Patents

Literature

268 results about "Sorptivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In 1957 John Philip introduced the term sorptivity and defined it as a measure of the capacity of the medium to absorb or desorb liquid by capillarity. According to C Hall and W D Hoff, the sorptivity expresses the tendency of a material to absorb and transmit water and other liquids by capillarity.

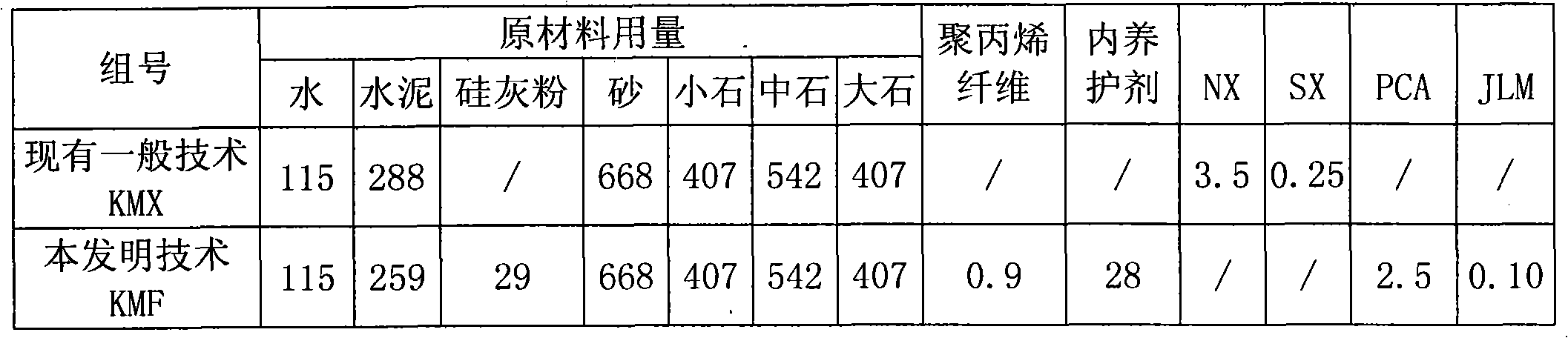

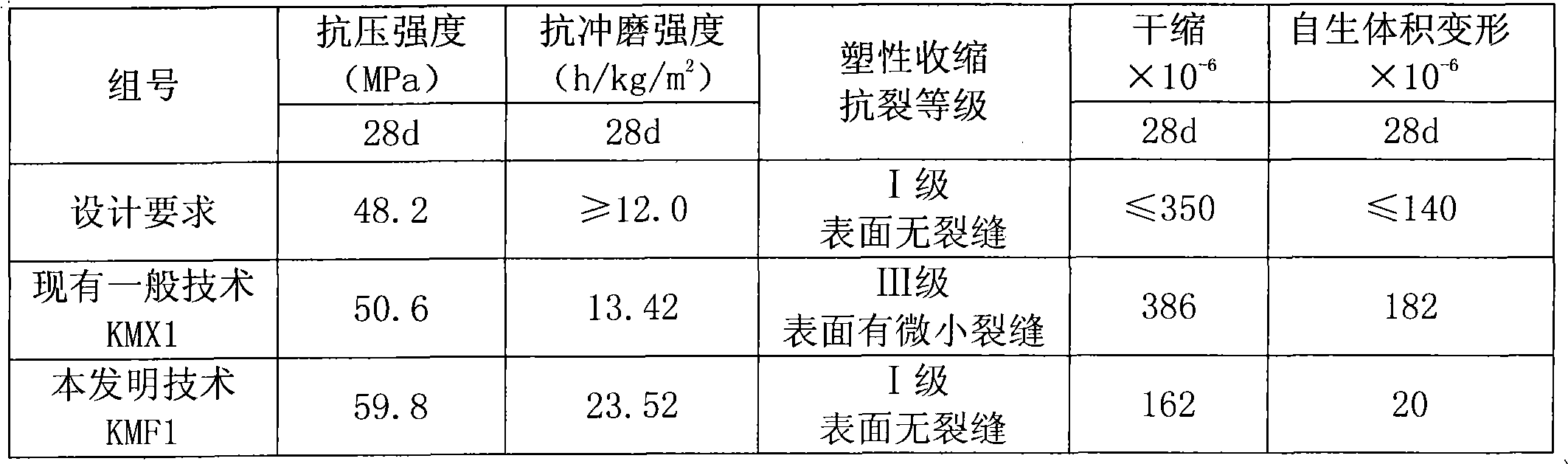

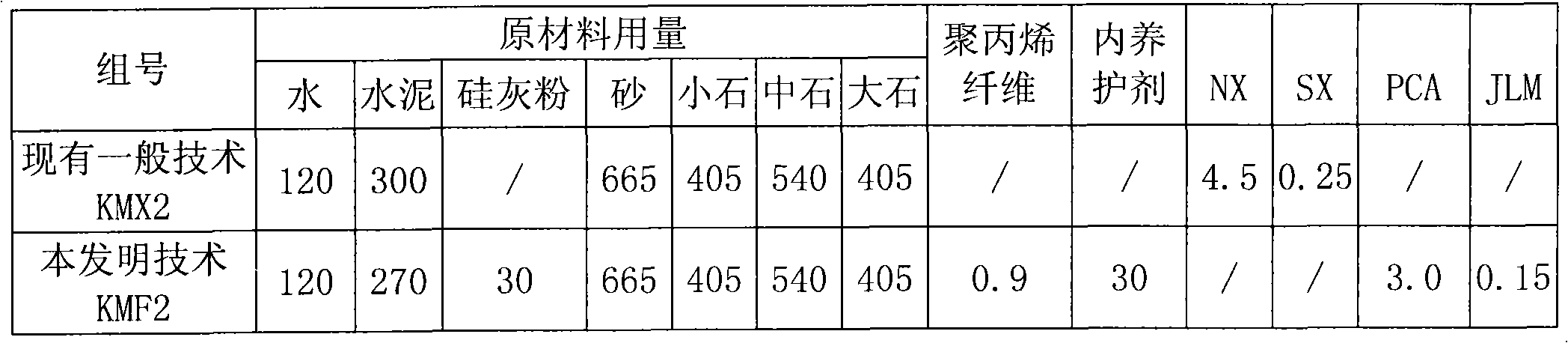

Crack-resistant abrasion-resistant hydraulic concrete and preparation method thereof

InactiveCN102010160AImprove performanceImprove abrasion resistanceSolid waste managementCrack resistanceVolume deformation

The invention discloses crack-resistant abrasion-resistant hydraulic concrete and a preparation method thereof. The hydraulic concrete comprises materials of cement, sand, stones, a polypropylene fiber, a water reducing agent, an air entraining agent and water, and is characterized in that: an internal curing agent and silica fume powder are added; by adopting the internal curing agent as a super absorbent resin, internal maintenance of the concrete is enhanced, the concrete shrinkage is reduced, the abrasion resistance of the concrete is improved, and the crack resistance of the concrete is improved; by adopting the silica fume powder, the concrete mixture performance and abrasion resistance are improved, the comprehensive utilization of industrial wastes and resource and energy conservation are realized, and the environment is protected; and taking concrete at C40 strength grade as an example, the abrasion resistance is 23.52h / kg / m<2>, the early plastic shrinkage crack resistance reaches the first grade, cracks are not formed on the surface of the concrete, an air shrinkage value within 28 days is 162*10<-6>, and the autogenous volume deformation within 28 days is 20*10<-6>. The technical scheme is simple in technical operation, readily available in raw materials, lower in production cost and better in economic and social benefits.

Owner:广西壮族自治区水利科学研究院

Pet food product and method of manufacture

InactiveUS20050031673A1High adsorption rateImprove adsorption capacityMeat/fish preservationPharmaceutical delivery mechanismCooking & bakingFood body

A pet food is provided, comprising a sorbent food body and a fluid carrier comprising a functional ingredient absorbed into the body. The body preferably is realtively moist, having a moisture content for example of from 35% to 60% by weight and firm structure that is resilient under initial biting by a pet animal. Protein content is preferably at least 20% by weight. The sorptivity of the body is increased by depleting the body of a first liquid, for example by causing drying by exposure to a source of dry heat, such as in roasting, grilling, frying and baking. Methods of manufacture are disclosed including providing a sorptive food body, causing the body to take up a carrier fluid containing a functional ingredient and packing the body in suitable packaging. The invention further provides delivery means for delivering a functional ingredient to a pet animal, the delivery means comprising a sorbent food body with the functional ingredient absorbed therein. The functional ingredient may be a nutrient or a pharmaceutical.

Owner:SOC DES PROD NESTLE SA

Fireproof diatomite plate and fabrication method thereof

The invention relates to a fireproof plate, in particular to a fireproof diatomite plate and a fabrication method thereof. The fireproof diatomite plate comprises the following components in parts by weight: 30-35 parts of diatomite, 50-55 parts of cement, 5 parts of fly ash, 1-1.5 parts of foaming agent, 1-1.5 parts of polyvinyl alcohol, 0.5-1 parts of early strength agent or accelerating agent, 0.5-1 parts of foam stabilizer, and 1-1.5 parts of anti-cracking fiber. The fireproof diatomite plate has the advantages and the effects that the disadvantages that a core plate of the original fireproof door is large in unit weight, low in strength and high in hydroscopicity, erodes a steel plate, and cannot be bonded with the steel plate easily are overcome, and the fireproof diatomite plate is an optimal filling material for a fireproof door. The fireproof diatomite plate is green, environment-friendly, nontoxic, innocuous, fireproof, flame-retardant and smokeless, and does not erode the steel plate.

Owner:营口盼盼硅藻材料集团有限公司

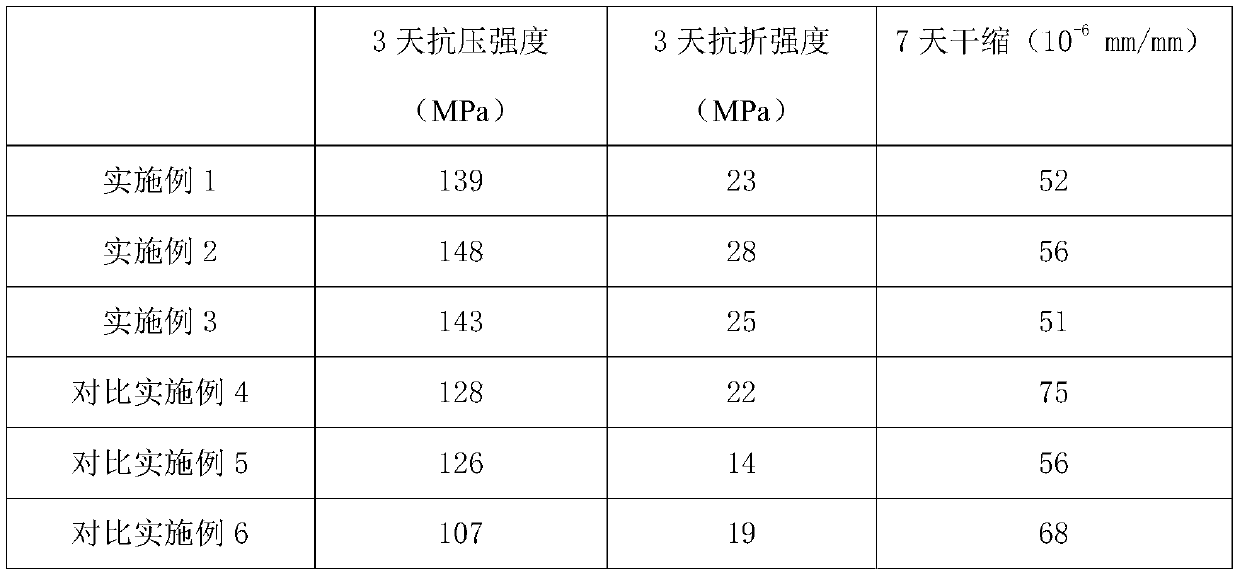

High-strength and high-toughness geopolymer material and preparation method thereof

ActiveCN111018435AHigh bonding strengthImprove mechanical propertiesCement productionFiberKaolin clay

The invention discloses a high-strength and high-toughness geopolymer material. The high-strength and high-toughness geopolymer material comprises, by weight, 500-700 parts of silicon-aluminum mineralraw materials, 600-800 parts of an alkali activator, 70-150 parts of a nanoscale efficient modifier, 2-5 parts of super absorbent resin, 2-6 parts of a hybrid fiber, 4-10 parts of a surfactant, 700-1000 parts of fine aggregates and 100-150 parts of deionized water, the silicon-aluminum mineral raw materials comprise 200-300 parts of metakaolin, 150-200 parts of fly ash, 50-100 parts of red mud, 40-60 parts of mineral slag, 40-60 parts of silica fume and 20-40 parts of Portland cement, and the nanoscale efficient modifier comprises 20-50 parts of condensed phosphate, 20-40 parts of nano-silica, 20-40 parts of nano-alumina and 10-20 parts of zeolite. The invention further discloses a preparation method of the high-strength and high-toughness geopolymer material. The problems of large earlyself-shrinkage and easy cracking of the geopolymer are solved, and the obtained geopolymer has strong toughness and high strength.

Owner:ZHEJIANG UNIV

Pet food product and method of manufacture

InactiveUS7842329B2Improve adsorption capacityReduce moisture contentMeat/fish preservationAnimal feeding stuffFood bodyAdditive ingredient

A pet food is provided, comprising a sorbent food body and a fluid carrier comprising a functional ingredient absorbed into the body. The body preferably is relatively moist, having a moisture content for example of from 35% to 60% by weight and firm structure that is resilient under initial biting by a pet animal. Protein content is preferably at least 20% by weight. The sorptivity of the body is increased by depleting the body of a first liquid, for example by causing drying by exposure to a source of dry heat, such as in roasting, grilling, frying and baking. Methods of manufacture are disclosed including providing a sorptive food body, causing the body to take up a carrier fluid containing a functional ingredient and packing the body in suitable packaging. The invention further provides delivery means for delivering a functional ingredient to a pet animal, the delivery means comprising a sorbent food body with the functional ingredient absorbed therein. The functional ingredient may be a nutrient or a pharmaceutical.

Owner:SOC DES PROD NESTLE SA

Cellulosic-reinforced composites having increased resistance to water absorption

Cellulosic-reinforced composites having increased resistance to water absorption are provided. The improved composites are obtained using a mixture of high density polyethylene and silane copolymer with the cellulosic filler.

Owner:EQUSR CHEM LP

Cavernous garden waste concrete

ActiveCN105174862AWater permeableWith breathable functionSolid waste managementMaterials scienceUrban construction

The invention discloses a concrete and a preparation method thereof. The concrete comprises cement, sand, stone, and garden wastes. Preferably, the garden wastes are fragmented garden wastes after grinding. The concrete is prepared by evenly mixing cement, sand, stone, fragmented garden wastes and water according to a weight ratio of 100:90-150:190-250:5-40:45-60. The garden wastes generated during the city construction process are recycled, and the wastes are converted into valuable resource. The concrete has the advantages of good water absorbing performance, water permeability, breathability, and high strength, and can be applied to parts that do not have high requirements on strength. Moreover, the raw materials are easily available, the preparation method is simple, and the preparation cost is low.

Owner:江苏香叶建材科技有限公司 +3

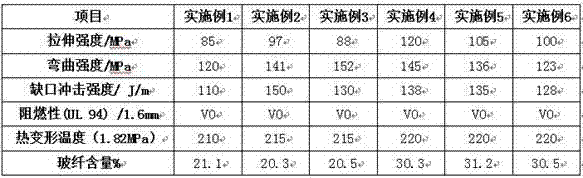

High temperate-resistant nanometer fire resistance-enhanced PA6 composite material and preparation method thereof

InactiveCN102391643AImprove impact resistanceSmall water absorptionGlass fiberHeat deflection temperature

The invention relates to a high temperate-resistant nanometer fire resistance-enhanced PA6 composite material and a preparation method of the composite material, belonging to the technical field of a material. The composite material comprises the following components in percentage by weight: 30-70% of nylon, 10-25% of main fire retardant, 3-12% of subsidiary fire retardant, 0.5-5% of nanommt, 10-30% of glass fiber, 2-12% of graft toughening modifier, 0.2-1% of antioxygen and 0.2-1% of lubrication dispersant. A preparation method of the composite material comprises the following steps of: taking each component according to weight percent; and putting each component into a high-speed mixing machine for 3-5min, discharging to obtain a mixture, controlling machining temperature of a double-screw extruder at 220-240 DEG C, and controlling the rotational frequency of screws at 180-600 revolutions per minute, putting the mixture into the double-screw extruder to carry out pelleting in an extruding way, so that the composite material is obtained. The invention has the following beneficial effects that the heat distortion temperature of the composite material is larger than 210 DEG C (1.82 M Pa), the shock resistance of the material is enhanced, compared with the conventional material, the water absorption ability is reduced to be at about 30%, and the composite material is higher in oxidation resistance, processing fluidity and environmental performance.

Owner:SHANGHAI SUNNY

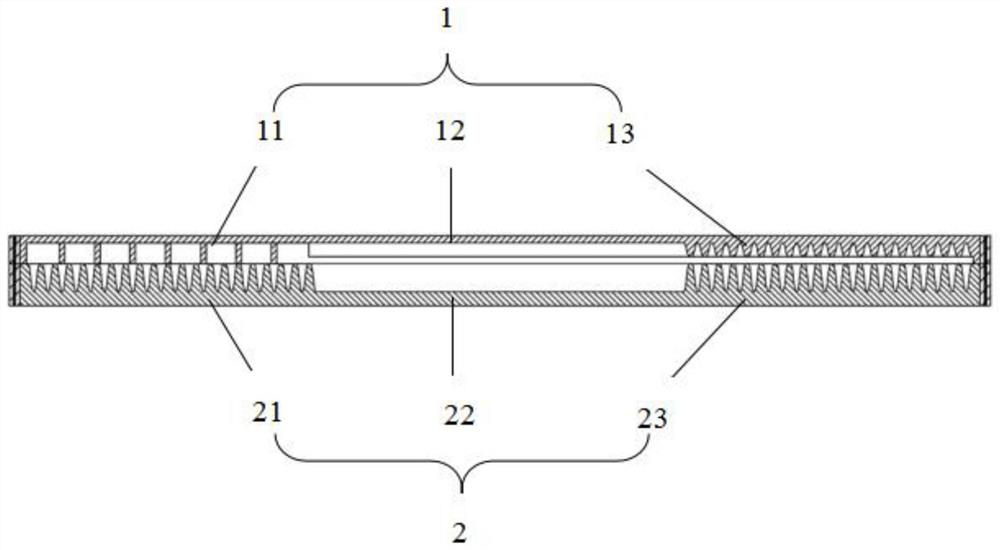

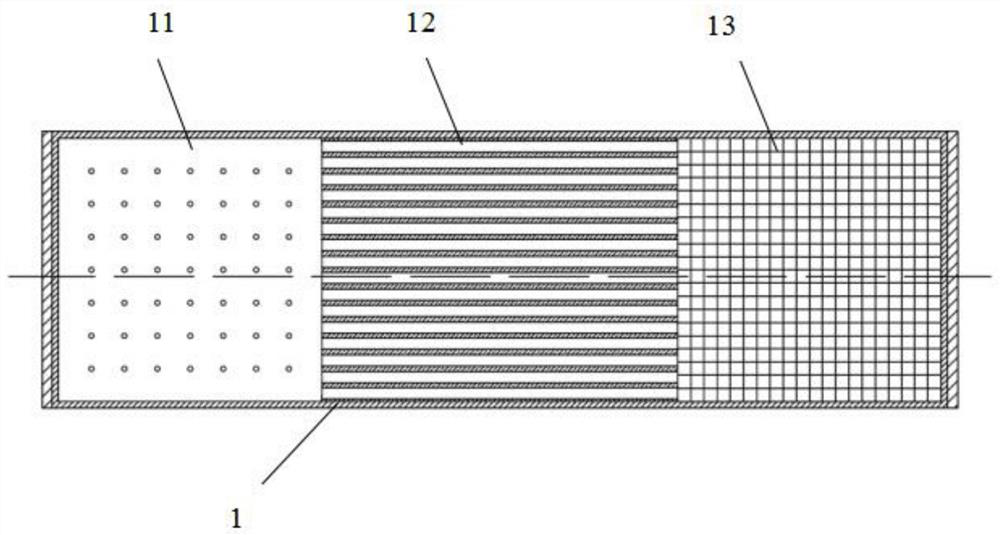

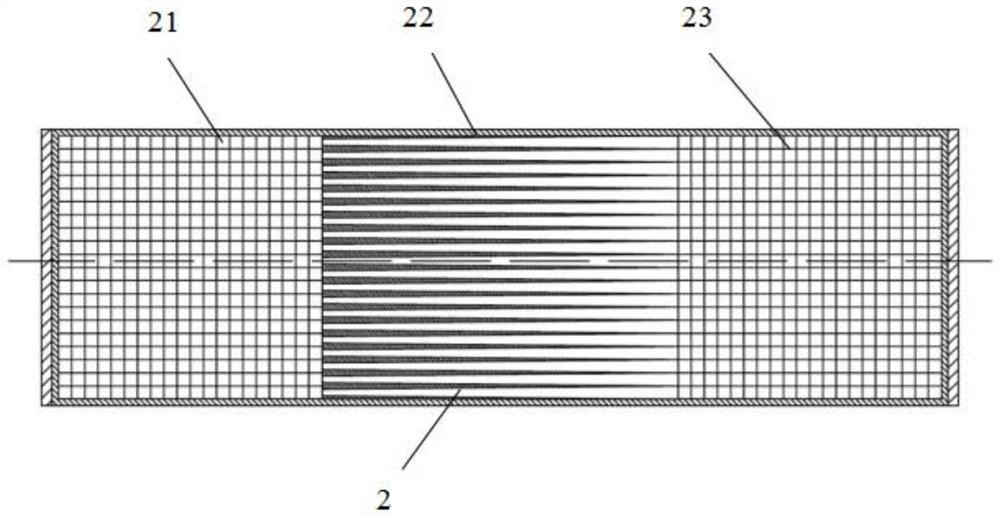

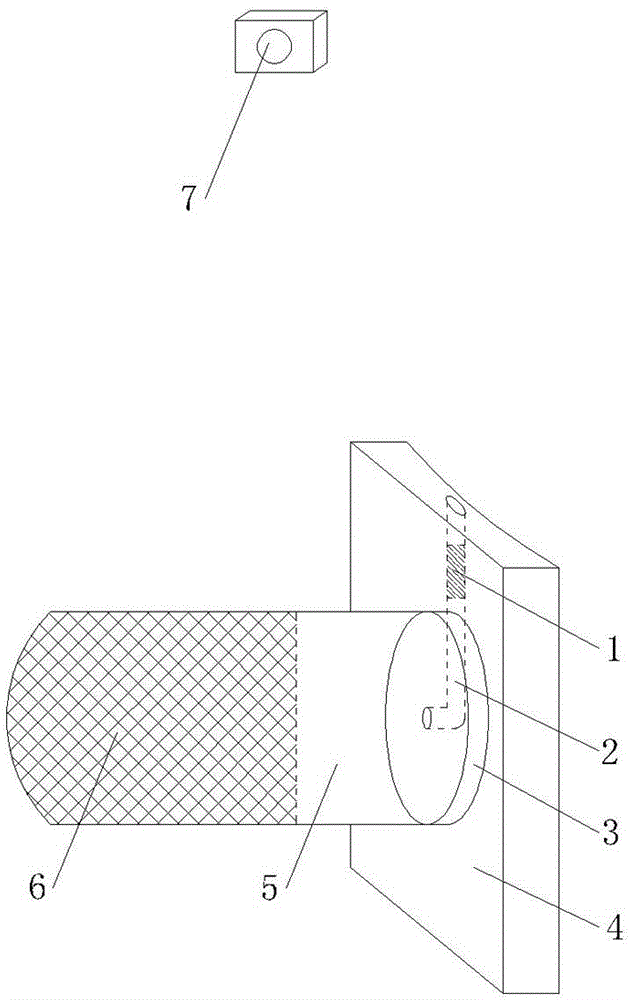

Partition-optimized ultrathin VC with thickness of 0.1-0.4 mm and preparation method

PendingCN111879158AEmission reductionSpeed up distributionIndirect heat exchangersMicro nanoNano structuring

The invention discloses a partition-optimized ultrathin VC with the thickness of 0.1-0.4 mm and a preparation method. The ultrathin VC comprises an upper cover plate and a lower cover plate, and the upper cover plate and the lower cover plate are welded. Each of the upper cover plate and the lower cover plate comprises an evaporation section, a heat insulation section and a condensation section; the surface of the evaporation section of the upper cover plate is of a super-hydrophilic cavity-shaped micro-nano structure, the surface of the heat insulation section of the upper cover plate is of asuper-hydrophilic equal-width groove micro-nano structure, and the surface of the condensation section of the upper cover plate is of a super-hydrophobic conical micro-nano structure; and a super-hydrophilic conical micro-nano structure is arranged on the surface of the area of the evaporation section of the lower cover plate, a super-hydrophilic cactus-like wedge-shaped groove micro-nano structure is arranged on the surface of the area of the heat insulation section, and a super-hydrophilic conical micro-nano structure is arranged on the surface of the area of the condensation section. The invention further discloses a preparation method of the ultrathin VC. A steam cavity structure, a liquid cavity structure and volume distribution in a heat pipe can be optimized, and good capillary water absorption performance and low water resistance and heat resistance of the heat pipe can be guaranteed.

Owner:绍兴镭纳激光科技有限公司

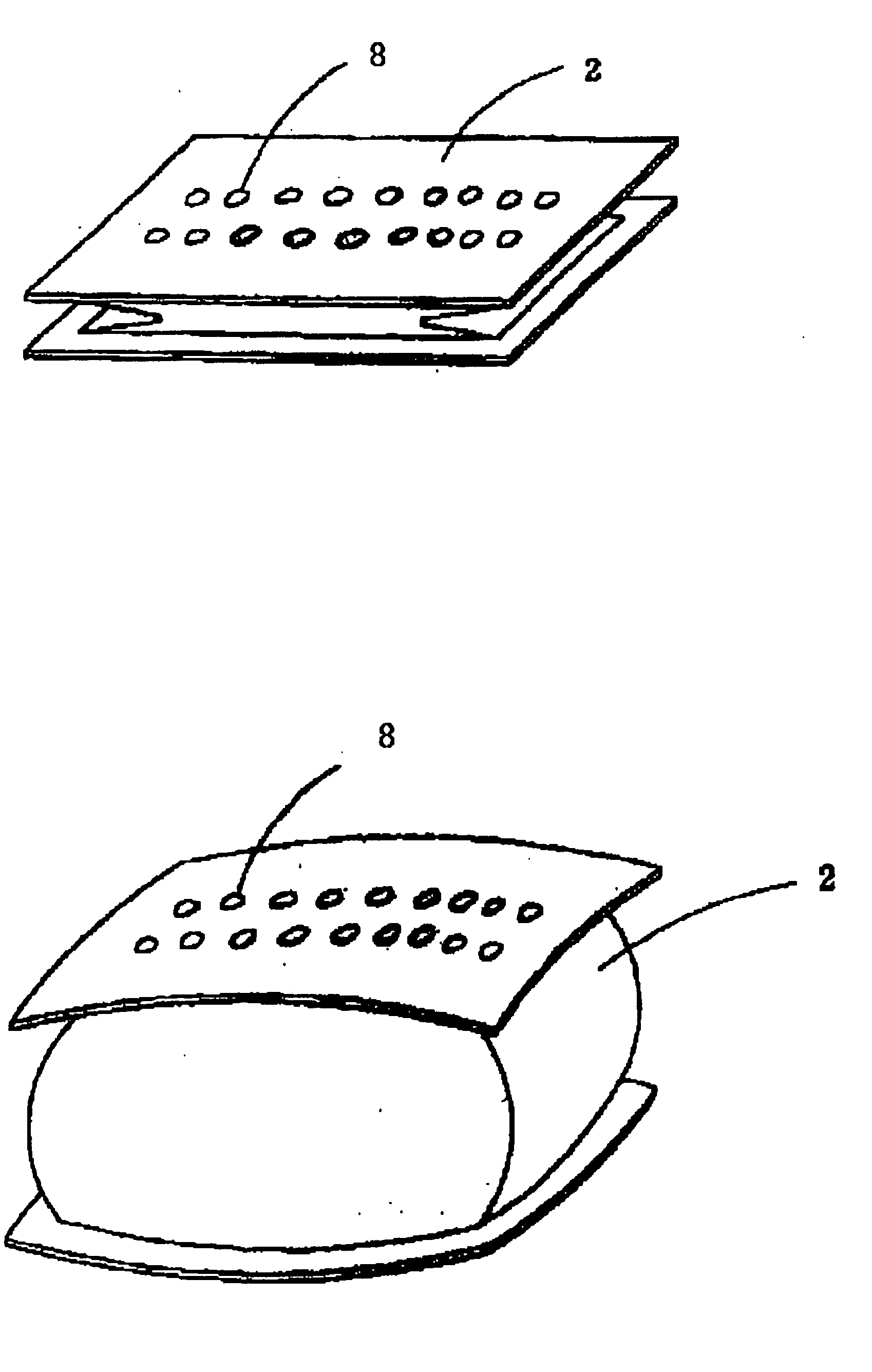

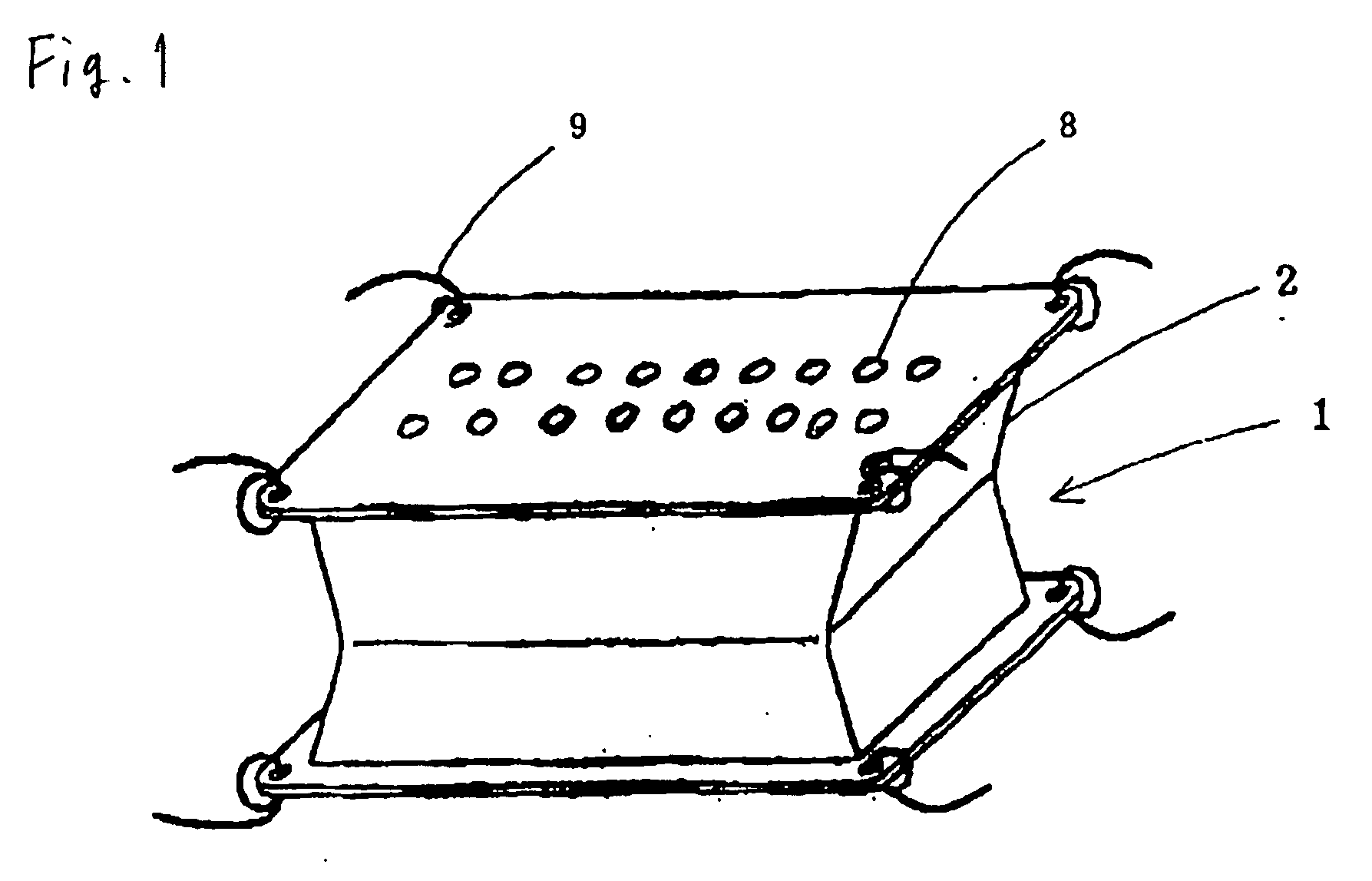

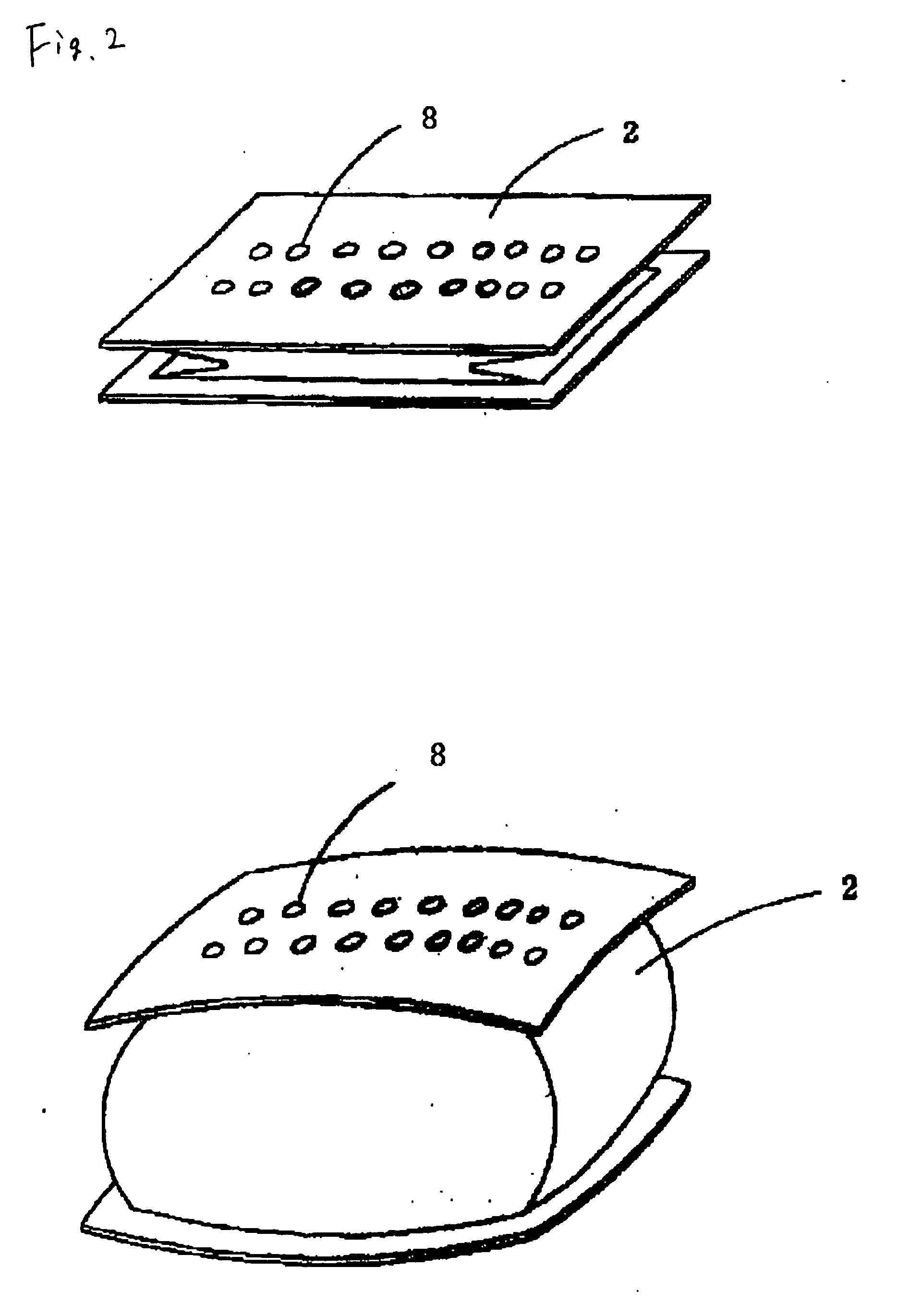

Water-swellable waterproof sealant

InactiveUS20070125568A1Easy to storeFast swellingDamsClimate change adaptationWater leakageWater flow

A water swelling water stop material comprised of a water permeable sheet, characterized in that water absorbent resin particles (A) are enclosed therein so that the water stop material upon water absorption and swelling has the configuration of polyhedron (B). The water stop material is thin to thereby facilitate storage thereof and is lightweight to thereby render carry thereof easy. The polyhedron (B) is so constructed that upon water absorption and swelling, at least two faces are planar. When the polyhedron (B) is formed into a rectangular solid or cube, even if multiple polyhedrons (B) are piled one upon another, they are stable and are resistant to collapse even under the influence of a a large amount of water. When polyhedrons (B) of the same configuration are piled one upon another, any gaps between water stop materials are slight so as to inhibit water leakage through the gaps. Moreover, when the polyhedron (B) has a cavity, the cavity can be packed with a heavy solid material or can have a stake hammered therein so that the water stop material can stably resist violent water streams. Therefore, this water swelling water stop material can be appropriately used as a water stop material for rainwater penetration prevention in order to protect banks, buildings, houses, etc. in the event of flood, heavy rain, etc.

Owner:SANYO CHEM IND LTD +1

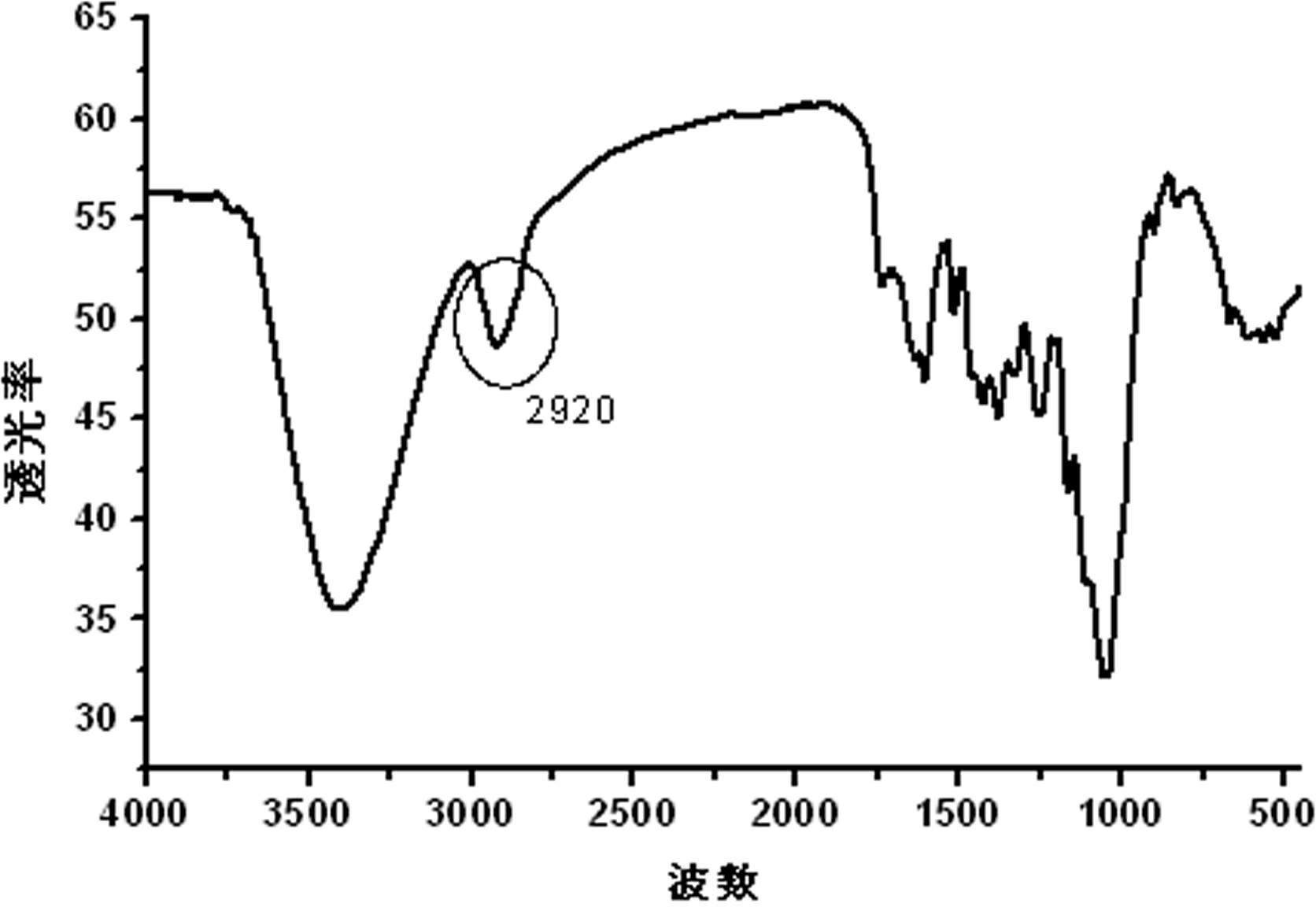

Preparation method of salt resistant composite water retention material

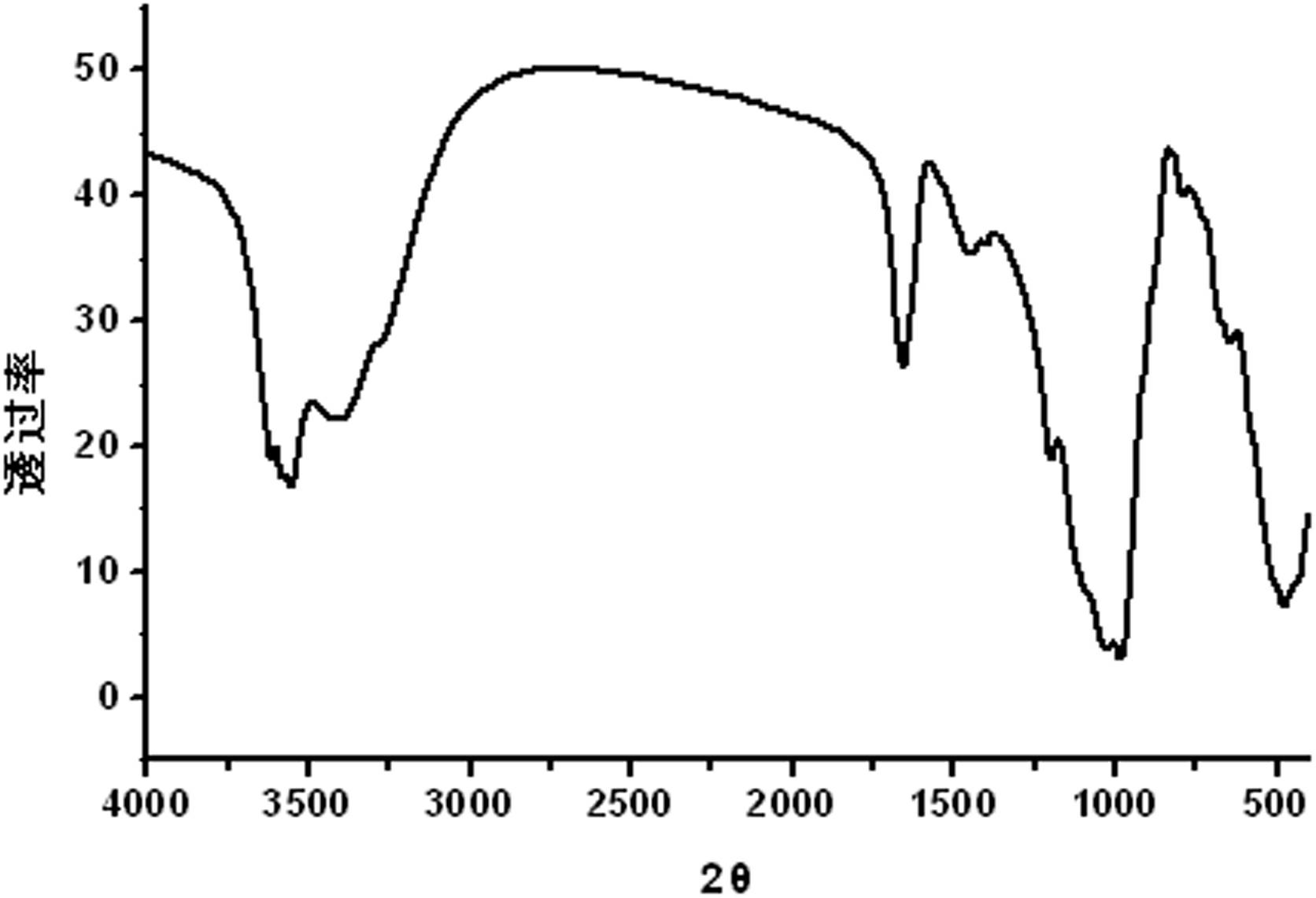

ActiveCN102617807AImprove water absorptionImprove water retentionAgriculture tools and machinesOrganic fertilisersPalygorskiteSorptivity

The invention discloses a preparation method of a salt resistant composite water retention material, which is obtained by triggering cross-linking polymerization of cob core powder, acrylic acid and palygorskite clay in a water phase, and belongs to the technical field of composite materials. The test shows that the composite material, prepared by the invention, has good water absorption propertyand water retention property; owing to addition of the palygorskite clay, the gel intensity, the heat resistance and the salt resistance of the composite material are effectively improved, so that the material is a drought resistant water retention composite material with excellent properties. In addition, by taking the natural cob core as the raw material, the invention has low cost, so that thewaste of resources is avoided, and the preparation method has important significance for expanding application range of the water retention composite material.

Owner:NORTHWEST NORMAL UNIVERSITY

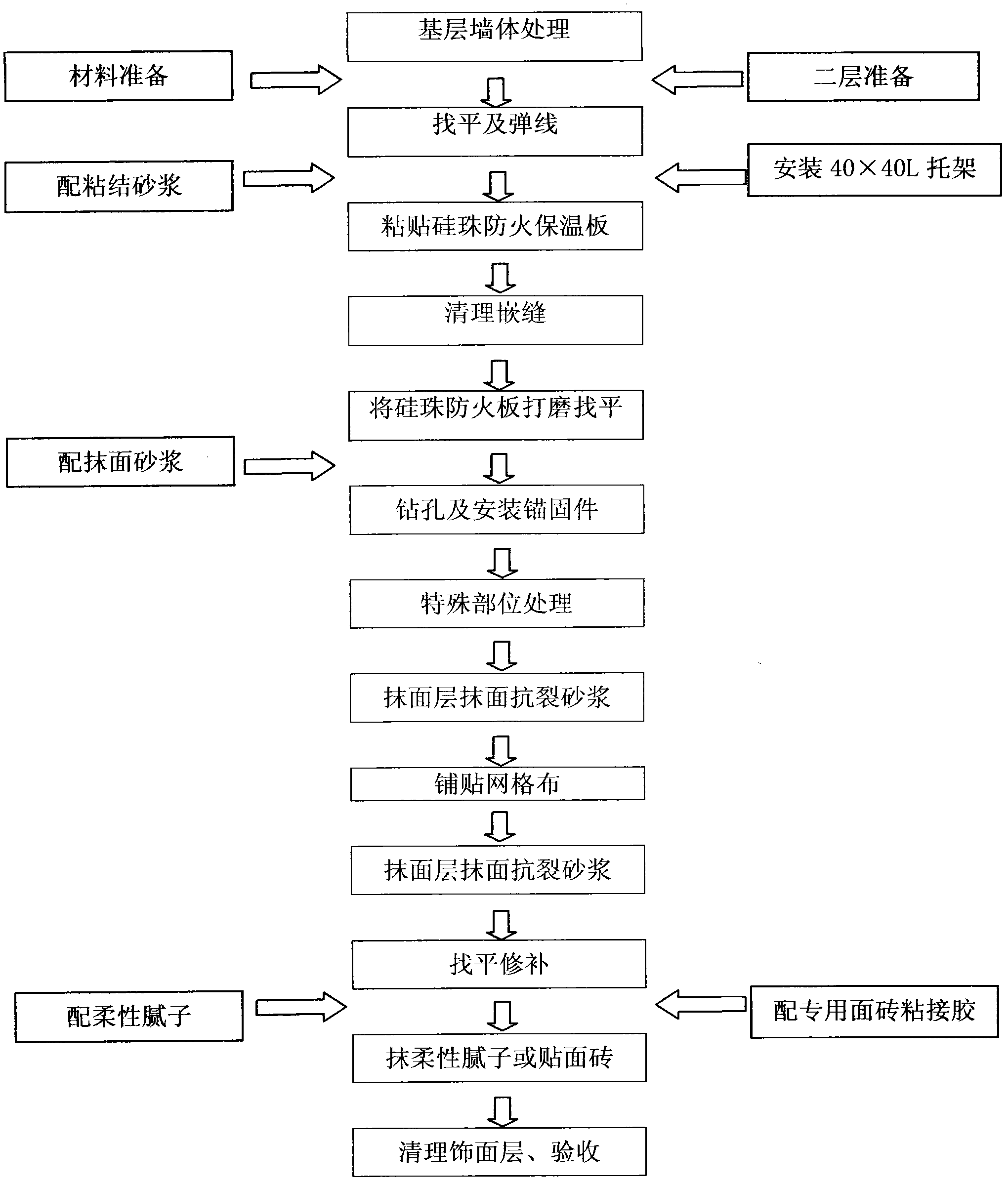

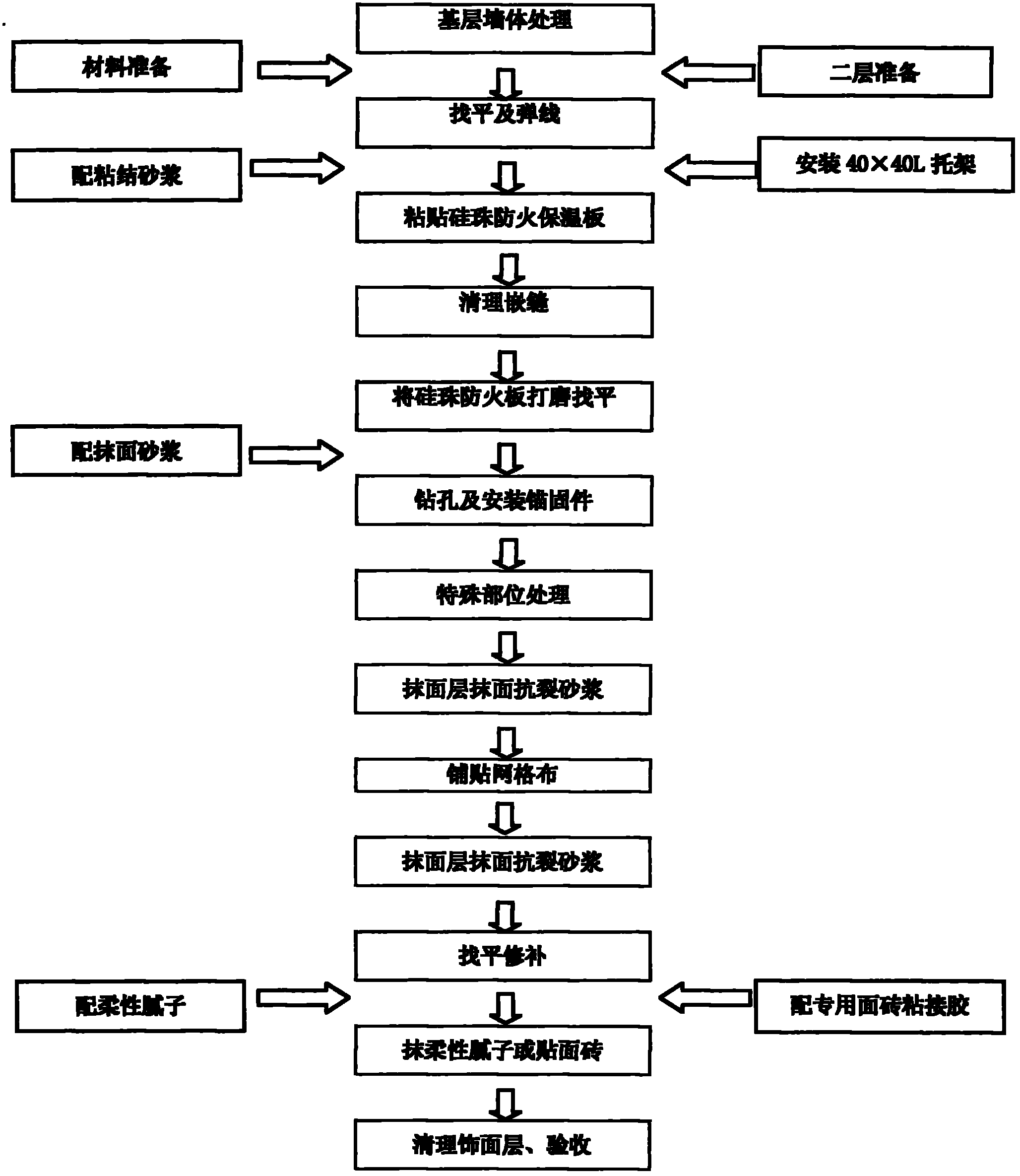

Inorganic heat-insulation fireproof plate

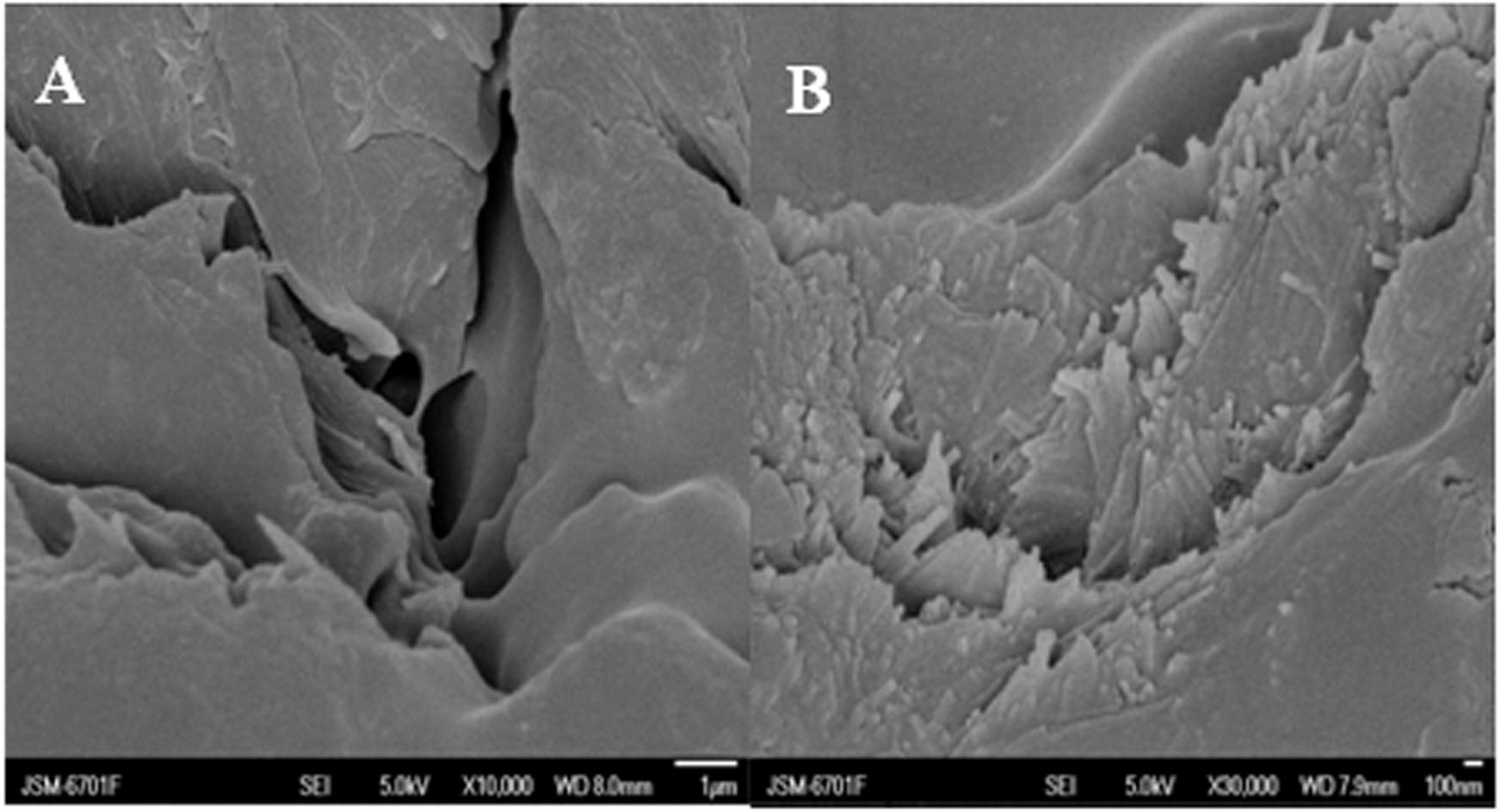

InactiveCN102619287ASolve easy pulverizationIncrease diversityHeat proofingBuilding material handlingPolymer scienceAging resistance

Disclosed is an inorganic heat-insulation fireproof plate, namely a silica bead fireproof heat-insulation plate. The fireproof plate is made of vitrified small balls and xonotlite, the weight ratio of the vitrified small balls to the xonotlite ranges from 1:2 to 1:5, in addition, waterproof materials with the weight ranging from 1% to 5% of the total weight of the fireproof plate and gel materials with the weight ranging from 8% to 10% of the total weight of the fireproof plate are added, and the fireproof plate is manufactured via working procedures including preparation, screening, pressure forming and drying. The vitrified small balls replace traditional common expanded perlite and traditional common polyphenyl particles to be used as lightweight aggregates of dry mixed heat-insulation mortar, shortcomings that the expanded perlite is high in water absorption and easy in pulverization and is high in volumetric shrinkage during slurry stirring, accordingly, low long-term strength, hollowing and cracking of a product are caused easily, and the like are overcome, defects of flammability, poor fireproof performance, harmful gas generation at a high temperature, low ageing resistance and weather fastness, high rebounding during construction and the like of the polyphenyl particles are also overcome, and comprehensive performances and construction property of the heat-insulation mortar are improved. In addition, the hydrophobic vitrified small balls cannot be degraded at a high temperature and are not easy to deform, and the flame retardant property of a polymer can be improved when the vitrified small balls are used as filling materials of the polymer.

Owner:QINGDAO FENGXIANG CHEM

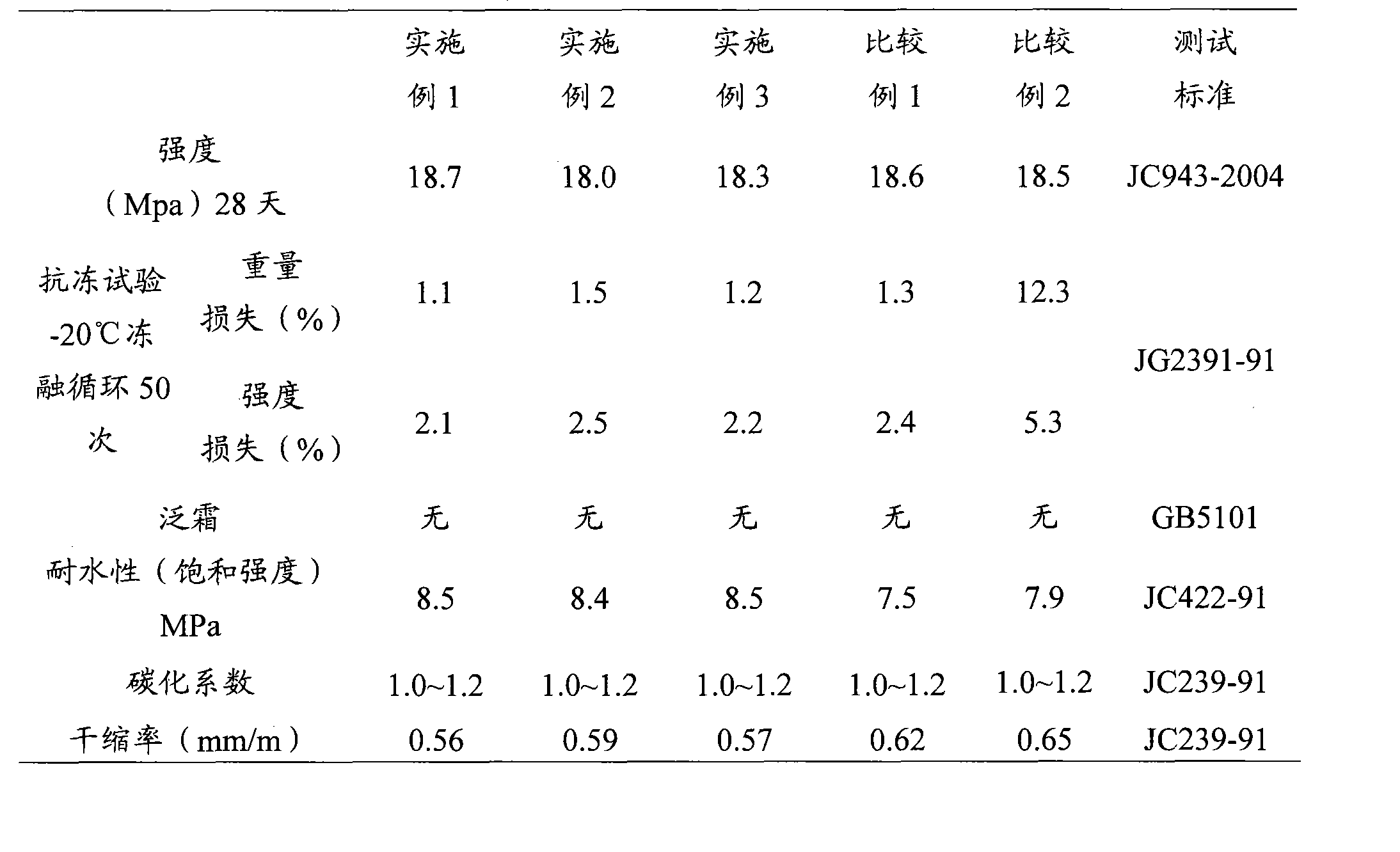

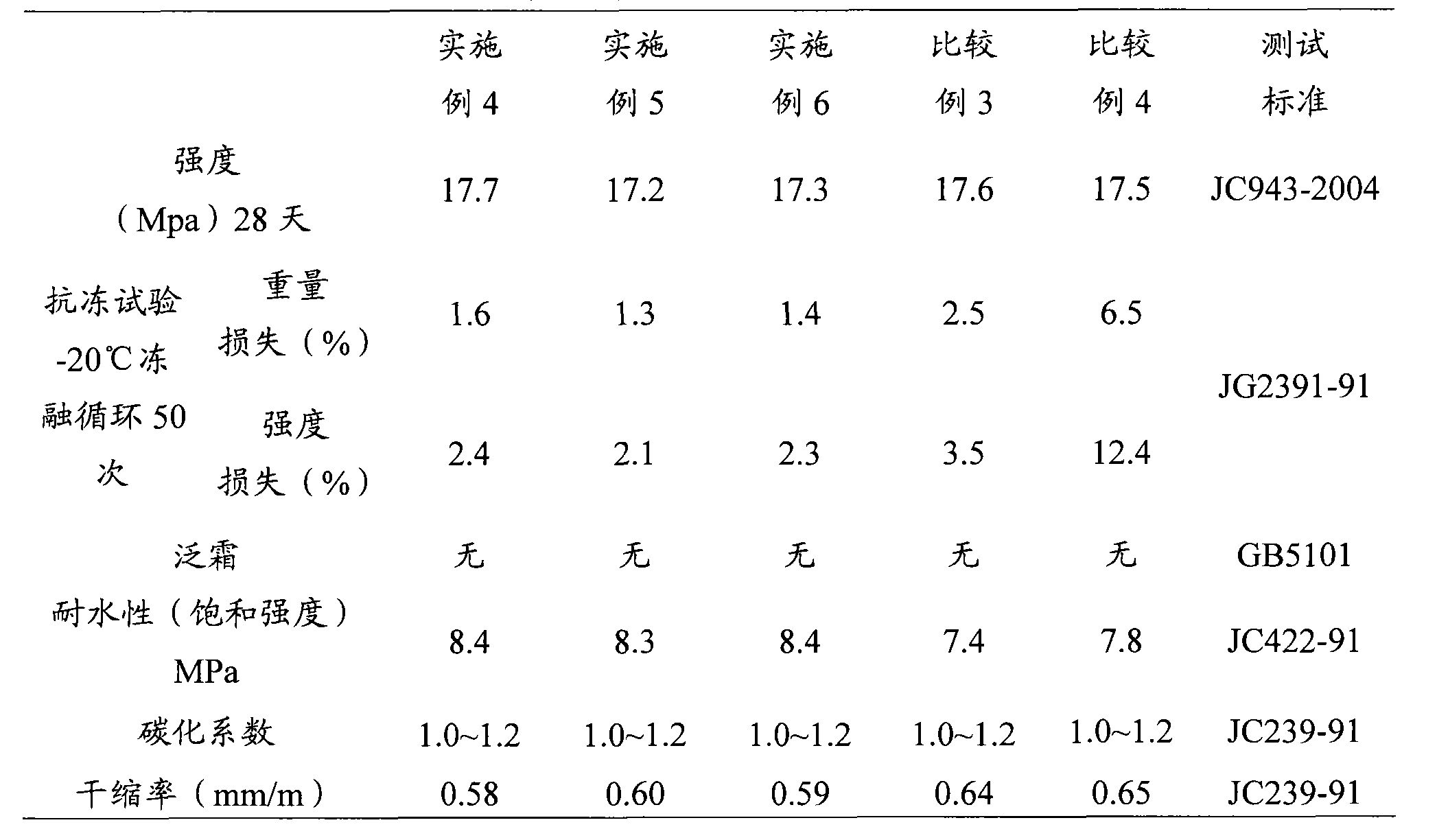

No-burned brick manufacture method

InactiveCN101417475AHigh densityHigh strengthConstruction materialSolid waste managementFreeze thawingBrick

The invention discloses a method for preparing baking-free bricks, comprising the following steps: a) the raw materials which contain the following components by weight percentage are mixed uniformly: 5wt percent to 20wt percent of cement, 8wt percent to 25wt percent of aggregate, 12wt percent to 25wt percent of fly ash and 40 percent to 70 percent of waste molding sand; and b) the mixed raw materials are vibrated, pressed and maintained, thus obtaining the baking-free bricks. The baking-free bricks provided by the invention use the waste molding sand as the main raw material, as the main component of the waste molding sand is quartz sand, the surface of which has binder film and the quartz sand has uneven surface which increases the contact area between the quartz sand and other auxiliary materials, thus being beneficial to increasing the density of the baking-free bricks and increasing the strength of the baking-free bricks. The binder film becomes soft under the alkali function of the cement, thus increasing the binding strength between the quartz sand and the auxiliary materials, and when the film becomes hard, the formed closed capillary bore reduces the water absorption of the baking-free bricks, thus avoiding the freeze thawing effect of the baking-free bricks.

Owner:齐齐哈尔中齐建材开发有限公司

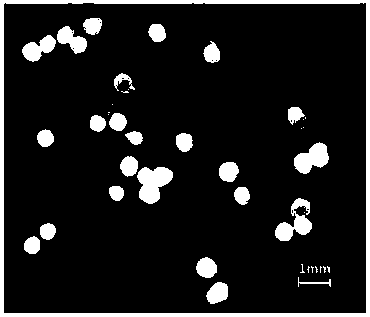

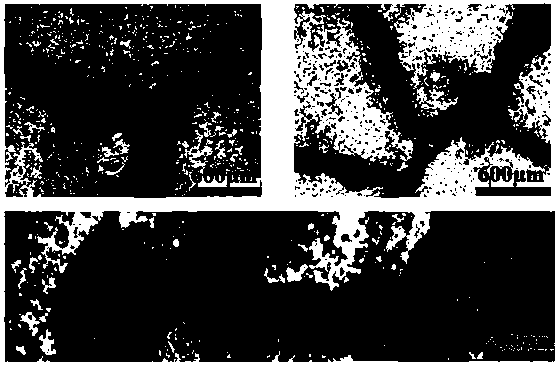

SAPs microcapsules and cement-based self-repairing material

InactiveCN110734243AEasy to prepareHigh mechanical strengthMicroballoon preparationMicrocapsule preparationPolymer scienceCrack resistance

The invention relates to SAPs microcapsules and a cement-based self-repairing material. The SAPs microcapsules are prepared by coating a hydrophobic adhesive with a water-absorbing polymer (SAPs), andthe particle size of the SAPs microcapsules ranges from 0.2 mm to 2.0 mm; the content of the core material of the microcapsule is 20-80wt%. The cement-based self-repairing material comprises the following basic components: cement, sandstone, the SAPs microcapsules and water. The SAPs microcapsules are prepared by adopting a sharp hole forming coagulating bath method, the process is easy for large-scale production, the mechanical properties meet the concrete mixing requirements, the matrix shrinkage can be reduced, the freeze thawing resistance and the cracking resistance can be improved, andthe strength of a set cement matrix can be improved; the cement-based self-repairing material has multiple crack self-repairing mechanisms, efficient self-repairing of the cement-based material can beachieved, durability is improved, and the service life is prolonged.

Owner:BEIJING UNIV OF TECH

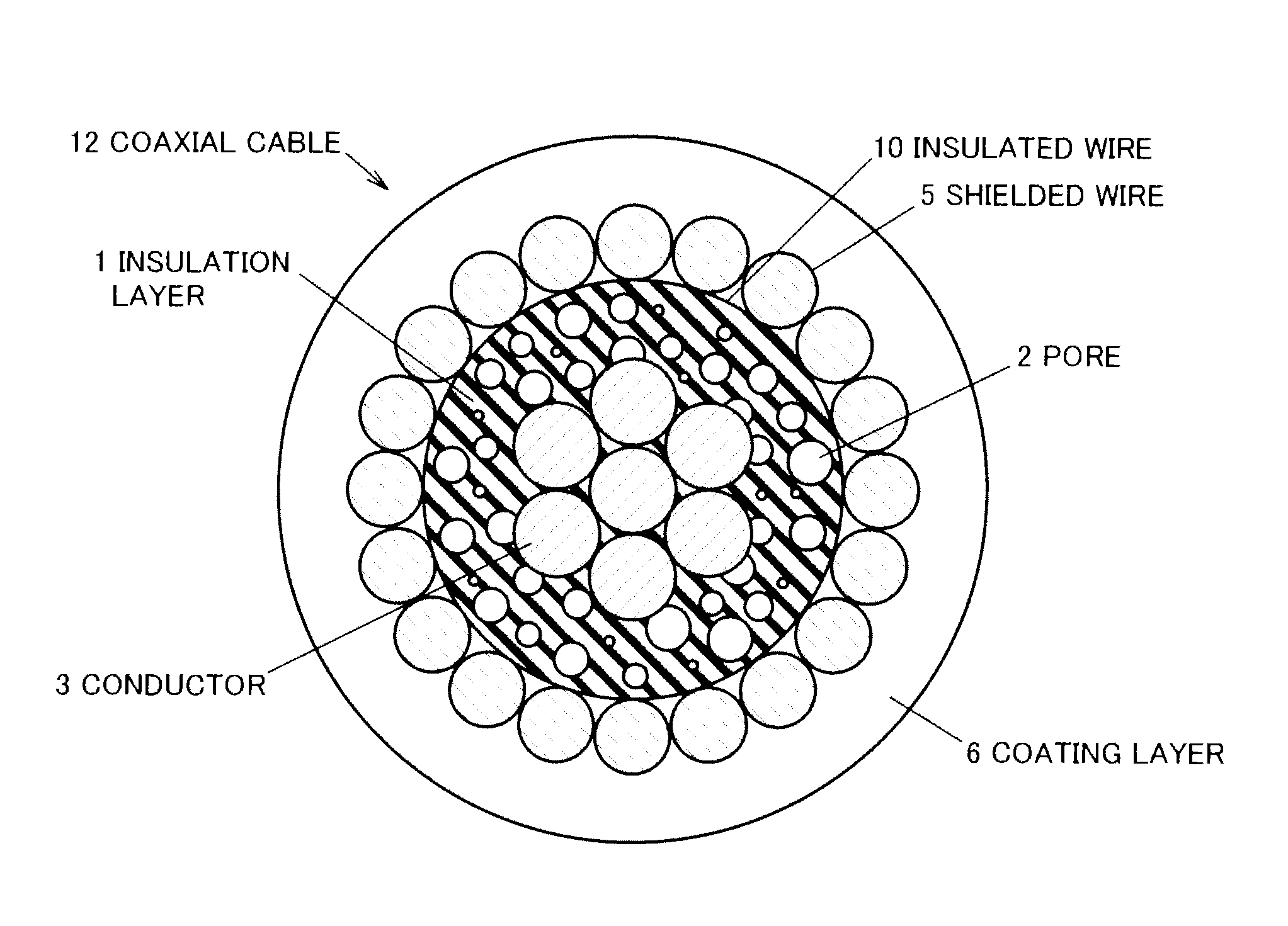

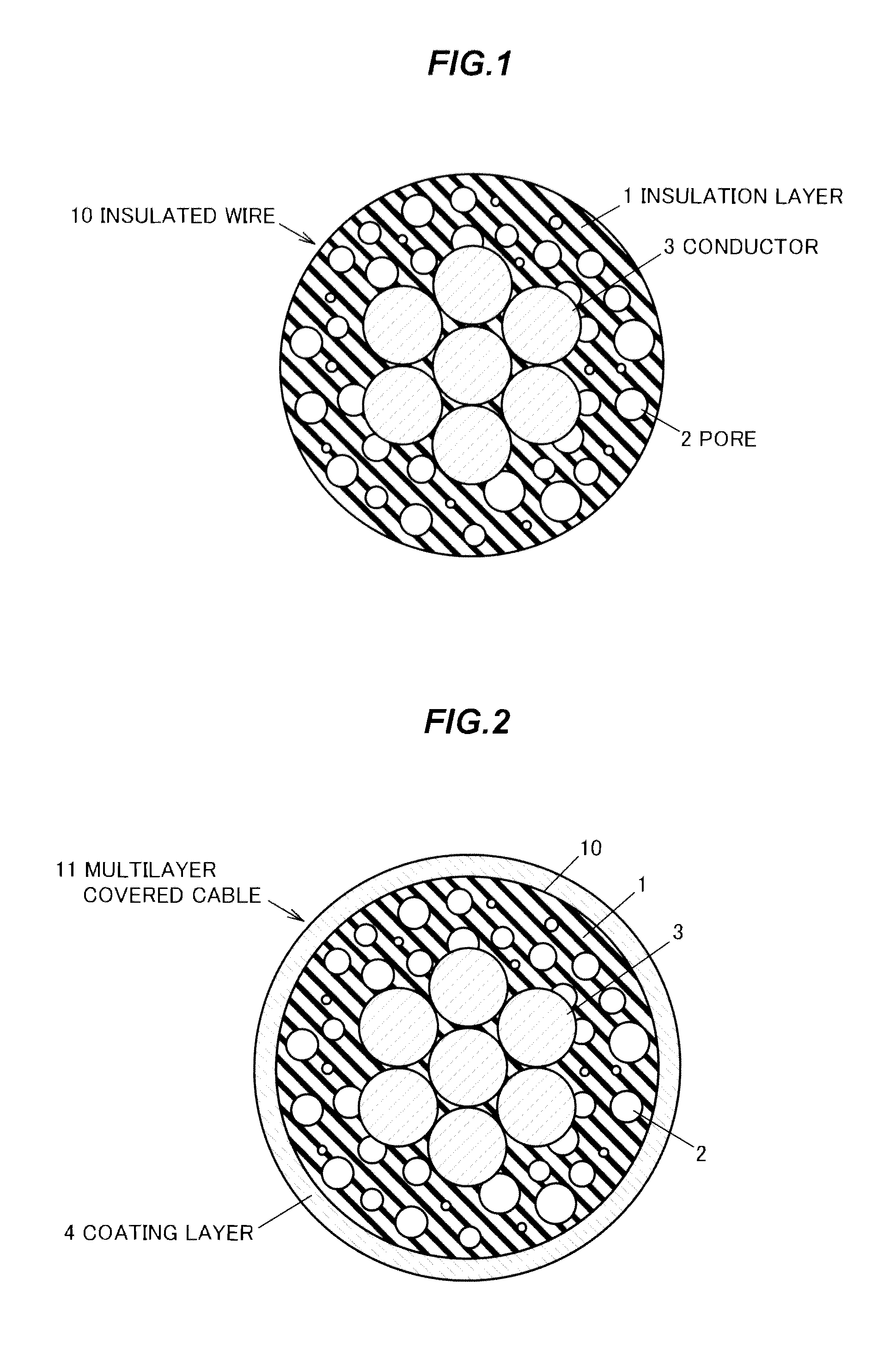

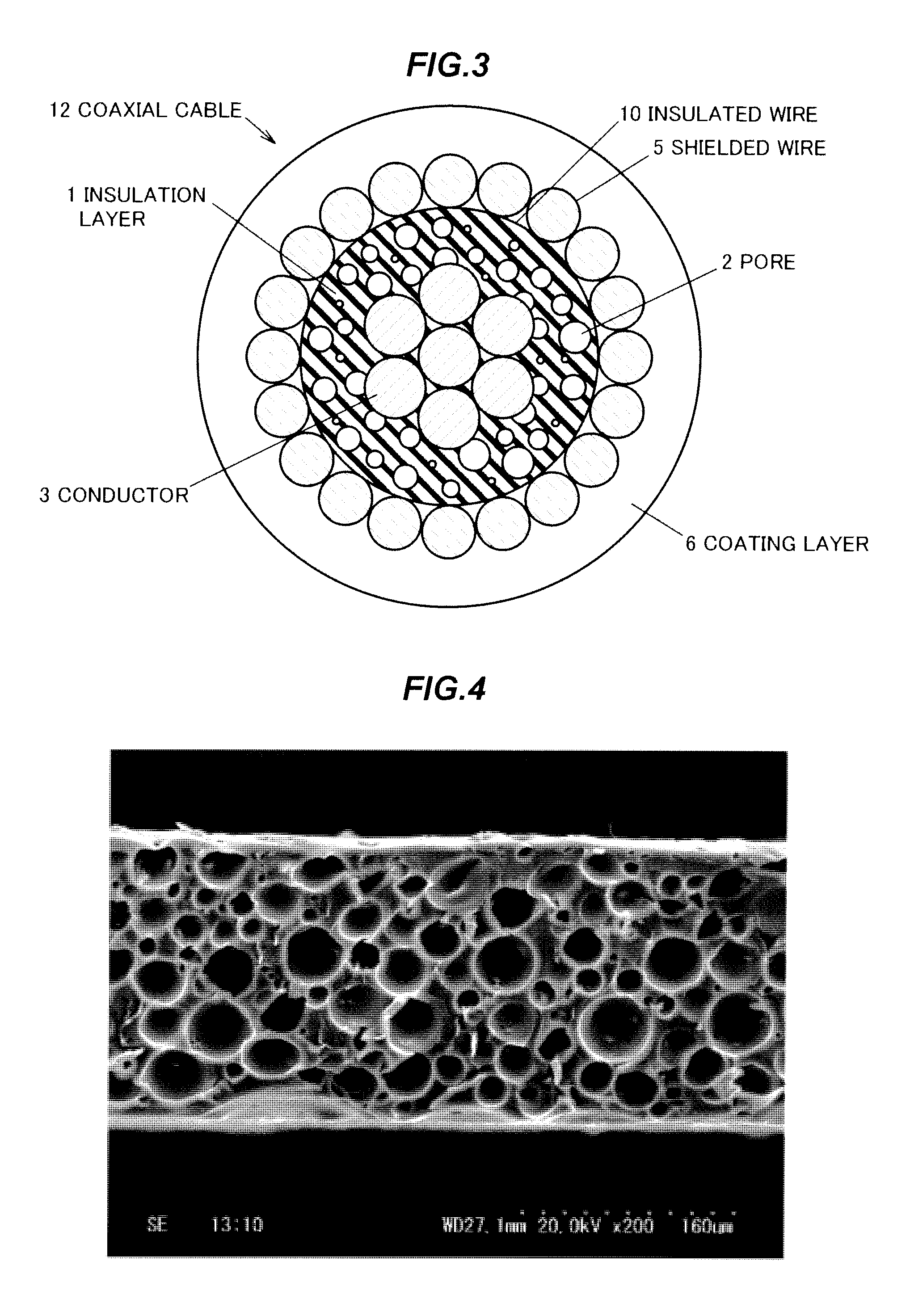

Hydrous water absorbent polymer-dispersed ultraviolet curable resin composition, porous substance, insulated wire, multilayer covered cable, coaxial cable using the same, method for fabricating a porous substance, and method for fabricating an insulated wire

InactiveUS20110180298A1Promote formationSuppress breakagePlastic/resin/waxes insulatorsOther chemical processesHydrophilic monomerCarbamate

A hydrous water absorbent polymer-dispersed ultraviolet curable resin composition, a porous substance, an insulated wire, a multilayer covered cable, a coaxial cable using the same, a method for manufacturing the porous substance and a method for manufacturing the insulated wire using the same. A hydrous water absorbent polymer preliminarily hydrated and swollen is dispersed in an ultraviolet curable resin composition. The ultraviolet curable resin composition includes an urethane oligomer having a molecular weight of 5000 or less and having a poly(ethylene-glicol-adipate)diol having a molecular weight of 500 to 3000 and having an acryloyl radical or a methacryloyl radical as a functional radical X at both ends by urethane bond via an alicyclic isocyanate as expressed by a following formula, at least one kind of alicyclic monomer, a hydrophilic monomer, and a photopolymerization initiator. 0.01 mass % to 0.5 mass % of a non-ionic fluorine based surface active agent or a non-ionic silicone-based surface active agent may be added to the resin composition.

Owner:HITACHI CABLE

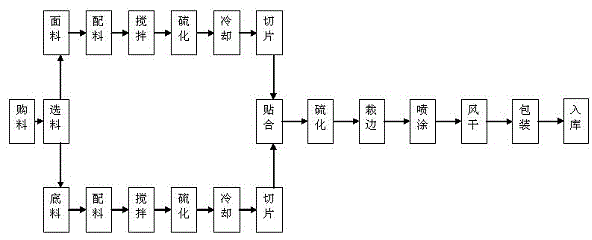

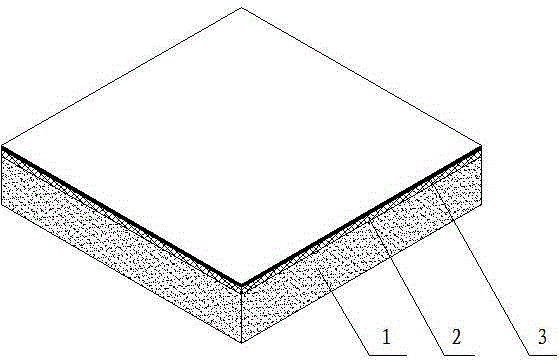

Rubber floor tile with elastic fitting effect and method for manufacturing rubber floor tile

ActiveCN102877626ALow costHigh specification accuracyLaminationLamination apparatusNitrile rubberSurface layer

Disclosed are a rubber floor tile with an elastic fitting effect and a method for manufacturing the rubber floor tile. The method for manufacturing the rubber floor tile with the elastic fitting effect sequentially includes steps of (A), selecting materials: (B), manufacturing a surface material; (C), manufacturing a bottom material; (D), fitting, vulcanizing, cutting edges and spraying; and (E), detecting. The rubber floor tile with the elastic fitting effect comprises a multi-colored ethylene propylene diene monomer particle layer, a nitrile rubber foaming particle layer and a PU (polyurethane) paint surface layer, the multi-colored ethylene propylene diene monomer particle layer is a surface material layer positioned on the surface of the rubber floor tile, the nitrile rubber foaming particle layer is a bottom material layer positioned at the bottom of the rubber floor tile, the surface material layer and the bottom material layer are adhered together by high-viscosity environment-friendly polyurethane curing agents, the PU paint surface layer is uniformly sprayed on the multi-colored ethylene propylene diene monomer particle layer, and the nitrile rubber foaming particle layer is directly adhered with the ground. The rubber floor tile and the method have the advantages that the rubber floor tile with the elastic fitting effect is high in dimensional precision, simple and convenient to install, good in fireproof performance, effective elasticity and protection performance, low in water absorption and long in service life.

Owner:WEIXIAN MINGREN RUBBER PRODS

Preparation method for cement hydration heat regulation and control material with internal curing function

The invention discloses a preparation method for a cement hydration heat regulation and control material with an internal curing function, which comprises the following steps of: (1) mixing starch anddextrin with water, heating to 50-70 DEG C, and continuing stirring for 2-4 hours to homogenize the solution, and (2) mixing acrylic acid, 2-acrylamide-2-methylpropanesulfonic acid, acrylamide, a pHregulator, an initiator and a cross-linking agent with water, uniformly stirring the mixture, adding the mixture into the starch paste, continuously reacting for 2-6 hours, and conducting filtering, drying and crushing to obtain the cement hydration heat regulation and control material with the internal curing function. According to the method, materials dextrin and starch with hydration regulation and control functions are connected with a water-absorbent resin molecular chain with an internal curing function through an addition reaction, the effect of cement hydration regulation and controlis achieved in the early stage, the interior of concrete can be continuously cured in the later stage, and cracks are reduced.

Owner:ZHENJIANG SOBUTE NEW MATERIAL CO LTD +1

Cellulosic-reinforced composites having increased resistance to water absorption

InactiveUS20070141337A1Improve the immunityHigh densitySynthetic resin layered productsWood treatment detailsCellulosePolymer science

Cellulosic-reinforced composites having increased resistance to water absorption are provided. The improved composites are obtained using a mixture of high density polyethylene and silane copolymer with the cellulosic filler.

Owner:EQUSR CHEM LP

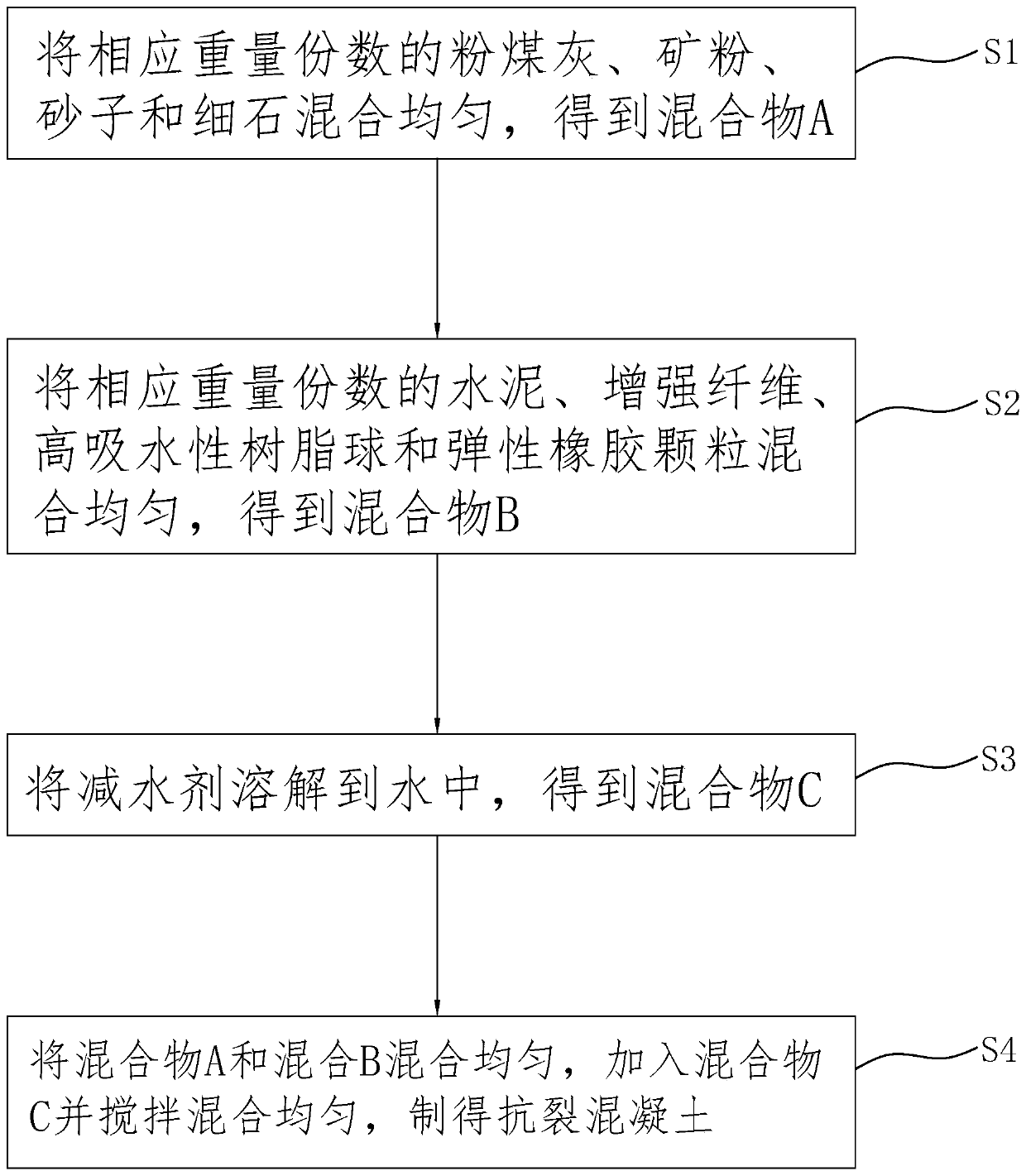

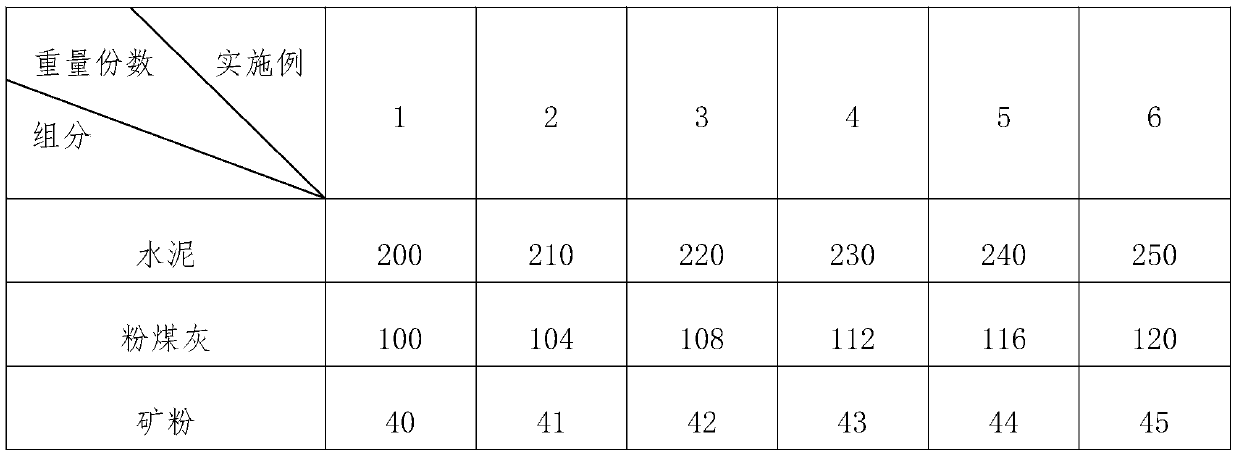

Anti-crack concrete and preparation method thereof

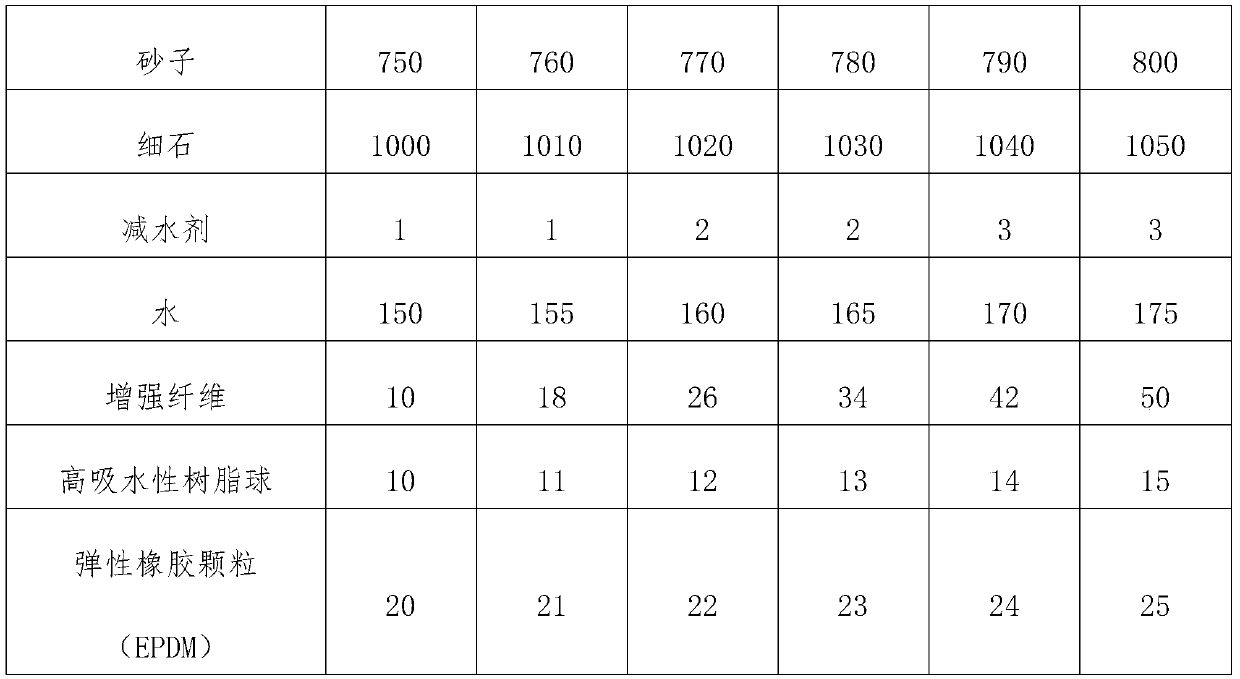

The invention discloses anti-crack concrete and a preparation method thereof, and relates to the technical field of concrete. The anti-crack concrete is characterized by comprising the following components in parts by weight: 200-250 parts of cement, 100-120 parts of fly ash, 40-45 parts of mineral powder; 750-800 parts of sand; 1000-1050 parts of fine stone; 1-3 parts of a water reducing agent; 150-175 parts of water; 10-50 parts of reinforcing fibers; 10-15 parts of super absorbent resin balls and 20-25 parts of elastic rubber particles. The anti-crack concrete prepared by adopting the formula has the advantages of high strength and high crack resistance.

Owner:上海石化安东混凝土有限公司

Glazed hollow bead thermal insulation mortar and preparation process thereof

InactiveCN101993228AIncrease diversityImprove performanceSolid waste managementPolymer scienceThermal insulation

The invention relates to a glazed hollow bead thermal insulation mortar and a preparation process thereof, which are applicable to interior and exterior thermal insulation plastering projects of enclosure walls of multi-storey and high-rise buildings and the like, as well as fire prevention and thermal insulation projects and thermal insulation transformation projects of old buildings. The glazed hollow bead thermal insulation mortar is prepared by the raw materials of ordinary Portland cement, ash calcium powder, sand, lignin, polypropylene staple fiber, silica fume and composite resin rubber powder in parts by weight, and can overcome great hydroscopicity and easy pulverization of expanded perlite, large volume shrinkage during stirring of slurry, and easy emergence of the phenomena of low strength, hollowing, cracking and the like during the late stage of a product, simultaneously make up for defects of flammability of polyphenyl granular organic material, poor fireproof performance, production of harmful gas due to high temperature, low aging resistance and weather resistance, large rebound resilience during construction and the like, and enhance and improve comprehensive performance and construction performance of the thermal insulation mortar.

Owner:沈杰铭

High-strength alkali-inhibiting construction waste regenerated water permeable brick and preparation method thereof

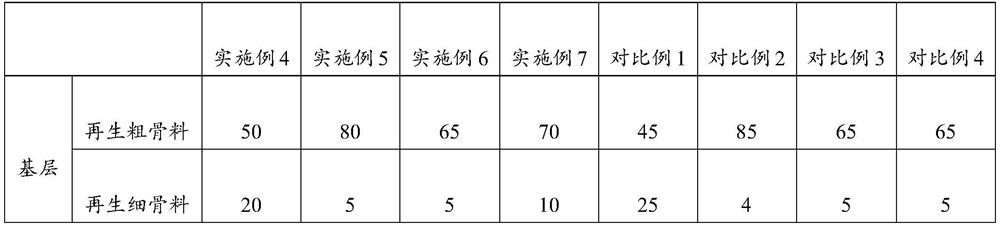

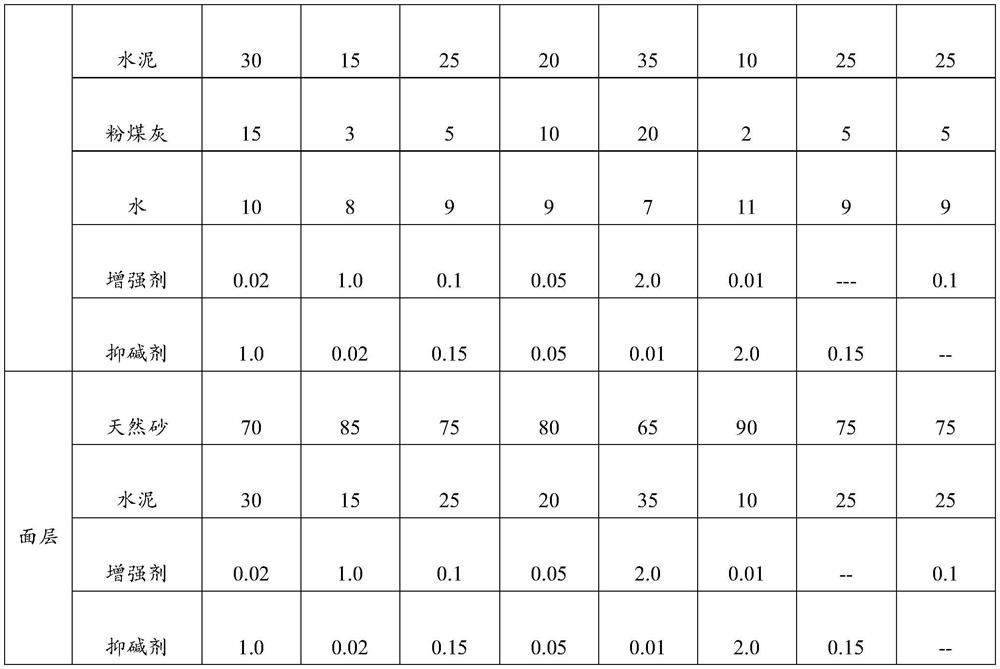

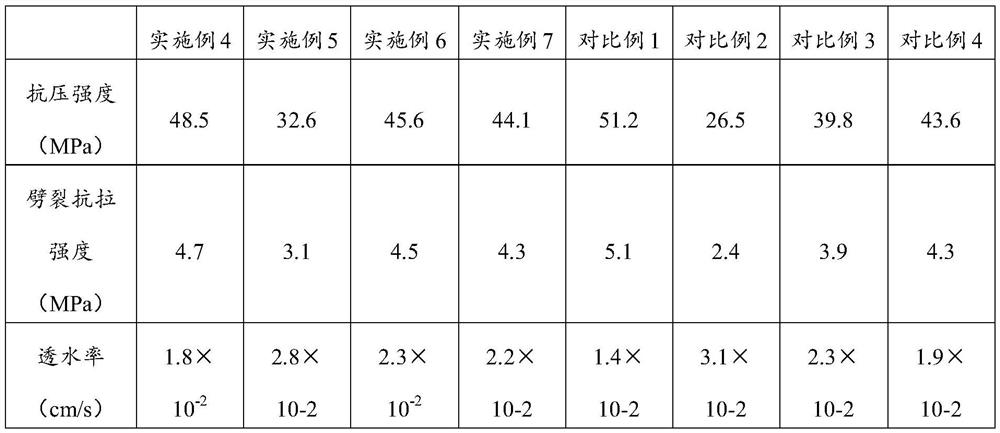

InactiveCN113582616ASolve the strength problemHigh strengthSolid waste managementCompressive resistanceBrick

The invention relates to a high-strength alkali-inhibiting construction waste recycled water permeable brick, which comprises a base layer and a surface layer, and the base layer comprises the following raw material components by weight: 50-80 parts of construction waste recycled coarse aggregate, 5-20 parts of construction waste recycled fine aggregate, 15-30 parts of cement, 3-15 parts of fly ash, 8-10 parts of water, 0.02-1.0 part of a reinforcing agent, and 0.02-1.0 part of an alkali inhibitor. The surface layer comprises the following raw material components in parts by weight: 70-85 parts of natural sand, 15-30 parts of cement, 0.02-1.0 part of a reinforcing agent and 0.02-1.0 part of an alkali inhibitor. According to the recycled water permeable brick prepared from the construction waste recycled aggregate, reduction and recycling of waste construction waste are achieved, and the recycled water permeable brick is green, energy-saving, high in porosity, high in water absorption, free of saltpetering, high in water permeability and high in compressive strength, the water permeability coefficient can reach 2.0 * 10 <-2 > cm / s or above, and the compressive strength can reach 40 MPa or above.

Owner:BCEG RESOURCES RECYCLING CO LTD

Closed water-saturated internal curing lightweight aggregate and preparation method thereof

The invention discloses a closed water-saturated internal curing lightweight aggregate and a preparation method thereof. The preparation method comprises the following steps: soaking the lightweight aggregate in water, keeping the water-absorbed lightweight aggregate under negative pressure for a certain period of time, spraying a polymer reaction solution onto the surface of the lightweight aggregate under negative pressure, continuously performing stirring, and performing pressurizing after spraying; Macromolecules are subjected to a cross-linking reaction in a microwave treatment mode to obtain the closed water-saturated internal curing lightweight aggregate. According to the invention, a super absorbent resin blocking coating layer is formed in surface pores of the water-saturated lightweight aggregate, so that the preparation of the closed water-saturated internal curing lightweight aggregate is realized, and the problems of quick draining and evaporation of the water-saturated lightweight aggregate and great change of moisture contents of upper and lower layers of a material pile are eliminated; admixture adsorption, slump loss and pipe blockage in the pumping process when the concrete additive is used for concrete are eliminated, the internal water storage capacity and internal humidity of concrete are improved, early self-shrinkage of concrete is improved, the requirement and frequency of external maintenance of concrete are reduced, and the closed water-saturated internal curing lightweight aggregate has important economic and practical value.

Owner:山东省建筑科学研究院有限公司

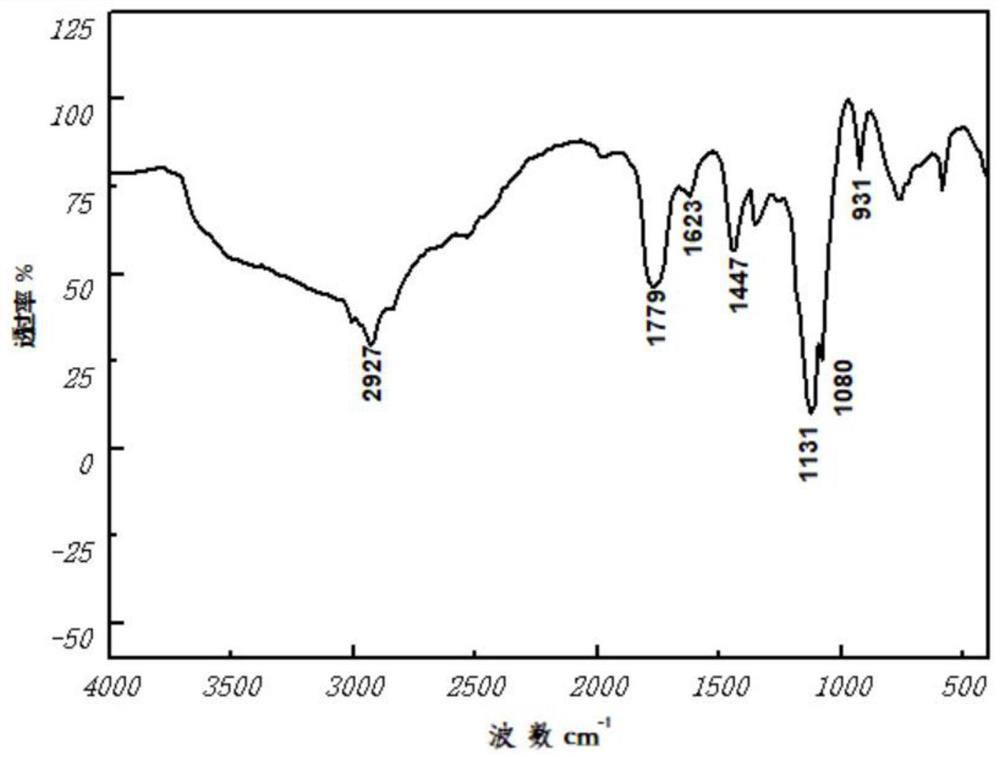

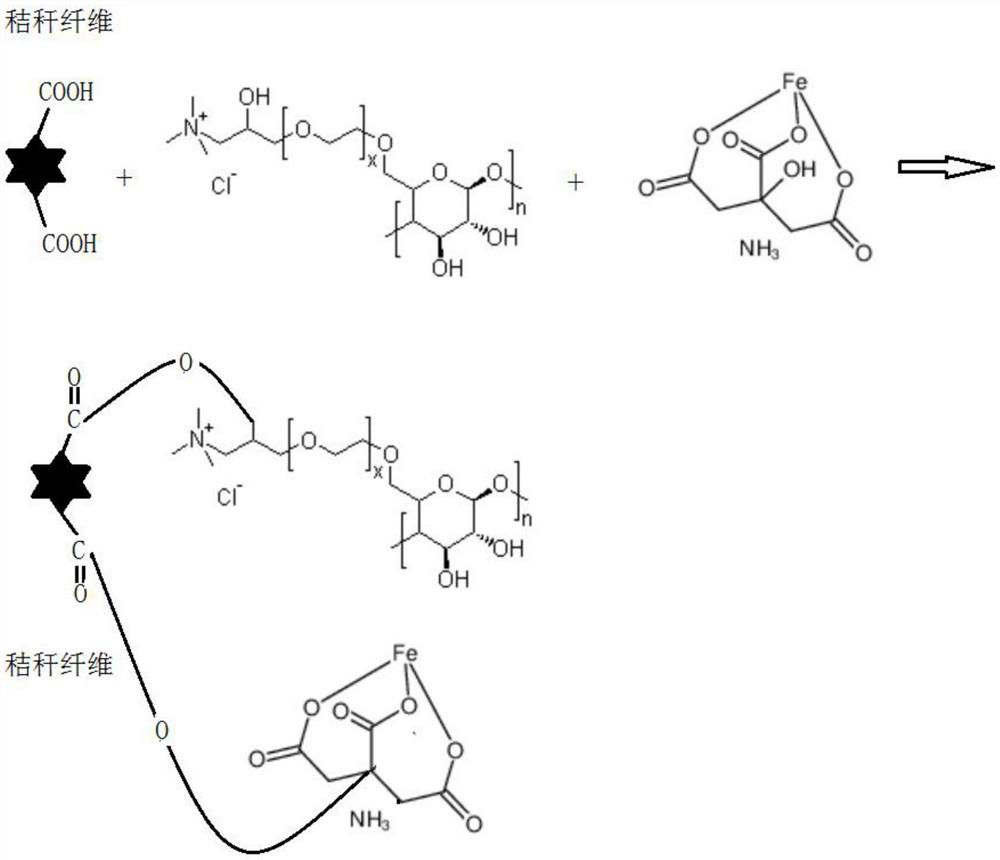

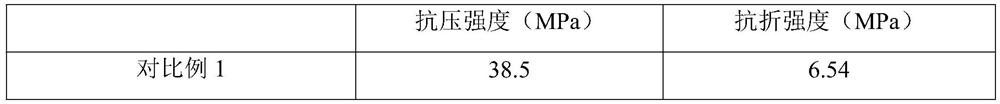

Preparation method of modified corn straw fiber reinforced recycled concrete

The invention relates to the field of preparation of building materials, in particular to a preparation method of modified corn straw fiber reinforced recycled concrete. According to the invention, corn straw fibers are used for reinforcing and modifying recycled concrete, and the hydrophilic modification of the corn straw fibers can effectively increase acting force between the corn straw fibersand the concrete, so the strength of the concrete is effectively improved; in addition, after the recycled coarse aggregate is modified with a closed modifier containing silica sol and calcium carbonate powder, pores and cracks in the surface of the recycled aggregate are filled, the effect of strengthening old mortar is achieved, the problems that the recycled aggregate is high in water absorption performance and low in bonding strength are solved, and the strength of the recycled concrete is further enhanced; the recycled concrete disclosed by the invention has very good mechanical properties through the synergistic enhancement effect of the modified recycled coarse aggregate and the modifying corn straw fibers; and the method is a promising method for recycling concrete construction waste.

Owner:瑞普环保新材料(广州)有限公司

Improved high strength ceramic for daily use

The invention relates to an improved high strength ceramic for daily use. The improved high strength ceramic for daily use is prepared from the following raw materials by weight: 3-8 parts of alumina, 5-7 parts of calcium oxide, 4-9 parts of kaolin, 3-10 parts of bauxite clay, 2-6 parts of water glass, 5-7 parts of graphene, 4-8 parts of reclaimed rubber, 6-9 parts of ceramic fiber, 4-8 parts of borax, 6-9 parts of mica, 3-10 parts of feldspar, 7-9 parts of ferrous sulfate, 3-8 parts of clay, 2-6 parts of gypsum, 6-10 parts of boron nitride, 1-5 parts of an active catalyst, 1-3 parts of epoxy resin, and 8-13 parts of aluminum silicate fiber. The improved high strength ceramic for daily use provided by the invention has very good mechanical strength, also has good water absorption and seismic rate, and can reduce breakage of porcelains.

Owner:QINGDAO KELIKE INFORMATION TECH

Surface film-covered ceramsite for light-weight aggregate concrete and preparation method for surface film-covered ceramsite

The invention provides a surface film-covered ceramsite for light-weight aggregate concrete and a preparation method for the surface film-covered ceramsite, and belongs to the technical field of concrete preparation. The surface film-covered ceramsite for the light-weight aggregate concrete consists of a ceramsite and a silicon mortar film layer covering the surface of the ceramic particle. The silicon mortar film layer contains small solid particles which can block a multiporous structure on the surface of the ceramsite; furthermore, the surface of the ceramsite has hydroscopicity, and the silicon mortar film layer contains water, so that the silicon mortar film layer can be easily attached to the surface of the ceramsite under the surface tension; the adhering force between the silicon mortar film layer and the surface of the ceramsite is high; even in a concrete stirring process, the mortar film layer cannot fall off. When the surface film-covered ceramsite is used for the light-weight aggregate concrete, mixed water cannot be adsorbed any more, and the working performance of the light-weight aggregate concrete can be greatly improved; meanwhile, the contraction rate of concrete or a concrete product is also lowered.

Owner:北京中联新航建材有限公司

Ceramic brick

The invention relates to a ceramic brick which is prepared from the following raw materials in parts by weight: 8-14 parts of fly ash, 7-12 parts of bentonite, 4-6 parts of limestone aggregate, 3.5-6.4 parts of cattle bone, 5-8 parts of castorite, 6-9 parts of sodium fluosilicate, 4-7 parts of calcite, 6-8 parts of calcined kaolin, 2.5-4.6 parts of forsterite, 5-13 parts of white wax, 4-6 parts of sodium borate, 7-9 parts of crystalline sodium carbonate, 12-16 parts of magnesium borate whisker, 4-11 parts of silicon micropowder and 16-26 parts of Portland cement. The ceramic brick has the advantages of favorable water absorptivity and favorable hardness, and can well reduce the waste of resources.

Owner:QINGDAO KANGTAIXIN ENVIRONMENTAL PROTECTION TECH

Thermo-sensitive composite material, as well as preparation method and application thereof

InactiveCN103554805ABring pollutionImprove performanceThermometers using physical/chemical changesAcetic acidPower station

The invention relates to a thermo-sensitive composite material, as well as a preparation method and application thereof. The thermo-sensitive composite material is prepared by mixing the following components in percentage by weight: 1-2 percent of high water absorption resin carrier, 5-20 percent of volatile substance, 0-1 percent of emulsifier, and the balance of water, wherein the volatile substance is one of ammonium hydroxide, ethanol, glacial acetic acid and ammonium bicarbonate. The composite material serving as an overheat warning material is applied to an overheat warning system of large power stations and motor distribution cabinets, and has the advantages of normal temperature stable performance, good thermosensitive property, little usage, environmental friendliness, timely and accurate warning and the like.

Owner:NO 33 RES INST OF CHINA ELECTRONICS TECHNOOGY GRP

High-water-absorption ceramic brick

InactiveCN104891974AImprove water absorptionGood water permeabilityCeramic materials productionClaywaresBrickSilicic acid

A high-water-absorption ceramic brick is composed of the following raw materials in parts by weight: 15-30 parts of ceramic waste, 4-9 parts of aluminum oxide, 3-8 parts of a waste glass powder, 5-9 parts of quartz sand, 3-6 parts of nepheline syenite, 1-3 parts of calcium oxide, 7-10 parts of white feldspar, 9-14 parts of zirconium silicate, 2-5 parts of barium carbonate, 1-4 parts of raw kaolin, 3-10 parts of nickel oxide, 4-8 parts of rosin, 8-14 parts of shale, 1-3 parts of silicon carbide, 6-11 parts of glass micro-beads, and 3-8 parts of silicon dioxide. The high-water-absorption ceramic brick has the beneficial effects that the ceramic brick has good water absorption and water permeability, besides, has quite good strength and hardness, and is not easy to crack.

Owner:青岛百千川海洋生态科技有限公司

Water-based seal primer for penetrative building wall surface

The invention belongs to the field of building materials and discloses a water-based seal primer for a penetrative building wall surface. The water-based seal primer comprises the following raw materials in parts by weight: 40-60 parts of de-ionized water, 0.1-0.3 part of a wetting agent, 0.1-0.2 part of a defoamer, 30-50 parts of modified acrylic emulsion, 5-10 parts of organic silicon emulsion, 0.1-0.5 part of a microbicide, 1-3 parts of a film forming aid and 0.1-0.2 part of a thickener. According to the water-based seal primer, the organic silicon emulsion and the modified acrylic emulsion are used as basic materials, and organic silicon groups are introduced, so that the penetrability of the coating is remarkably improved, the adhesion on the basic materials is excellent, the coating hardness and density can be enhanced, the water absorptivity is reduced, the effect of effectively sealing the basic materials is achieved, and the alkali efflorescence phenomenon is prevented.

Owner:安徽铁创新材料科技有限公司

Freeze-thaw resistant recycled concrete and preparation method thereof

The invention relates to the field of concrete, and particularly discloses freeze-thaw resistant recycled concrete and a preparation method thereof. The freeze-thaw resistant recycled concrete is prepared from the following raw materials in parts by weight: 300 to 400 parts of cement, 250 to 300 parts of modified recycled coarse aggregate, 150 to 200 parts of superfine slag powder, 100 to 150 parts of water, 150 to 200 parts of fly ash, 100 to 150 parts of silica fume, 20 to 30 parts of an air entraining agent, 20 to 25 parts of a water reducing agent and 20 to 30 parts of polyacrylamide. The preparation method comprises the following steps of: uniformly stirring the cement, the modified recycled coarse aggregate, the superfine slag powder, the fly ash, the silica fume, the air entraining agent, the water reducing agent and the water, adding the uniformly mixed modified recycled coarse aggregate and polyacrylamide, and uniformly stirring to obtain the recycled concrete. According to the recycled concrete, the porosity of the recycled concrete can be reduced, the water absorption is reduced, and the freeze-thaw resistance of the recycled concrete is improved.

Owner:兴隆县城泰建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com