Flat harmonic transmission device with drum-shaped gear teeth

A harmonic transmission, flat technology, applied in the direction of gear transmissions, transmissions, components with teeth, etc., can solve the problems of increasing the equivalent stress and reducing the overall strength and stiffness of the harmonic reducer, so as to improve the strength and stiffness, reduce axial dimension growth or assembly error, and avoid stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

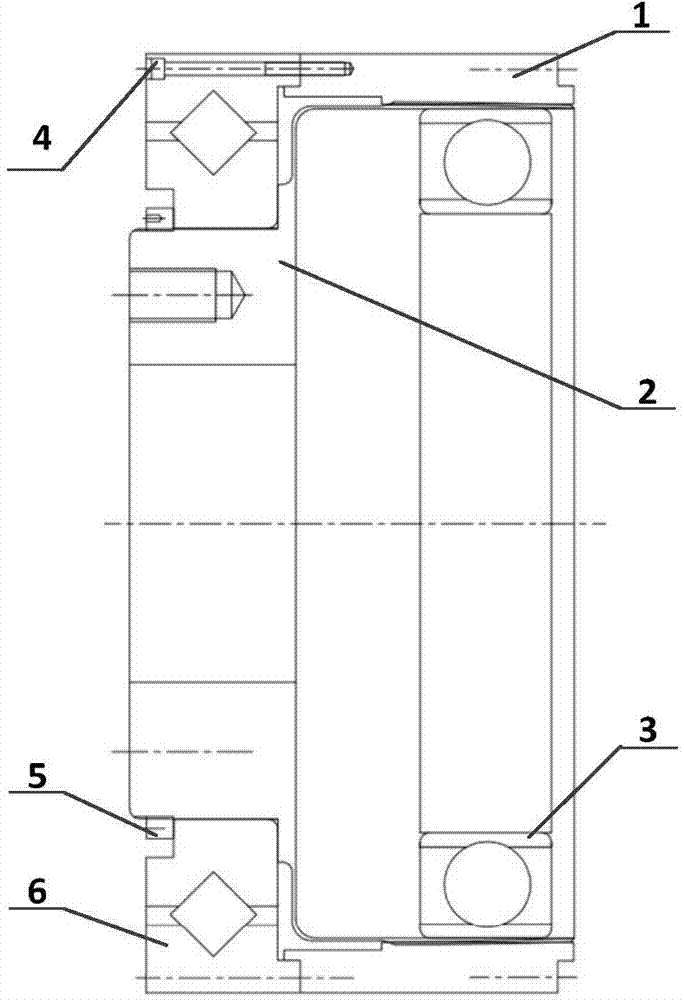

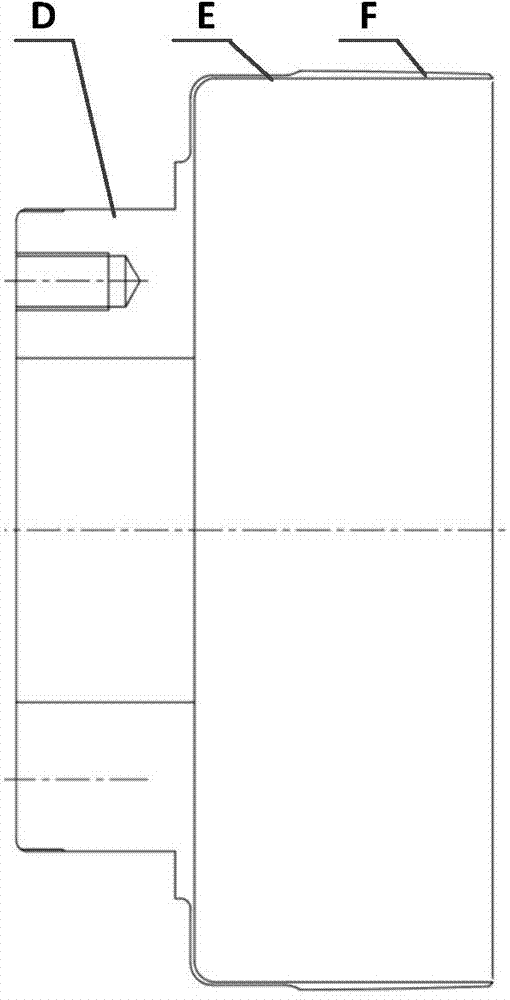

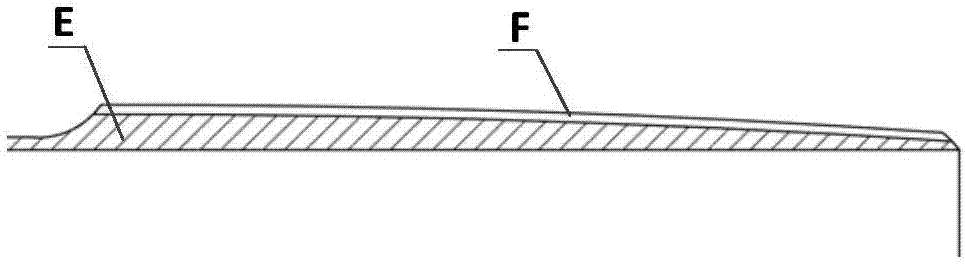

[0018] Such as figure 1 As shown, a flat harmonic transmission device with drum-shaped gear teeth includes a rigid spline 1, a flexspline 2, a wave generator 3 and a crossed roller bearing 6, and the wave generator 3 is installed inside the cylinder of the flexspline 2. The rigid spline 1 is set on the outer ring of the flexible spline 2, the teeth of the rigid spline 1 mesh with the teeth of the flexible spline 2, the outer ring of the cross roller bearing 6 and the rigid spline 1 are connected by bolts 4, and the output shaft of the flexible spline 2 Part D is provided with threads, and the inner ring of the cross roller bearing 6 is fastened on the output shaft of the flexible spline 2 through the lock nut 5 . Such as figure 2 As shown, the middle of the flexible spline 2 is a cylinder part E, the outer ring of the cylinder part E is processed with a gear tooth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com