Worm gear structure

A worm gear and semi-worm gear technology, which is applied to belts/chains/gears, portable lifting devices, components with teeth, etc., can solve the problems of low processing efficiency, high cost and poor processing consistency of worm gears, and achieve good self-locking effect. , increased yield, easy consistency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

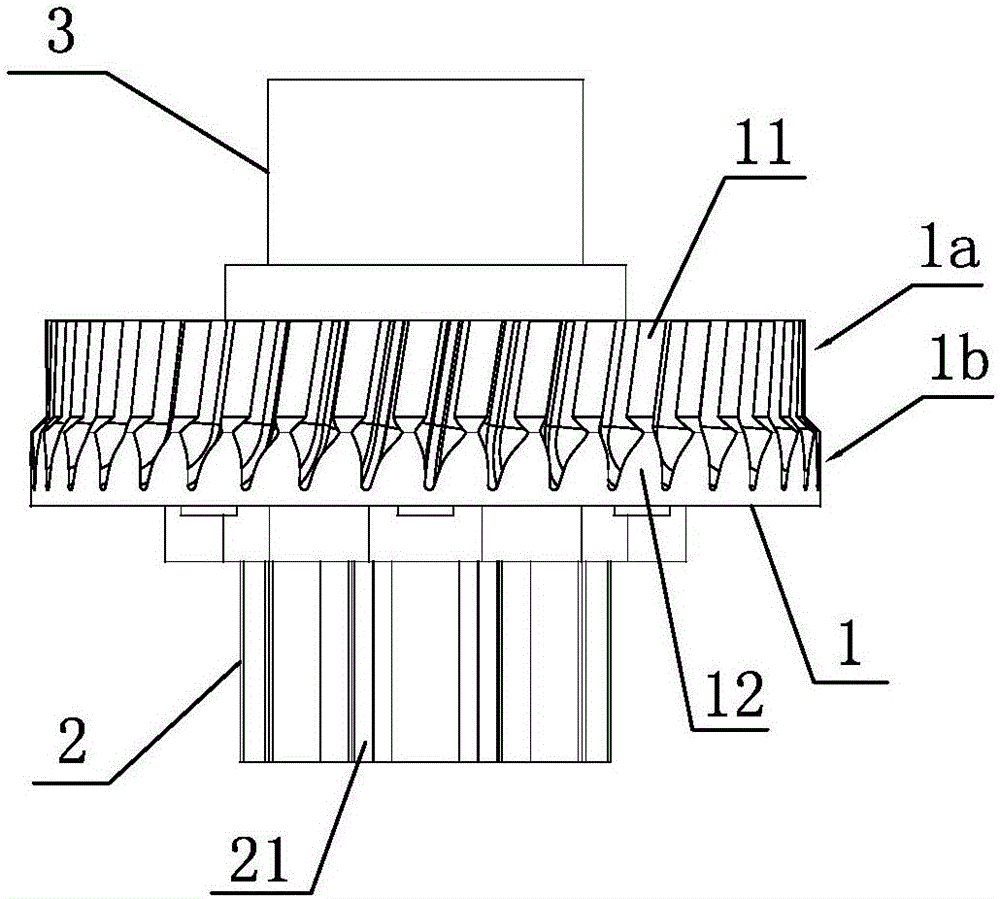

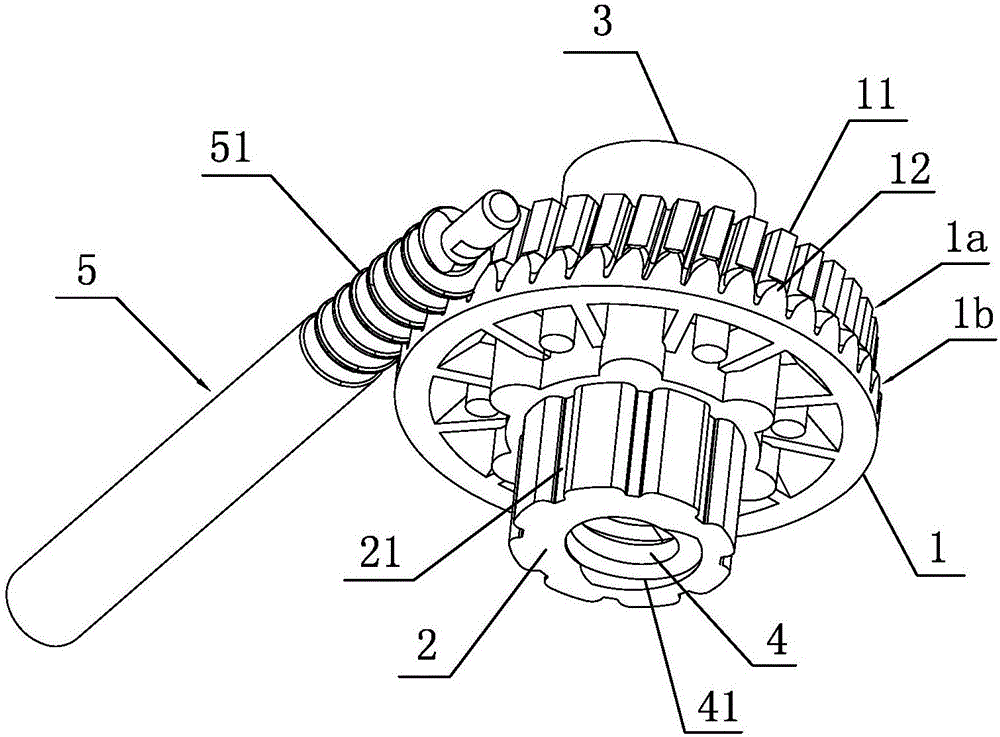

[0017] Such as figure 1 with figure 2 As shown, the present invention provides a worm gear structure, including a wheel body 1, the outer peripheral surface of the wheel body 1 includes a first outer peripheral surface 1a and a second outer peripheral surface 1b, and helical gear teeth 11 are evenly distributed on the first outer peripheral surface 1a, Half worm gear teeth 12 in the shape of half worm gear teeth are evenly distributed on the second outer peripheral surface 1b. The tooth portion of the structure is cut radially to form roughly half a worm gear tooth structure, wherein the helical gear tooth portion 11 and the half worm gear tooth portion 12 are in one-to-one correspondence and connected in the radial direction. Therefore, the helical gear tooth portion The tooth grooves formed by 11 and the tooth grooves formed by the half worm gear part 12 are correspondingly connected one by one, and the wheel body 1, the helical gear tooth part 11 and the half worm gear pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com