Hub bearing with spline shielding structure

A hub bearing and spline technology, applied in the field of hub bearings, can solve the problems affecting the service life of the overall structure, uneven power transmission, difficult processing and assembly, etc., and achieve the effects of improving fuel economy, not easy to slip, and easy to maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

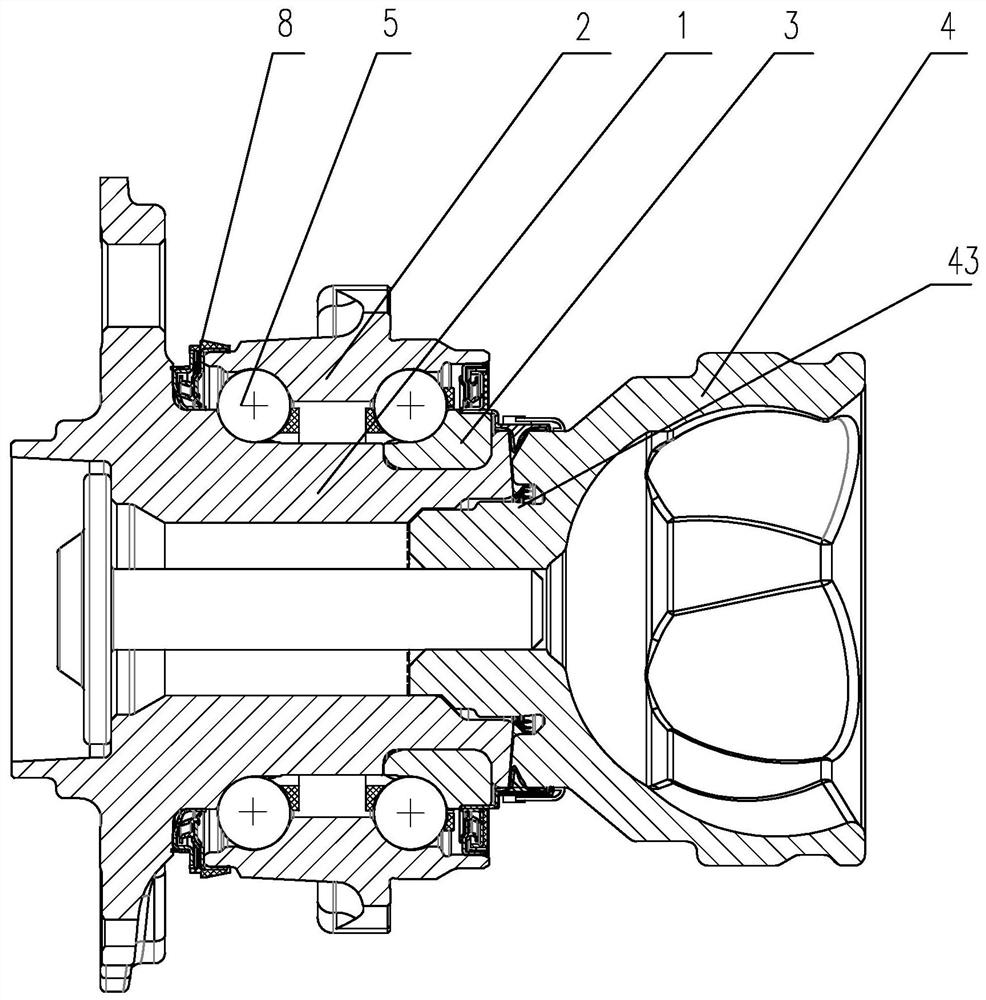

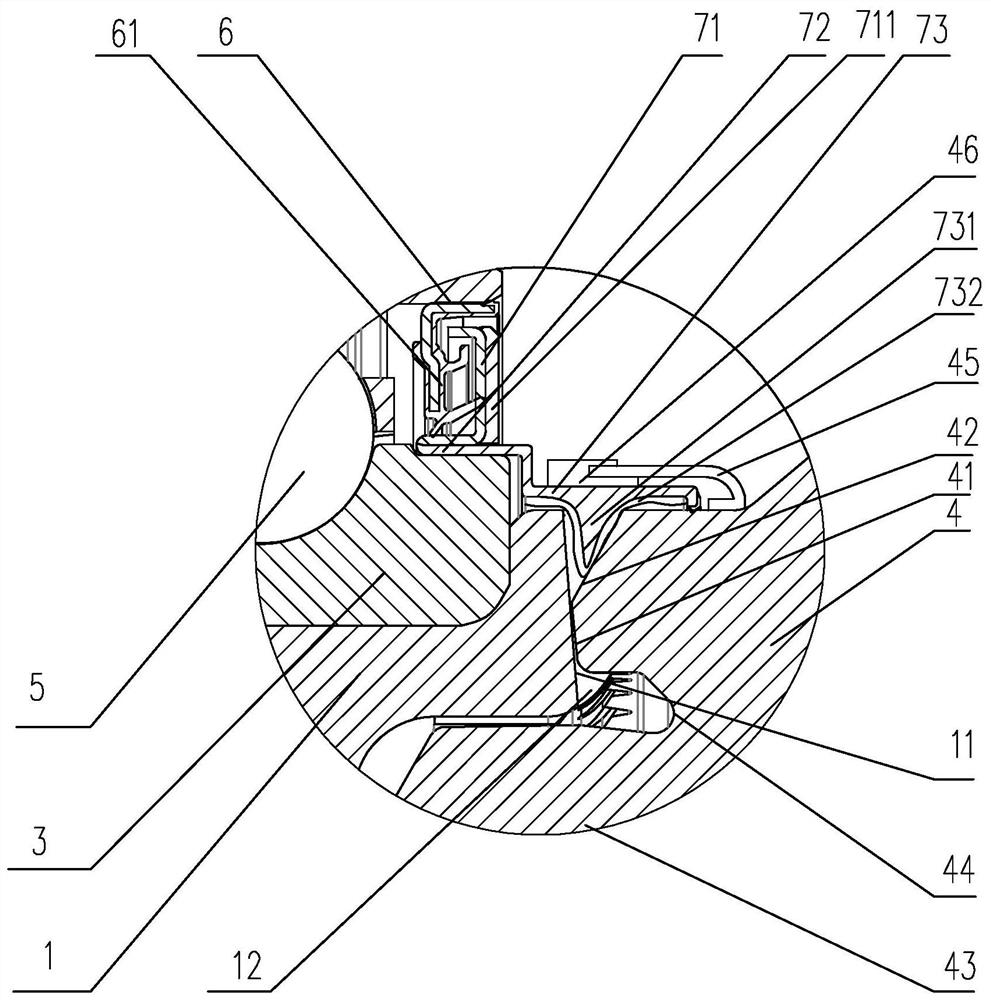

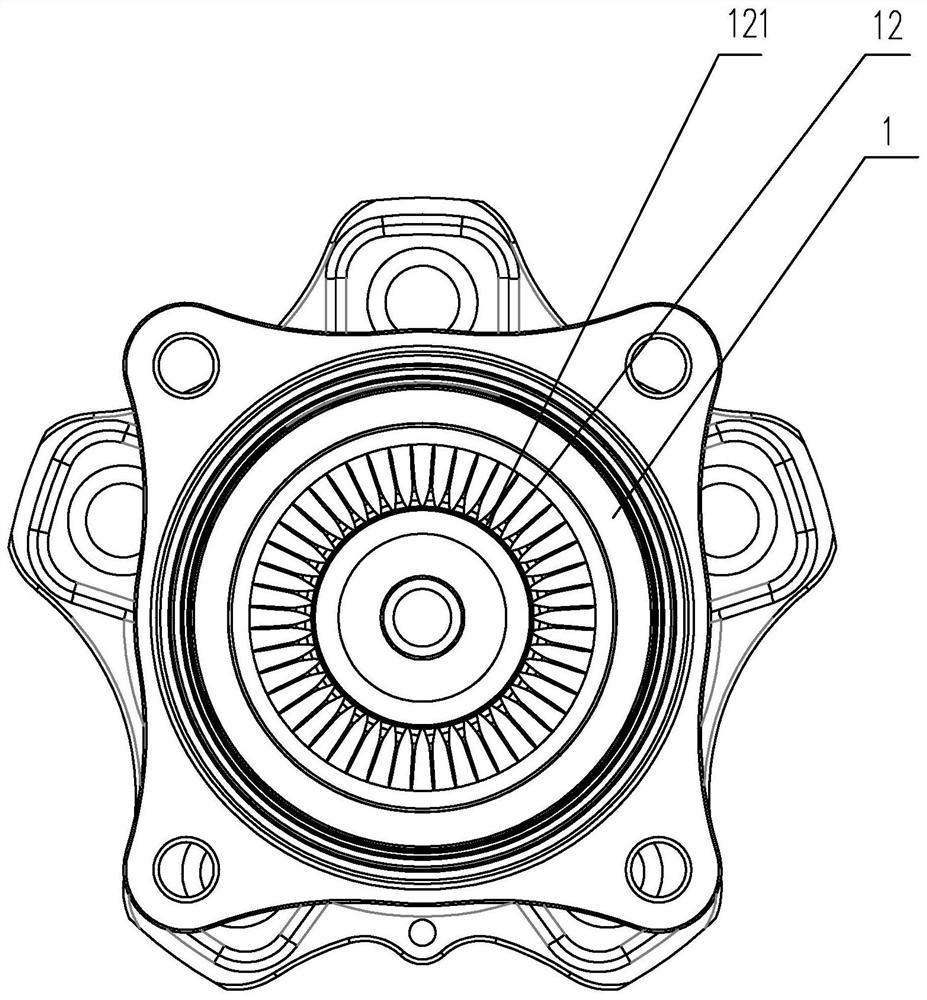

[0025] Embodiments of the hub bearing with the spline shielding structure of the present invention are as follows Figure 1 to Figure 3 As shown: including the rotary joint 4, the flange inner ring 1, the flange outer ring 2 and the connecting inner ring 3, the outer wall of the flange inner ring 1 and the flange outer ring 2 are provided with a first rolling groove, so A positioning step is also formed on the flange inner ring 1, the connecting inner ring 3 is engaged with the positioning step, and a second roll groove is formed between the outer wall of the connecting inner ring 3 and the flange outer ring 2, and the Rolling bodies 5 are arranged in the first rolling groove and the second rolling groove, and a positioning protrusion 43 is formed on the end of the rotary joint 4 facing the flange inner ring 1, and a positioning groove is arranged on the inner wall of the flange inner ring 1, The positioning protrusion 43 fits with the positioning groove in a gap, and the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com