Building wall surface rammed earth imitating manufacturing technology and auxiliary lining curve mold strip thereof

A curve and wall technology, applied in the field of imitation rammed earth production technology and its accessories, can solve the problems of difficult to meet the design requirements and aesthetics, poor imitation rammed earth production effect, easy to fall off the mud and other problems, to achieve the effect of pulling Good, firm bonding, not easy to crack effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

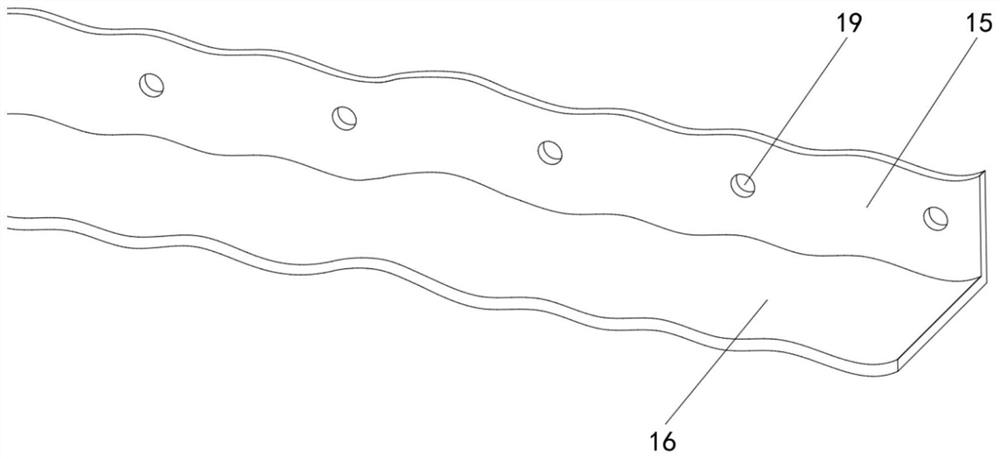

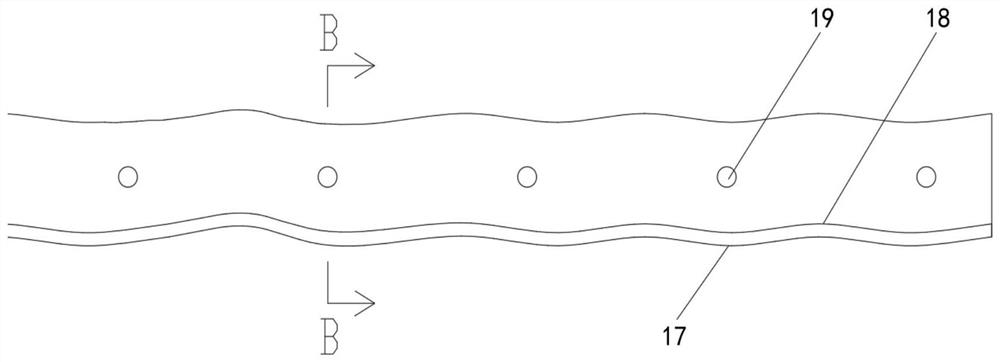

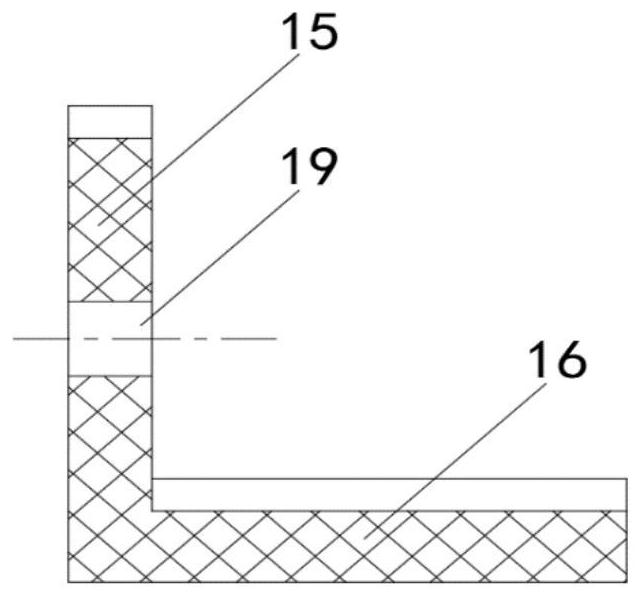

[0039] exist figure 1 , figure 2 , image 3 ,, The one made with rammed earth building wall imitation curve mold liner strip includes a fixed plate (15), the curved plates (16), curved troughs (17) of peaks (18), fixing the mounting hole ( 19); the fixing plate (15) and the curved plates (16) are combined into L-shaped structural angle member; said curved plate (16) provided with the trough profile (17) of peaks (18); the fixing plate ( mounting a fixing hole (19) 15).

[0040] exist figure 1 , figure 2 , image 3 In the fixing plate (15) and the curved plates (16) consisting of an L-shaped angle bar; the fixing plate (15) is provided with a fixed mounting hole (19); fixing said plate (15) and the curved plates (16) perpendicular to each other; the height of the fixing plate (15) of 10-45mm, wall thickness 0.5 to 5 mm; diameter of the fixing mounting hole (19) in 1-5mm, fixing the mounting hole (19) fixedly mounted pitches of the holes (19) is 100-600mm; the width of the curved plat...

Embodiment 2

[0063] exist figure 1 , figure 2 , image 3 ,, The one made with rammed earth building wall imitation curve mold liner strip includes a fixed plate (15), the curved plates (16), curved troughs (17) of peaks (18), fixing the mounting hole ( 19); the fixing plate (15) and the curved plates (16) are combined into L-shaped structural angle member; said curved plate (16) provided with the trough profile (17) of peaks (18); the fixing plate ( mounting a fixing hole (19) 15).

[0064] exist figure 1 , figure 2 , image 3 In the fixing plate (15) and the curved plates (16) consisting of an L-shaped angle bar; the fixing plate (15) is provided with a fixed mounting hole (19); fixing said plate (15) and the curved plates (16) perpendicular to each other; the height of the fixing plate (15) of 5-25mm, wall thickness 0.3-3mm; fixing the diameter of the mounting hole (19) in 1-6mm, fixing the mounting hole (19) fixedly mounted pitches of the holes (19) is 100-500mm; the width of the curved plate...

Embodiment 3

[0086] exist figure 1 , figure 2 , image 3 ,, The one made with rammed earth building wall imitation curve mold liner strip includes a fixed plate (15), the curved plates (16), curved troughs (17) of peaks (18), fixing the mounting hole ( 19); the fixing plate (15) and the curved plates (16) are combined into L-shaped structural angle member; said curved plate (16) provided with the trough profile (17) of peaks (18); the fixing plate ( mounting a fixing hole (19) 15).

[0087] exist figure 1 , figure 2 , image 3 In the fixing plate (15) and the curved plates (16) consisting of an L-shaped angle bar; the fixing plate (15) is provided with a fixed mounting hole (19); fixing said plate (15) and the curved plates (16) perpendicular to each other; the height of the fixing plate (15) of 15-65mm, 1-6mm in thickness; the diameter of the fixing mounting hole (19) in 2-8mm, fixing the mounting hole (19) fixedly mounted pitches of the holes (19) is 200-800mm; the width of the curved plate (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com