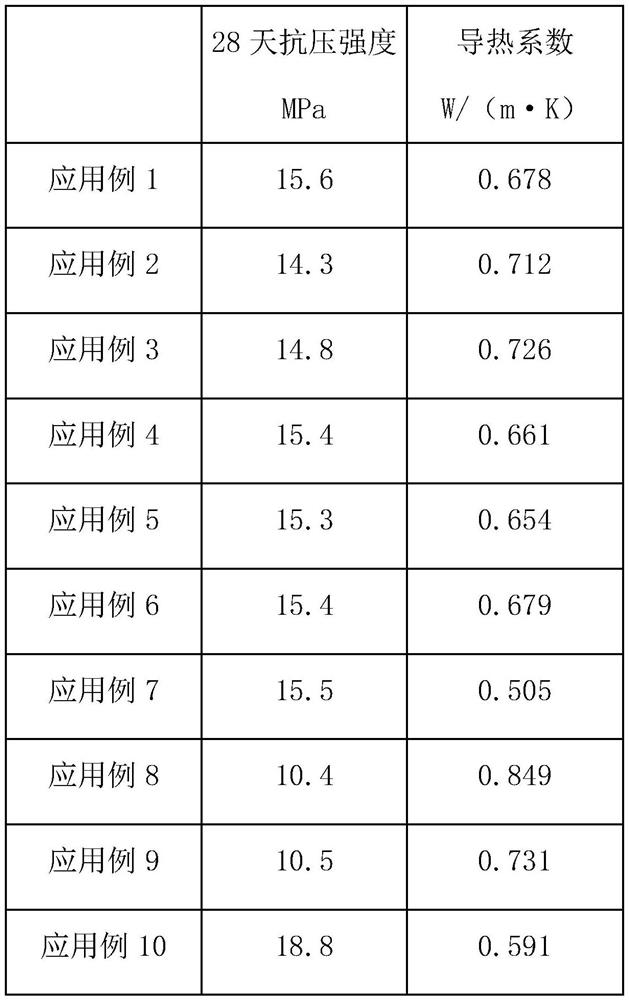

Modified aggregate, preparation method thereof and concrete applying modified aggregate

InactiveCN112608053AImprove thermal insulation effectIncrease heat preservation and heat storage effectSolid waste managementSaturated-surface-dryStructural engineering

The invention relates to the field of concrete, in particular to modified aggregate, a preparation method thereof and concrete applying the modified aggregate. The modified aggregate comprises aggregate and an ionic liquid-like phase change energy storage modifier, and the ionic liquid-like phase change energy storage modifier is located in pores in the surface of the aggregate; and the ionic liquid-like phase change energy storage modifier comprises an ionic liquid-like material with a phase change temperature range of 20-38 DEG C. The preparation method comprises the following steps: dipping: dipping the aggregate in a liquid ionic liquid-like phase change energy storage modifier to enable the ionic liquid-like phase change energy storage modifier to enter gaps of the aggregate, taking out the aggregate, and cooling the aggregate to a saturated surface dry state; slurry wrapping: wrapping the surface of the aggregate in the saturated surface dry state with cement-based slurry, forming a layer of shell, and preparing the modified aggregate. Concrete prepared from the modified aggregate has good heat preservation and energy storage effects, and a concrete product prepared from the modified aggregate has good strength.

Owner:中建西部建设北方有限公司 +1

Concrete processing method and device for engineering construction

ActiveCN113601718AReduce processingLess chance of chippingCement mixing apparatusSolid waste managementSaturated-surface-dryDry ice

The invention relates to a concrete processing method and device for engineering construction. The concrete processing method and device for engineering construction comprise the following steps that S1, mountain sand with the size of 0.3-0.6 mm and mountain sand with the size of 0.8-1.18 mm are screened out to serve as fine aggregate, and pebbles with the size of 5-9.5 mm are screened out to serve as coarse aggregate; and S2, the gravel coarse aggregate screened out in S1 is put into a polishing mechanism to be subjected to surface roughening primary treatment. According to the concrete processing method and device for engineering construction, round and full pebble surfaces can be subjected to roughening treatment for multiple times, dry ice particles and ice particles are adopted for conducting cleaning type polishing treatment on the pebble surfaces in the multiple stirring processes, a certain roughening effect can be achieved while the pebble surfaces are cleaned, and secondary filtering is not needed. Wherein the ice particles permeate into gaps of the pebbles after being melted, so that the pebbles reach a saturated surface dry state, the treated pebbles are mixed with other materials to form the concrete with high flowability and high strength after solidification, and the use effect is relatively good.

Owner:嘉兴市天坤营造工程设计有限公司

Internal curing sand for special concrete as well as preparation method and application thereof

PendingCN111892315ALarge particle sizeHigh strengthSolid waste managementSaturated-surface-dryCompressive strength

The invention discloses internal curing sand for special concrete as well as a preparation method and application of the internal curing sand. The internal curing sand is a core-shell inorganic spherical particle, the particle size of the internal curing sand is 1.0-6.0 mm, the wet bulk density of the internal curing sand in a saturated surface dry state is 800-1200 kg / m <3>, the cylinder compressive strength of the internal curing sand is greater than 6.0 MPa, and the water absorption rate of the internal curing sand is greater than 20%. The internal curing sand is prepared from waste materials, and is small in particle size, high in strength, large in stacking density and high in water absorption rate. The mixing amount of the internal curing sand in special concrete accounts for 10-30%of the use amount of a cementing material, and the internal curing sand can improve workability, reduce bleeding rate, improve pumpability, promote hydration of cement in concrete, significantly reduce self-shrinkage of high-strength concrete, improve expansion rate of expansive concrete, obviously improve crack resistance of the concrete and improve middle and later strength of the concrete. Theinternal curing sand of the invention is especially used for high-strength and ultrahigh-strength concrete, expansive concrete, fair-faced concrete and special structural concrete which is difficult to maintain.

Owner:江苏智晟节能科技股份有限公司

Tail end process for improving quality of machine-made sand

InactiveCN111992317AImprove screening efficiencyEasy to handleSievingScreeningSaturated-surface-dryWater volume

The invention relates to the technical field of machine-made sand, in particular to a tail end process for improving the quality of machine-made sand. The tail end process comprises the following steps of S1, selecting rock blocks; S2, crushing rock blocks; S3, conducting screening; S4, performing dust removal; and S5, obtaining machine-made sand. A sand washer water tank is provided with a watersupply system; and the water supply system comprises a high-water-level liquid level meter, a middle-water-level liquid level meter, a low-water-level liquid level meter, a submerged pump, a sewage pump, a water adding valve and a liquid level controller. A square-hole screen is selected as the screen; the size of each sieve pore is 3.5 to 4.5 mm; the inclination angle of the screen surface is generally about 20 degrees; good screening efficiency and treatment capacity of the materials can be achieved; the water volume in water tank is effectively controlled; the submerged pump is protected; the water is saved; the saturated surface drying effect of the machine-made sand is achieved; the national requirements are met; and the quality of the machine-made sand can be effectively improved, and the performance of machine-made sand concrete is improved through the technical requirements of mine mother rock, the technical requirements of a vibration feeding screen, a material crushing methodand the mechanism of the material crushing method in the machine-made sand production technological process.

Owner:JIANGSU SHANBAO GRP

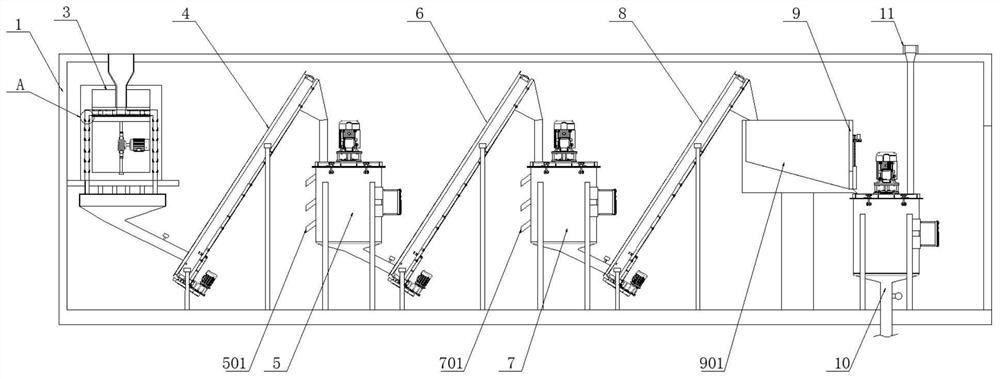

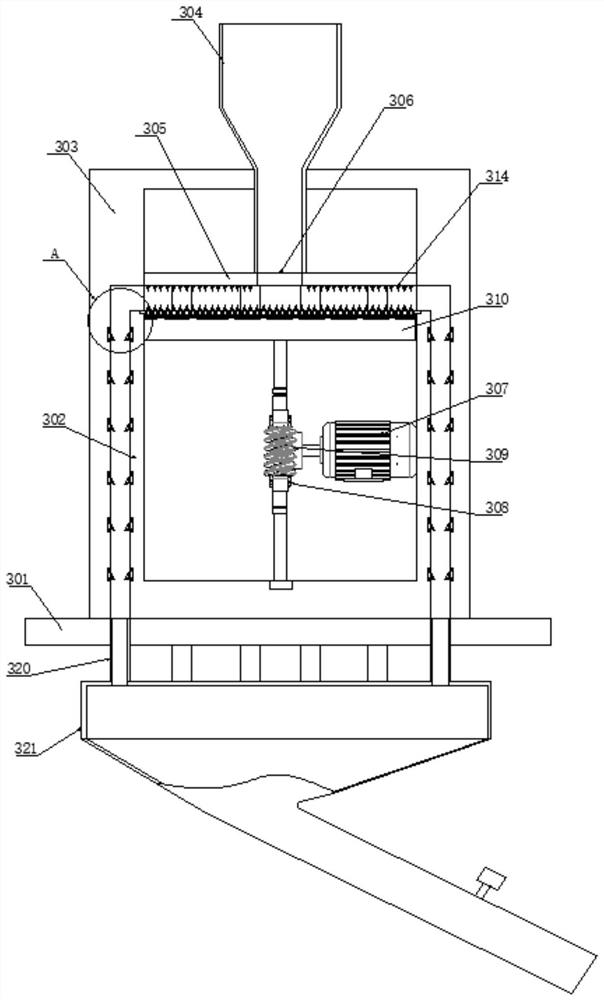

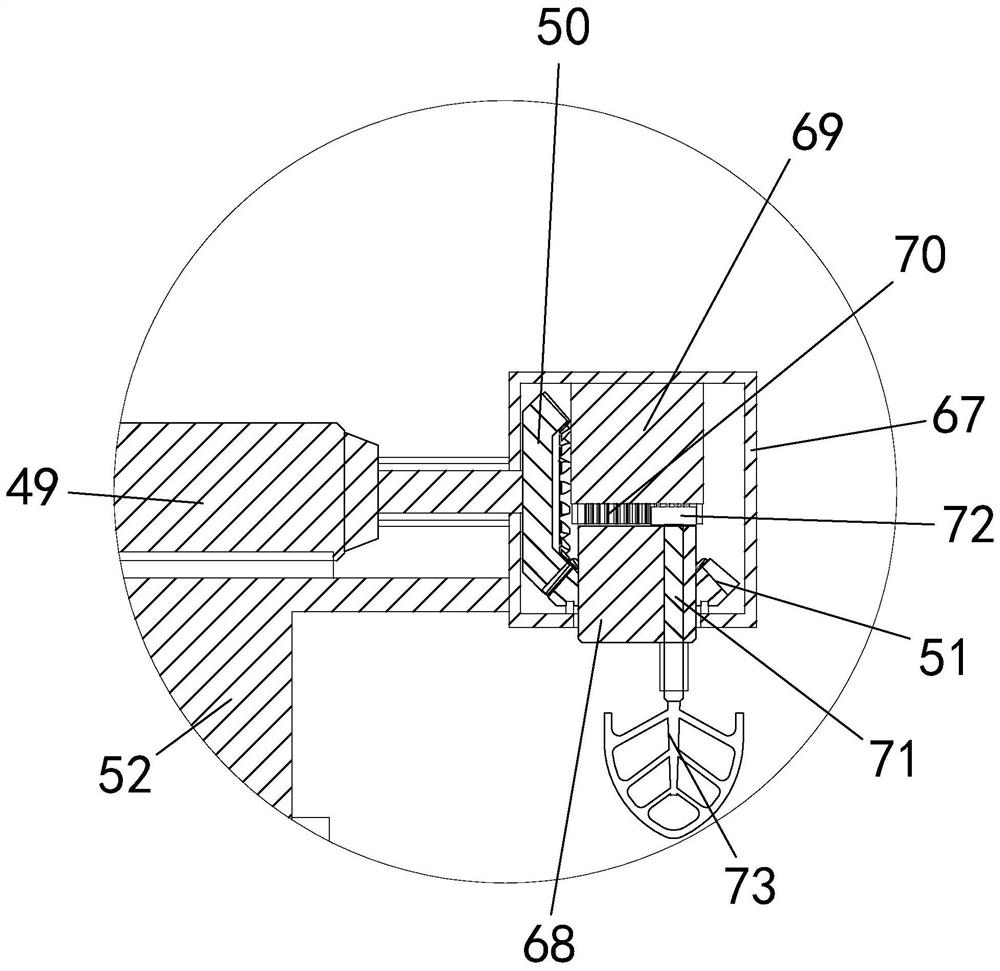

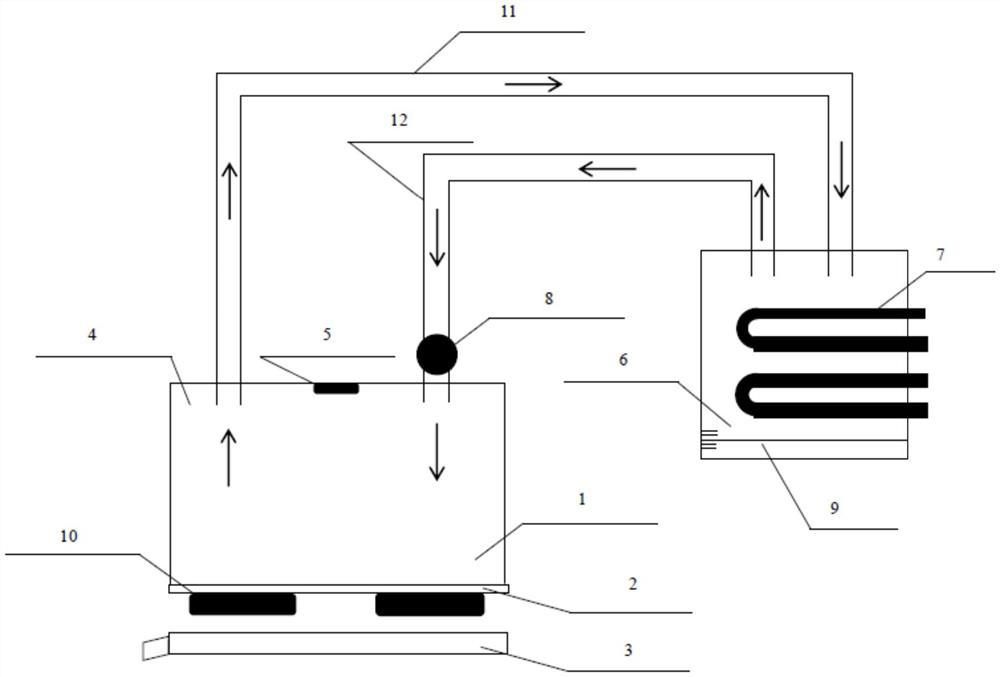

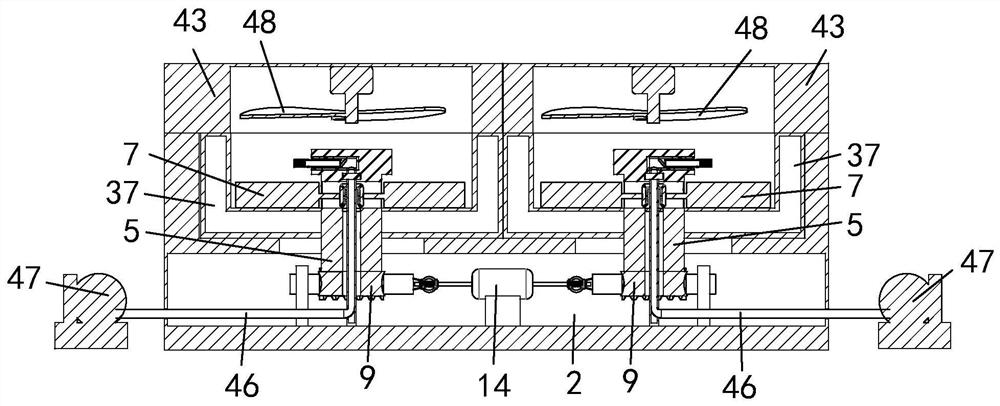

Efficient aggregate saturated surface dry stirring device

PendingCN112791654AEasy to take out completelyTransportation and packagingRotary stirring mixersSaturated-surface-dryMechanical engineering

The present invention discloses an efficient aggregate saturated surface dry stirring device which comprises a bottom plate, a plurality of supporting columns, a base and a stirring device, and further comprises a material placing device, a heating assembly and a moving device, the material placing device comprises a first rotating rod and a second rotating rod, a placing groove is formed in the upper surface of the base, and a stirring barrel is slidably arranged in the placing groove; one end of the first rotating rod is hinged to one side of the inner wall of the containing groove, one end of the second rotating rod is hinged to the other side of the inner wall of the containing groove, a first T-shaped sliding groove and a second T-shaped sliding groove are formed in the lower surface of the stirring barrel, a first sliding rod fixed to one end of the first rotating rod is slidably arranged in the first T-shaped sliding groove, and a square through groove is formed in one side wall of the T-shaped sliding groove. A square driving rod is slidably arranged in the square through groove, a second sliding rod is slidably arranged in the second T-shaped sliding groove, concave holes are formed in the two ends of the second sliding rod, first springs are fixed in the concave holes, triangular clamping blocks are slidably arranged in the concave holes, and one ends of the first springs are fixed to the triangular clamping blocks. The stirring device has the advantage that stirring raw materials can be conveniently and completely taken out.

Owner:浙江立州交通工程检测有限公司

A kind of concrete hollow block adding waste tire rubber particles and preparation method thereof

InactiveCN104058661BSimple processReduce manufacturing costSolid waste managementSaturated-surface-dryPolymer science

The invention discloses a concrete hollow building block with junked tire rubber granules and a preparation method thereof. The concrete hollow building block is prepared from the following raw materials in parts by weight: 302-375 parts of cement, 565.7-607.2 parts of medium river sand, 1180-1300 parts of gravel and / or rubble, 21.8-59.3 parts of rubber granule, 2.385 parts of water reducing agent and 106-134 parts of water. The preparation method comprises the following steps: immersing the rubber granules in a 20% KOH solution for 20 minutes, cleaning with clear water, and airing to the saturated-surface dry condition; adding the medium river sand, cement, water reducing agent and rubber granules into a stirrer, and stirring; and adding the gravel and / or rubble, adding water, stirring to obtain mixed concrete grout, forming the mixed concrete grout in a forming machine, curing, stripping, and naturally curing. The granularity of the rubber granules is 0.1-5mm, and the size distribution is reasonable. The hollow building block prepared by the method has favorable thermal insulation property, heat insulation property, sound insulation property, light weight and other comprehensive properties, and is suitable to be used as a building load-bearing building block for different load-bearing strength demands.

Owner:SHANDONG UNIV OF SCI & TECH

Lime-fly ash macadam waste recycling method

InactiveCN111747704AEasy accessMeet strength requirementsSaturated-surface-dryEnvironmental engineering

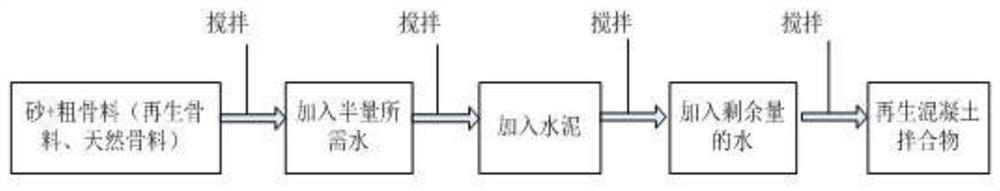

The invention discloses a lime-fly ash macadam waste recycling method, which comprises the following steps: (1) screening lime-fly ash macadam waste and natural aggregate, and synthesizing required gradation; (2) soaking the lime-fly ash waste recycled coarse aggregate in water for 24-28 hours, and air-drying free water on the surface to obtain saturated surface dry lime-fly ash waste recycled aggregate; (3) weighing 3.9-7.8 parts of lime-fly ash gravel waste recycled coarse aggregate, 5.2-9.1 parts of natural aggregate and 6.5-7.5 parts of medium sand, and uniformly mixing the components; (4)weighing 0.5-0.7 part of water, pouring into a mixing container, and mixing with the product obtained in the step (3) for 50-60 seconds; (5) adding 2.8-3.6 parts of cement into the mixture obtained in the step (4), and mixing the components for 30-40 seconds; and (6) pouring 0.5-0.8 part of water, continuously mixing the components for 110-120 seconds, and maintaining the mixture to obtain the lime-fly ash gravel waste recycled concrete. According to the lime-fly ash gravel waste recycled concrete prepared by the method, the strength can reach C50, the strength requirements of most concrete components are met, the application limitation of the original lime-fly ash gravel waste is broken through, and the utilization way is broadened.

Owner:SOUTHEAST UNIV

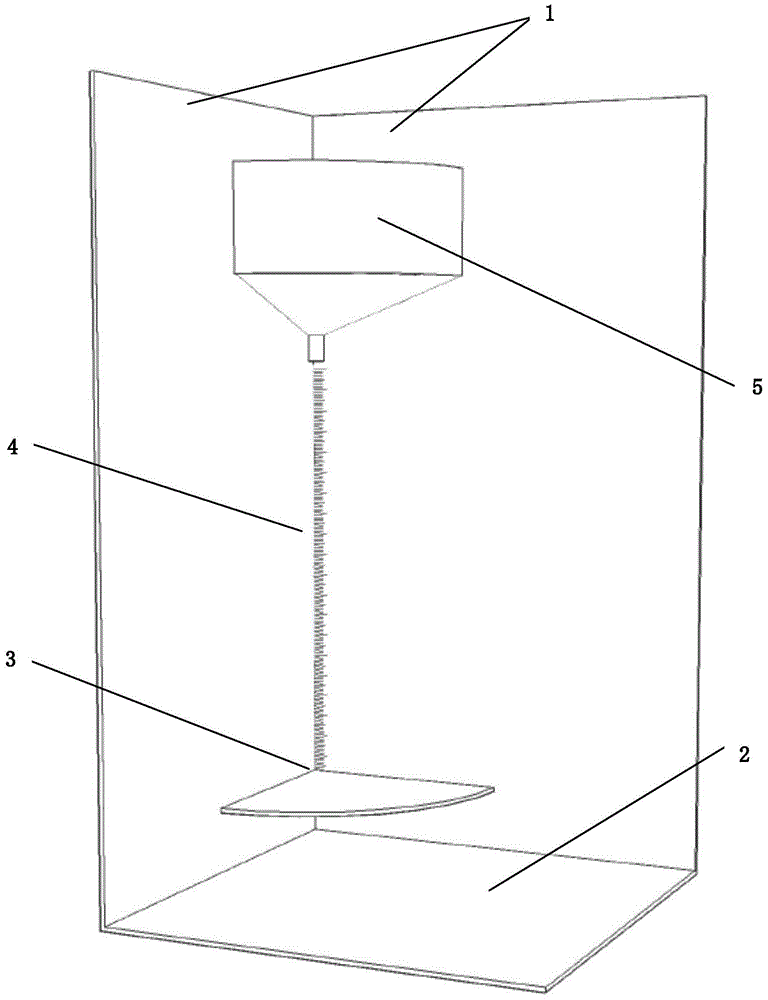

Quantitative determining device for saturated surface dry state of fine aggregates and method thereof

InactiveCN105043942AContinuous and even drippingHigh precisionFlow propertiesSaturated-surface-dryEngineering

The invention discloses a quantitative determining device for the saturated surface dry state of fine aggregates and a method thereof. The quantitative determining device is characterized by comprising two back plates, a hopper and a bearing platform. The two back plates are vertically intersected, and the intersection line is vertical. The hopper is fixedly connected with the upper portions of the two back plates. A discharge spout is arranged on the intersection line of the two back plates. The bearing platform is horizontally arranged on the lower portions of the back plates in the mode of being spaced from the bottom faces of the back plates by a certain distance and used for bearing the fine aggregates freely dripping from the discharge spout. The two edges of the bearing platform are fixedly connected with the two back plates respectively, and the circle center is located on the intersection line of the two back plates. The fine aggregates dripping onto the bearing platform from the hopper form a quarter cone gradually, when the radius of the quarter cone is equal to the radius of the bearing platform, the height of the quarter cone is measured, accordingly, the surface state of the fine aggregates at the moment can be represented quantitatively, and then whether the fine aggregates are in the saturated surface dry state is judged.

Owner:SHANDONG UNIV

Recycling thickness test method for asphalt pavement in hot in-place recycling project

ActiveCN104567600AEasy to disengageAccurate valueMechanical thickness measurementsRoads maintainenceSaturated-surface-dryPortland cement

The invention discloses a recycling thickness test method for an asphalt pavement in a hot in-place recycling project. The method comprises the following steps: step 1, ordinary Portland cement is uniformly spread on a milled and planed pavement in a hot in-place recycling construction process of the asphalt pavement; step 2, after paving and rolling in a cement spreading position and the pavement temperature is reduced to 50 DEG C, a pavement core drilling rig is used for core drilling at a cement spreading center point; step 3, the diameter d of a core sample is measured; step 4, the core sample is placed in a hydrostatic balance, the weight m1 of the core sample in water is weighed, and the saturated surface dry mass m2 of the core sample is measured after the core sample is taken out; and step 5, the thickness of a recycling layer is calculated. The recycling thickness of the asphalt pavement in the hot in-place recycling project can be described effectively and accurately with the test method.

Owner:SOUTHEAST UNIV +1

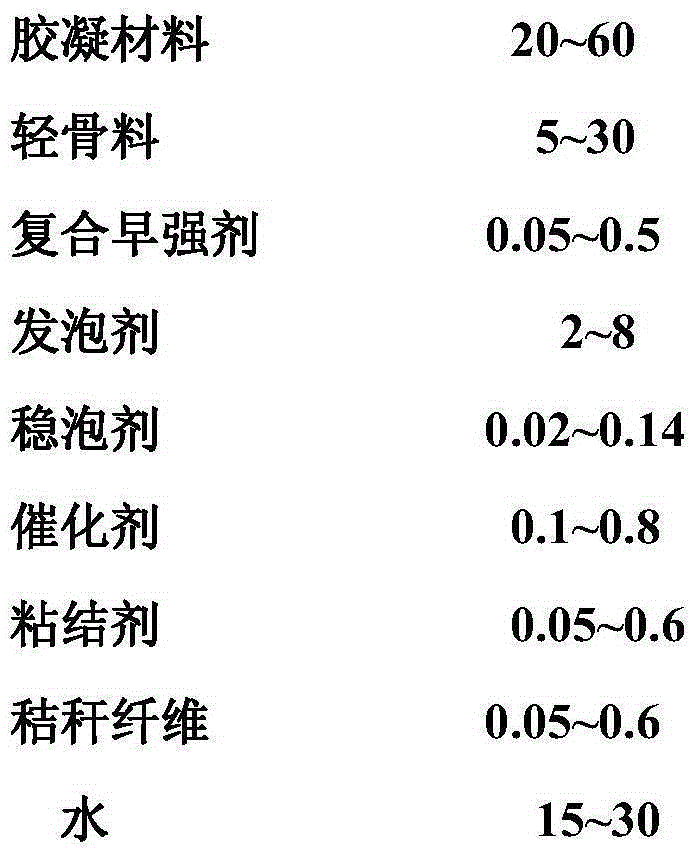

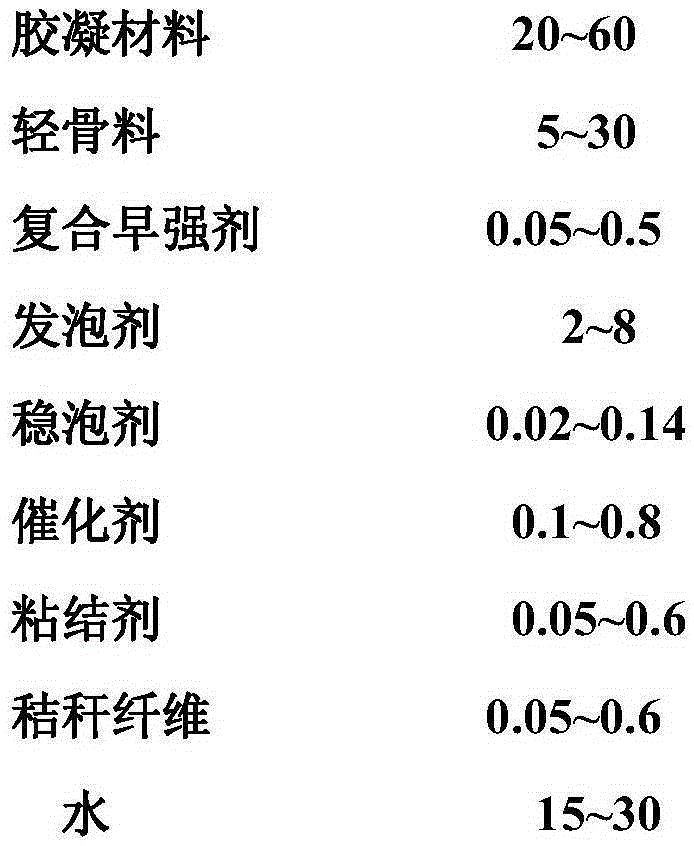

A self-insulating lightweight wallboard containing hollow ceramsite and its preparation method

ActiveCN104129959BUniform porous structureReduce voidsSolid waste managementCeramicwareFiberThermal insulation

The invention discloses a self-heat-insulation light weight wallboard containing hollow ceramsites and a preparation method thereof, and belongs to the technical field of building materials. The self-heat-insulation light weight wallboard comprises the following components by mass: 20-60 parts of a cementitious material, 5-30 parts of a lightweight aggregate, 0.05-0.5 part of a composite early strength agent, 2-8 parts of a foaming agent, 0.02-0.14 part of a foam stabilizing agent, 0.1-0.8 part of a catalyst, 0.05-0.6 part of a binder, 0.05-0.6 part of straw fiber and 15-30 parts of water. The preparation method is as follows: putting the cementitious materials, the straw fiber and the binder together, then mixing, then orderly adding the water, the foaming agent, the stabilizer and the catalyst, stirring to obtain a slurry mixture, adding hollow ceramsites, obturator perlite and expanded vermiculite in saturated surface-dry condition, stirring, then using an injection pump to inject into a wallboard forming machine for molding, and 3-5 hours after the concrete is solidified and hardened, demoulding to obtain the self-heat-insulation light weight wallboard containing the hollow ceramsites. The self-heat-insulation light weight wallboard containing the hollow ceramsites has energy saving, environmentally-friendly, fire insulating, sound-insulation, high-strength, lightweight, waterproof, thermal-insulation, corrosion-resistant, durable and other characteristics.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

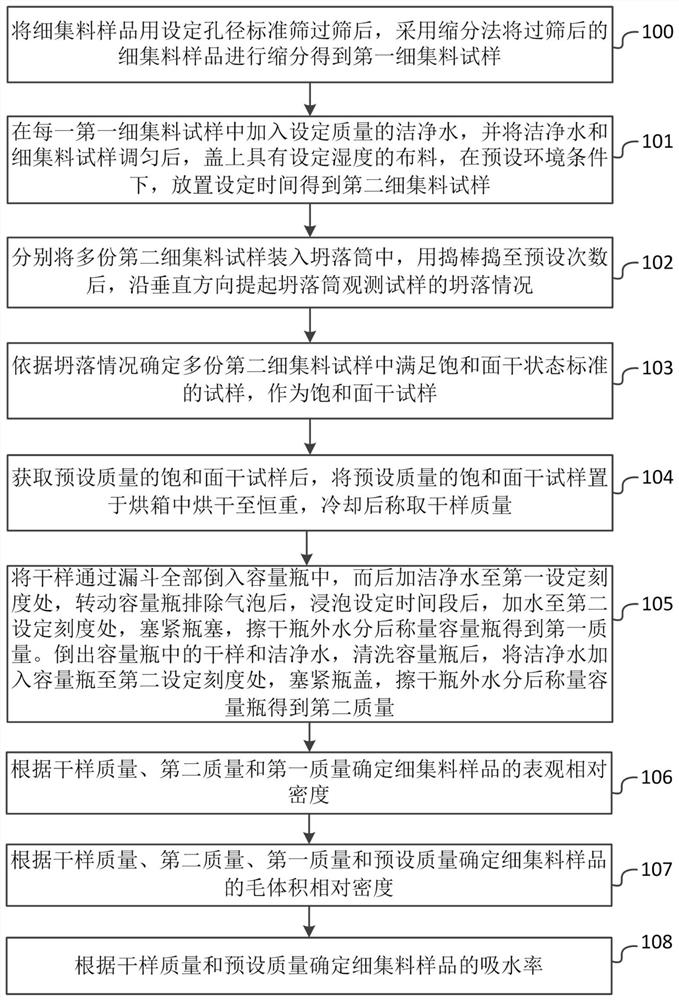

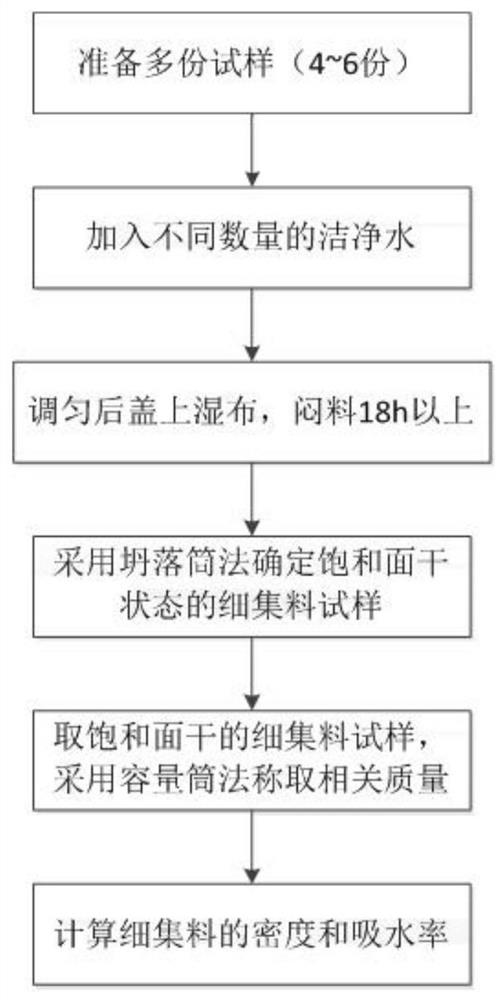

Novel fine aggregate density and water absorption testing method and system

PendingCN113533115APrevent drynessEasy to manufactureWeighing by removing componentSpecific gravity measurementSaturated-surface-dryTest sample

The invention relates to a novel fine aggregate density and water absorption testing method and system. The method comprises the following steps: preparing fine aggregate samples with different water contents by adding water with different set masses into fine aggregate and covering the materials, taking the sample which is closest to a saturated surface dry state through a slump cylinder method, and air-drying while stirring by adopting a blower and micro-warm air or adding a small amount of water properly to stir and wet the sample, and therefore, the test efficiency can be greatly improved. Moreover, the samples are prepared from water with different masses, so that the loss of part of fine powder of the fine aggregate samples due to water pouring can be avoided, and the accuracy of fine aggregate grading is ensured; and only the test sample closest to the saturated surface dry state is subjected to short-time micro-warm air drying or even does not need to be subjected to blowing air drying, the problems that the fine aggregate test sample is not uniform in dryness and wetness or is excessively dried due to excessive blowing and fine aggregate particles are blown away in the air drying process can be avoided, and the test result test accuracy can also be ensured.

Owner:广东长亨石业有限公司 +1

A Grading and Evaluation System for Low-Quality Recycled Aggregate

ActiveCN104276775BEfficient recyclingSmall sturdinessSolid waste managementSaturated-surface-dryBrick

The invention discloses a grading evaluation system of low-quality recycled aggregates. The grading evaluation system comprises the following steps: (1) carrying out grading evaluation on low-quality recycled aggregates; (2) carrying out grading evaluation on ordinary aggregates; (3) carrying out grading evaluation on mixed aggregates, wherein mixed coarse aggregates are composed of low-quality coarse recycled aggregates and ordinary coarse aggregates; the performance indexes of the mixed coarse aggregates meet the requirements as follows: the crushing value index is less than 30%, the sturdiness is less than 12%, and the water absorption of an hour is less than 3%; mixed fine aggregates are composed of low-quality fine recycled aggregates and ordinary fine aggregates; and the performance indexes of the mixed fine aggregates meet the requirements as follows: the compressive strength rate of 28 days is greater than or equal to 85%, the sturdiness is less than 10%, and the saturated-surface-dried moisture retention is less than 5%. When the low-quality brick recycled aggregates of meeting the grading evaluation indexes disclosed by the invention are applied to recycled aggregate concrete, the recycled aggregate concrete has the advantages of high compressive strength, stable performance and the like, and the problem of recycling of the low-quality recycled aggregates can be effectively solved.

Owner:北京东方建宇混凝土科学技术研究院有限公司

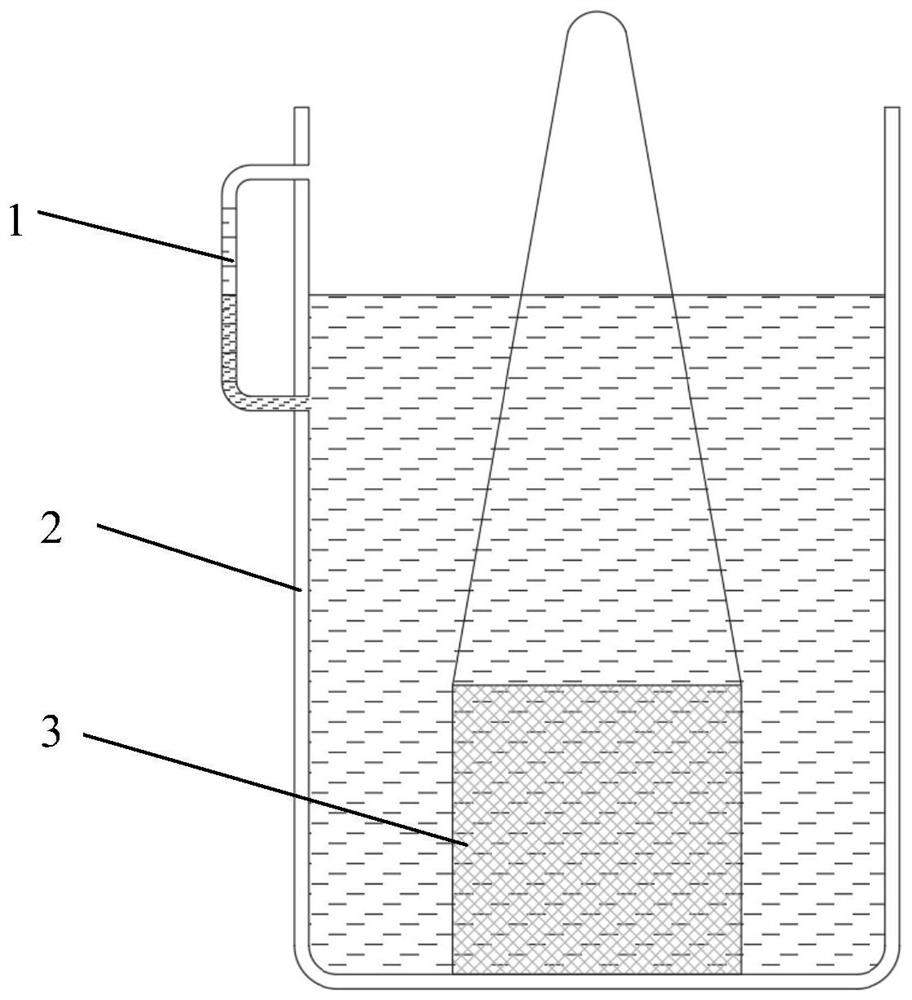

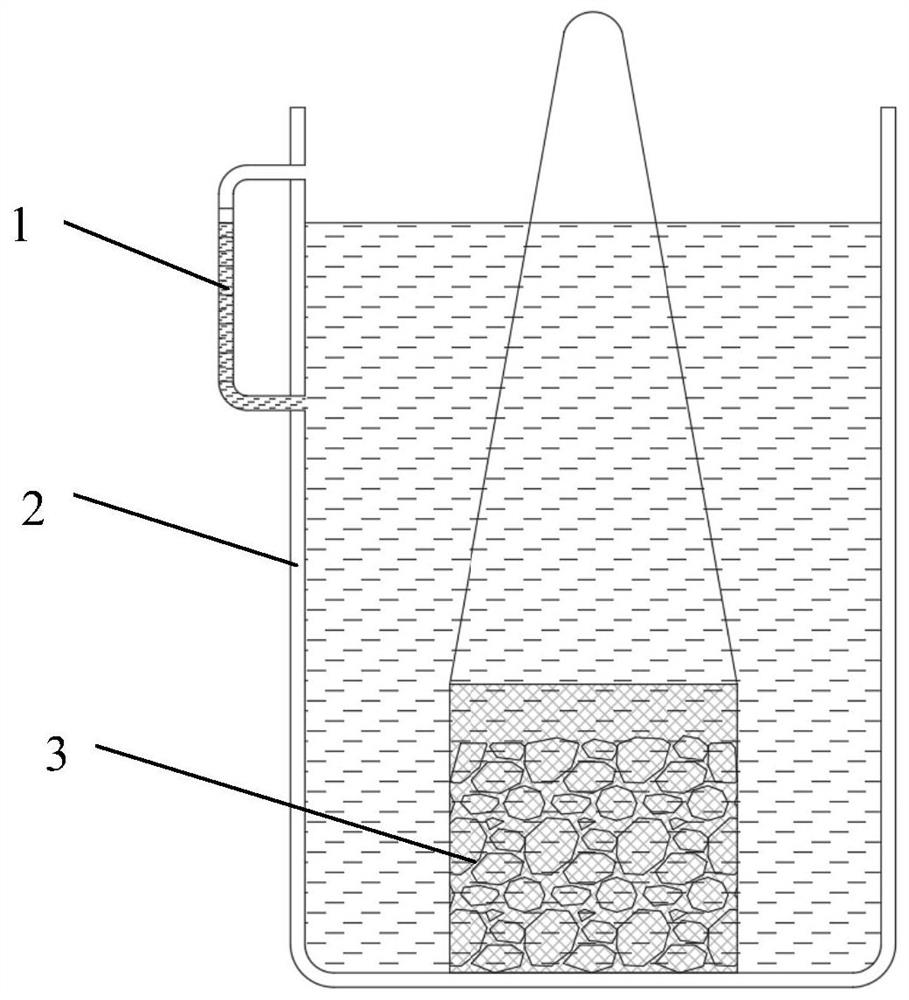

Integrated device for measuring apparent density of aggregate and measuring method

PendingCN113758827ALower requirementEfficient use ofSpecific gravity measurementSaturated-surface-dryCommunicating vessels

The invention discloses an integrated device for measuring the apparent density of aggregate. The integrated device comprises a water containing barrel and a mesh basket, wherein a vertical columnar communicating vessel is arranged on the side surface of the water containing barrel, the mesh basket can be placed in the water containing barrel, and scales are arranged on the vertical columnar communicating vessel. The determination method comprises the following steps that an aggregate sample soaked for 24 hours is treated into a saturated surface dry state according to engineering requirements, and the mass of the aggregate is weighed; a net basket is completely immersed in a water containing barrel filled with water, and the water level height is read from a dial gauge of the columnar communicating vessel; all the aggregate samples in the saturated surface dry state are put into a mesh basket and are immersed into a water containing barrel filled with water, and the water level height is read from a dial gauge of the columnar communicating vessel; and the measured aggregate apparent density is calculated according to a formula. Compared with a traditional measuring device and method, the method is novel, the structure is integrated, operation is easy, the requirement for testers is not high, calculation is easy, and efficiency is high.

Owner:CHINA WATER RESOURCES BEIFANG INVESTIGATION DESIGN & RES

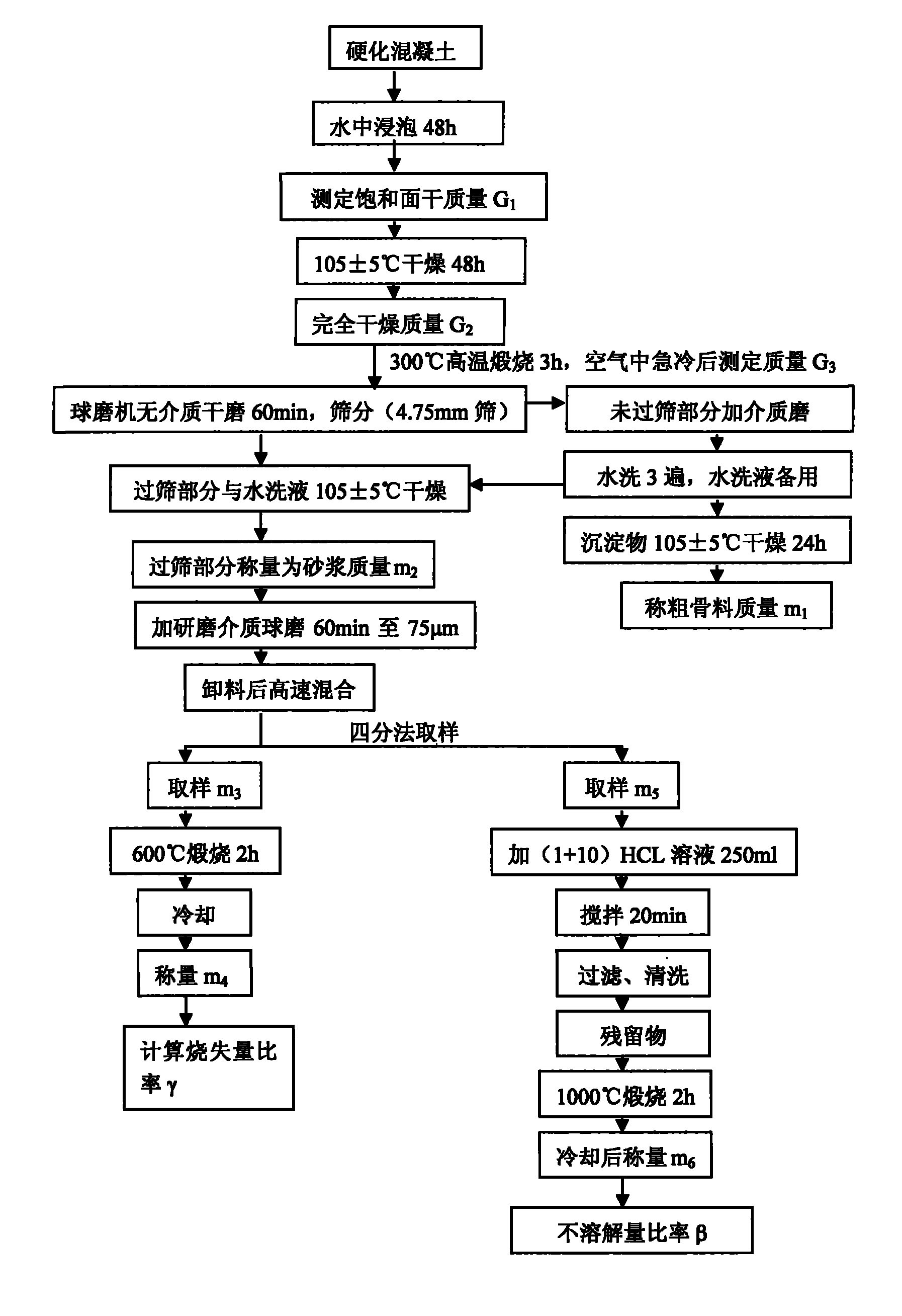

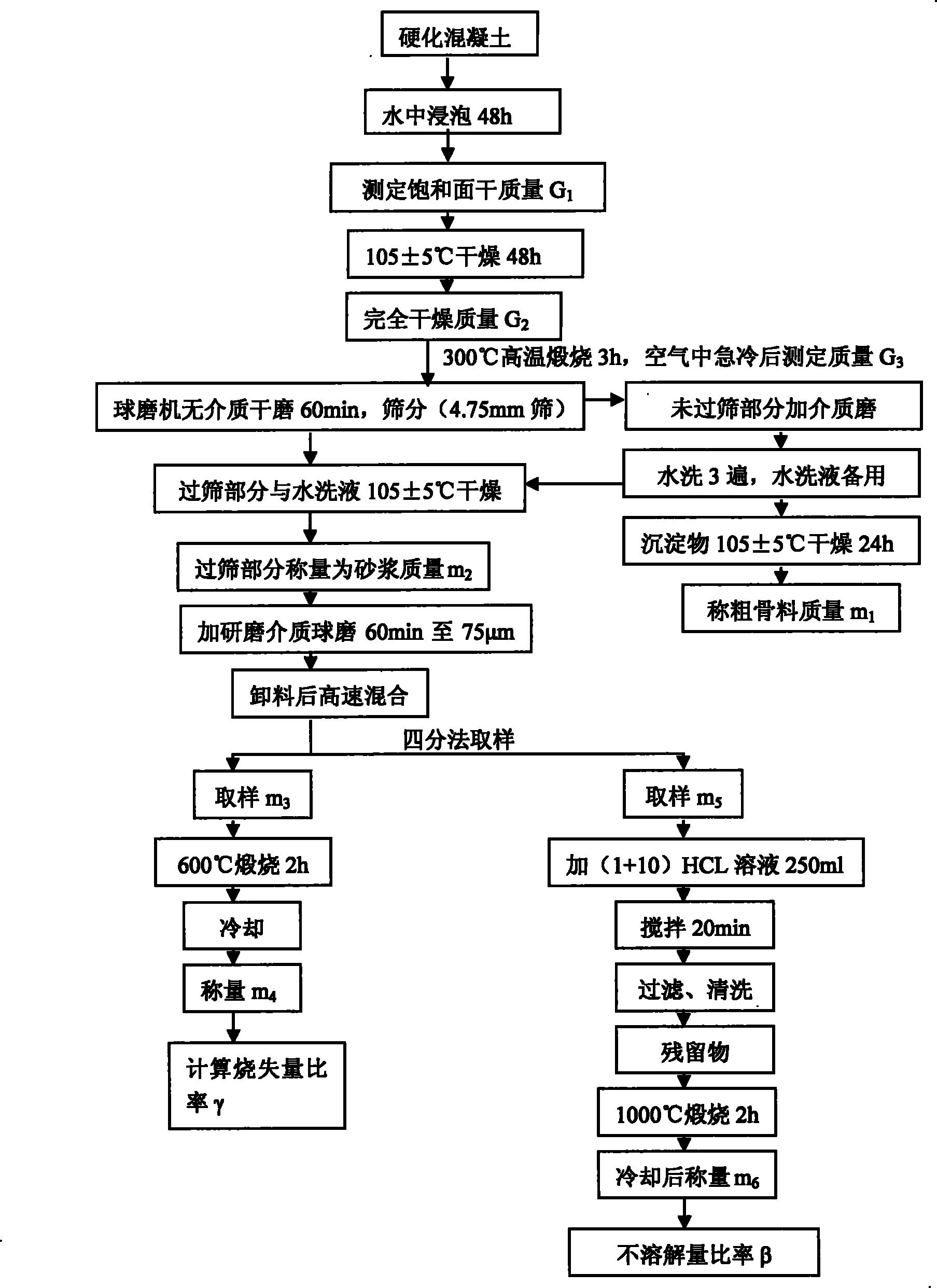

Deductive method of hardened concrete mixing ratio

InactiveCN101539499BImprove accuracyHigh precisionWeighing by removing componentChemical analysis using combustionSaturated-surface-dryTest sample

Owner:ZHEJIANG UNIV OF TECH

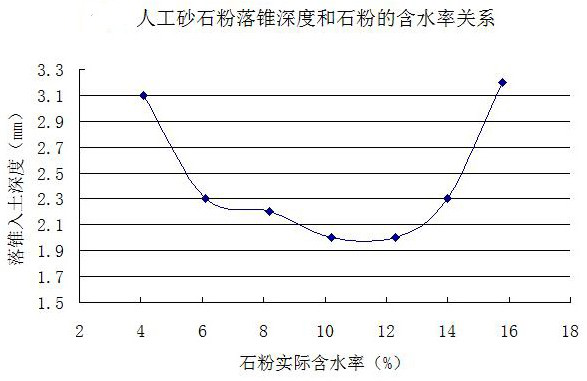

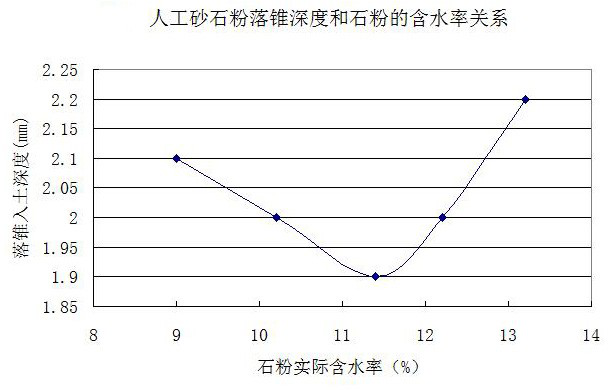

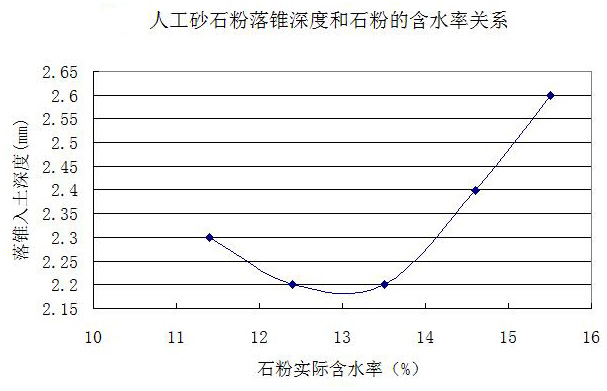

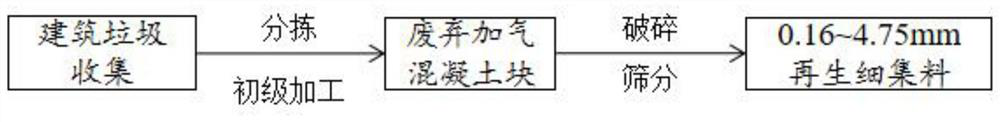

Method for comprehensively measuring saturated surface dry water absorption of artificial sand

The invention discloses a method for comprehensively measuring saturated surface dry water absorption of artificial sand, which is characterized by comprising the following steps: 1, taking a certain amount of artificial sand sample, screening the artificial sand sample into an oversize part and an undersize part by using a 0.08 mm sieve, and recording the fractions of the oversize part and the undersize part in the total sample; 2, measuring the oversize part by using a natural sand saturated surface dry water absorption test method; 3, preparing a plurality of stone powder sub-samples with different water contents from the undersize part according to the estimated saturated surface dry water absorption rate, sequentially determining the water contents at equal intervals, and determining the saturated surface dry water absorption rate of the stone powder sub-samples; and 4, multiplying the saturated surface dry water absorption of the oversize part by the fraction of the oversize part, and multiplying the saturated surface dry water absorption of the stone powder by the fraction of the undersize part to obtain the saturated surface dry water absorption of the artificial sand sample. According to the invention, the artificial sand is sieved into the oversize part and the undersize part by the 0.08 mm sieve, the measurement result is accurate, the practicability is strong, and the method can be applied to the field with weaker test conditions, and the data can be output on the field to give the result.

Owner:SINOHYDRO BUREAU 16 CO LTD +1

Anti-cracking alkali slag recycled concrete and preparation method thereof

The invention discloses anti-cracking alkali slag recycled concrete and a preparation method thereof. According to the invention, sodium sulfate, sodium silicate and cement are used as composite excitants, such that advantages of cracking resistance, good strength, and the like are provided. The recycled coarse aggregate with the saturated surface dry can return water to achieve an internal curing effect, so that the shrinkage of the material is reduced, and the anti-cracking performance is improved; magnesium oxide is adopted to compensate shrinkage of the alkali slag concrete, and cracking is further reduced; by adopting the PTB emulsion, the development of micro-cracks in the material can be inhibited, and the waterproof performance and the workability are relatively good; and the used slag and recycled aggregate are wastes which are recycled, so that garbage landfill can be reduced, and environmental management and protection are facilitated. The anti-cracking alkali slag recycled concrete has good economic, social and environment-friendly benefits and is suitable for large-scale popularization and application.

Owner:FUJIAN AGRI & FORESTRY UNIV

Recycling Thickness Test Method in Hot-in-Place Recycling Project of Asphalt Pavement

ActiveCN104567600BEasy to disengageAccurate valueMechanical thickness measurementsRoads maintainenceSaturated-surface-dryPortland cement

The invention discloses a recycling thickness test method for an asphalt pavement in a hot in-place recycling project. The method comprises the following steps: step 1, ordinary Portland cement is uniformly spread on a milled and planed pavement in a hot in-place recycling construction process of the asphalt pavement; step 2, after paving and rolling in a cement spreading position and the pavement temperature is reduced to 50 DEG C, a pavement core drilling rig is used for core drilling at a cement spreading center point; step 3, the diameter d of a core sample is measured; step 4, the core sample is placed in a hydrostatic balance, the weight m1 of the core sample in water is weighed, and the saturated surface dry mass m2 of the core sample is measured after the core sample is taken out; and step 5, the thickness of a recycling layer is calculated. The recycling thickness of the asphalt pavement in the hot in-place recycling project can be described effectively and accurately with the test method.

Owner:SOUTHEAST UNIV +1

Pavement concrete and preparation method thereof

PendingCN113277798AGuaranteed construction effectStrong water absorptionSaturated-surface-dryStructural engineering

The invention provides pavement concrete as well as a preparation method and application thereof, and belongs to the field of comprehensive recycling of waste aerated concrete. As waste aerated concrete recycled fine aggregate is loose and porous and has very strong water absorption, pre-wetted fine aggregate in a saturated surface dry state is obtained by pre-wetting in advance, it can be ensured that the slump is within a reasonable range, and the result shows that the pre-wetted waste aerated concrete particles have an internal curing effect under the condition that other factors are not changed, on the basis of ensuring the construction performance of the pavement concrete, the mechanical property, wear resistance and the like of the pavement concrete meet related requirements, and compared with the performance of a control group (pavement concrete not replaced by waste aerated concrete), the performance of the pavement concrete is not greatly reduced, and engineering practice can be guided.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL +1

Device and method for continuously measuring saturated surface dry state of pre-wetted aggregate

ActiveCN114018751ASimple structureSimple and fast operationWeighing by removing componentDrying gas arrangementsSaturated-surface-drySoil science

The invention relates to a device and a method for continuously measuring a saturated surface dry state of pre-wetted aggregate, belongs to the technical field of preparation of concrete materials, and aims to provide a simple lightweight aggregate saturated surface drying device, so that the lightweight aggregate with the wet surface can rapidly reach the saturated surface drying state. The method comprises the following steps: firstly, measuring the standard water absorption rate of the dry aggregate in a saturated surface dry state; secondly, before the dry aggregate is pre-wetted, weighing the mass of the dry aggregate in a hopper; then, calculating and obtaining the moisture content of the batch of aggregate in a surface dry and saturated state; then, after the dry aggregate is pre-wetted, weighing the mass of the pre-wetted aggregate in the hopper; then, loading the wet aggregate on a porous plate, feeding the porous plate into a drying chamber for drying treatment, and measuring the relative humidity of the drying chamber; then, calculating the moisture mass in the drying chamber; then respectively weighing the mass of water flowing out of a water collecting tank below the porous plateand the mass of condensate water in a heat exchanger; and finally, calculating the actual water carrying amount in the dried saturated surface dry aggregate when the water content is close to the water content in the aggregate surface dry and saturated water state.

Owner:SHANGHAI CONSTRUCTION GROUP

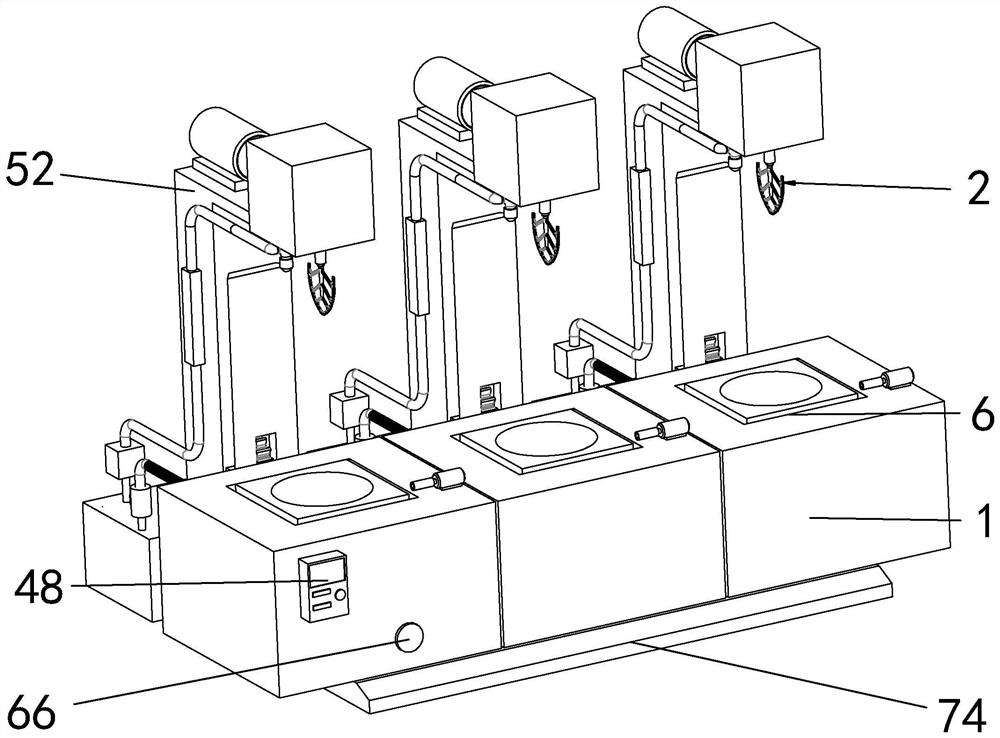

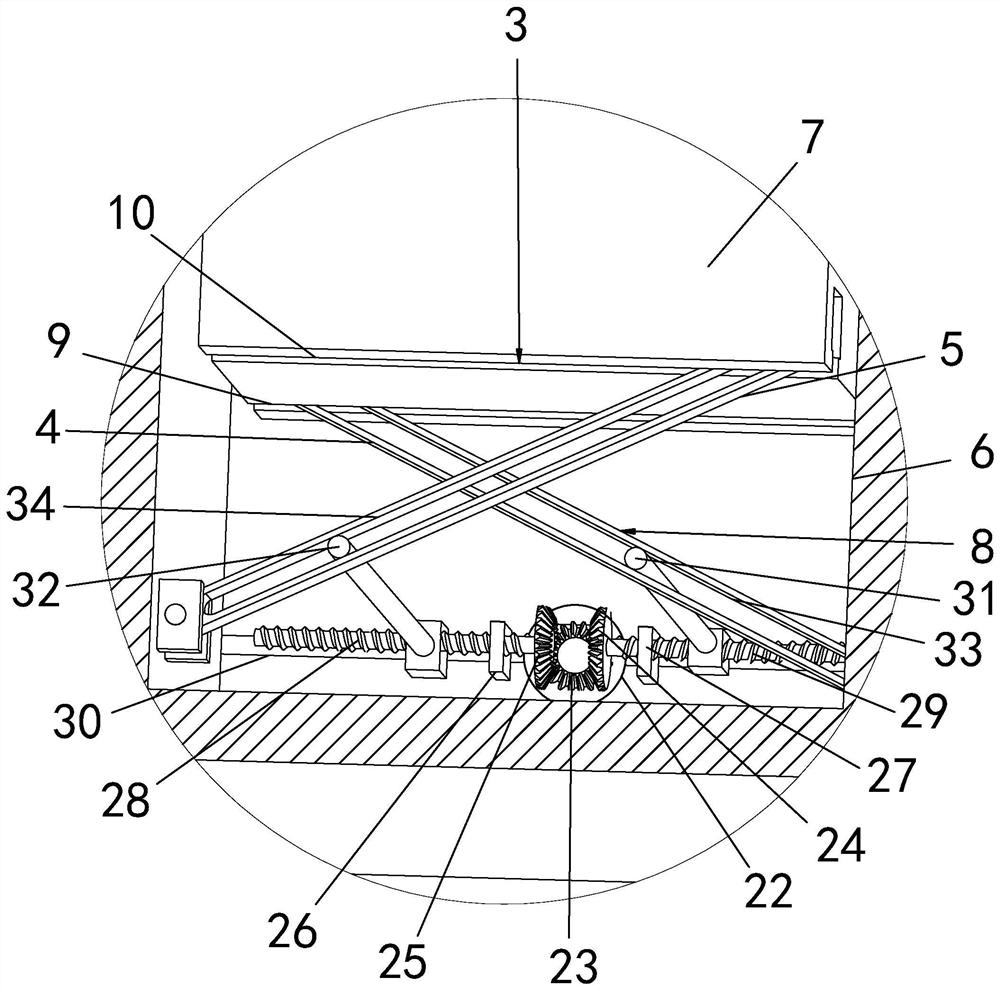

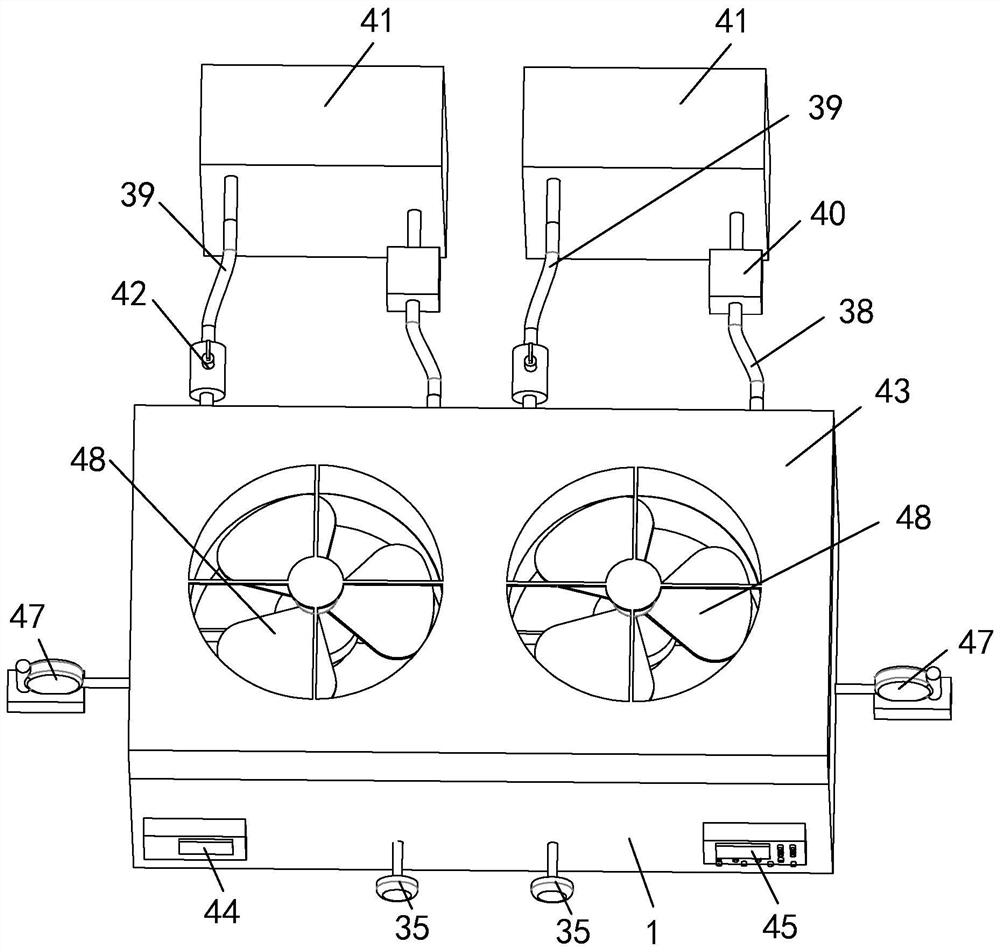

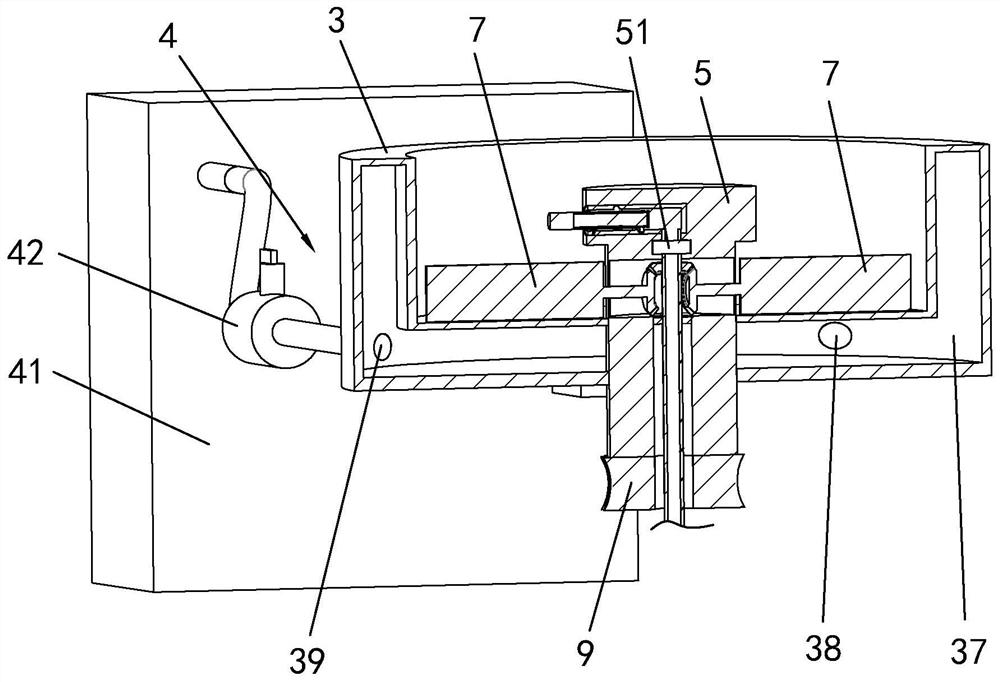

A high-efficiency aggregate saturated surface dry mixing device

ActiveCN112873548BMixing operation control apparatusPretreatment controlSaturated-surface-dryElectric machine

The invention discloses a high-efficiency aggregate saturated surface dry mixing device, which comprises a box body, a cavity arranged in the box body, and mixing drums symmetrically arranged in the box body. The heating component, the two sets of mixing drums are equipped with stirring rollers, and the stirring rollers are equipped with an air outlet component for blowing the surface of the aggregate. There are a number of stirring blades arranged in a ring on the side wall of the stirring rollers, and the rotating shaft of the stirring blades runs through the The side wall of the stirring roller is fixed with a bevel gear 1, and a worm wheel ring is installed for rotation in the cavity. , There is a double-axis motor fixed in the cavity, which can evenly stir the aggregate and at the same time quickly dry the moisture on the surface of the aggregate, speed up the evaporation of moisture on the surface of the aggregate, and reduce the working intensity of the staff.

Owner:杭州惟进科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com