Rubber floor tile with elastic fitting effect and method for manufacturing rubber floor tile

A technology of elastic fit and production method, applied in rubber layer products, chemical instruments and methods, lamination and other directions, can solve the problems of low product specification accuracy, short service life, poor protection performance, etc., and achieve a wide range of use. , long service life, low water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

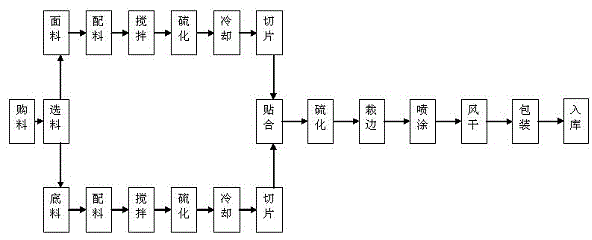

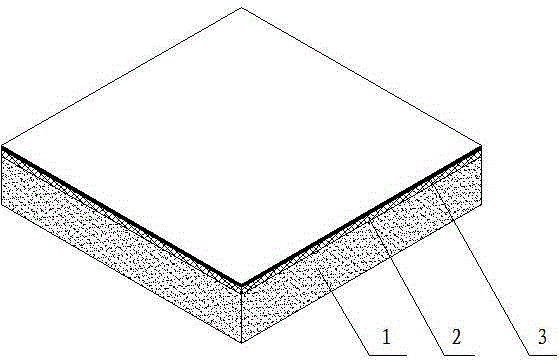

[0027] Such as figure 1 Shown, a kind of manufacture method of rubber elastic lamination floor tile is characterized in that comprising the following process step of carrying out in sequence:

[0028] (A) Material selection: Weigh the raw materials, the ingredients and their mass percentages in the raw materials are: multi-color EPDM rubber particles 15%, NBR foam particles 74.5%, high-viscosity environment-friendly polyurethane curing agent 10% , PU paint 0.5%;

[0029] (B) Fabrication: First, mix multi-color EPDM particles with high-viscosity environment-friendly polyurethane curing agent according to the mass ratio of 100: (8-10) and add them to the mixer, stirring for 10-15 minutes Then add it to the vulcanizer, heat it to 140-160°C with electricity, and vulcanize the mixture of multi-color EPDM rubber particles and high-viscosity environment-friendly polyurethane curing agent at this temperature for 20-30 minutes to make a flat cube blank Rubber material Ⅰ, place the fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com