Aggregate and concrete production equipment and aggregate and concrete production process

A technology for production equipment and concrete, which is applied in the fields of clay preparation device, mixing operation control, chemical instrument and method, etc., can solve the problems of secondary dust, harsh environment of aggregate production site, great influence on human health and atmospheric environment quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

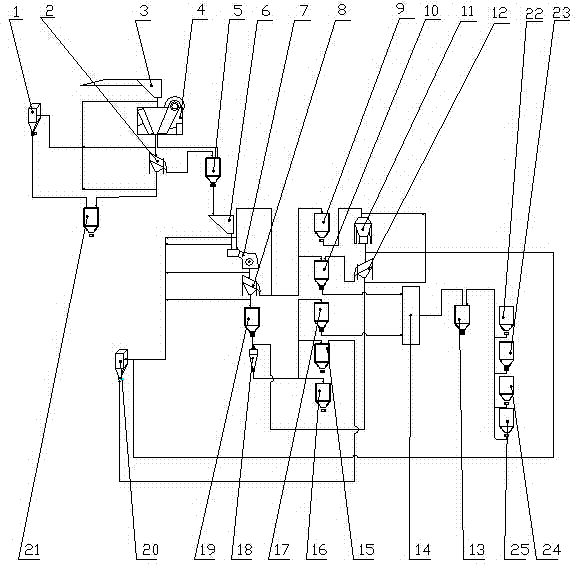

[0013] A set of aggregate and concrete production equipment, including: DCS central control system, the DCS central control system controls the soil low-pressure pulse dust collector 1, soil screen 2, jaw crusher feeder 3, jaw type crusher 4, buffer bin 5, impact crusher feeder 6, impact crusher 7, circular vibrating screen 8, sand making storage bin 9, finished product bin 10, sand making machine 11, finished product circular vibrating screen 12, mixer 13, ingredients Bin 14, fine powder bin 15, medium powder bin 16, sand bin 17, V selection 18, mixing bin 19, powder low-pressure pulse dust collector 20, soil bin 21, sealing conveyor belt, field instrument, cement bin 22, mineral powder Bin 23, fly ash bin 24, admixture bin 25, pool, among which the jaw crusher feeder 3 is located above the jaw crusher 4 feed inlet, and the residual material sieved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com