Preparation method of modified corn straw fiber reinforced recycled concrete

A technology of corn stalk fiber and recycled concrete, which is applied in the field of building material preparation, can solve the problems of weak bonding between recycled aggregate and new mortar, limit the application and development of recycled aggregate, and poor strength of recycled aggregate, and solve the problem of bonding Low strength, good mechanical properties, enhanced strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of modified corn stalk fiber reinforced recycled concrete, the specific preparation scheme is as follows:

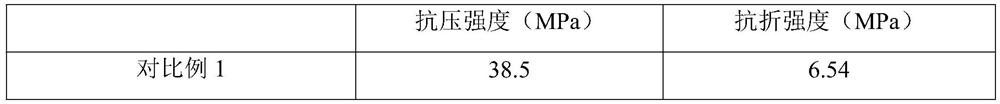

[0028] Add 48kg of river sand, 100kg of sealed and modified recycled coarse aggregate, 3.8kg of slag, 11kg of surface-modified corn stalk fiber and 5kg of steel slag into the mixing mixer, mix and stir for 10 minutes, then add 70kg of cement, 5kg of fly ash, 3kg of Add the perlite tailings sand into the mixer and mix evenly; then mix 45kg of water, 0.5kg of water reducer, 0.6kg of sodium thiosulfate, 0.1kg of polyvinyl alcohol, 1.2kg of glass fiber and 0.8kg of β-naphthalenesulfonic acid formaldehyde condensate After uniformity, add it into a mixer, mix and stir for 15 minutes, then pour the concrete into a mold, and after curing, the above-mentioned modified corn stalk fiber reinforced recycled concrete can be obtained.

[0029] The processing method of the regenerated coarse aggregate of described closure modification is:

[0030] Putting t...

Embodiment 2

[0038] A preparation method of modified corn stalk fiber reinforced recycled concrete, the specific preparation scheme is as follows:

[0039] Add 54kg of river sand, 110kg of closed modified recycled coarse aggregate, 4.6kg of slag, 14kg of surface-modified corn stalk fiber and 8kg of steel slag into the mixing mixer, mix and stir for 20min, and then add 78kg of cement, 8kg of fly ash, 5kg of Add the perlite tailings sand into the mixer and mix well; then mix 55kg of water, 0.7kg of water reducing agent, 0.8kg of sodium thiosulfate, 0.4kg of polyvinyl alcohol, 2.8kg of glass fiber and 1.2kg of β-naphthalenesulfonic acid formaldehyde condensate After being uniform, add it to a mixer, mix and stir for 20 minutes, then pour the concrete into a mold, and after curing, the above-mentioned modified corn stalk fiber reinforced recycled concrete can be obtained.

[0040] The processing method of the regenerated coarse aggregate of described closure modification is:

[0041] Put the ...

Embodiment 3

[0050] A preparation method of modified corn stalk fiber reinforced recycled concrete, the specific preparation scheme is as follows:

[0051] Add 62kg of river sand, 120kg of closed modified recycled coarse aggregate, 5.6kg of slag, 17kg of surface-modified corn stalk fiber and 11kg of steel slag into the mixing mixer, mix and stir for 30min, and then add 86kg of cement, 12kg of fly ash, 7kg of Add the perlite tailings sand into the mixer and mix well; then mix 62kg of water, 1.2kg of water reducer, 1.0kg of sodium thiosulfate, 0.8kg of polyvinyl alcohol, 4.1kg of glass fiber and 2.2kg of β-naphthalenesulfonic acid formaldehyde condensate After uniformity, add it into a mixer, mix and stir for 30 minutes, then pour the concrete into a mold, and after curing, the above-mentioned modified corn stalk fiber reinforced recycled concrete can be obtained.

[0052] The processing method of the regenerated coarse aggregate of described closure modification is:

[0053] Put the regene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com