Preparation method of salt resistant composite water retention material

A technology of water-retaining materials and salt resistance, which is applied in the preparation of salt-resistant composite water-retaining materials, and in the field of salt-resistant composite water-retaining materials prepared by acrylic acid crosslinking, which can solve the problems of few reports and achieve low cost, excellent performance, and expanded application range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

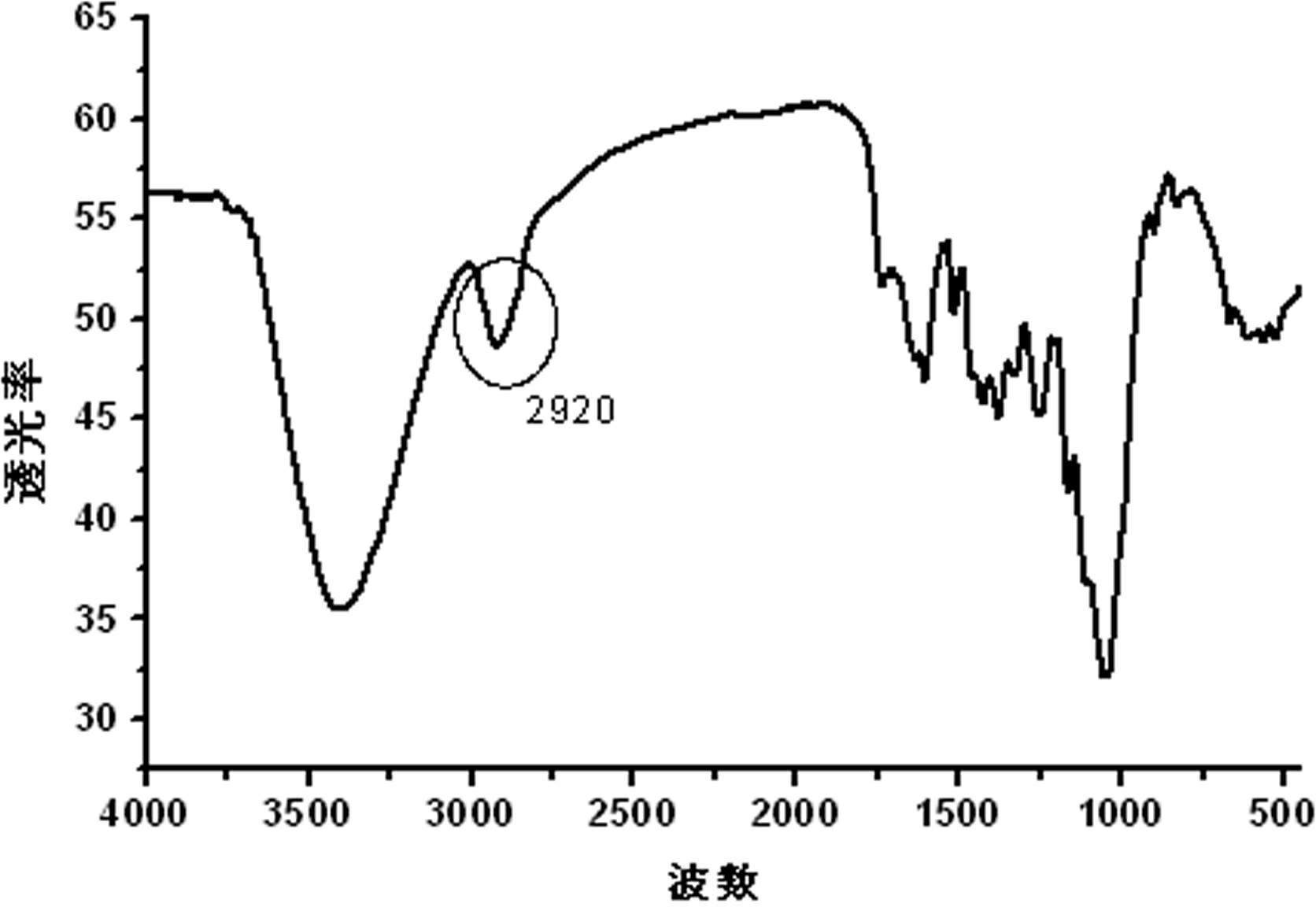

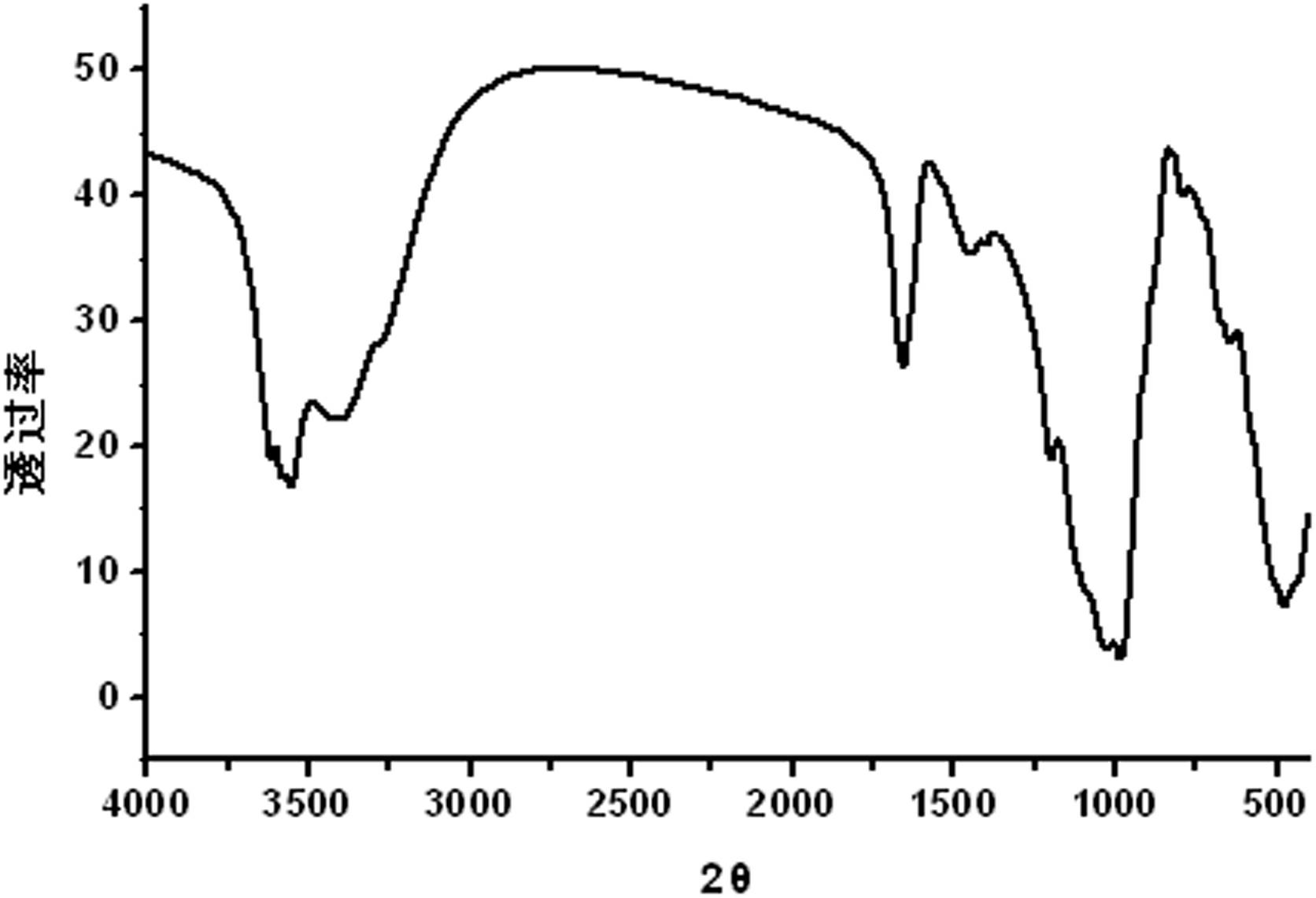

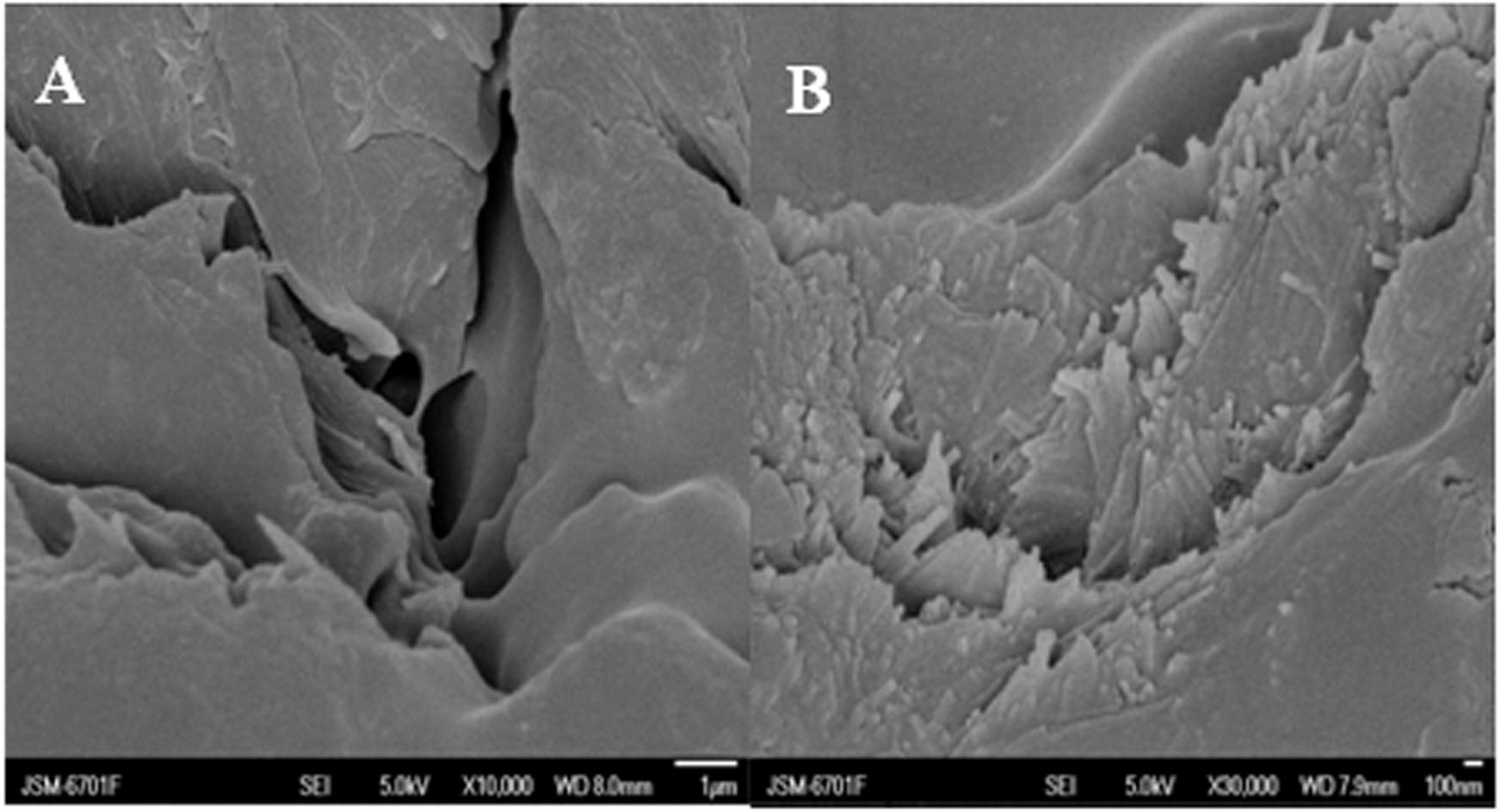

Method used

Image

Examples

Embodiment 1

[0047] Crush 3g of corn cobs and disperse them in water, heat to 40°C under nitrogen protection, gelatinize for 25min, heat up to 60°C, add 9g of acrylic acid, 1.5g of palygorskite clay, 0.018g of cross-linking agent ( N,N ′-methylenebisacrylamide), stirred at high speed for 5 minutes (rotation speed: 70~90 rpm), added 0.15g initiator (potassium persulfate), and cross-linked and polymerized at 60°C for 30 minutes; the cross-linked product was used Dehydrated with anhydrous methanol, washed with anhydrous ethanol, dried and pulverized.

[0048] The performance indicators are as follows:

[0049] Water absorption performance: the absorption of pure water is about 470g / g, and the absorption of tap water is about 190 g / g; salt resistance: the absorption of water in 0.5% sodium chloride solution is 160g / g, and the absorption of 0.9 wt% sodium chloride solution is about 80 g / g, the amount of absorbing 1.5% sodium chloride solution is 65g / g; the gel strength is 15pa.

Embodiment 2

[0051] Crush 3g of corn cob cores and disperse them in water. Under the protection of nitrogen, heat to 45°C for gelatinization for 25 minutes, then raise the temperature to 60°C, add 15g of acrylic acid, 2g of palygorskite clay, and 0.02g of crosslinking agent ( N,N ′-methylenebisacrylamide), high-speed stirring for 6 minutes (rotation speed: 70~90 rpm), add 0.17g initiator (ammonium persulfate), and cross-link polymerization at 65°C for 35 minutes; Dehydrated with anhydrous methanol, washed with anhydrous ethanol, dried and pulverized.

[0052] The performance indicators are as follows:

[0053] Water absorption performance: the absorption of pure water is about 460g / g, and the absorption of tap water is about 173 g / g; salt resistance: the absorption of water in 0.5% sodium chloride solution is 152g / g, and the absorption of 0.9 wt% sodium chloride solution is about 74 g / g, the amount of absorbing 1.5% sodium chloride solution is 55g / g; gel strength: 12pa.

Embodiment 3

[0055] Crush 3g of corncobs and disperse them in water. Under the protection of nitrogen, heat to 50°C for gelatinization for 30min, then raise the temperature to 65°C, add 11g of acrylic acid, 2.5g of palygorskite clay, 0.025g of cross-linking agent (diperoxide Cumene), high-speed stirring for 7min (rotation speed: 70~90r / min), add 0.19g initiator (ammonium persulfate), and cross-link polymerization at 70°C for 40 min; the cross-linked product is dehydrated with anhydrous methanol , washed with absolute ethanol, dried, and crushed.

[0056] The performance indicators are as follows:

[0057] Water absorption performance: the absorption of pure water is about 451g / g, and the absorption of tap water is about 170 g / g; salt resistance: the absorption of water in 0.5% sodium chloride solution is 143g / g, and the absorption of 0.9 wt% sodium chloride solution is about 70 g / g, the amount of absorbing 1.5% sodium chloride solution is 45g / g; gel strength: 10pa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com