Anti-crack concrete and preparation method thereof

A technology of concrete and mixture, applied in the field of concrete, can solve the problems of reducing the heat of hydration, reducing the tensile strength and compressive strength of concrete, etc., to achieve the effect of improving the bearing capacity, avoiding the shrinkage deformation, and improving the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

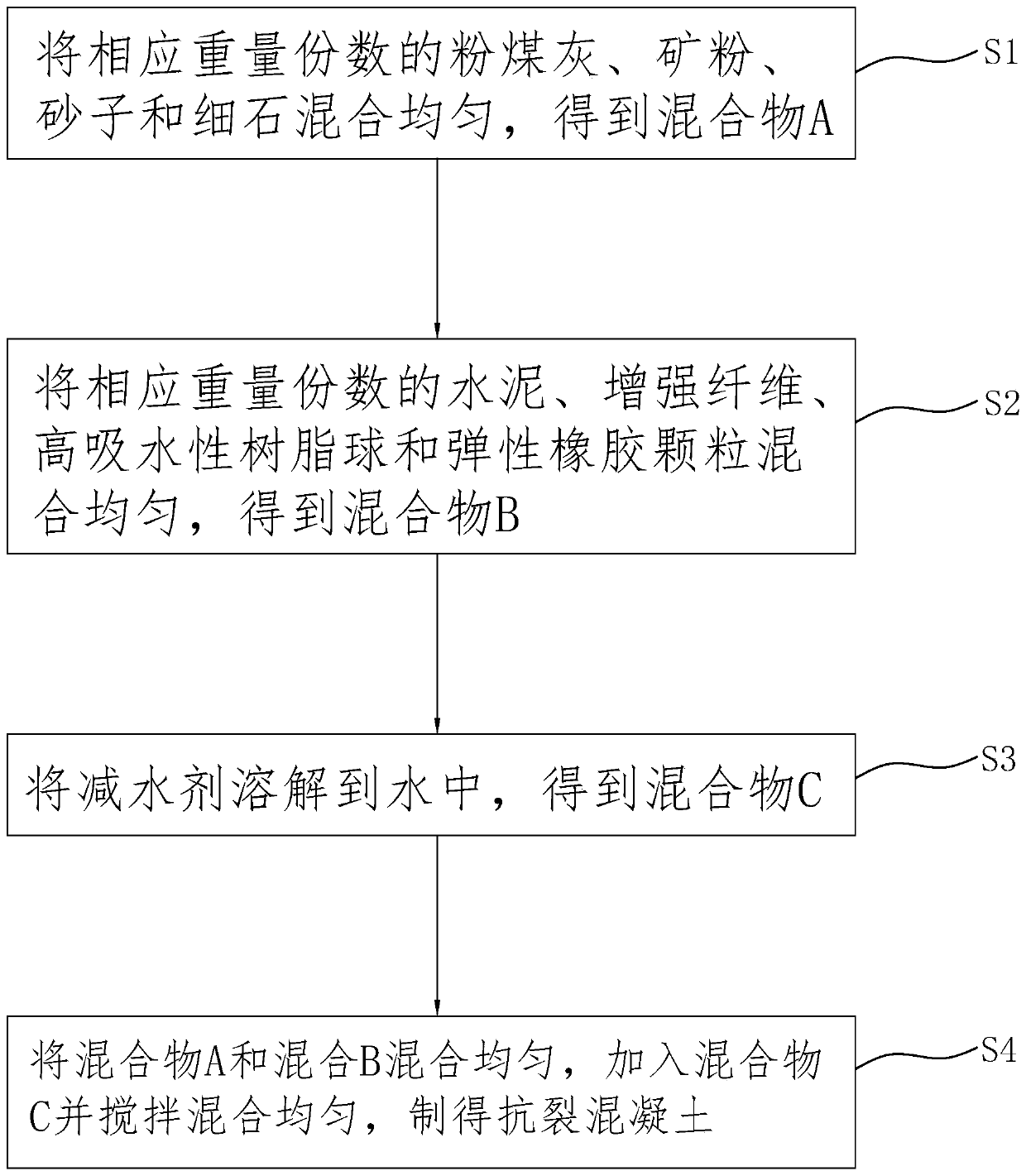

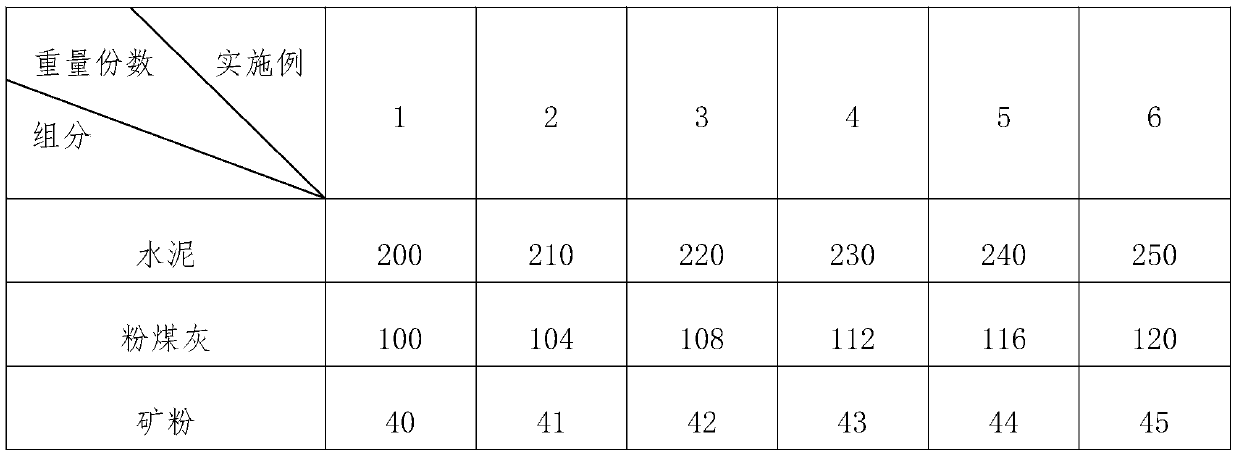

[0052] Embodiment 1: A kind of anti-cracking concrete, each component and its corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0053] S1, uniformly mix fly ash, mineral powder, sand and fine stones in corresponding parts by weight to obtain mixture A;

[0054] S2, uniformly mixing cement, reinforcing fibers, superabsorbent resin balls and elastic rubber particles in corresponding parts by weight to obtain a mixture B;

[0055] S3, dissolving the water reducing agent into water to obtain a mixture C;

[0056] S4, mix mixture A and mixture B uniformly, add mixture C and stir and mix uniformly to prepare crack-resistant concrete.

[0057] The particle size of the superabsorbent resin ball is 1mm, the particle size of the elastic rubber particle is 3mm, and the reinforcing fiber is steel fiber.

Embodiment 2-6

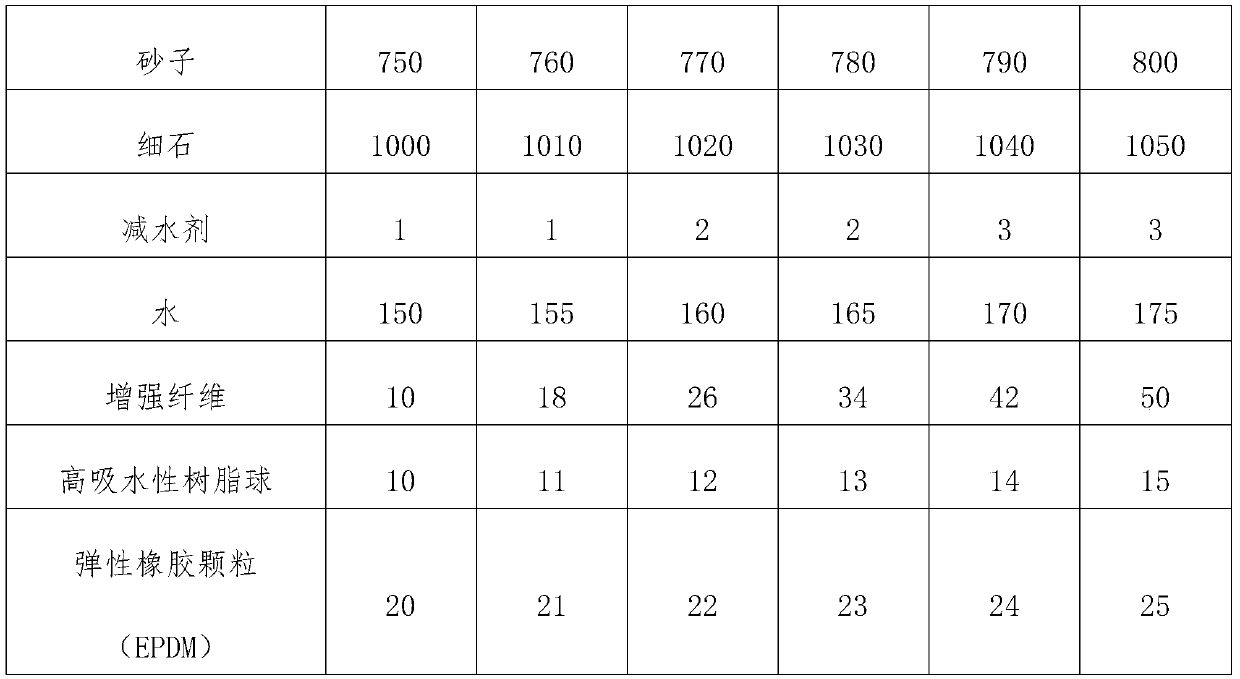

[0058]Embodiment 2-6: A crack-resistant concrete, the difference from Embodiment 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0059] Each component and parts by weight thereof in table 1 embodiment 1-6

[0060]

[0061]

Embodiment 7

[0062] Example 7: A crack-resistant concrete, the difference from Example 1 is that steel fibers and nylon fibers are used as reinforcing fibers, and the dosage ratio is 1:1 in parts by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com