Electrode and manufacture method thereof

An electrode manufacturing and electrode technology, applied in the field of electrode sheets and their manufacturing, can solve the problems of low battery capacity, easy short circuit, and large fluctuation of battery internal resistance, so as to ensure battery capacity, improve flexibility, and avoid low battery capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

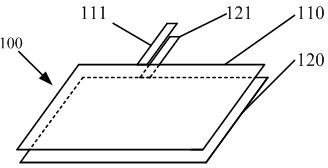

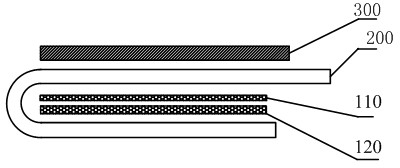

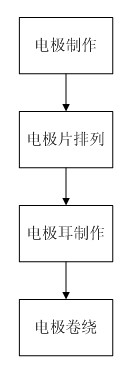

[0039] A specific embodiment: making capacity is the AA Ni-MH battery of 2500mAh, press image 3 The process shown produces two electrode sheets 110 and 120 with thicknesses of 0.3mm and 0.4mm respectively (in the prior art, AA2500mAh batteries are produced, and the thickness of a single nickel electrode is 0.7mm), these two electrode sheets The total amount of filled positive electrode active materials of 110 and 120 is equal to the amount of filled positive electrode active materials used to make AA2500mAh battery monolithic nickel electrodes in the prior art. Under the condition that the surface density of foamed nickel and the length and width of the electrode sheet are fixed, compared with the prior art, the amount of positive electrode active material filled in the electrode sheets 110 and 120 is smaller than that of a single nickel electrode, so the two made The flexibility of electrode sheet 110 and 120 will be very good, then, according to figure 2 After the relati...

Embodiment

[0041] Embodiment: adopt the present invention to make the battery of 10000 AA2500mAh

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com