Patents

Literature

231 results about "Earth materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Earth materials include minerals, rocks, soil and water. These are the naturally occurring materials found on Earth that constitute the raw materials upon which our global society exists. Earth materials are vital resources that provide the basic components for life, agriculture and industry. Earth materials can also include metals and precious rocks.

NOx Storage Materials and Traps Resistant to Thermal Aging

InactiveUS20080120970A1Promote lowerExhaust apparatusDispersed particle separationChemical conditionEarth materials

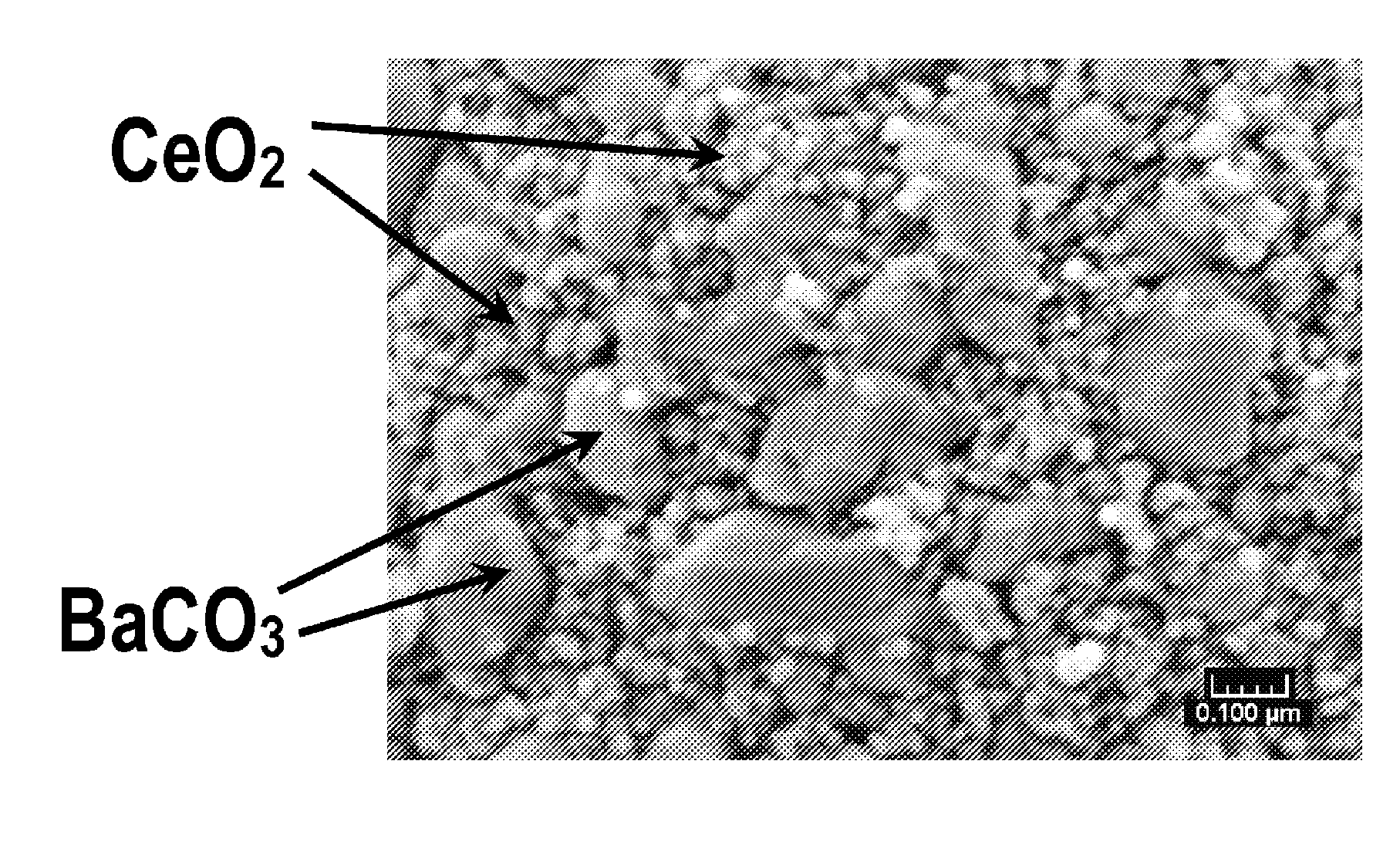

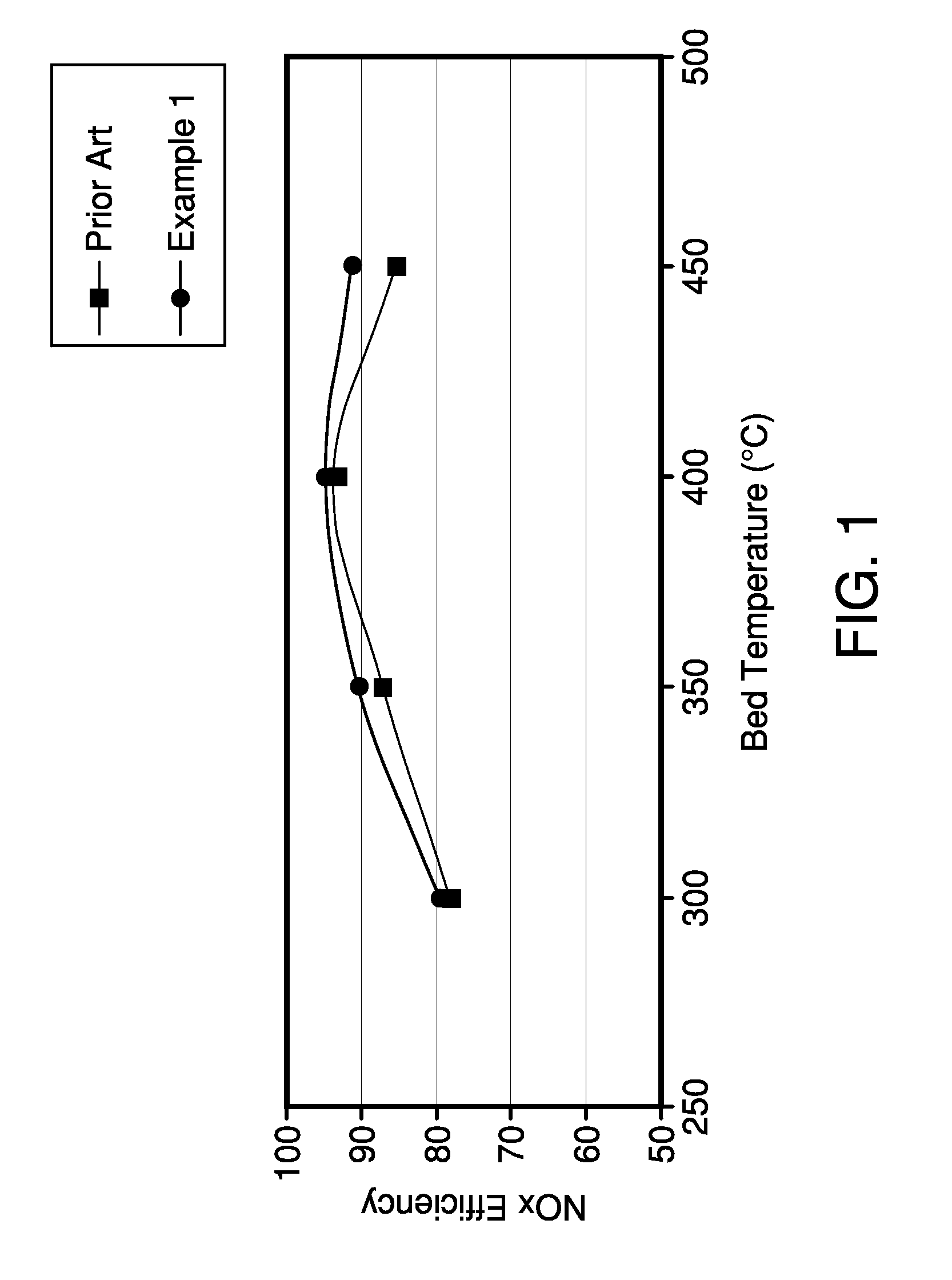

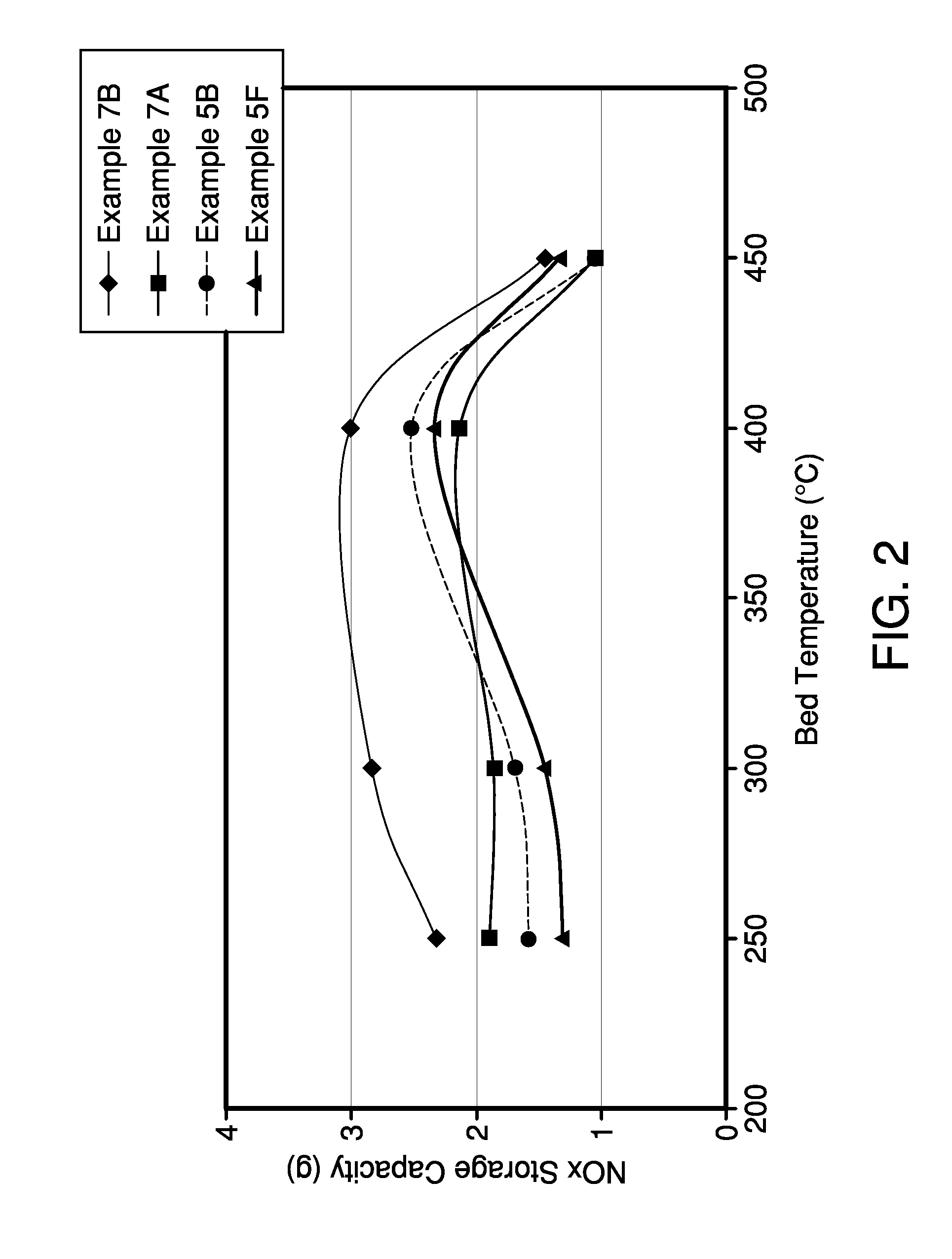

Nitrogen oxide storage materials and methods of manufacturing nitrogen oxide storage materials are disclosed. The nitrogen oxide storage materials can be used to manufacture catalytic trap disposed in an exhaust passage of an internal combustion engine which is operated periodically between lean and stoichiometric or rich conditions, for abatement of NOx in an exhaust gas stream which is generated by the engine. In one embodiment, the nitrogen oxide storage material comprises alkaline earth material supported on ceria particles having a crystallite size of between about 10 and 20 nm and the alkaline earth oxide having a crystallite size of between about 20-40 nm.

Owner:BASF CATALYSTS LLC

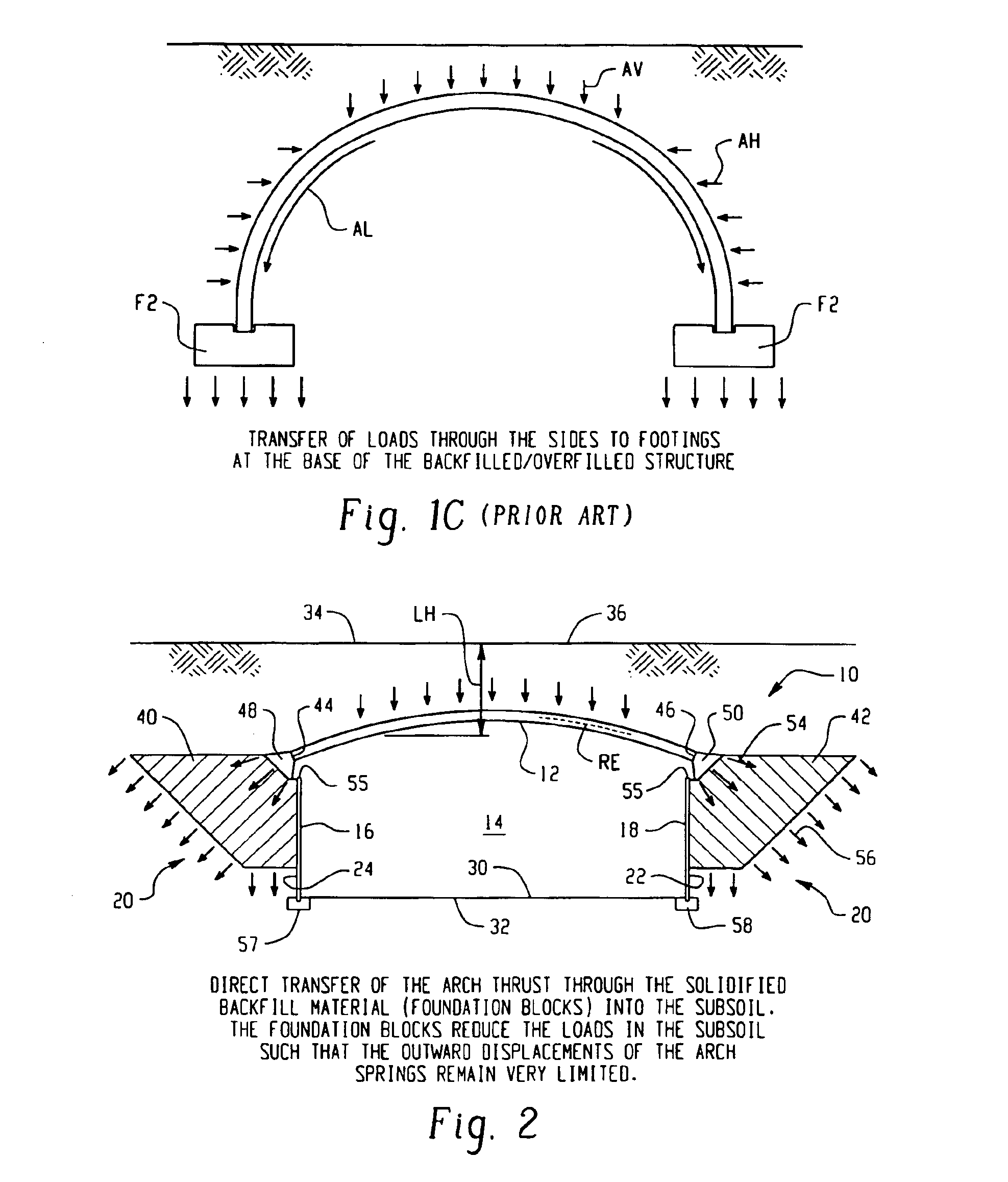

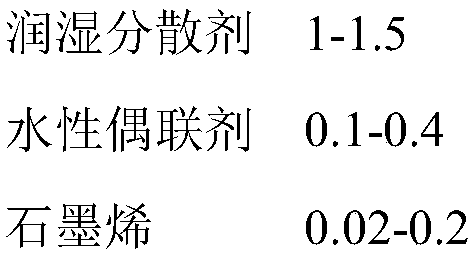

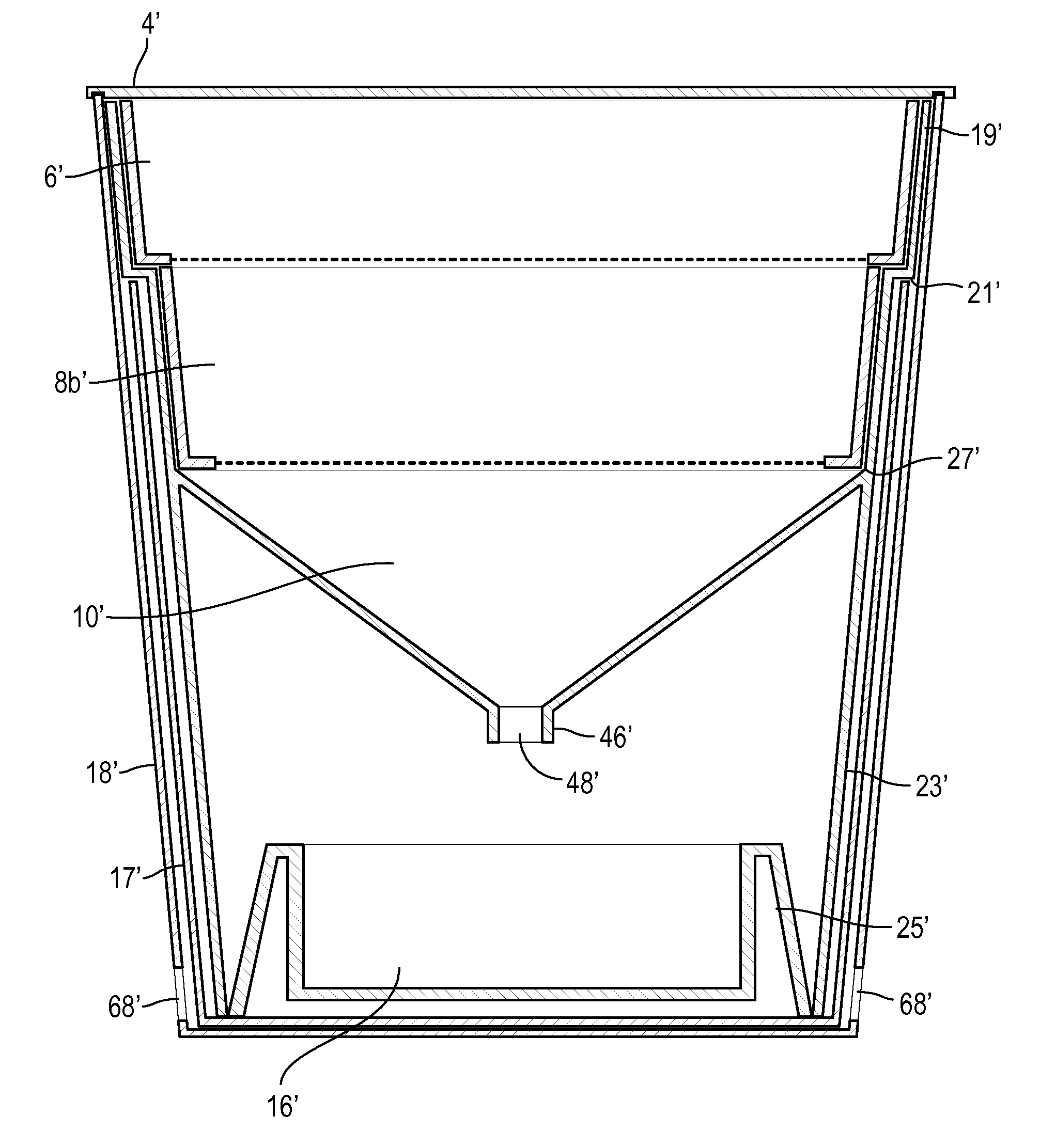

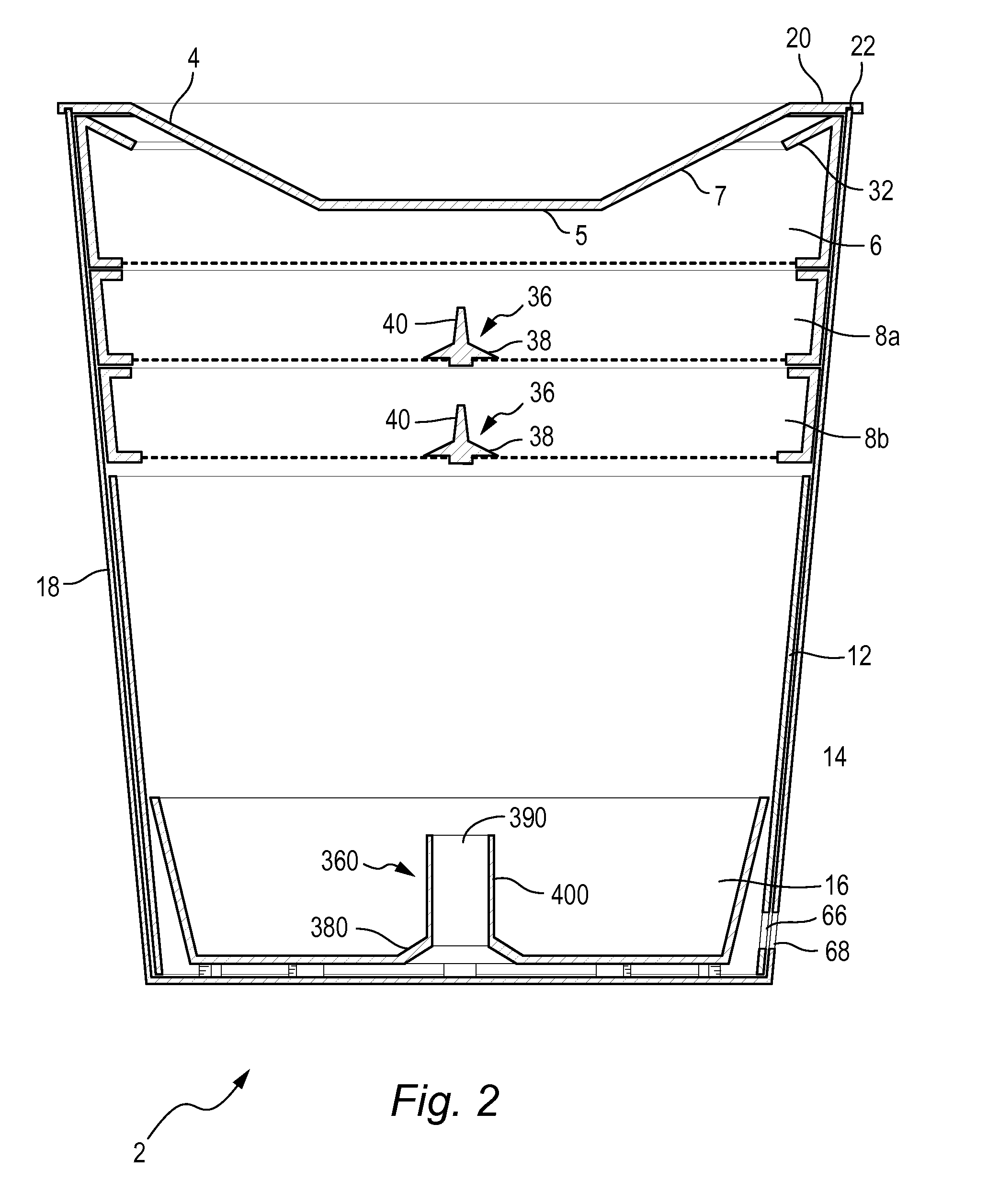

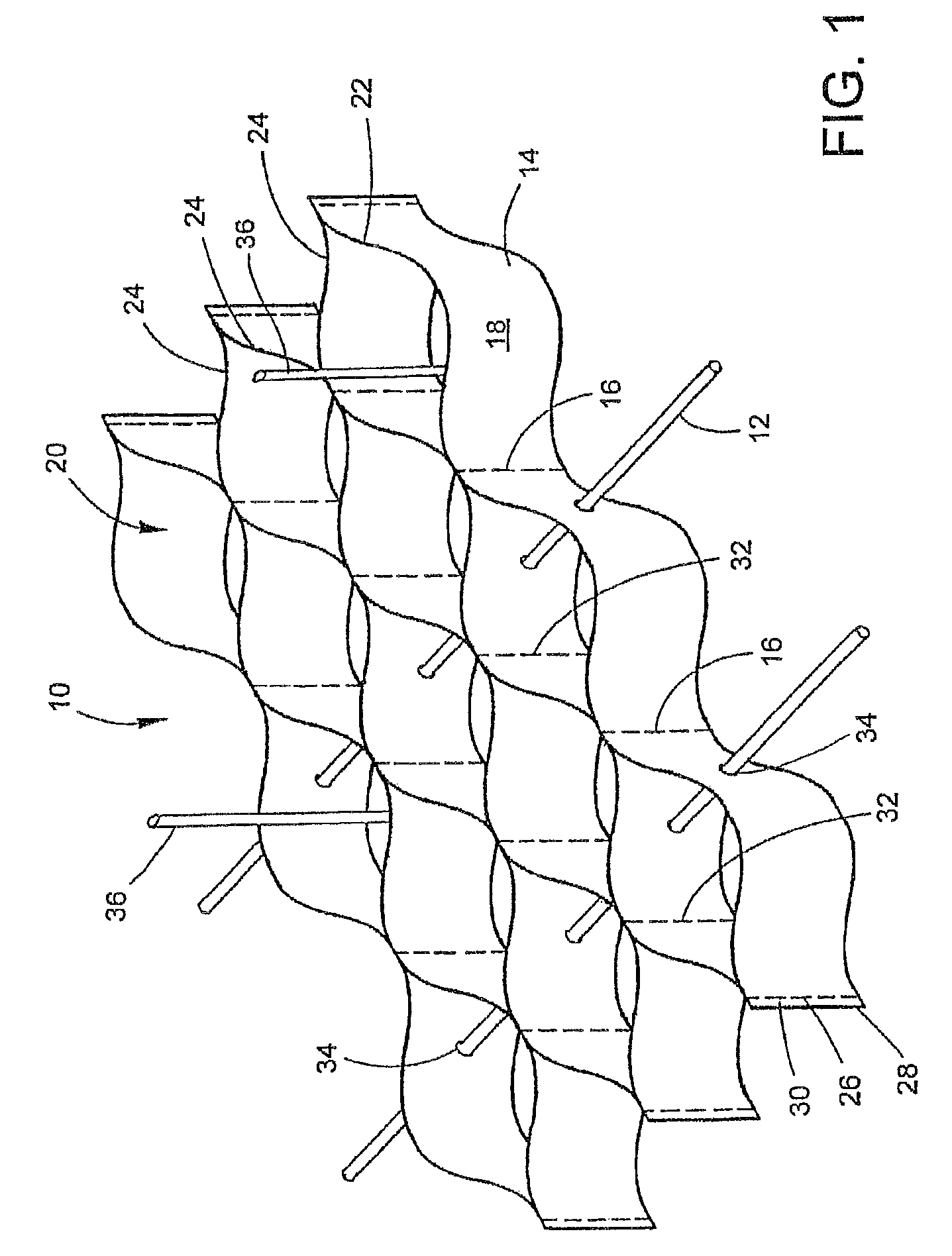

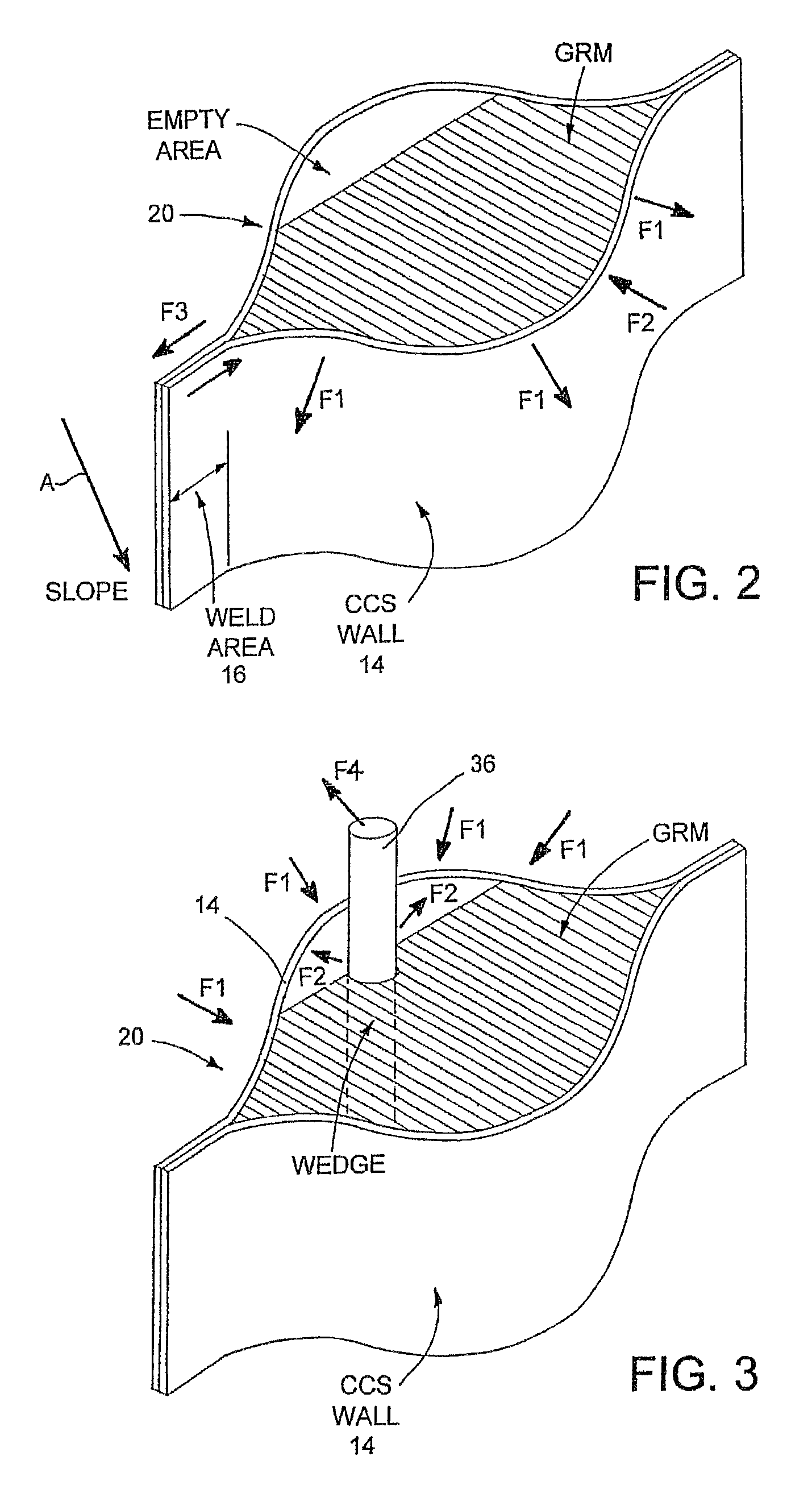

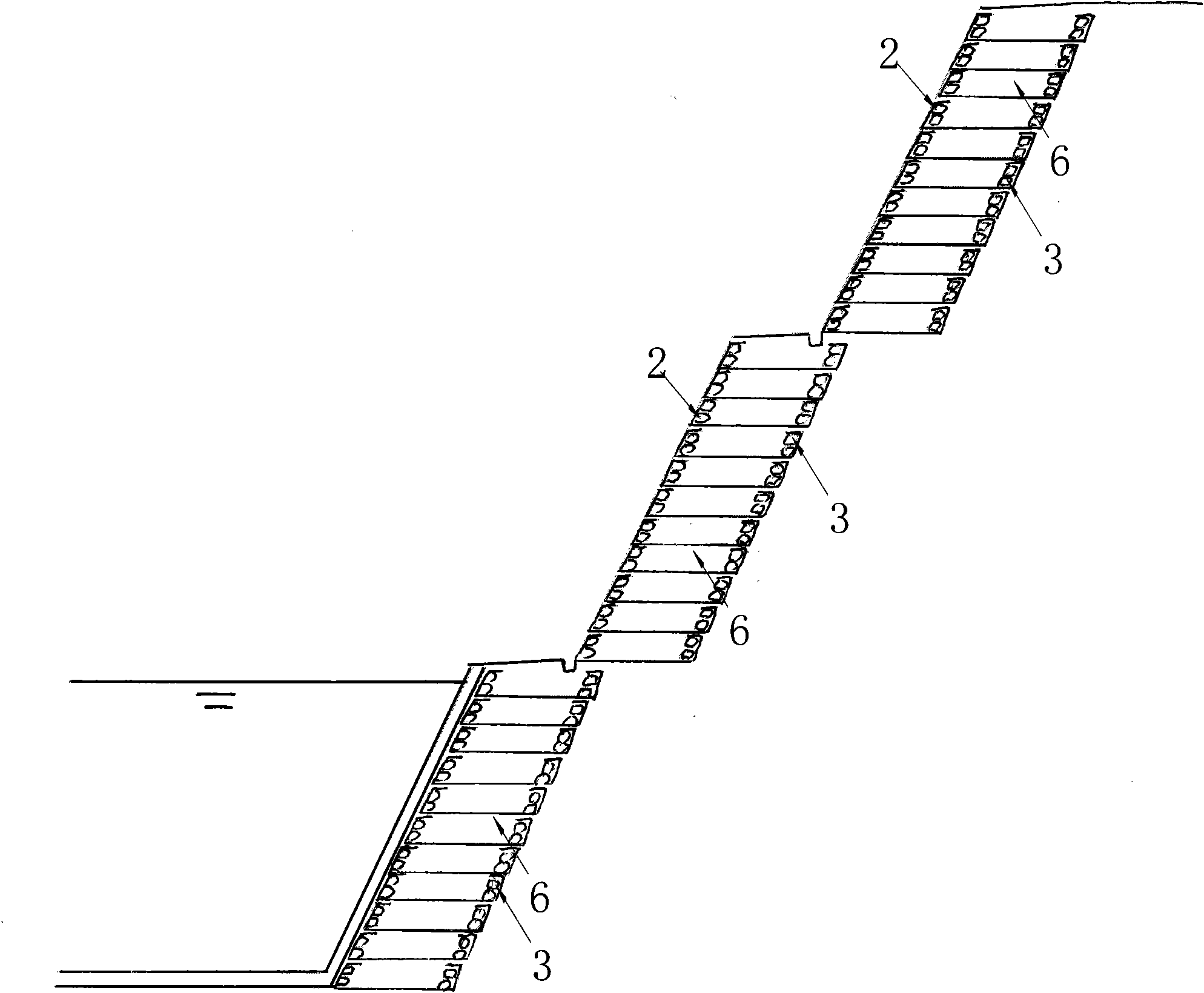

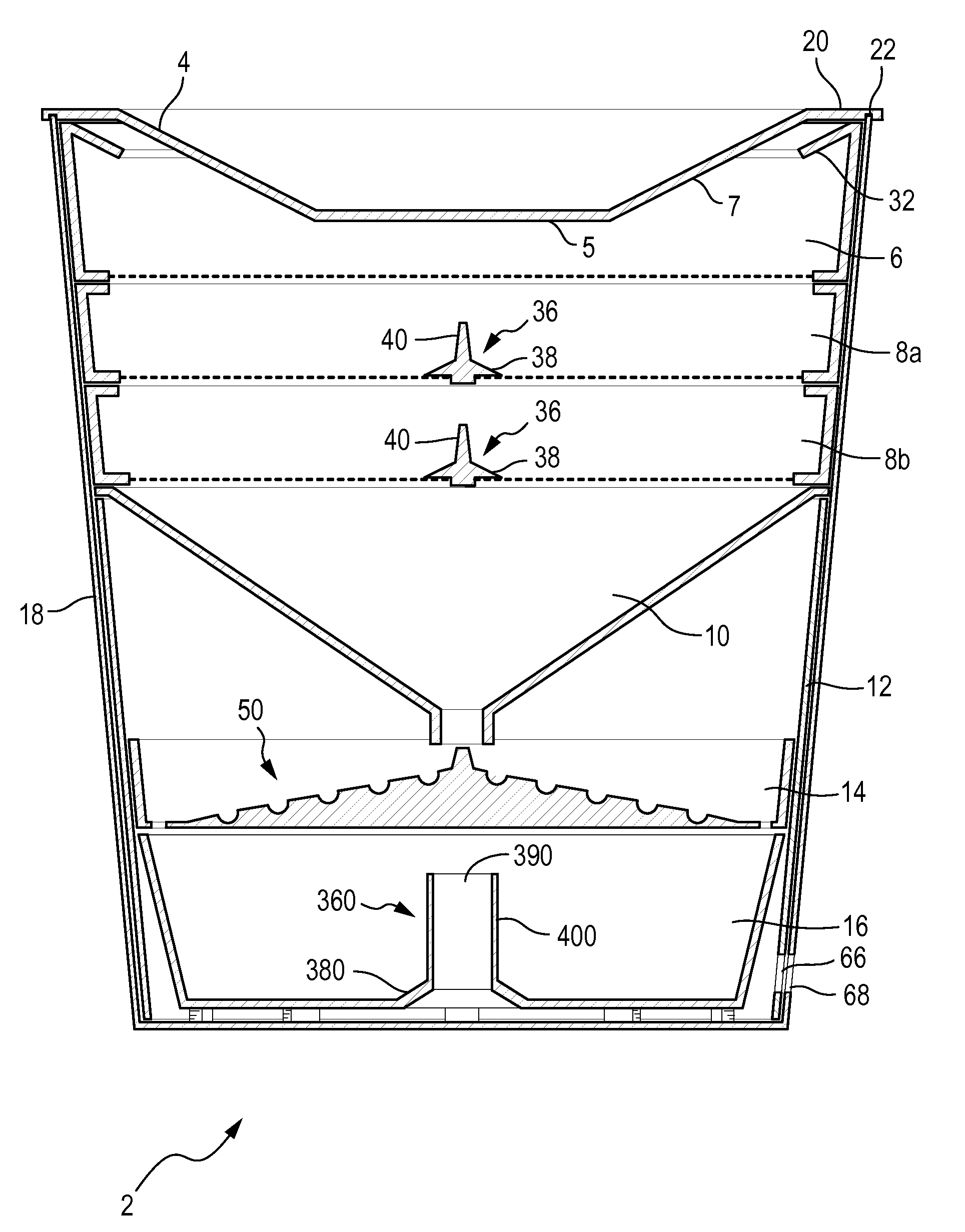

Top arch overfilled system

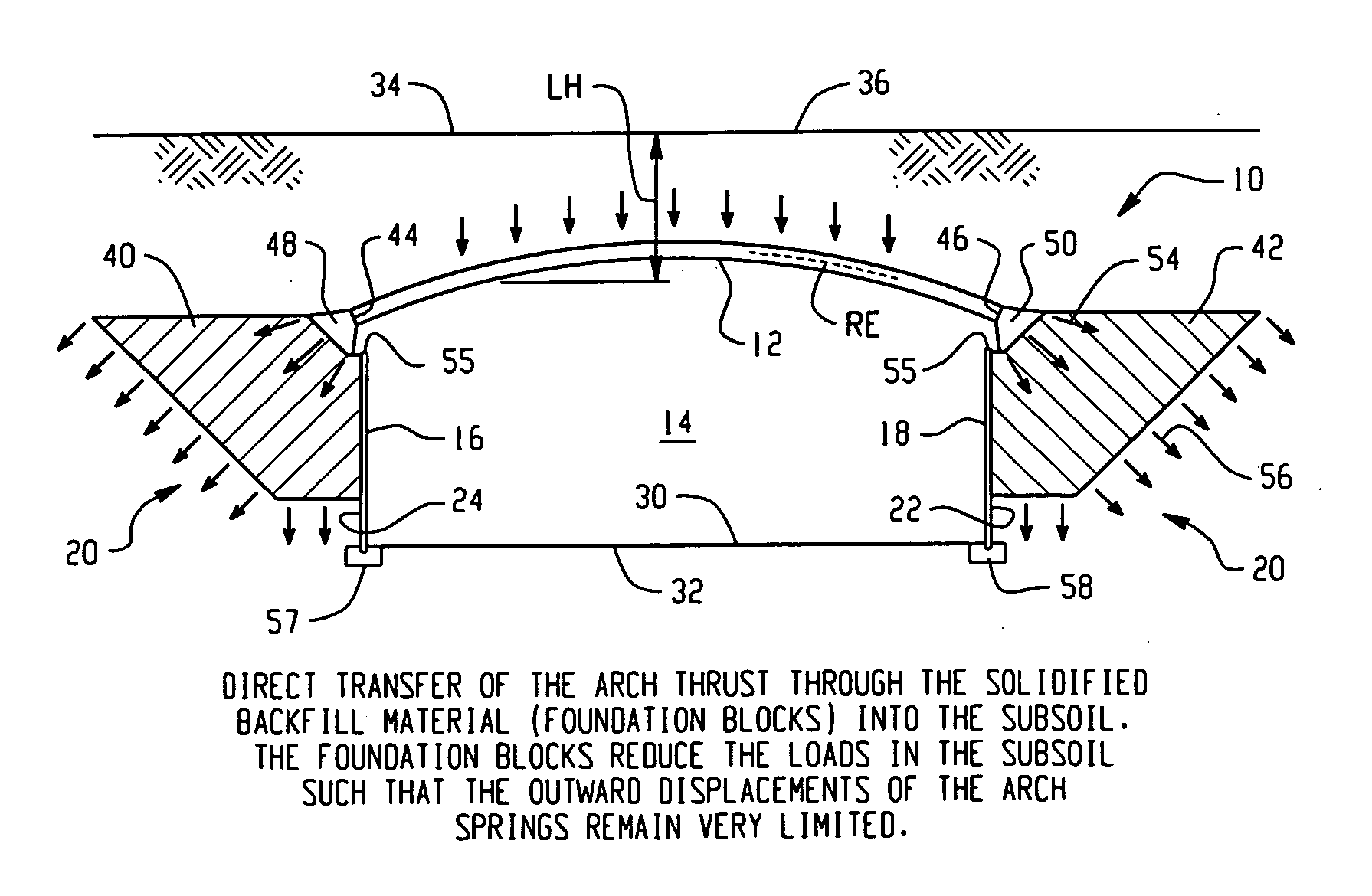

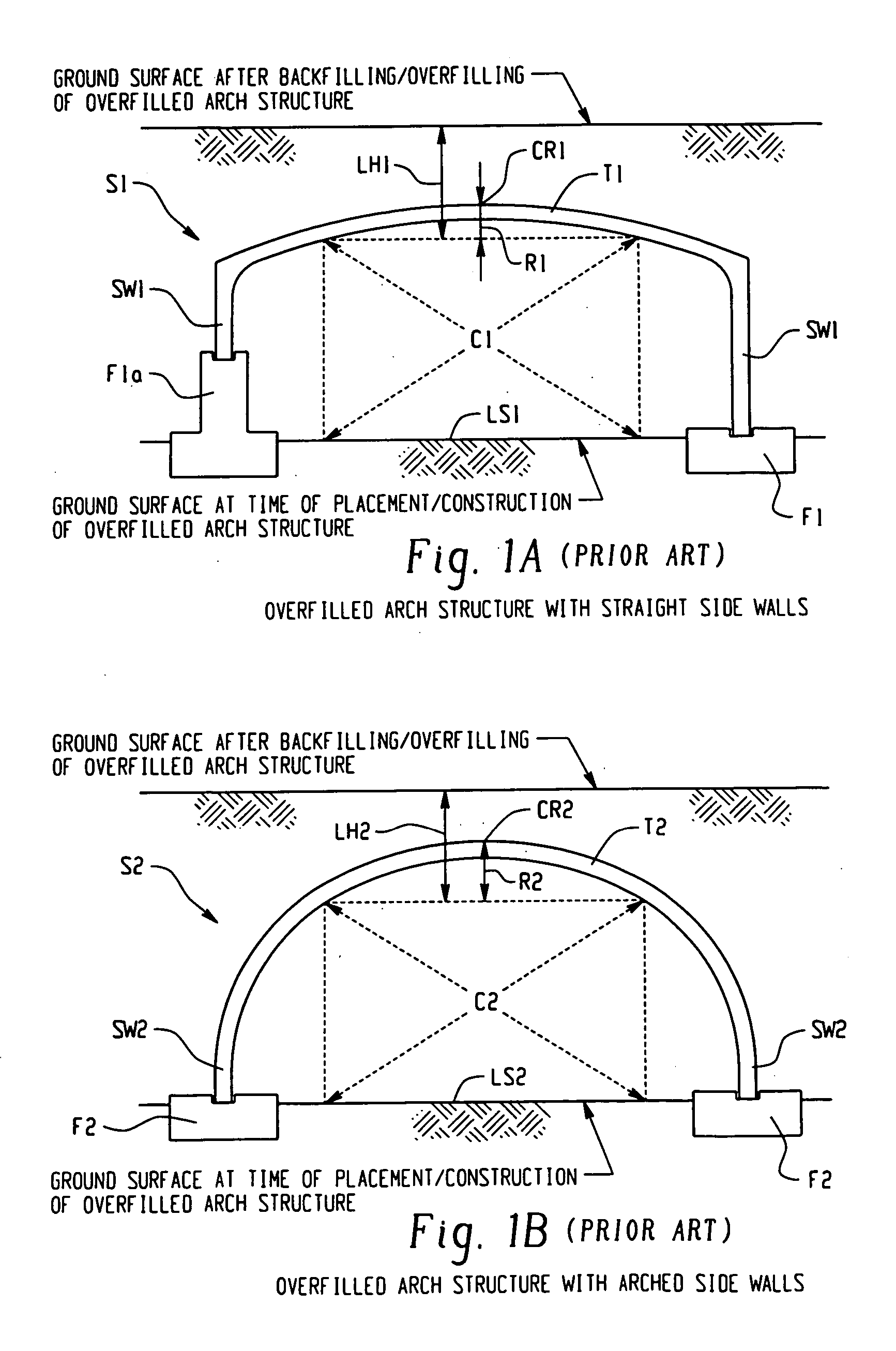

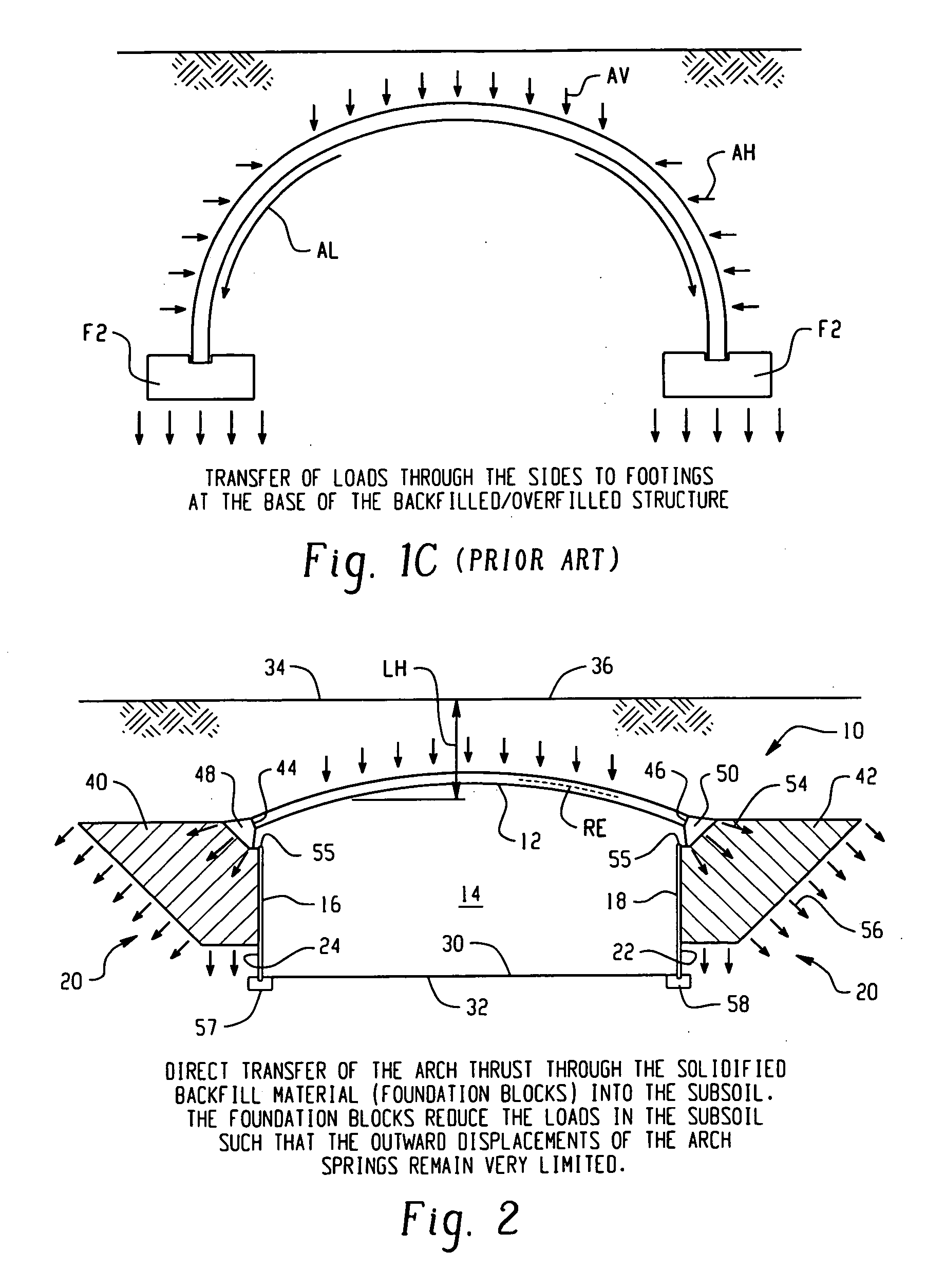

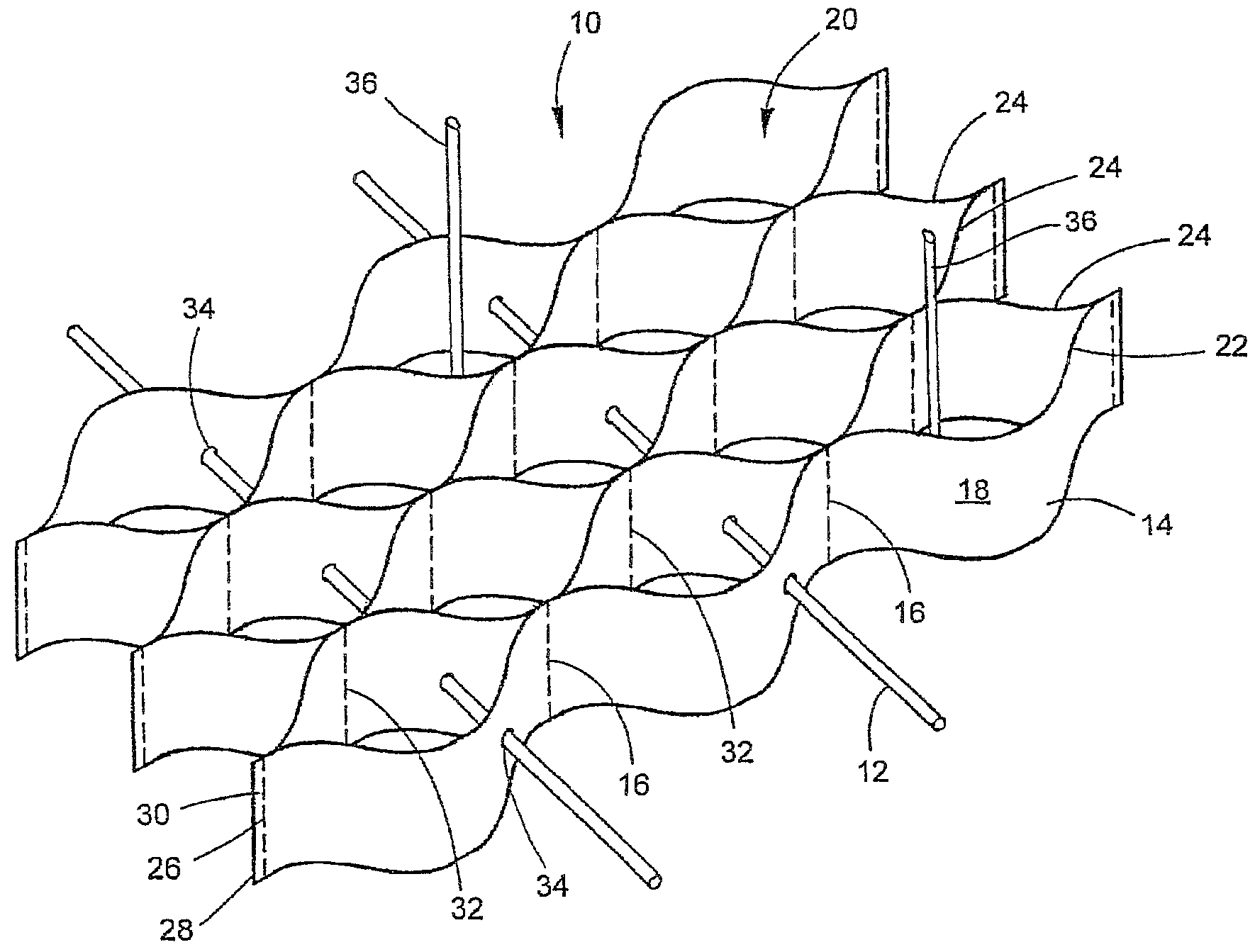

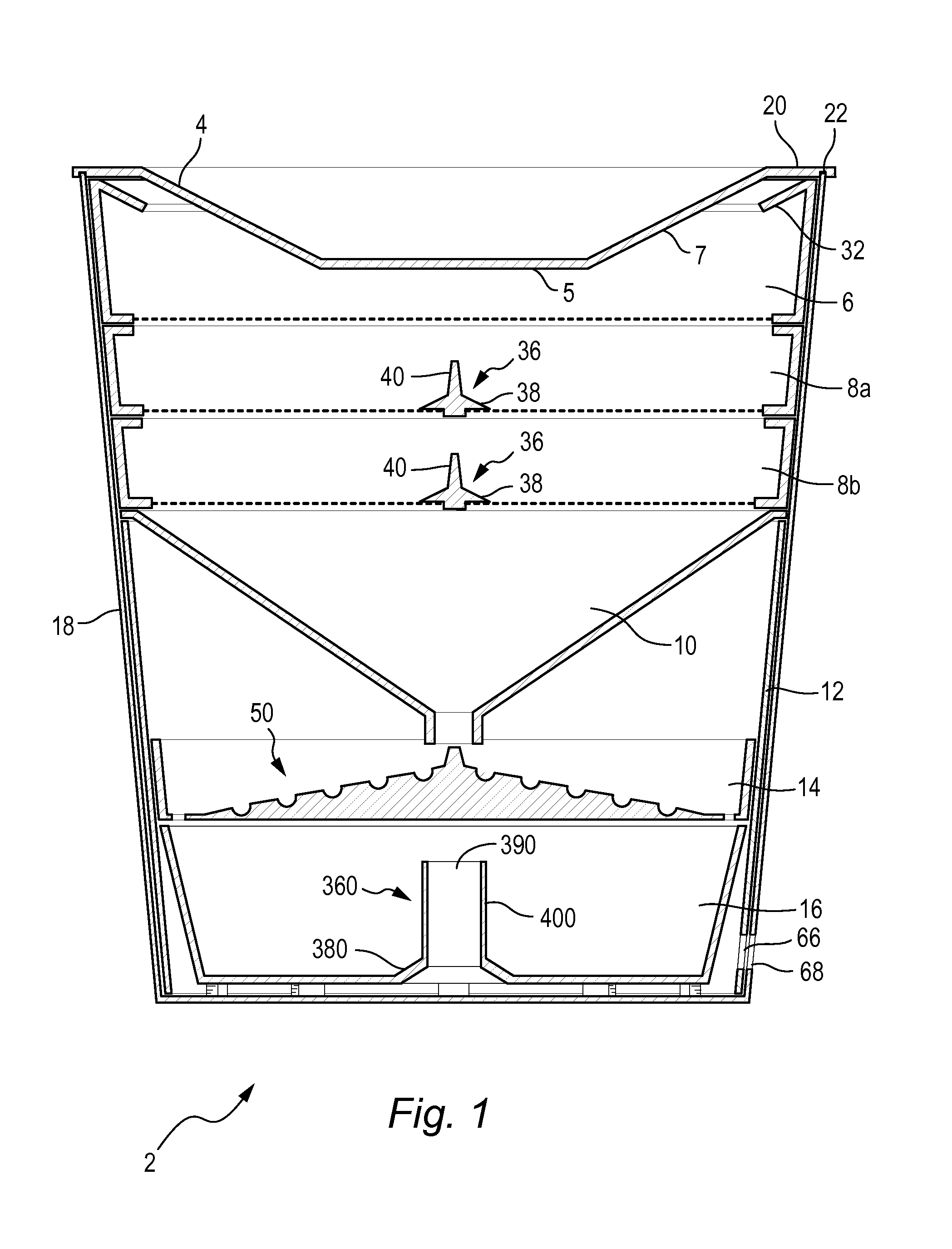

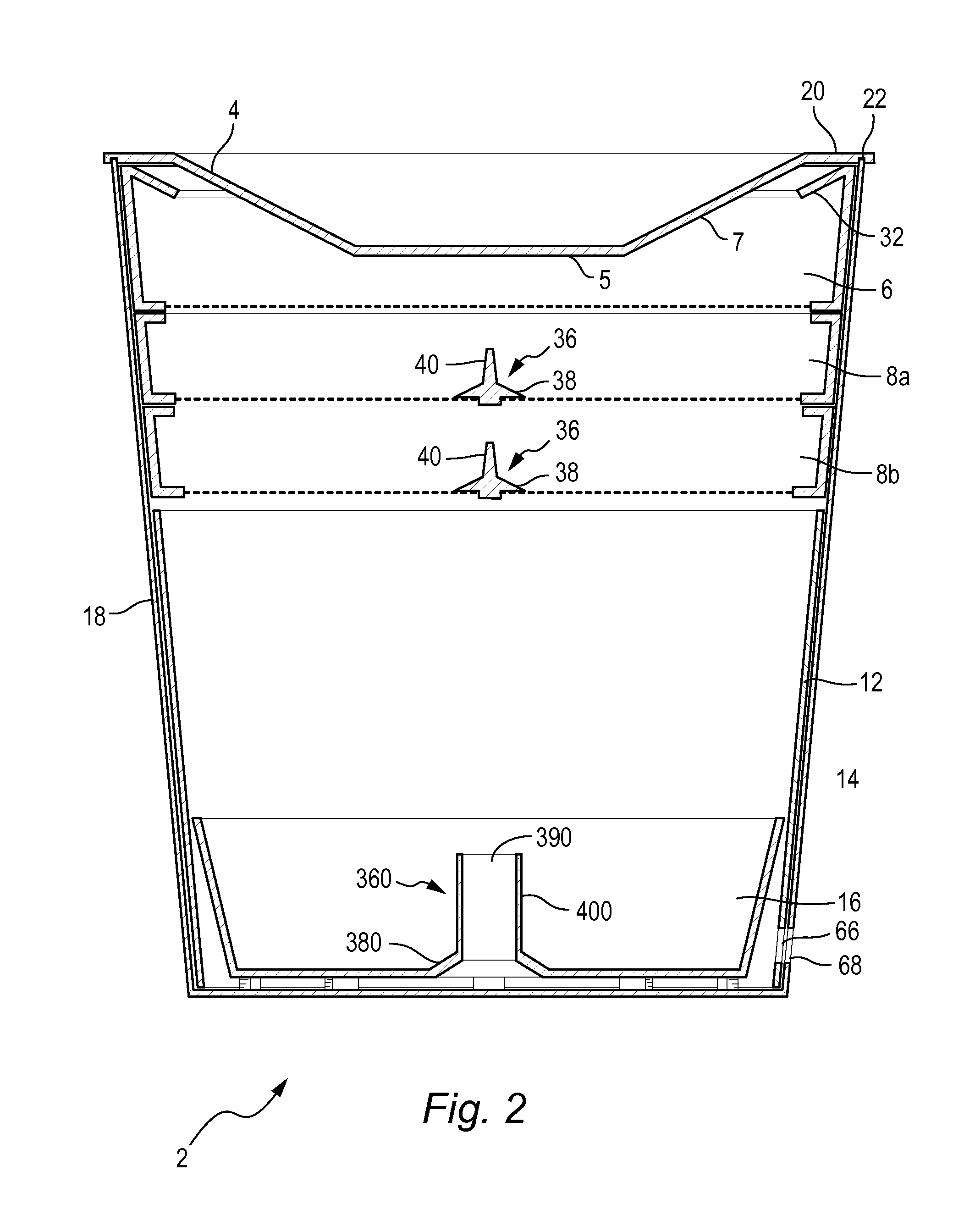

InactiveUS6719492B1DistanceReduce the overall heightArtificial islandsGround-workStructural engineeringEarth materials

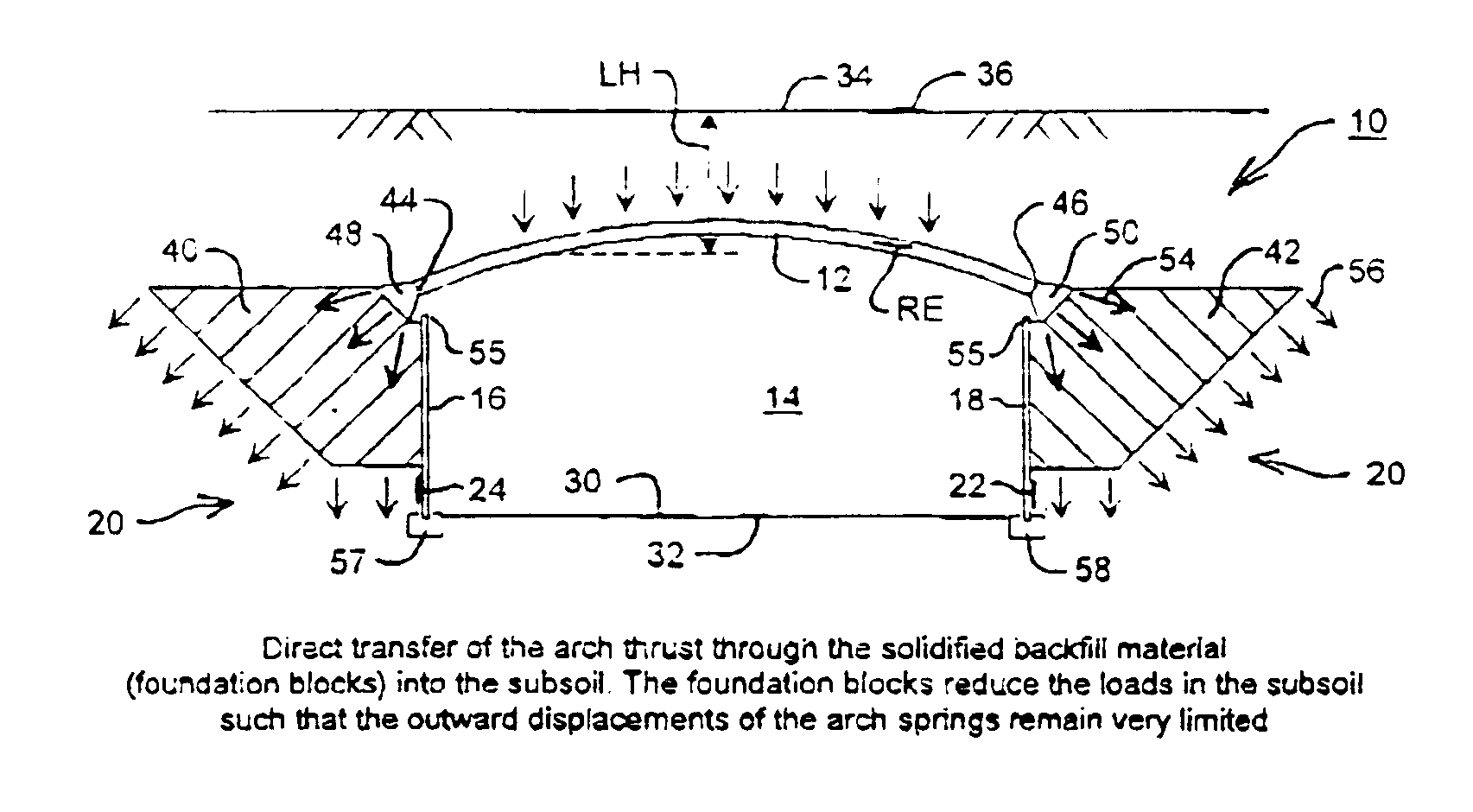

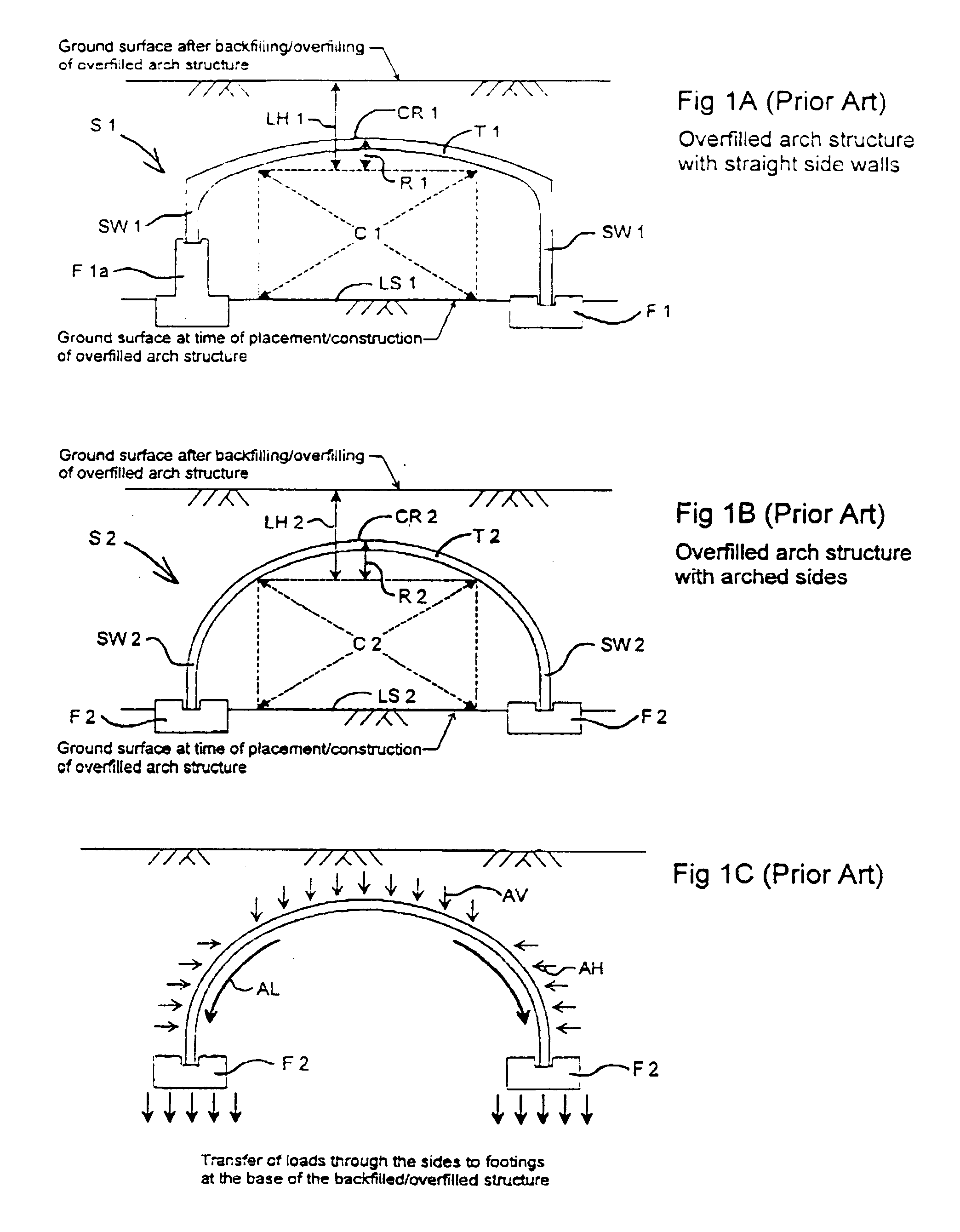

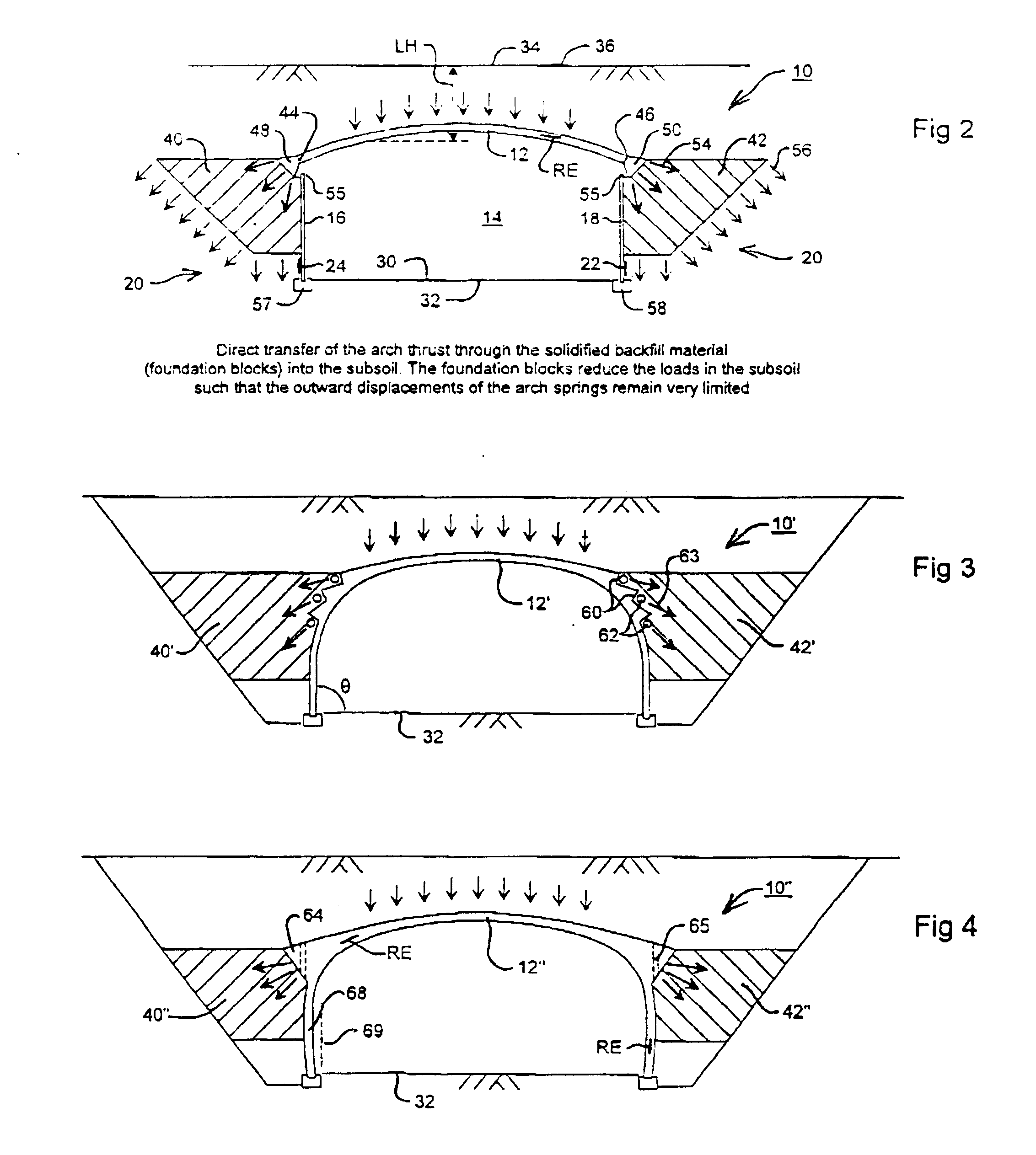

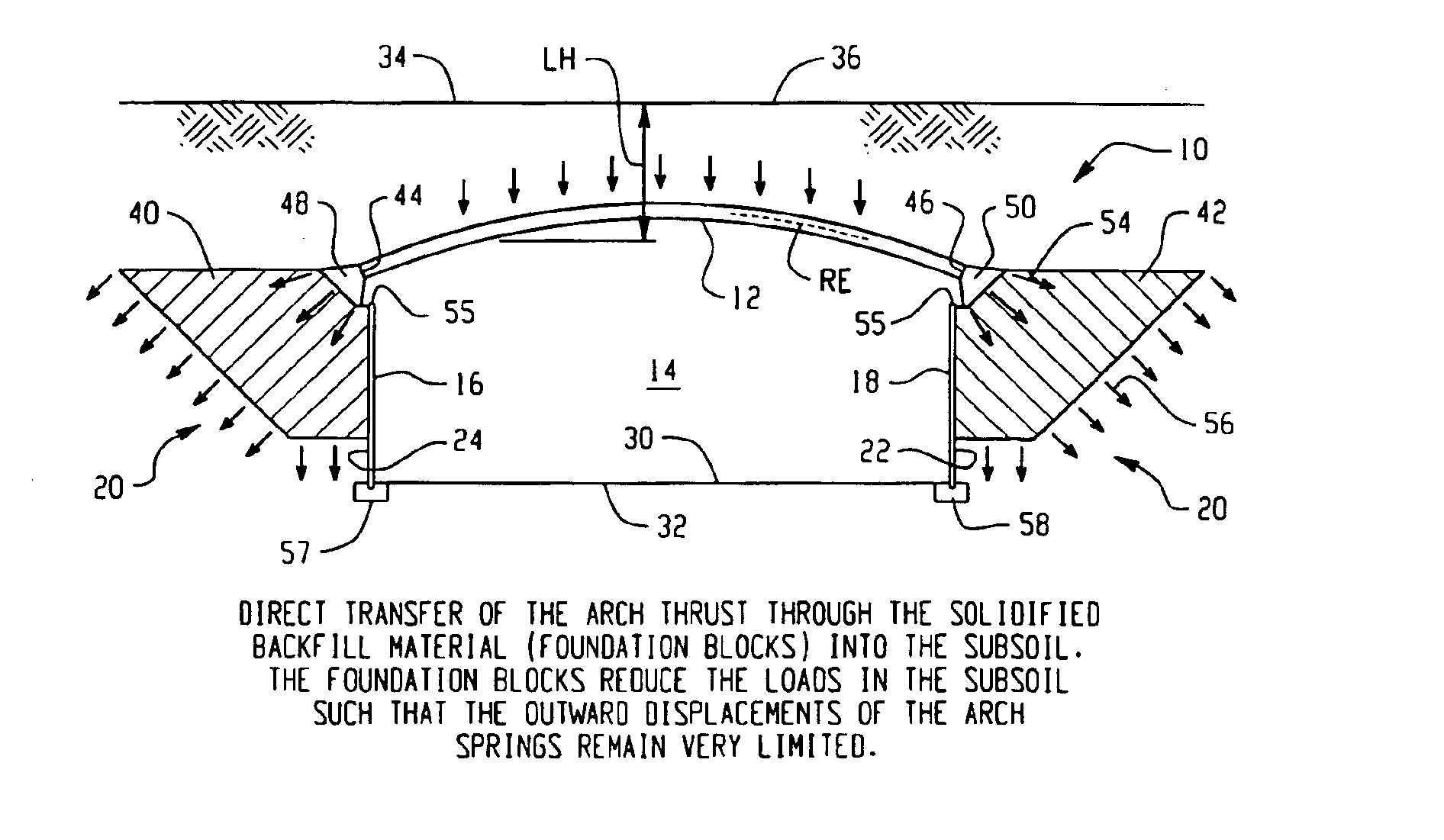

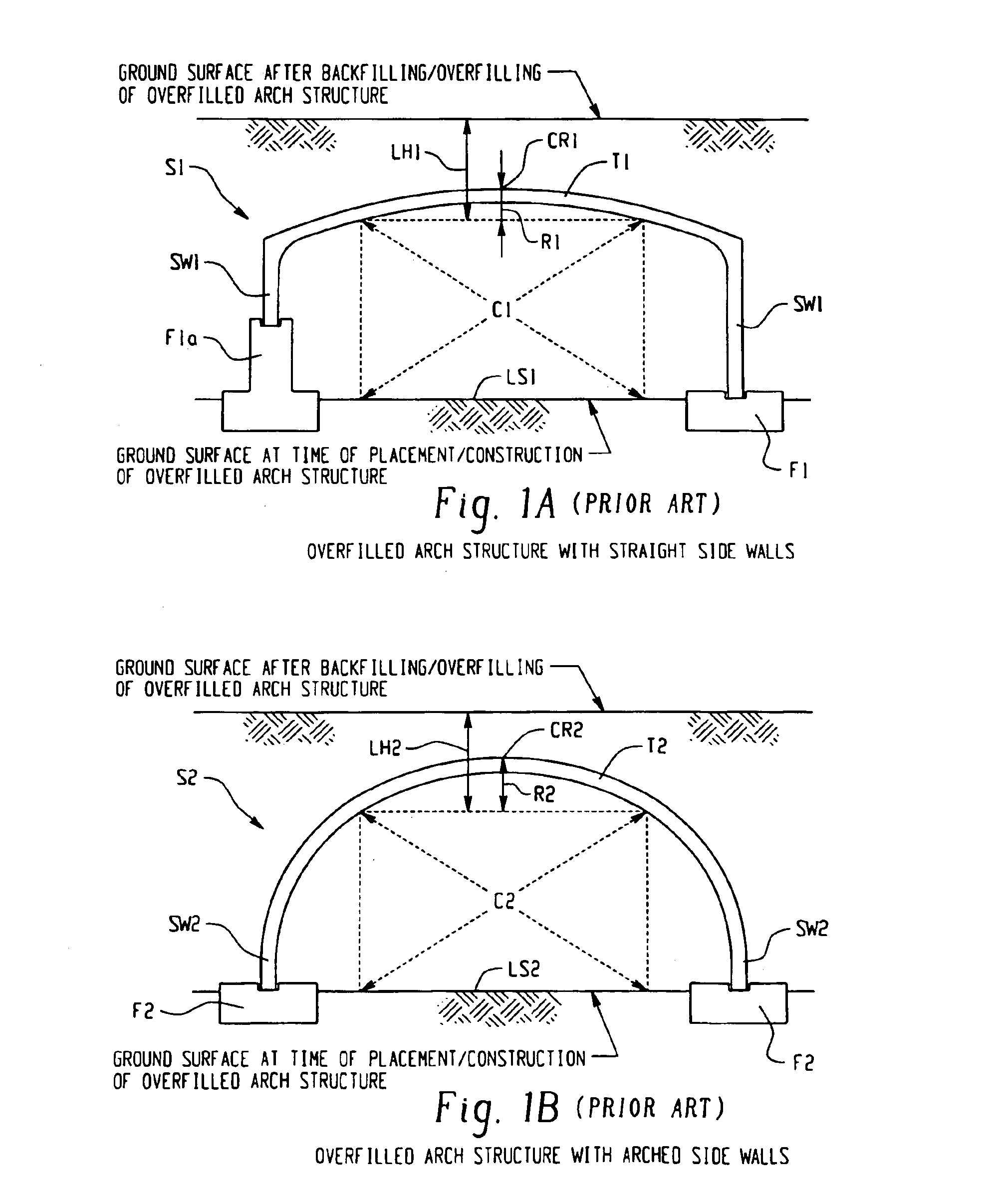

An earth overfilled arched structure includes a shallow arch spanning a clear space. The sides of the clear space are formed by curved or straight walls. Solidified zones of earth material (backfill or in situ) against the springs of the arch and / or behind the walls form foundation blocks which are in intimate contact via arch footings with the springs of the arch and / or with the upper part of the sidewalls in such a way that the arched structure delivers most or all of its support forces into the foundation blocks. These, due to their size and weight, transfer and spread the support forces to the subsoil so that displacements, especially in the horizontal directions, are minimal.

Owner:CONTECH ENGINEERED SOLUTIONS

Preparation method of large quartz ceramic crucible

The invention discloses a preparation method of a large quartz ceramic crucible, which is formed based on the method of gel casting molding, and particularly comprises the following steps: a) taking fused quartz with purity of 99.0-99.9% according to the mass percent as a raw material, and carrying out granular grading on the grains of the fused quartz; b) uniformly mixing the raw material proportioned by the step a), adding gel solution, preparing into pulp in a ball mill or a blender; c) injecting or pressure-injecting the prepared pulp prepared by the step b) into a preheated metal mold, and taking out from the metal mold after the pulp is solidified into green bodies; d) naturally drying the green bodies; and e) putting the dried green bodies into a high-temperature furnace, baking toobtian the large quartz ceramic crucible. Raw material grain proportioning and the preparation method, optimized by the invention, can product the quartz ceramic crucible with larger overall dimension and thin wall for fusion of special glass, casting of polycrystalline and calcining of rear earth material.

Owner:洛阳北苑新材料技术有限公司

Top arch overfilled system

An earth overfilled arched structure includes a shallow arch spanning a clear space. The sides of the clear space are formed by curved or straight walls. Solidified zones of earth material (backfill or in situ) against the springs of the arch and / or behind the walls form foundation blocks which are in intimate contact via arch footings with the springs of the arch and / or with the upper part of the sidewalls in such a way that the arched structure delivers most or all of its support forces into the foundation blocks. These, due to their size and weight, transfer and spread the support forces to the subsoil so that displacements, especially in the horizontal directions, are minimal.

Owner:CONTECH ENGINEERED SOLUTIONS

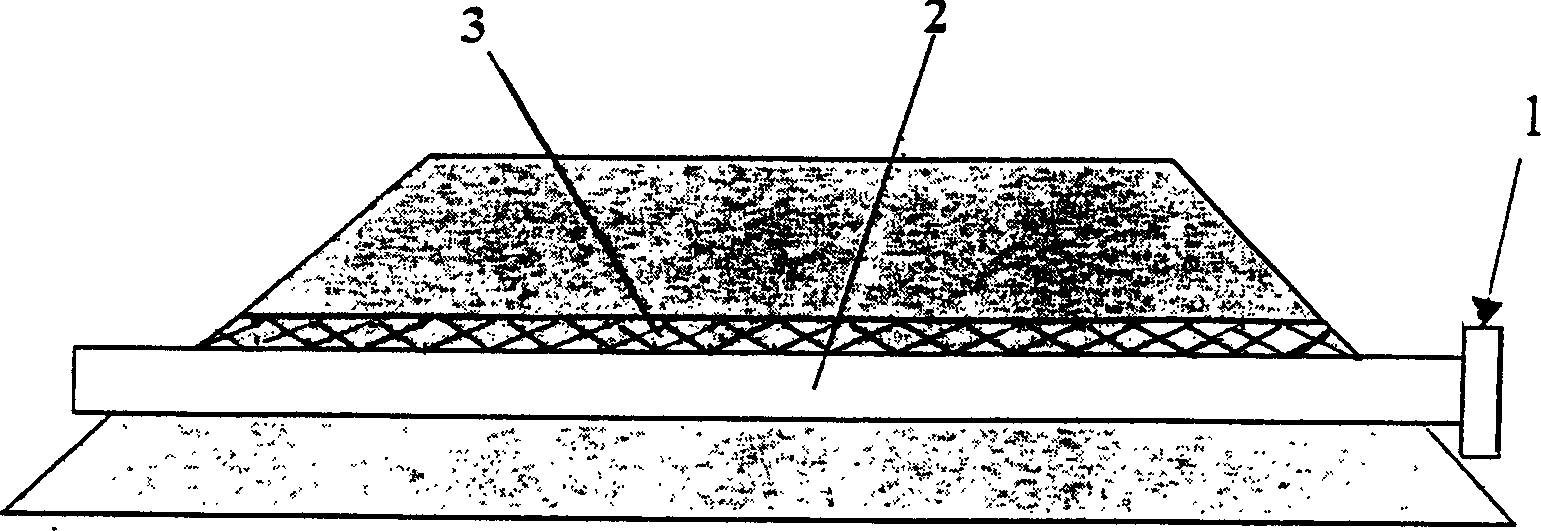

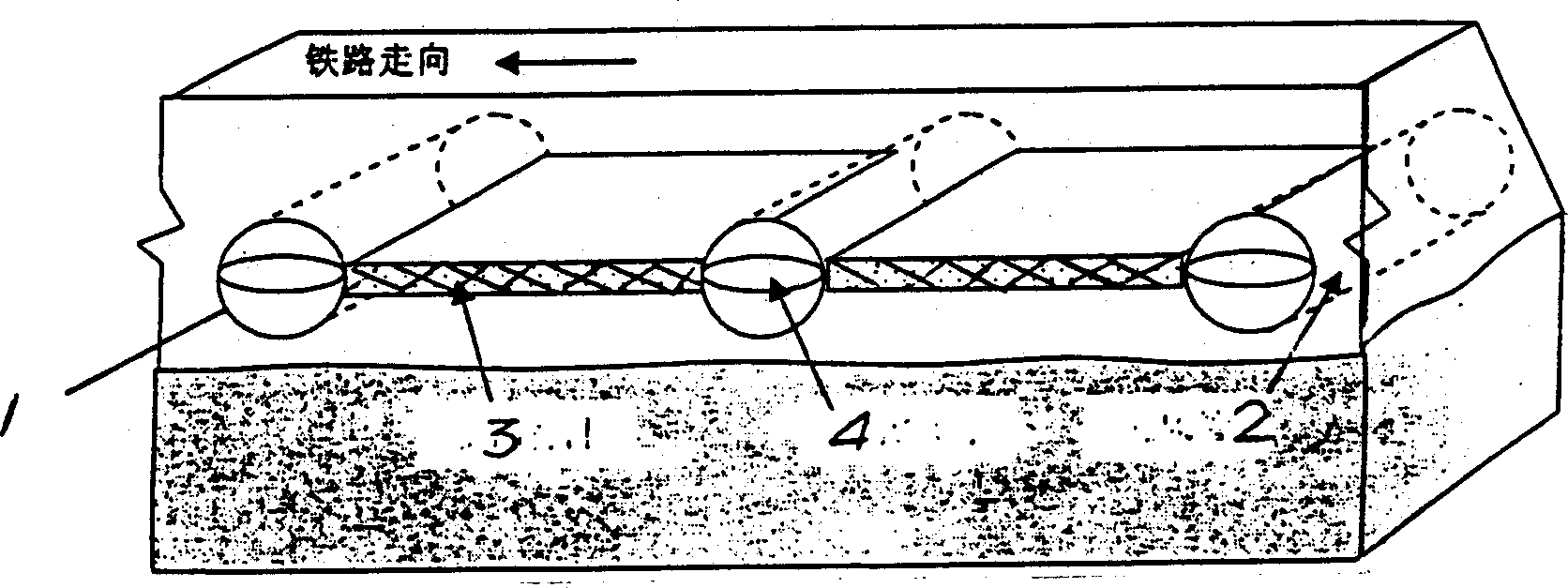

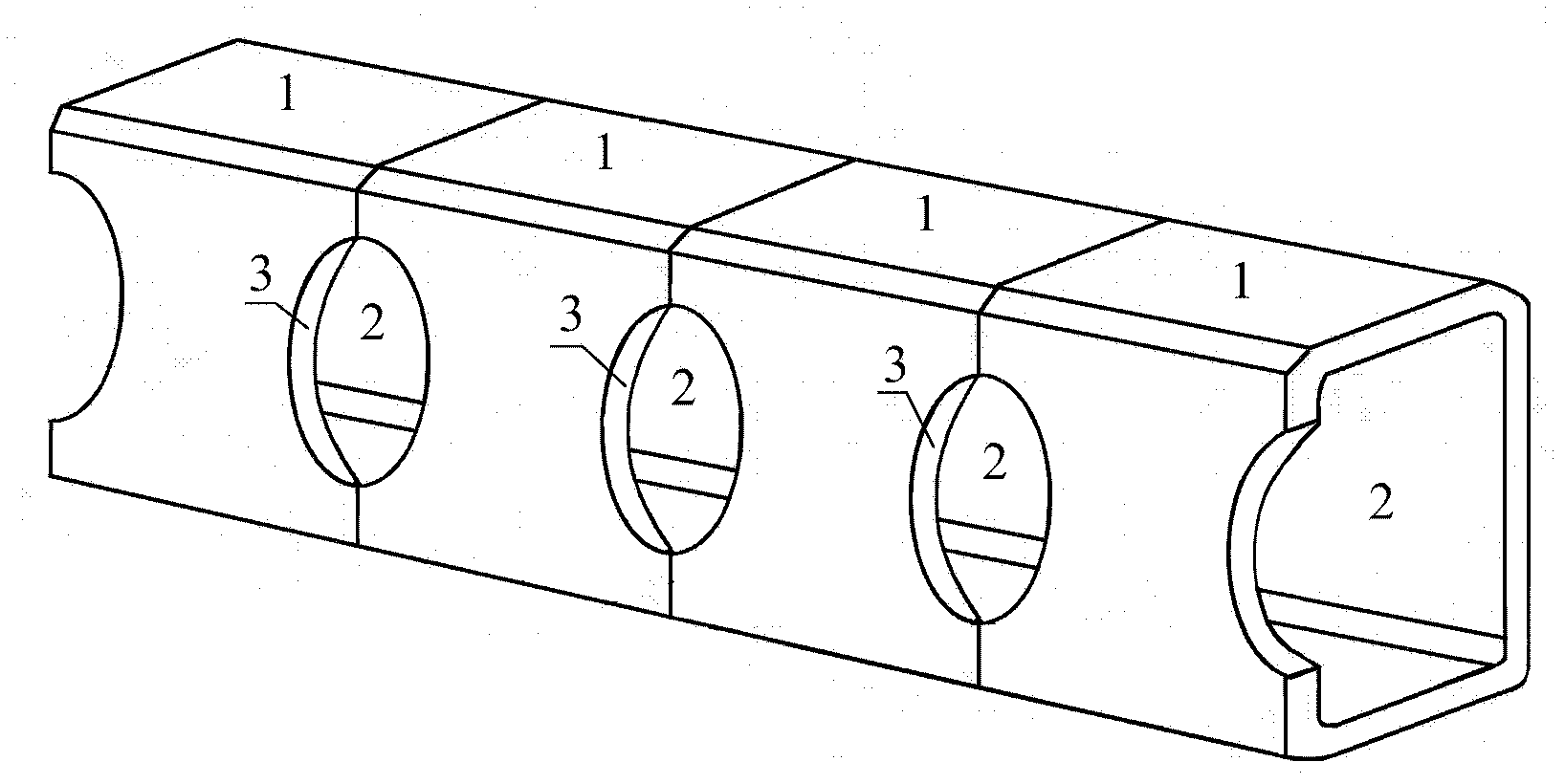

Composite temperature controlled ventilation roadbed

InactiveCN1556284AStop the flowBlock incomingRoadwaysFoundation engineeringVentilation tubeTemperature control

Construction features of roadbed are as follows: building vent-pipes perpendicular to direction of roadbed in certain depth of road embankment; installing ventilating units of automatic controlling temperature at end part of vent-pipe; setting up thermal-protection material between vent-pipes / entire up part of vent-pipes with earth material being covered and tamped. The said automatic controlling ventilating units carries out heat exchange between inside roadbed and airflow in low temperature outside. The thermal-protection material protects ever frost effectively. Thus, the invention prevents frost heave and thaw collapse caused by season change so as to keep stability of roadbed in high level. The invention solves issue of carrying construction in zone of frozen earth.

Owner:COLD & ARID REGIONS ENVIRONMENTAL & ENG RES INST CHINESE

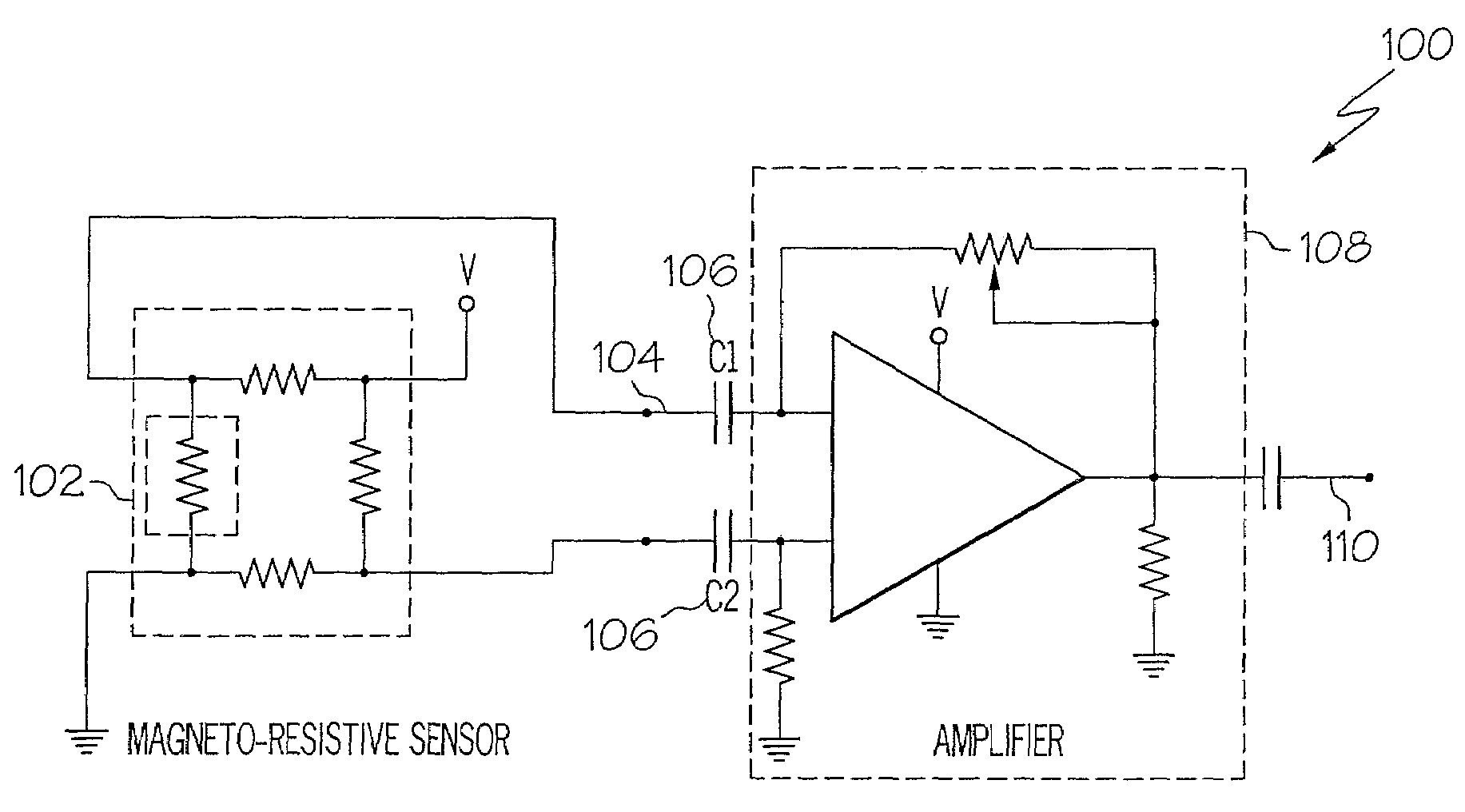

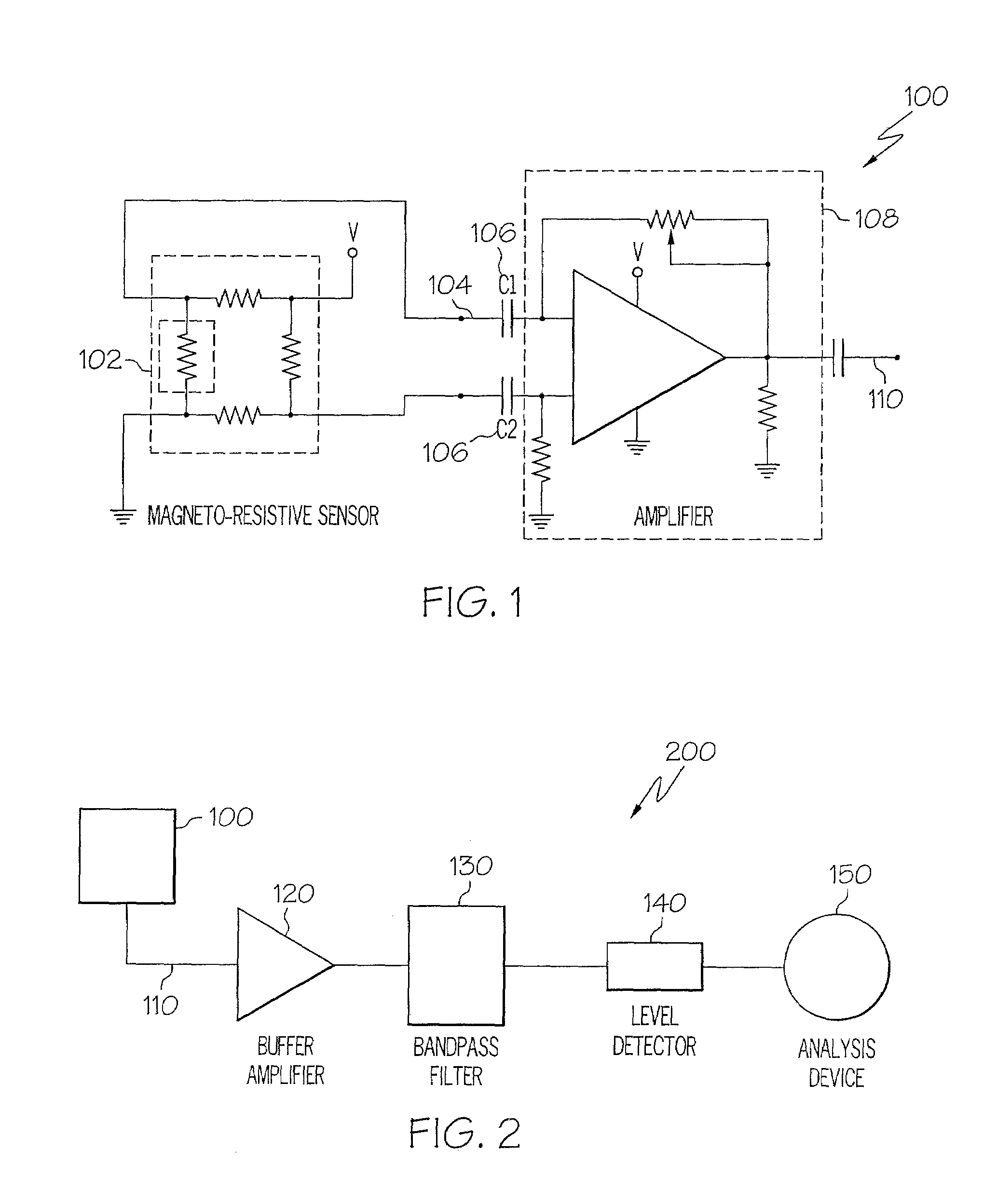

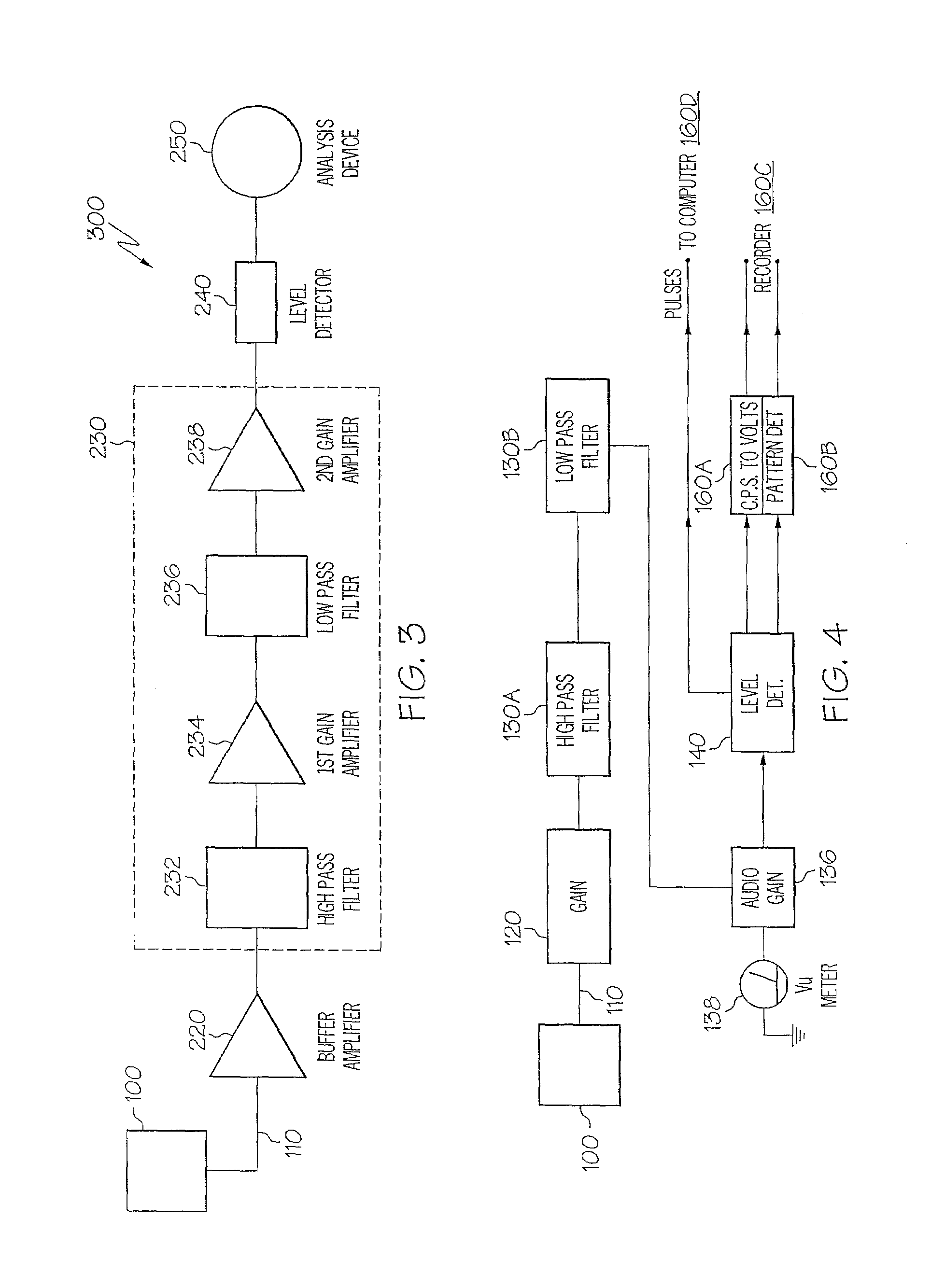

Electromagnetic impulse survey apparatus and method utilizing a magnetic component electromagnetic antenna

ActiveUS7397417B2Radio wave reradiation/reflectionElectric/magnetic detection for transportJet aeroplaneEngineering

The invention relates to an apparatus and method for performing passive geophysical prospecting. More particularly, the present invention relates to an improved apparatus and method for locating and selected subsurface Earth material deposits or geologic formations bearing hydrocarbons, oil, gas, or commercially important ore deposits, precious metals, as a function of impulse discontinuities in the near surface atmosphere of the invention. A passive geophysical prospecting method and apparatus are provided. The apparatus has a magnetic component antenna for detecting electromagnetic radiation naturally emanating from the Earth's surface and an electrical signal from the detected electromagnetic radiation while traversing the Earth's surface by a vehicle traveling over land or water or in an airplane.

Owner:JACKSON BARBARA MRS

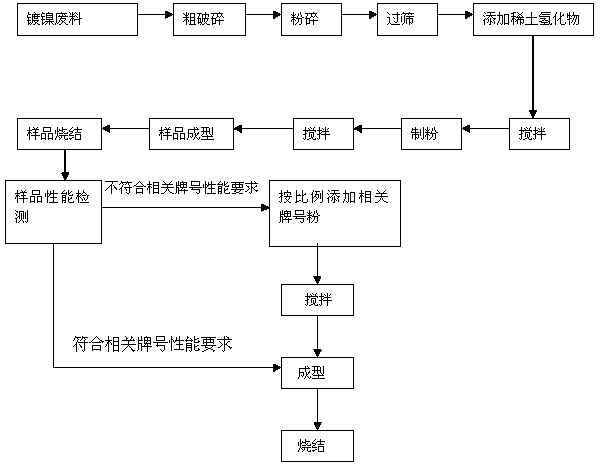

Method for recycling nickel-plated sintered NdFeB waste

ActiveCN103426579AIncrease profitSimple processInorganic material magnetismEarth materialsWaste material

The invention provides a method for recycling nickel-plated sintered NdFeB waste. The method includes the steps that a material is smashed into powder with the grain size below 3mm, the powder is sieved in a sealed nitrogen tank to remove most of flaky things of a nickel-plated layer, rare earth hydride is added in the sieved powder, the mixture is stirred evenly, the powder is made into 3-5-micrometer fine powder through a jet mill, the appropriate powder is taken to be formed in a compression mode, a sample is sintered to perform performance test, 0-60% by weight of powder of a related trade mark is added according to sample testing results and product performance requirements, the mixture is stirred evenly, and the qualified powder is formed in a compression mode and sintered into NdFeB magnets. For recycling of the nickel-plated sintered NdFeB waste, nickel-plated sintered NdFeB waste does not need to be roasted or remelted, sieving is performed after the smashing process, the rare earth hydride is added for powder manufacturing, the sample is trial-manufactured firstly to test the performance of the powder, a certain amount of powder of the related trade mark is added according to the performance requirements of products to be manufactured, and various sintered NdFeB products meeting the different performance requirements can be manufactured. The technological process is simple, the utilization rate of the NdFeB material and the utilization rate of the rear earth material are improved, and energy conservation and environment protection are also facilitated.

Owner:宁波科田磁业股份有限公司 +1

Aggregate and concrete production equipment and aggregate and concrete production process

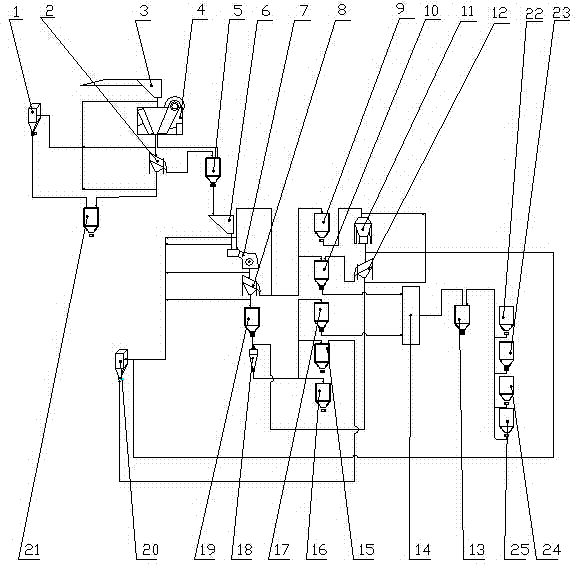

ActiveCN104493980AKeep healthyMixing operation control apparatusPretreatment controlLow voltageControl signal

The invention discloses aggregate and concrete production equipment. The aggregate and concrete production equipment comprises a DCS central control system which is used for controlling an earth material low-voltage pulse dust collator, an earth sieve, a jaw crusher feeder, a jaw crusher, a buffer bin, an impact crusher feeder, an impact crusher, a circular vibrating sieve, a sand making storage bin, a finished product bin, a sand making machine, a circular finished product vibrating sieve, a stirring station, a material distributing bin, a fine powder bin, a medium powder bin, a sand bin, a V selector, a mixing bin, a low-voltage powder pulse dust collector, an earth bin, a sealing carrying belt, a field meter, a cement bin, a mineral powder bin, a coal ash bin, an additive bin and a water tank through a control signal. An aggregate and concrete production process comprises the following processes: a crushing process by adopting the jaw crusher; a crushing process by adopting the impact crusher; a sorting process by adopting the circular vibrating sieve; a sand making process; a centralized dust collecting process; and a finished product conveying and loading process. The aggregate and concrete production equipment and the aggregate and concrete production process have the advantages that dust during full-automatic sealing production is little, the environment is protected and the harm on body health is avoided.

Owner:山东连银山环保建材有限公司

Preparation method of rare-earth permanent magnet, preparation device and rare-earth permanent magnet prepared thereby

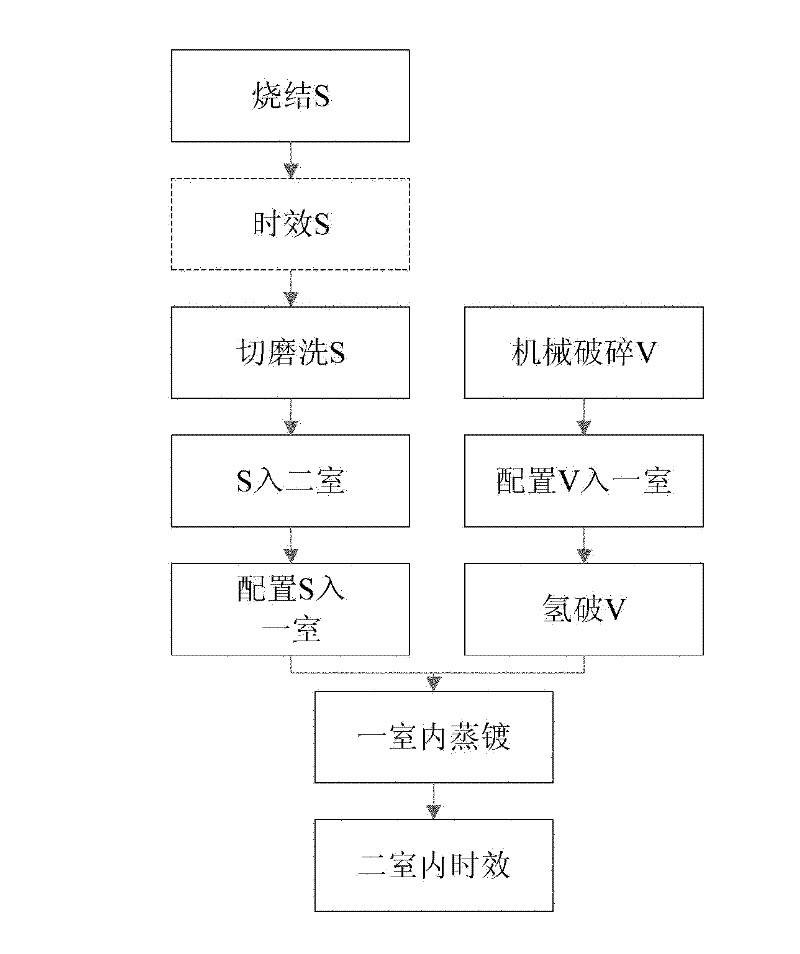

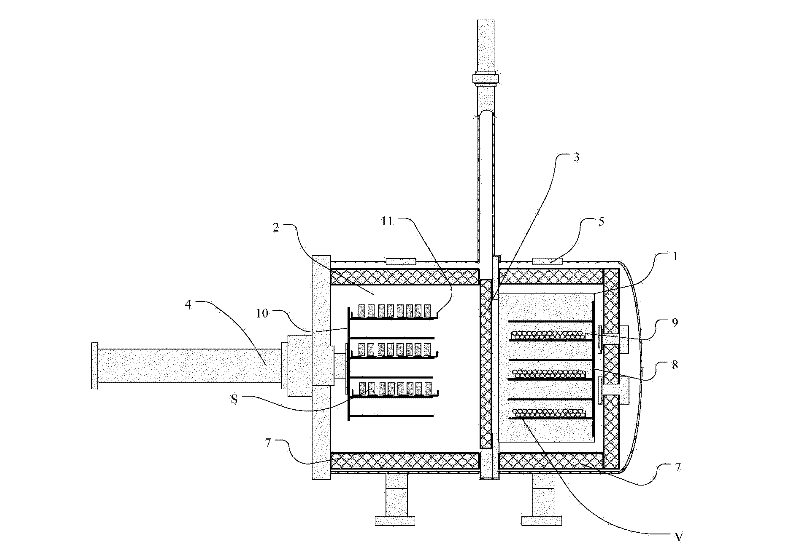

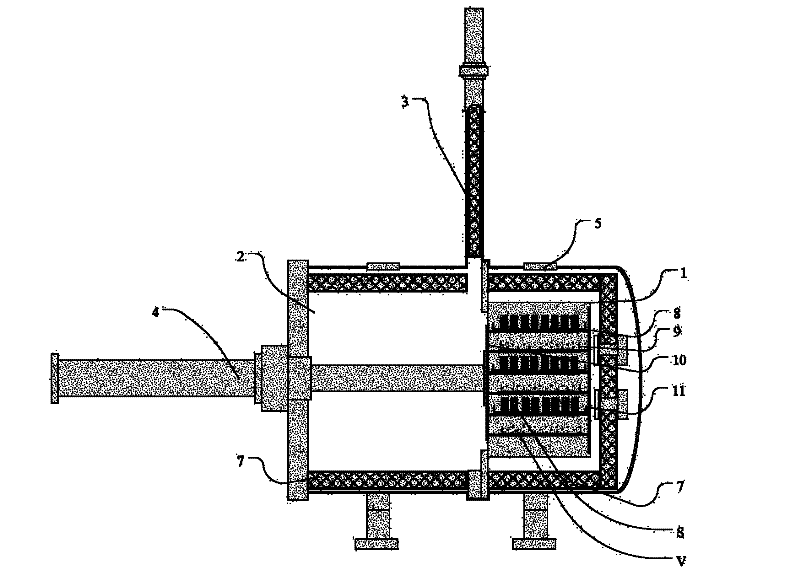

ActiveCN102682987AImprove coercive forceStrong corrosion resistanceVacuum evaporation coatingSputtering coatingPressure decreaseRemanence

The invention discloses a preparation method of a rare-earth permanent magnet, a preparation device and a rare-earth permanent magnet prepared thereby, and relates to the preparation technology of sintered rare-earth permanent magnet with high coercivity. The invention is characterized in that the preparation method is carried out in two-chamber vacuum equipment which can be communicated with each other and also can carry out pressure increasing and decreasing treatment and heating treatment, and comprises the following steps of: firstly putting an evaporation material in a first chamber for crushing; putting a treated piece in a second chamber, vacuumizing the second chamber and enabling the vacuum degree of the second chamber to be equivalent to that of the first chamber; transferring the treated piece into the first chamber and carrying out heat diffusion treatment in the first chamber; carrying out pressure decreasing on the first chamber, and enabling the vacuum degree of the first chamber to be equivalent to that the second chamber; and transferring the treated piece back into the second chamber, and carrying out aging treatment in the second chamber. The preparation method disclosed by the invention has the advantages that no powder is remained on the surface of the magnet; the metal powder is adopted for evaporation, so that the evaporation efficiency is greatly increased, and the purpose of providing high-coercivity and high-remanence magnet by using fewer heavy rare-earth materials can be realized; and simultaneously, the magnet has stronger corrosion resistance.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

Carbon fiber sheet and method for producing the same

InactiveUS20030027471A1High bulk densityAppropriate flexibilityMaterial nanotechnologyWood working apparatusCarbon fibersPolymer science

The present invention discloses a process for producing a carbon fiber sheet, which comprises allowing, as necessary, an oxidized polyacrylonitrile fiber sheet to contain 0.2 to 5% by mass of a resin, then subjecting the resin-containing oxidized polyacrylonitrile fiber sheet to a compression treatment in the thickness direction under the conditions of 150 to 300° C. and 5 to 100 MPa (10 to 100 MPa when no resin treatment is made) to obtain a compressed, oxidized fiber sheet having a bulk density of 0.40 to 0.80 g / cm3 and a compression ratio of 40 to 75%, and thereafter subjecting the compressed, oxidized fiber sheet to a carbonizing treatment. The carbon fiber sheet has a thickness of 0.15 to 1.0 mm, a bulk density of 0.15 to 0.45 g / cm3, a carbon fiber content of 95% by mass or more, a compression deformation ratio of 10 to 35%, an electric resistance of 6 mOMEGA or less and a feeling of 5 to 70 g. Having a small electric resistance in the thickness direction, the carbon fiber sheet is suitable as an earth material and a conductive material such as battery electrode material or the like.

Owner:TOHO TAYON CO LTD

Fuel composition containing molybdenum source and metal-containing detergent, and its use in two-stroke engines

InactiveUS20040211112A1Low economyLower performance requirementsCooking-vessel materialsExhaust apparatusAfter treatmentAlkaline earth metal

A fuel composition, and a method and an apparatus for combusting it in a two-stroke engine, in which molybdenum introduced from the fuel will interact with alkaline earth metal originating from a detergent or other co-ingredient of the fuel in the combustion products to increase detergency without increasing the level of alkaline earth metal or compounds present in the fuel or combustion products thereof. In this manner, the engine operates more cleanly and efficiently without increasing the risk of harmful alkaline earth materials and compounds thereof blocking and poisoning catalysts, sensors and / or automotive on-board diagnostic devices, and it can lead to improved durability of exhaust after treatment systems.

Owner:AFTON CHEMICAL

Method for protecting wet earthen site

The invention provides a method for protecting a wet earthen site. The method includes the steps that quick lime is evenly mixed into wet earth materials to obtain lime earth materials, China wood oil is added to and evenly mixed into the lime earth materials to obtain China wood oil lime earth materials, and the mixed China wood oil lime earth materials are filled into collapsed positions of the wet earthen site. Quick lime is combined with earth particles after a series of reaction to form an eutectic whole, and therefore strength and water stability of an earth body are improved; by the utilization of China wood oil oxide film water repellency and permselectivity and irreversibility of reactions and the effect of wrapping the earth particles, the earth particles are prevented from making contact with water, the earth body has water repellency, and therefore water stability of the whole earth site is improved. The mixed earth materials which have water repellency and good strength and water resistance are filled into the collapsed regions of the earth site, so that buckling failure generated when the earth body makes contact with water can be avoided. The method is new, feasible and used for long-term preservation of the wet earthen site.

Owner:LANZHOU UNIVERSITY

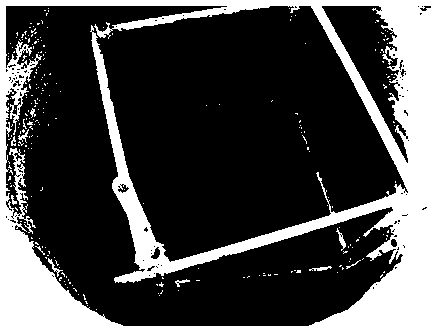

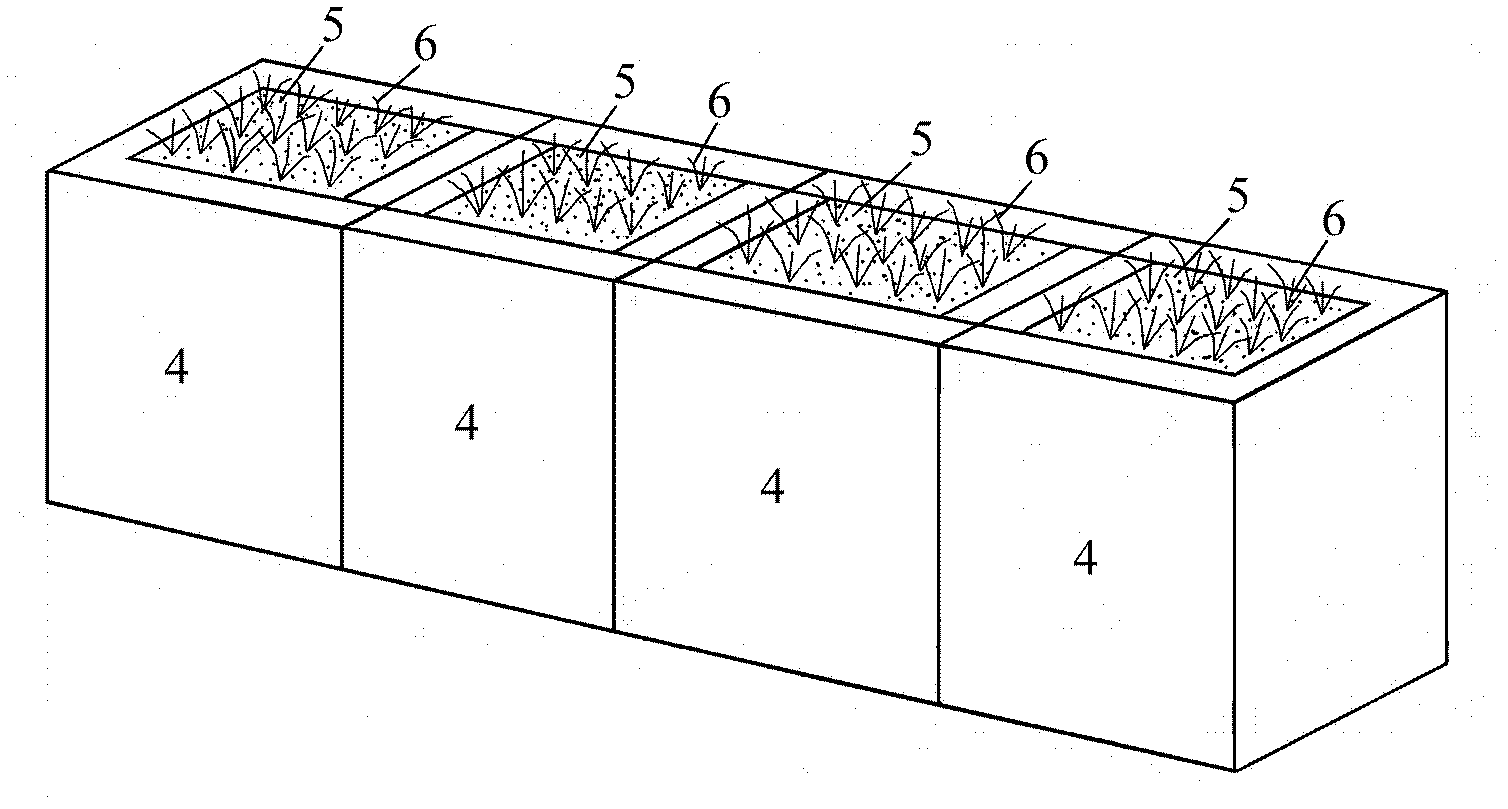

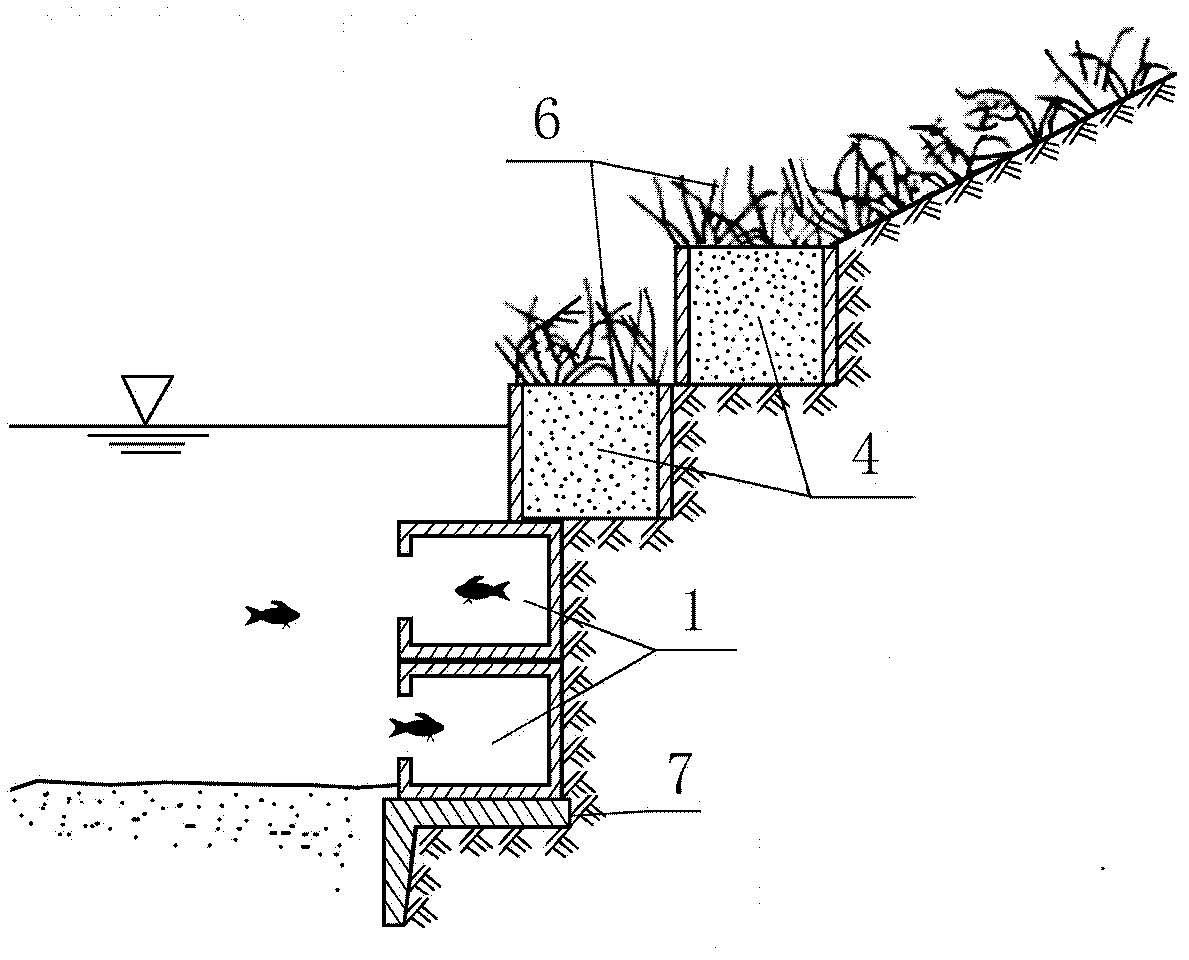

Ecotype prefabricated building bock bank revetment

InactiveCN102322040APromote growthPromote reproductionBreakwatersQuaysAquatic ecosystemWater quality

The invention discloses an ecotype prefabricated building bock bank revetment. The upper part is built by dryly laying plant type cavity building blocks, and the lower part is built by dryly laying fish nest type cavity building blocks; the plant type cavity building blocks are built into a stepped bank revetment and are provided with top-to-bottom cavities; the cavities of the plant type cavity building blocks are filled with an earth material in which plants are planted; the fish nest type cavity building blocks are provided with run-through cavities in water flow direction and are provided with holes on the water side; the fish nest type cavity building blocks and the plant type cavity building blocks are made of water-permeable concrete or water-impermeable concrete; and when the cavity building blocks are made of the water-impermeable concrete, the back side is provided with water-permeable holes. The bank revetment has a certain structural strength, is resistant against scour and has a protection effect on the revetment; the cavity structure of the building block meets an ecological design principle and contributes to plant growth and small organism propagation; and the building blocks are water-permeable, are used for communicating an aquatic ecosystem with a land ecosystem and have a certain natural purification effect on water pollution.

Owner:TIANJIN UNIV

Haydite and preparation method thereof

InactiveCN102351559AImprove thermal expansion and contractionImprove thermal stabilityCeramic materials productionCeramicwareSodium BentoniteSludge

The invention discloses a haydite and a preparation method thereof. The haydite is characterized by comprising the following components in percentage by weight: 40-100% of ceramic factory waste tail mud, 0-40% of bentonite and 0-50% of water treatment sludge. The preparation method comprises the following steps: 1) crushing the raw materials, mixing, and evenly stirring to obtain a composite semi-finished earth material; naturally drying or baking the semi-finished earth material until the water content is 15-25%, and granulating in a granulator; and 2) firing the granules in a rotary kiln while adjusting the rotation speed of the kiln and the supply amount of fuel according to the firing effect, thereby obtaining the 5-30mm continuous grading haydite. In order to overcome the defects in the prior art, the invention provides an environment-friendly haydite capable of substituting clay as a raw material. The invention also aims to provide a preparation method of the haydite.

Owner:中山建华墙体材料有限公司

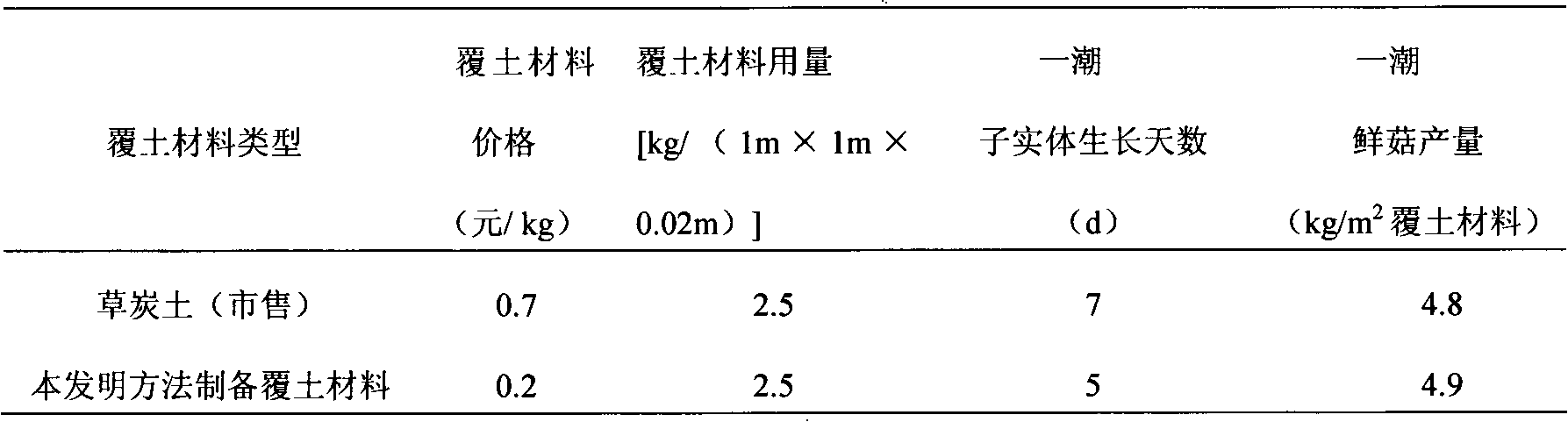

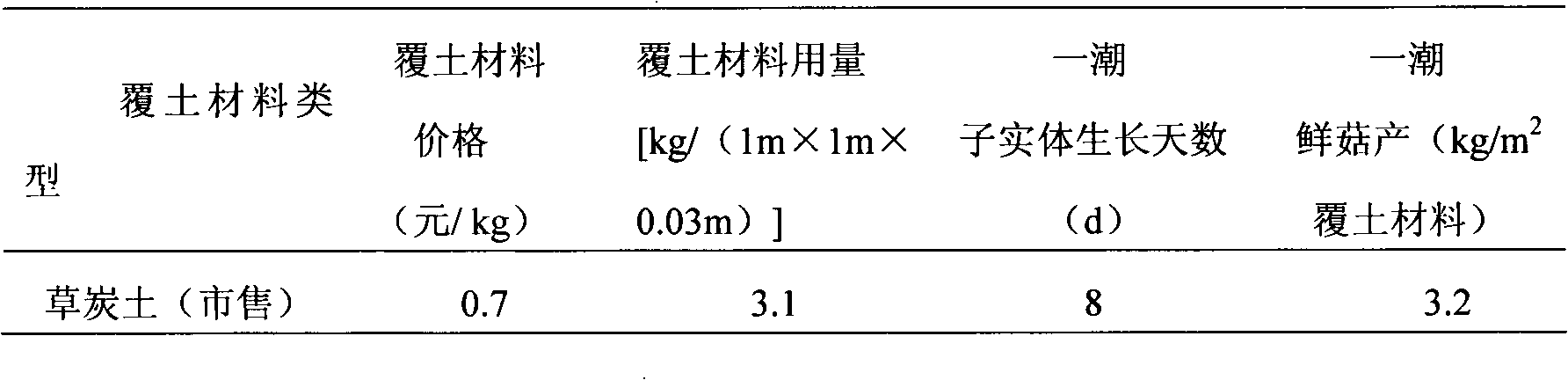

Method for preparing earthing material for cultivating edible fungi

The invention aims to provide a method for preparing an earthing material for cultivating edible fungi. The method comprises the following steps of: sun-drying or drying fungus chaff of the edible fungi, crushing and sieving; adding water, and adjusting the moisture content of fungus chaff powder of the edible fungi, and putting the fungus chaff powder into an extrusion bulking machine for extruding and bulking; crushing the bulked fungus chaff powder of the edible fungi; and adding a certain amount of pulverized coal, gypsum powder and / or lime powder, and stirring uniformly to obtain the earthing material for cultivating the edible fungi. The method is easy to operate; and compared with the common turfy soil, the prepared earthing material for cultivating the edible fungi is cheaper, but does not influence the quality and yield of sporophores of the edible fungi.

Owner:天津市农业科学院

Biomass carbon matrix environment-friendly brick and making method

InactiveCN107324773AGood environmental protection functionIncrease profitCeramic materials productionClaywaresBiomass carbonToxic gas

The invention discloses a biomass carbon matrix environment-friendly brick and a making method. The biomass carbon matrix environment-friendly brick is characterized by comprising the following components (in percentage by weight): 35-45% of biological black carbon, 55-65% of an earth material and 1-3% of molding aids, wherein the brick is made by treating the earth material, mixing with the biological black carbon, molding, drying and roasting; the biological black carbon is biological black carbon granules or powder ash made of biomasses via high-temperature carbonization; the earth material comprises 15-35% of clay, 15-25% of shale powder ash, 15-25% of coal gangue powder ash and 15-25% of coal ash; the 1-3% of molding aids comprise bentonite, fulvic acid powder and tapioca flour. The making method comprises the following steps: performing high-temperature carbonization on various types of biomass straw so as to obtain biological black carbon granules or powder ash; grinding shale, coal gangue and coal residues into a powder material; uniformly mixing with the clay and the molding aids; making bricks by using a brick making machine, drying, and sintering. Due to adoption of a biomass black carbon material, the biomass carbon matrix environment-friendly brick is capable of adsorbing toxic gases as a whole for a long time, is light and environmentally friendly, and is capable of purifying indoor polluted air and lowering cost.

Owner:湖北金日生态能源股份有限公司

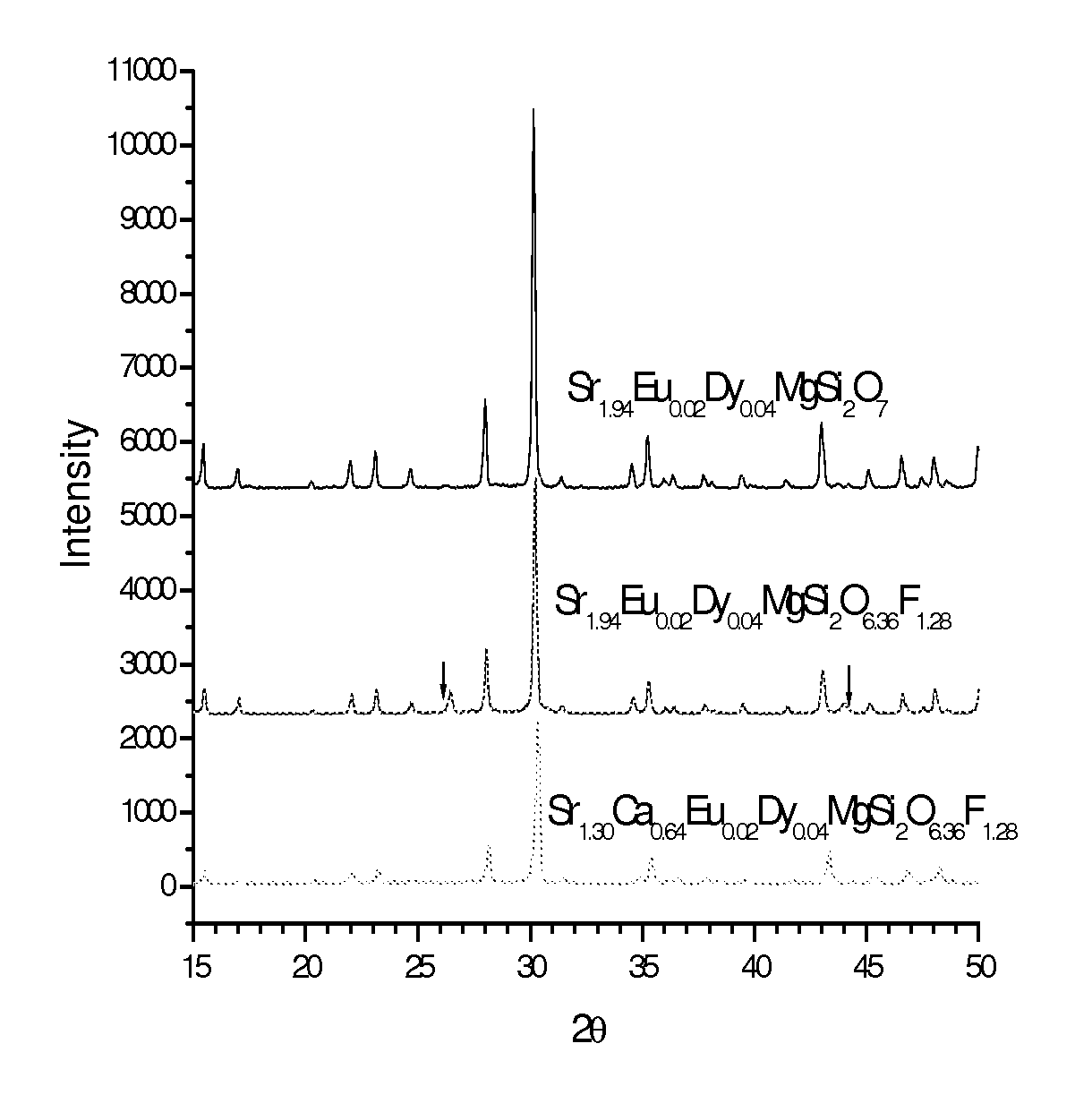

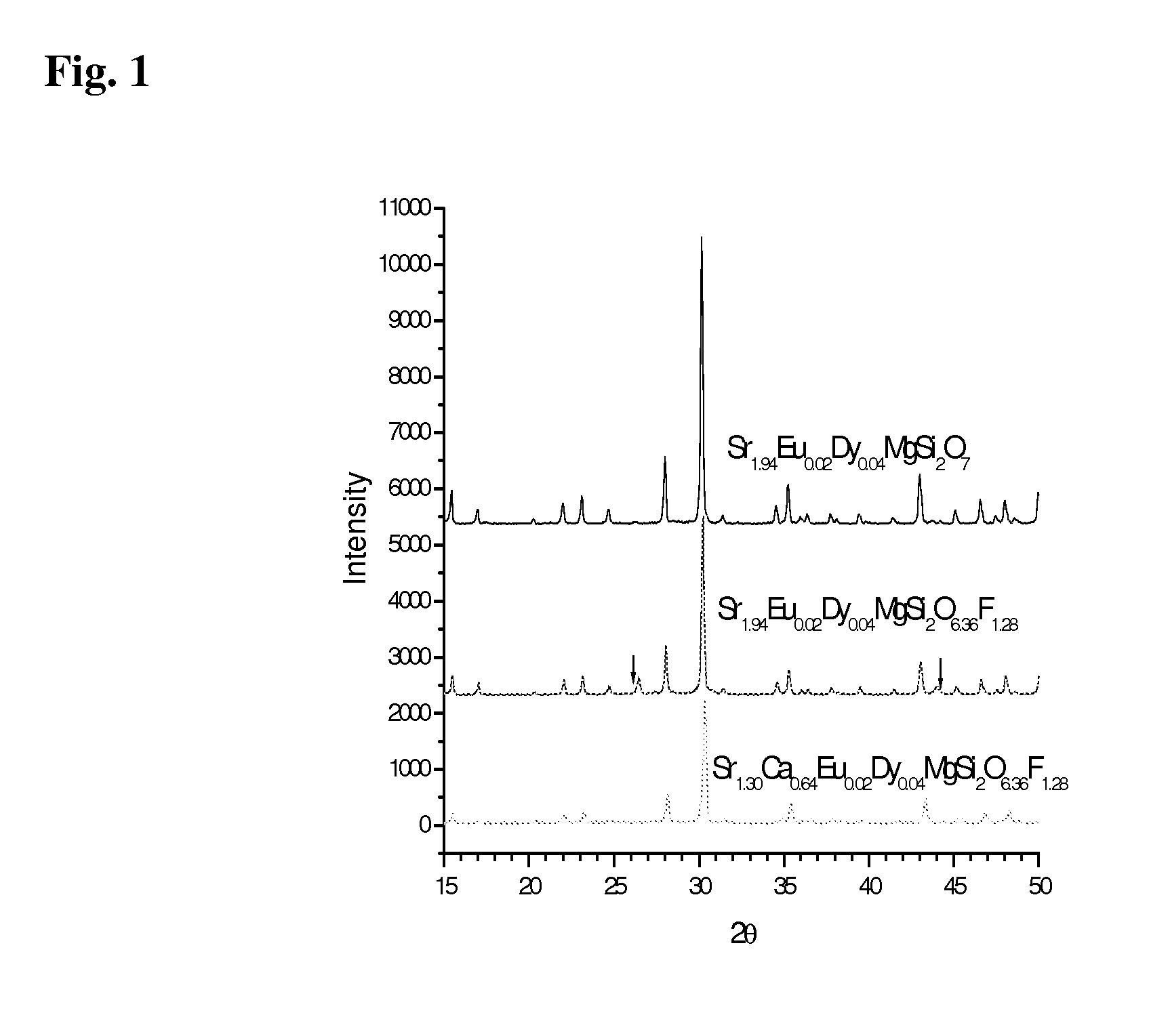

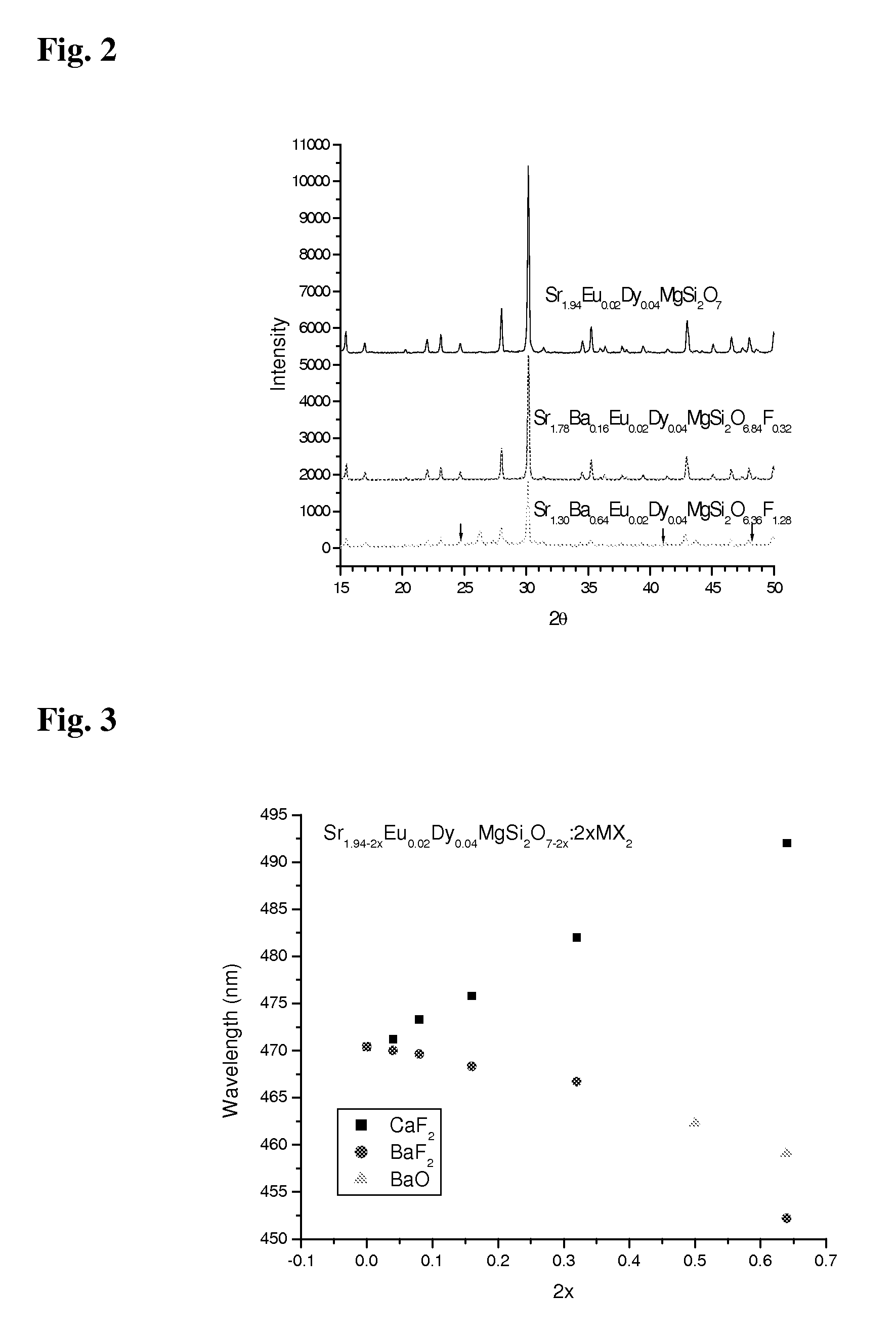

Persistent phosphors of alkaline earths modified by halides and 3d ions

Phosphorescent compositions including silicate of alkaline earth materials which are modified by at least one halide are provided. The phosphorescent compositions may include 3d ions. A variety of embodiments may be realized. The appearance of some embodiments may be glassy (i.e., vitreous).

Owner:PERFORMANCE INDICATOR LLC

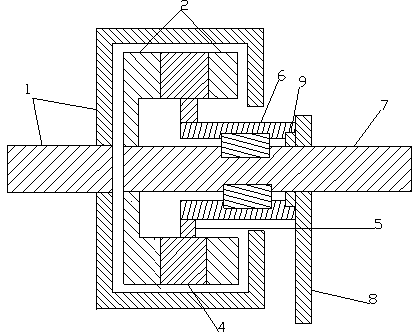

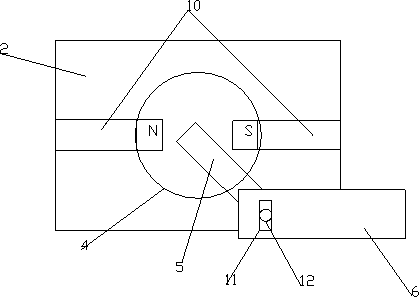

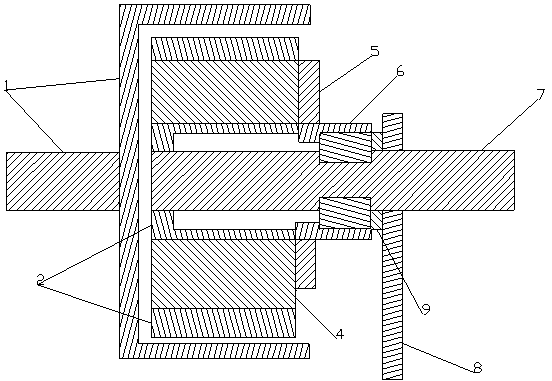

Permanent magnet speed governor with fixed magnetic gap

ActiveCN103904863AIncrease meshing areaReduce power consumptionDynamo-electric gearsPermanent magnet rotorDrive shaft

The invention relates to a permanent magnet speed governor with a fixed magnetic gap. The permanent magnet speed governor with the fixed magnetic gap comprises a cylindrical conductor rotor and a permanent magnet rotor inside the cylindrical conductor rotor, wherein the permanent magnet rotor comprises a driven shaft and at least one rotary permanent magnet surrounding the circumference of the driven shaft; the rotary permanent magnets are cylindrical and are divided into N poles and S poles in the diameter direction; two magnetizers are wrapped around the two sides of the rotary permanent magnets and are spaced by a non-magnetizer; each rotary permanent magnet is connected with the driven shaft through the magnetizer on the corresponding side; a magnetic circuit regulator is arranged at one end of each rotary permanent magnet. Due to the adoption of the fixed magnetic gap structure, the meshing area of the speed governor is increased greatly, the assembly difficulty is lowered, waste of rear earth materials is reduced, and the torque transmission capacity is improved greatly. In addition, the power consumption of an executing and adjusting mechanism is reduced greatly, the overall size of the speed governor is greatly decreased, material consumption is reduced, installation space is saved, and convenience is brought to on-site installation construction.

Owner:刁俊起

Comb type polycarboxylic acid efficient ceramic water reducer and preparation method and application thereof

The invention belongs to the technical field of preparation of ceramic water reducers, and discloses a comb type polycarboxylic acid efficient ceramic water reducer and a preparation method and an application thereof. The method comprises the following steps: carrying out a reaction on a macromolecular monomer, sodium methylacrylsulfonate, acrylic acid, a neutralizer and a chain transfer agent under initiation by an initiator; terminating the reaction by a chain terminator to obtain the comb type polycarboxylic acid efficient ceramic water reducer. According to the obtained comb type polycarboxylic acid efficient ceramic water reducer, a lot carboxylate group ions and sulfonate group ions exist on the molecular chain on one hand, so that the zeta potential and the repulsive interaction between clay particles are increased; on the other hand, a long side chain of polyoxyethylene ether is contained to form the comb structure, so that the mutual inhibition among the clay particles is increased, and the reducer has a better water reducing effect. The reducer has a certain wear-assistant effect to a ceramic earth material and has a remarkable reinforcing effect to a ceramic biscuit, and use of a grinding aid and a reinforcer in the ceramic preparation process can be reduced. The preparation method provided by the invention is simple in synthetic process and easy for industrialized production.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

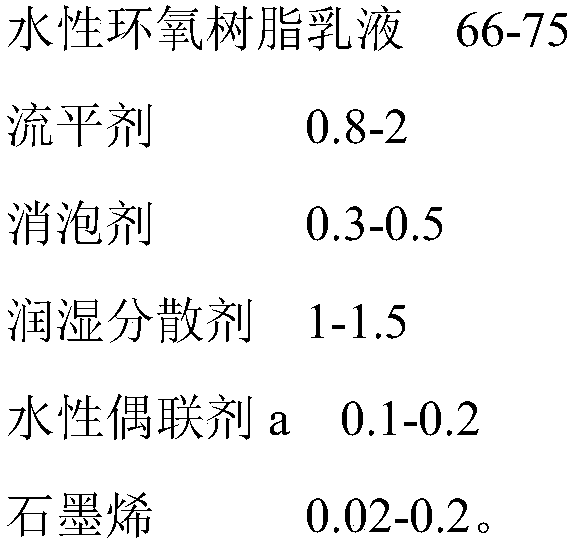

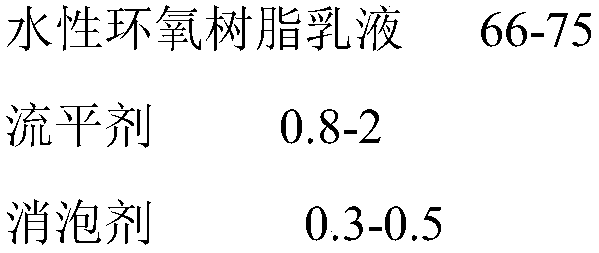

Graphene modified water-based epoxy coating reinforcing steel bar as well as preparation method thereof

ActiveCN108659673AReduce volatilityImprove mechanical propertiesPretreated surfacesAnti-corrosive paintsWater basedEpoxy

The invention belongs to the field of reinforcing steel bar corrosion-resistant metal and particularly discloses a graphene modified water-based epoxy coating reinforcing steel bar. The graphene modified water-based epoxy coating reinforcing steel bar comprises a reinforcing steel bar and a corrosion-resistant coating adhering to the surface of the reinforcing steel bar; the corrosion-resistant coating is obtained by curing water-based epoxy anti-rust coating; the water-based epoxy anti-rust coating comprises a component A, a component B and a component C; the component A comprises water-basedepoxy resin emulsion, a leveling agent, a defoaming agent, a wetting dispersing agent, a water-based coupling agent a and graphene; the component B comprises a curing agent, an anti-settling thixotropic agent and a water-based coupling agent b; the component C is a corrosion-resistant filler, namely a mixed material of rare earth materials, composite iron titanium powder, zinc powder and aluminumpowder; the grain diameter of the composite iron titanium powder is greater than or equal to that of zinc powder, the grain diameter of the zinc powder is greater than or equal to that of aluminum powder, and the grain diameter of the aluminum powder is greater than that of rear earth materials. The water-based epoxy coating reinforcing steel bar prepared according to the method is environmentally friendly, high in corrosion resistance and convenient and rapid in construction, and can be used for repairing defects.

Owner:CENT SOUTH UNIV +1

Classifying kits

Owner:PETERSON MARK

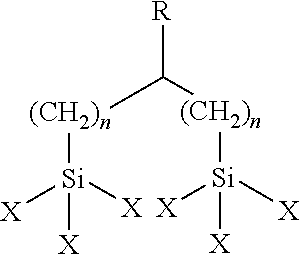

Silane Modified Diatomaceous Earth Mechanical Insecticide

ActiveUS20130101654A1Enhance and increase functionalityEnhance and increase and applicabilityBiocideInorganic active ingredientsSilanesSprayer

A mechanical insecticide is made by mixing water with at least one type of silane to make a silane solution which is then mixed with diatomaceous earth until there is substantial deposition of the silane material on the diatomaceous earth material, to make a silanized diatomaceous earth. The silanized diatomaceous earth can be diluted with water and applied to vertical and overhead surfaces using a sprayer, for the control of insects. The silanized diatomaceous earth can also be dried into a powder for broadcast application, or mixed as a paste for brush / roller / caulk application.

Owner:EARTHCOAT PLUS LLC

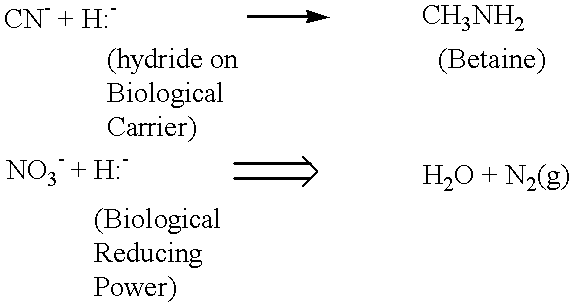

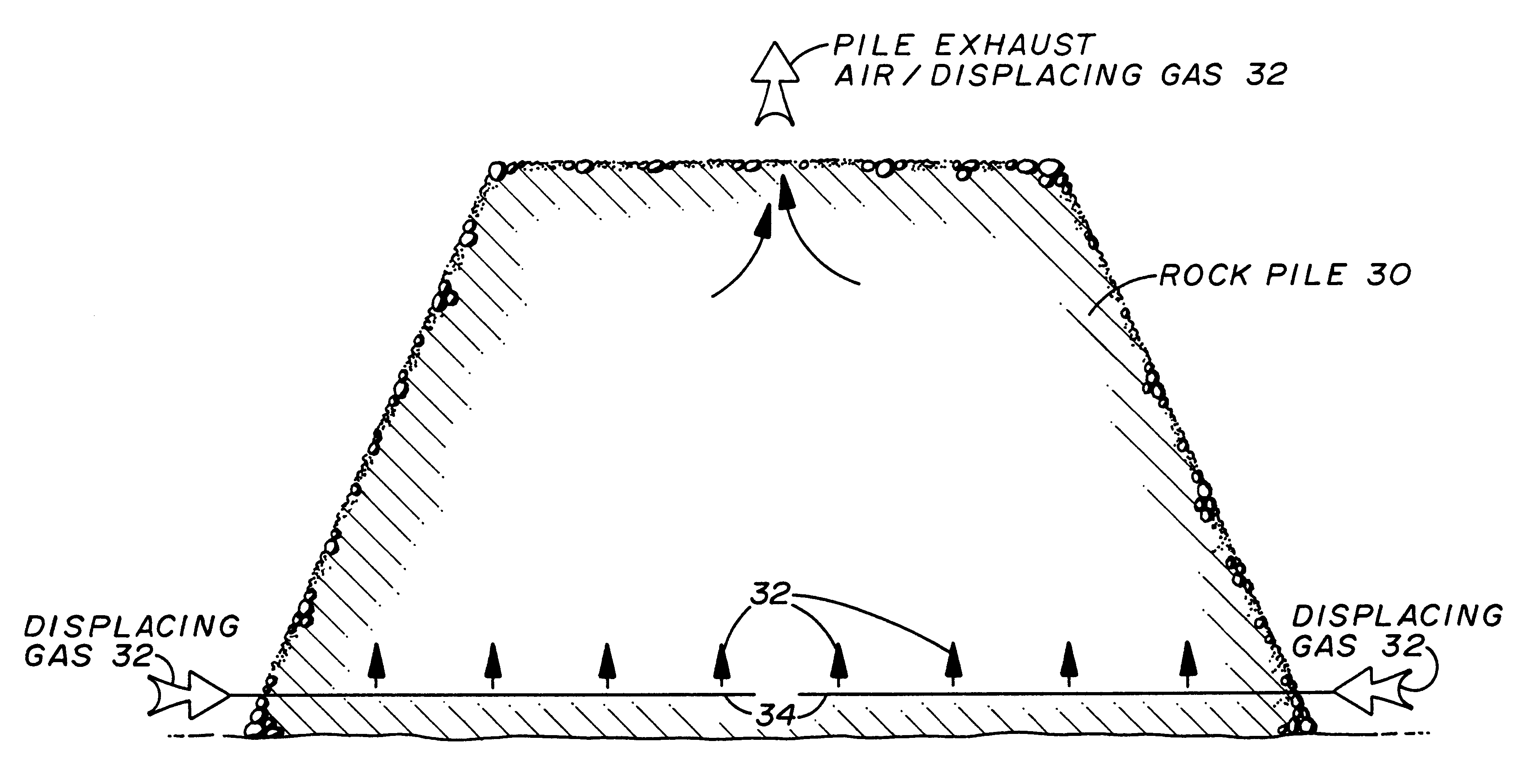

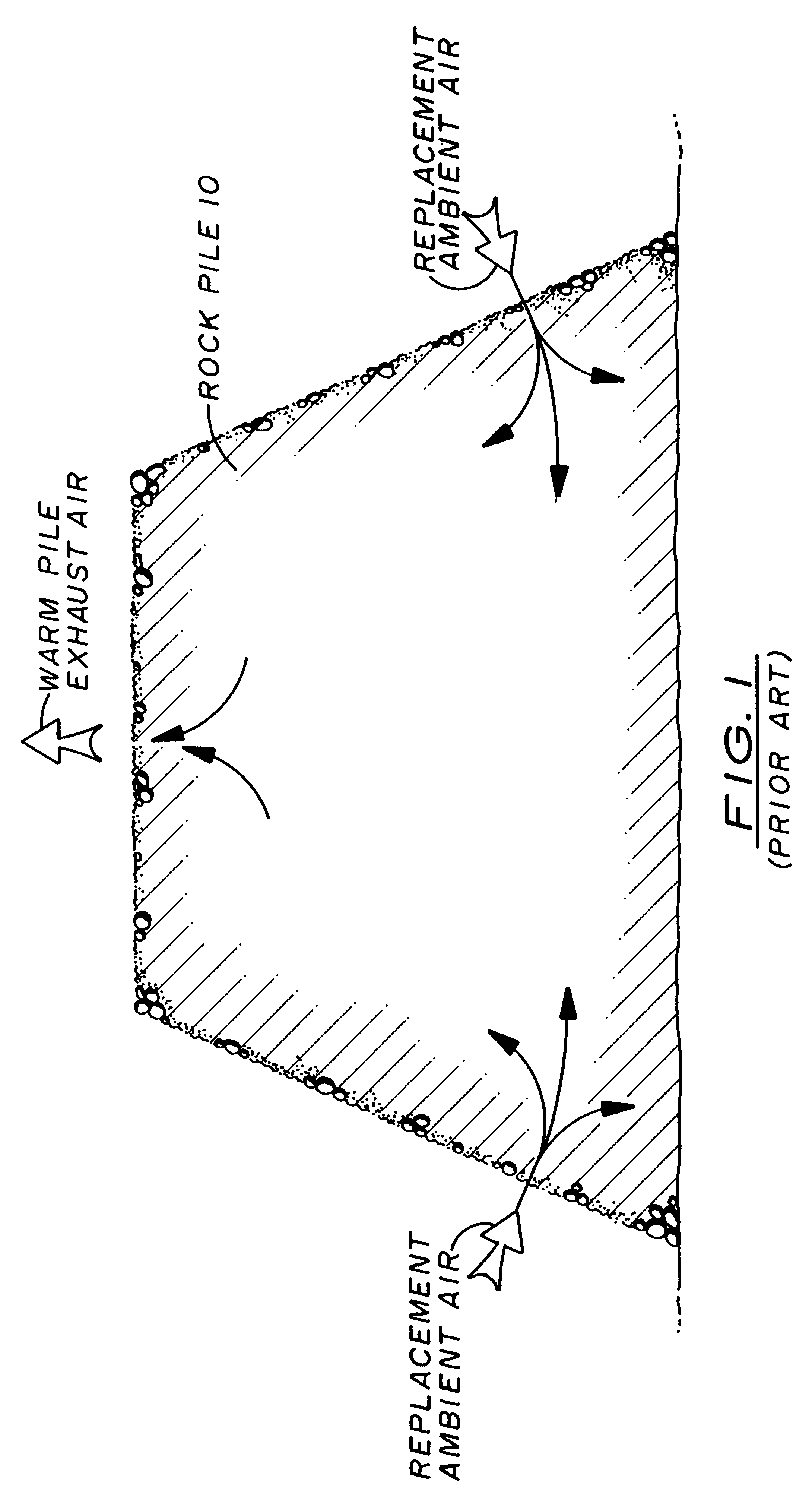

Inhibiting acid mine drainage by displacing oxygen in rock heap

InactiveUS6196765B1Low densityHigh densitySolid waste disposalContaminated soil reclamationVegetationGas phase

A process for treating earth materials such as rock heaps to prevent acid rock drainage therefrom is disclosed. First, the oxygen concentration in the gas-phase of the rock heap is decreased, that is, displaced and / or depleted. This first step may be accomplished physically, chemically or biologically. Then, the gas-phase oxygen concentration in the heap is maintained at a low level. This second step may be provided for in a self-sustaining manner, like, for example, by covering the rock heap with soil and vegetation so that acid rock drainage is prevented indefinitely. Alternatively, the density of the gas-phase of the rock heap may be increased, and maintained at an elevated level indefinitely. The process is applicable to waste heaps from mining and industrial operations such as power generation and minerals processing, and to rubble collections in open and closed mines.

Owner:ALEXCO WATER & ENVIRONMENT INC

Construction method for anti-seismic rammed earth wall with reinforced surface skin and core columns

The invention relates to a construction method for an anti-seismic rammed earth wall with a reinforced surface skin and core columns and belongs to the technical field of construction engineering. According to the method, a rammed earth wall formwork is manufactured, and pre-embedded core molds are placed into the rammed earth wall formwork. The effect of the surface skin is reinforced under the tying and connecting action of two kinds dovetail joint type earth materials in the mode that different earth materials are added twice; the anti-seismic performance of the rammed earth wall is enhanced under the action of criss-cross tying and connecting action by prefabricating the pore-forming core columns, earth mass reinforcing columns and steel wire sewn mesh sheets. The method has the advantages that the construction cost of the rammed earth wall is lowered, and the durability and reliability of the rammed earth wall are improved.

Owner:KUNMING UNIV OF SCI & TECH

Top arch overfilled system

An earth overfilled arched structure includes a shallow arch spanning a clear space. The sides of the clear space are formed by curved or straight walls. Solidified zones of earth material (backfill or in situ) against the springs of the arch and / or behind the walls form foundation blocks which are in intimate contact via arch footings with the springs of the arch and / or with the upper part of the sidewalls in such a way that the arched structure delivers most or all of its support forces into the foundation blocks. These, due to their size and weight, transfer and spread the support forces to the subsoil so that displacements, especially in the horizontal directions, are minimal.

Owner:CONTECH ENGINEERED SOLUTIONS

UV resistant multilayered cellular confinement system

InactiveUS7648754B2Increased durabilityPrevent penetrationButtress damsLayered productsTelecommunicationsUltraviolet

Owner:GEOTECH TECHNOLOGIES LTD

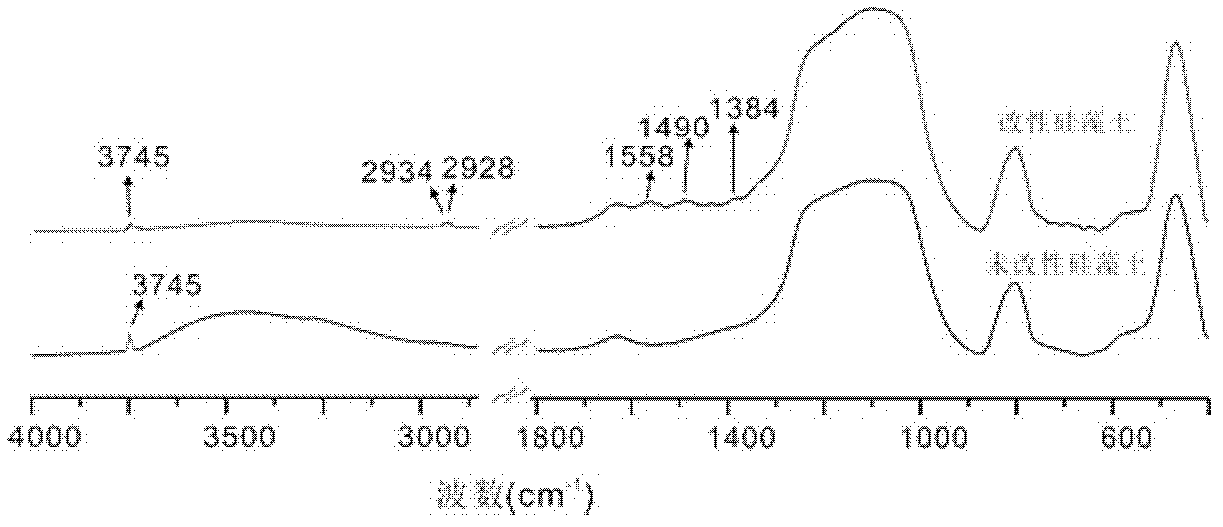

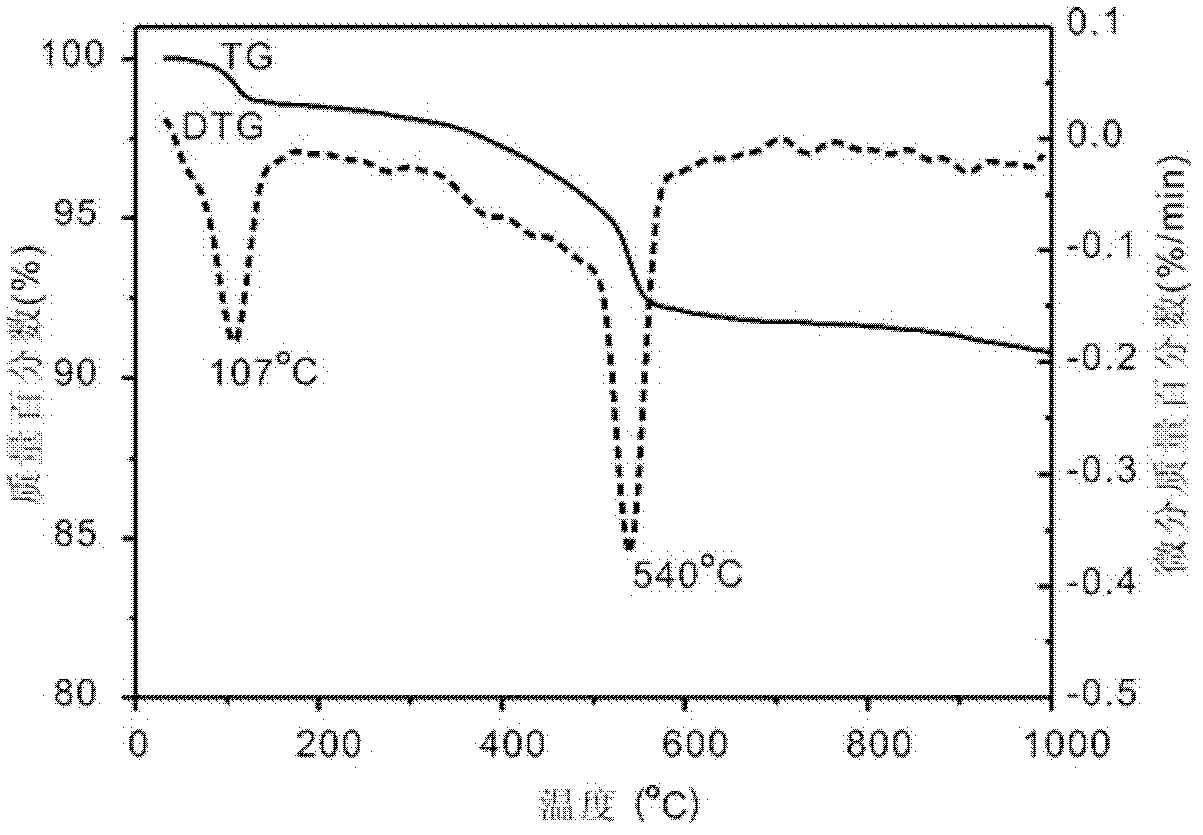

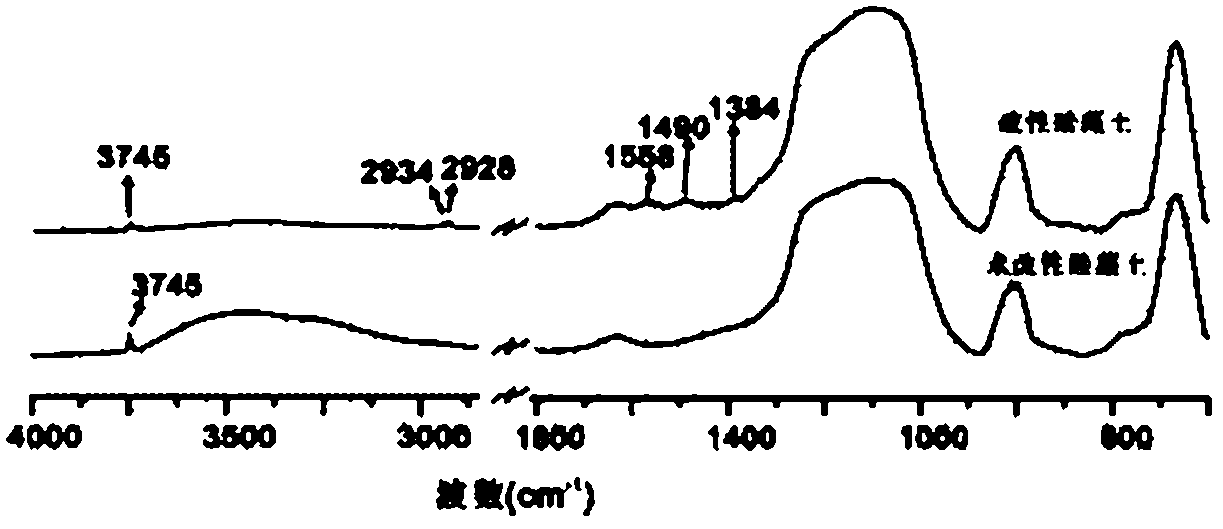

Preparation method of modified diatomaceous earth material for absorbing divalent copper ions in water solution

InactiveCN102500326AEasy picklingAchieve recyclingOther chemical processesWater/sewage treatment by sorptionSilanesWastewater

The invention relates to a preparation method of a modified diatomaceous earth material for absorbing divalent copper ions in water solution, which comprises the following steps of: carrying out heat-processing to a diatomaceous earth raw material; mixing and dissolving amino organic silane and a non-aqueous solvent; adding diatomaceous earth; carrying out reflux reaction; washing-filtering; drying; crushing; and the like. In the invention, the obtained modified diatomaceous earth material can absorb and process Cu2+ in the aqueous solution. The invention has the advantages of efficiency, low cost, stably absorption material, recovery and the like, and can be widely applied for copper-contained waste water processing, trace copper absorption and recovery, and the like.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

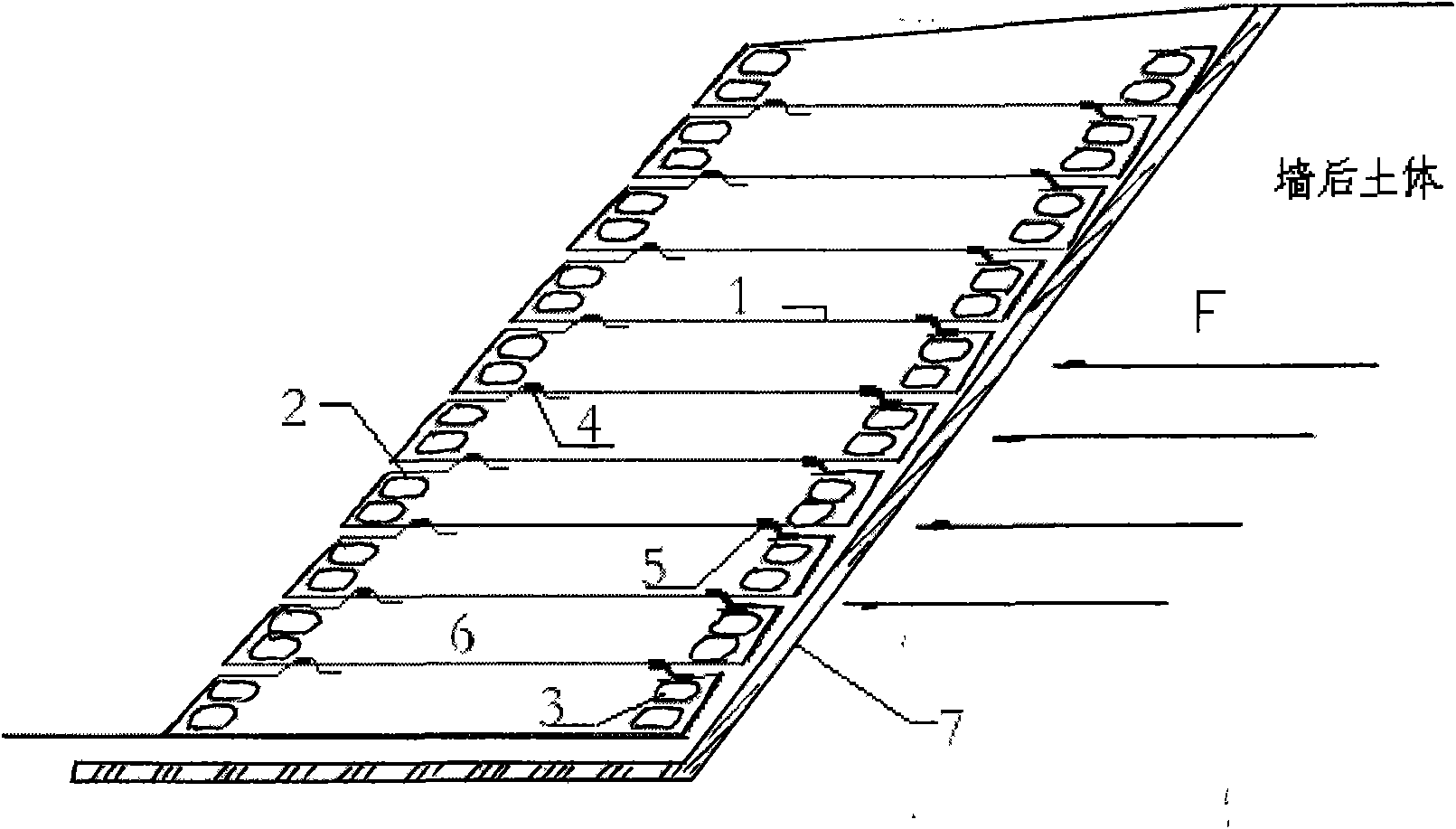

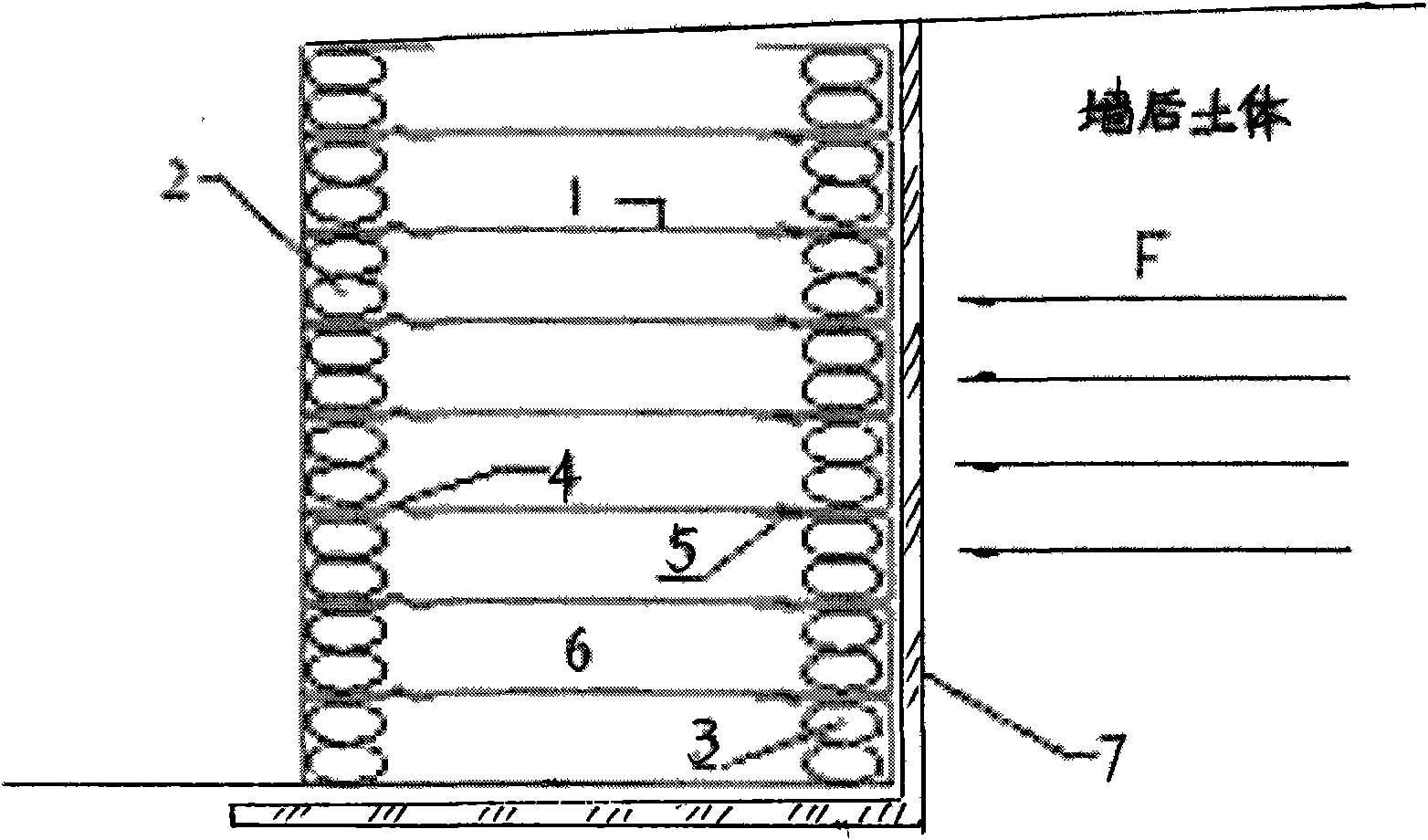

Reinforced core-enveloped structural slope protector

InactiveCN101555693AShorten design lengthImprove skid stabilityExcavationsEngineeringEarth materials

The invention relates to a reinforced core-enveloped structural slope protector, which mainly comprises a unidirectional geotechnological grid, fillings, an anti-aging plant-growing geotextile bag and connecting pieces. The slope protector is made from the fillings reinforced with the unidirectional geotechnological grid. The structural slope protector can obtain the raw materials from local resources and can be constructed with the earth material on the construction site, thus significantly saving energy; the reinforced materials of the structural slope protector has good durability; the structural slope protector also has the advantages of convenient construction, lower construction cost and the like.

Owner:朱海龙 +2

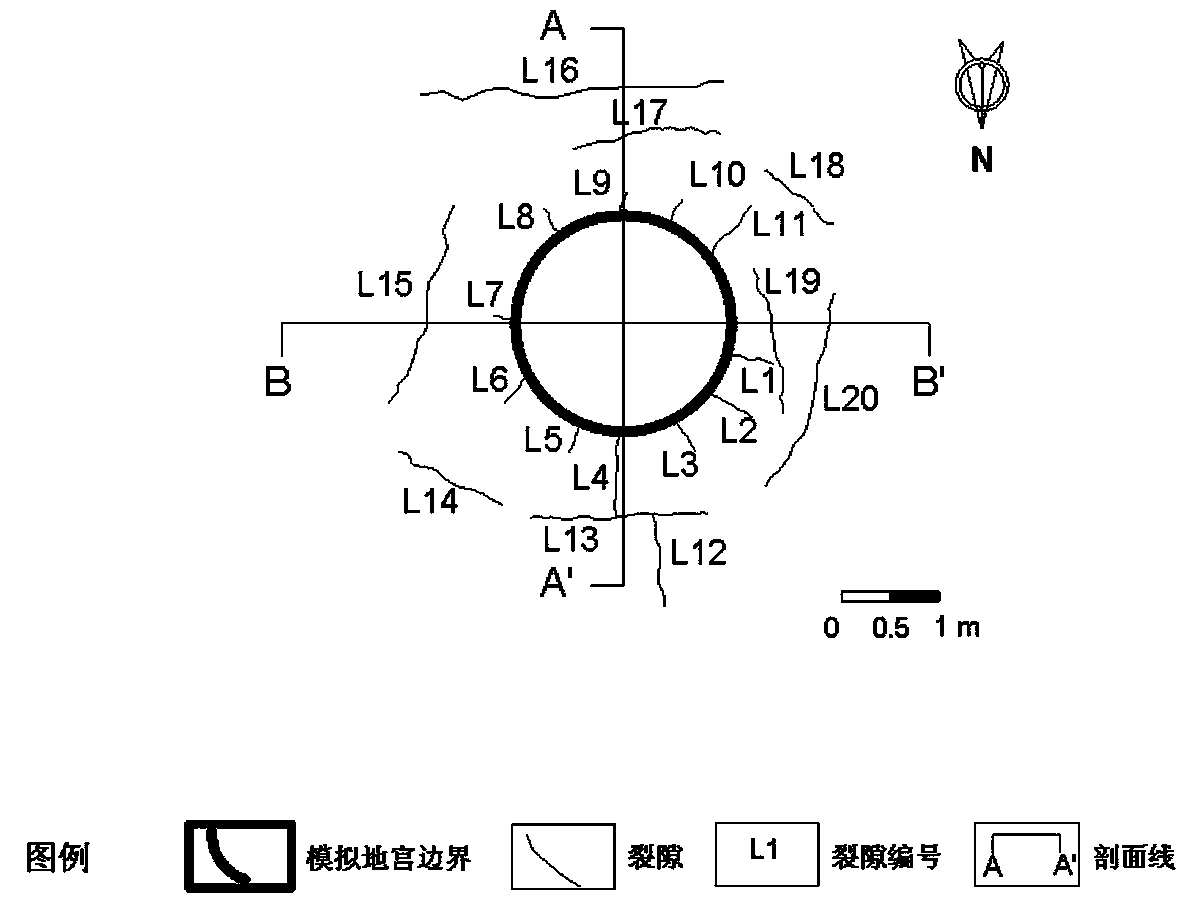

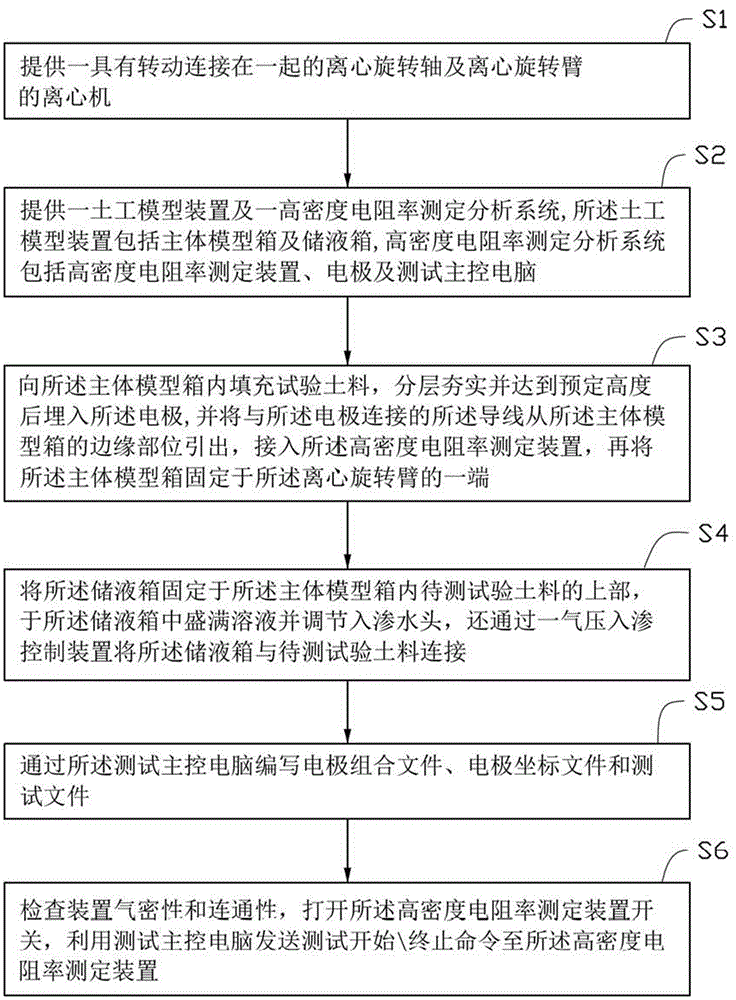

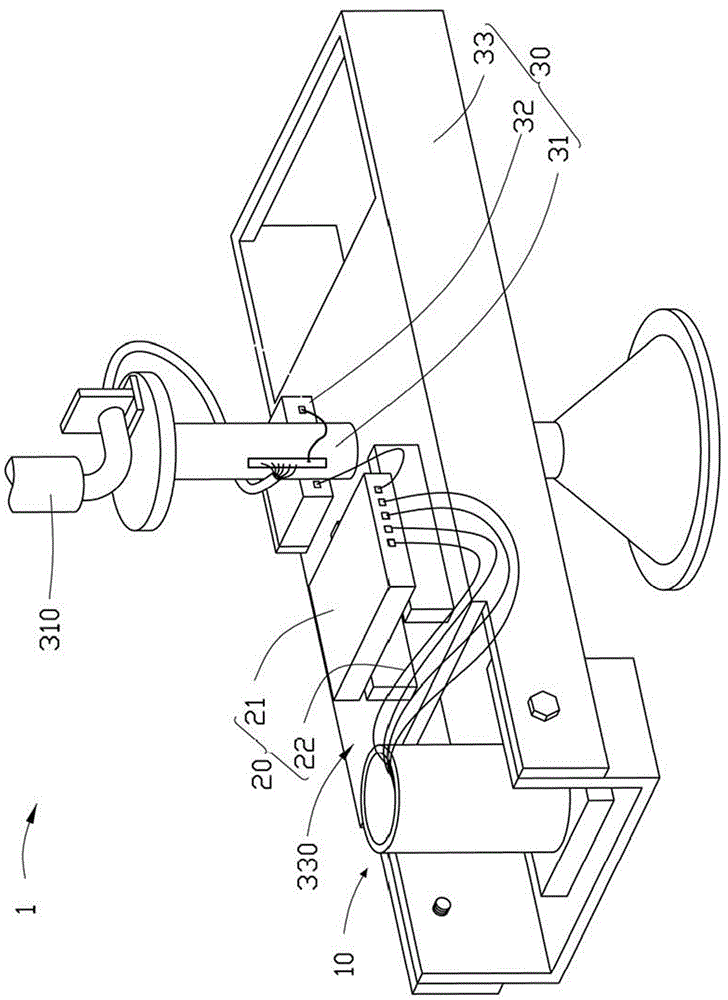

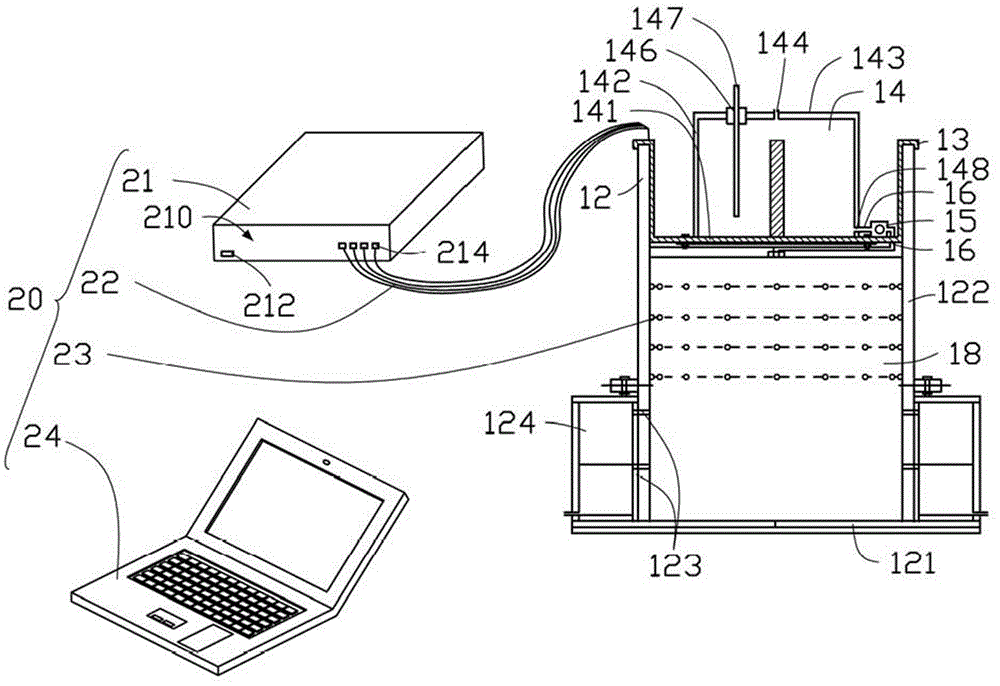

Seepage and solute migration measuring method based on high-density resistivity method

ActiveCN104535474ARealize real-time measurementSurface/boundary effectPermeability/surface area analysisElectricityHigh density

The invention provides a seepage and solute migration measuring method based on a high-density resistivity method. The method comprises the following steps that a test master control computer is placed at a position suitable for a tester and is in wireless connection with a centrifugal machine load host, a high-density resistivity measuring device is connected with the centrifugal machine load host through a data line, and electrodes are electrically connected with the high-density resistivity measuring device through wires. A body model box is fixed to one end of a centrifugal rotary arm, and the electrodes are evenly distributed on the edge of the body model box clockwise. A liquid storage box is fixed to the upper portion of a to-be-measured test earth material in the body model box. The test master control computer sends a test start / stop command to the high-density resistivity measuring device, and the high-density resistivity measuring device carries out a test action or stops the test action according to the command. The seepage and solute migration measuring method based on the high-density resistivity method can meet three-dimensional damage-free real-time measurement needs.

Owner:TSINGHUA UNIV

Classifying Kits

Owner:PETERSON MARK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com