Crack-resistant abrasion-resistant hydraulic concrete and preparation method thereof

A hydraulic concrete and anti-scouring technology, which is applied in the field of hydraulic concrete to improve the performance of concrete mixtures and anti-scour performance, the effect of readily available and cheap raw materials, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

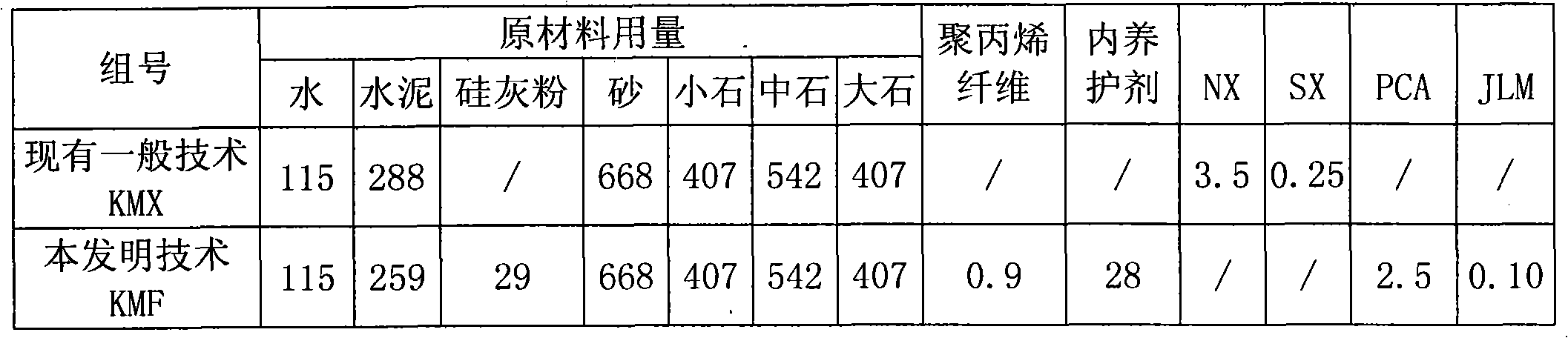

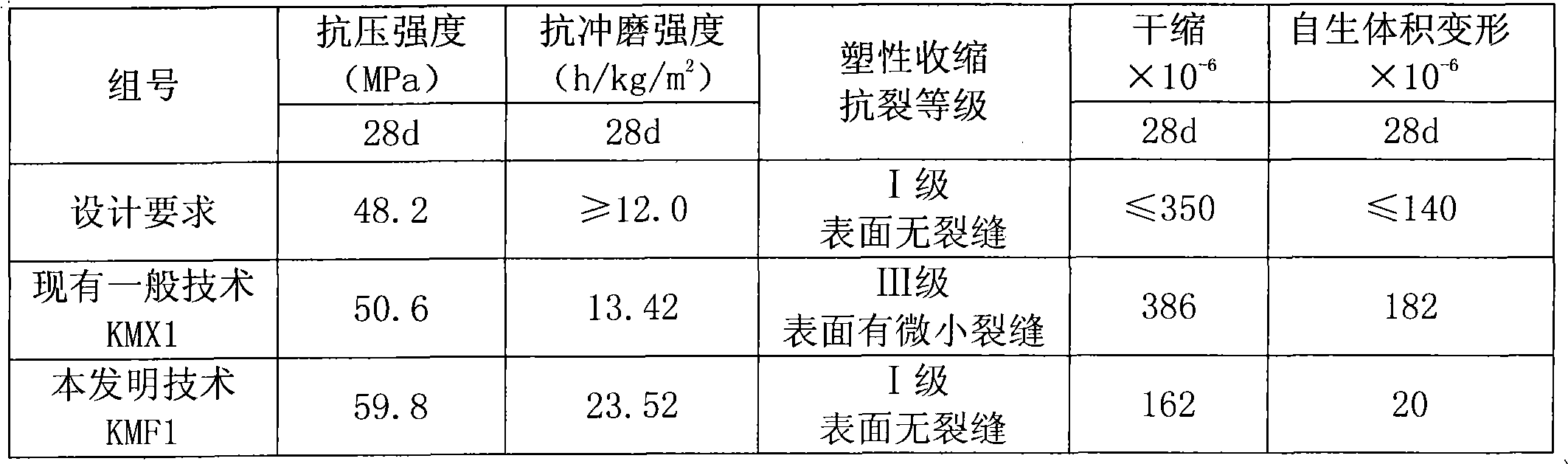

Embodiment 1

[0032] The technical solution of the present invention is trially applied to anti-scouring concrete of a water conservancy project in Guilin, Guangxi, with design grade of compressive strength C40 and anti-scouring strength ≥ 12.0h / kg / m 2 , 28d drying shrinkage value≤350×10 -6 , 28d self-generated volume deformation value ≤ 140×10 -6 , requiring no cracks after concrete pouring. The preparation method is as follows:

[0033] (1) Dry mix the cement, silica fume powder and polypropylene fiber evenly, then put the mixture and 1 / 2 water into the mixer, and stir for 35-40 seconds;

[0034] (2) Put sand, small stones, medium stones and large stones into the mixer on the basis of the completion of step (1), and stir for 45 to 50 seconds;

[0035] (3) On the basis of the completion of step (2), add internal curing agent, water reducing agent, air-entraining agent and the remaining 1 / 2 water into the mixer, and stir for 85-90 seconds;

[0036] (4) Install the concrete that has been...

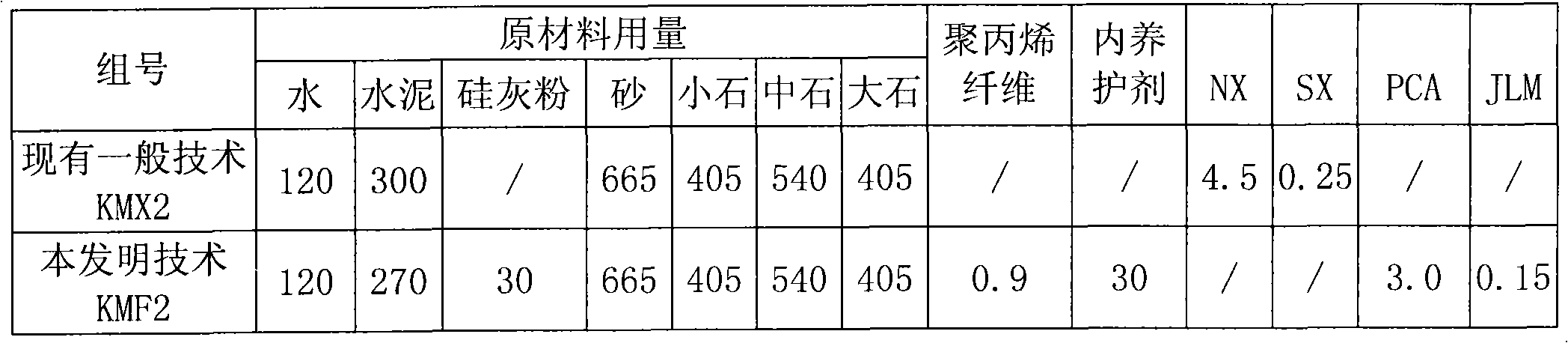

Embodiment 2

[0043] The technical solution of the present invention is trially applied to anti-scouring concrete of a water conservancy project in Chuanjiang, Guilin, Guangxi. The design grade of compressive strength is C40, and the anti-scouring strength is ≥ 14.0h / kg / m 2 , 28d dry shrinkage value ≤ 300 × 10-6, 28d self-generated volume deformation value ≤ 120 × 10-6, requiring no cracks after concrete pouring. The preparation method is as follows:

[0044] (1) Dry mix the cement, silica fume and polypropylene fiber evenly, then put the mixture and 1 / 2 water into the mixer, and stir for 30-35 seconds;

[0045] (2) Put sand, small stones, medium stones and large stones into the mixer on the basis of the completion of step (1), and stir for 40 to 45 seconds;

[0046] (3) On the basis of the completion of step (2), add internal curing agent, water reducing agent, air-entraining agent and the remaining 1 / 2 water into the mixer, and stir for 80-85 seconds;

[0047] (4) Install the concrete t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com