High temperate-resistant nanometer fire resistance-enhanced PA6 composite material and preparation method thereof

A composite material and nano flame retardant technology, applied in the field of high temperature resistance nano, can solve the problems of decreased impact resistance of materials, large proportion of flame retardants, less high temperature resistance nano flame retardant reinforcement materials, etc., to achieve enhanced impact resistance, The effect of high environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

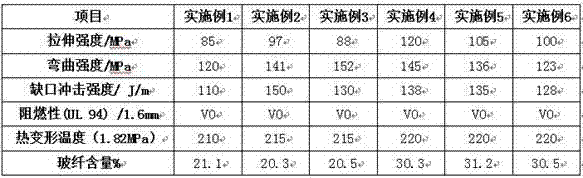

Examples

Embodiment 1-9

[0033] In the following examples,

[0034] Nylon is nylon 6 with an intrinsic viscosity of 2.4;

[0035] The main flame retardant is decabromodiphenylethane and cyanurate, and the mass ratio of the two is 4:1;

[0036] Auxiliary flame retardant is Sb 2 o 3 ;

[0037] The nano-montmorillonite is a montmorillonite aluminosilicate with a purity of 90%-98%, a particle size of 200-500 mesh, and an interlayer distance>1.9nm; -200meq / 100g;

[0038] The glass fiber is alkali-free glass fiber, and the surface is soaked in γ-aminopropyltriethoxysilane;

[0039] The graft type toughening modifier is ethylene-octene graft copolymer;

[0040] The antioxidant is compounded by HD98 and 168 in a weight ratio of 1:1;

[0041] The lubricating dispersant is silicone.

[0042] The preparation method of composite material in embodiment 1-9 comprises the steps:

[0043] Step 1, get raw material by the component weight percentage of each embodiment composite material in table 1;

[0044] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| cation exchange capacity (equivalent) | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com