Method for preparing earthing material for cultivating edible fungi

A technology of covering soil materials and production methods, applied in the fields of botany equipment and methods, applications, gardening, etc., can solve the problem of high price, and achieve the effect of low price and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

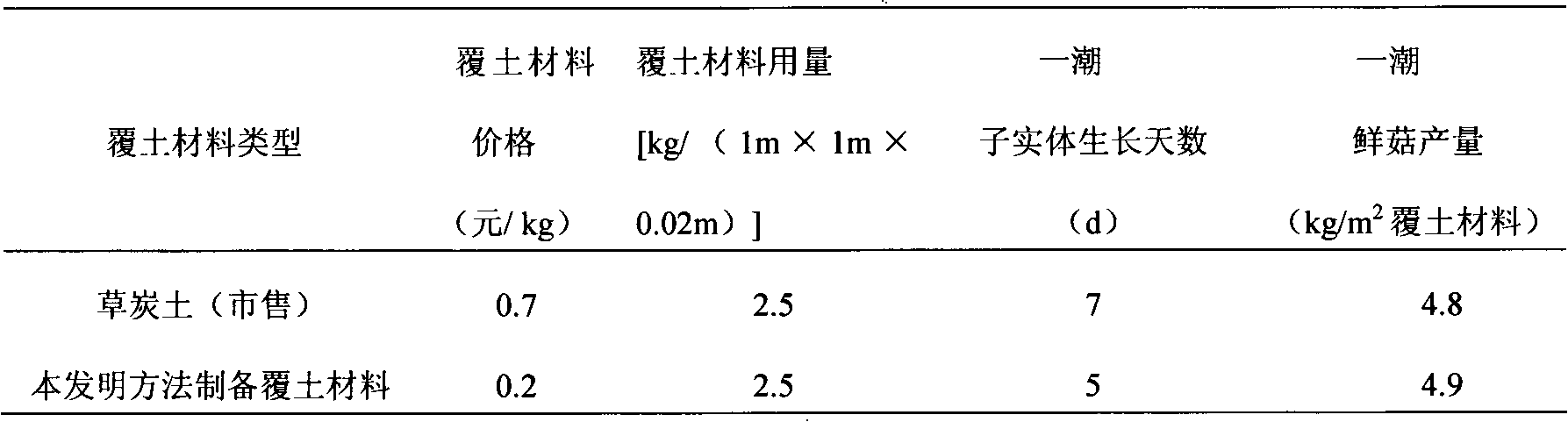

[0016] Embodiment 1. cover soil material for flat mushroom cultivation

[0017] 1) Pretreatment of the chaff of edible fungus: first dry or dry the chaff of Flammulina velutipes, crush it and pass through an 80-mesh sieve, then add water to adjust the water content of the chaff of edible fungus to 18%.

[0018] 2) Extrusion and puffing: first set the working parameters of the extrusion puffing machine, and after the extrusion puffing machine meets the requirements of the set working parameters, put the edible fungus chaff obtained in step 1) into the extrusion puffing machine for extrusion Pressing and puffing to obtain puffed Flammulina velutipes chaff.

[0019] Wherein, the extruder is a twin-screw extruder, and the working parameters of the twin-screw extruder are as follows:

[0020] Working parameters of twin-screw extrusion extruder: screw speed is 220rpm; feed rate is 50kg / h; barrel / or sleeve temperature is 115°C; die hole / or die opening diameter is 5mm.

[0021] 3) P...

Embodiment 2

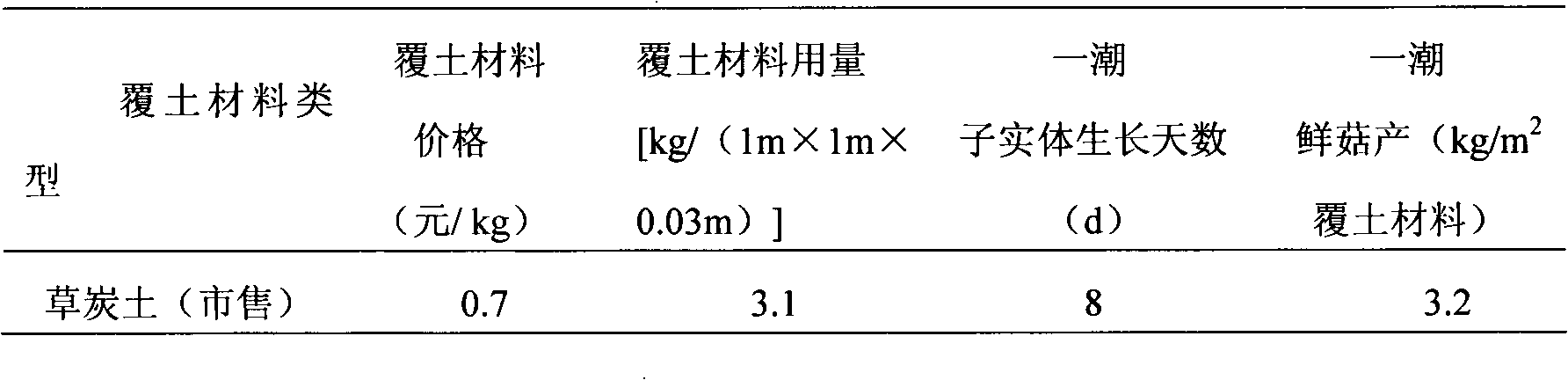

[0027] Embodiment 2. cover soil material for Coprinus comatus cultivation

[0028] 1) Pretreatment of edible fungus chaff: first dry or dry the chaff of ganoderma lucidum, champignon velutipes and flat mushroom chaff, crush them and pass through a 60-mesh sieve, then add water to adjust the water content of the chaff powder to 36%.

[0029] 2) Extrusion and puffing: first set the working parameters of the extrusion puffing machine, and after the extrusion puffing machine meets the requirements of the set working parameters, put the edible fungus chaff obtained in step 1) into the extrusion puffing machine for extrusion Pressing and puffing to obtain puffed mixed edible fungus chaff.

[0030] Wherein, the extruder is a twin-screw extruder, and the working parameters of the twin-screw extruder are as follows:

[0031] Working parameters of twin-screw extrusion extruder: screw speed is 260rpm; feed rate is 100kg / h; barrel / or sleeve temperature is 205°C; die hole / or die opening d...

Embodiment 3

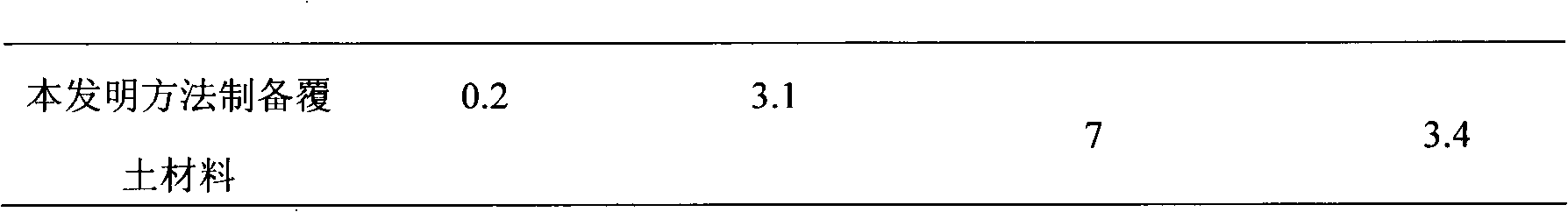

[0039] Embodiment 3. earth-covering material for shiitake mushroom cultivation

[0040] 1) Pretreatment of edible fungus chaff: first dry or dry the Ganoderma lucidum chaff and Bailing mushroom chaff, crush them and pass through a 40-mesh sieve, then add water to adjust the water content of the edible fungus chaff powder to 36%.

[0041] 2) Extrusion and puffing: first set the working parameters of the extrusion puffing machine, and after the extrusion puffing machine meets the requirements of the set working parameters, put the edible fungus chaff obtained in step 1) into the extrusion puffing machine for extrusion Pressing and puffing to obtain puffed mixed edible fungus chaff.

[0042] Wherein, the extruder is a twin-screw extruder, and the working parameters of the twin-screw extruder are as follows:

[0043] Working parameters of twin-screw extrusion extruder: screw speed is 320rpm; feed rate is 150kg / h; barrel / or sleeve temperature is 165°C; die hole / or die opening diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com