Patents

Literature

63results about How to "Increase meshing area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

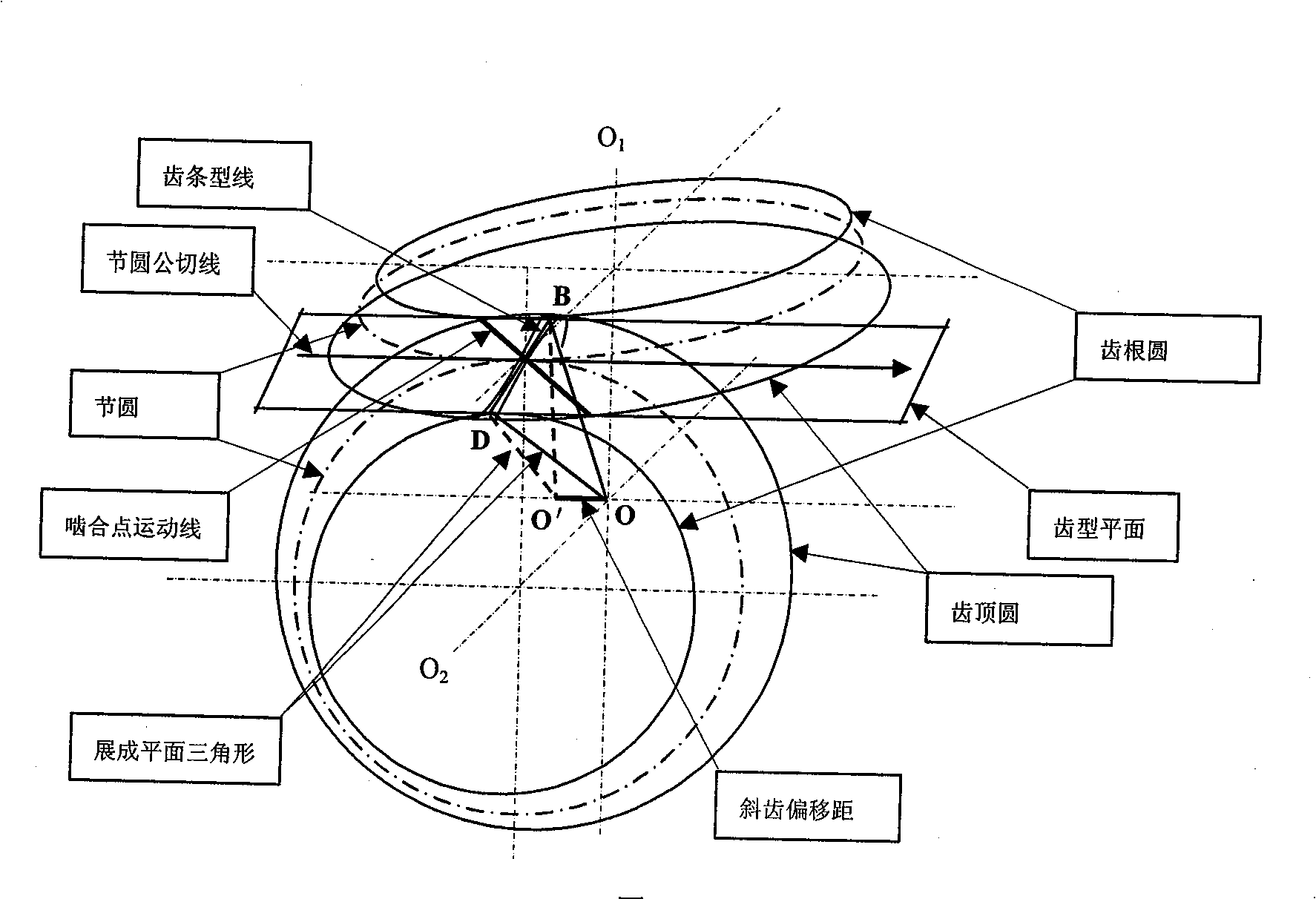

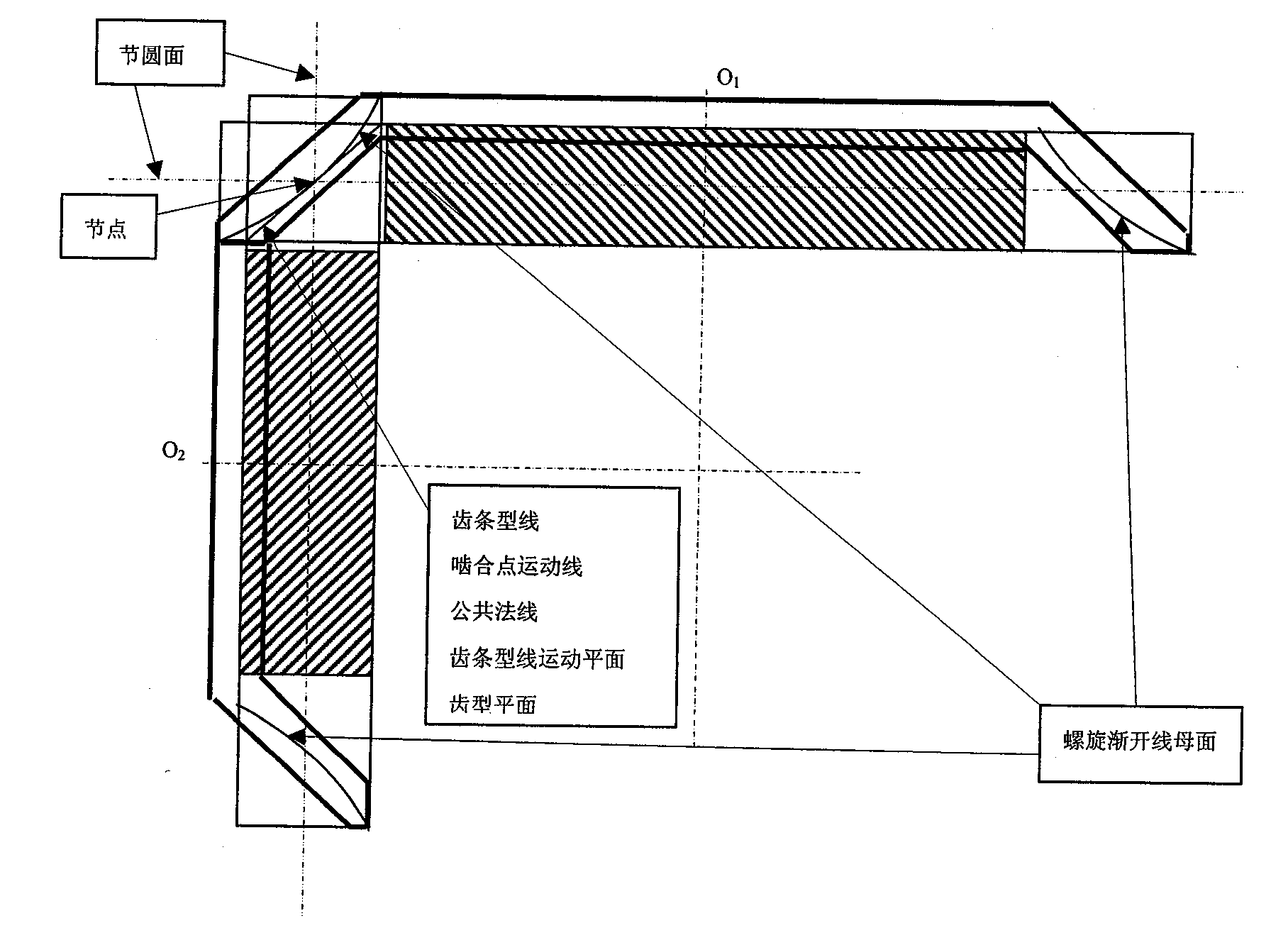

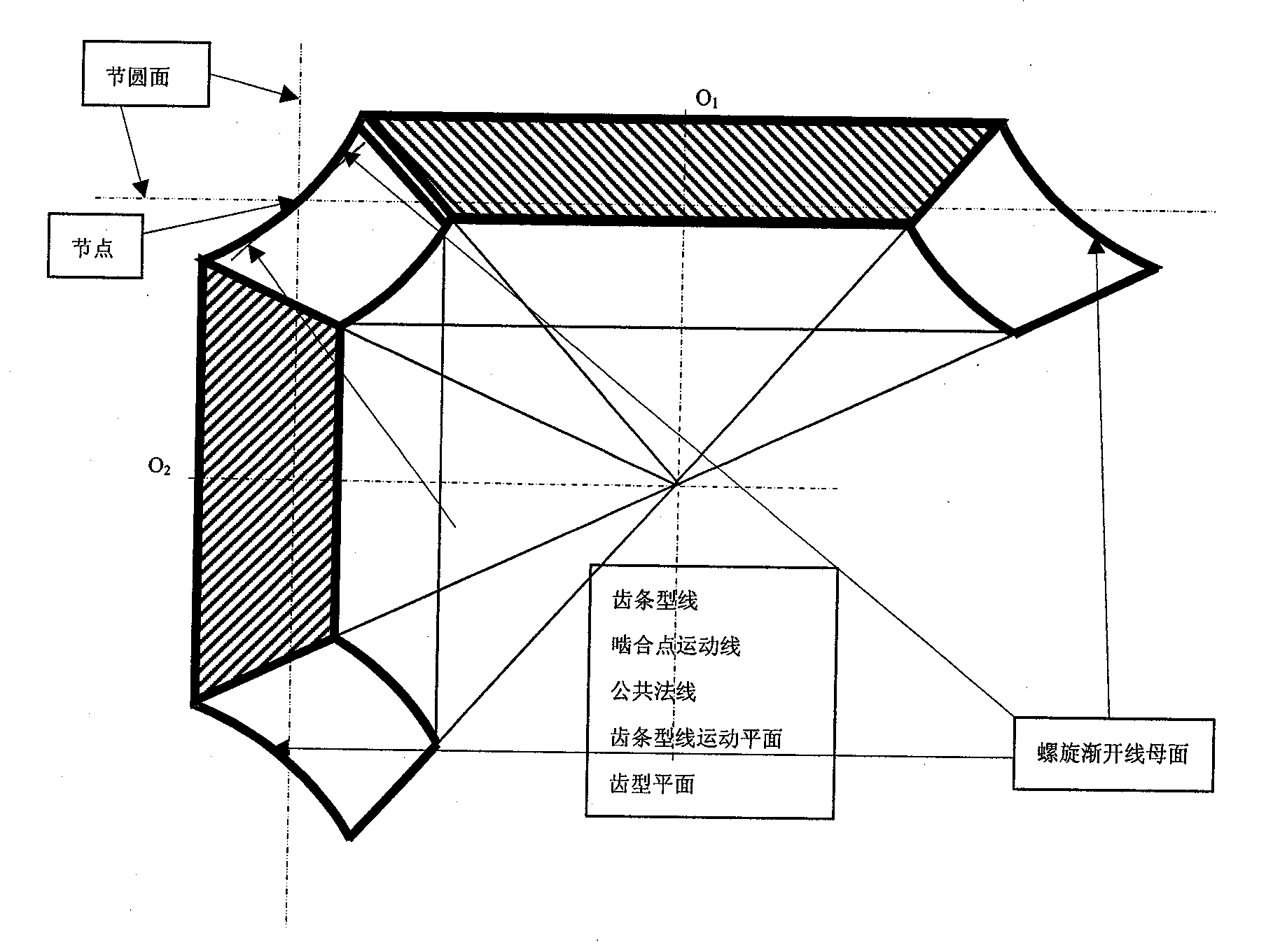

Helical involute gear and processing method thereof

InactiveCN101526129AEasy to processClear and easy to understand the transmission principlePortable liftingGear teethGear driveInvolute gear

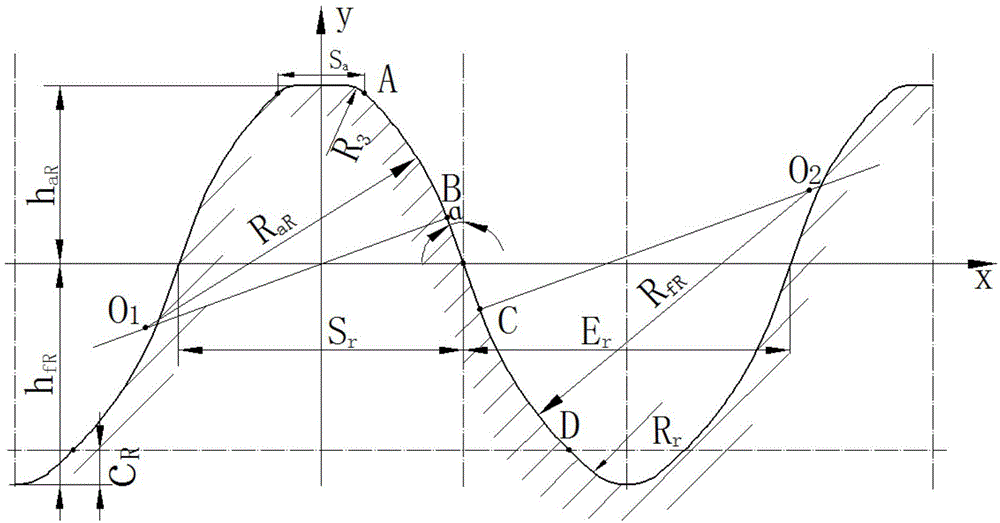

The invention relates to a helical involute gear and a processing method thereof. The helical involute gear is characterized in that a tooth surface molded line is a helical involute which is a curve spread by a rack type line straightly moving along the pitch circle tangent line and pure-rolling with a gear pitch circle. The helical involute gear has clear and easy drive principle, can ensure the drive continuity and the drive uniformity, and can realize surface meshing with large meshing area so that the bearing capacity is strong; the helical involute gear has long meshing line and large superposition coefficient, especially, an inclined helical involute conical gear is easy to implement speed reduction at high speed ratio. The helical involute conical gear can realize the expansion processing, thereby having high processing accuracy, low processing cost and high processing tooth surface hardness, improving the motion stability of the gear and the bearing capacity, and prolonging the service life. Meanwhile, processing equipment required by the helical involute gear can be conveniently processed by utilizing the method, thereby solving the difficulties of large processing difficulty and high cost of a gear drive pair with intersecting axes.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

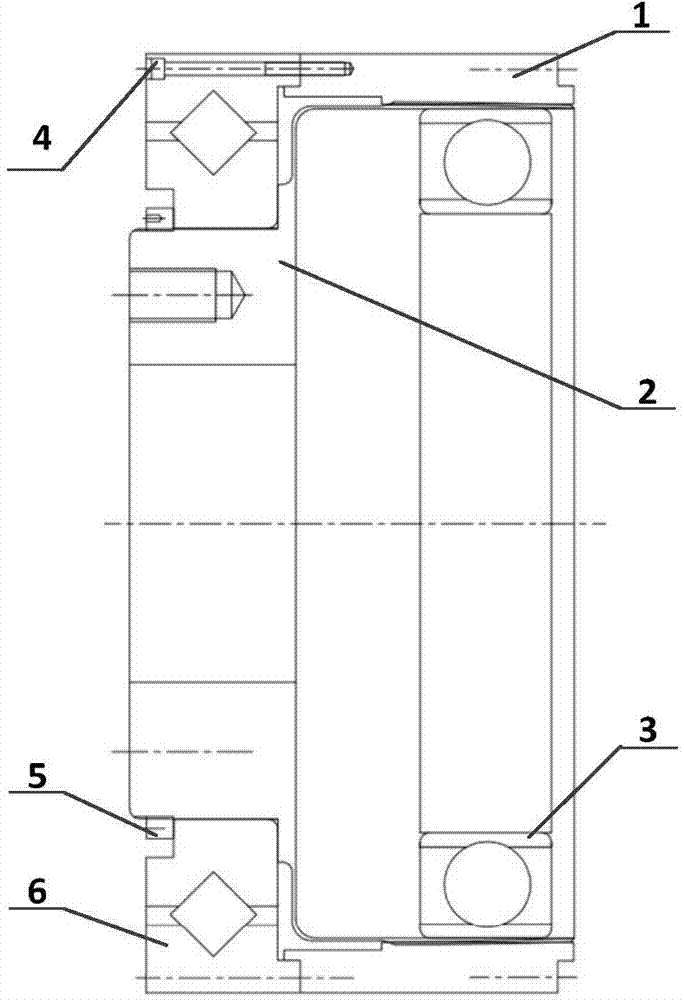

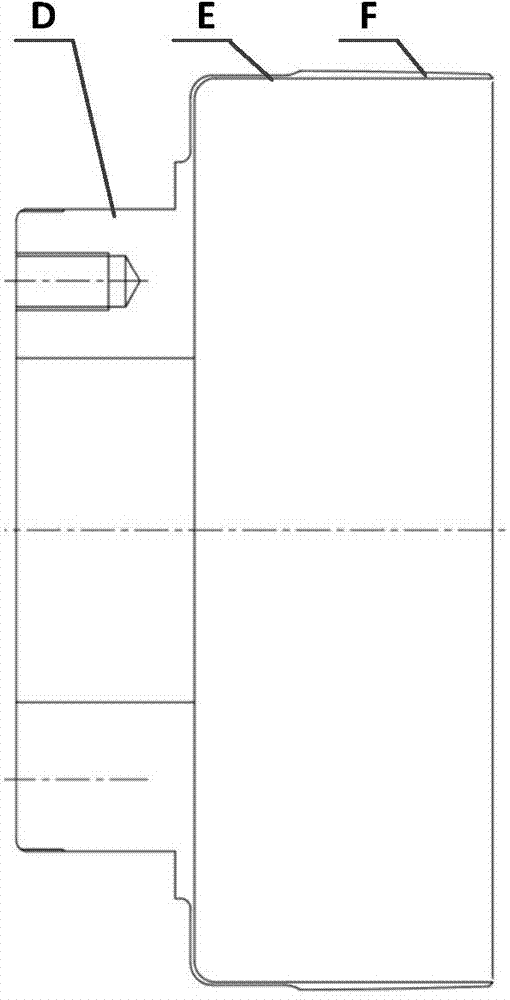

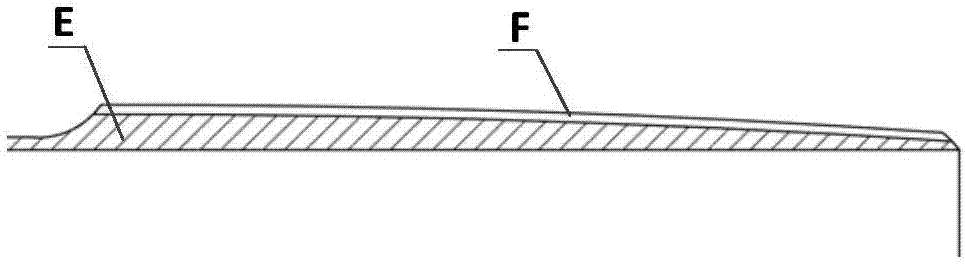

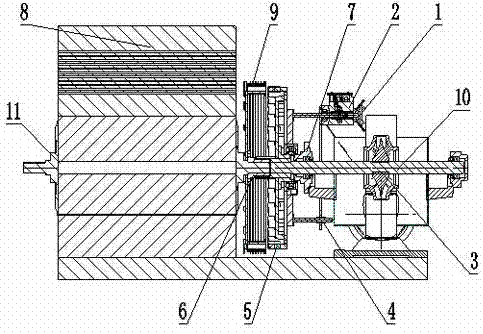

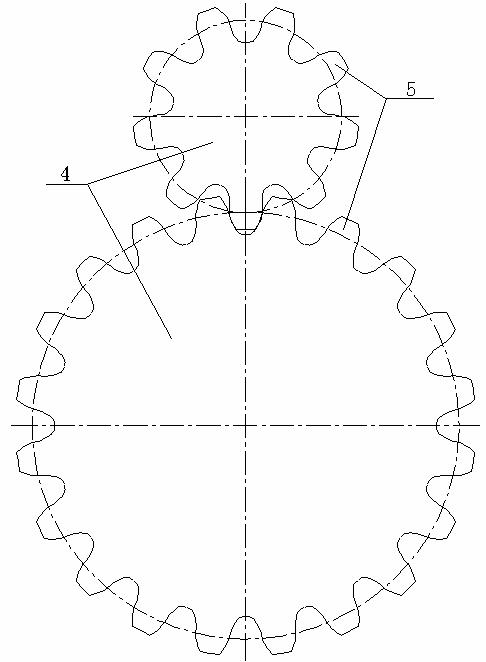

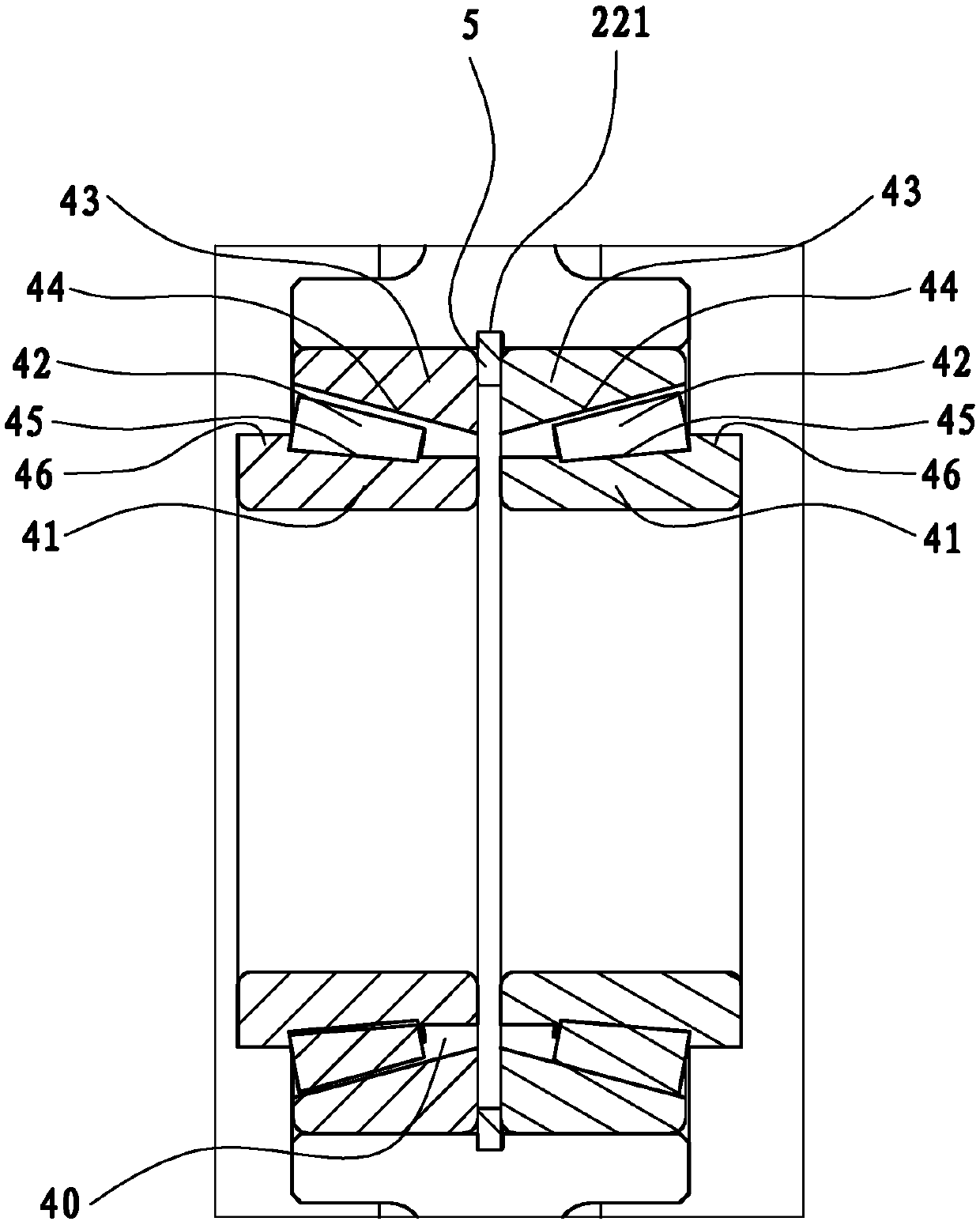

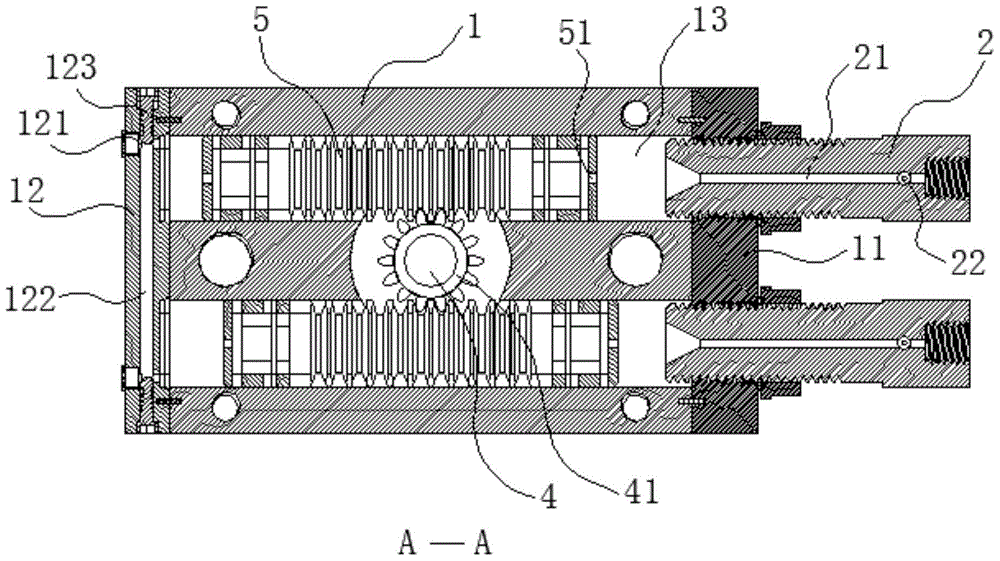

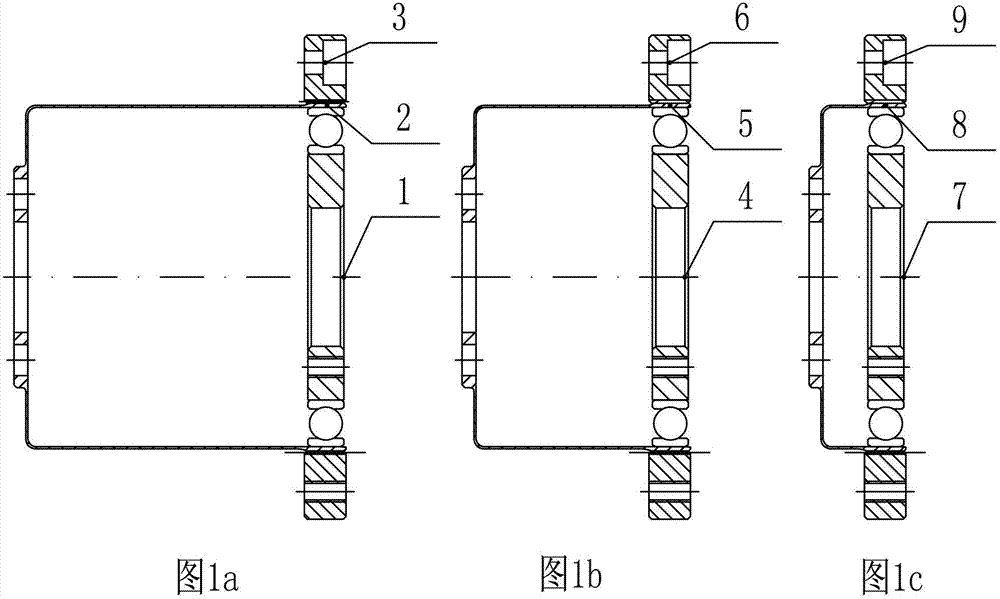

Rigid gear and flexible gear which are used for short-tube flexible-gear harmonic speed reducer and machining process thereof

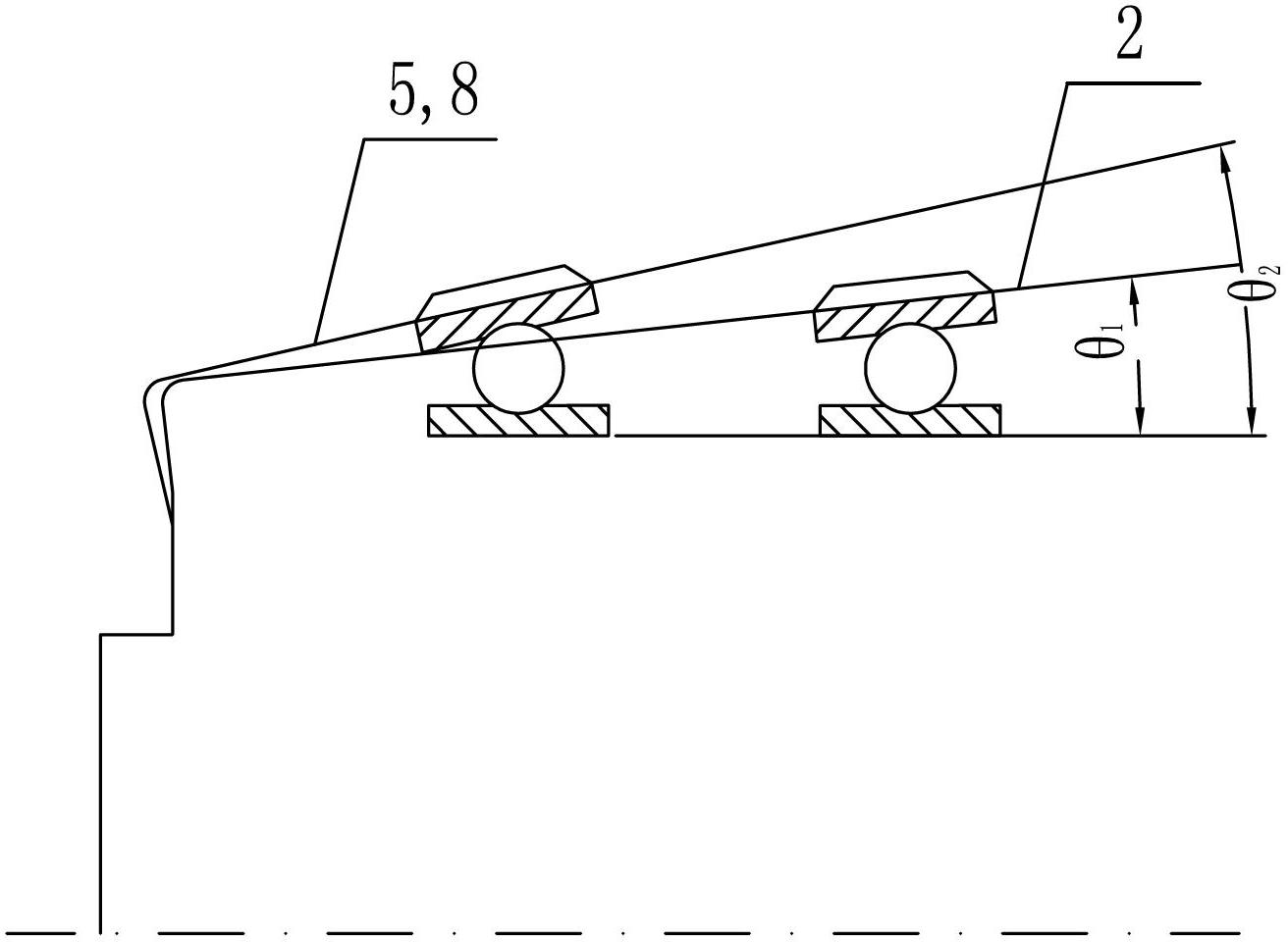

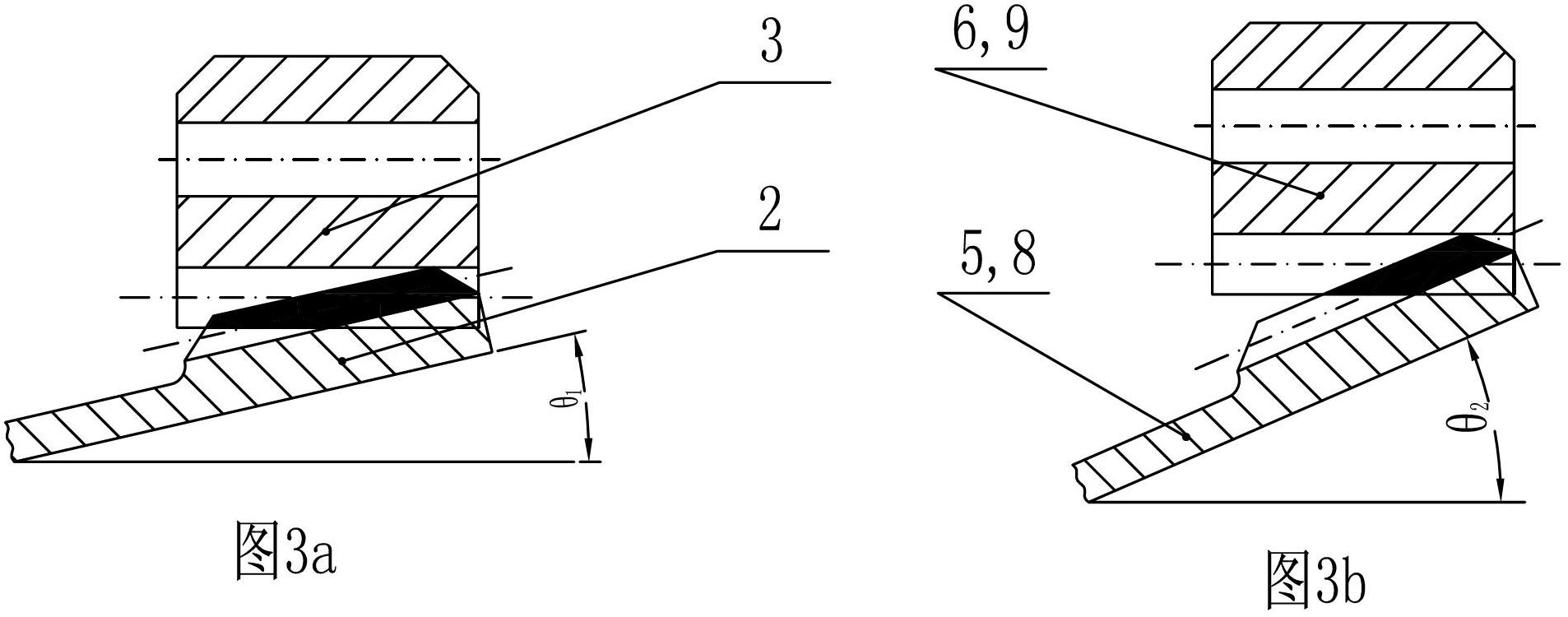

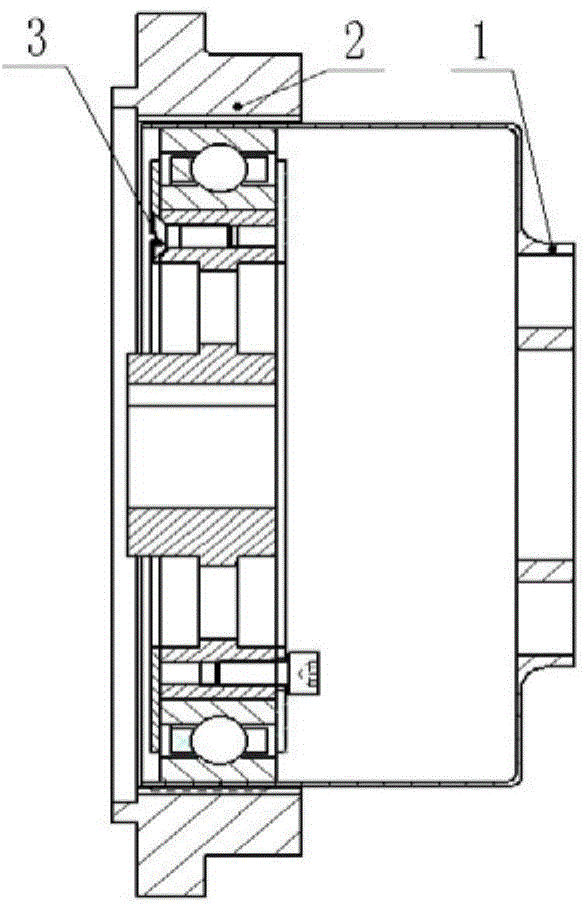

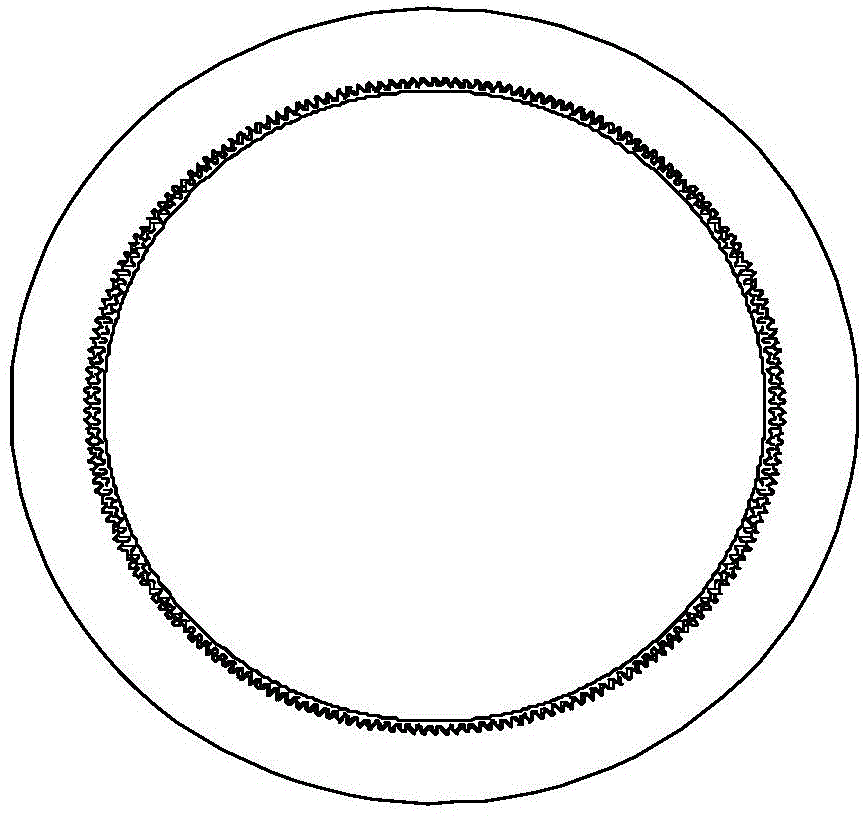

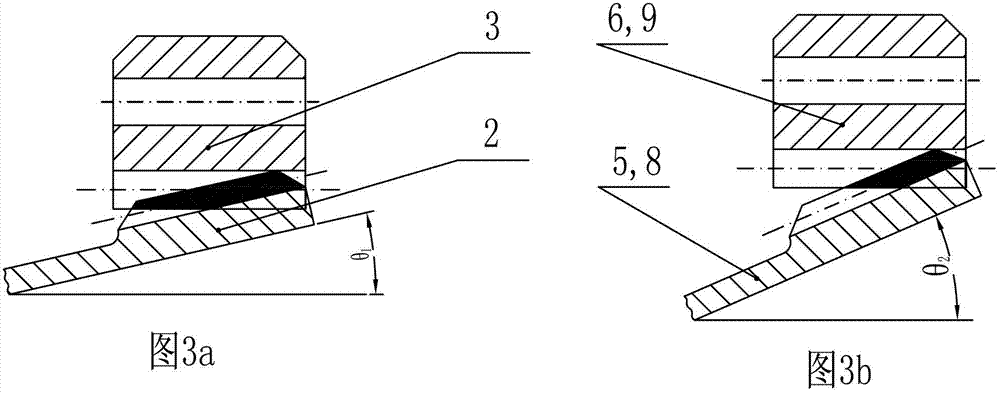

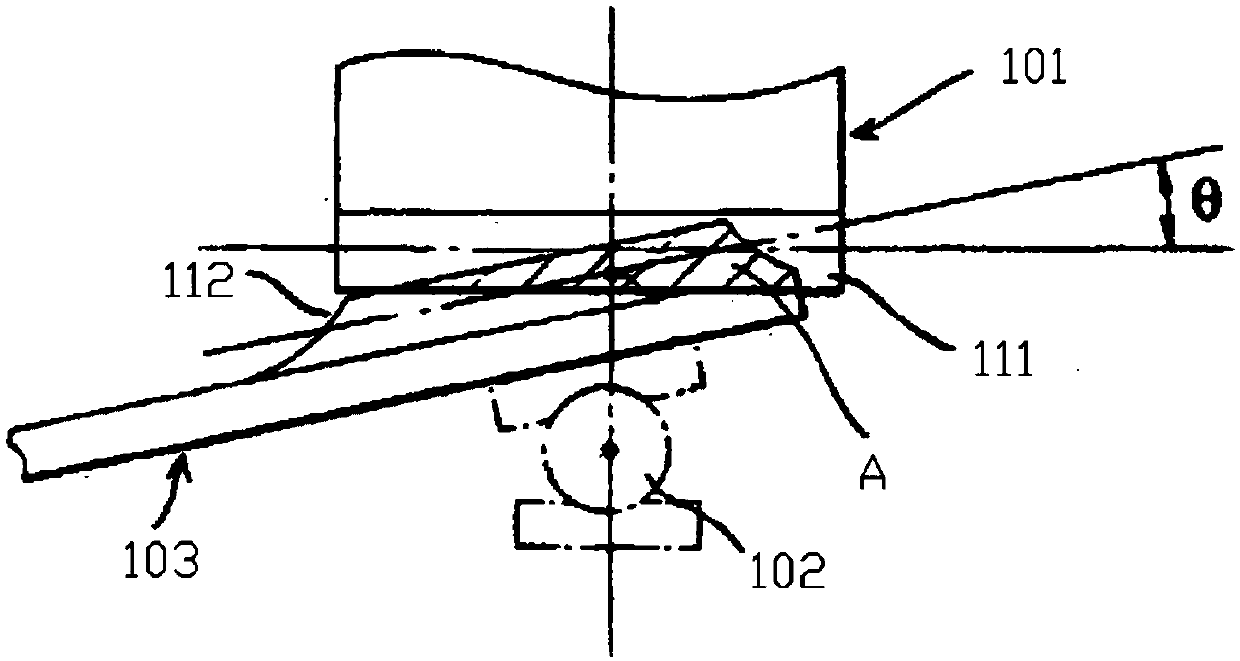

Provided are a rigid gear and flexible gear which are used for short-tube flexible-gear harmonic speed reducer and a machining process thereof. Inner teeth of the rigid gear are gear teeth with an inclination angle alpha, the inclination direction of the inclination angle alpha is consistent with the field angle theta2 at the position of a long shaft of the flexible gear, and the inclination angle alpha is 0.1 degree to 2 degrees. Top ends of two tooth profile curve line sections of the outer tooth profile of the flexible gear are connected through a tooth top straight line section. Each tooth profile curve line section is formed by connecting upper circular radius and lower circular radius in smooth transition mode. The harmonic speed reducer comprises the rigid gear, the flexible gear and a wave generator. The ratio of the length and the inner diameter of the flexible gear is smaller than 1. The flexible gear and the rigid gear in the short-tube flexible-wheel harmonic speed reducer are both machined through a slow-feeding wire cutting off machine. The gear teeth of the flexible gear and the gear teeth of the rigid gear are meshed in the certain inclination angle. The total contact area of the meshing teeth pair is increased by 15% compared with the condition where no inclination angle exists. Overlapping ratio of the harmonic gears is improved, and harmonic transmission rigidity is improved.

Owner:DONGGUAN RICHTEK ELECTRONICS CO LTD

Harmonic gear reducer

ActiveCN105299151AIncrease mesh stiffnessImprove transmission efficiencyToothed gearingsReduction driveGear wheel

The invention discloses a harmonic gear reducer which comprises a flexible gear, a rigid gear and an elliptical cam wave generator. The cup bottom of the flexible gear is connected with an output shaft. The elliptical cam wave generator is connected with an input shaft. The outer wall, along the cup rim, of the flexible gear is provided with an arc-involute-arc-tooth profile. The elliptical cam wave generator is arranged on the inner wall of the cup rim of the flexible gear. The rigid gear is fixedly connected with a shell and the inner wall is provided with an arc-involute-arc-tooth profile matched with the flexible gear tooth profile. The rigid gear is connected with the flexible gear through the tooth profiles in an engaged manner. In the engagement process, the flexible gear is in continuous conjugated engagement with the rigid gear, a convex tooth profile and a concave tooth profile of the flexible gear and a concave tooth profile and a convex tooth profile of the rigid gear are located in the double-conjugation engagement interval of the conjugation motion at the same time. The harmonic gear reducer has the beneficial effects that both arc tooth-shaped harmonic driving and involute-tooth-shaped harmonic driving are achieved; and deflection driving can be achieved, the gear tooth engagement region can be enlarged, and the engagement rigidity, driving efficiency and bearing capacity of the harmonic gear reducer are improved.

Owner:瑞邦智能科技(南京)有限公司

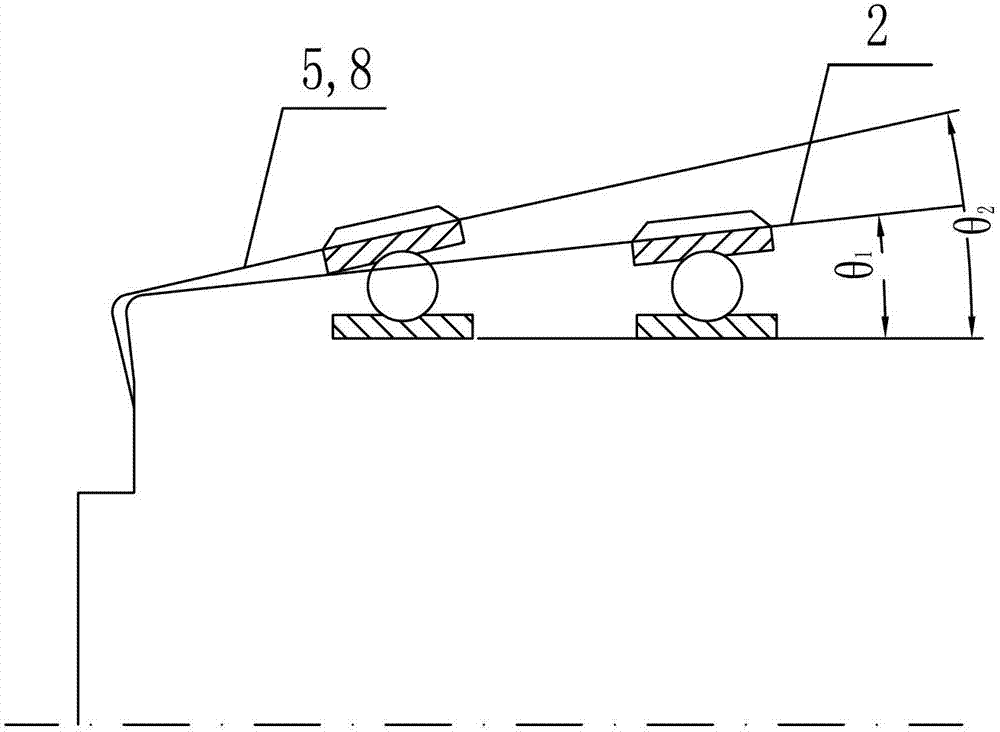

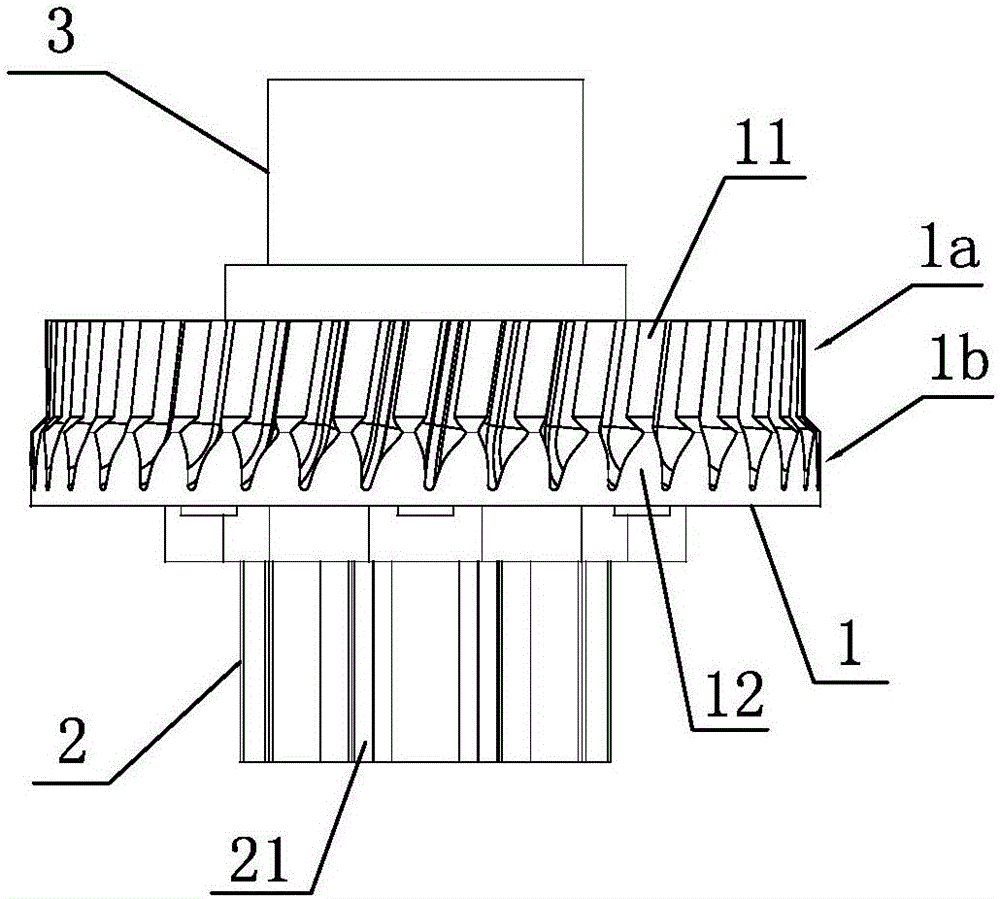

Flat harmonic transmission device with drum-shaped gear teeth

ActiveCN104514847AIncrease meshing areaIncreased Strength and RigidityToothed gearingsPortable liftingTooth lengthDiameter ratio

A flat harmonic transmission device with a drum-shaped gear teeth comprises a flexible gear, wherein the flexible gear is divided into a gear tooth part, a barrel part and an output shaft part; the length-diameter ratio of the barrel part is 1 / 4-1 / 2; the diameter of a maximum shaft section of the output shaft part is smaller than or equal to the diameter of an outer ring of the barrel part of the flexible gear; a bolt hole is formed in the output shaft part and the output shaft part is directly connected with a subsequent execution mechanism; the diameter of a gear tooth circle of the gear tooth part of the flexible gear becomes larger and lager in a non-linear manner from a cup opening of a barrel to the axial direction of the rear end; the gear teeth of the flexible gear have the same tooth outline shape in a tooth length direction; the width of tooth grooves of gear teeth of a rigid gear continuously becomes smaller and smaller, and then continuously becomes larger and larger from the cup opening of the barrel of the flexible gear to the axial direction of the rear end. The front ends and the middle parts of the gear teeth of the flexible gear are in an engaged state so that the engagement area is enlarged and the strength and rigidity are improved.

Owner:XI AN JIAOTONG UNIV

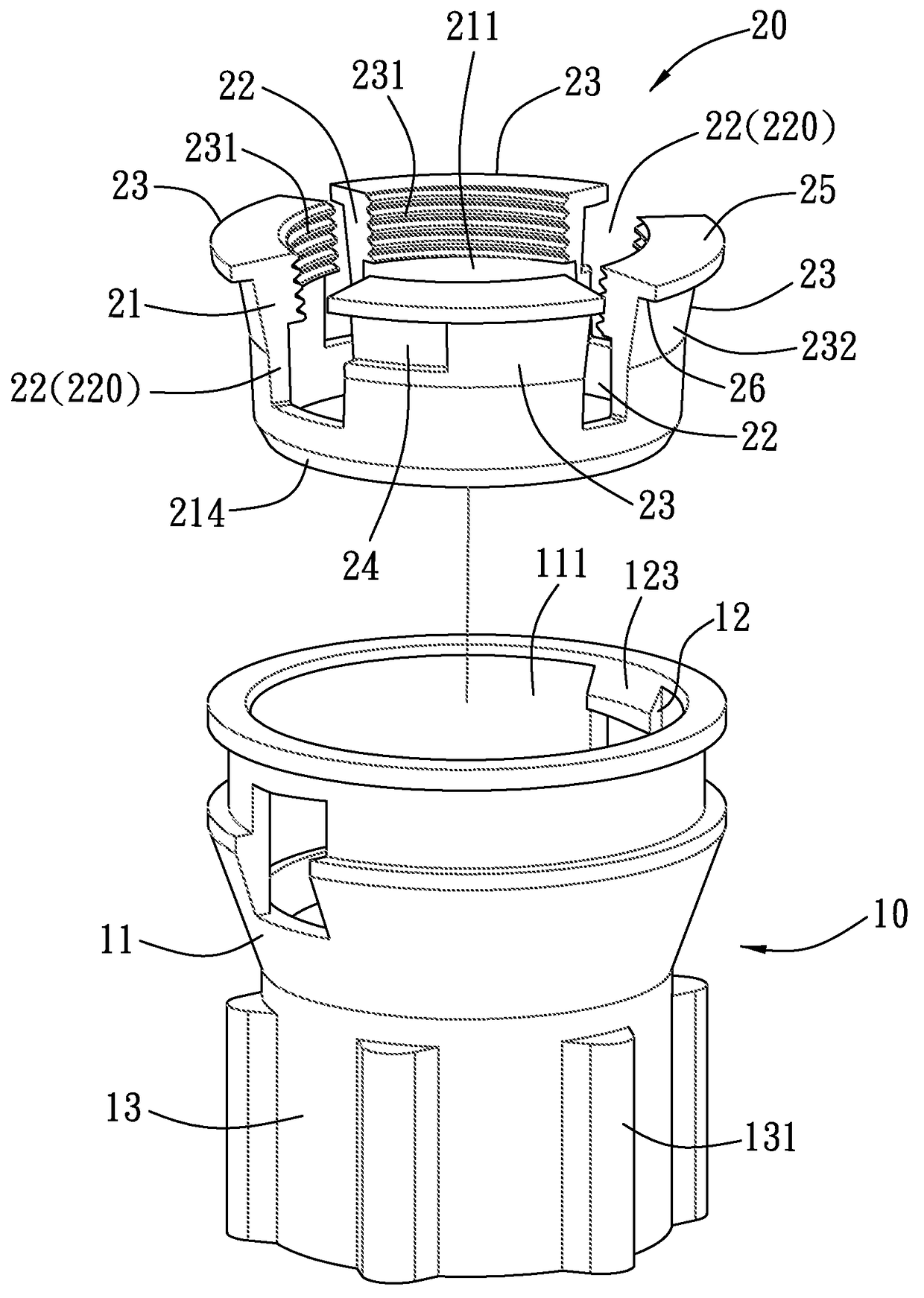

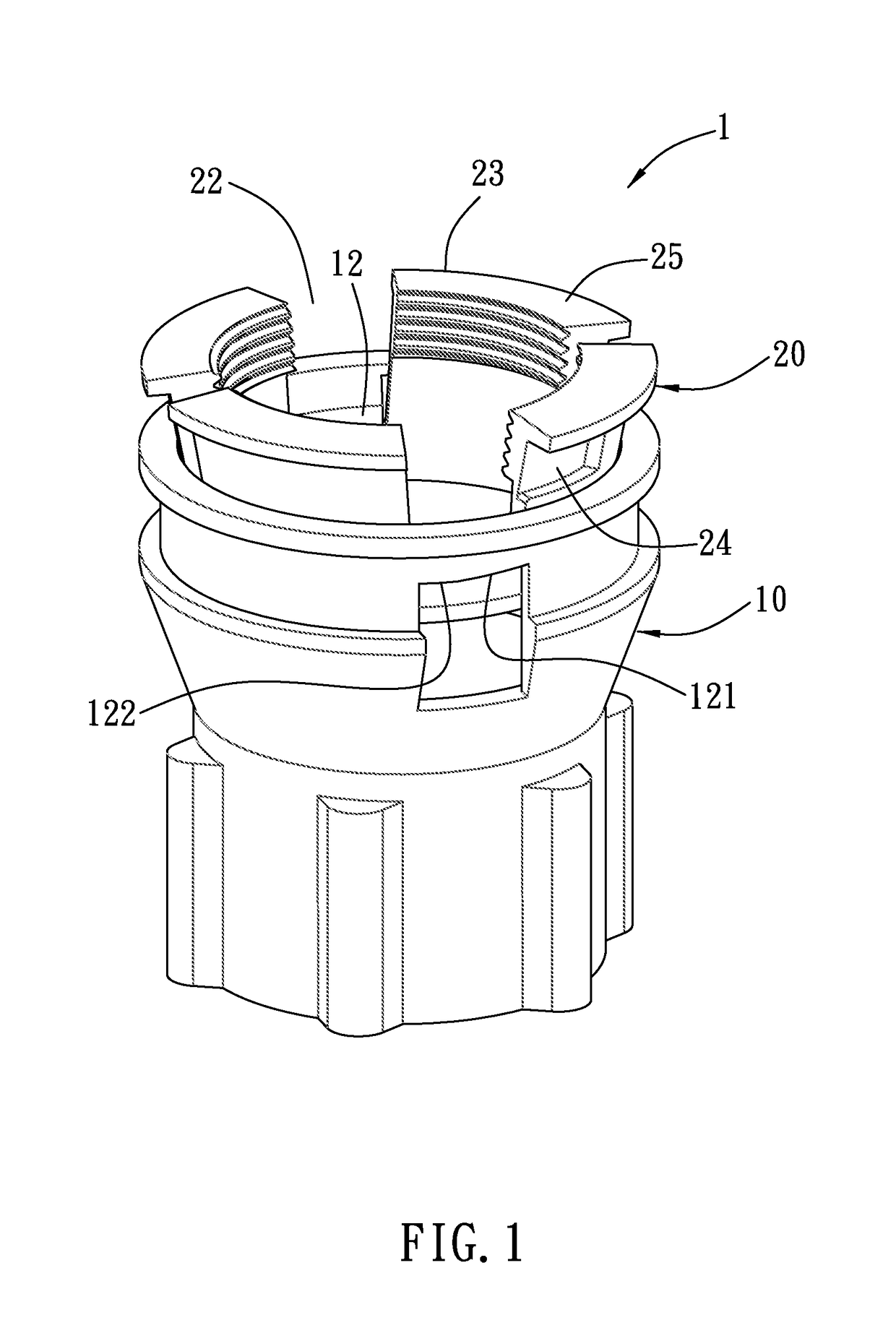

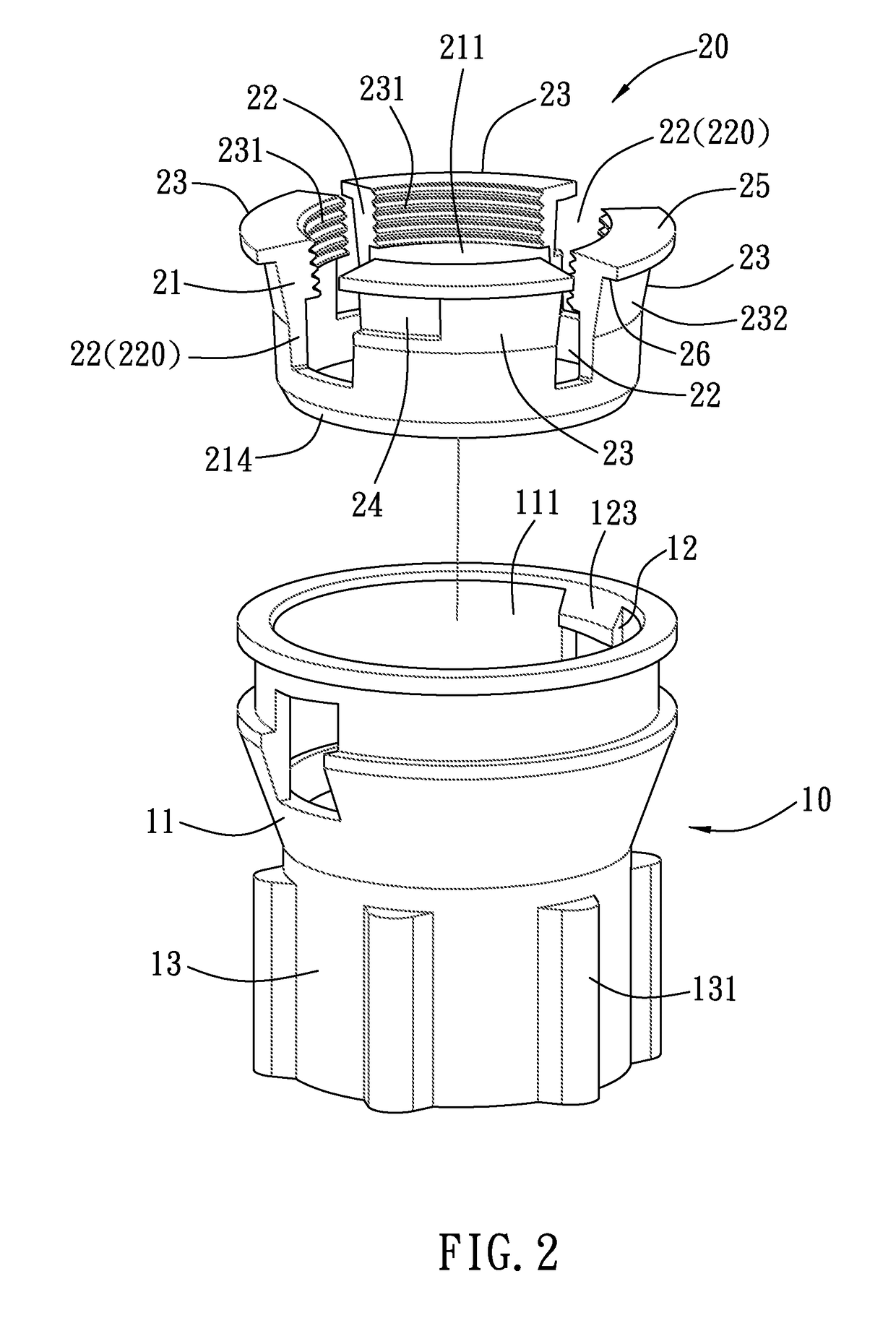

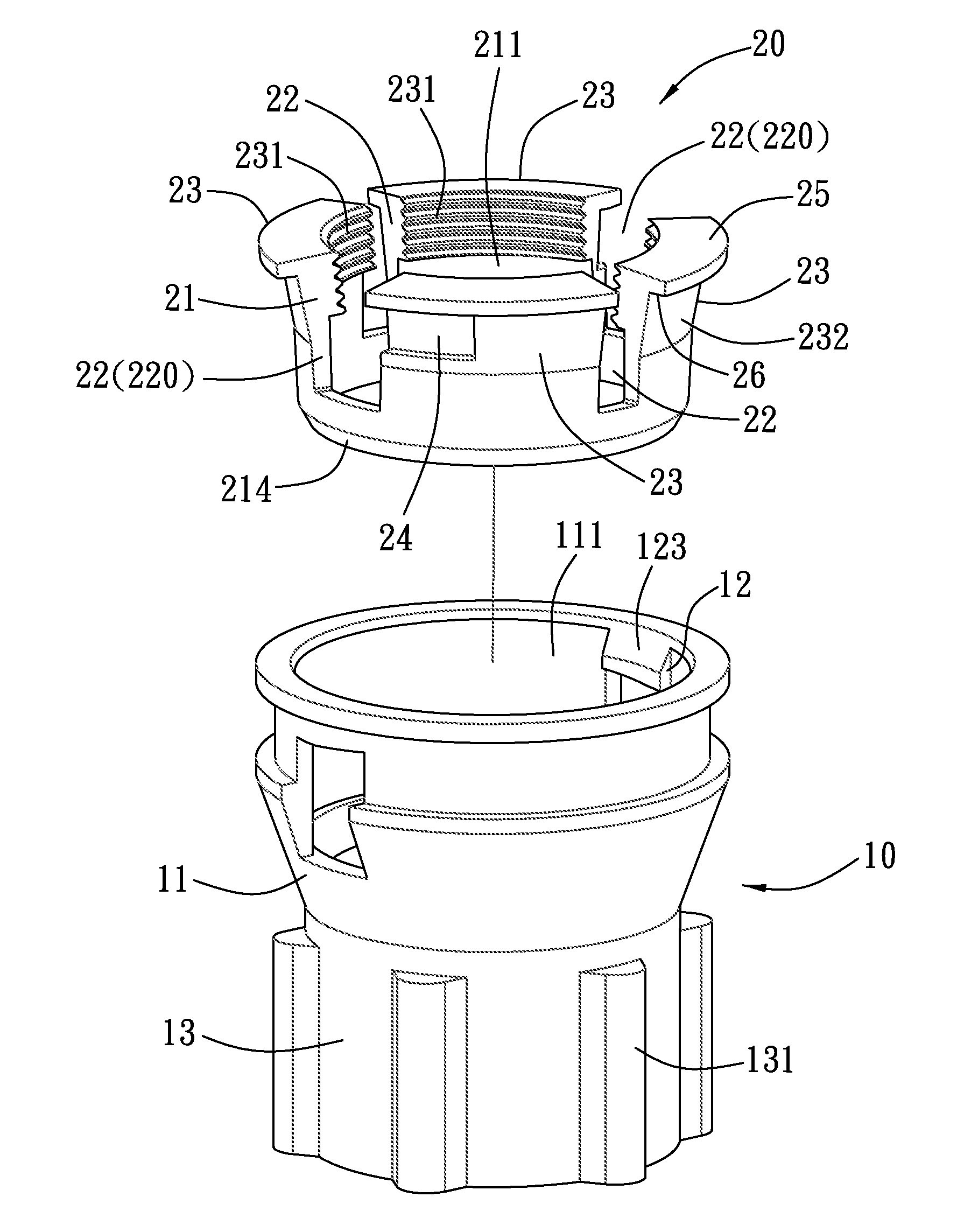

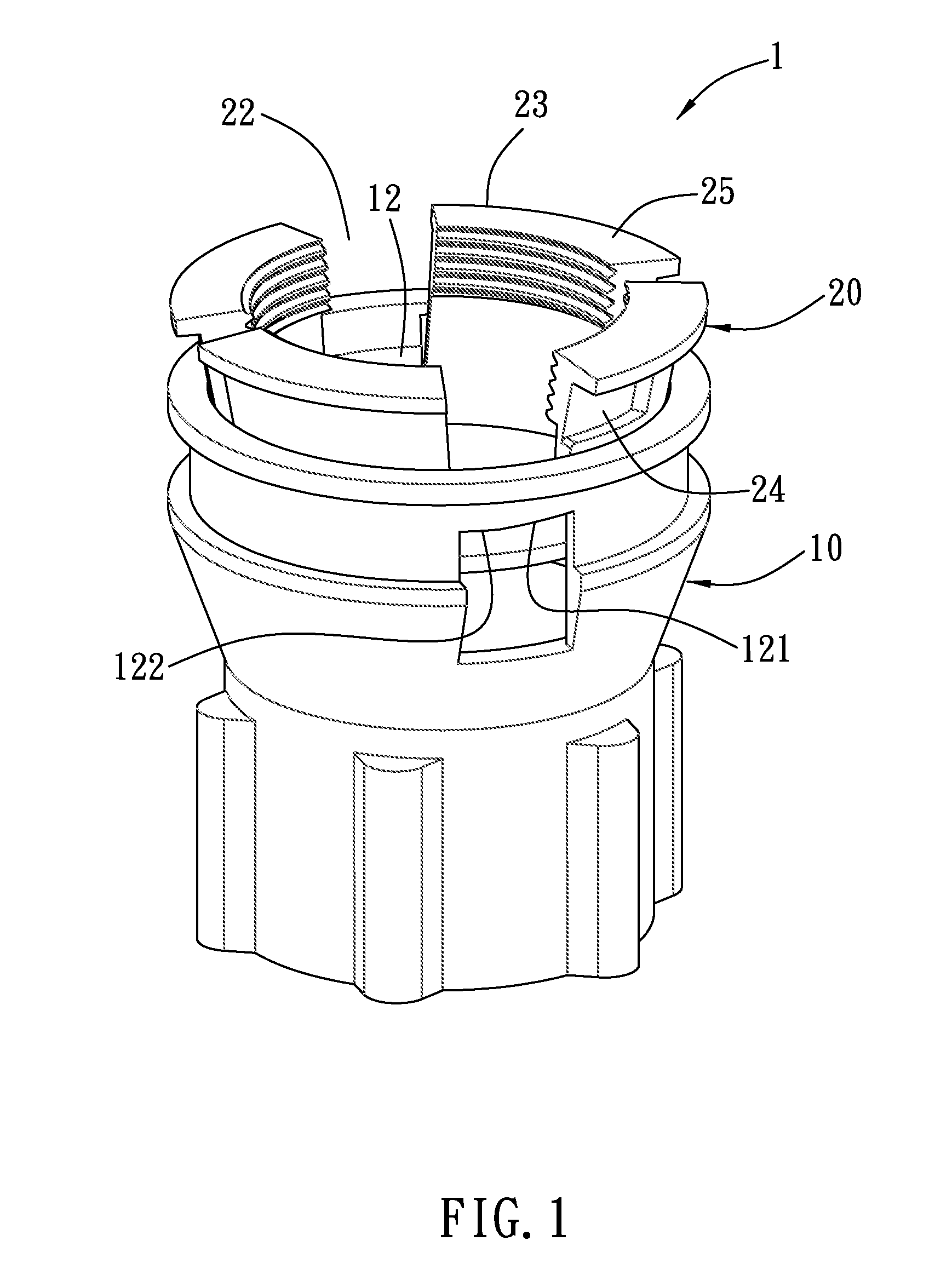

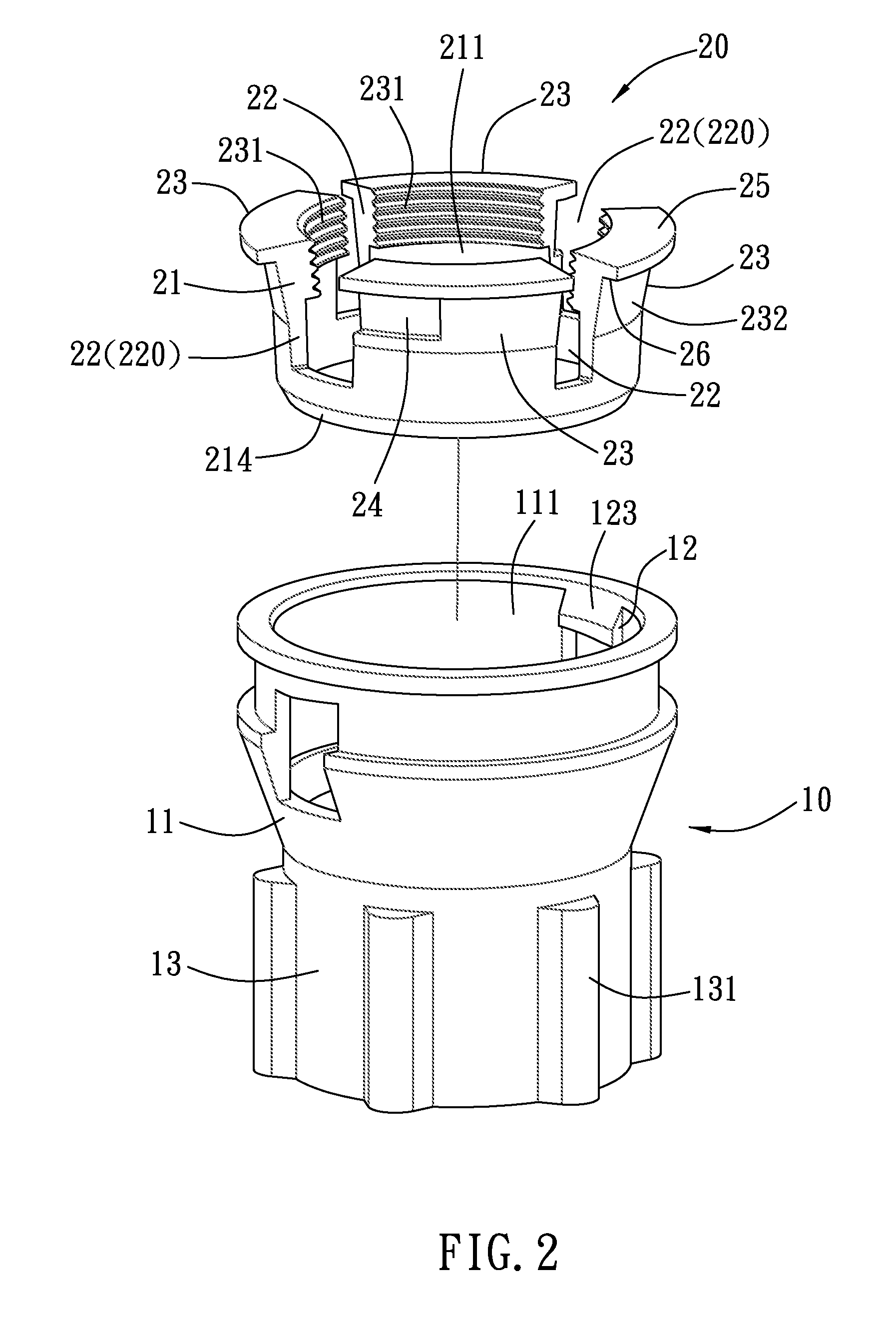

Nut for providing quick assembly and disassembly

A nut is employed to fix a faucet on a wash basin or a kitchen basin and contains an external driving member and an internal screwing member. The external driving member includes a cylindrical fence, an accommodating cavity, a first edge, and a second edge; the cylindrical fence has at least one limiting block and a griping face. The internal screwing member is fitted into and retained with the accommodating cavity and includes an annular cliff, a through orifice, a third edge, and a fourth edge; the annular cliff has plural slots longitudinally extending and isometrically arranged to the fourth edge from the third edge so as to define a plurality of flexible retaining portions, each having an inner threaded section; the annular cliff also has at least one longitudinal recess for retaining with the at least one limiting block of the external driving member and has a contacting fringe.

Owner:GLOBE UNION INDAL

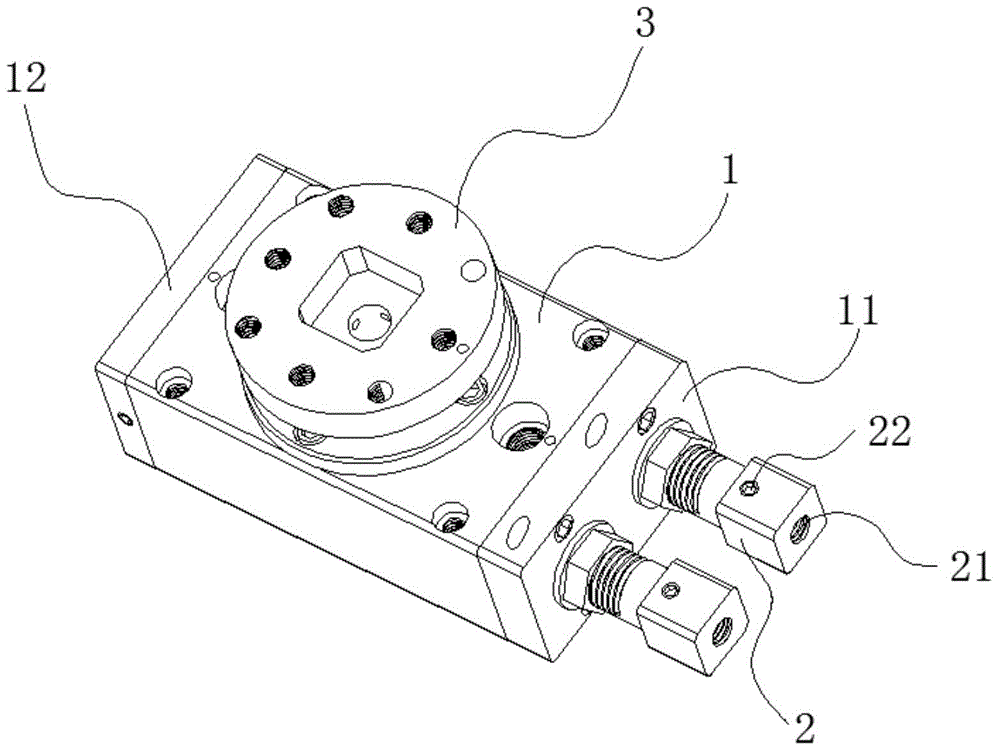

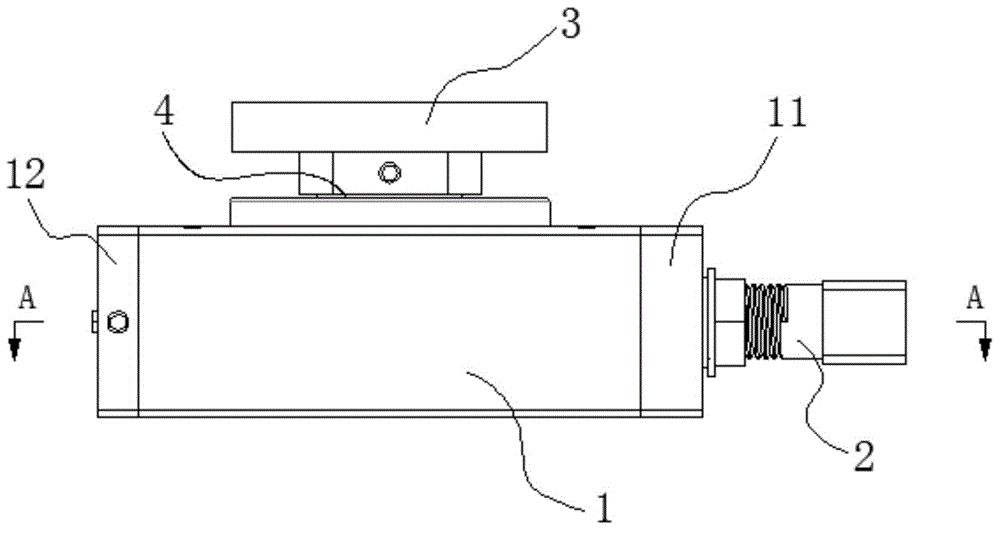

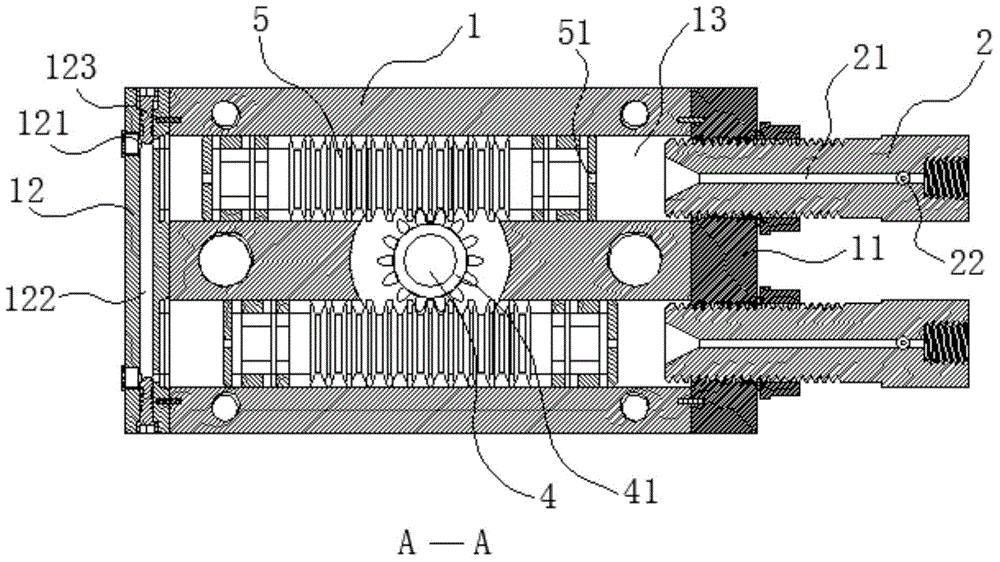

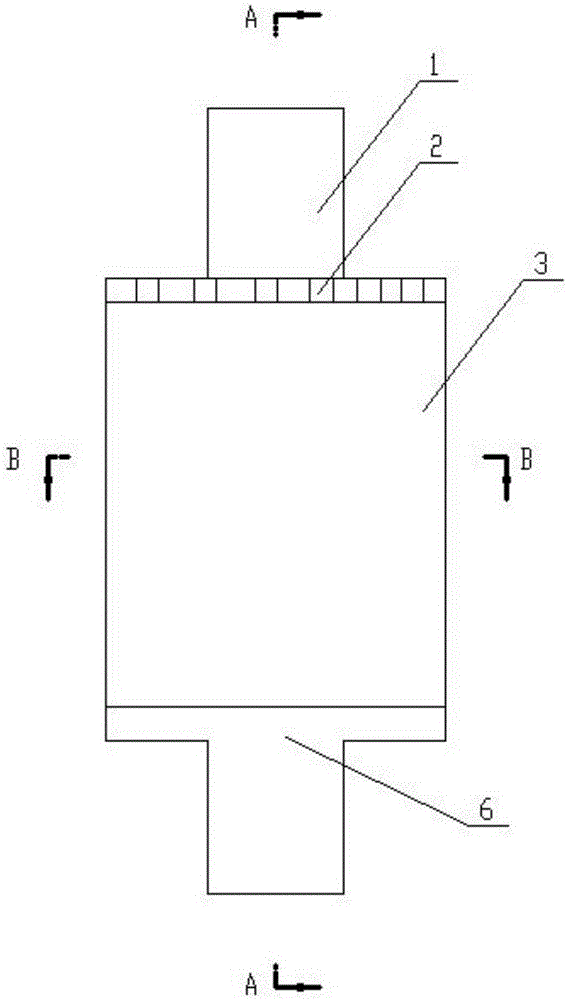

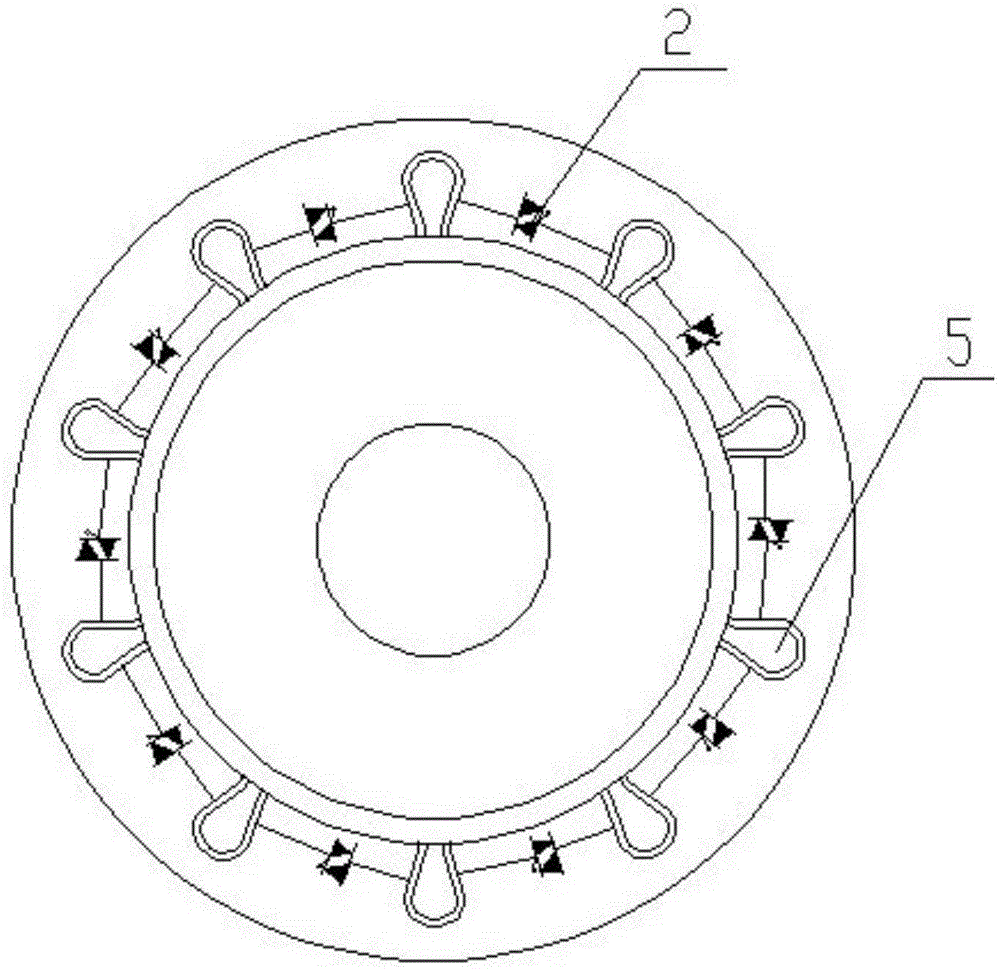

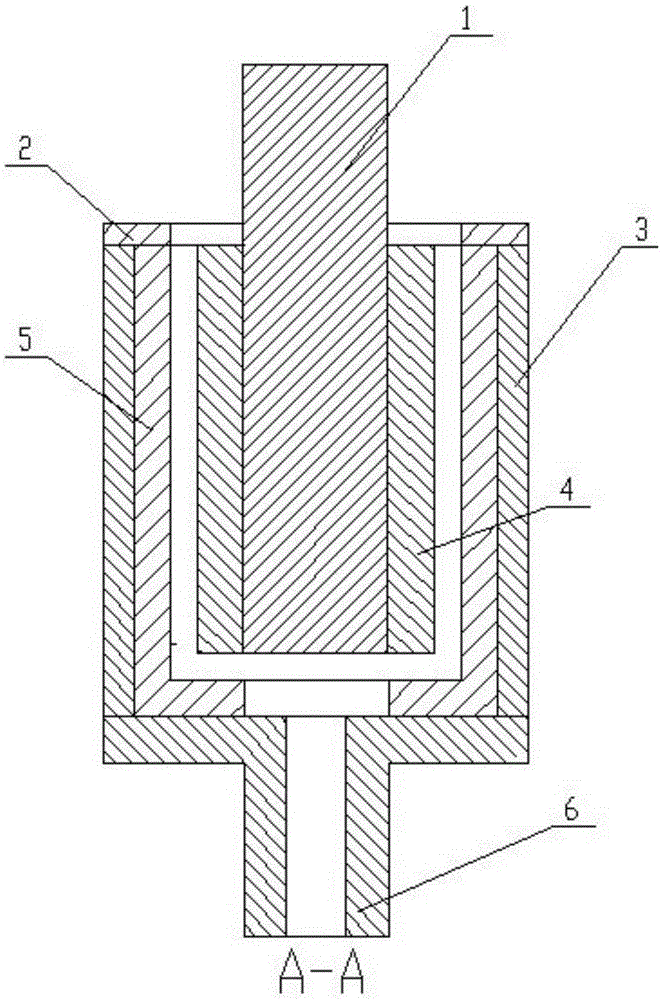

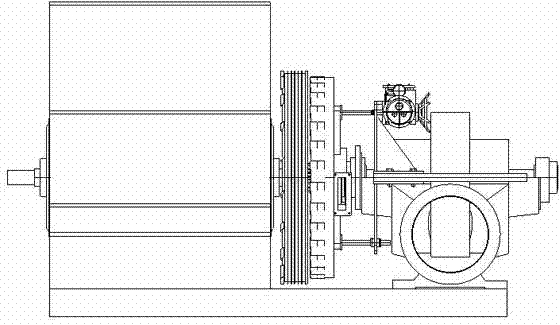

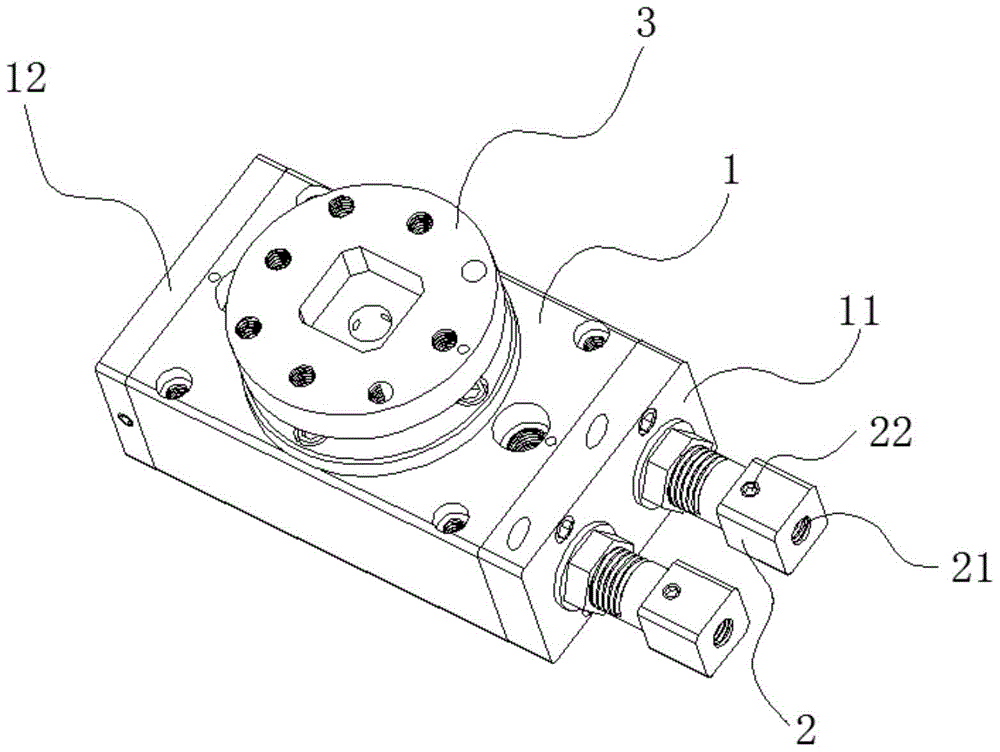

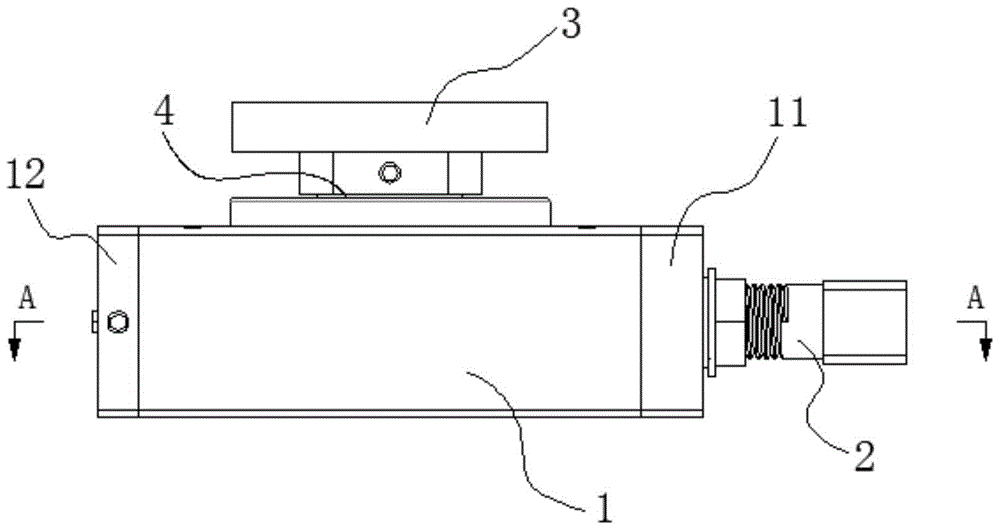

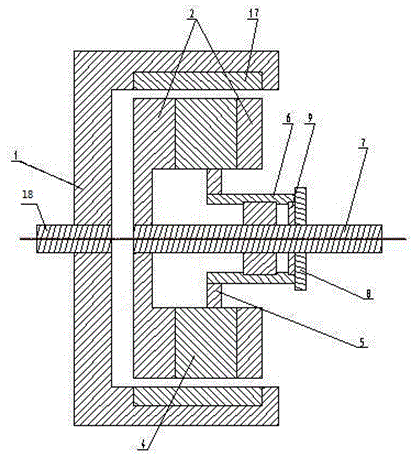

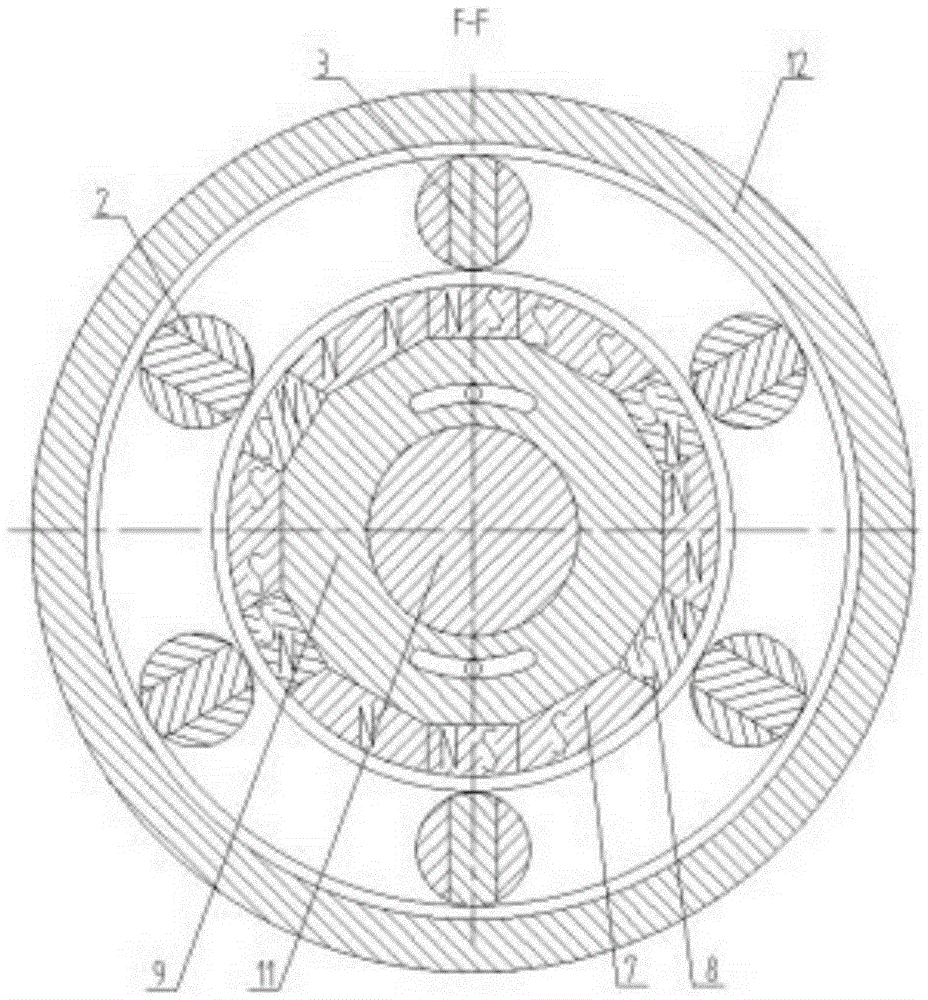

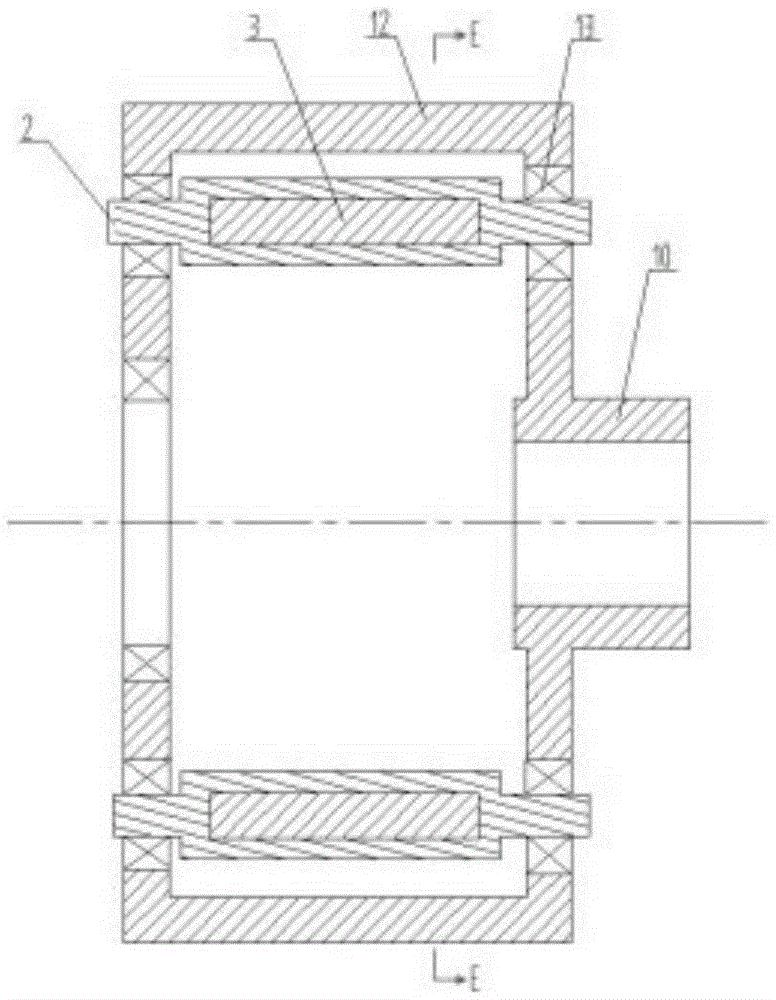

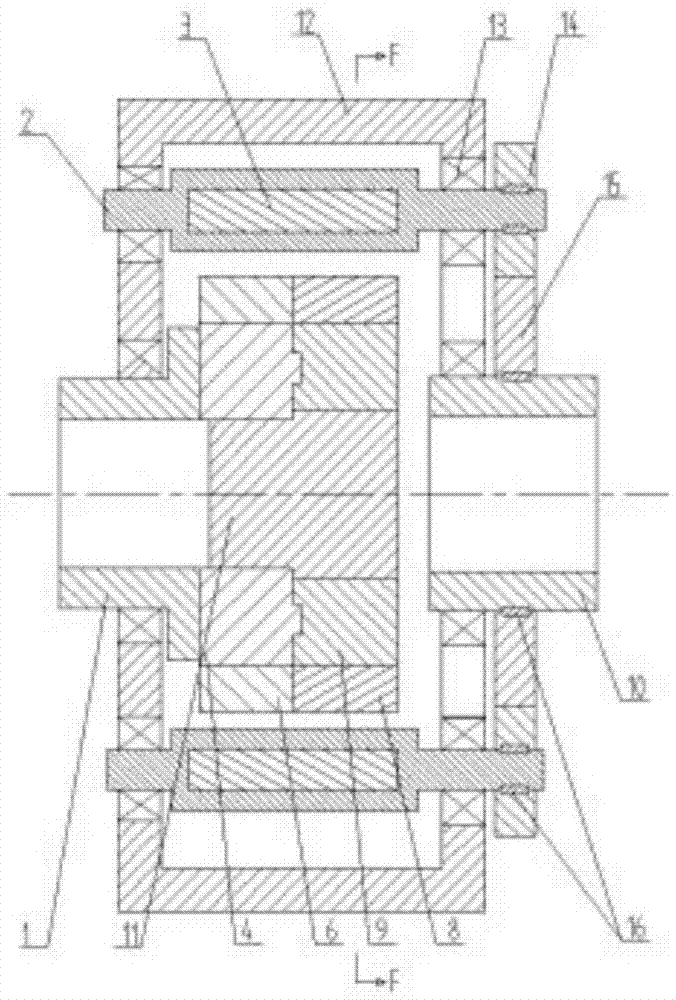

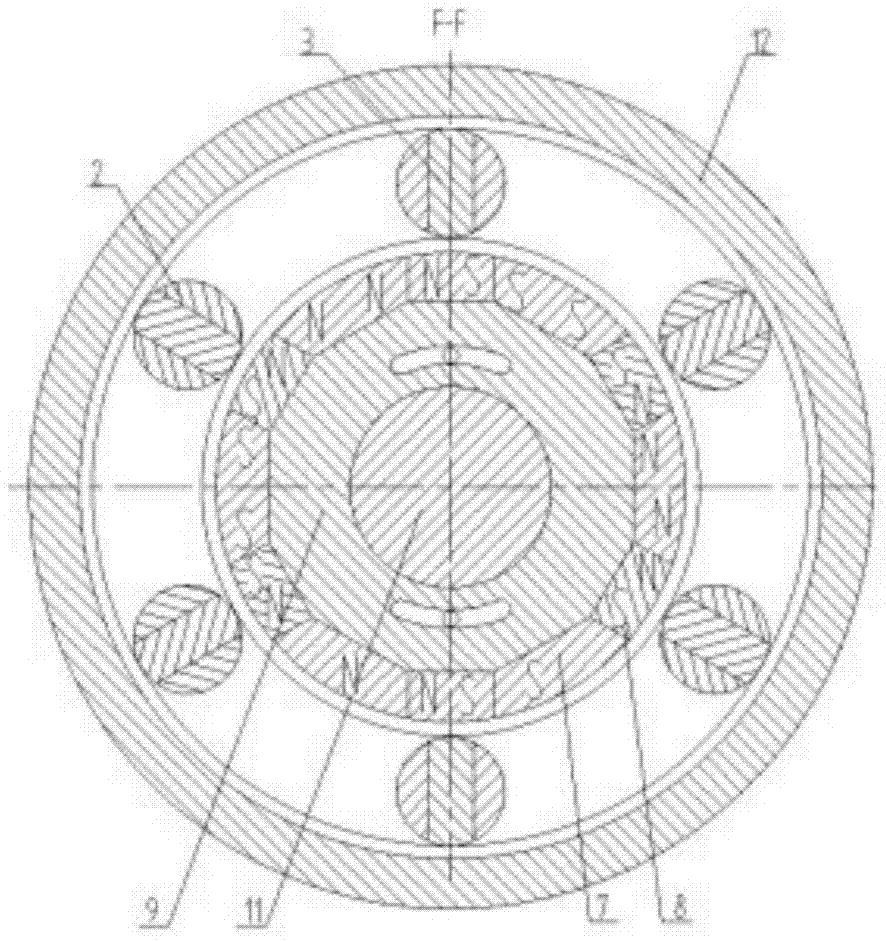

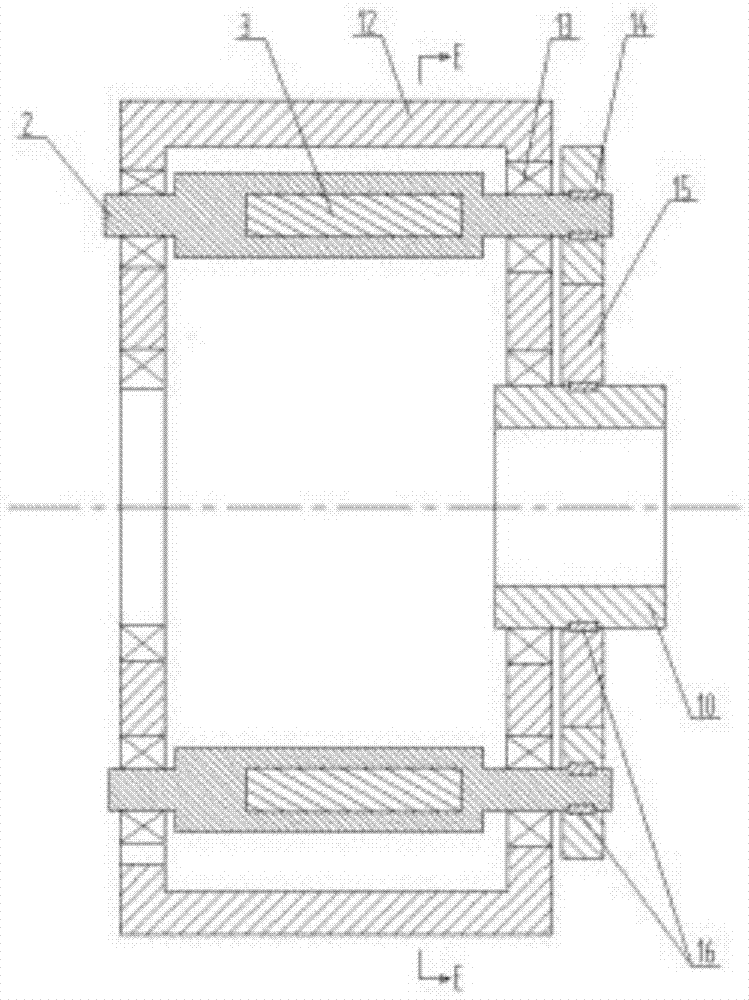

Piston type oscillating cylinder

ActiveCN104632751ASmooth motionReduce collision forceFluid-pressure actuatorsCylinder blockMechanical engineering

The invention discloses a piston type oscillating cylinder which comprises a cylinder body, rack-shaped piston rods, adjusting screw rods and an output shaft. The cylinder body is provided with two cylinder chambers and two end covers. The two rack-shaped piston rods are arranged in the two cylinder chambers respectively. The two adjusting screw rods are arranged on one end cover. The output shaft is fixedly provided with a gear which is in meshed connection with the two rack-shaped piston rods. The output shaft is connected with a rotary disk. The end cover where the adjusting screw rods are placed is a gas inlet end cover, and the other end cover is a gas outlet end cover. Each adjusting screw rod is provided with a gas inlet hole and a gas inlet adjusting mechanism. Each rack-shaped piston rod is provided with a vent hole. The gas outlet end cover is provided with two exhaust holes and two exhaust adjusting mechanisms which correspond to the two cylinder chambers respectively. According to the piston type oscillating cylinder, the rack-shaped piston rods are provided with the vent holes so that gas can flow to the other end from one end of each cylinder chamber, a buffer effect is achieved on the movement of the rack-shaped piston rods, the movement of the rack-shaped piston rods is stable and collision force is reduced.

Owner:GUANGXI UNIV

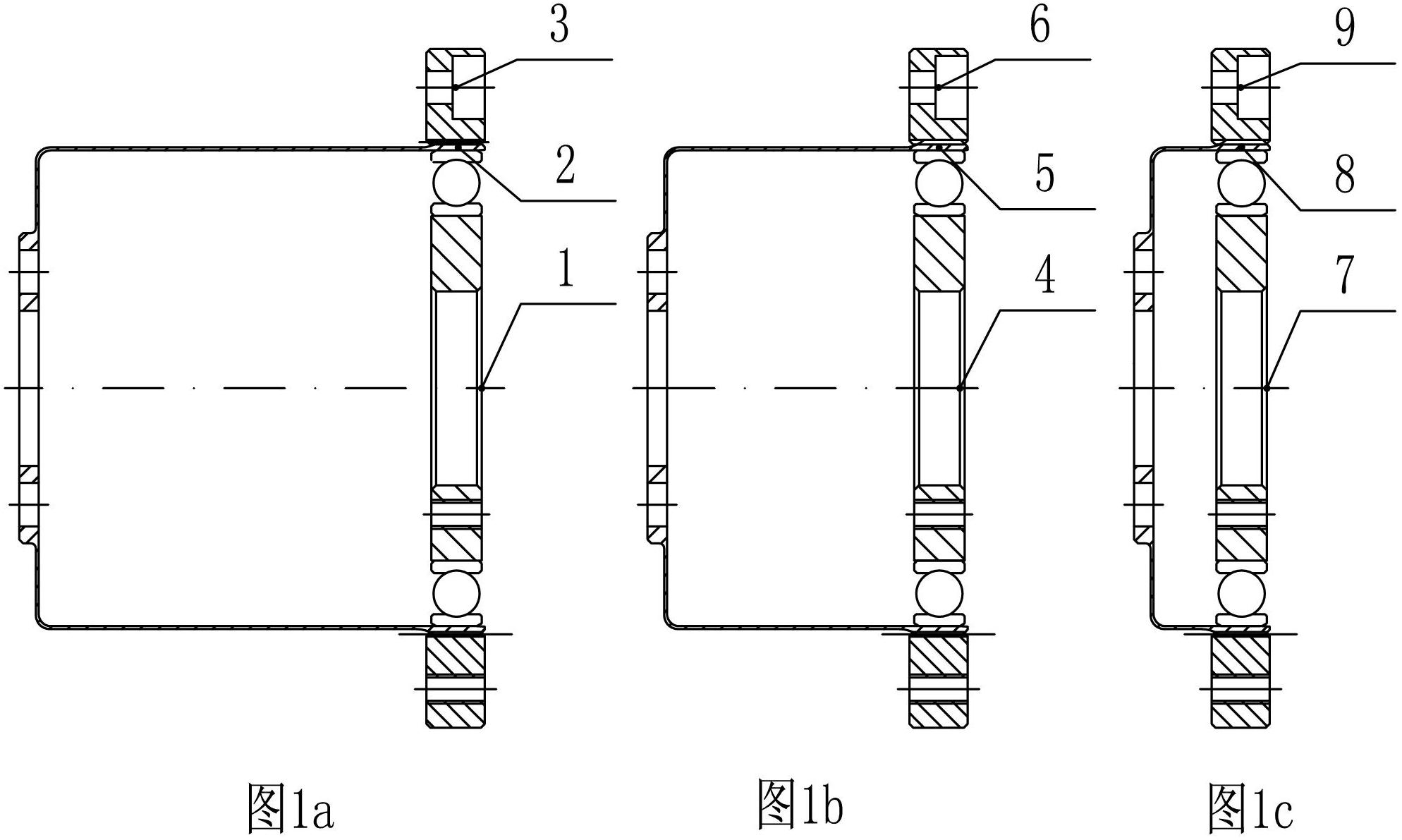

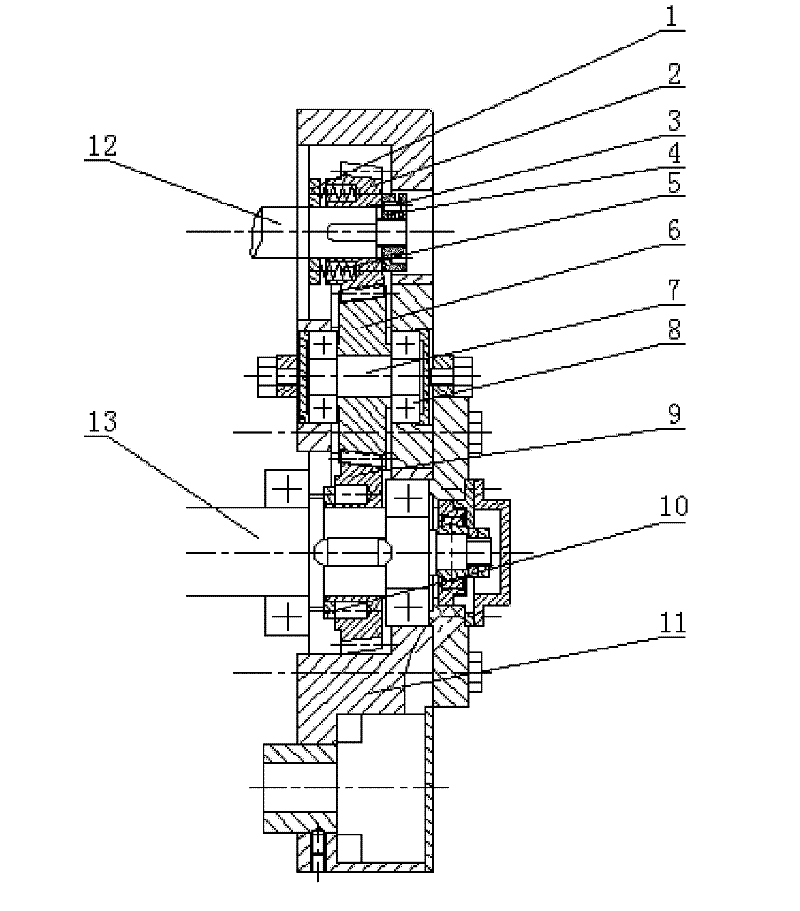

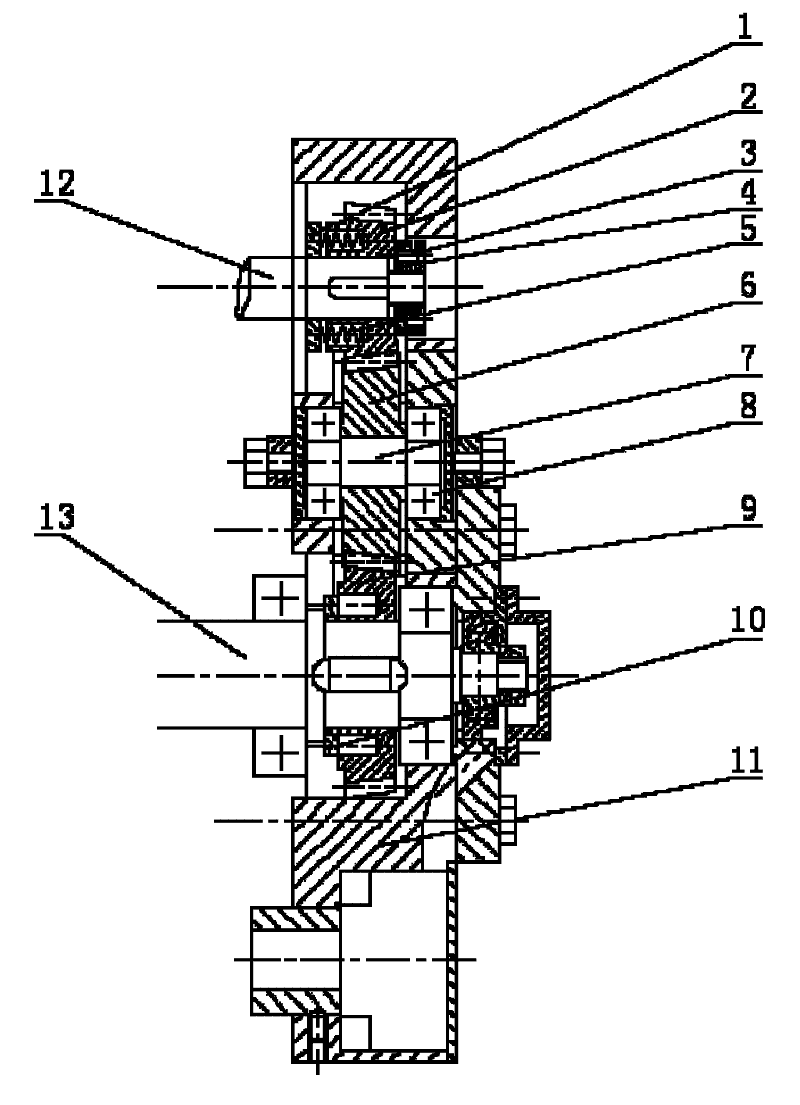

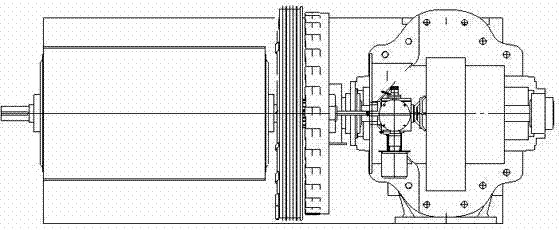

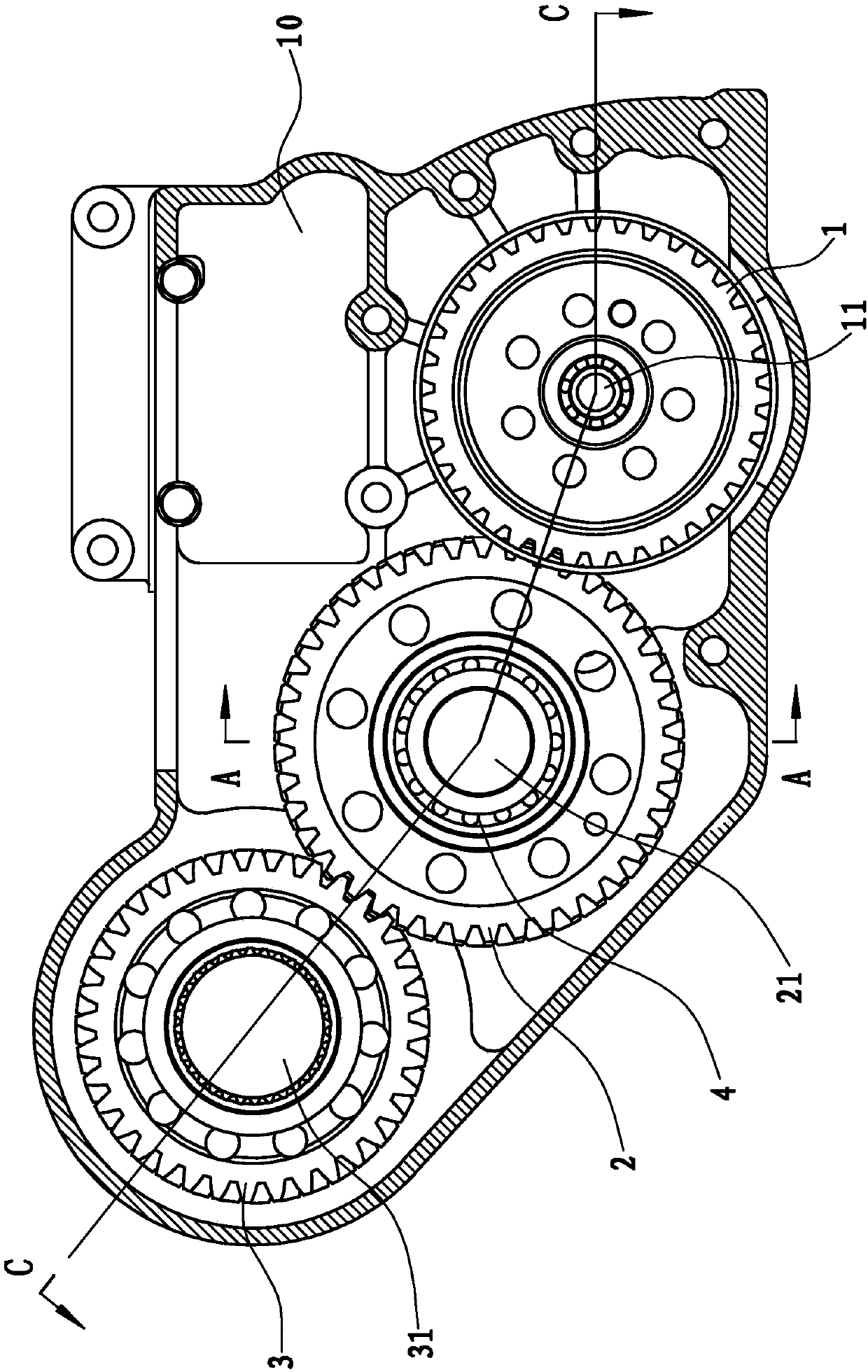

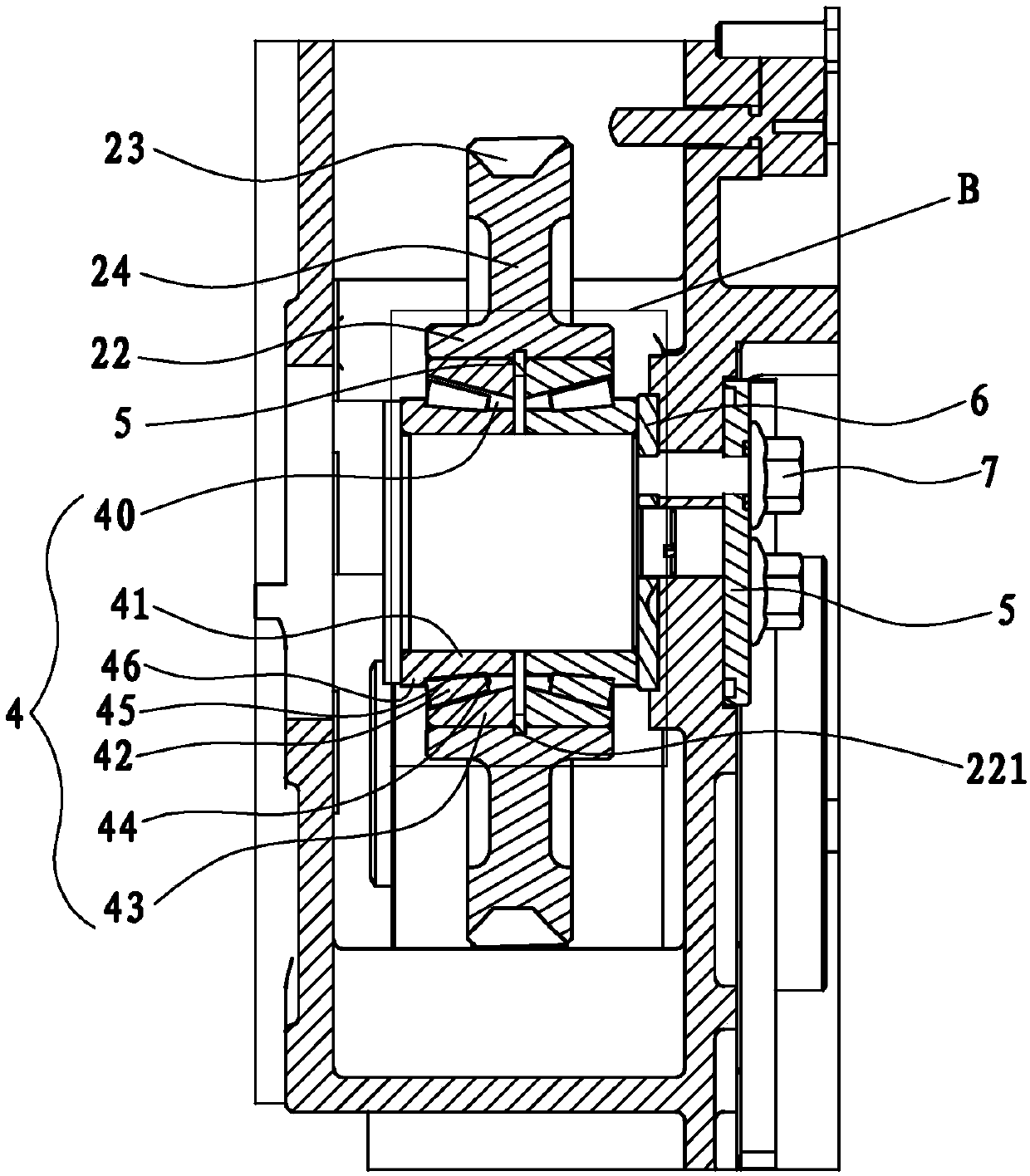

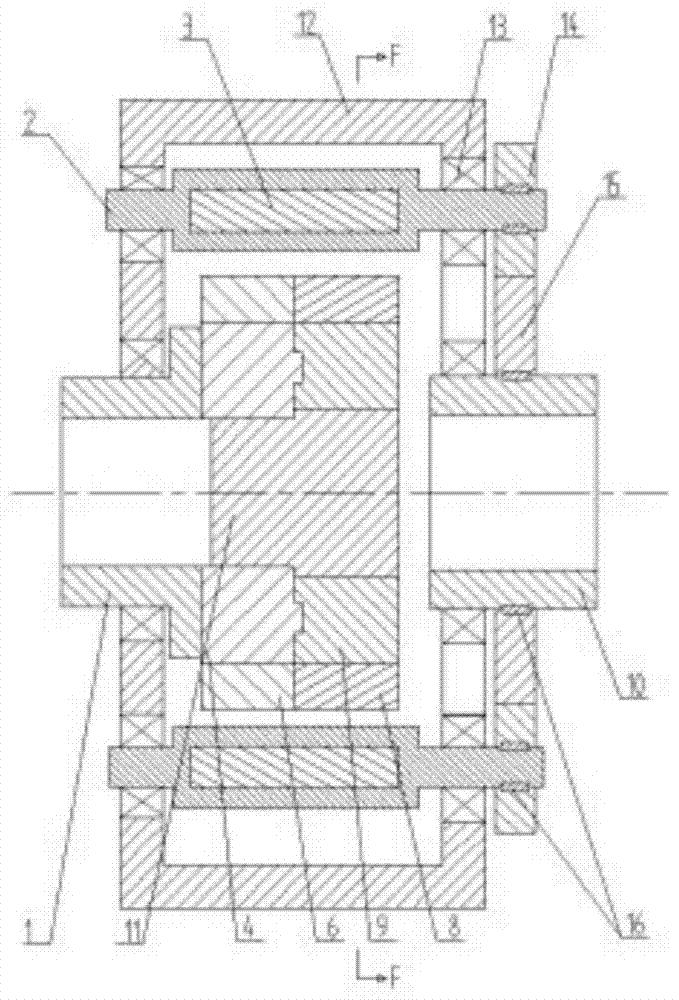

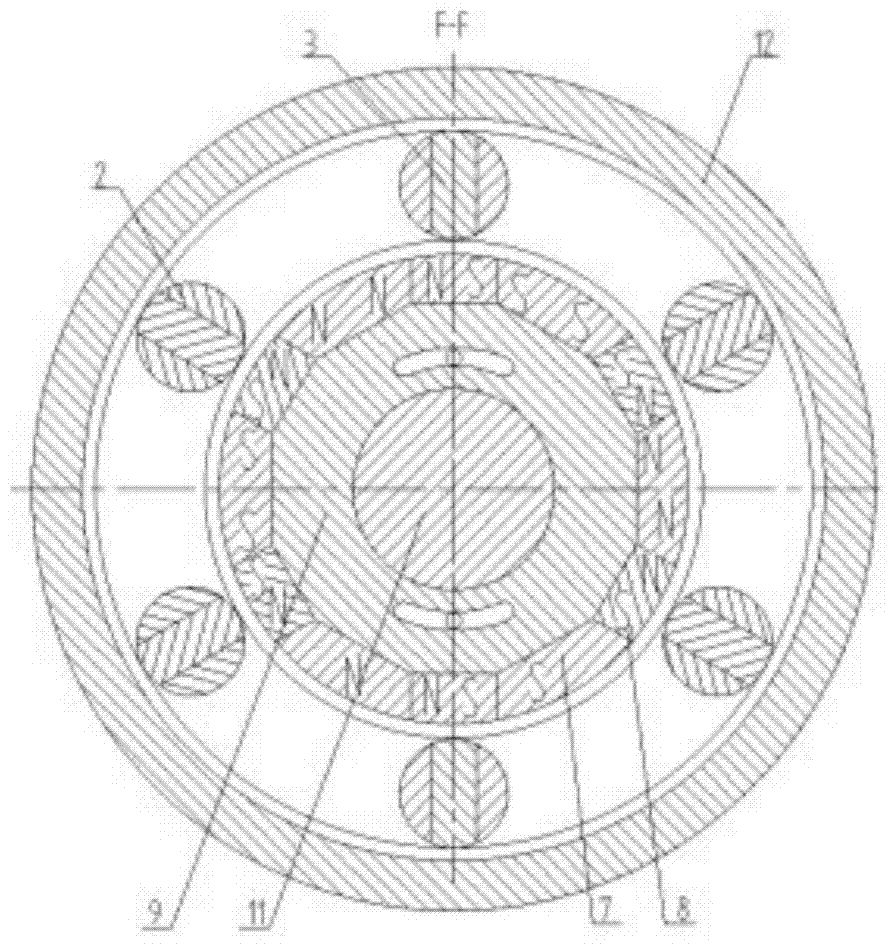

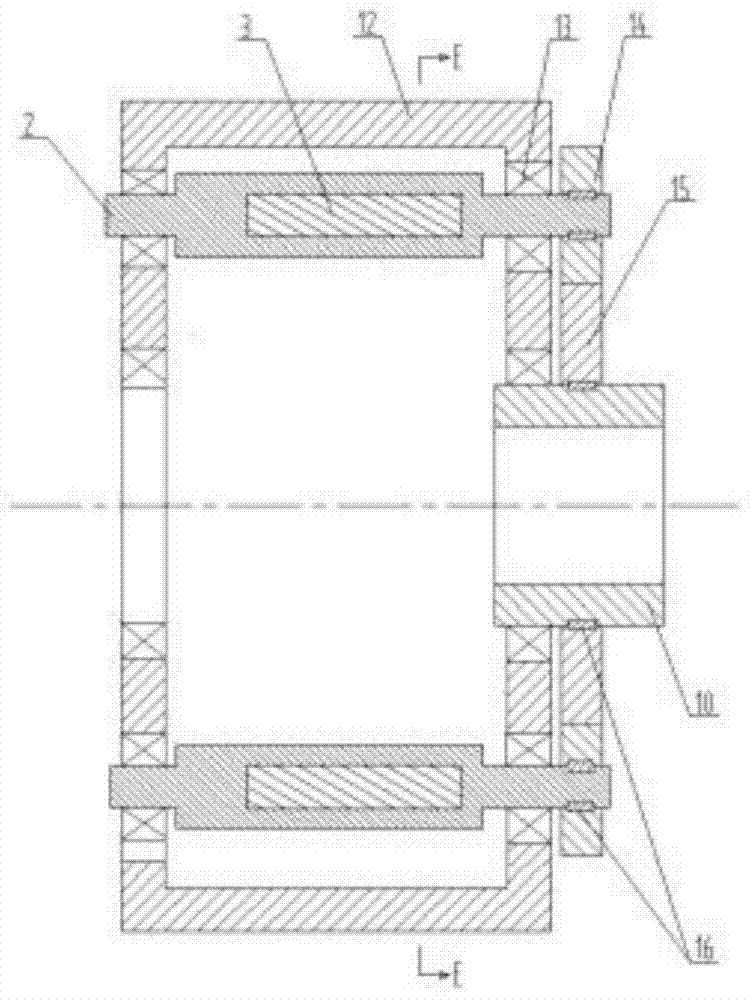

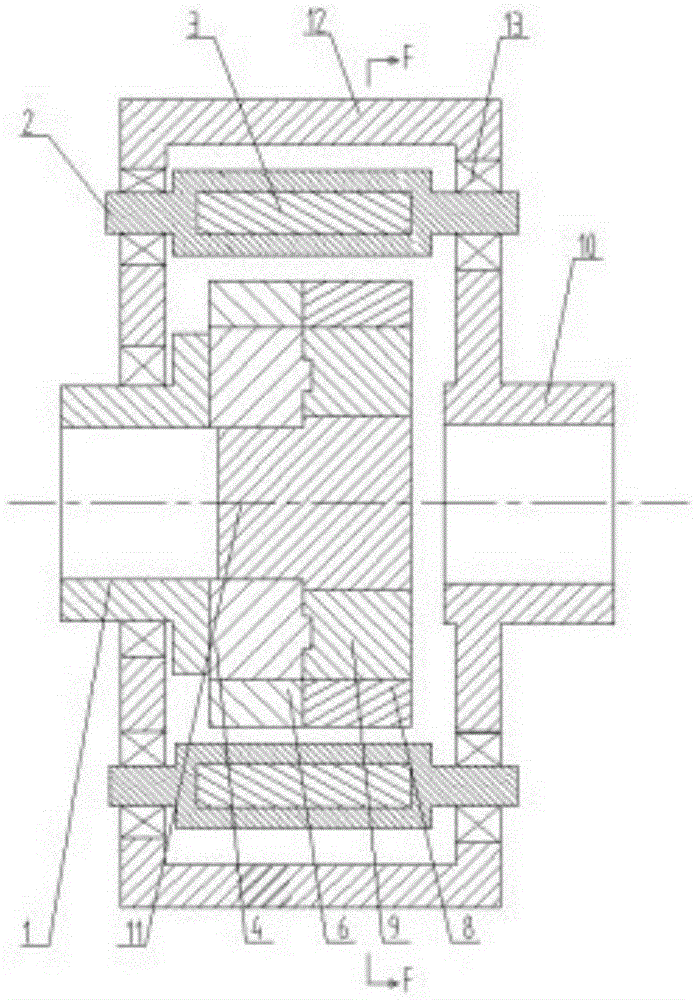

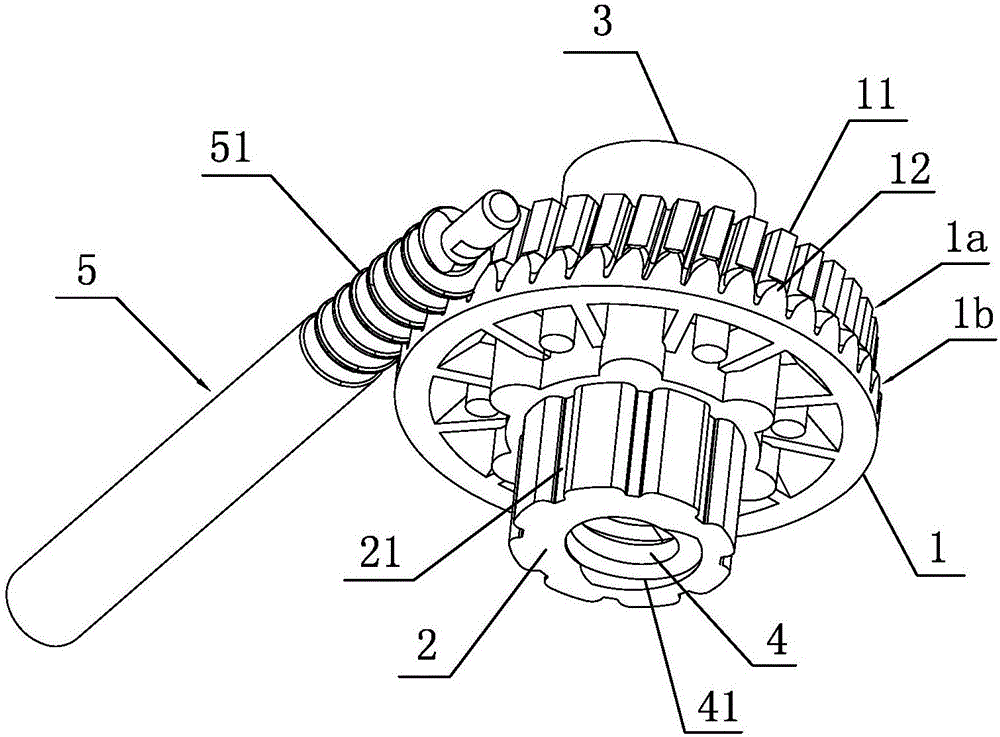

Compact type zero side clearance parallel-shaft gear speed reducer

InactiveCN102478098AImprove performanceSmall sizeToothed gearingsGearing detailsServo actuatorElectromechanical actuator

The invention belongs to an electromechanical servo actuator, particularly relates to a compact type zero side clearance parallel-shaft gear speed reducer and aims at providing the gear speed reducer which can meet requirements of an electromechanical actuator for installation space, interface size, moment of force, rotating speed, side clearance and the like. The gear speed reducer comprises a shell (11), a ball screw actuator input shaft (13), a large gear retainer ring (10), a large gear (9), a transition gear (6), a transmission gear (7), a transmission shaft (7), a shell (11), a bearing (8), a small gear (2), a motor output shaft (12), a small gear baffle ring (1) and an adjusting spring (5). The gear speed reducer has the advantages that a variable tooth thickness bevel wheel is adopted so that the side clearance of the gear can be very conveniently adjusted by adjusting the size of spring force, thereby the performance of the speed reducer is increased; and the spring is arranged in a cylindrical hole of the end surface of the gear, thereby the size of the speed reducer in the axial direction is saved.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

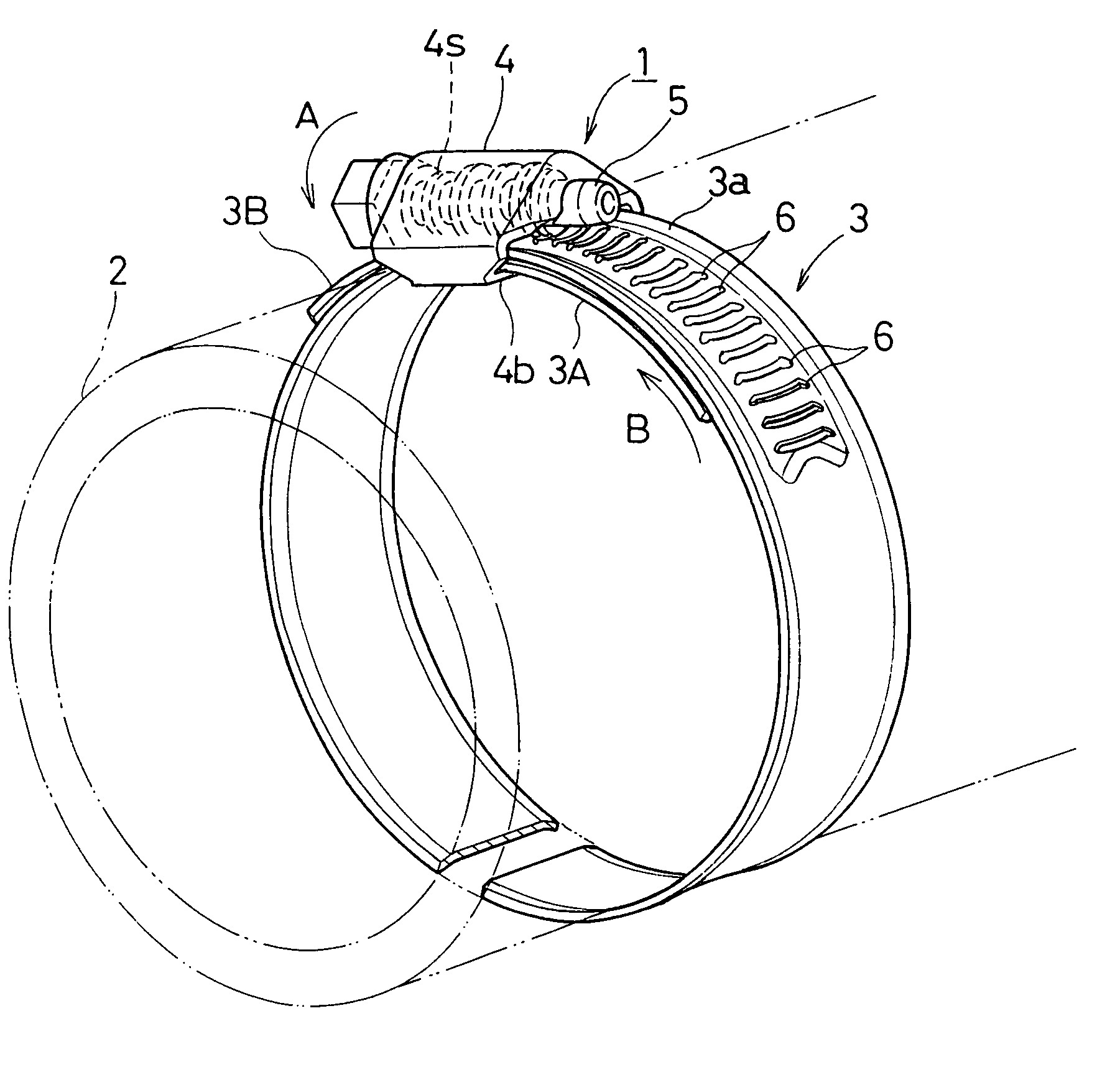

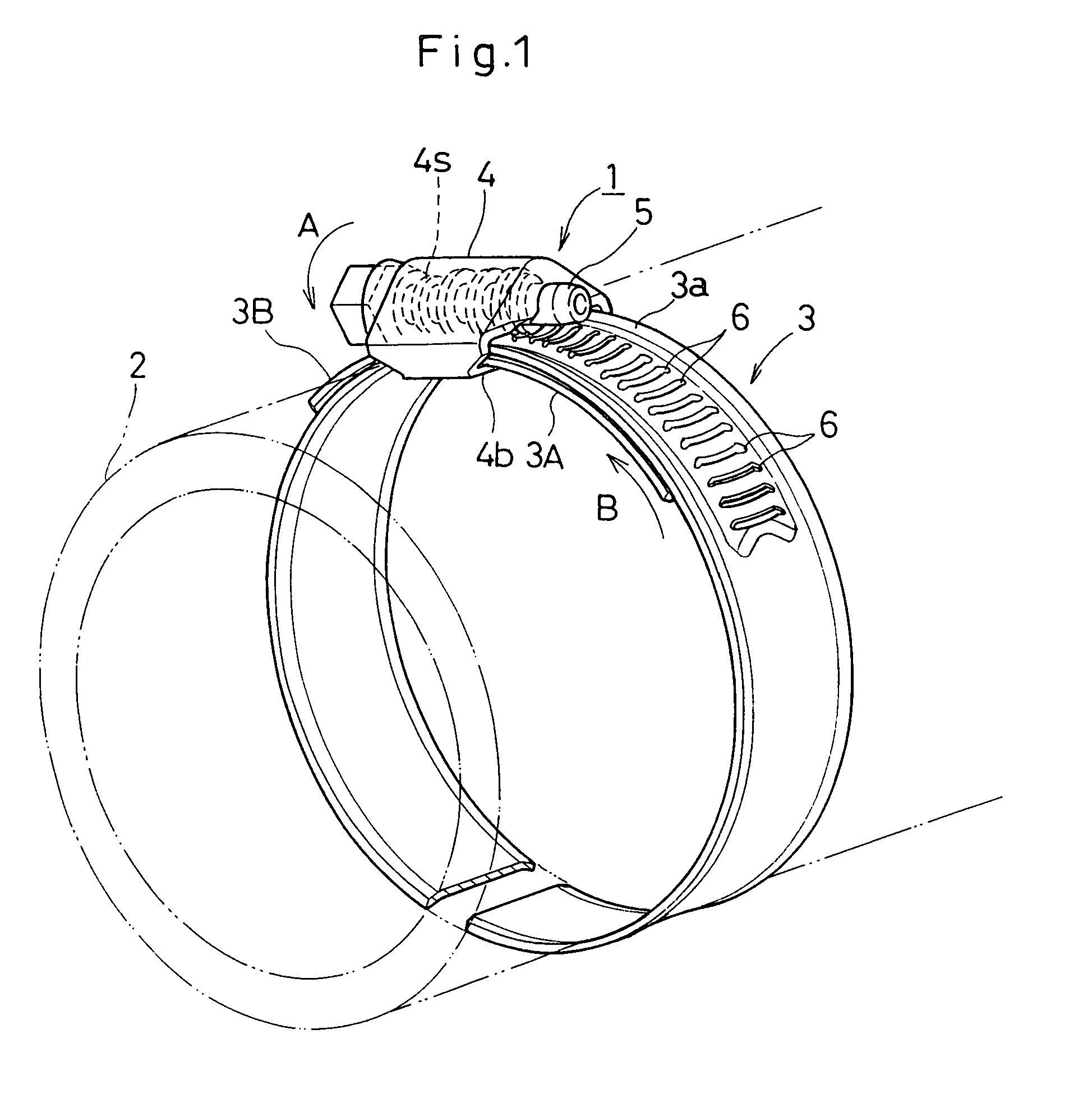

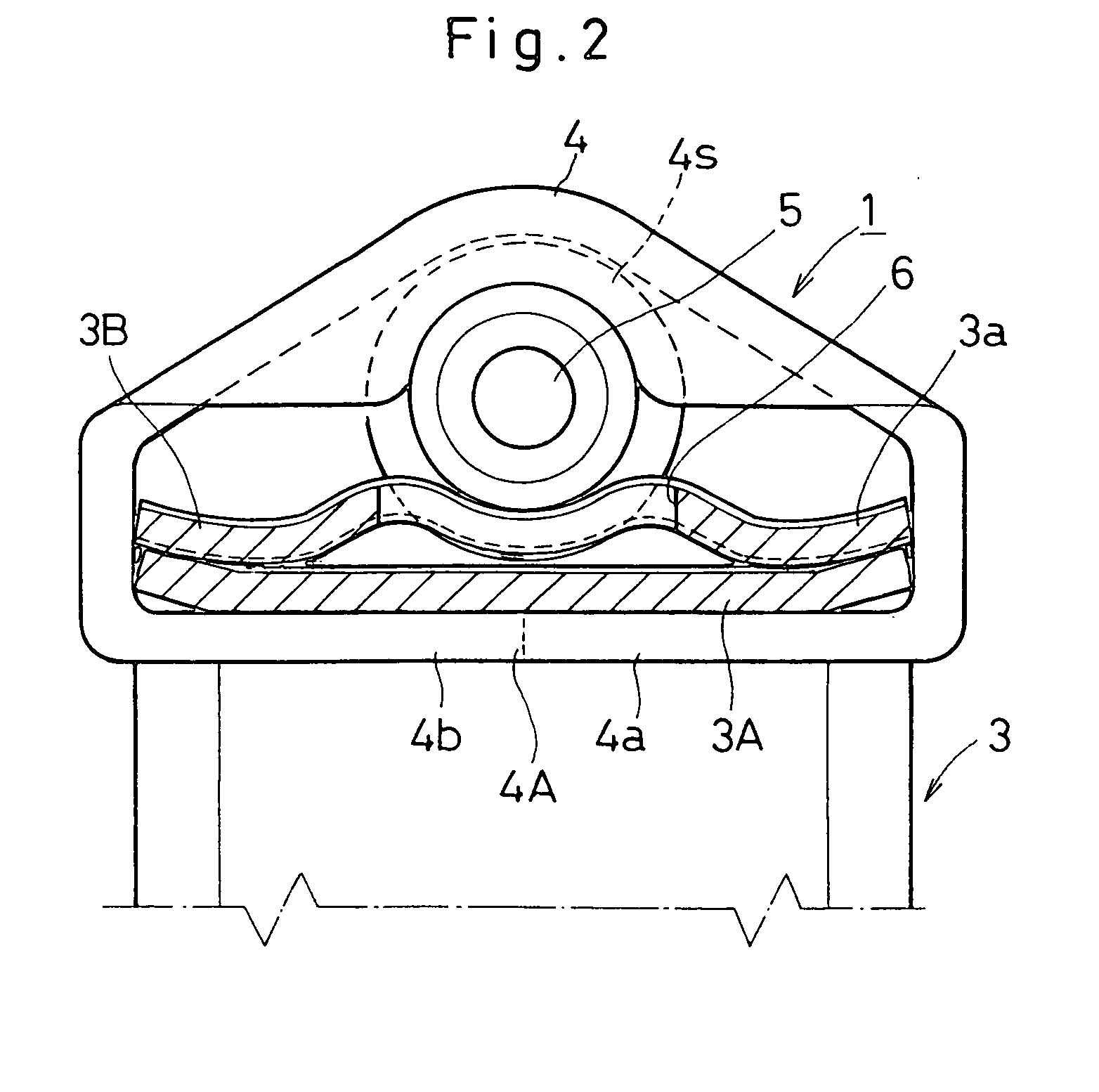

Clamp Device for Connection

InactiveUS20070283538A1Increase meshing areaTightly woundSnap fastenersFlexible elementsEngineeringElectrical and Electronics engineering

Owner:TAKAGI MFG

Nut for providing quick assembly and disassembly

A nut is employed to fix a faucet on a wash basin or a kitchen basin and contains an external driving member and an internal screwing member. The external driving member includes a cylindrical fence, an accommodating cavity, a first edge, and a second edge; the cylindrical fence has at least one limiting block and a griping face. The internal screwing member is fitted into and retained with the accommodating cavity and includes an annular cliff, a through orifice, a third edge, and a fourth edge; the annular cliff has plural slots longitudinally extending and isometrically arranged to the fourth edge from the third edge so as to define a plurality of flexible retaining portions, each having an inner threaded section; the annular cliff also has at least one longitudinal recess for retaining with the at least one limiting block of the external driving member and has a contacting fringe.

Owner:GLOBE UNION INDAL

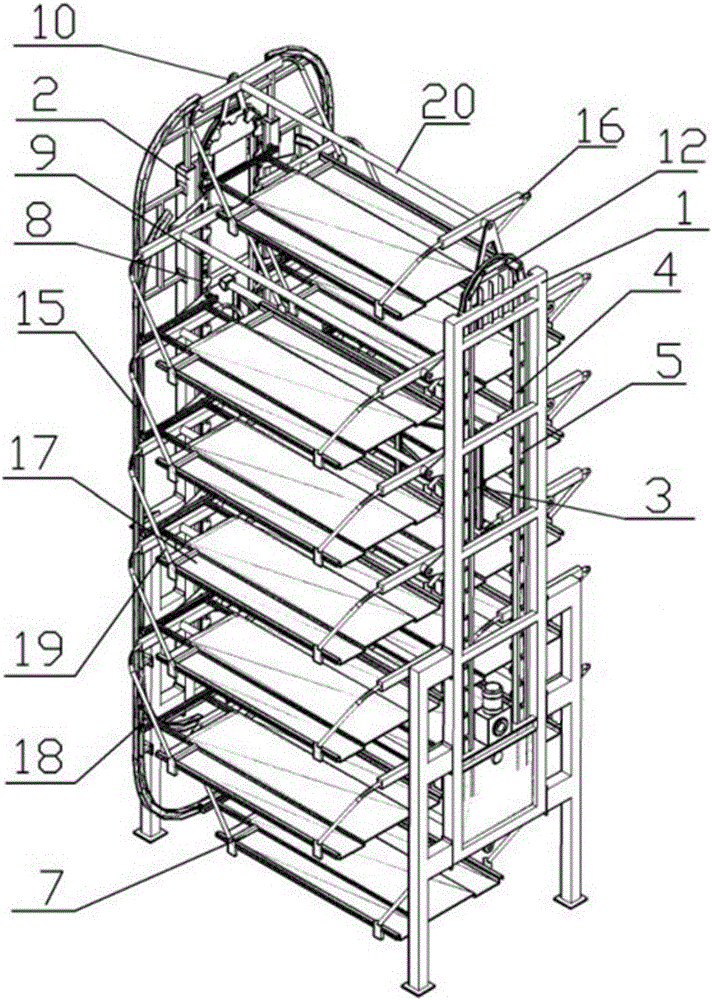

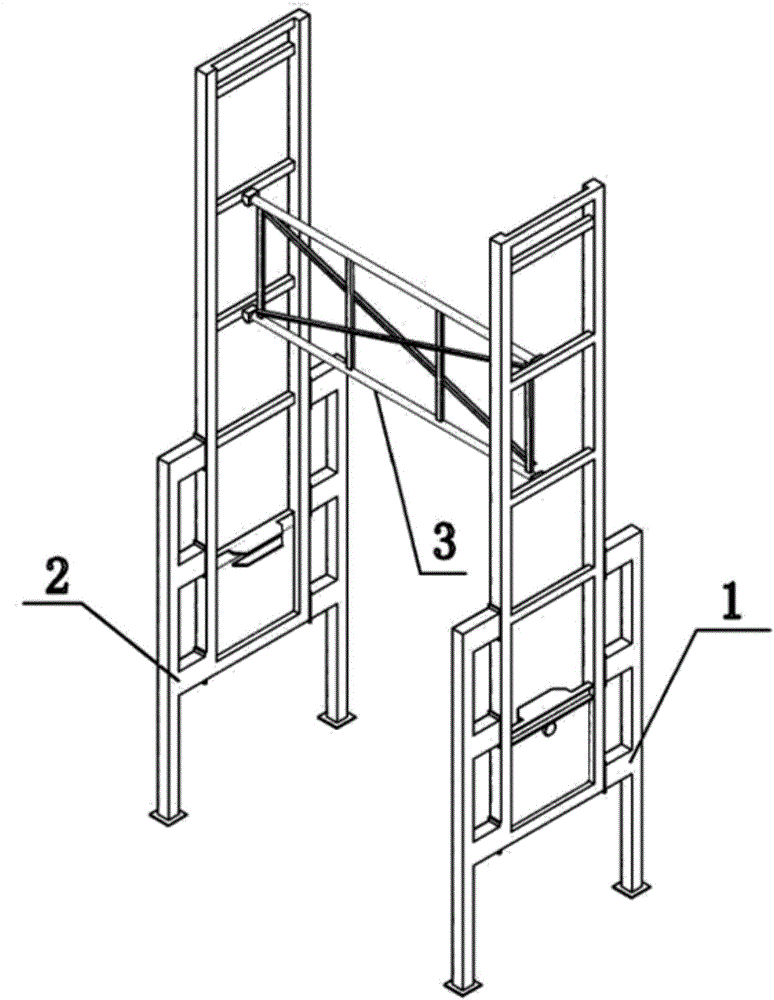

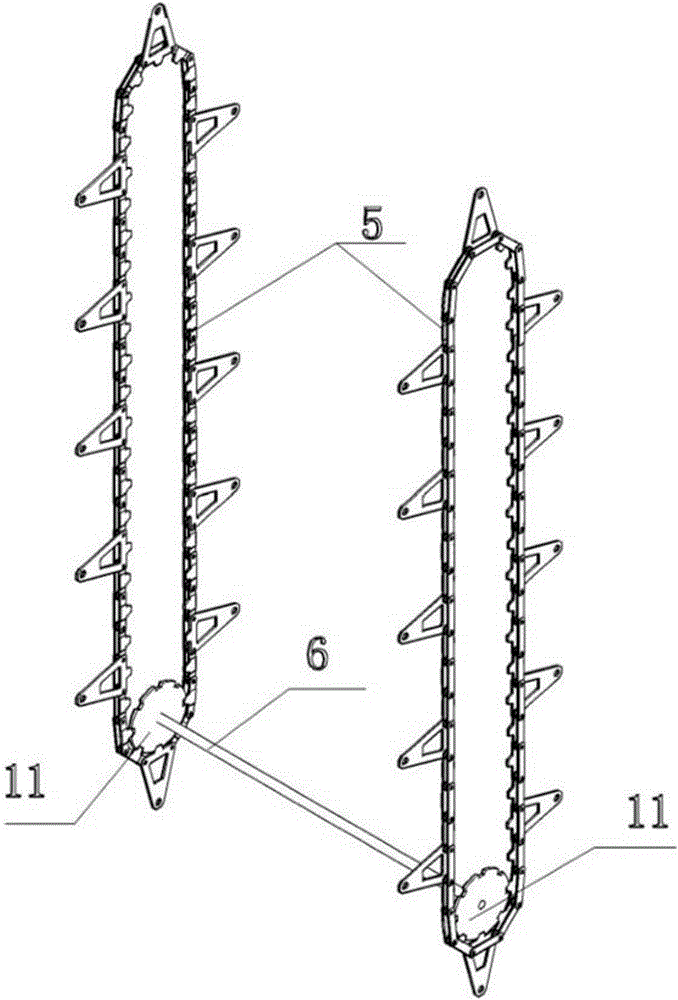

Stereo garage

A stereo garage comprises a driving framework, a guiding framework, a fixed beam, sealed guiding rails, lifting chains, a driving shaft, bearing frameworks, lifting chain sheets and a guiding rail. The driving framework and the guiding framework are of framework structures formed by square steel tubes which are welded; the fixed beam is fixedly connected between the driving framework and the guiding framework and forms a bearing main body with the driving framework and the guiding framework; the sealed guiding rails are respectively arranged in a vertical frame body of the driving framework and a vertical frame body of the guiding framework; the lifting chains are arranged on the sealed guiding rails, the lifting chains can circularly move in the sealed guiding rails and form a lifting system with the sealed guiding rails; the guiding rail is arranged on the outer side of the guiding framework; a plurality of lifting chain sheets are evenly distributed on each lifting chain; a plurality of bearing frameworks are horizontally arranged between two corresponding lifting chains in parallel, and hinge shafts of beams on the two sides of each bearing framework are in hinge connection with corresponding lifting chain sheets. The stereo garage is small in floor area, easy to process, flexible in transmission and low in construction cost.

Owner:朱德海

Connecting piece and electronic device with same

ActiveCN105889308AReduce tooth stressIncrease meshing areaToothed gearingsDetails for portable computersEngineeringBevel gear

The invention provides a connecting piece and an electronic device with the same. The connecting piece is used for rotationally connecting the first part with the second part of the electronic device. The connecting piece comprises a first bevel gear fixedly connected with the first part of the electronic device, a second bevel gear fixedly connected with the second part of the electronic device, and an intermediate bevel gear engaged with the first bevel gear and the second bevel gear. The axis of the intermediate bevel gear and the axes of the first bevel gear and the second bevel gear are orthogonal, and accordingly through rotation of the intermediate bevel gear, the first bevel gear and the second bevel gear can rotate synchronously so that the first part and the second part of the electronic device can rotate relatively. Since the intermediate bevel gear is an enveloping surface gear, the first bevel gear and the second bevel gear are engaged with the intermediate bevel gear in a linear contact mode.

Owner:LENOVO (BEIJING) LTD

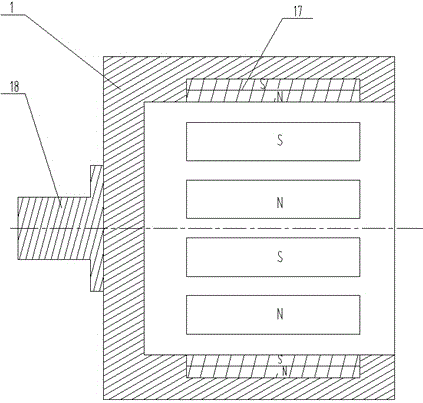

Current-controlled permanent magnet speed controller

InactiveCN105322756AIncrease meshing areaIncreased torque transfer capabilityAssociation with control/drive circuitsPermanent-magnet clutches/brakesMagnetic tension forcePermanent magnet rotor

The invention relates to a current-controlled permanent magnet speed controller. The current-controlled permanent magnet speed controller comprises a mouse cage conductor rotor connected with a driving shaft and a permanent magnet rotor connected with a driven shaft, wherein the mouse cage conductor is inlaid in the inner surface of the mouse cage conductor rotor, the end parts of mouse cage conductors are connected by arranging end rings, so as to form a mouse cage structure; and a thyristor which can be controlled to be on or off is connected between every two adjacent mouse cage conductors. The current-controlled permanent magnet speed controller adopts a fixed magnetic gap structure, so that meshing area of the speed controller is greatly increased, assembling difficulty is reduced, size is reduced, rare earth material is saved, and torque transmitting capacity is greatly improved; electric heating loss is reduced by enlarging the cross sections of the mouse cage conductors and reducing resistances of the conductors; and a magnetic gap or magnetic force regulating mechanism is eliminated, so that a control mechanism is greatly simplified, the size is reduced, the aims of saving energy and reducing consumption are realized to the utmost extent, material and electric energy consumption is reduced, mounting space is also saved, and convenience is provided for field mounting construction.

Owner:刁俊起

Permanent magnetic speed regulator

InactiveCN104852552AIncrease meshing areaReduce volumeDynamo-electric gearsMagnetic tension forceCoupling

Provided is a permanent magnetic speed regulator, comprising a conductor rotor and a permanent magnetic rotor. The conductor rotor and the permanent magnetic rotor are respectively connected with an input shaft and an output shaft. The conductor rotor is provided with cylindrical conductor rotors. The permanent magnetic rotor is provided with a cylindrical permanent magnetic rotor. The cylindrical conductor rotor arranged on the conductor rotor is in a double layer cylindrical shape. The cylindrical permanent magnetic rotor is between the cylindrical conductor rotors in the double layer cylindrical shape. The permanent magnetic speed regulator is advantaged in that meshing area between the cylindrical conductor rotors and the cylindrical permanent magnetic rotor is effectively increased, and objectives of small volume and large transmission torque are realized, axial movement of a permanent magnet between the double layer cylindrical conductor rotors is adjusted to change meshing area, so as to realize speed regulation, fan blades are used to radiate heat, volume of the permanent magnetic speed regulator can be made smaller, the radius where magnetic force is in can be changed according to power requirement, the permanent magnetic speed regulator can be installed by just changing a coupling without moving a motor, the permanent magnetic speed regulator can be used directly, and use is convenient, and purposes are wider.

Owner:GUANGXI CHUANJIAN IND TECH CO LTD

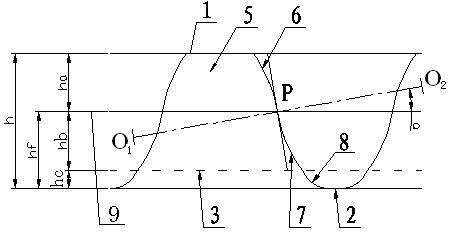

Single-tangent double-circular-arc gear

InactiveCN102494104AHigh strengthIncrease meshing areaPortable liftingGearing elementsSingle tooth rootRooted tooth

The invention discloses a single-tangent double-circular-arc gear, which is provided with a plurality of gear teeth, wherein a cambered convex trace and a cambered concave trace are formed on the same side face of each gear tooth; one end of the convex trace is contacted with a trace on the top of each tooth top; one end of the concave trace is contacted with a cambered transitional trace; the transitional trace is combined with a section of straight line to form a tooth root part; the convex trace is externally tangent and contacted with the concave trace at a position passing through a tangent line to form a tangent point; an included angle formed between the horizontal line passing through the tangent point and a connecting line of the circle centers of the convex trace and the concave trace is 0 to 30 degrees; and contact points of the concave trace and the transitional trace are always kept between a tooth root trace and a tooth top gap line. The single-tangent double-circular-arc gear has the characteristics of high contact strength, high bearing capacity, steady engagement, reliable operation, low impact noise, low sensitivity to central distance error, long service life and the like, and has the characteristics of simple gear tooth structure, high tooth root strength, large gear engagement area, small tooth surface contact stress, convenience for processing and manufacturing, high processing precision and the like.

Owner:许奉成

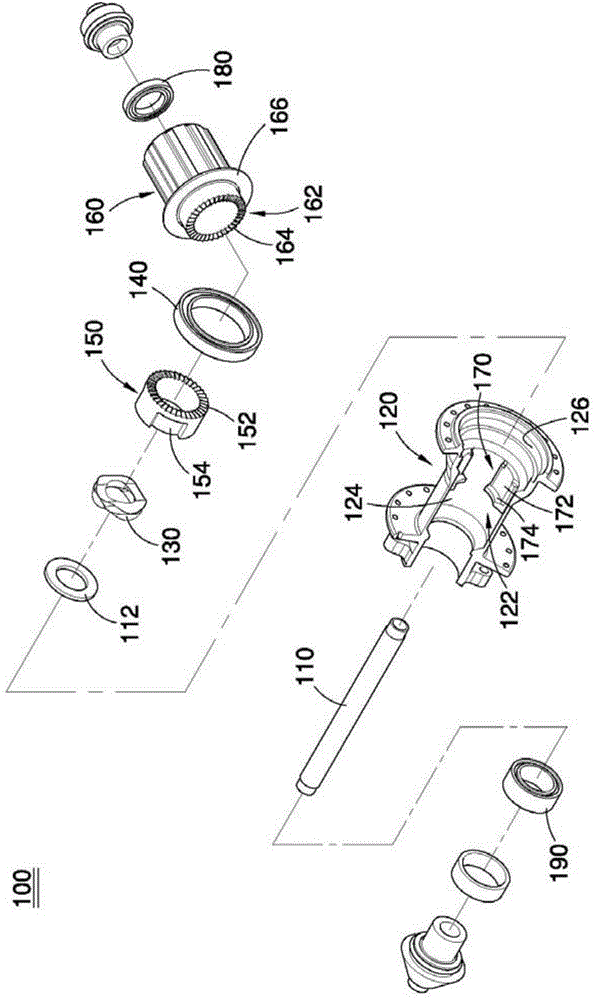

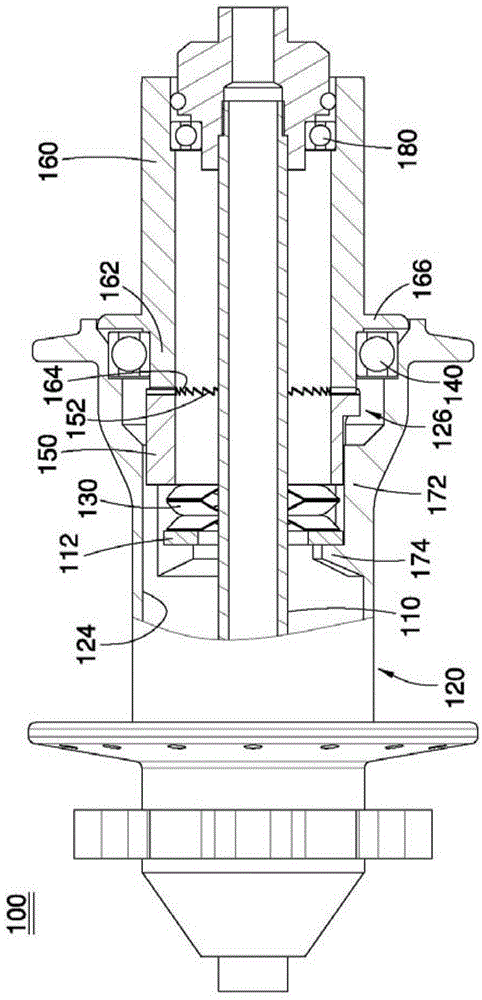

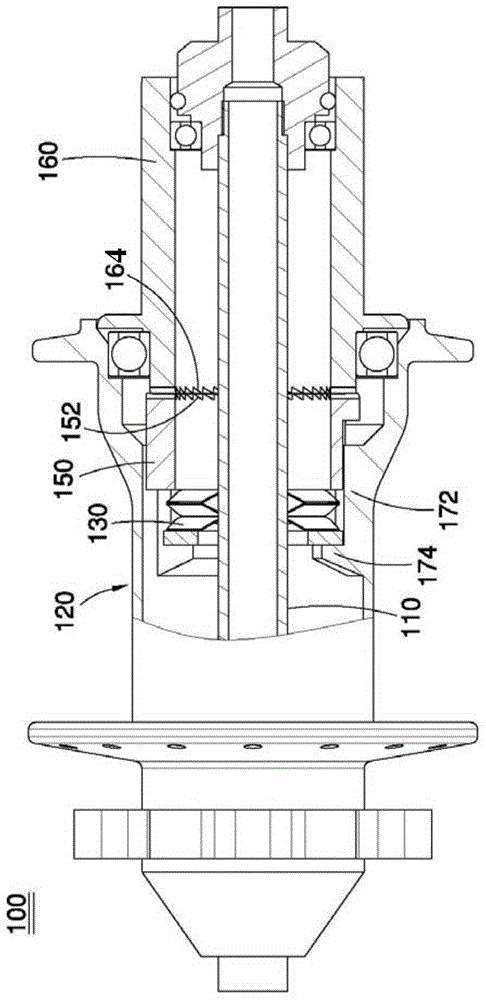

Hub structure

The invention provides a hub structure. The hub structure is mainly characterized in that a shell is connected with a transmission device, and the transmission devices drives the shell to rotate; the transmission device is composed of a driving ratchet wheel and a driven ratchet wheel; one end face of the driving ratchet wheel is provided with a first ratchet ring, and on end face of the driven ratchet wheel is provided with a second ratchet ring; the first ratchet ring of the driving ratchet wheel is meshed with the second ratchet ring of the driven ratchet wheel; and the driven ratchet wheel is fixed to the shell in a radial manner and can axially displace in the shell.

Owner:VOG IMAGE POLICE

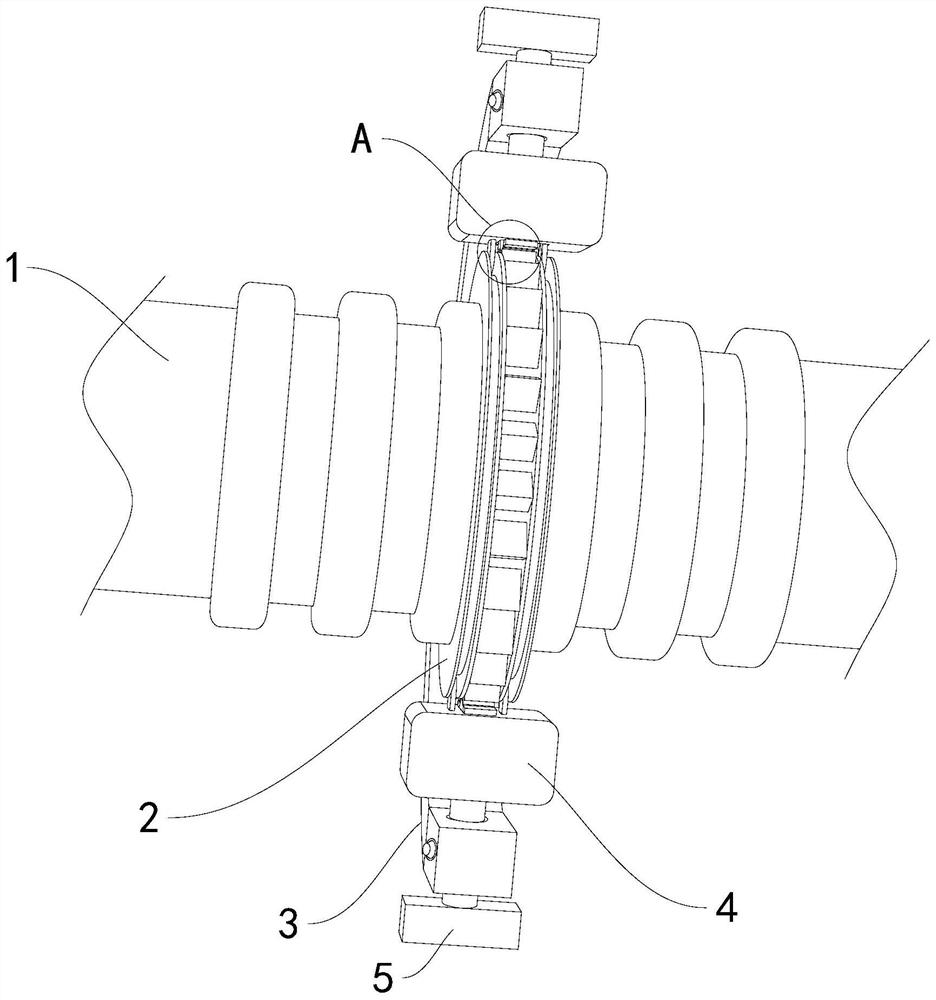

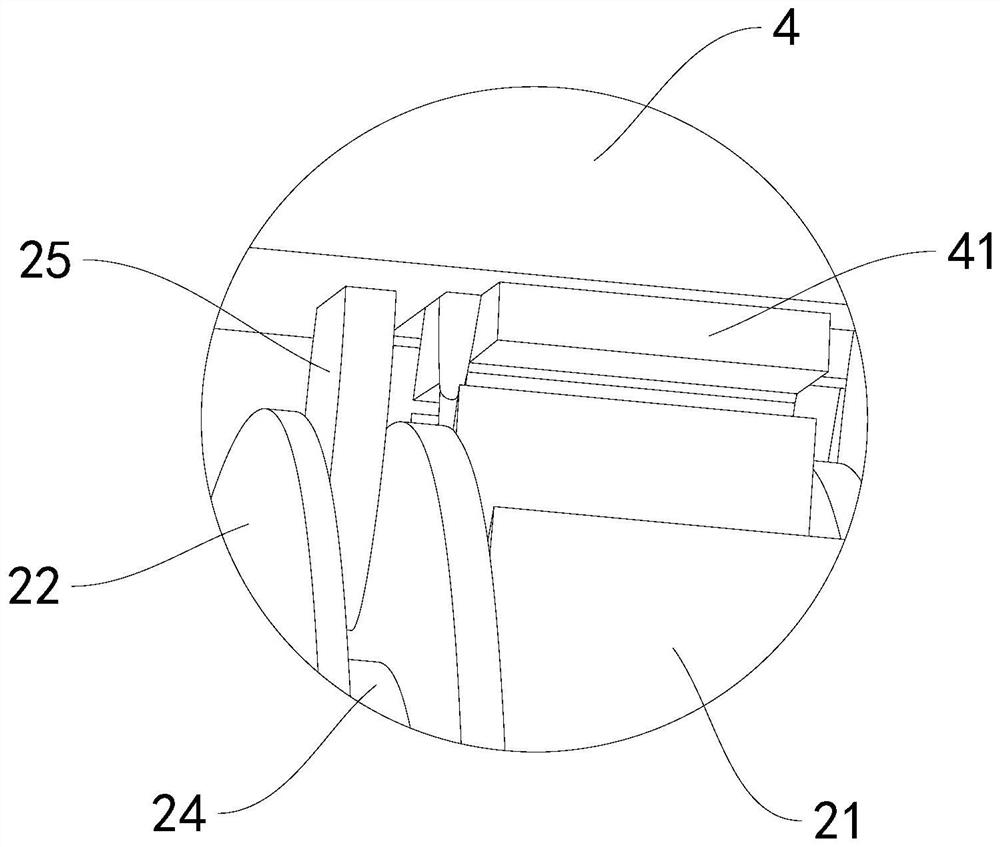

Corrugated pipe facilitating cleaning of gaps between corrugations

InactiveCN111618047AEasy to cleanImprove cleanlinessPipeline expansion-compensationHollow article cleaningStructural engineeringTube cleaning

The invention discloses a corrugated pipe facilitating cleaning of gaps between corrugations, and belongs to the field of corrugated pipes. The corrugated pipe facilitating cleaning of the gaps between the corrugations comprises a corrugated pipe body. A cleaning main ring is in cup joint to the outer end of the corrugated pipe body. The upper end and the lower end of the cleaning main ring are inmeshing connection with power boxes. Cleaning auxiliary rings are arranged on the outer side of the cleaning main ring. Movable holes are chiseled in the two ends of each cleaning auxiliary ring. A distance adjusting device is connected between each power box and the corresponding movable holes. A plurality of dust suction auxiliary pipes are fixedly connected to the inner ends of the cleaning auxiliary rings. The ends, away from the dust suction auxiliary pipes, of the cleaning auxiliary rings are provided with dust suction main pipes. The interiors of the dust suction auxiliary pipes, the interiors of the cleaning auxiliary rings and the interiors of the dust suction main pipes are sequentially in communication, and dust in the corrugation gaps of the corrugated pipe can be convenientlycleaned. A cleaning device and the corrugated pipe are detachably connected, meanwhile, dust raising after cleaning is collected, cleanliness of the corrugated pipe is effectively guaranteed, dust isnot likely to influence the corrugated pipe telescopic degree, and the corrugated pipe is integrally more attractive.

Owner:HANGZHOU LESHOU TECH CO LTD

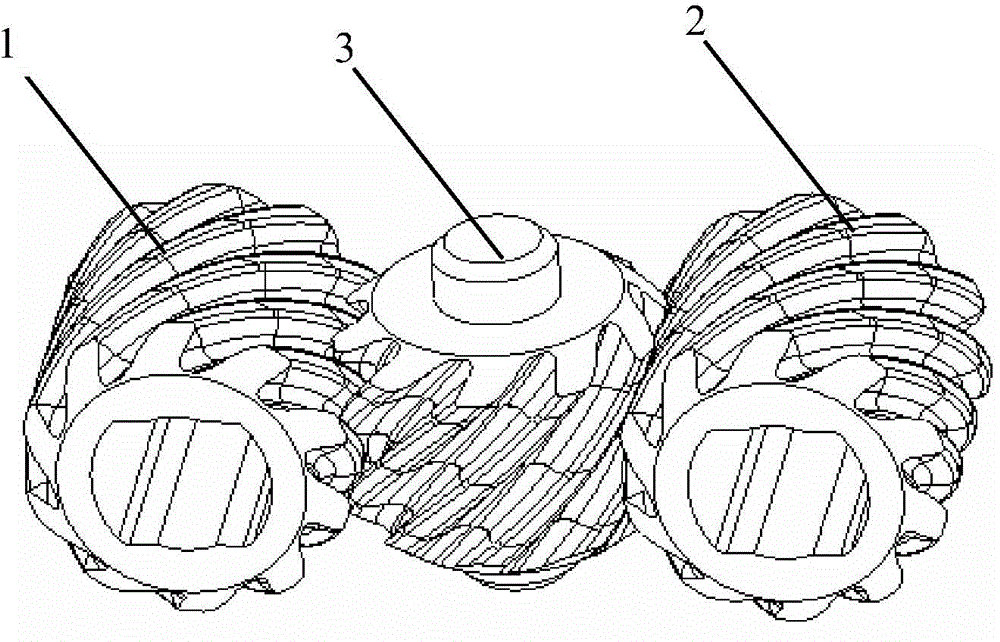

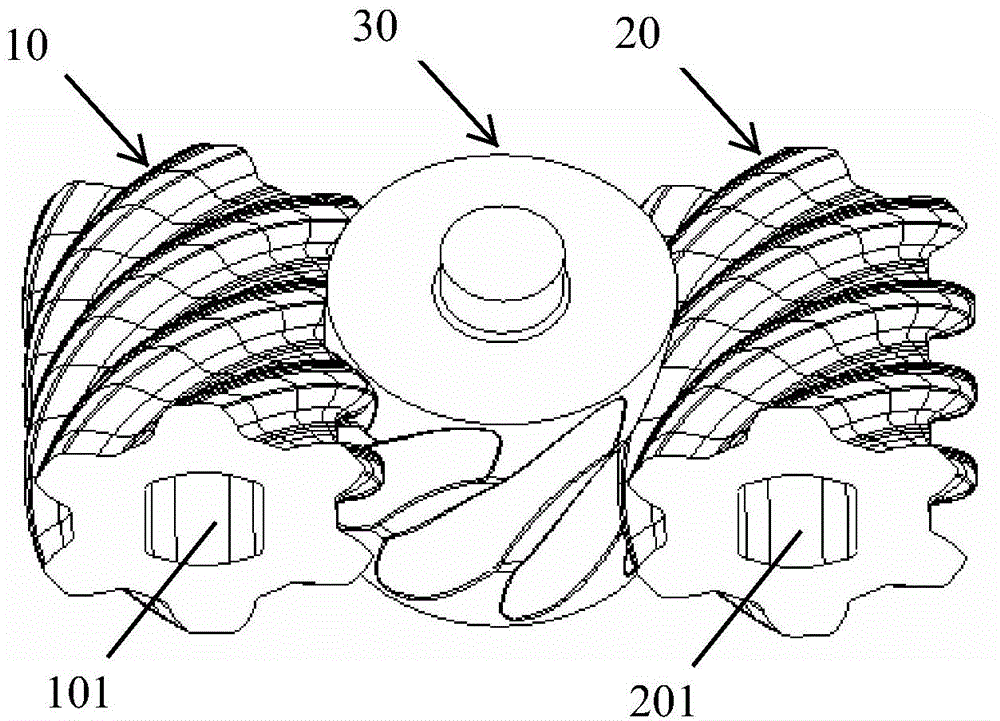

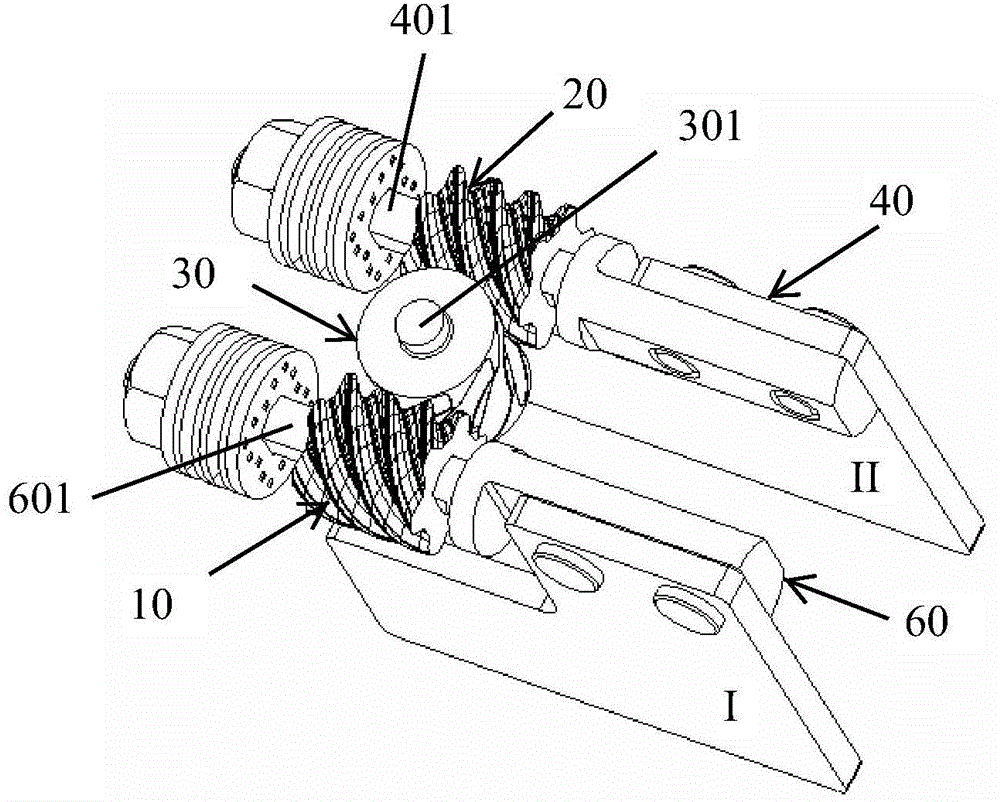

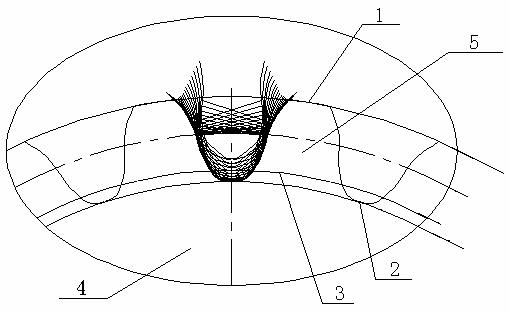

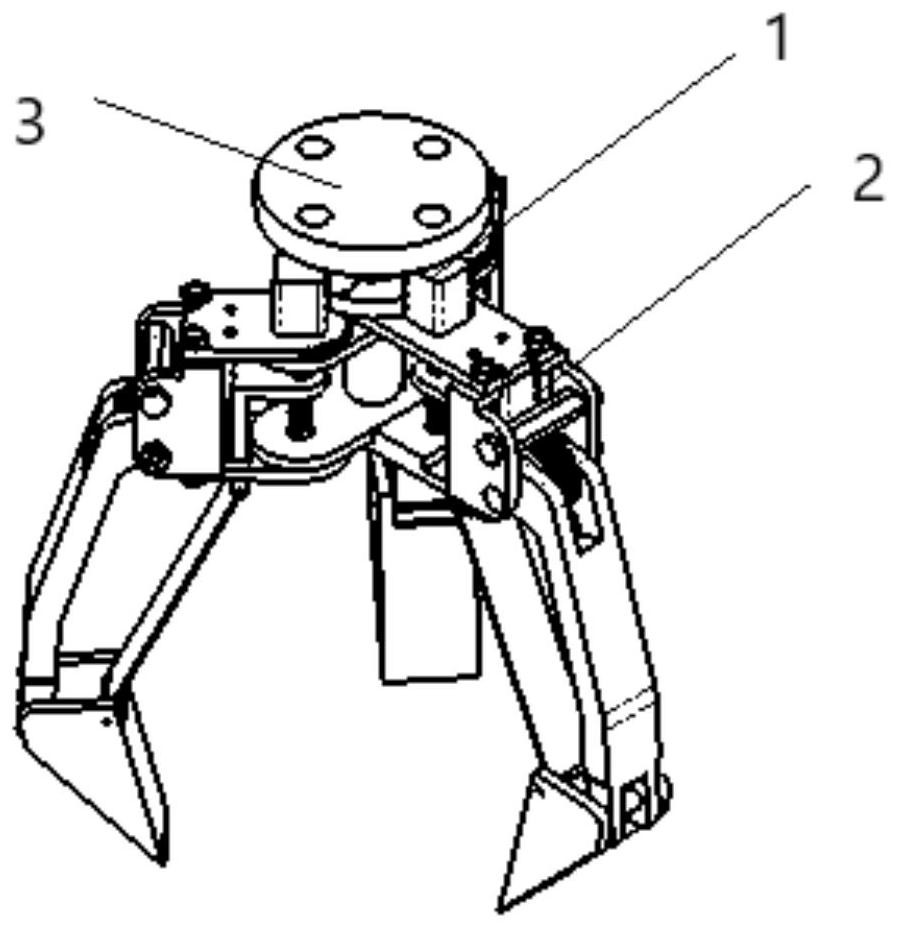

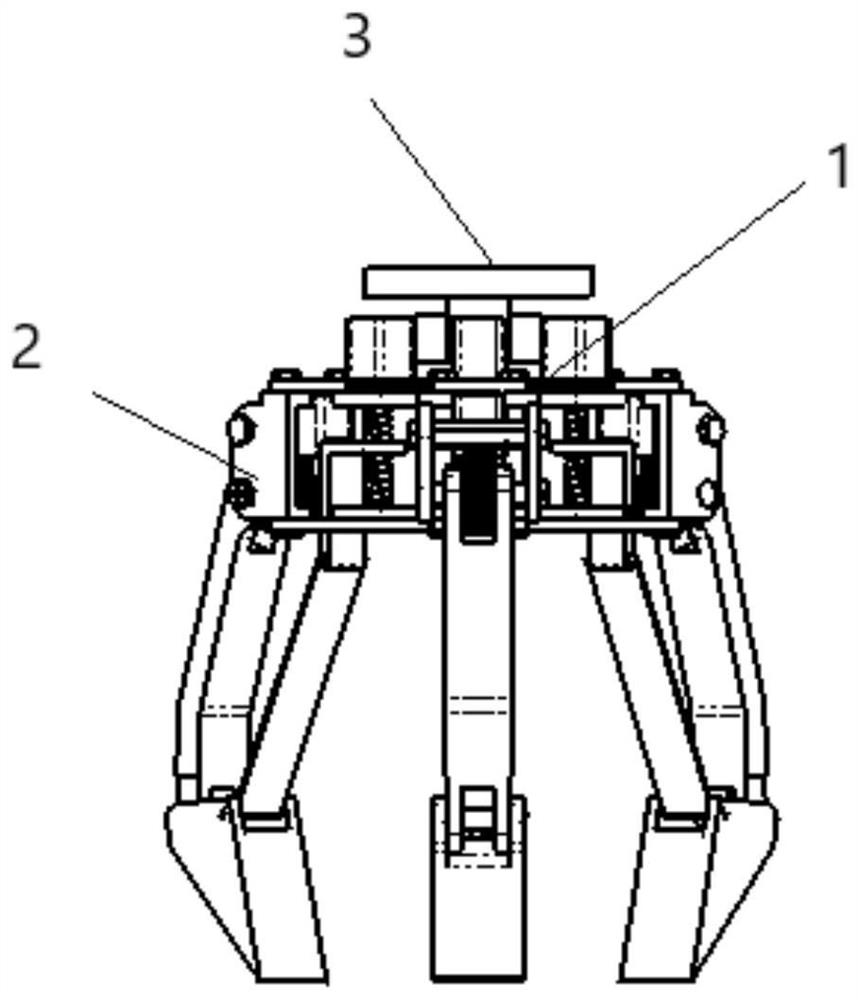

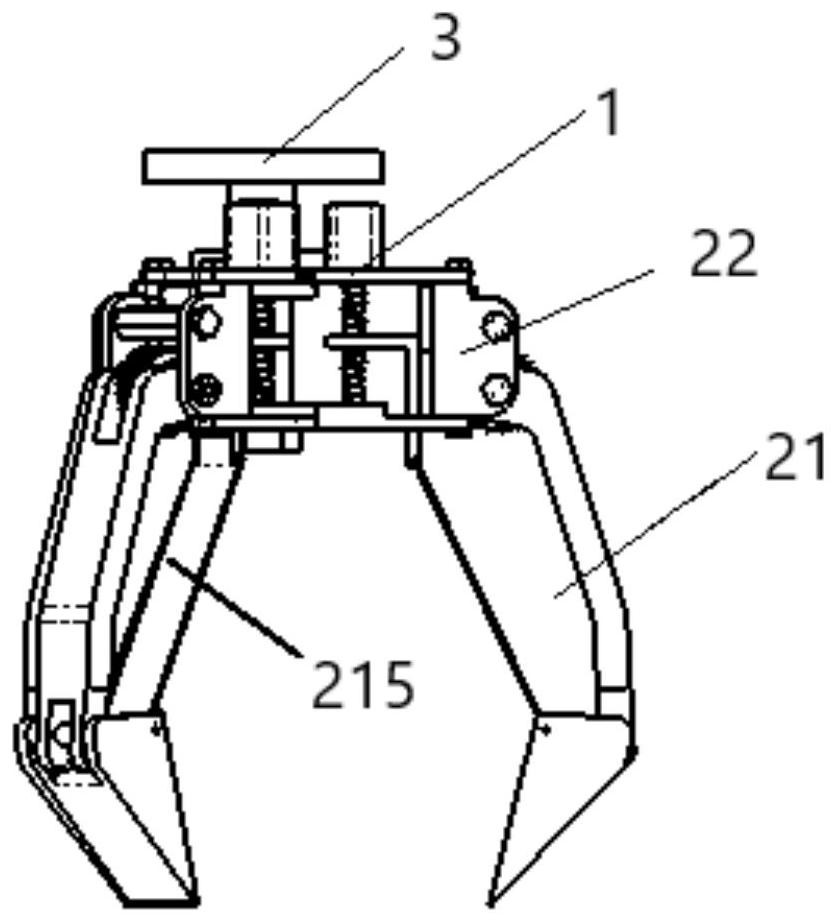

Semi-flexible multi-finger manipulator based on soft steel belt and toroidal worm and control method

PendingCN112659174AEnhanced surface contactApply pressure evenlyGripping headsControl engineeringControl switch

The invention discloses a semi-flexible multi-finger manipulator based on a soft steel belt and a toroidal worm and a control method. The multi-finger manipulator comprises a support unit, a grabbing unit, a manipulator hoisting unit and a control unit, wherein the support unit comprises a main support and a side support and is used for installing the grabbing unit; the grabbing unit is arranged on the outer side of the support unit and comprises multiple sets of single-finger driving mechanisms and an angle rotating mechanism, and the upper end of one set of single-finger driving mechanism is hinged to the mounting area of the main support; the angle rotating mechanism is mounted at the connecting end of the side support; the manipulator hoisting unit is arranged above the support unit, the upper end of the manipulator hoisting unit is connected with a mechanical arm, and the lower end of the manipulator hoisting unit is connected with the support unit; and the control unit comprises a controller and a control switch. The control method comprises the following steps that the spatial arrangement of the grabbing unit is adjusted according to an object; the grabbing unit is opened to be aligned with the target object; the position of the grabbing unit is adjusted, and the finger tips clamp the target object; and the clamping degree of the grabbing unit is adjusted. The semi-flexible multi-finger manipulator has the beneficial effects of adapting to target objects in various shapes, and realizing flexible clamping and stable carrying.

Owner:ZHEJIANG UNIV OF TECH

Efficient energy-saving transmission case

PendingCN109538737AReduce volumeImprove carrying capacityGearboxesGearing detailsDrive shaftHydraulic pump

The invention discloses an efficient energy-saving transmission case. The efficient energy-saving transmission case comprises a shell and a transmission mechanism; the transmission mechanism is provided with a drive gear, a transition gear and a driven gear which sequentially mesh with one another and adopt bevel gears; the drive gear is provided with a drive shaft connected with an engine, the driven gear is provided with a driven shaft connected with a hydraulic pump, and the transition gear is provided with a transition gear shaft and two conical roller bearings which are symmetrically arranged; each conical roller bearing is provided with a conical annular rolling space, each rolling space is provided with a conical small-head end with the small radius and a conical large-head end withthe large radius, the two conical small-head ends of the two conical roller bearings are arranged inwards and adjacently, and the two conical large-head ends are arranged outwards; and the drive shaft, the transition gear shaft and the driven shaft are arranged in parallel, and the axis of the drive shaft, the axis of the transition gear shaft and the axis of the driven shaft are arranged in a triangular vertex mode. According to the efficient energy-saving transmission case, the three gears cooperate with speed ratio adjustment, the hydraulic pump fully absorbs the torque of the engine, andhigh efficiency and energy conversation are achieved; the bearing capacity of the conical roller bearings is high, and therefore the service life of the transition gear can be prolonged; and comparedwith the existing installing structure that the three gears mesh with one another side by side, the size of the transmission case can be decreased.

Owner:QUANZHOU KINHO CONSTR MACHINERY TECH

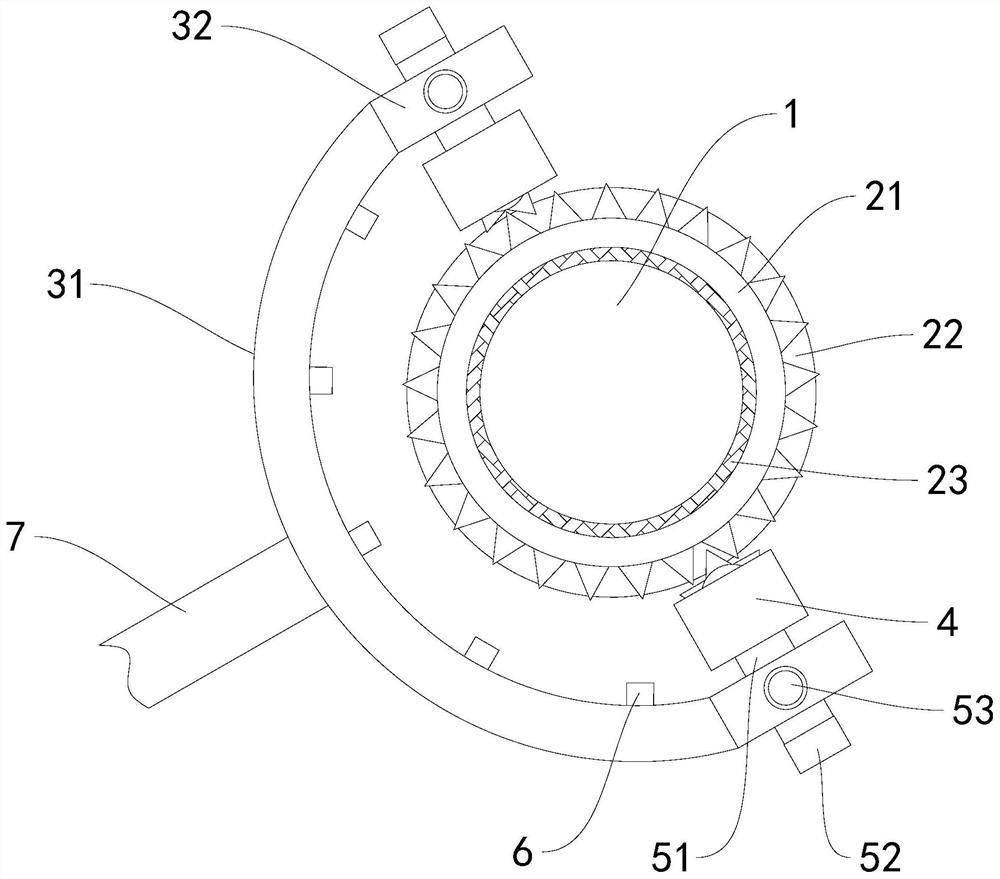

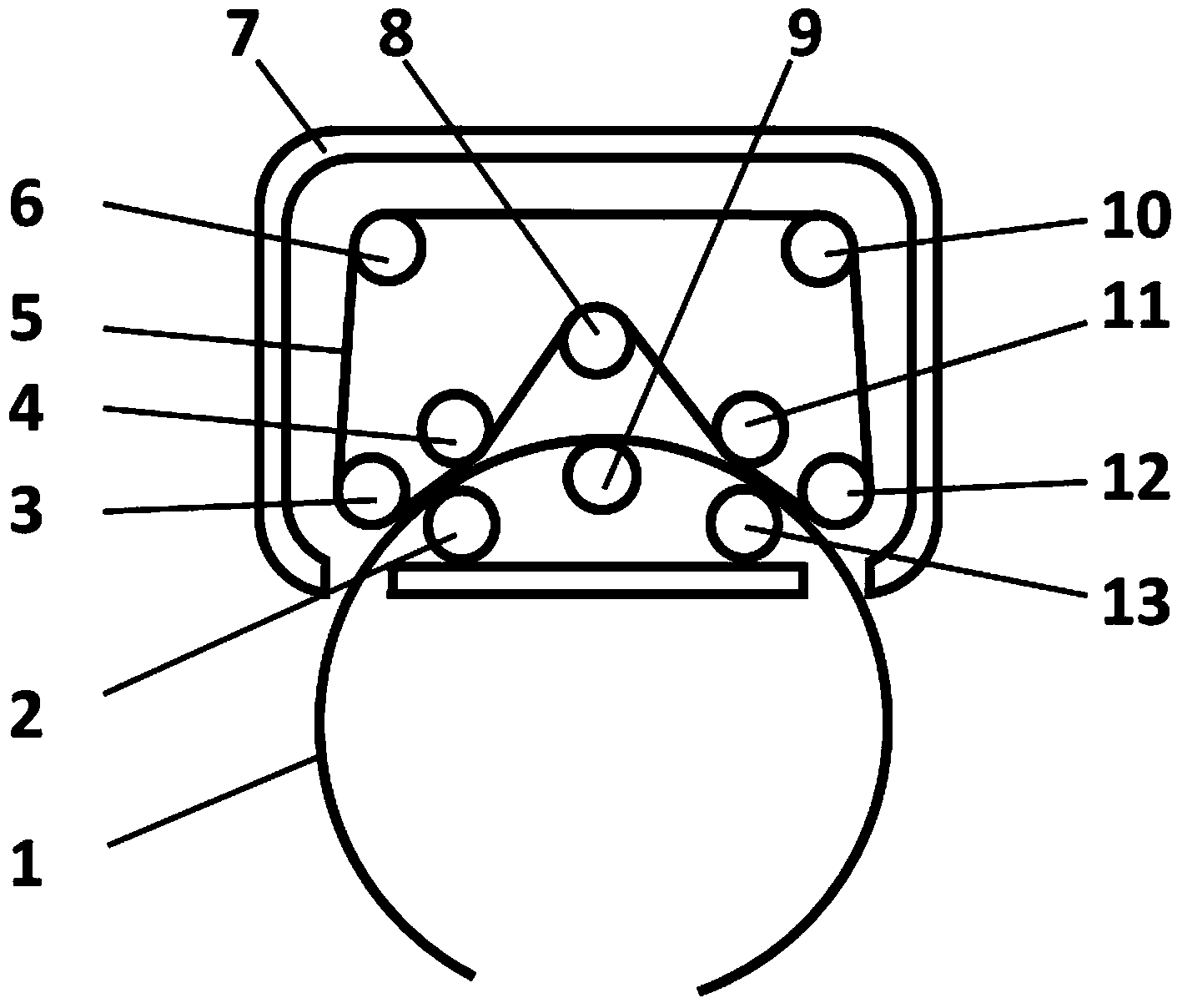

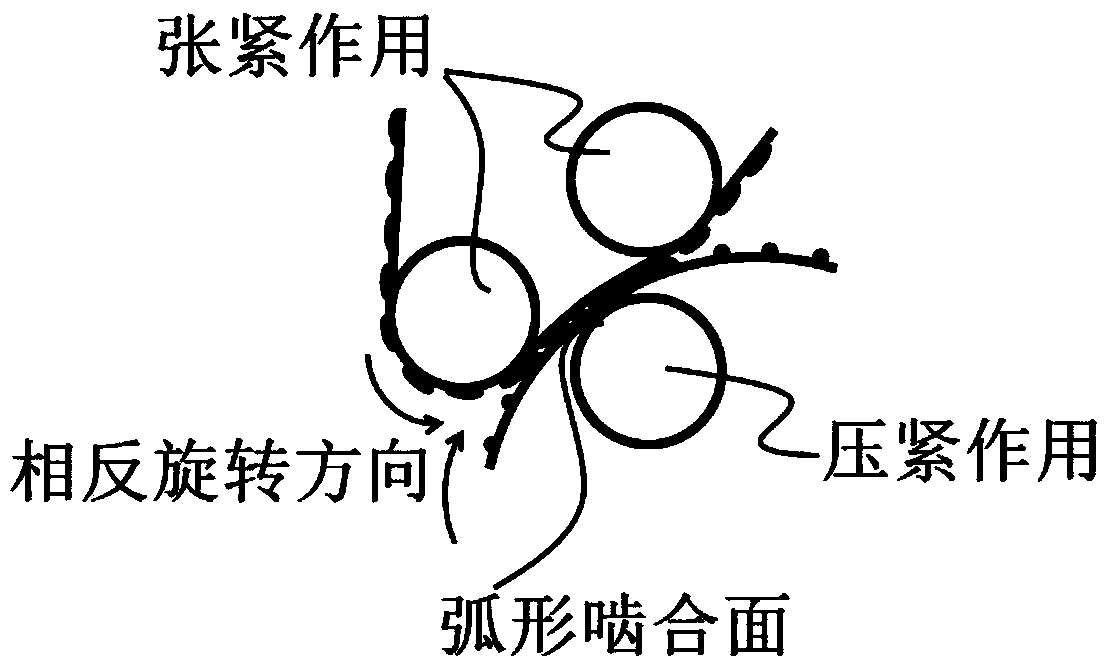

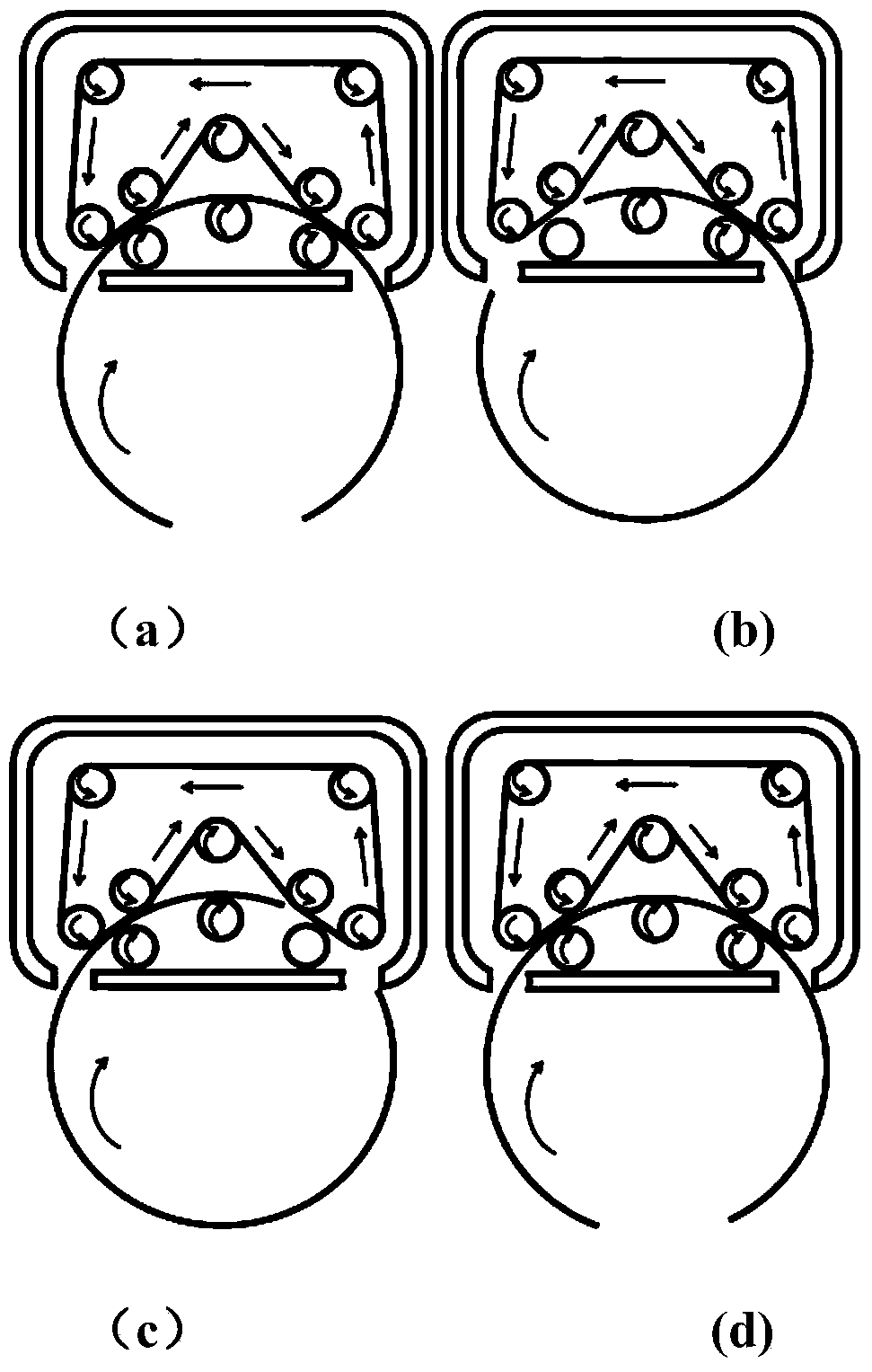

Flexible transmission mechanism of non-closed type annular rotator and application method of flexible transmission mechanism

The invention discloses a flexible transmission mechanism of a non-closed type annular rotator and an application method of the flexible transmission mechanism. The flexible transmission mechanism comprises the non-closed type annular rotator, three pinch rollers, six tensioning wheels, a toothed belt, a housing and a gear, wherein the pinch rollers, the tensioning wheels and a central spindle of the gear are fixed on a base plate of the housing; the gear, the second tensioning wheel, the first tensioning wheel, the third tensioning wheel, the fourth tensioning wheel, the sixth tensioning wheel and the fifth tensioning wheel are arranged clockwise; the inner side of the toothed belt is fitted with the outer sides of the five tensioning wheels to form a closed ring; the outer side of the toothed belt is meshed with the gear and the outer tooth shape of the non-closed type annular rotator; the three pinch rollers are fitted with the inner side of the non-closed type annular rotator. The flexible transmission mechanism of the non-closed type annular rotator and the application method of the flexible transmission mechanism, disclosed by the invention, can enlarge the meshing area of the flexible transmission mechanism, the gear and the non-closed type annular rotator, so as to increase the meshing force, and meanwhile avoid interference and clamping between the flexible transmission mechanism, the gear and the rigid tooth shape of the non-closed type annular rotator.

Owner:ZHUJI CANU AUTOMATION EQUIP CO LTD

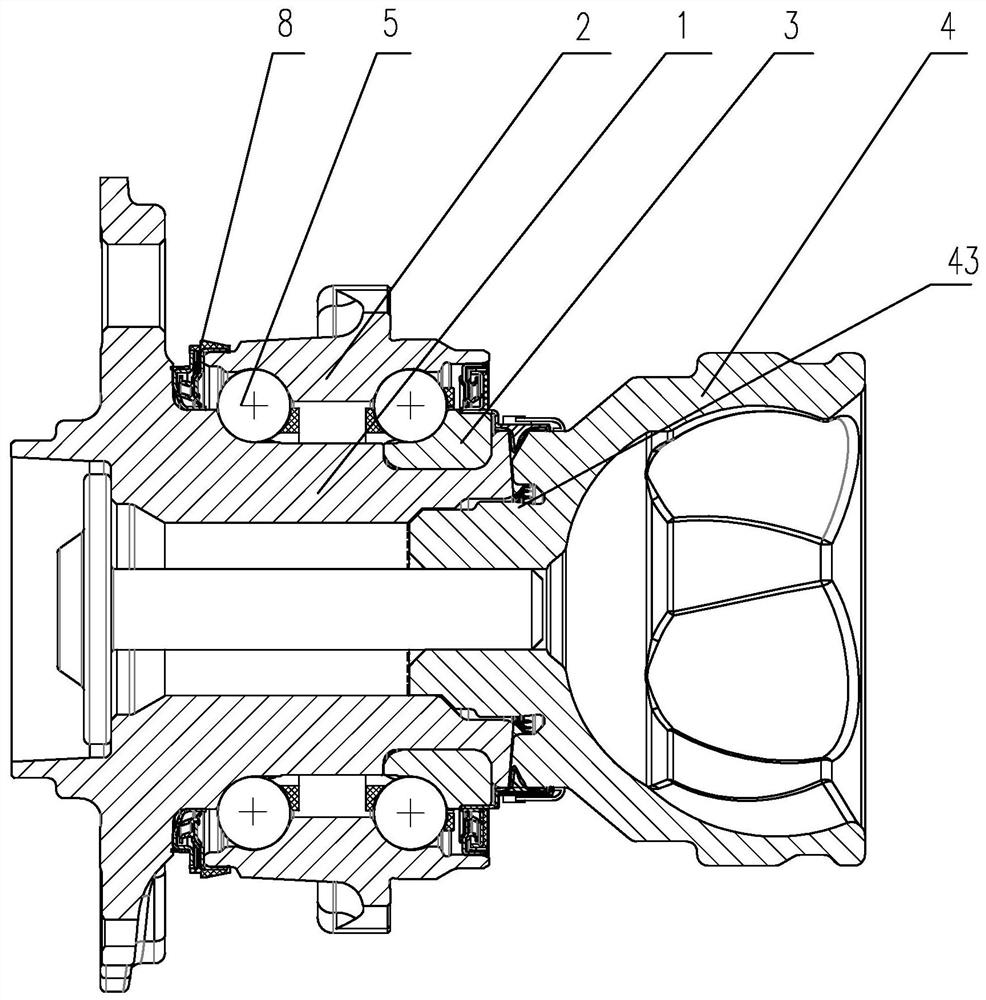

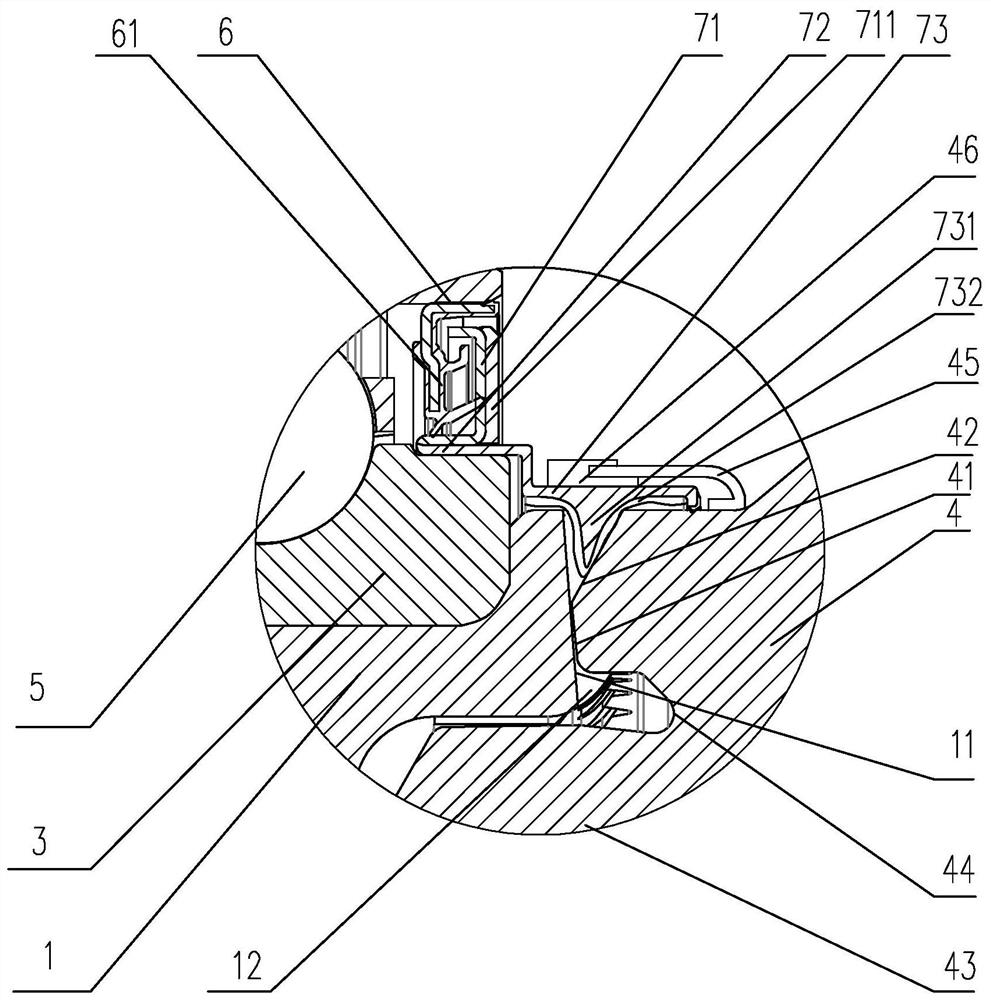

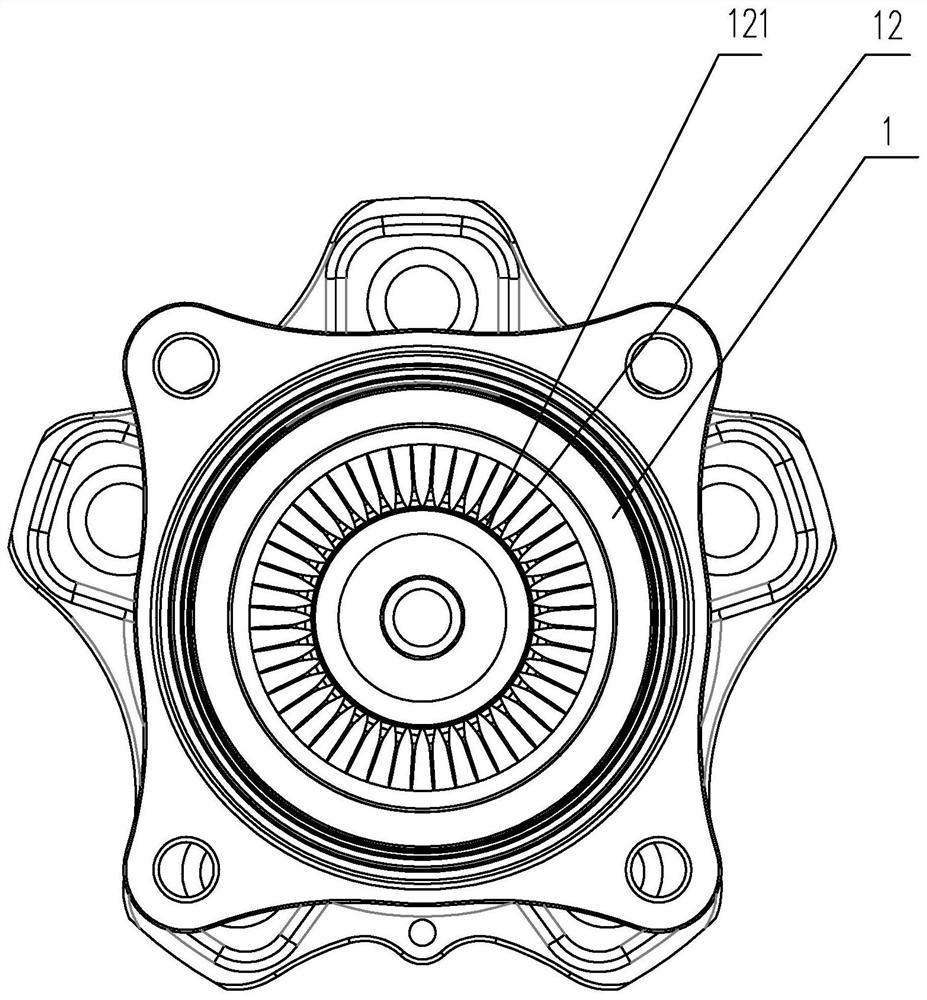

Hub bearing with spline shielding structure

ActiveCN113464567AHigh matching precisionLight in massEngine sealsBearing assemblyEngineeringStructural engineering

The invention discloses a hub bearing with a spline shielding structure. The hub bearing comprises a rotary connector, a flange inner ring, a flange outer ring and a connecting inner ring, rolling bodies are arranged between the flange inner ring and the flange outer ring and between the connecting inner ring and the flange outer ring, and a positioning protrusion is formed at the end, facing the flange inner ring, of the rotary connector; the inner wall of the flange inner ring is provided with a positioning groove, the positioning protrusion is in clearance fit with the positioning groove, the end face of the flange inner ring is arranged to be a conical face, connecting teeth are evenly distributed on the conical face, an abutting face is formed at the end of the rotary connector, clamping teeth are arranged on the abutting face, the connecting teeth are connected with the clamping teeth in a clamped manner, and the abutting face is connected with the edge of the rotary connector through a transition inclined face; and a first sealing check ring is arranged between the flange outer ring and the connecting inner ring, the first sealing check ring extends towards the connecting teeth to form a shielding lip, the first sealing check ring comprises a shielding protrusion, and the shielding protrusion is arranged between the transition inclined face and the conical face. The hub bearing is compact in structure, the installation precision is high, power transmission is stable, and the sealing effect is good.

Owner:C&U CO LTD +1

Piston swing cylinder

ActiveCN104632751BSmooth motionReduce collision forceFluid-pressure actuatorsEngineeringCylinder block

The invention discloses a piston type oscillating cylinder which comprises a cylinder body, rack-shaped piston rods, adjusting screw rods and an output shaft. The cylinder body is provided with two cylinder chambers and two end covers. The two rack-shaped piston rods are arranged in the two cylinder chambers respectively. The two adjusting screw rods are arranged on one end cover. The output shaft is fixedly provided with a gear which is in meshed connection with the two rack-shaped piston rods. The output shaft is connected with a rotary disk. The end cover where the adjusting screw rods are placed is a gas inlet end cover, and the other end cover is a gas outlet end cover. Each adjusting screw rod is provided with a gas inlet hole and a gas inlet adjusting mechanism. Each rack-shaped piston rod is provided with a vent hole. The gas outlet end cover is provided with two exhaust holes and two exhaust adjusting mechanisms which correspond to the two cylinder chambers respectively. According to the piston type oscillating cylinder, the rack-shaped piston rods are provided with the vent holes so that gas can flow to the other end from one end of each cylinder chamber, a buffer effect is achieved on the movement of the rack-shaped piston rods, the movement of the rack-shaped piston rods is stable and collision force is reduced.

Owner:GUANGXI UNIV

Rigid gear and flexible gear which are used for short-tube flexible-gear harmonic speed reducer and machining process thereof

Provided are a rigid gear and flexible gear which are used for short-tube flexible-gear harmonic speed reducer and a machining process thereof. Inner teeth of the rigid gear are gear teeth with an inclination angle alpha, the inclination direction of the inclination angle alpha is consistent with the field angle theta2 at the position of a long shaft of the flexible gear, and the inclination angle alpha is 0.1 degree to 2 degrees. Top ends of two tooth profile curve line sections of the outer tooth profile of the flexible gear are connected through a tooth top straight line section. Each tooth profile curve line section is formed by connecting upper circular radius and lower circular radius in smooth transition mode. The harmonic speed reducer comprises the rigid gear, the flexible gear and a wave generator. The ratio of the length and the inner diameter of the flexible gear is smaller than 1. The flexible gear and the rigid gear in the short-tube flexible-wheel harmonic speed reducer are both machined through a slow-feeding wire cutting off machine. The gear teeth of the flexible gear and the gear teeth of the rigid gear are meshed in the certain inclination angle. The total contact area of the meshing teeth pair is increased by 15% compared with the condition where no inclination angle exists. Overlapping ratio of the harmonic gears is improved, and harmonic transmission rigidity is improved.

Owner:DONGGUAN RICHTEK ELECTRONICS CO LTD

A permanent magnet governor with fixed magnetic gap

ActiveCN105449980BRealize speed regulation functionBroaden the fieldPermanent-magnet clutches/brakesDrive shaftRare earth

The invention relates to a permanent magnet speed regulator with a fixed magnetic gap, and the speed regulator comprises a first internal magnetic rotor, a second internal magnetic rotor, and an external magnet rotor frame, wherein a driving shaft coaxially passes through the first and second internal magnetic rotors, and the external magnet rotor frame is connected with a driven shaft. The external magnet rotor frame is provided with an external magnetic rotor through a bearing. In addition, one end, close to the driven shaft, of the external magnetic rotor is provided with an external magnetic rotor planetary gear. A driven shaft planetary gear is disposed between the external magnetic rotor planetary gear and the driven shaft. The speed regulator employs a fixed magnetic gap structure, so the speed regulator greatly increases the engagement area, reduces the assembly difficulty, reduces the generated heat, enlarges the range of speed regulation, saves rare earth materials, and greatly improves the capability of torque transmission. Because the speed regulator employs a planetary gear transmission structure, the speed regulator achieves a function of 0-%N speed regulation of input and output rotating speeds through changing the gear ratio of the external magnetic rotor planetary gear to the driven shaft planetary gear. In addition, the speed regulator employs a bearing structure, and prevents the continuous shaking of the driven shaft in two directions from causing that the driven shaft cannot rotate normally in one direction to drive a load.

Owner:刁俊起

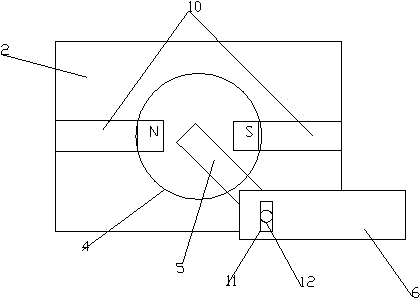

Permanent magnet speed controller with fixed magnetic gap

InactiveCN104362829AIncrease meshing areaReduce generationDynamo-electric brakes/clutchesElectric motor controlMagnetic polesTorque transmission

The invention relates to a permanent magnet speed controller with a fixed magnetic gap. The permanent magnet speed controller comprises an outer magnet rotor and an inner magnet rotor, wherein at least two outer permanent magnets are uniformly distributed along the circumferential direction of the inner circumferential surface of the outer magnet rotor; the magnetic poles of the outer permanent magnets are arranged along the radial direction, and the magnetisms of exposed magnetic pole surfaces of every two adjacent outer permanent magnets are different; at least one rotatable permanent magnet is distributed along the circumferential direction of the outer circumferential surface of the inner magnet rotor; the rotatable permanent magnet is cylindrical, and the pole N and the pole S are arranged along the diameter direction; and one end of the rotatable permanent magnet is provided with a magnetic circuit regulator. Due to the adoption of the fixed magnetic gap, the meshing area of the speed controller is greatly increased, the assembling difficulty is lowered, the heat generation is reduced, the speed control range is widened, rare earth materials are saved, the torque transfer capacity is greatly improved, the function of controlling the speed at the input and output rotating speed of 0-N% is achieved, the material consumption is reduced, the mounting space is saved, and more importantly, the convenience is brought for field installation and construction.

Owner:刁俊起

Permanent magnet speed adjuster with fixed magnetic gap

ActiveCN105245084AIncrease meshing areaReduce generationPermanent-magnet clutches/brakesDrive shaftRare earth

The invention relates to a permanent magnet speed adjuster with a fixed magnetic gap, which comprises a first inner magnetic rotor, a second inner magnetic rotor and an outer magnetic rotor frame, wherein a driving shaft concentrically passes through the first inner magnetic rotor and the second inner magnetic rotor; the outer magnetic rotor frame is connected with a driven shaft; the outer magnetic rotor frame is provided with an outer magnetic rotor via a bearing; the first inner magnetic rotor and the second inner magnetic rotor are both provided with at least two first inner permanent magnets and second inner permanent magnets distributed circumferentially and uniformly along the outer circumferential surfaces; and the first inner magnetic rotor is provided with a magnetic circuit adjustment executor driving the first inner magnetic rotor to rotate relative to the second inner magnetic rotor. As the fixed magnetic gap structure is adopted, the meshing area of the speed adjuster is greatly improved, the assembly difficulty is reduced, heat generation is reduced, the speed adjustment range is increased, rare earth materials are saved, and the torque transfer capability is greatly improved. As the bearing structure is adopted, the phenomenon that as the driven shaft shocks back and forth along two directions, the driven shaft can not rotate normally along one direction to drive a load can be avoided.

Owner:刁俊起

Permanent magnet speed regulator with fixed magnetic gap

ActiveCN105449980ARealize speed regulation functionExpand the scope of usePermanent-magnet clutches/brakesDrive shaftRare earth

The invention relates to a permanent magnet speed regulator with a fixed magnetic gap, and the speed regulator comprises a first internal magnetic rotor, a second internal magnetic rotor, and an external magnet rotor frame, wherein a driving shaft coaxially passes through the first and second internal magnetic rotors, and the external magnet rotor frame is connected with a driven shaft. The external magnet rotor frame is provided with an external magnetic rotor through a bearing. In addition, one end, close to the driven shaft, of the external magnetic rotor is provided with an external magnetic rotor planetary gear. A driven shaft planetary gear is disposed between the external magnetic rotor planetary gear and the driven shaft. The speed regulator employs a fixed magnetic gap structure, so the speed regulator greatly increases the engagement area, reduces the assembly difficulty, reduces the generated heat, enlarges the range of speed regulation, saves rare earth materials, and greatly improves the capability of torque transmission. Because the speed regulator employs a planetary gear transmission structure, the speed regulator achieves a function of 0-%N speed regulation of input and output rotating speeds through changing the gear ratio of the external magnetic rotor planetary gear to the driven shaft planetary gear. In addition, the speed regulator employs a bearing structure, and prevents the continuous shaking of the driven shaft in two directions from causing that the driven shaft cannot rotate normally in one direction to drive a load.

Owner:刁俊起

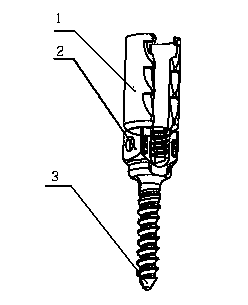

Minimally invasive composite self-tapping pedicle screw

InactiveCN103784190ASolve the shortcomings of limited anchoring effectReduced risk of breakageInternal osteosythesisFastenersSpinal columnBall screw

The invention provides a minimally invasive composite self-tapping pedicle screw which aims at overcoming the shortcoming that the existing pedicle screw is inconvenient to apply and poor in stability in the actual operation. The screw comprises a hollow ball threaded nail rod and a U-shaped nail arm which are arranged integrally. Negative taper double-line wide-tooth threads are arranged on the hollow ball screw, the threads close to the spherical portion of the head portion are compact threads, the threads close to the screw tip portion are sparse threads, and a self-tapping edge is further arranged on the screw tip portion. By means of the improvement, the pedicle screw is easy to locate and good in stability by means of self-tapping puncture and enables a minimally invasive spine fusion operation to be conducted smoothly.

Owner:王国喜

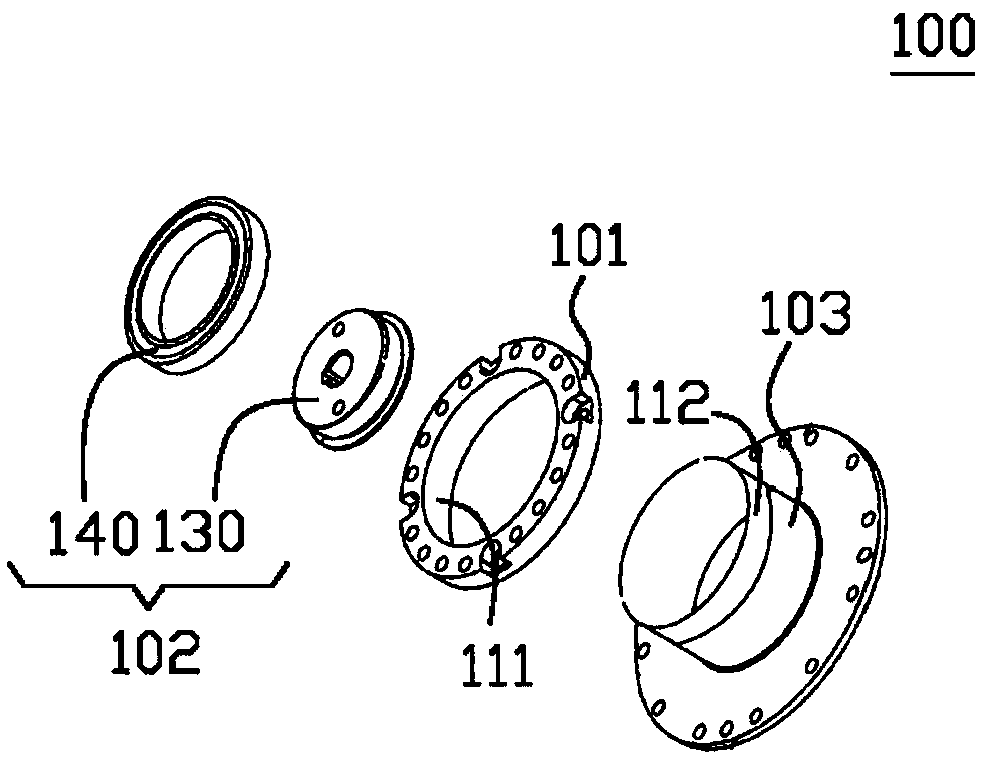

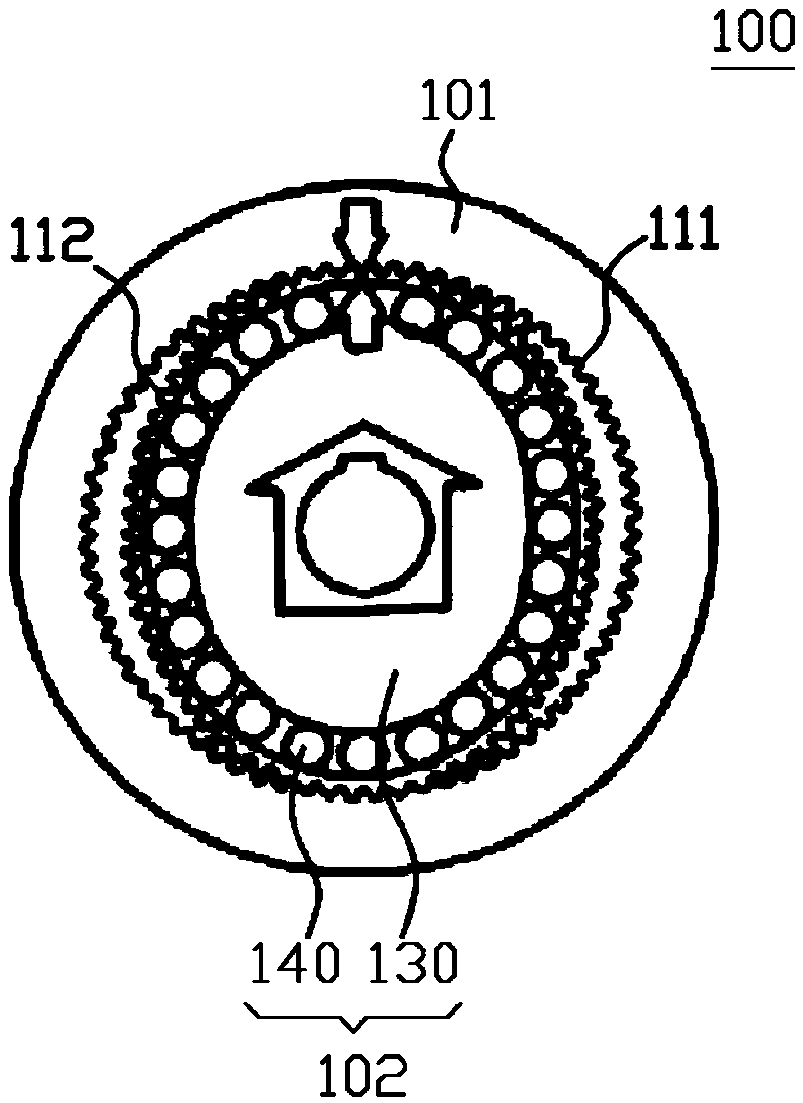

Harmonic gear speed reducer

The invention provides a harmonic gear speed reducer. The harmonic gear speed reducer comprises a rigid gear, a flexible gear and a wave generator, the rigid wheel is provided with a plurality of inner teeth, the flexible gear is arranged in the rigid gear and comprises a cylinder body and a plurality of outer teeth, the outer teeth are connected to a first side of the cylinder body and engaged with the inner teeth, the wave generator is arranged in the flexible gear, moreover, a plurality of grooves are formed in the cylinder body and are arranged in at least one row, and the grooves in the at least one row discontinuously surround the periphery of the cylinder body. According to the harmonic gear speed reducer, discontinuous elastic deformation is generated at the positions of the grooves, the external expansion inclination angle of the cylinder body of the flexible gear is slowed down, and the effect of increasing the meshing area of the tooth parts of the rigid gear and the flexible gear is achieved.

Owner:SIMPLO TECH COMPANY

Worm gear structure

InactiveCN106246872AAvoid differencesEnsure consistencyPortable liftingGearing elementsEngineeringInjection moulding

The invention discloses a worm gear structure, belongs to the technical field of transmission devices, and solves the technical problem that a conventional worm gear is low in processing efficiency, high in cost and poor in processing uniformity. The technical scheme which solves the problem lies in that the worm gear structure mainly comprises a gear body; peripheral surfaces of the gear body comprise a first peripheral surface and a second peripheral surface; bevel gear tooth parts are uniformly distributed on the first peripheral surface; half-worm gear tooth-shaped half-worm gear tooth parts are uniformly distributed on the second peripheral surface; the bevel gear tooth parts and the half-worm gear tooth parts are in one-to-one correspondence and are connected in the radial direction; and the gear body, the bevel gear tooth parts and the half-worm gear tooth parts are formed through integral casting.

Owner:ZHEJIANG JIECHANG LINEAR MOTION TECH

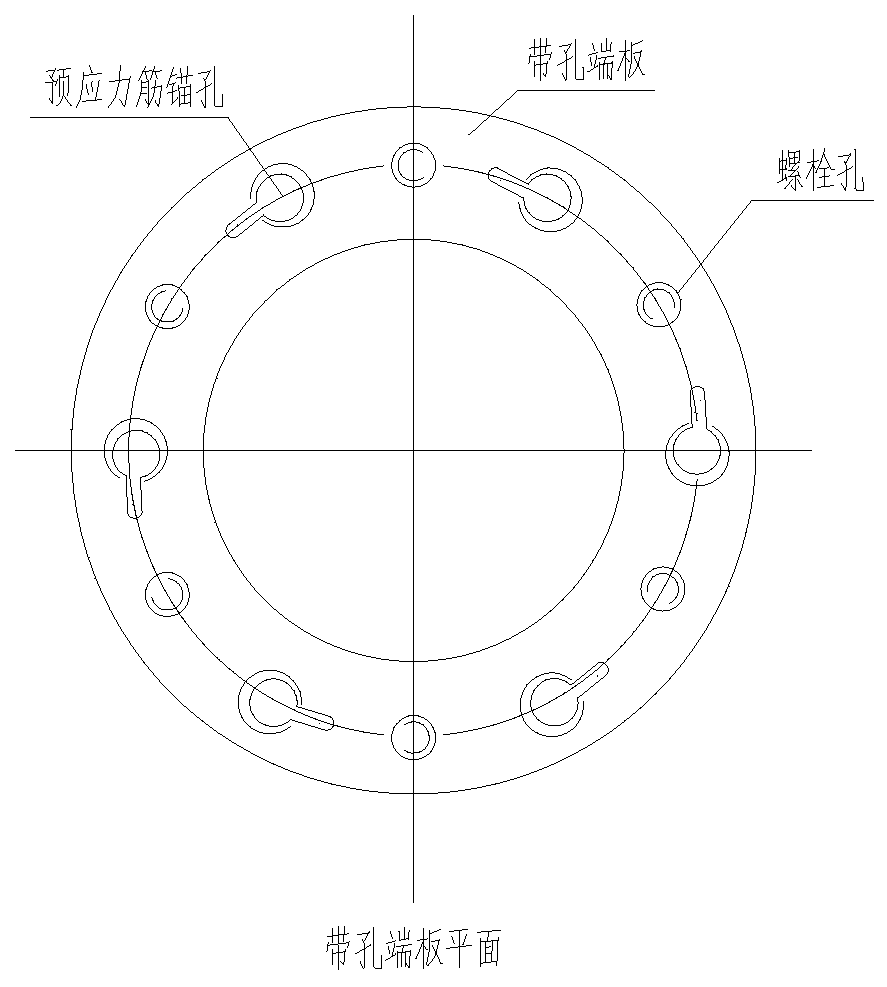

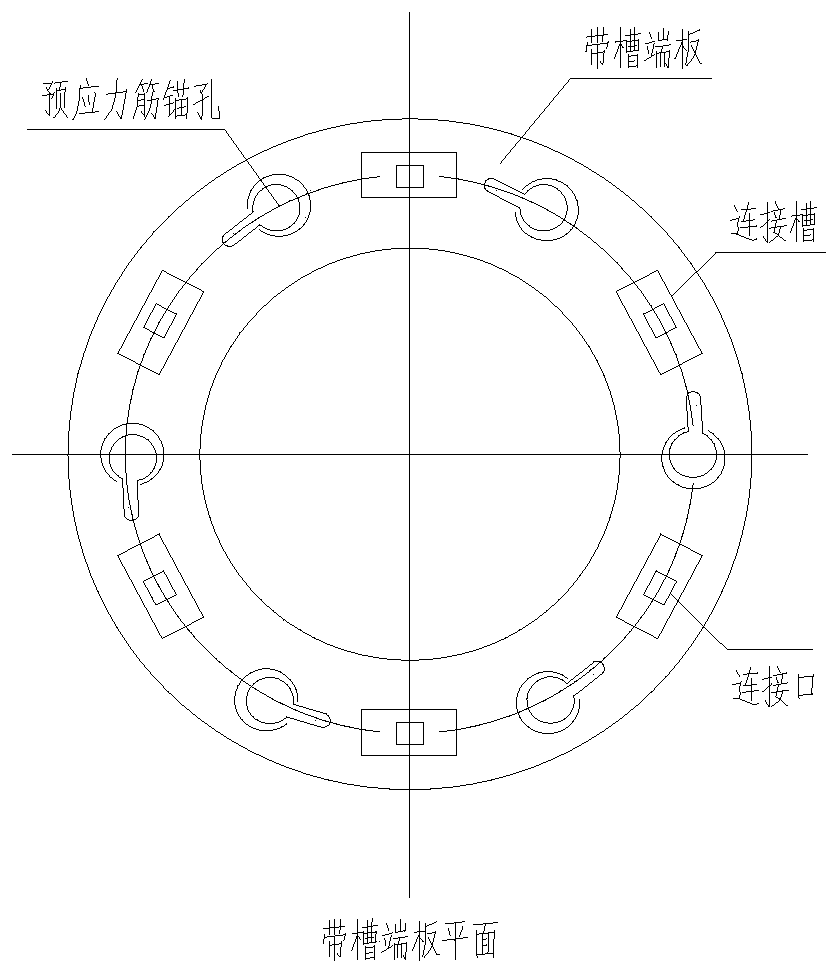

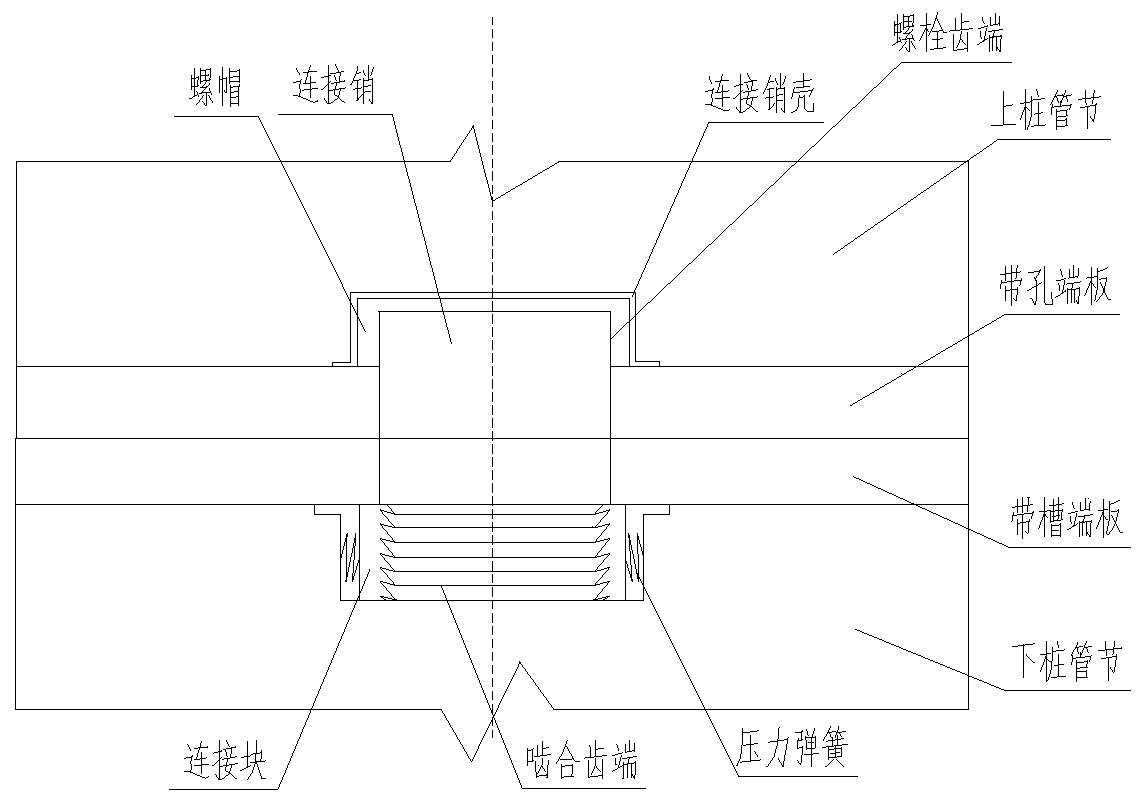

Meshing type pipe pile quick coupling structure

PendingCN110016913AReduce the probability of misalignmentReduce shearBulkheads/pilesCouplingSelf locking

The invention belongs to the technical field of pipe pile joints, and relates to a meshing type pipe pile quick coupling structure. The main body structure comprises an upper-section pipe pile, an upper end plate, a lower-section pipe pile, a lower end plate, bolt holes, connecting grooves, connecting openings, prestressed rib anchoring holes, connecting pins, lower meshing teeth, nuts, connectingblocks, upper meshing teeth and pressure springs. The number of the bolt holes, the connecting grooves and the prestressed rib anchor holes in the upper end plate and the lower end plate is reduced to four, thus the probability of inaccurate alignment of the connecting pins and the connecting grooves is reduced, and the construction operation time is shortened; the lower parts of the connecting pins are changed into a cross-shaped section tooth form from a rectangular tooth form, the lower meshing teeth inclined downwards are arranged on the surfaces of the cross-shaped bodies, and the uppermeshing teeth which are inclined upwards are arranged on the surface of the connecting blocks, so that the lower meshing teeth are easily pressed into the upper meshing teeth and are not easy to pullout; and the self-locking function is achieved, and the reduction of shear resistance and bending-resistant bearing capacity of a joint of the upper-section pipe pile and the lower-section pipe pile due to the reduction of the bolt holes and the connecting grooves is avoided.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com