Pavement concrete and preparation method thereof

A technology of concrete and air-entrained concrete, which is applied in the field of comprehensive recycling of waste air-entrained concrete, which can solve problems such as decline in mechanical properties, pollution of soil and water resources, increase of waste air-entrained concrete, etc., and achieve strong reproducibility and operability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

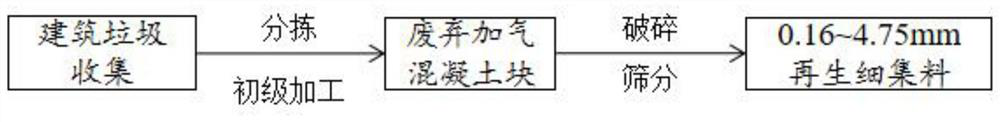

[0025] The invention provides a kind of preparation method of pavement concrete, comprises the following steps:

[0026] Crushing and grading waste aerated concrete in sequence to obtain recycled fine aggregate of waste aerated concrete;

[0027] Pre-wetting the regenerated fine aggregate of waste aerated concrete to obtain pre-wet fine aggregate;

[0028] The pavement concrete is obtained by mixing the pre-wet fine aggregate, cement, gravel, river sand and water.

[0029] In the present invention, unless otherwise specified, the raw materials used are all commercially available products in this field.

[0030] The invention sequentially crushes and classifies the waste aerated concrete to obtain recycled fine aggregate of the waste aerated concrete.

[0031] In the present invention, the particle size of the recycled fine aggregate of waste aerated concrete is preferably 0.16-4.75 mm.

[0032] In the present invention, the waste air-entrained concrete is preferably sorted ...

Embodiment 1

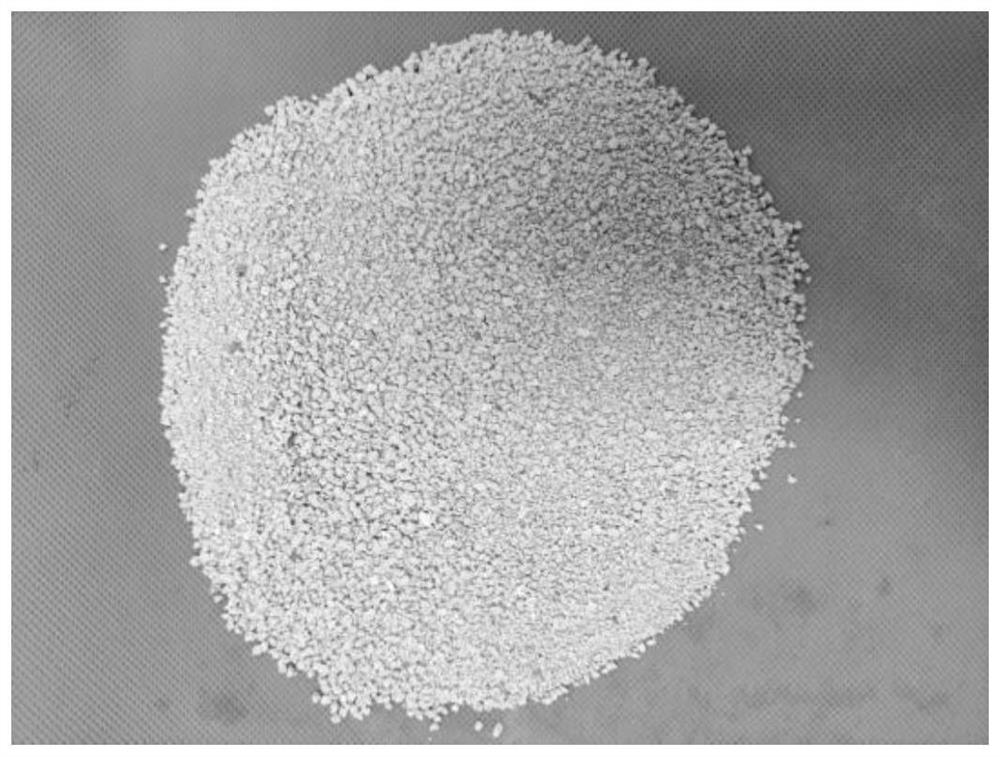

[0048] Firstly, the waste air-entrained concrete is sorted out from the construction waste, and the cement mortar attached to the air-entrained concrete block is removed; then the jaw crusher is used for crushing; and then the broken air-entrained concrete obtained is classified by a vibrating screen. The waste air-entrained concrete regenerated fine aggregate with a particle size between 0.16mm and 4.75mm was screened out.

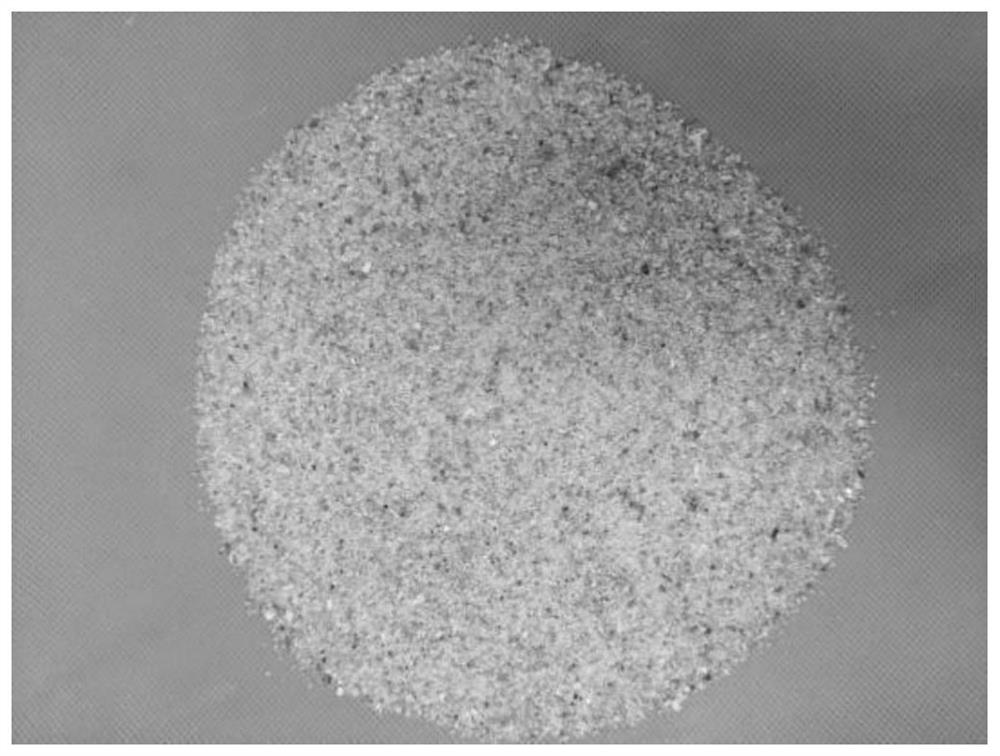

[0049] figure 2 It is the physical figure of river sand in embodiment 1, image 3 It is the physical picture of the recycled fine aggregate of waste aerated concrete in Example 1, and Table 1 is a comparison of the physical properties of river sand and recycled fine aggregate of waste aerated concrete.

[0050] Table 1 Comparison of physical properties between river sand and recycled fine aggregate of waste aerated concrete

[0051]

[0052]

[0053] Pre-wet the waste aerated concrete regenerated fine aggregate (mass water absorption rate is 35%)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com