Patents

Literature

58results about How to "Not prone to cracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

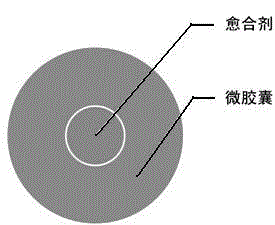

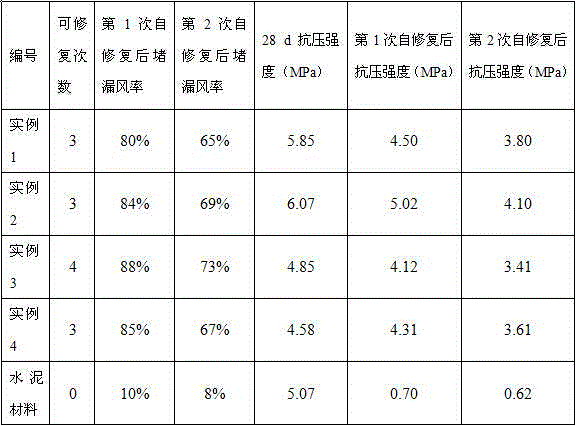

Bionic self-healing material for air leakage stoppage in coal mine

The invention relates to a bionic self-healing material for air leakage stoppage in a coal mine. The bionic self-healing material comprises a fast-setting expanding material, microcapsules containing a healing agent, and a catalyst, wherein the fast-setting expanding material comprises several of a cement clinker, coal ash, steel slag, mountain flour, salty mud, carbide slag, an expanding agent, a water reducing agent and sand, and each microcapsule is composed of a wall material (polymer resin) and a core material (the healing agent); the wall material of each microcapsule is at least one of urea resin, melamino-formaldehyde resin, melamine urea-formaldehyde resin and polyurethane, the healing agent is at least one of olefins containing double bonds, such as polyurethane prepolymer, isocyanate, phenolic resin, epoxy resin, styrene, acrylics and dicyclopentadiene (DCPD), and the catalyst is at least one of Grubbs catalyst, dibutyltin dilaurate and amines. The bionic self-healing material for air leakage stoppage in the coal mine disclosed by the invention has the advantages of being automatic in detection and healing, moderate in expansion, fast to set, good in conveying performance, strong in setting performance, green and environmentally friendly, and low in price.

Owner:胡相明

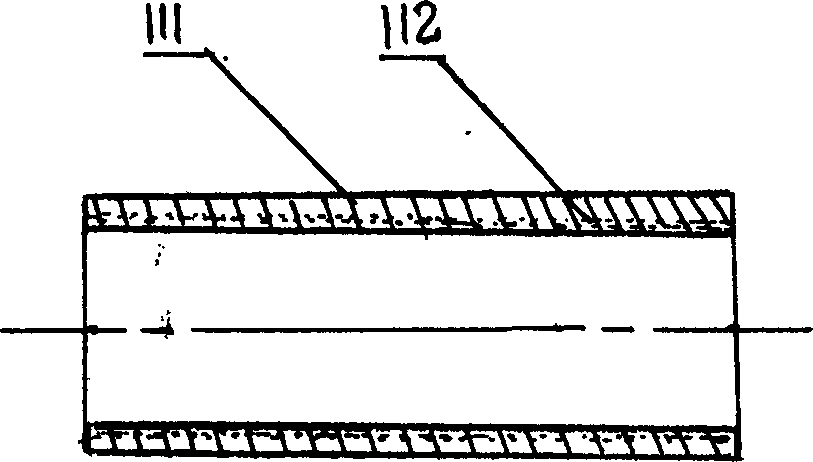

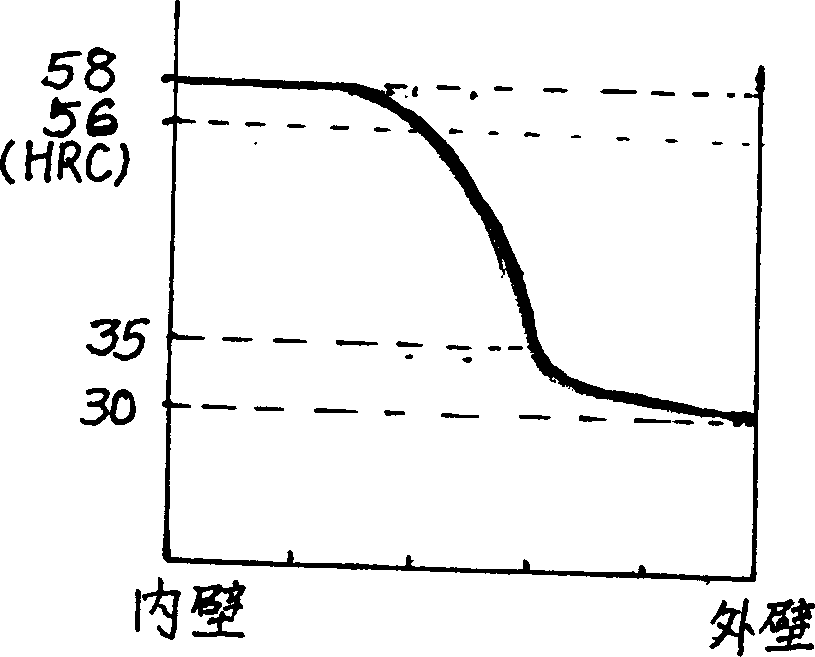

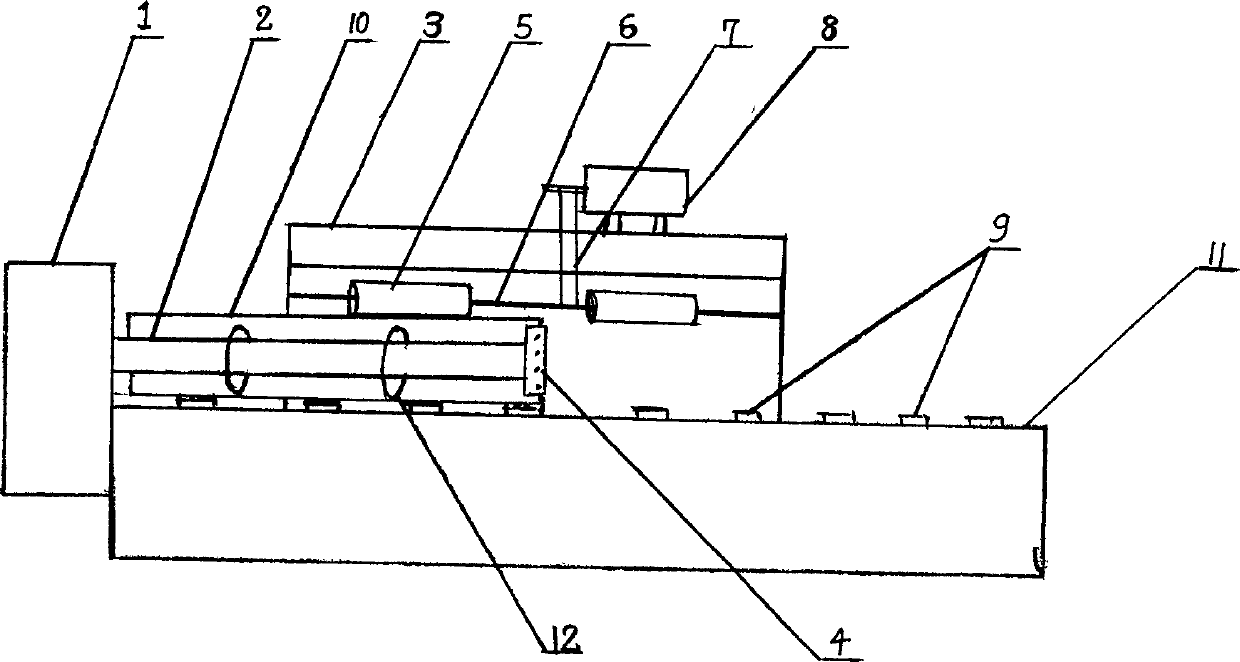

Cylinder shape pipe piece with inner harden layer and production method and equipment

InactiveCN1433942ALarge caliberSave materialIncreasing energy efficiencyFurnace typesFrictional coefficientEngineering

The present invention relates to a cylindrical pipe with internal hardened layer, its production method and special-purpose equipment. Said cylindrical pipe has small wall thickness and long length, its pipe wall has internal layer and external layer with different hardness, the hardness of its internal layer is greater than that of external layer, and said pipe is applicable for conveying material with high frictional coefficient. Its production method adopts the mode utilizing frequency to control pipe movement and proper hardening temp. range, and is special-purpose equipment is simple in structure, stable in operation, and can accurately control hardening temp., pipe moving speed nad depth of hardened layer.

Owner:王克发 +1

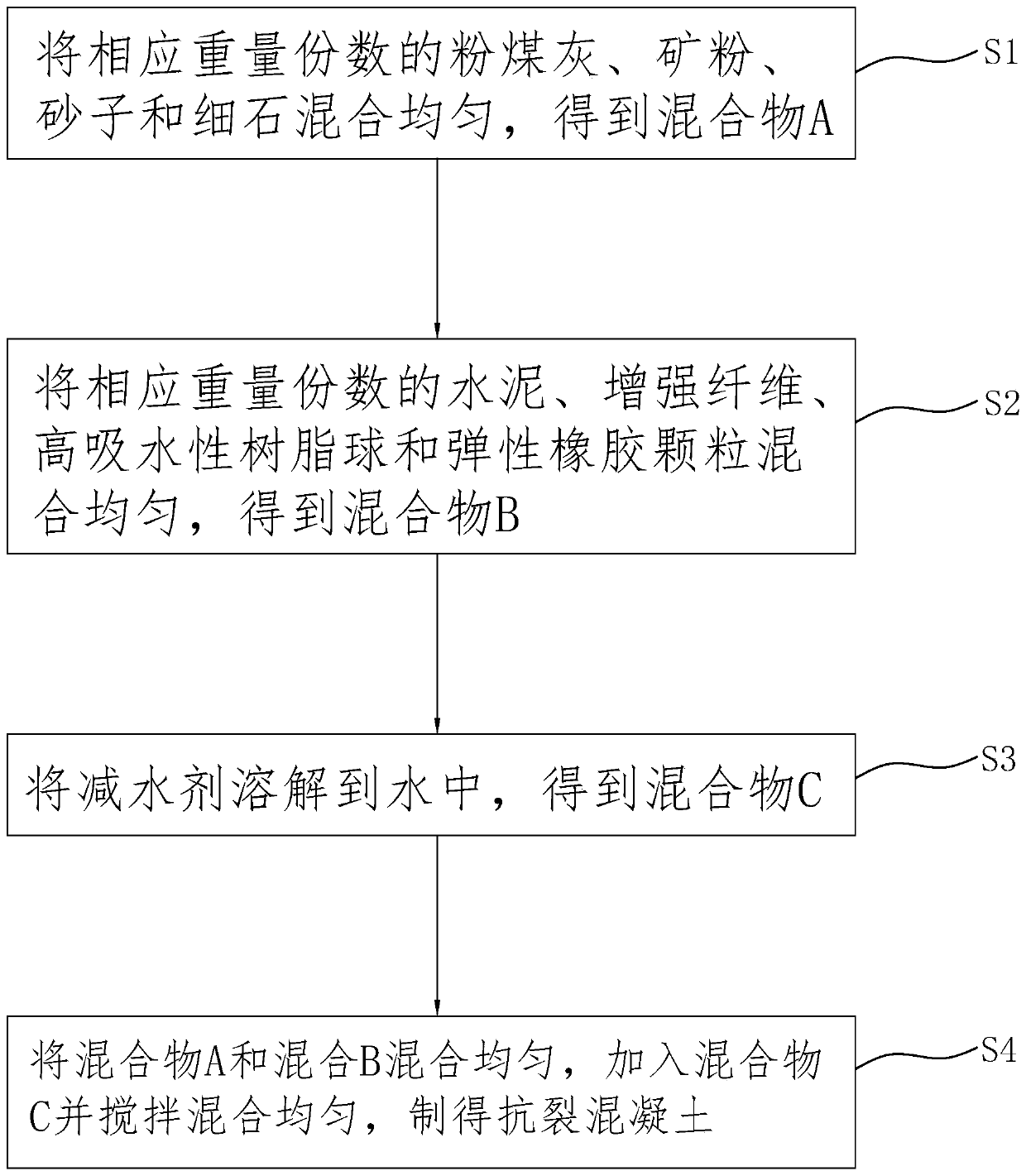

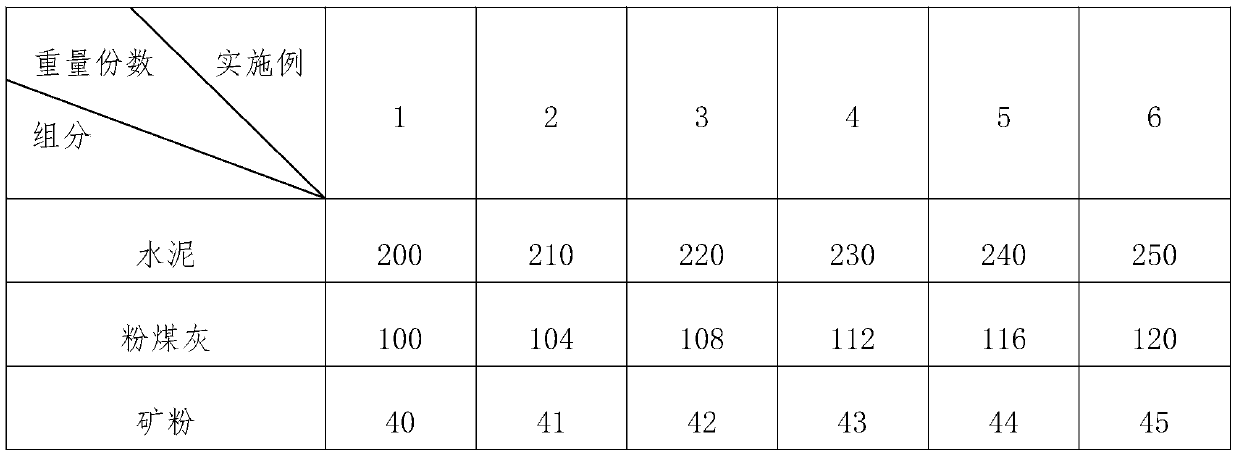

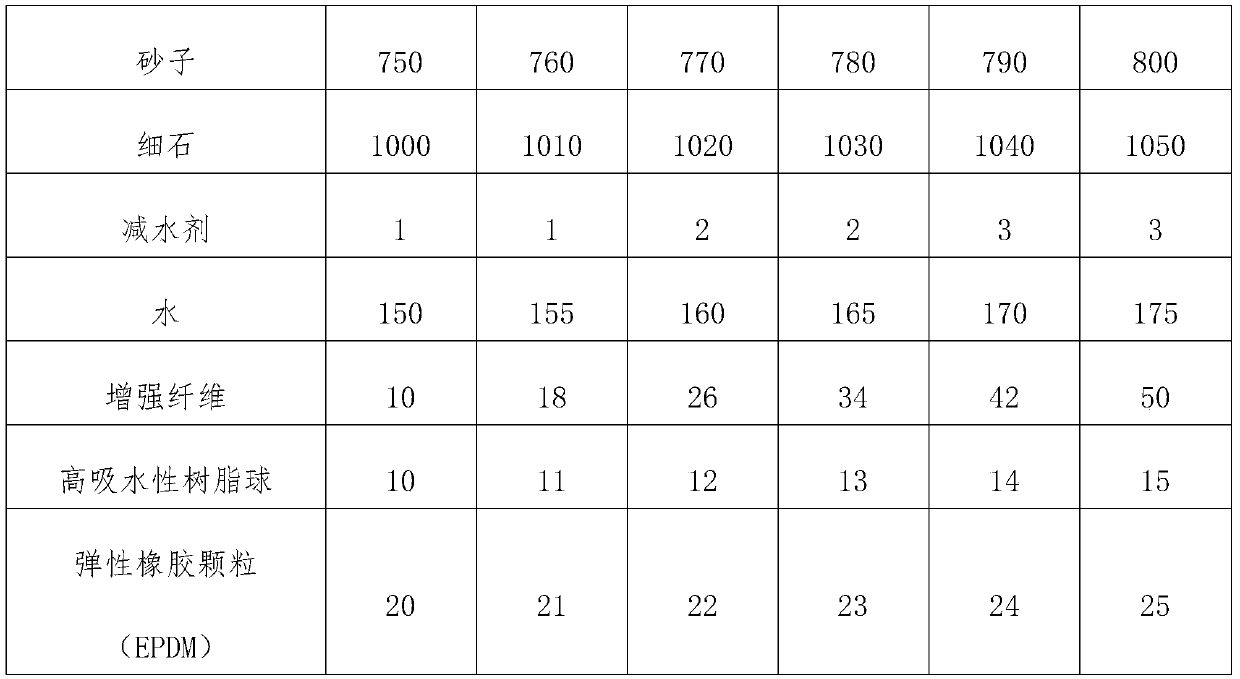

Anti-crack concrete and preparation method thereof

The invention discloses anti-crack concrete and a preparation method thereof, and relates to the technical field of concrete. The anti-crack concrete is characterized by comprising the following components in parts by weight: 200-250 parts of cement, 100-120 parts of fly ash, 40-45 parts of mineral powder; 750-800 parts of sand; 1000-1050 parts of fine stone; 1-3 parts of a water reducing agent; 150-175 parts of water; 10-50 parts of reinforcing fibers; 10-15 parts of super absorbent resin balls and 20-25 parts of elastic rubber particles. The anti-crack concrete prepared by adopting the formula has the advantages of high strength and high crack resistance.

Owner:上海石化安东混凝土有限公司

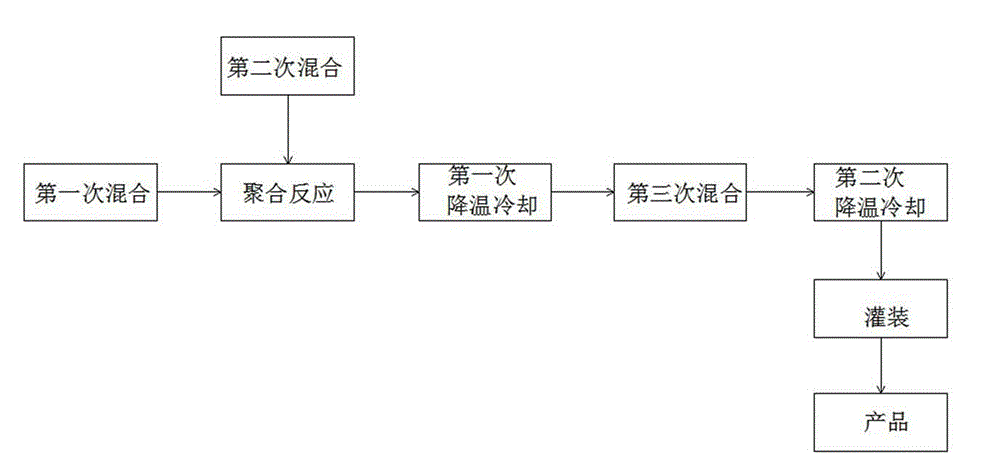

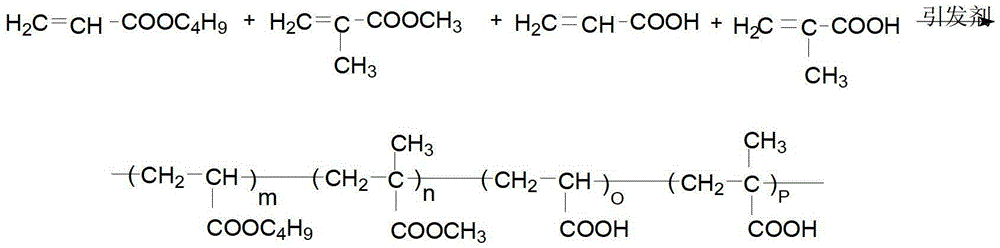

Production method of spray water paste

The invention relates to the technical field of paste production methods, and specifically relates to a production method of spray water paste. The method comprises the following steps: (1) first mixing: sequentially adding 2-4 parts of an acrylic acid, 3-5 parts of butyl acrylate, 4-6 parts of methyl methacrylate and 1-3 parts of a methacrylic acid into a polymerization kettle to stir in part by weight, and heating the obtained mixture to 80 DEG C; (2) second mixing: dropwise adding 1-3 parts of water, 2-4 parts of an emulsifier and 2-4 parts of an initiator into the polymerization kettle in the step (1) to stir in part by weight, and after the dropwise adding is completed, carrying out heat preservation on the obtained product 4 hours, wherein the dropwise adding temperature is 80-85 DEG C, and the dropwise adding time is 5-6 hours. According to the invention, through adopting the steps of mixing, polymerization and cooling and the like, the prepared spray water paste has the characteristics of low viscosity, good heat dissipation, good heat shrinkable property, less impurities, uneasiness for blistering, and uneasy production of cracks on paste membranes, and the like, and the concentration of odor emitted by the prepared spray water paste is low. In addition, the method disclosed by the invention is simple in production method, low in cost, and small in environmental pollution.

Owner:NANTONG HONGRUI CHEM

Extra-high voltage suspension composite rod insulator

InactiveCN105529117AImprove water repellencyImprove antifouling performanceSuspension/strain insulatorsGlass fiberComposite insulators

The invention belongs to the field of power materials, relates to an extra-high voltage suspension composite rod insulator. The extra-high voltage suspension composite rod insulator comprises the following raw materials in parts by weight: 100 parts of clay, 80 parts of blast furnace slag, 30 parts of No. 42.5 portland cement, 10 parts of feldspar powder, 3 parts of talcum powder, 2 parts of straw powder, 1 part of a glass fiber and 100 parts of water. The extra-high voltage suspension composite rod insulator is excellent in hardness and bending strength and good in stability performance.

Owner:STATE GRID SHANDONG ELECTRIC POWER +2

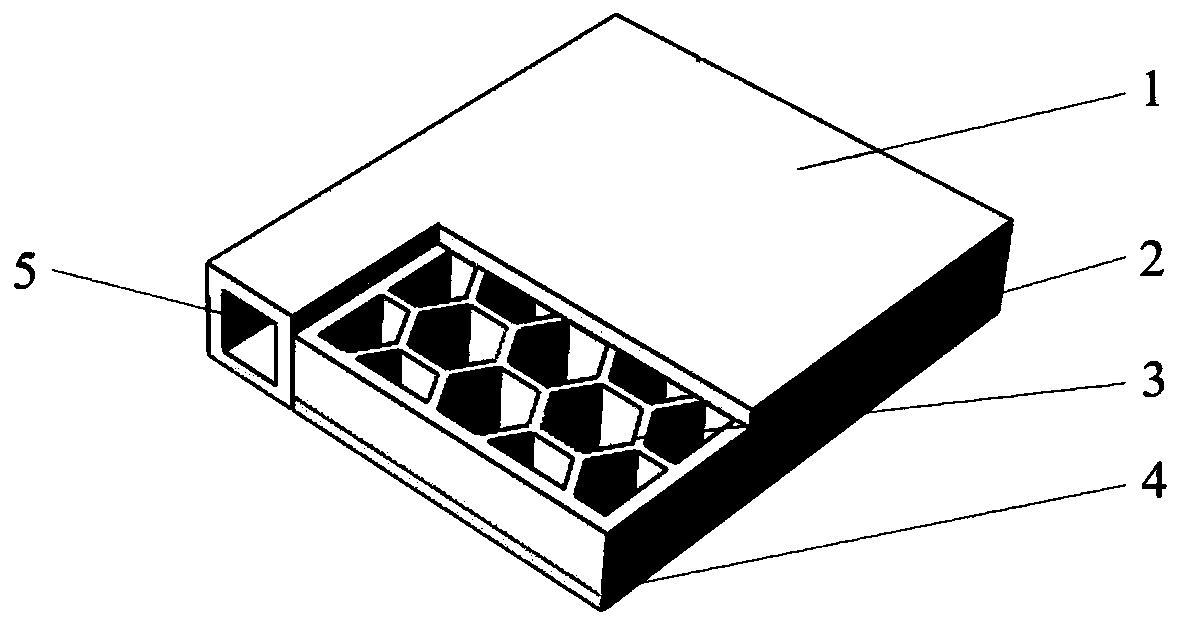

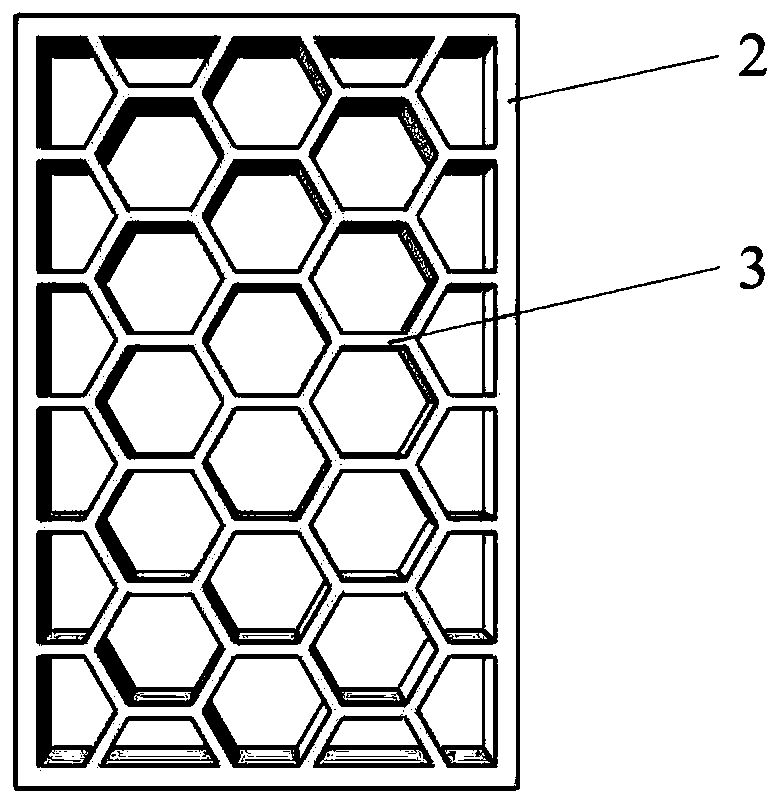

Recycled engineering plastic assembled pavement and paving method thereof

ActiveCN110105784ARealize recycling of resourcesLow densitySingle unit pavingsPaving gutters/kerbsGlass fiberHoneycomb

Belonging to the technical field of road construction, the invention puts forward a recycled engineering plastic assembled pavement and a paving method thereof. The assembled pavement is formed by assembling a plurality of honeycomb recycled plastic face plates, each honeycomb recycled plastic face plate consists of a cover panel, a side plate, a honeycomb core plate and a base plate, the cover plate and the base plate are respectively arranged on the upper surface and lower surface of the honeycomb core plate, the side plate is arranged at the periphery of the honeycomb core plate, and one honeycomb recycled plastic face plate and an adjacent honeycomb recycled plastic face plate are connected through the side plates. The honeycomb recycled plastic face plate is prepared from waste plastics, filler, glass fiber, a flame retardant, a coupling agent and a lubricant in mass parts. The main raw material of the honeycomb recycled plastic face plate is waste plastics, waste plastics are prefabricated into honeycomb recycled plastic face plates for road paving, the honeycomb recycled plastic face plates have excellent mechanical properties and can better bear the load of vehicles runningon the pavement.

Owner:CHANGAN UNIV

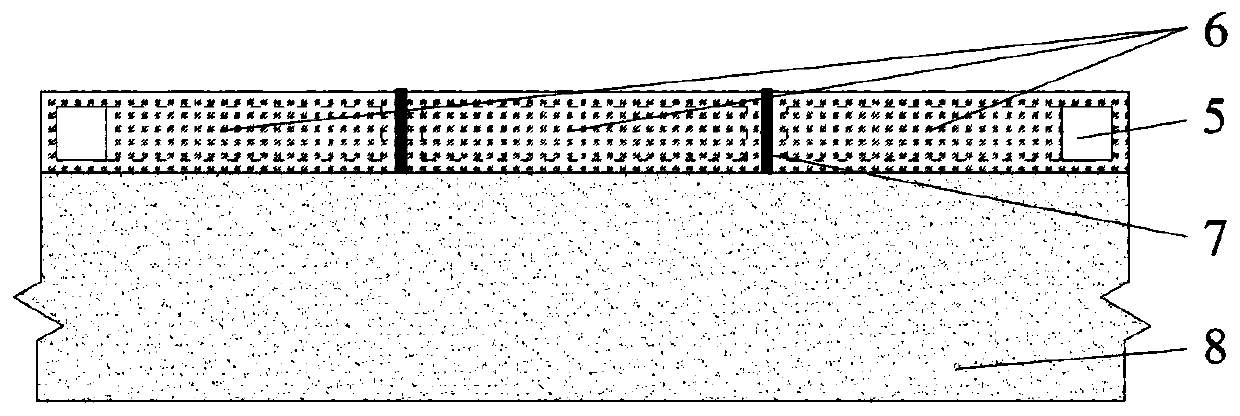

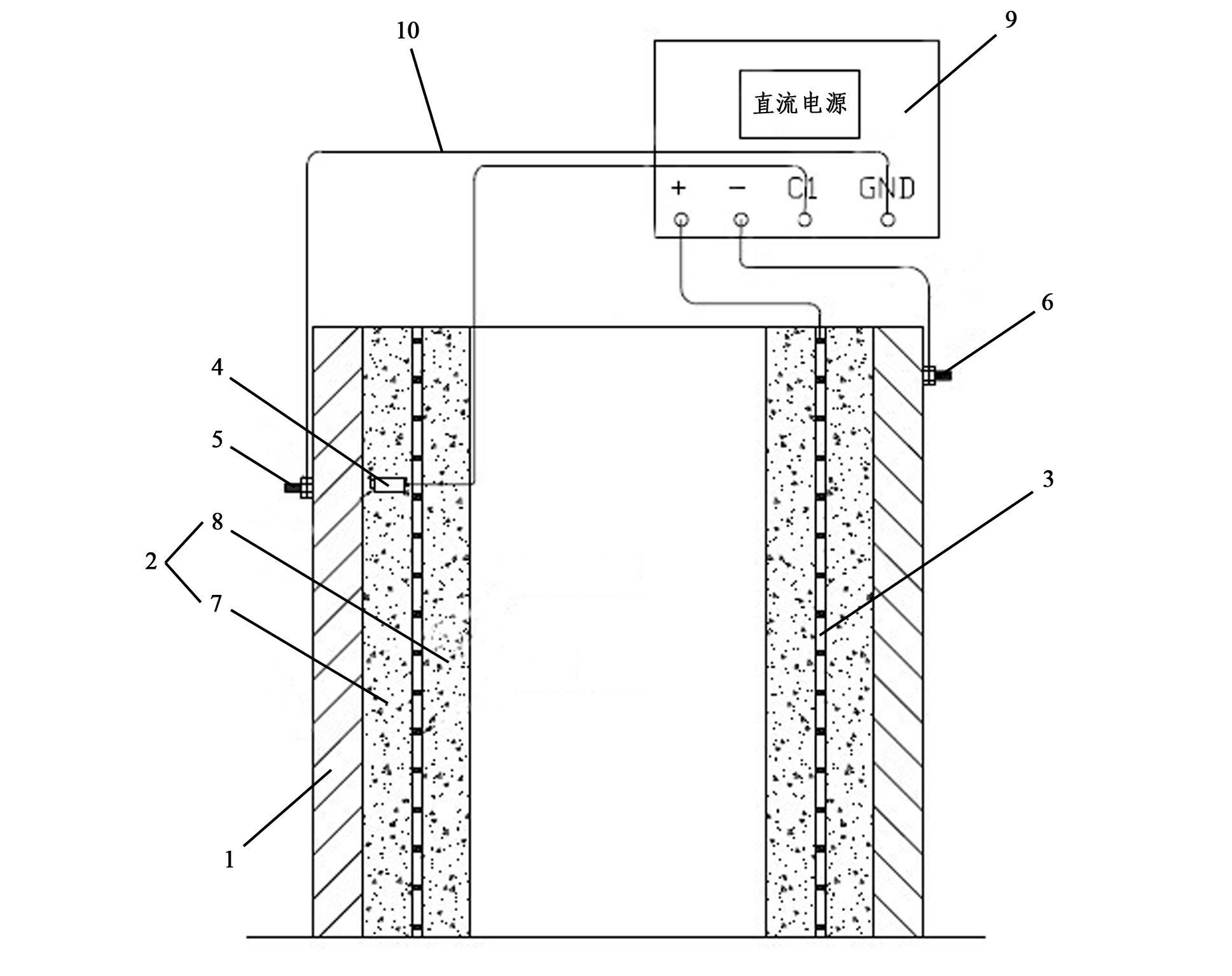

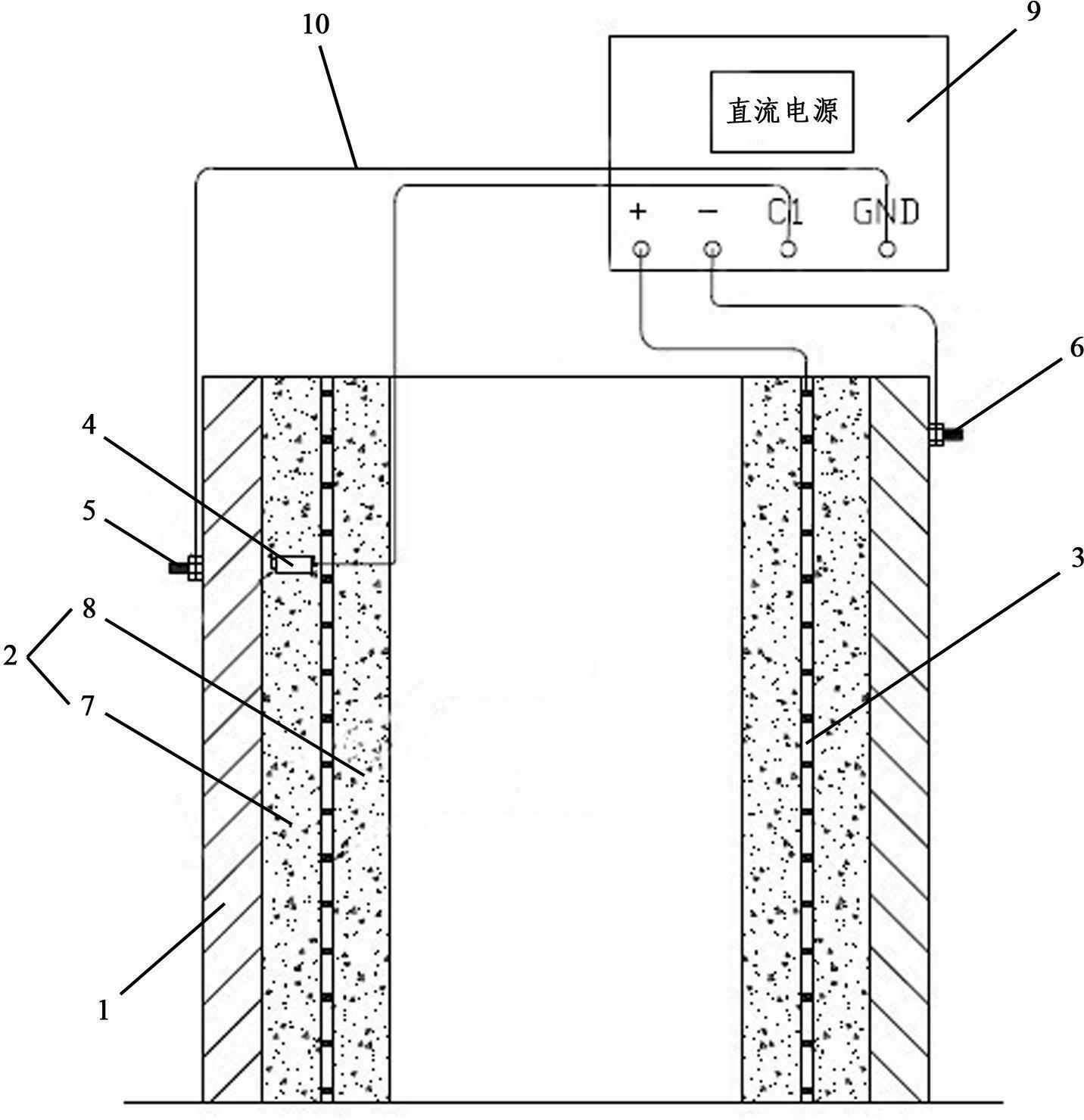

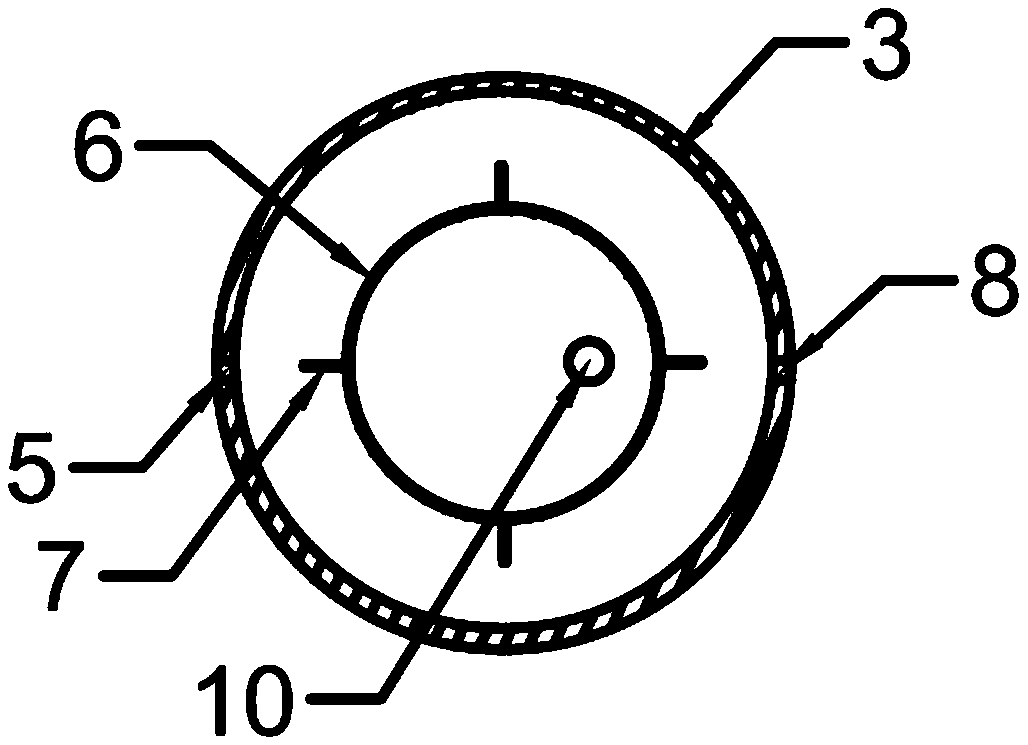

Cathodic protection system of wet desulfurized funnel

The invention relates to a cathodic protection system for a wet desulfurized funnel, which is used for the treatment of corrosion on the wet desulfurized funnel in a thermal power plant. The wet desulfurized funnel comprises a basal body surrounding the funnel, wherein the basal body is provided with an inner wall and an outer wall, an outlet of the wet desulfurized funnel is formed at the end part of the basal body. The cathodic protection system of the wet desulfurized funnel comprises an acid resisting layer which is arranged along the inner wall, an anode screen which is laid in the acid resisting layer, a reference electrode which is embedded in the acid resisting layer, and a measurement grounding device, a cathode and a constant potential rectifier which are arranged on the outer wall of the wet desulfurized funnel, wherein the reference electrode, the measurement grounding device, the cathode, and the anode screen are respectively led out by cables and are connected with the constant potential rectifier. Since the cathodic protection is combined based on the acid resisting layer, corrosion can be effectively resisted, and the acid resisting property is excellent; and meanwhile, the acid resisting layer is compact, flaws are not easy to occur, and the leakage resisting property is good, the load of the funnel can be reduced after the cathodic protection is applied, the service life of the funnel is long, and economic benefits are significant.

Owner:SUZHOU NUCLEAR POWER RES INST +1

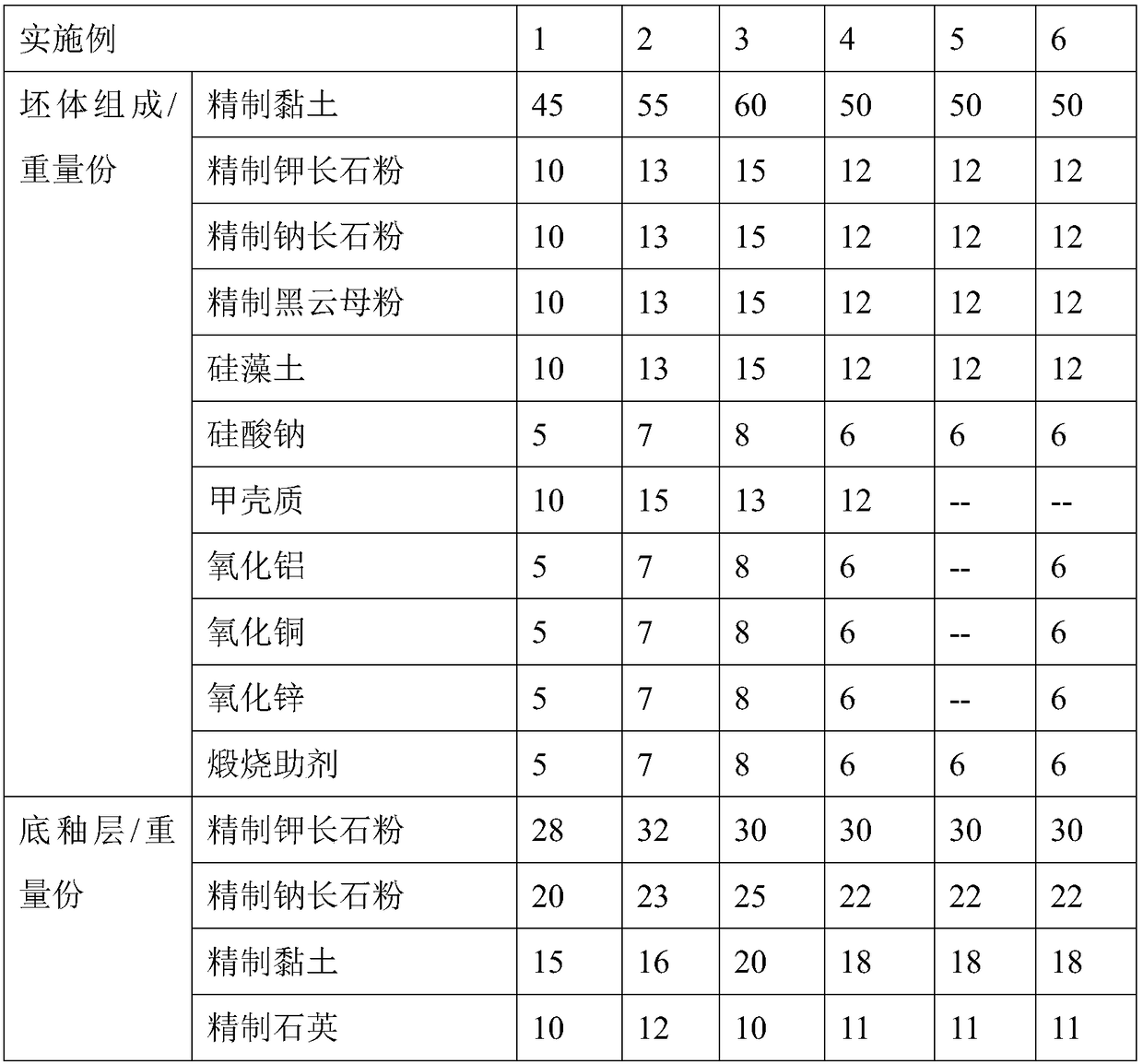

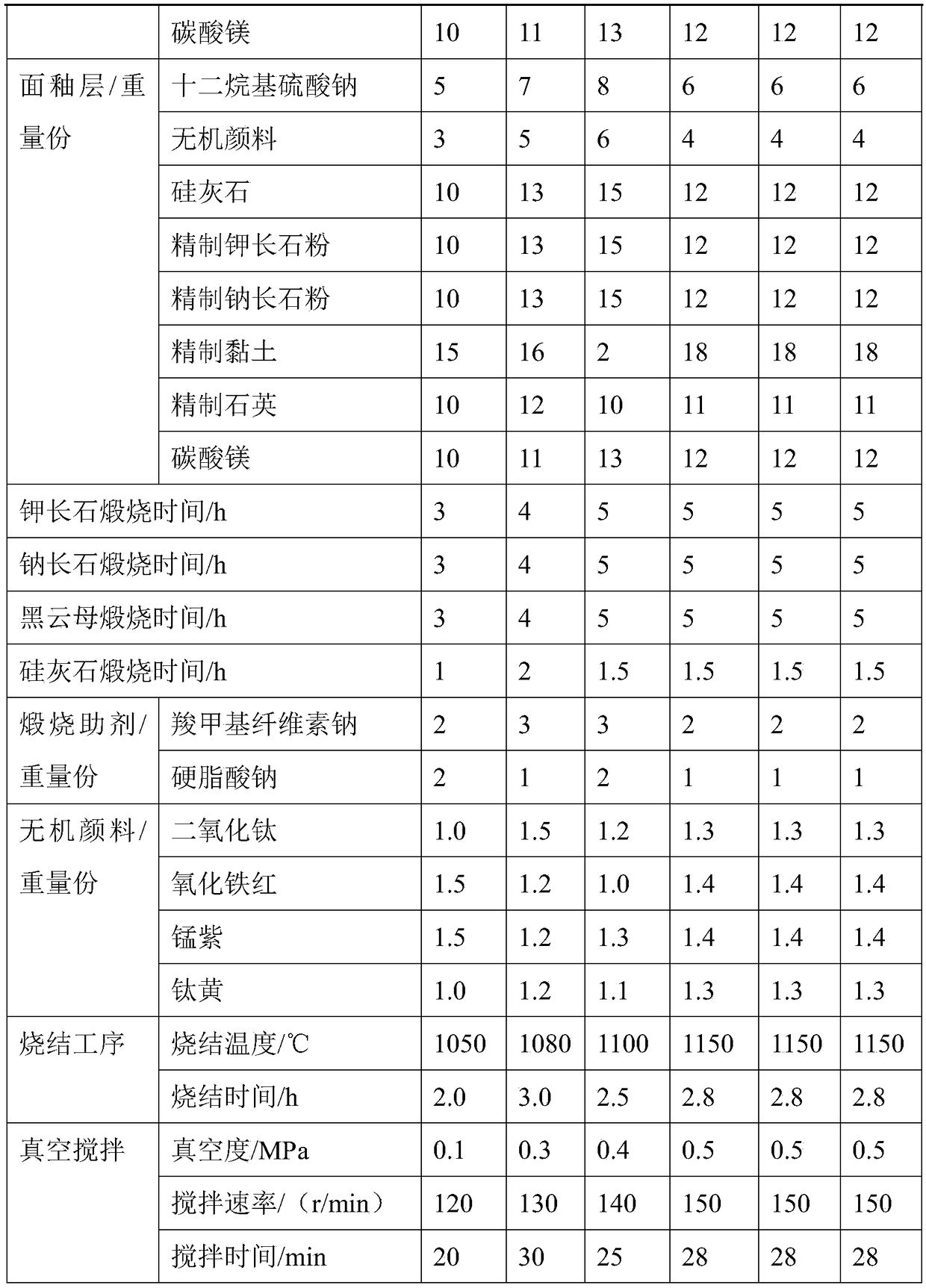

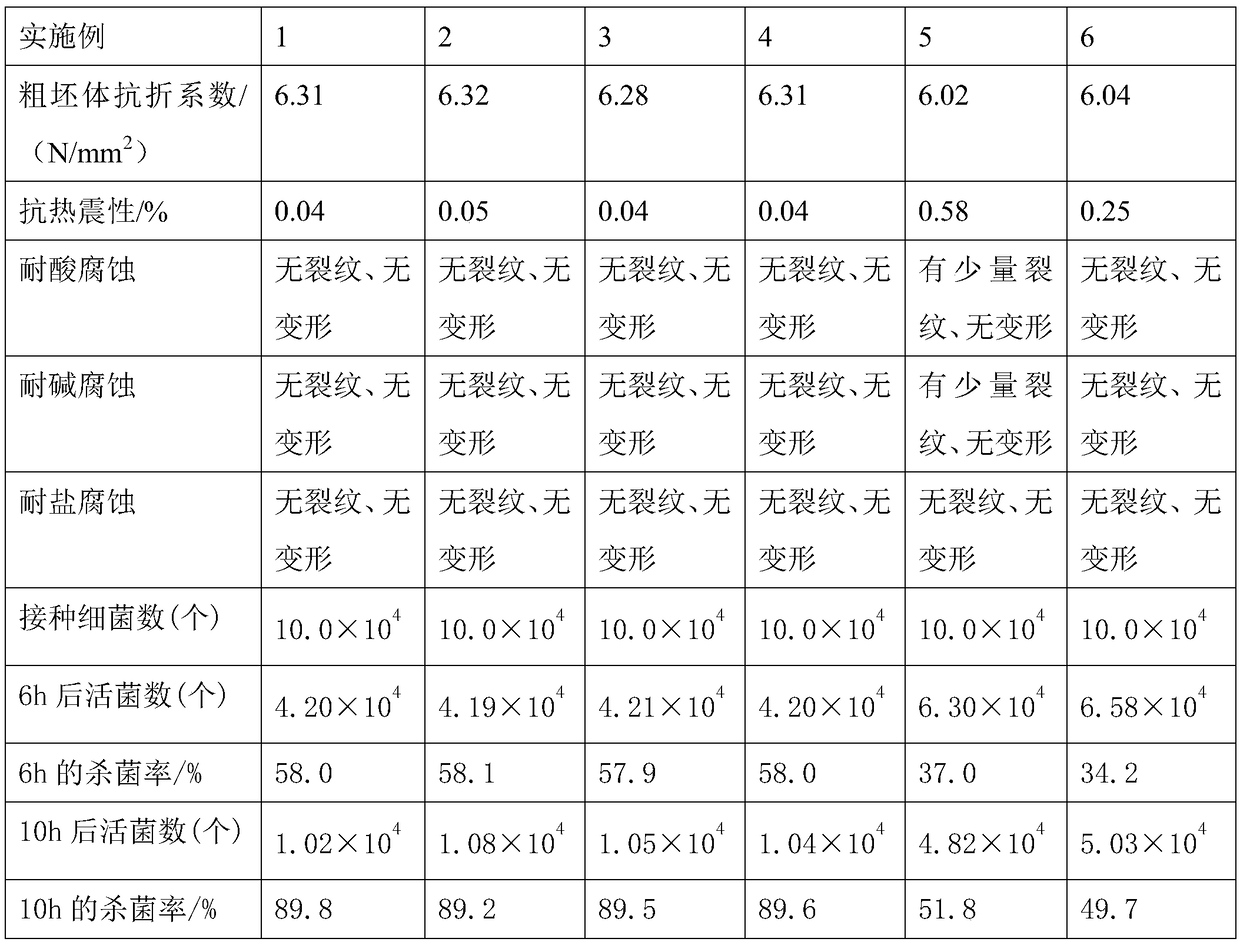

Low-temperature one-time-sintered antibacterial domestic ceramic, and preparation method thereof

The invention more specifically relates to a low-temperature one-time-sintered antibacterial domestic ceramic, and a preparation method thereof, and belongs to the technical field of domestic ceramicand preparation technology. The low-temperature one-time-sintered antibacterial domestic ceramic comprises a blank body, and a glaze layer used for covering the surface of the blank body; the glaze layer is composed of a ground glaze layer and an over glaze layer successively; the ground glaze layer is directly contacted with the blank body. The preparation method comprises following steps: a blank body is prepared; the blank body is provided with the ground glaze layer; the upper surface of the ground glaze layer is provided with the over glaze layer; and low temperature one time sintering iscarried out so as to obtain a finished product. The preparation method is capable of solving problems in the prior art that domestic ceramic preparation technology is complex, the whole quality is not balance, and quality is low; the preparation method is simple; the antibacterial effect is excellent; and the quality is stable and high.

Owner:福建省德化龙顺陶瓷有限公司

Adhesive special for sand aerated concrete boards and preparation method of adhesive

The invention discloses an adhesive special for sand aerated concrete boards and a preparation method of the adhesive. The adhesive comprises, by weight percentage, 25-30% of Portland cement, 50-58% of quartz sand, 15-20% of sand aerated concrete board waste, 1.5-2.0% of redispersible latex powder, 0.1-0.3% of hydroxypropyl methyl cellulose ether, 0.1-0.3% of wood fibers, 0.04-0.08% of starch ether and 0.1-0.2% of polypropylene fibers. The adhesive is good in water-retaining property and adhesive property, small in shrinkage ratio, high in crack resistance and less prone to interface crack generation, the recycled sand aerated concrete board waste is used as the raw material, and consistency with the color of a wall after filling is achieved.

Owner:SHAANXI NITYA NEW MATERIALS TECH CO LTD

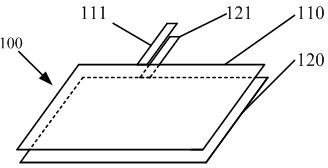

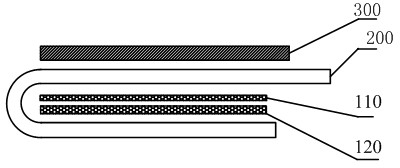

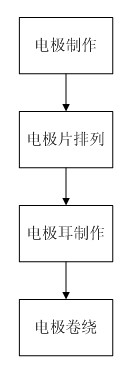

Electrode and manufacture method thereof

InactiveCN102088083AReduce thicknessGood flexibilityElectrode carriers/collectorsAlkaline accumulator electrodesInternal resistanceElectrical battery

The invention discloses an electrode and a manufacture method thereof. The electrode comprises at least two parallel electrode plates, and each electrode plate has a pore structure in which an electrode active substance is filled. The electrode has the advantages that the flexibility of the electrode plate is greatly improved; thus, in the coiling process, the electrode plate has small possibility of cracking or breaking so as to avoid low battery capability; and meanwhile, micro short circuit because of power falloff has small possibility of formation, the battery short circuit caused by that burrs pierce the membrane has small possibility of formation, and large internal resistance fluctuation of the battery can be avoided.

Owner:SHENZHEN EPT BATTERY

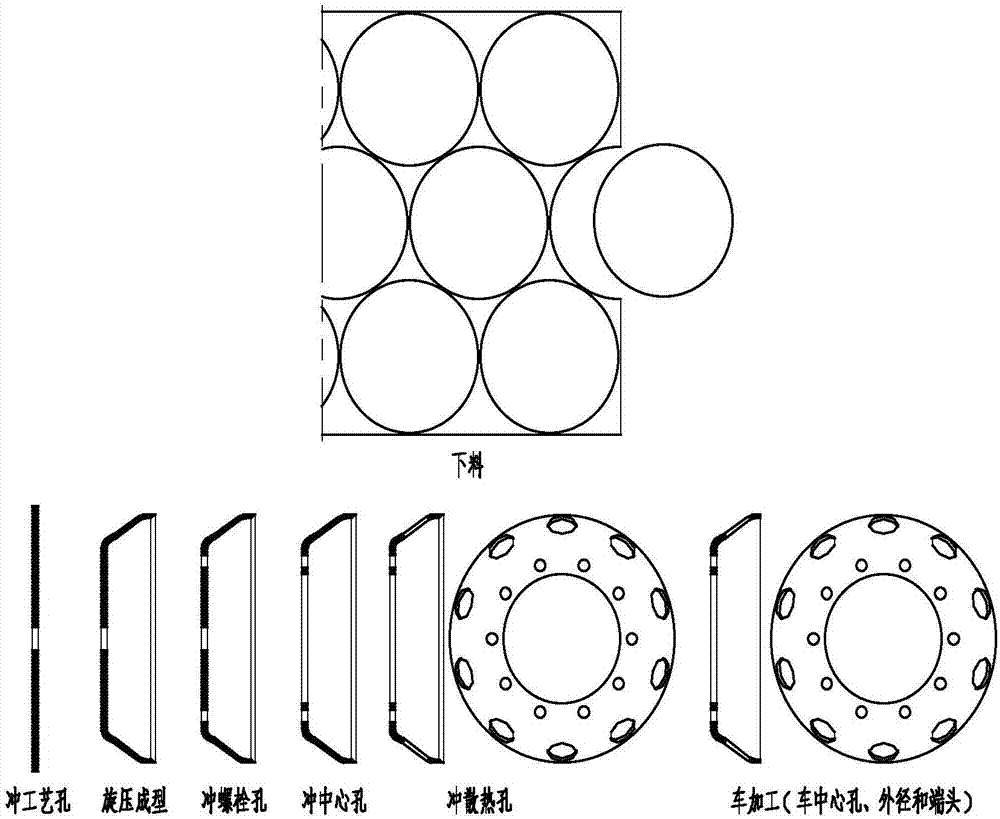

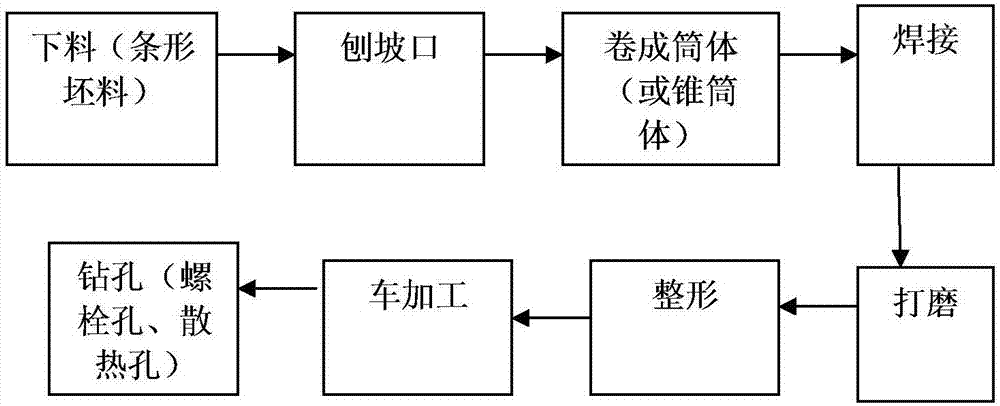

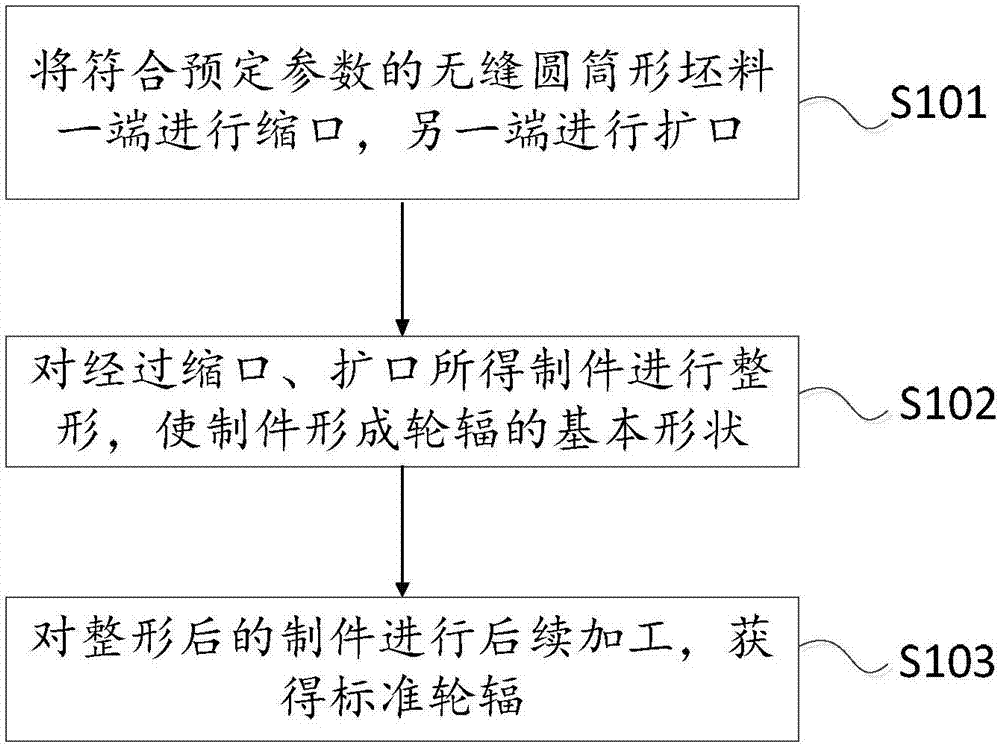

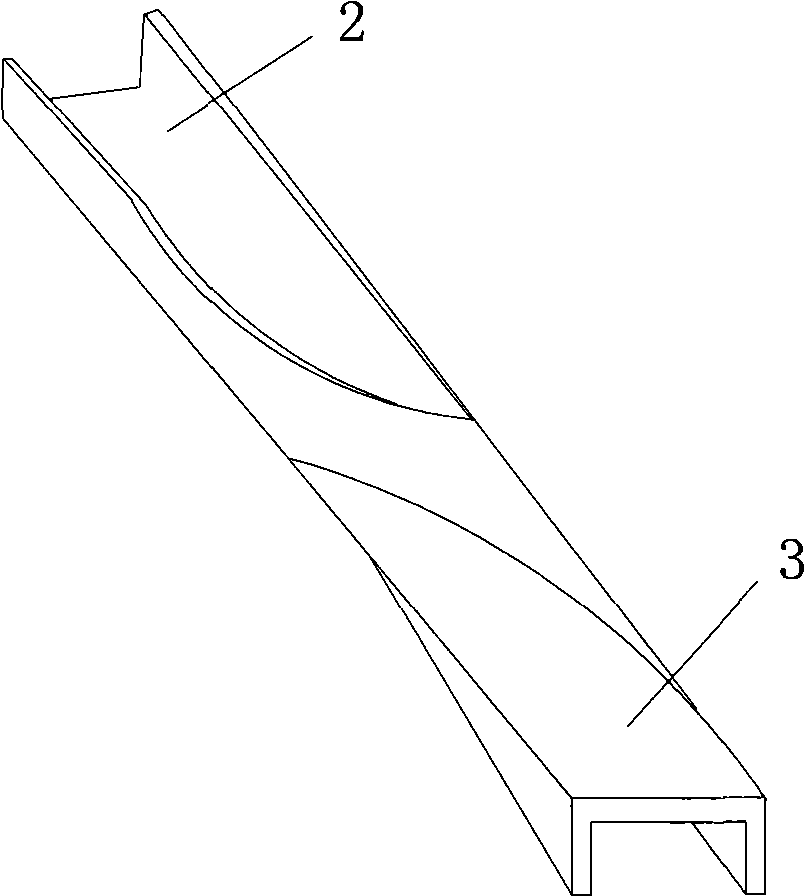

Machining method of wheel spoke and wheel spoke

InactiveCN106938385AIncrease profitNot prone to cracksVehicle componentsMachining processEngineering

The application discloses a method for processing a wheel spoke and a wheel spoke. Wherein, the processing method of the wheel spokes includes: shrinking one end of a seamless cylindrical blank conforming to predetermined parameters, and flaring the other end; The basic shape of the spokes; subsequent processing is performed on the shaped parts to obtain standard spokes. Adopting the method provided by this application can effectively solve the problems of low material utilization rate in the shear blanking and center hole processing in the existing processing methods, and the problems caused by welding the strip material into a cylindrical material or a cone material. The problem of poor spoke strength caused.

Owner:东风汽车车轮随州有限公司

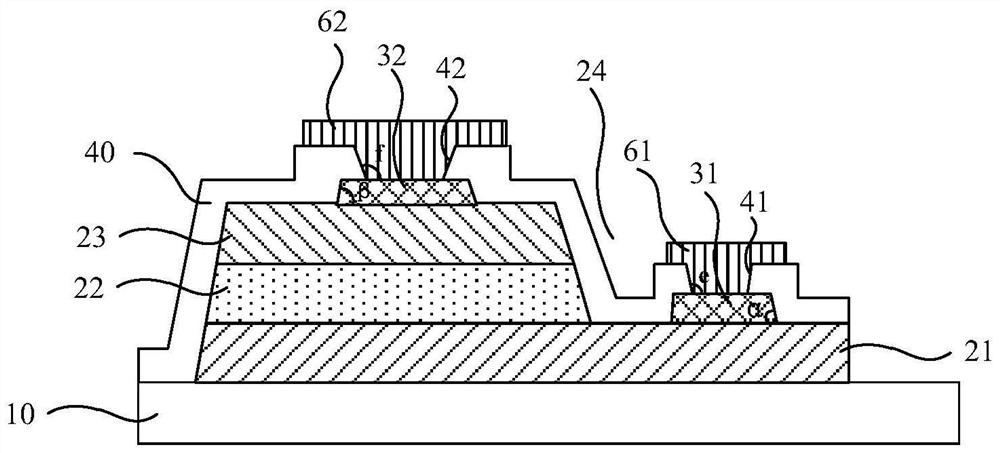

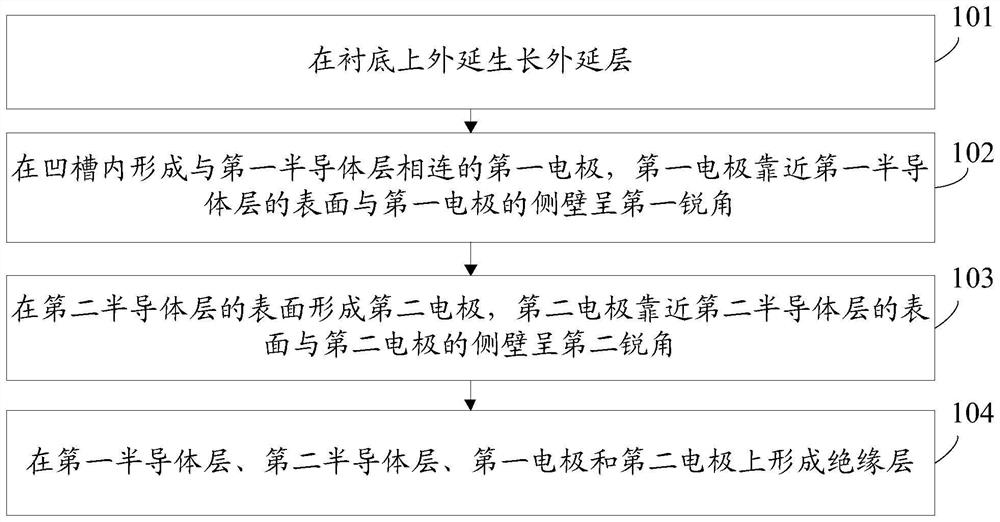

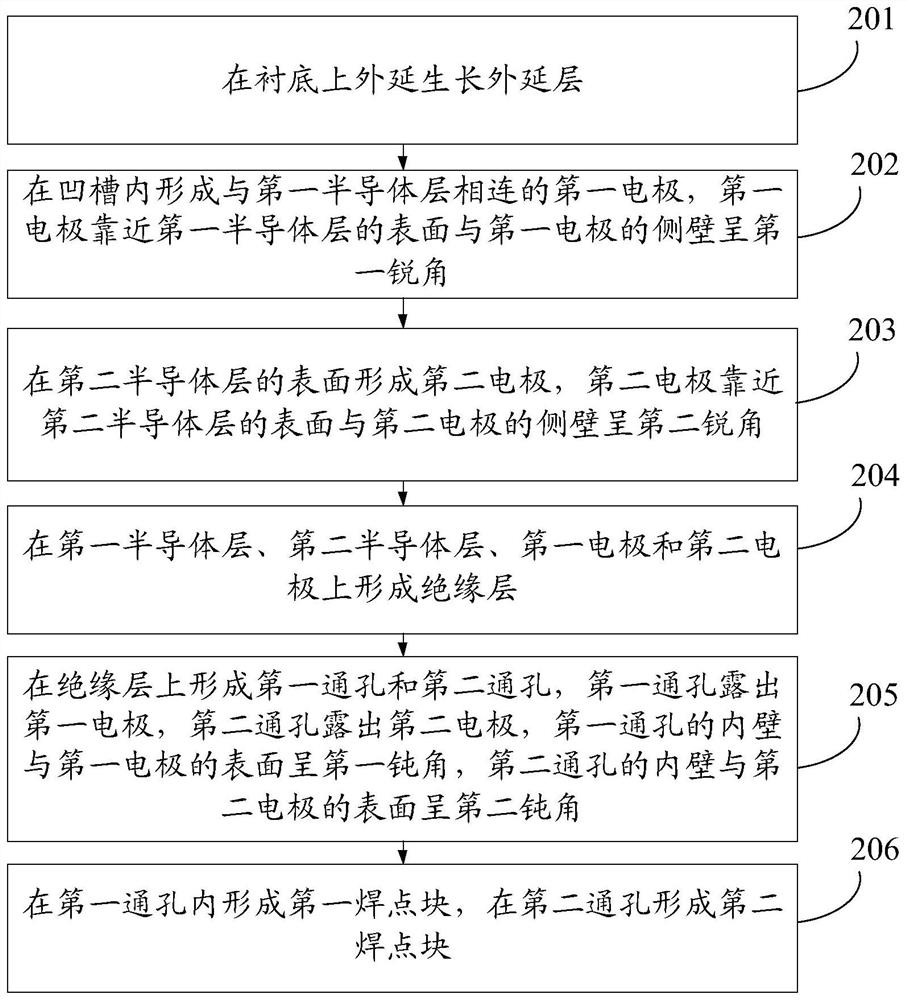

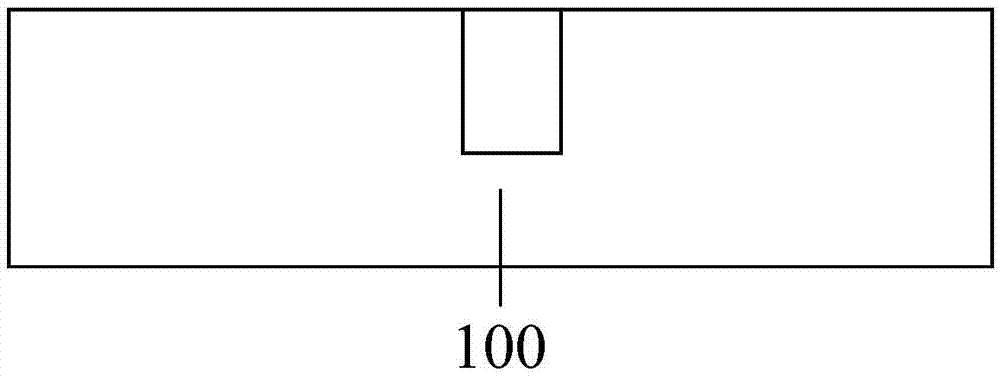

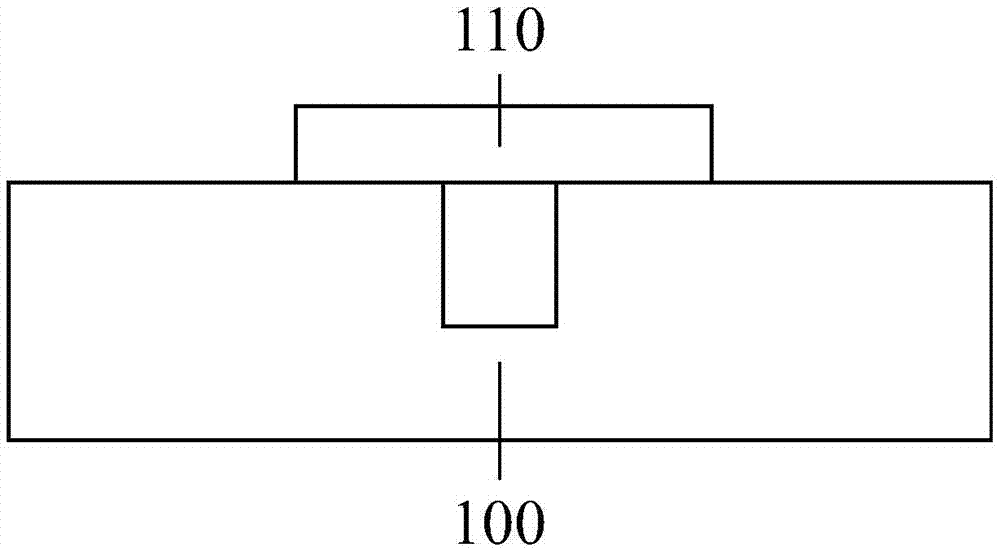

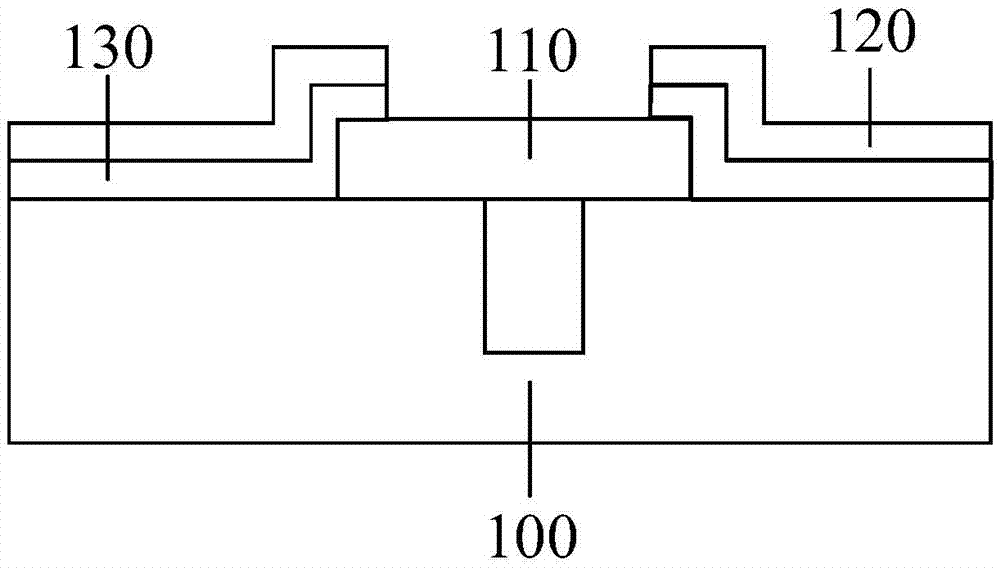

Light-emitting diode chip capable of improving cracks of insulating layer and preparation method of light-emitting diode chip

PendingCN114744091AQuality improvementSmooth transitionSemiconductor devicesLight-emitting diodeSemiconductor

The invention provides a light-emitting diode chip for improving cracks of an insulating layer and a preparation method thereof, and belongs to the technical field of photoelectron manufacturing. The light-emitting diode chip comprises a substrate, an epitaxial layer, a first electrode, a second electrode and an insulating layer, the epitaxial layer comprises a first semiconductor layer, a multi-quantum well layer and a second semiconductor layer which are sequentially stacked on the substrate, and the surface of the second semiconductor layer is provided with a groove exposing the first semiconductor layer; the first electrode is located in the groove and connected with the first semiconductor layer, and the surface, close to the first semiconductor layer, of the first electrode and the side wall of the first electrode form a first acute angle; a second acute angle is formed between the surface, close to the second semiconductor layer, of the second electrode and the side wall of the second electrode; the insulating layer is located on the first semiconductor layer, the second semiconductor layer, the first electrode and the second electrode. According to the embodiment of the invention, the problem that the insulating layer is easy to crack when extending to the semiconductor layer from the vertical corner of the electrode can be improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

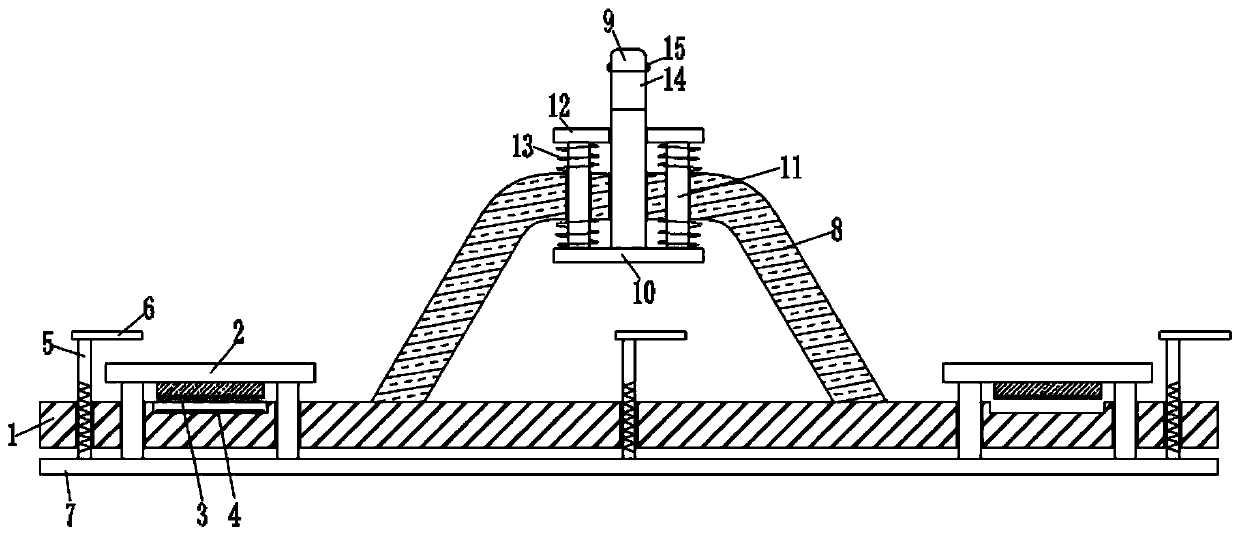

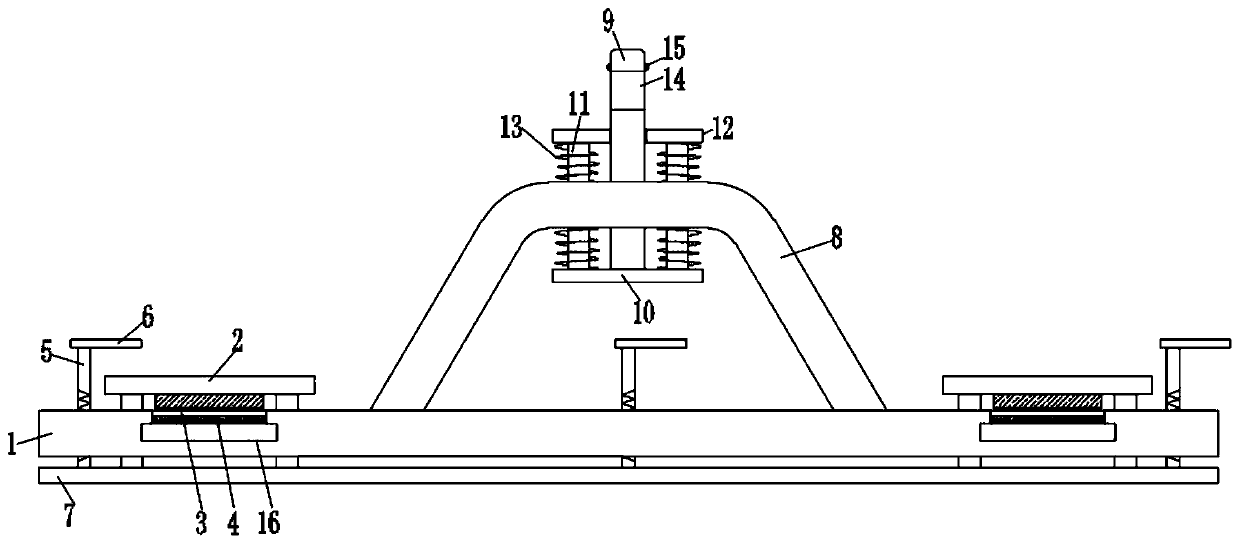

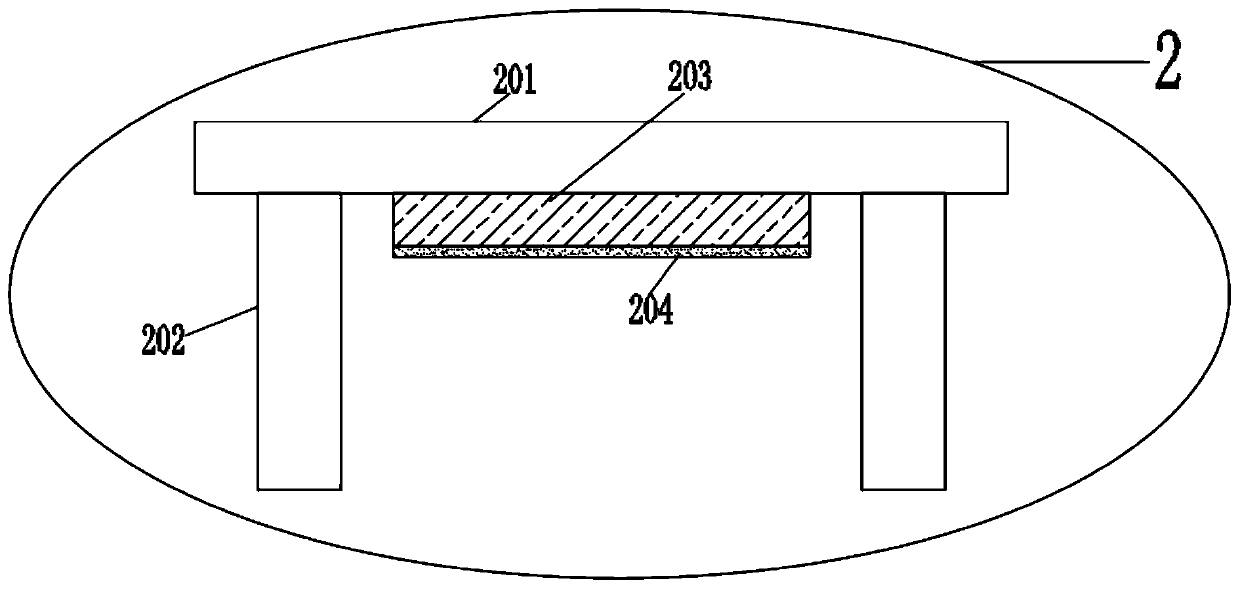

Hoisting protection device for assembling building

The invention discloses a hoisting protection device for assembling a building. The hoisting protection device comprises a first flat plate. Pressing devices are slidingly connected to the first flatplate, grooves are formed in the two sides of the top end of the first flat plate, first rubber cushions are mounted at the bottom ends of the grooves, the two sides of the first flat plate are in threaded connection with threaded rods, third flat plates are welded to the top ends of the threaded rods, a fourth flat plate is welded to the bottom ends of the threaded rods, a triangular beam is welded to the top end of the first flat plate, a lifting rod is slidingly connected to the triangular beam, a fifth flat plate is welded to the bottom end of the lifting rod, and first sliding rods are welded to the two sides of the top end of the fifth flat plate. It can be guaranteed that phenomenon that a lifting rope slides cannot happen in the lifting process of workpieces, the phenomenon that the workpieces slide down in the hoisting process is effectively reduced, the main lifting rope connected with a crane can be effectively protected against cracks or breakage, thus, the stability of a hoisting mechanism is protected, and high practicality is achieved.

Owner:CHINA CONSTR EIGHTH ENG DIV

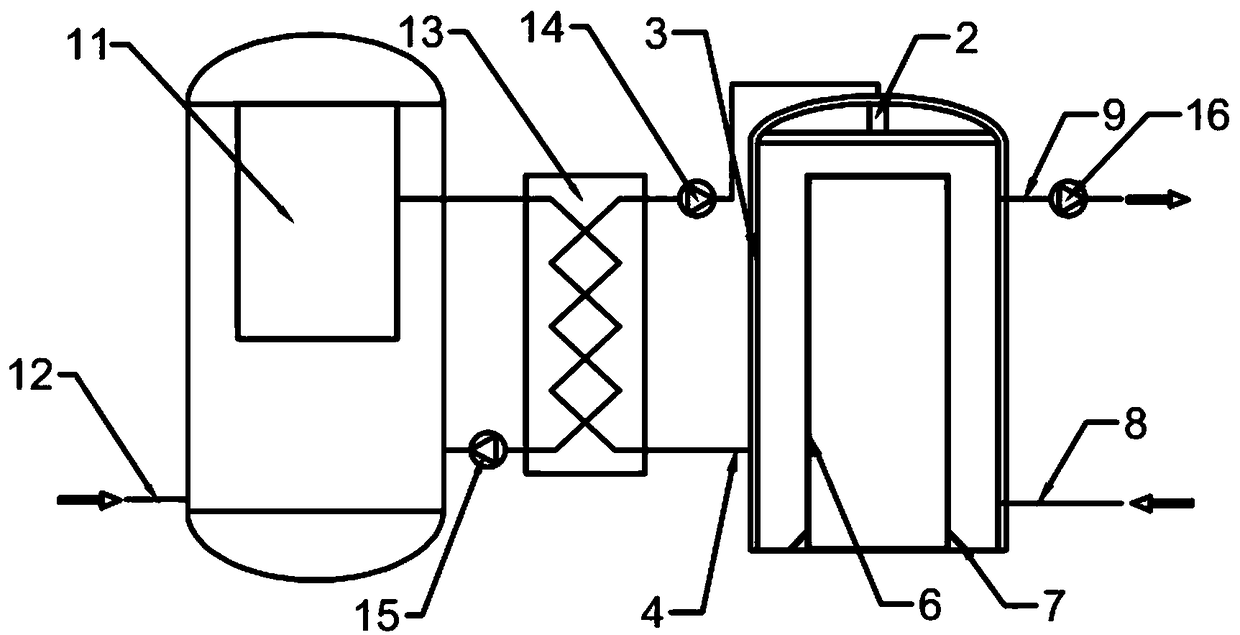

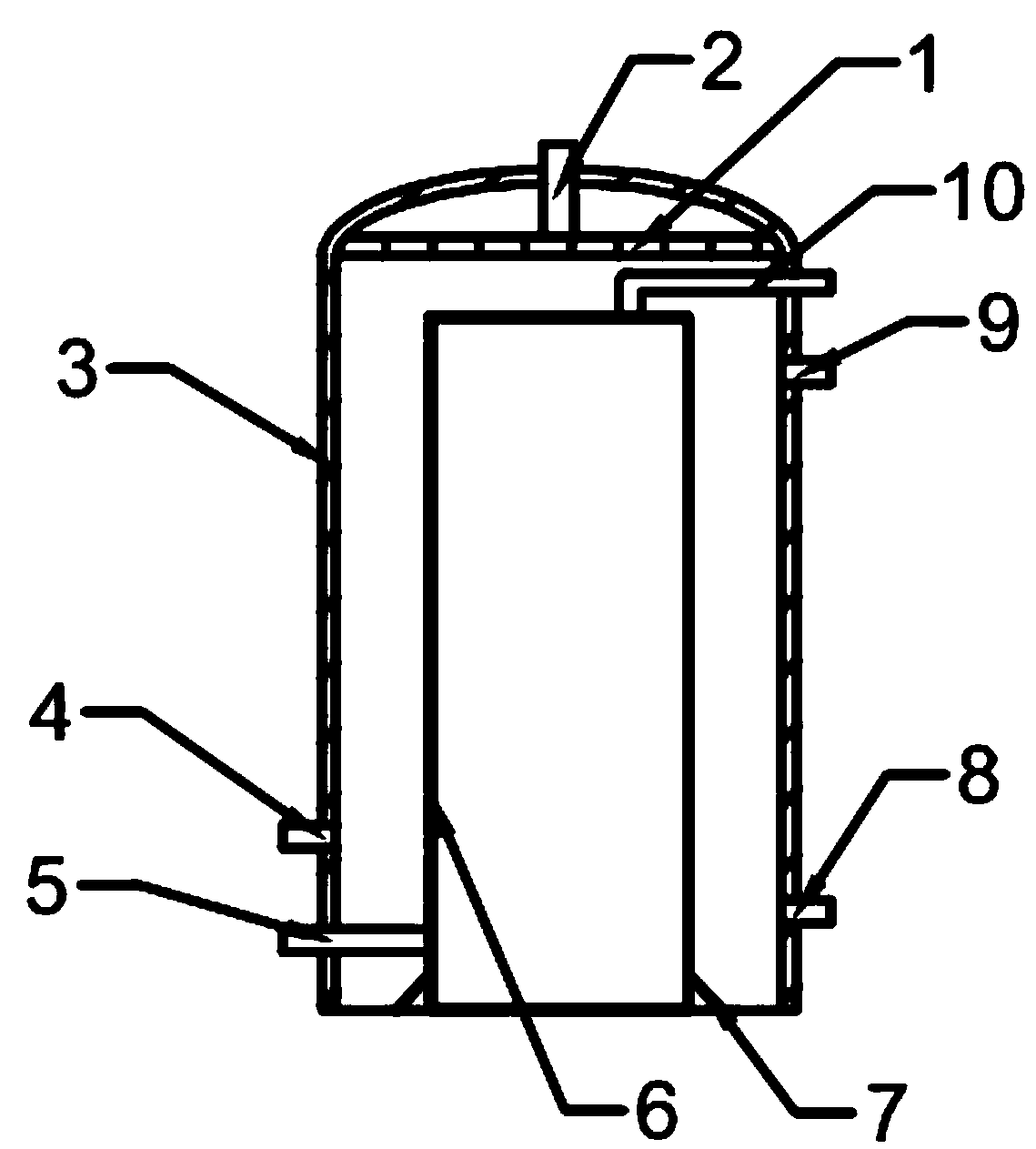

Heat storage type electrode boiler equipment

PendingCN108644750ASimple structureImprove heating efficiencyHeat storage plantsElectrode boilersEngineeringPhase-change material

The invention provides heat storage electrode boiler equipment. The heat storage electrode boiler equipment comprises an electrode boiler, a heat storage device and a heat exchanger. The heat storagedevice comprises a first heat storage tank and a second heat storage tank. The heat storage tank is used for filling a phase change material. The first heat storage tank is arranged in the second heatstorage tank. The second heat storage tank is provided with a first inlet, a first outlet, a second inlet and a second outlet. The first inlet and the first outlet are arranged on one side of the second heat storage tank. The second inlet and the second outlet are arranged on the other side of the second heat storage tank. The heat exchanger is used for exchanging heat of the electrode boiler andthe heat storage device. The first inlet and the first outlet communicate with the heat exchanger correspondingly. The second inlet and the second outlet communicate with heating equipment.

Owner:ZHEJIANG SHENGDA STEEL TOWER

Composite membrane for packing biological medicines

InactiveCN107757043AHas antibacterial propertiesImprove puncture strengthFlexible coversWrappersPolyurethane adhesiveEngineering

The invention discloses a composite film for biomedical packaging, which comprises a CPP layer, an aluminum foil layer, a PET layer, a polyurethane adhesive layer and an antibacterial layer, and is characterized in that: a CPP layer, an aluminum foil layer, a PET layer, and a polyurethane adhesive The agent layer and the antibacterial layer are successively connected together from top to bottom. The invention has the characteristics of simple structure, strong high temperature resistance, good antibacterial property and high strength, and can well meet the requirements of biomedical packaging.

Owner:成都汇鲤科技有限公司

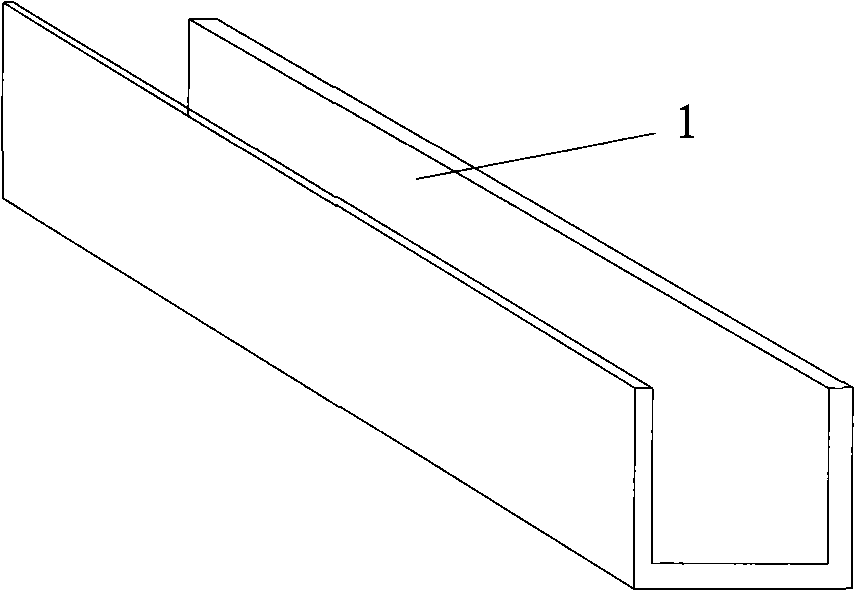

Blank dropping guide rail for soft magnetic ferrite communication products

InactiveCN101531027ANot prone to cracksNot prone to missing feetDischarging arrangementTransmission beltEngineering

The invention relates to a blank dropping guide rail for soft magnetic ferrite communication products, which is characterized by comprising a first end face with an upward opening, and a second end face provided with a downward opening twisted by 180 degrees at the back part of the first end face. A series of high-tech communication products such as the prior EOP, EPC, EFD, EP and the like can be transferred to a rotary press to mold; and the produces molded on a stand pass through the blank dropping guide rail for the soft magnetic ferrite communication products by means of personal inertia, then are conveyed down to a transmission belt, and finally are discharged by an operator. The blank dropping guide rail has the advantages that the products are not easy to crack and lose a corner, the equipment cost and manpower are reduced, and simultaneously the yield is increased.

Owner:SHANGHAI JISHUN MAGNETIC MATERIAL

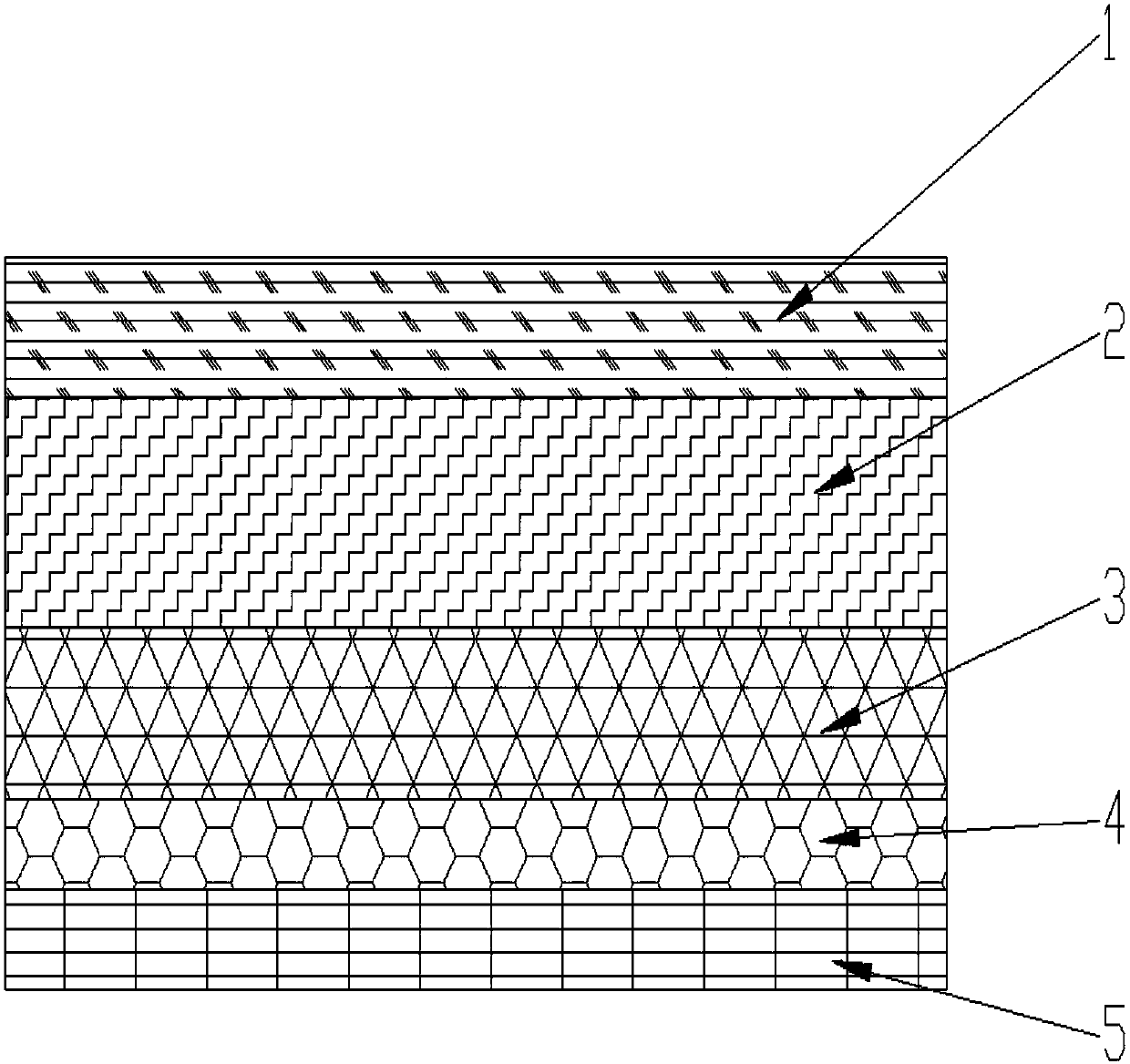

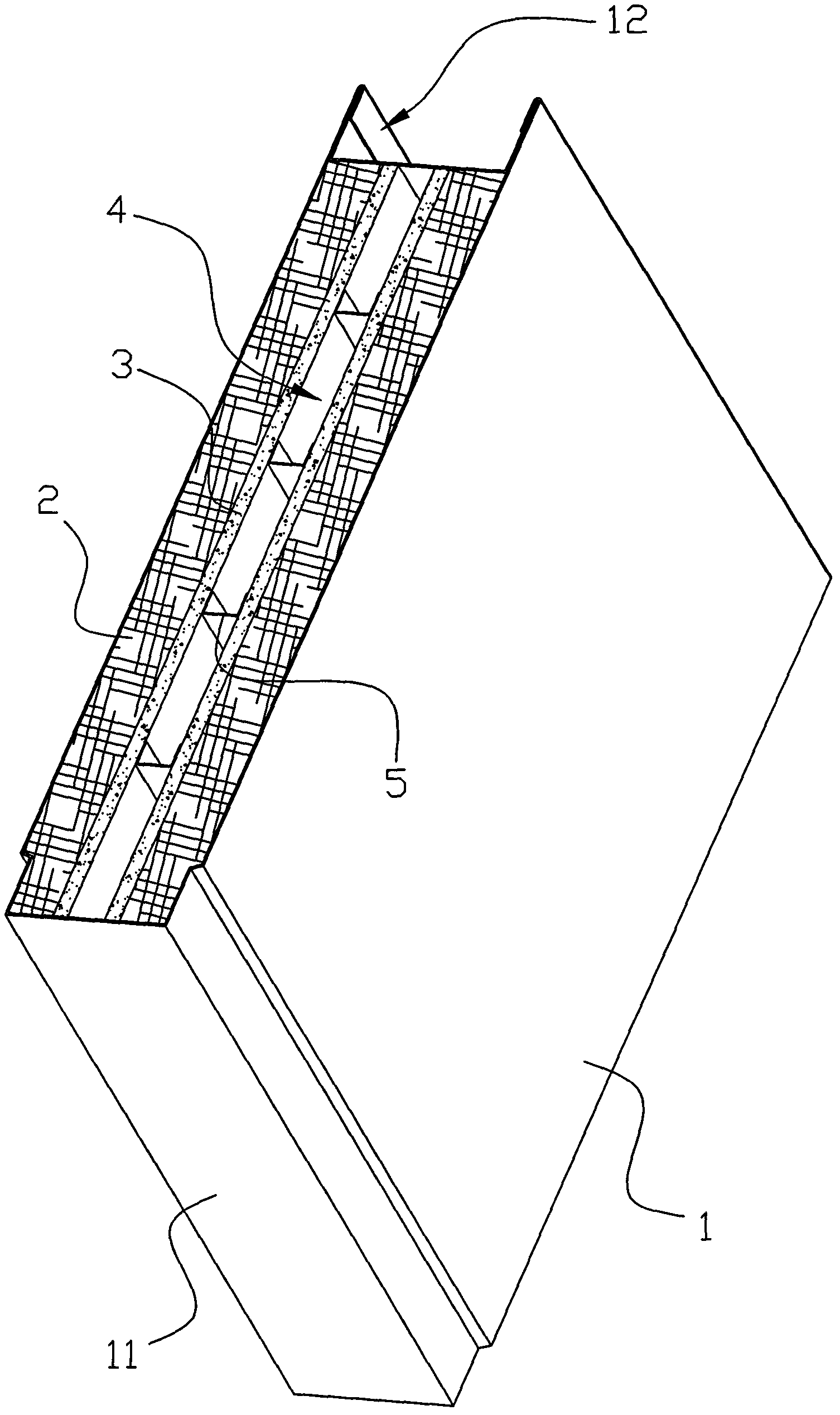

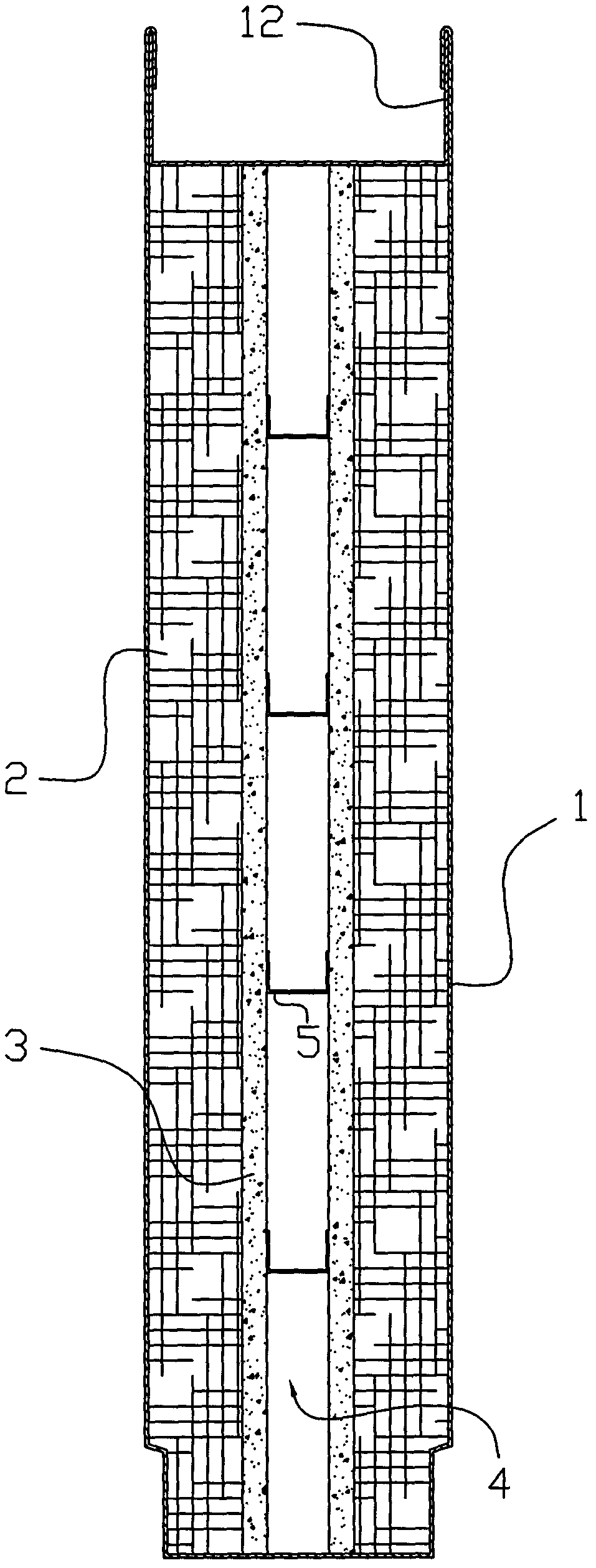

Decorative board with heat-insulating and sound-insulating performance

A decorative board with heat-insulating and sound-insulating performance comprises a board body which comprises an outer wrapping layer (1), rock wool board layers (2), carbonate silicon board layers (3) and a cavity layer (4). The carbonate silicon board layers (3) are arranged in the middle of the board body in a left-right interval manner, a spacing portion between the carbonate silicone board layers (3) on the left and on the right forms the cavity layer (4), the rock wool board layers (2) are arranged on the outer surfaces of the carbonate silicone board layers (3) on the left and on the right respectively , and the rock wool board layers (2) positioned on two sides of the cavity layer (4) are wrapped in the outer wrapping layer (1). The decorative board with the heat-insulating sound-insulating performance has the advantages that rock wool boards and carbonate silicon boards are adopted, so that the decorative board is light in weight, moistureproof, good in fireproof performance, convenient to construct, good in processing performance, capable of being sawed and nailed, less prone to warping and cracking, mothproof and free of heat generation, has good heat-insulating and sound-insulating performance and can meet using requirements of buildings and related decorative places. Especially due to good fireproof performance, under the circumstance of accidents, the decorative board can effectively prevent flame from spreading, so that good safety effect is realized.

Owner:舟山市金海舟船舶设备有限公司

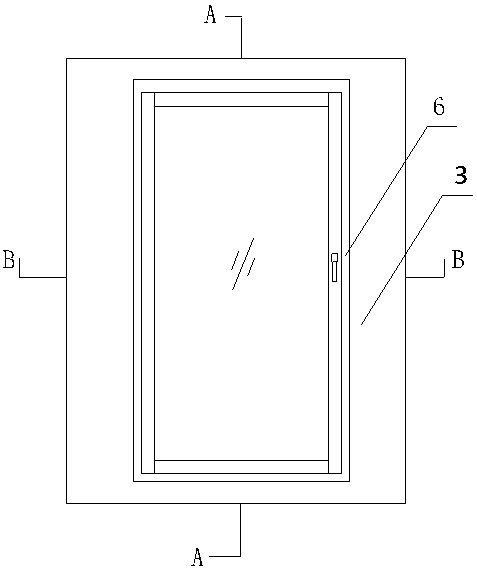

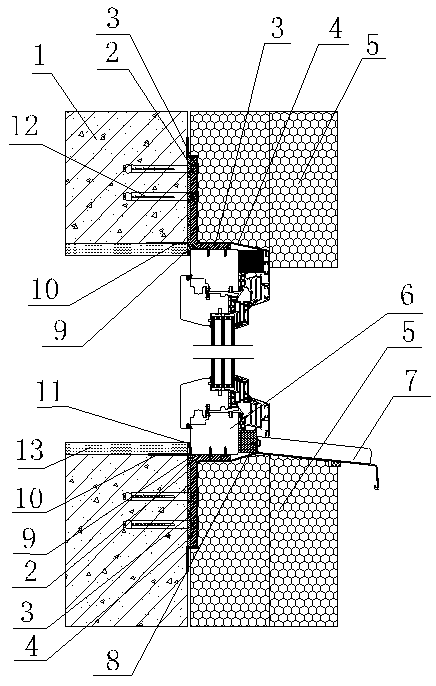

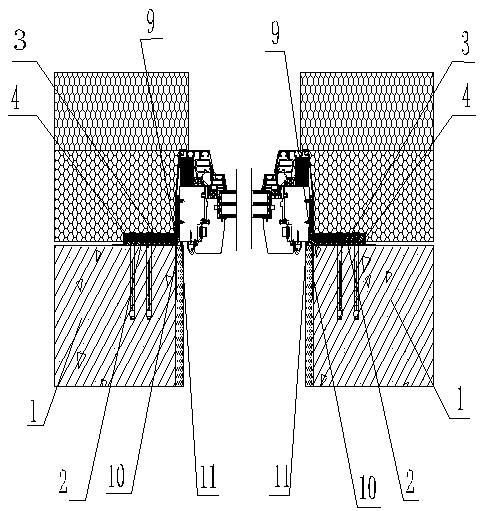

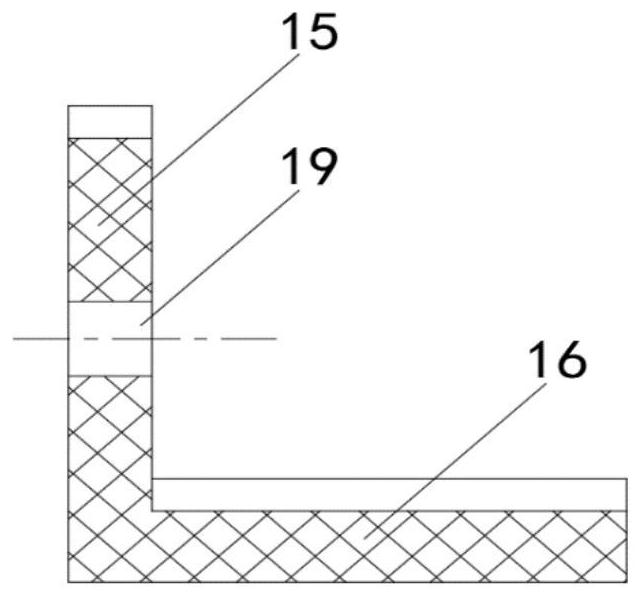

Installing method of passive externally hanging window of house

InactiveCN109707276ANot prone to cracksAvoid crackingFrame fasteningWindow/door framesThermal isolationPolystyrene

The invention discloses an installing method of a passive externally hanging window of a house. The method comprises the following steps of uniformly fixing long-wall ends of a plurality of L-shaped metal fixing plates onto a wall body at the left, right, upper and lower sides of a hole opening; bonding and fixing a circle of waterproof airtight film with most parts extending out of the indoor endonto the outer side of the indoor end of a window frame; fixing the short wall end of the L-shaped metal plate to the window frame; totally covering the outdoor end of the window frame by a waterproof ventilation film in a way of exceeding the edge; bonding the waterproof ventilation film totally covering the L-shaped metal fixing plate into the position of the L-shaped metal fixing plate; fixinga window sill onto the lower end of the outdoor end surface of the window frame at the lower end of the window; totally covering and fixing one layer or multiple layers of graphite polystyrene boardsonto the wall in the position of the waterproof ventilation film; unfolding the waterproof airtight film; pasting the waterproof airtight film onto the wall of the hole opening; and pasting and fixing a wall plate. Installed doors and windows cannot easily generate cracks; the airtightness and water tightness performance is good; seepage cannot easily occur; the heat insulation and thermal isolation performance is good; the heat transfer coefficient is low; and the installation requirements of the passive doors and windows of the house can be met.

Owner:HEBEI ORIENT SUNDAR WINDOW

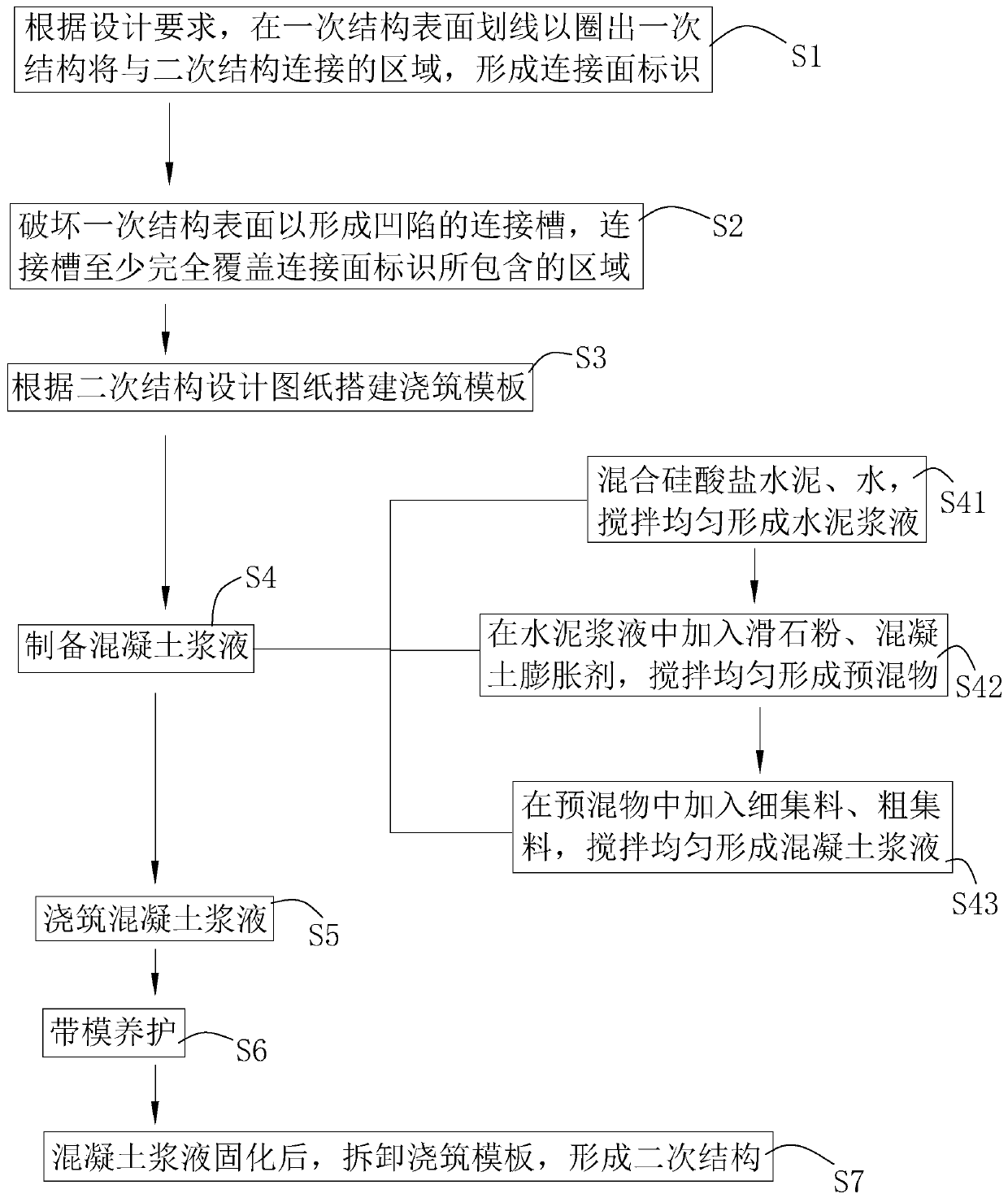

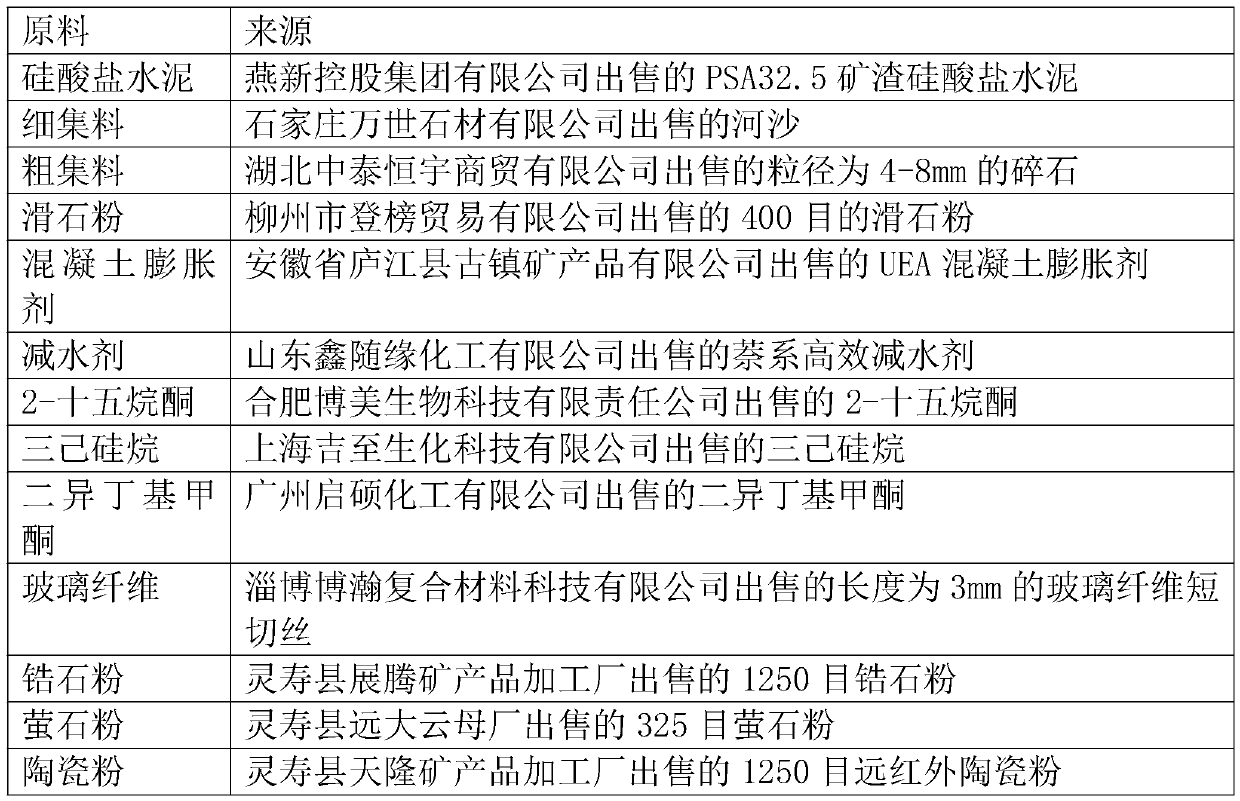

Secondary structure impervious leakproof construction method

ActiveCN111287485AClosely connectedPrevent leakageBuilding repairsPortland cementArchitectural engineering

The invention relates to the technical field of secondary structure construction, in particular to a secondary structure impervious leakproof construction method. The method comprises the following steps that S1, the surface of a primary structure is marked so that the area, to be connected with a secondary structure, of the primary structure can be circled, thereby forming a connecting surface mark; S2, the surface of the primary structure is damaged so that a dented connecting groove can be formed, wherein the connecting groove at least completely covers the area indicated by the connectingsurface mark; S3, a casting template is built according to secondary structure design drawings; S4, concrete slurry is prepared; S5, the concrete slurry is cast; S6, curing with the template is performed; and S7, the casting template is detached after the concrete slurry is solidified, and the secondary structure is formed. The concrete slurry comprises the following components including, by mass,100 parts of Portland cement, 300-350 parts of fine aggregate, 150-200 parts of coarse aggregate, 30-40 parts of talcum powder, 6-8 parts of a concrete expanding agent and 90-110 parts of water. Thesecondary structure impervious leakproof construction method has the effect that leakage is not prone to occurring in the position where the primary structure is connected with the secondary structure.

Owner:广州芳建工程建设集团有限公司

Refractory brick for hot air furnace

The invention discloses a refractory brick for a hot air furnace and relates to the technical field of refractory material manufacturing. The refractory brick consists of the following raw materials in parts by weight: 40-50 parts of alumina clinker, 15-20 parts of silicon carbide powder, 10-15 parts of silicon nitride powder, 20-30 parts of magnesia and 5-8 parts of paper pulp waste liquid; and the refractory brick for the hot air furnace is prepared by the steps of dosing, mixing, ageing, blank making, drying and firing. Compared with the prior art, the refractory brick disclosed by the invention has the advantages of corrosion resistance, high temperature resistance, strong compressive strength and good thermal shock resistance; and moreover, cracks do not appear easily in the using process of the refractory brick for the hot air furnace, and thus the service life is prolonged.

Owner:LIUZHOU YITING TRADE

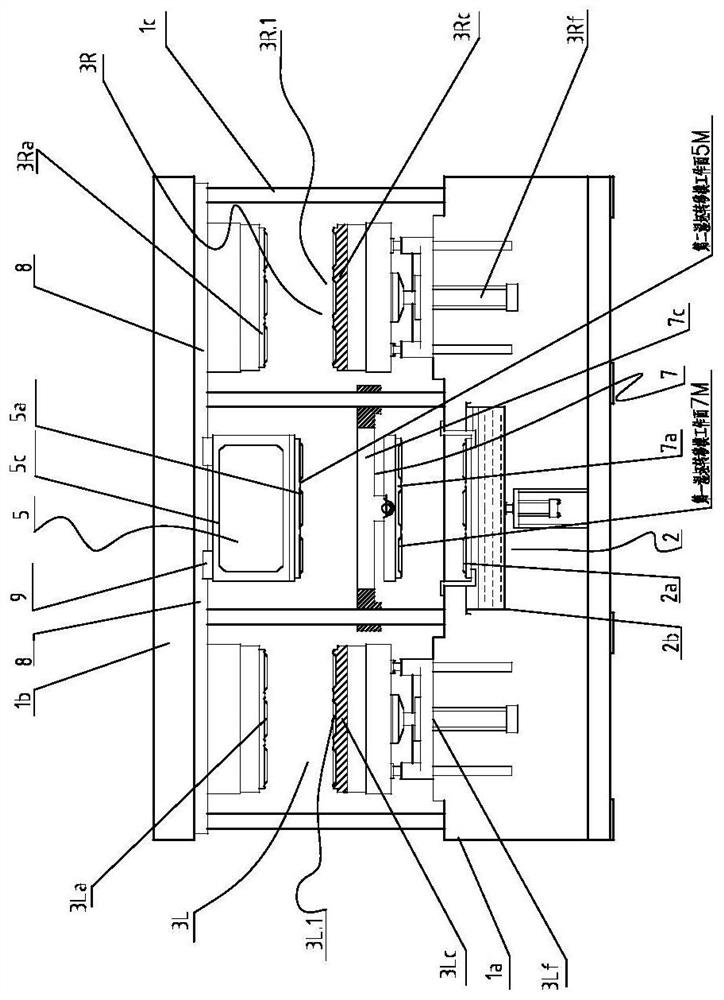

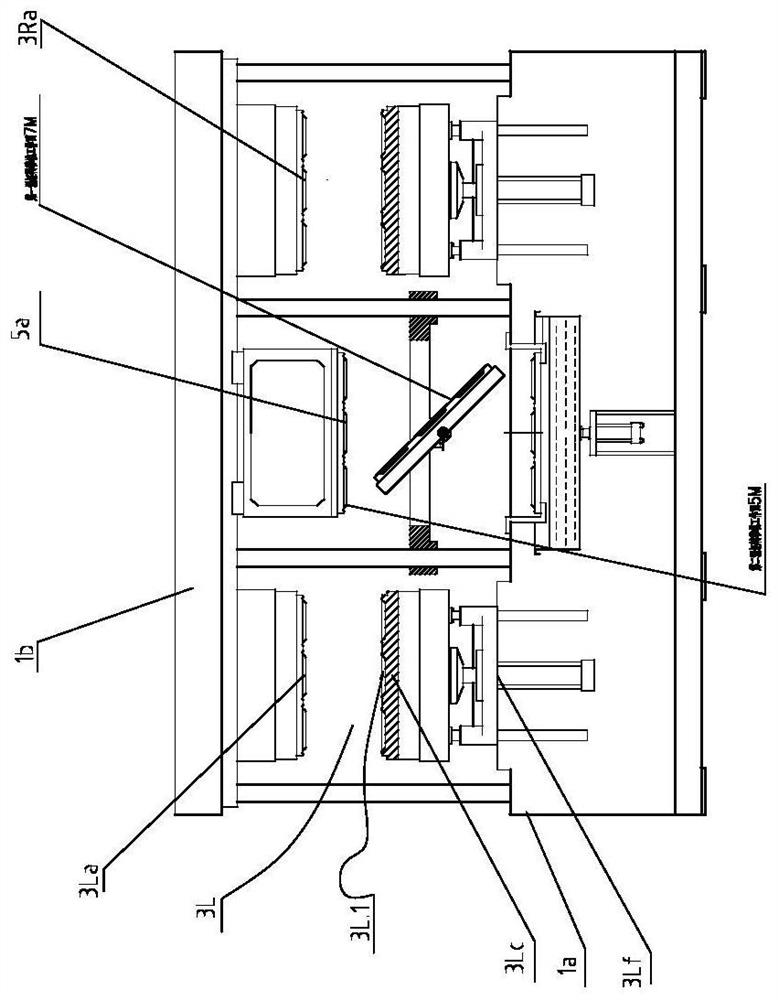

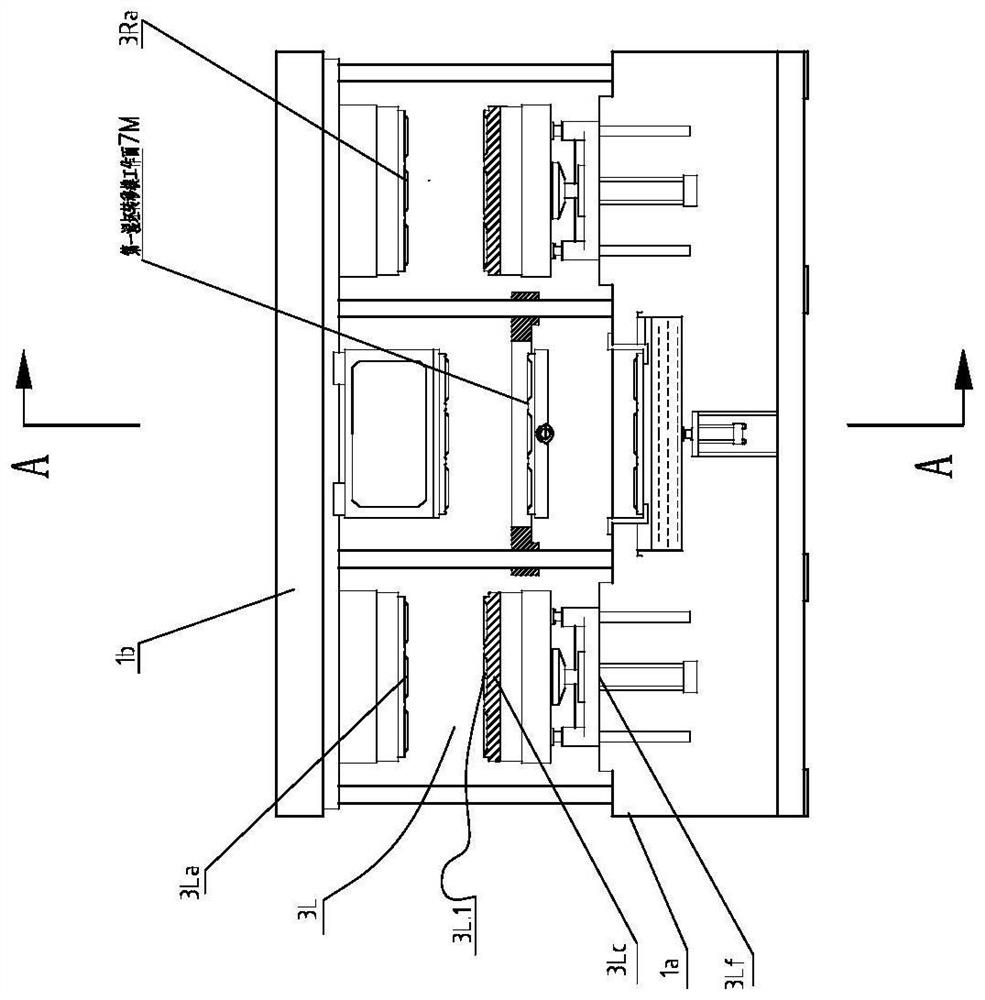

Manufacturing method of paper pulp molded product and paper pulp molding equipment for transferring wet blank by turner

PendingCN114059393AReduce the chance of fracturing and wrinklingEasy to processTextiles and paperConveyor partsMolded pulpPlant fibre

The invention relates to a method and a device for manufacturing a plant fiber product comprising paper pulp in a molding forming mode. According to the method and the device, the two surfaces of a plant fiber molded product have better effects. According to the technical scheme, the manufacturing method of the paper pulp molded product is carried out according to the following steps that after being manufactured in a suction filtration forming mold, a wet blank is transferred to a hot-pressing shaping device, and is subjected to hot-pressing, drying and shaping to manufacture the paper pulp molded product. The method is characterized in that in a transferring process, a first wet blank transferring device and a second wet blank transferring device are adopted to transfer a wet blank from a suction filtration forming mold to a hot-pressing shaping device, wherein the first wet blank transferring device is used for extracting the wet blank from the suction filtration forming mold and transferring the wet blank to the second wet blank transferring device, then the second wet blank transferring device is used for transferring the wet blank to the hot-pressing shaping device, the number of the hot-pressing shaping devices can be one or more, and the multiple hot-pressing shaping devices comprise a left hot-pressing shaping device and a right hot-pressing shaping device.

Owner:郑天波

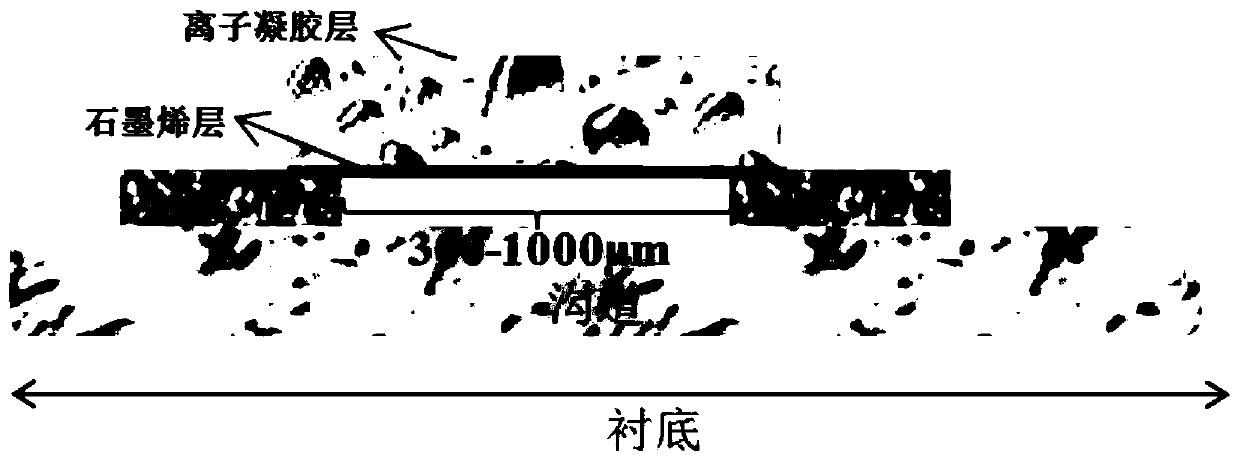

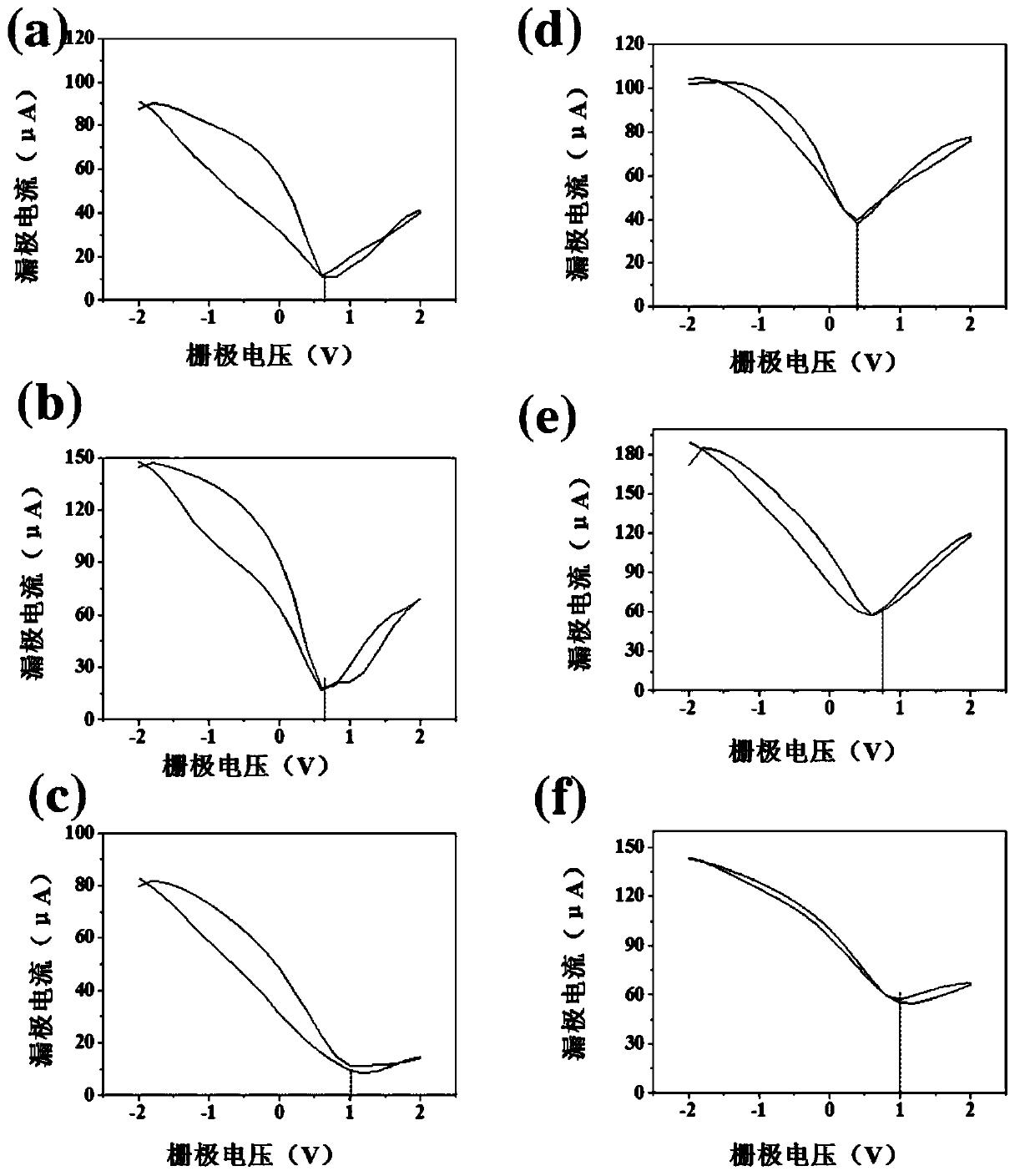

Application of ion gel in graphene transfer and graphene transistor fabrication, graphene transistor and fabrication method of graphene transistor

ActiveCN110600538AReduce usageSolve the capture trapSemiconductor/solid-state device manufacturingSemiconductor devicesHysteresisGate dielectric

The invention relates to the technical field of graphene, and discloses application of ion gel in graphene transfer and graphene transistor fabrication, a graphene transistor and a fabrication methodof the graphene transistor. An ion liquid and an initiator are contained in the ion gel, and the ion liquid comprises 1-ethyl-3-methylimidazole-bi (trifluoromethanesulfonic acid) imidazole and a polyethylene glycol diacrylate monomer. By using the ion gel to do graphene transfer, the ion gel is not needed to be removed, capture trap formed by PMMA residue on graphene is solved, the cost is reduced, and a poisonous solvent is prevented from being used; and the ion gel is large in elastic modulus, and a gap is difficult to generate. Moreover, in the graphene transistor fabricated by the method,the ion gel is directly used as a gate dielectric layer, fabrication of the gate dielectric layer is not needed to be independently performed, and the process is simplified; and in the obtained graphene transistor, a threshold voltage and hysteresis both are reduced, the source current is increased under the same gate voltage, and the mobFabrication method of array substrate and array substrateility is improved.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

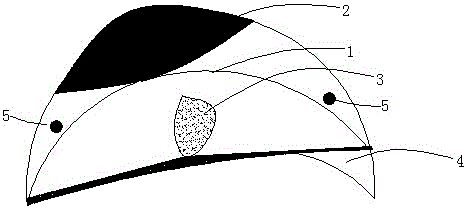

Intelligent anti-impact safety helmet

InactiveCN106235489AImprove impact resistanceWill not harmHatsHeadwear capsEngineeringElectrical and Electronics engineering

The invention discloses an intelligent anti-impact safety helmet and belongs to the field of safety supplies. The purpose is to solve the problems that the safety performance and anti-noise performance of an existing safety helmet are not good enough. The intelligent anti-impact safety helmet comprises a safety helmet body and a buffering device located at the top of the safety helmet body. Anti-noise devices are arranged on the inner sides of the two sides of the safety helmet body respectively, and provided with buckles. Clamping grooves or clamping hooks are formed in / arranged on the inner wall or the outer wall of the safety helmet body. The buckles on the anti-noise devices are matched with the clamping grooves or the clamping hooks on the safety helmet body to fix the anti-noise devices, cuboid grooves are formed in the inner walls of the anti-noise devices, the inner walls of the grooves are covered with layers of sponge, a neck-protecting device is arranged on the rear side of the safety helmet body, safety warning lights are arranged on the outer wall of the safety helmet body, and a solar panel is arranged on the outer wall of the safety helmet body and used for supplying power to the safety warning lights.

Owner:CHENGDU 90 DEGREE IND PROD DESIGN CO LTD

Method for constructing composite lightweight batten walls

The invention discloses a method for constructing composite lightweight batten walls. The composite lightweight batten walls comprise a plurality of wallboards. The method includes steps of smearing mortar at the edges of the wallboards; shifting the multiple wallboards with the smeared mortar to assembling locations and assembling the wallboards; tilting the wallboards by the aid of prying rollers until the mortar is squeezed from the tops of the wallboards and then filling spaces between the wallboards and the ground with wooden wedges; knocking steel nails in spaces between every two adjacent wallboards in oblique downward directions; fixing the wallboards and beams by the aid of connecting reinforcing steel bars, fixing the wallboards and columns by the aid of connecting reinforcing steel bars, filling assembly seams between the wallboards and the beams with mortar, and filling assembly seams between the wallboards and the columns with mortar; taking out the wooden wedges after therequirements on the strength of the mortar are met, and then fully filling gaps between the wallboards and the ground with mortar; sealing board joints between the various wallboards by anti-crackingstrips and then troweling the board joints by mortar. The method has the advantages that the method includes simple processes, and the construction quality and efficiency can be effectively improved.

Owner:SHANGHAI BAOYE GRP CORP

Soft soil curing agent and preparation method thereof

ActiveCN112159164ARealize in-situ harmless consumptionReduce manufacturing costSolid waste managementGlass fiberAlcohol

The invention discloses a soft soil curing agent and a preparation method thereof. The soft soil curing agent comprises activated tailings, alcohol compounds, glass fibers, inorganic acid liquid, water, liquid resin and the like, and the activated tailings are obtained by calcining and activating tailings and an alkaline activation excitant. The soft soil curing agent is applied to soil solidification, and flying dust pollution is reduced; meanwhile, the compressive strength and breaking strength of a solidified body can be obviously improved, the solidified soil is not prone to cracking, theheavy metal stabilizing effect is good, construction is easy, the production cost is low, and in-situ harmless absorption of industrial tailings is effectively achieved, and the green production requirement of treating waste with waste is met.

Owner:肇庆市武大环境技术研究院

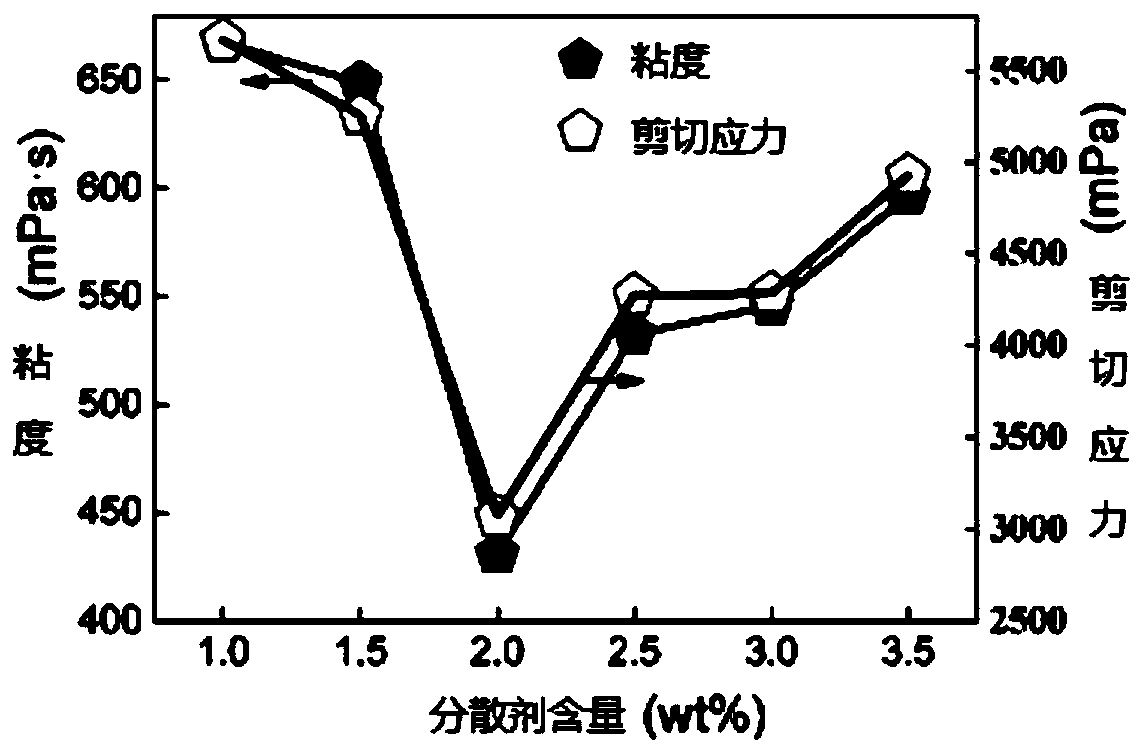

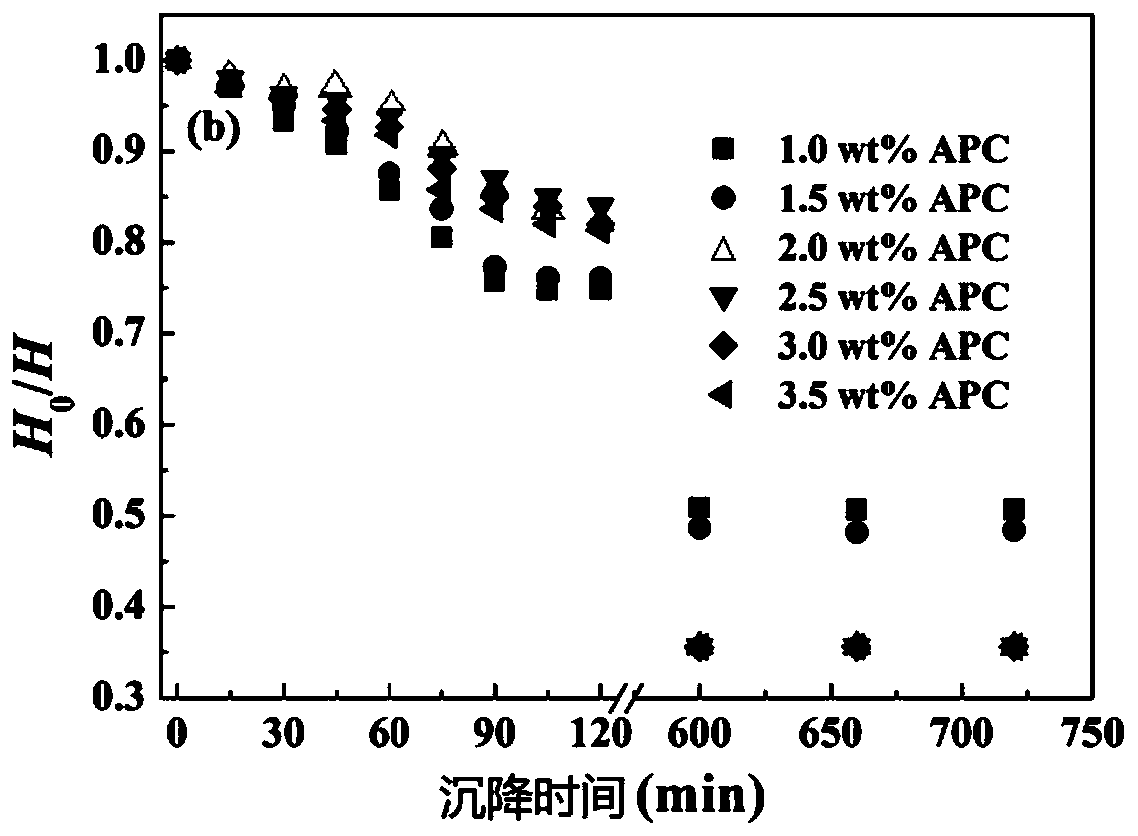

Water-based ceramic slurry, preparation method of ceramic film and chip multilayer ceramic capacitor

InactiveCN111484324AImprove rheologyQuality improvementFixed capacitor dielectricCeramic shaping apparatusBarium titanateCeramic capacitor

The invention belongs to the technical field of ceramic capacitors, and particularly relates to water-based ceramic slurry, a preparation method of a ceramic film and a chip multilayer ceramic capacitor. The water-based ceramic slurry provided by the invention comprises barium titanate powder, polycarboxylate, polyacrylate, phthalate, an antifoaming agent and water according to a specific weight part ratio, wherein water is used as a solvent; polycarboxylate is used as a dispersing agent; polyacrylate is used as a binding agent; phthalate is used as a plasticizer; the components have a synergistic effect, so that the water-based ceramic slurry is endowed with good rheological property, a ceramic film formed by tape casting of the water-based ceramic slurry is smooth and compact in surfaceand good in mechanical property, surface defects such as cracks do not easily occur, and the quality of a ceramic film layer is greatly improved.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

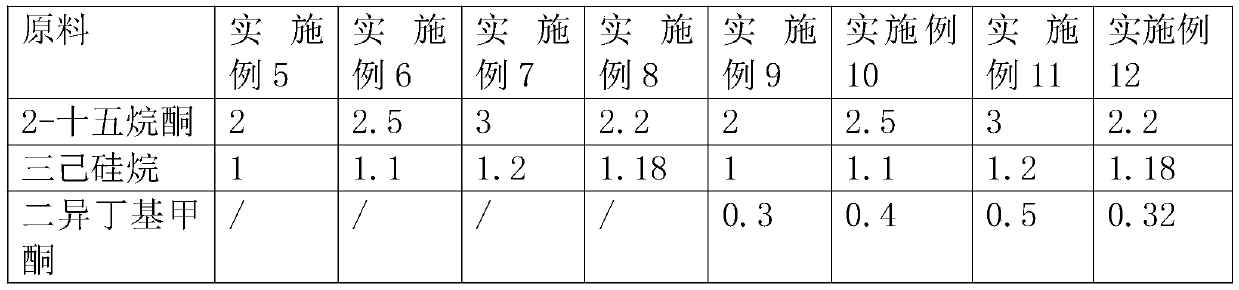

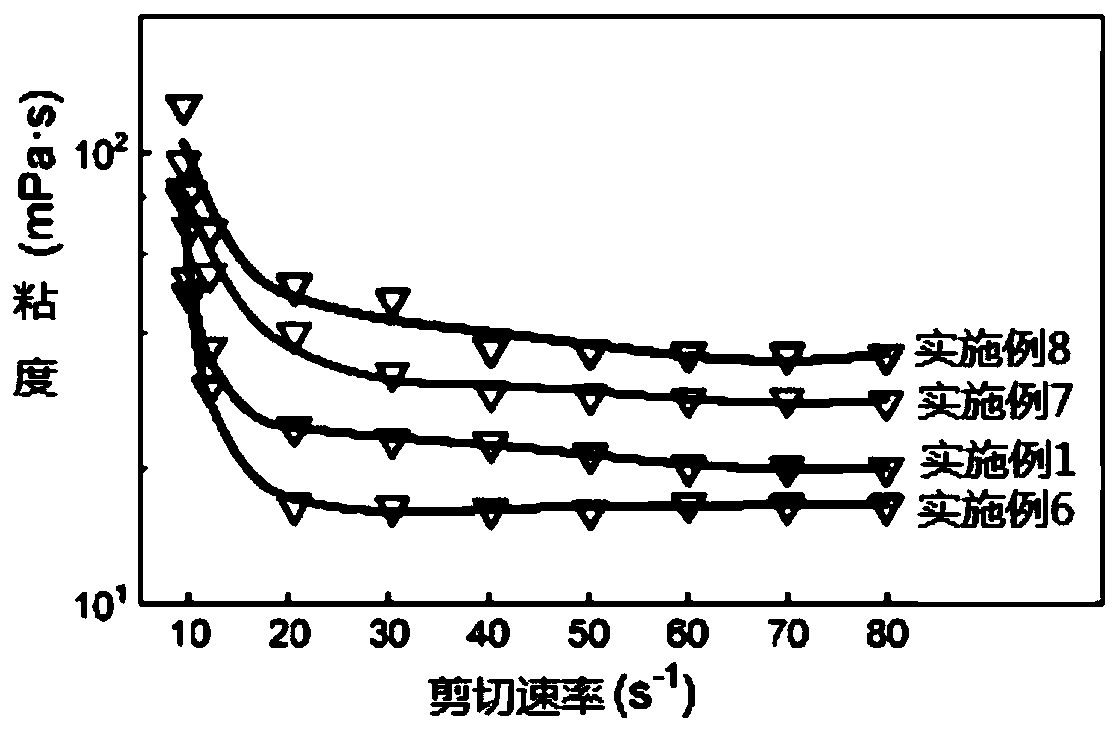

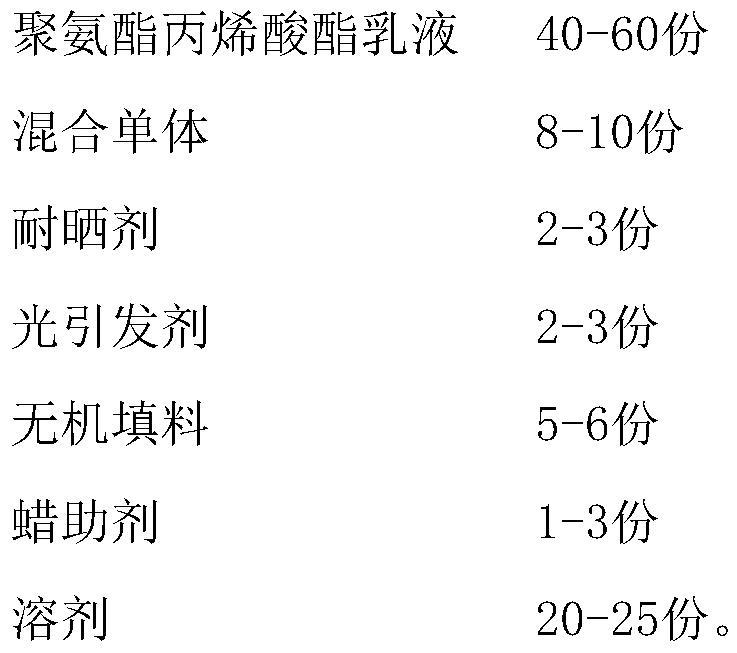

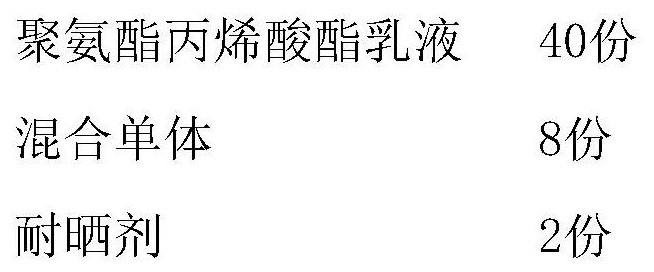

High-sun-resistance printing ink for impregnated paper and preparation method of high-sun-resistance printing ink

The invention relates to the technical field of printing ink, in particular to high-sun-resistance printing ink for impregnated paper and a preparation method of the high-sun-resistance printing ink.The high-sun-resistance printing ink for the impregnated paper is prepared from the following raw materials in parts by weight: 40-60 parts of a urethane acrylate emulsion, 8-10 parts of mixed monomer, 2-3 parts of a sun-resistant agent, 2-3 parts of photoinitiator, 5-6 parts of inorganic filler, 1-3 parts of a wax additive and 20-25 parts of a solvent. The high-sun-resistance printing ink for theimpregnated paper is good in adhesive force and can be stably attached to the surface of the impregnated paper, and an ink layer formed after painting is sun-resistant, not prone to yellowing and aging and good in stability. The adopted urethane acrylate emulsion contains an acrylic functional group and a polyurethane component, is good in adhesion, can be stably attached to the stable surface ofimpregnated paper, and is fast to cure, and meanwhile, the contained polyurethane component can enable the ink to have relatively good flexibility and peel strength after being cured.

Owner:GUANGDONG FUMEI NEW MATERIAL TECH CO LTD

Glue for bonding corrugated boards and preparation method and application method thereof

InactiveCN108676521ANot prone to cracksLess likely to burstNon-macromolecular adhesive additivesStarch adhesivesFiberSlag

The invention relates to a glue and a production technology thereof, and specifically relates to a glue for bonding corrugated boards and a preparation method and application method thereof. The gluefor bonding corrugated boards is characterized by comprises a component (A) and a component (B). The component (A) comprises following components in parts by weight: 2 to 3 parts of starch, 10 to 20 parts of water, 0.3 to 0.5 part of caustic soda, 1 to 2 parts of borax, and 0.5 to 0.7 part of water retainer. The component (B) comprises following components in parts by weight: 3 to 5 parts of starch, 25 to 30 parts of water, 0.2 to 0.7 part of caustic soda, 2 to 4 parts of borax, 1 to 3 parts of corrosion inhibitor, 3 to 4 parts of fiber, and 3 to 4 parts of metal slag. The glue has good permeability and high viscosity, and is capable of improving the strength of bonded corrugated boards.

Owner:浙江美森包装股份有限公司

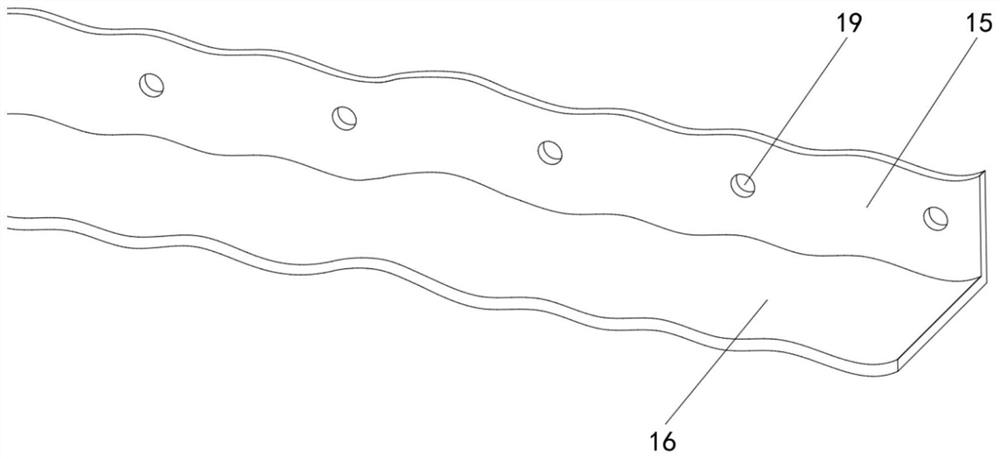

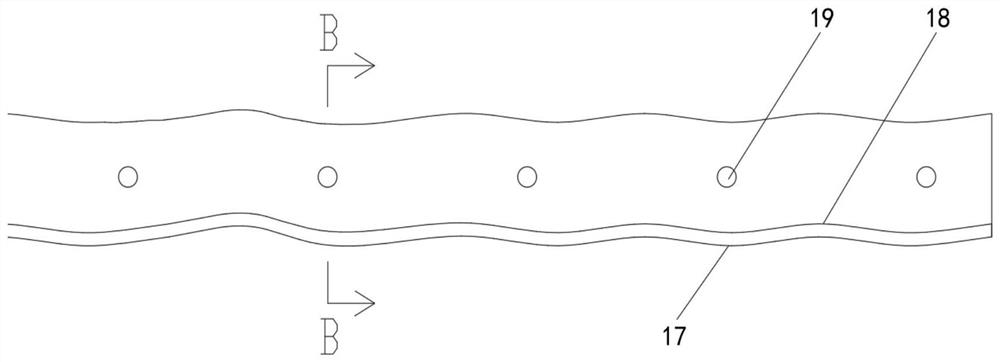

Building wall surface rammed earth imitating manufacturing technology and auxiliary lining curve mold strip thereof

ActiveCN113802844AWon't fall offImprove plasticityCovering/liningsWallsManufacturing technologyRammed earth

The invention relates to a rammed earth imitating manufacturing technology and an auxiliary material thereof, in particular to a building wall rammed earth imitating manufacturing technology and an auxiliary lining curve mold strip thereof. The auxiliary lining curve mold strip for building wall surface rammed earth imitating manufacturing is characterized by comprising a fixing plate, a curve plate, curve wave troughs, curve wave crests and fixing mounting holes; the fixing plate and the curve plate are combined to form an L-shaped structural angle section; the curve wave troughs and the curve wave crests are arranged on the curve plate; and a fixed mounting hole is formed in the fixing plate. The auxiliary lining curve mold strip has the beneficial effects that the auxiliary lining curve mold strip is firmly connected with a wall surface, is lined on the wall surface in an auxiliary mode, is beneficial to curve forming of rammed earth imitating marl, supports the rammed earth imitating marl, and is beneficial to stable forming without falling off; and the production efficiency is improved, the production cost is reduced, energy and labor are saved, low carbon and environmental protection are achieved, the environment is beautified, and the society is harmonious.

Owner:浙江异涂新材料有限公司

Semiconductor structure and formation method therefor

ActiveCN106952830AReduce contentDangling keysSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureDangling bond

The present invention provides a semiconductor structure and a method for forming the same. The method for forming the semiconductor structure includes: providing a substrate; forming a spacer on the substrate, and the spacer includes a first surface opposite to the substrate , a second face opposite to the first face, and a side face between the first face and the second face, where the second face meets the side face as an edge; a hydrogen-containing reactant is used to form a cover covering the substrate and the second face The dielectric layer of the edge, the dielectric layer contains silicon-hydrogen bonds, and the dielectric layer includes: a first dielectric layer covering the substrate and the edge, and the silicon-hydrogen bonds in the first dielectric layer occupy The mole percentage is less than 2.8%. Wherein, by reducing the content of silicon-hydrogen bonds in the first silicon nitride layer, the first silicon nitride layer is not easy to generate dangling bonds, thereby increasing the stability of the silicon nitride layer; in addition, the low silicon-hydrogen bond content The warpage and deformation of the silicon nitride film is small under external influence, so the silicon nitride layer is not easy to produce cracks.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com