Reinforced core-enveloped structural slope protector

A reinforcement and slope technology, which is applied in basic structure engineering, excavation, construction, etc., can solve the problems of increasing construction difficulty, construction difficulty, and high total project cost, and achieve the goal of reducing design length and improving anti-sliding stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, the filler is sandy soil, no drainage net is required

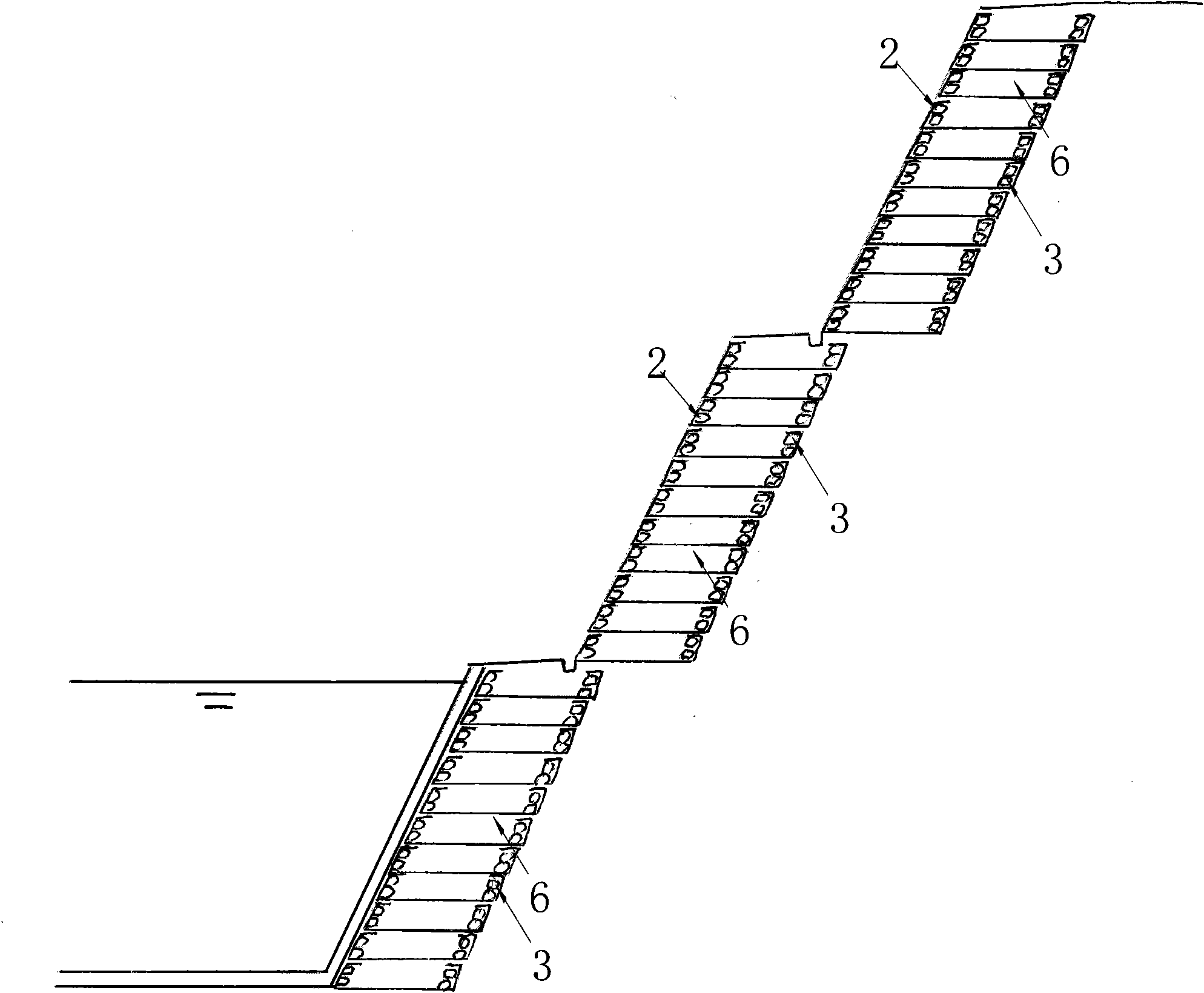

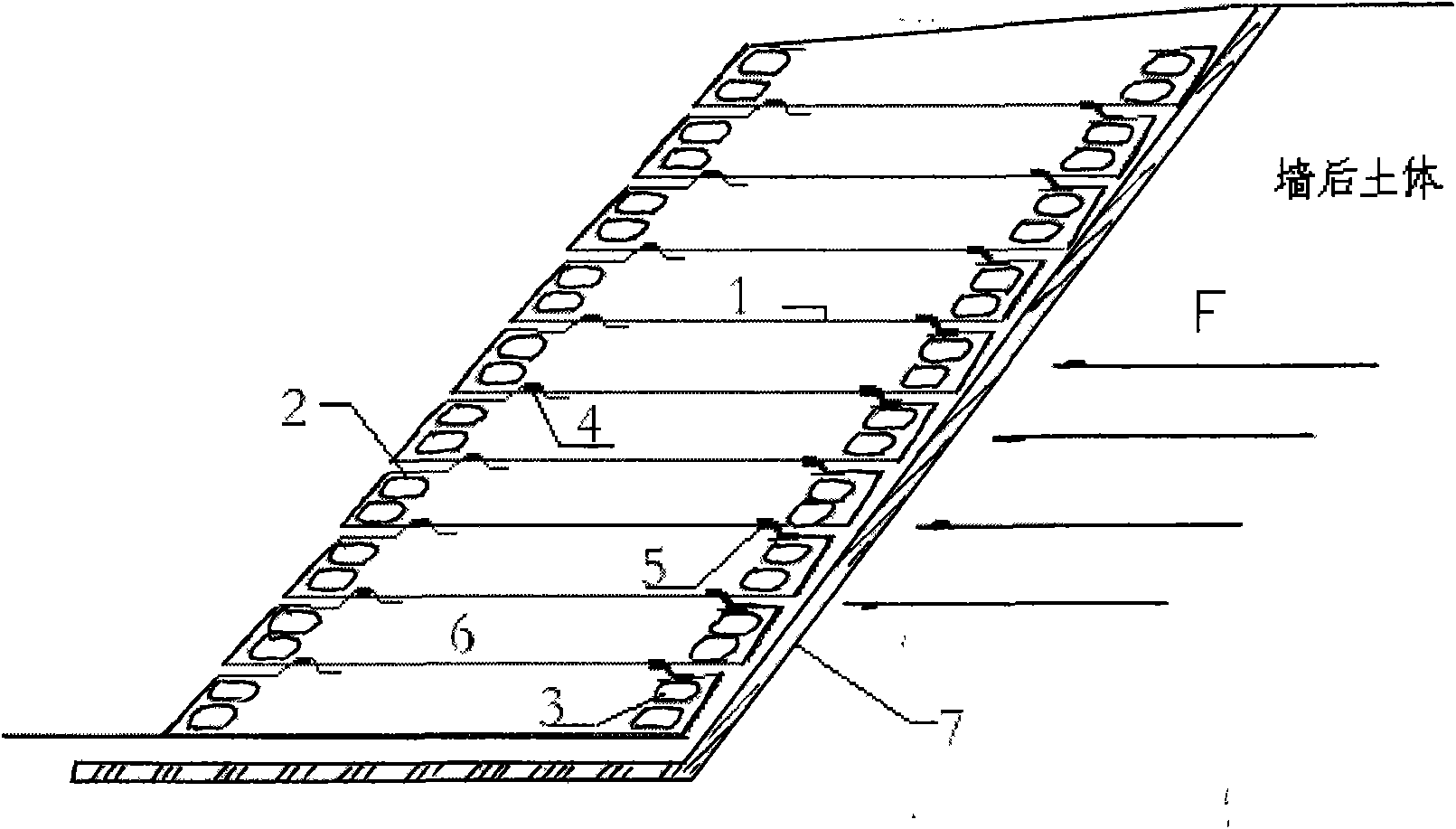

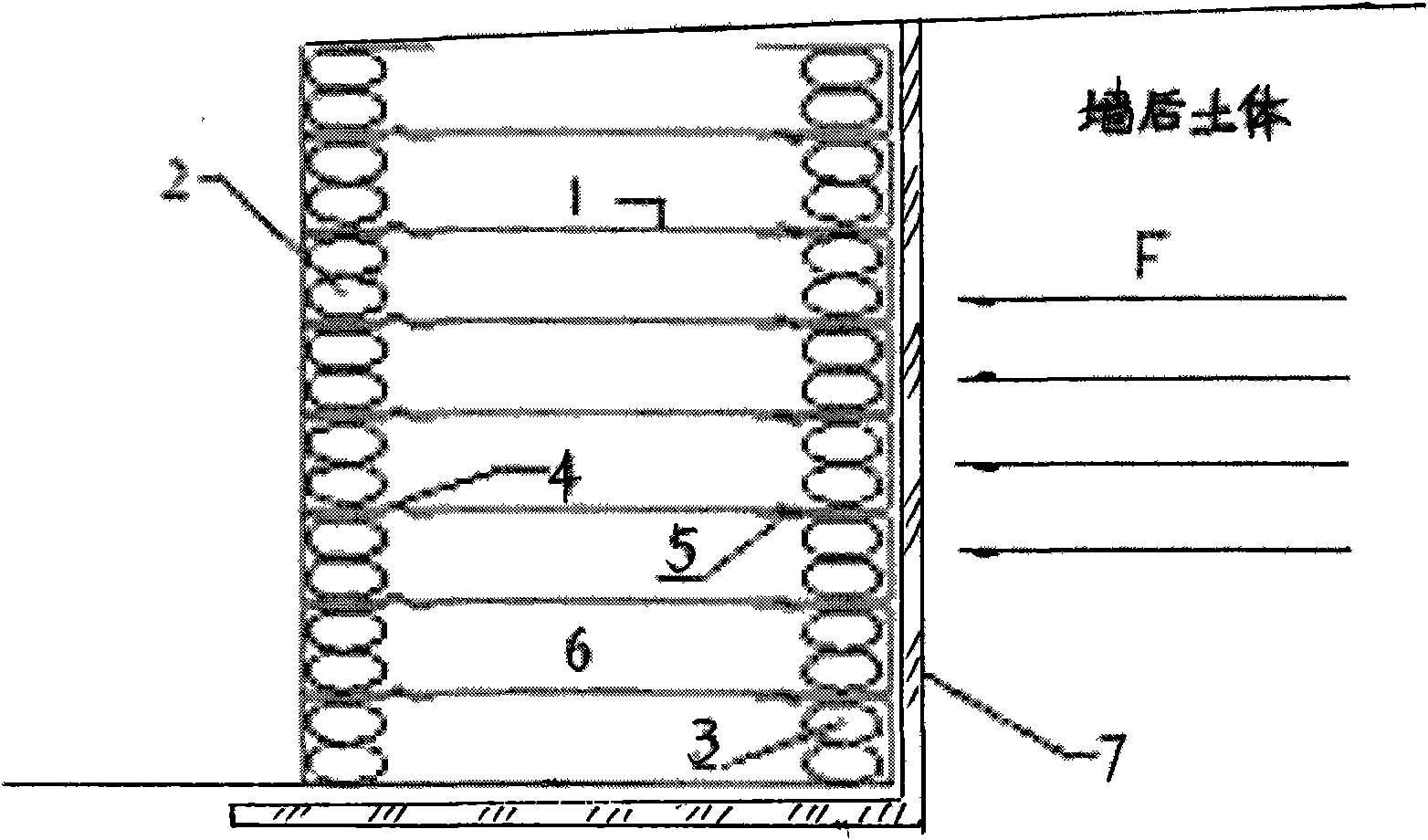

[0028] Such as Figure 1 to Figure 6 As shown, the slope protection body with reinforced wrapping structure of the present invention includes geotechnical reinforcement material 1, planting geotechnical bag 2, connecting rod 4, filler 6, geotechnical reinforcement material 1 and filler 6 are pressed alternately, and the next layer of geotechnical processing The reinforcement material 1 is connected to the upper layer and the geotechnical reinforcement material 1 through the connecting rod 4, and the planting geotechnical bag 2 is wrapped in the upper and lower layers of geotechnical reinforcement adjacent to the empty surface of the slope protection body of the reinforced wrapping structure. Between the materials 1, a geotechnical bag 3 is reversely wrapped between the upper and lower layers of geotechnical reinforcement materials 1 adjacent to the back of the reinforced wrapping structure slope prote...

Embodiment 2

[0039] Example 2 When the filling material is clay, a drainage board needs to be provided

[0040] Such as Figure 1 to Figure 6 As shown, the slope protection body with reinforced wrapping structure of the present invention includes geotechnical reinforcement material 1, planting geotechnical bag 2, connecting rod 4, filler 6, geotechnical reinforcement material 1 and filler 6 are pressed alternately, and the next layer of geotechnical processing The reinforcement material 1 is connected to the upper layer and the geotechnical reinforcement material 1 through the connecting rod 4, and the planting geotechnical bag 2 is wrapped in the upper and lower layers of geotechnical reinforcement adjacent to the empty surface of the slope protection body of the reinforced wrapping structure. Between the materials 1, a geotechnical bag 3 is reversely wrapped between the upper and lower layers of geotechnical reinforcement materials 1 adjacent to the back of the reinforced wrapping struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com