Control system for multiphase rotary machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

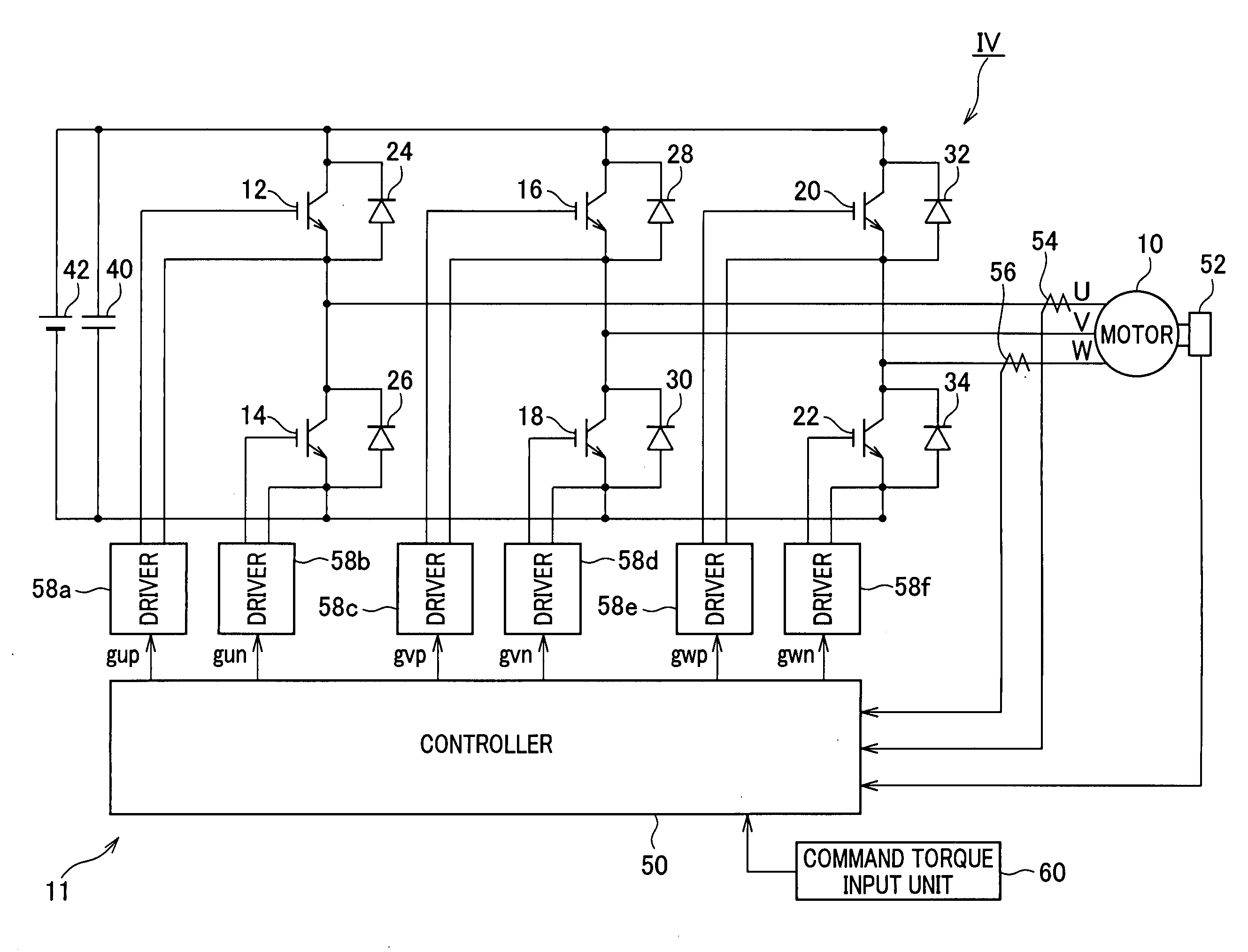

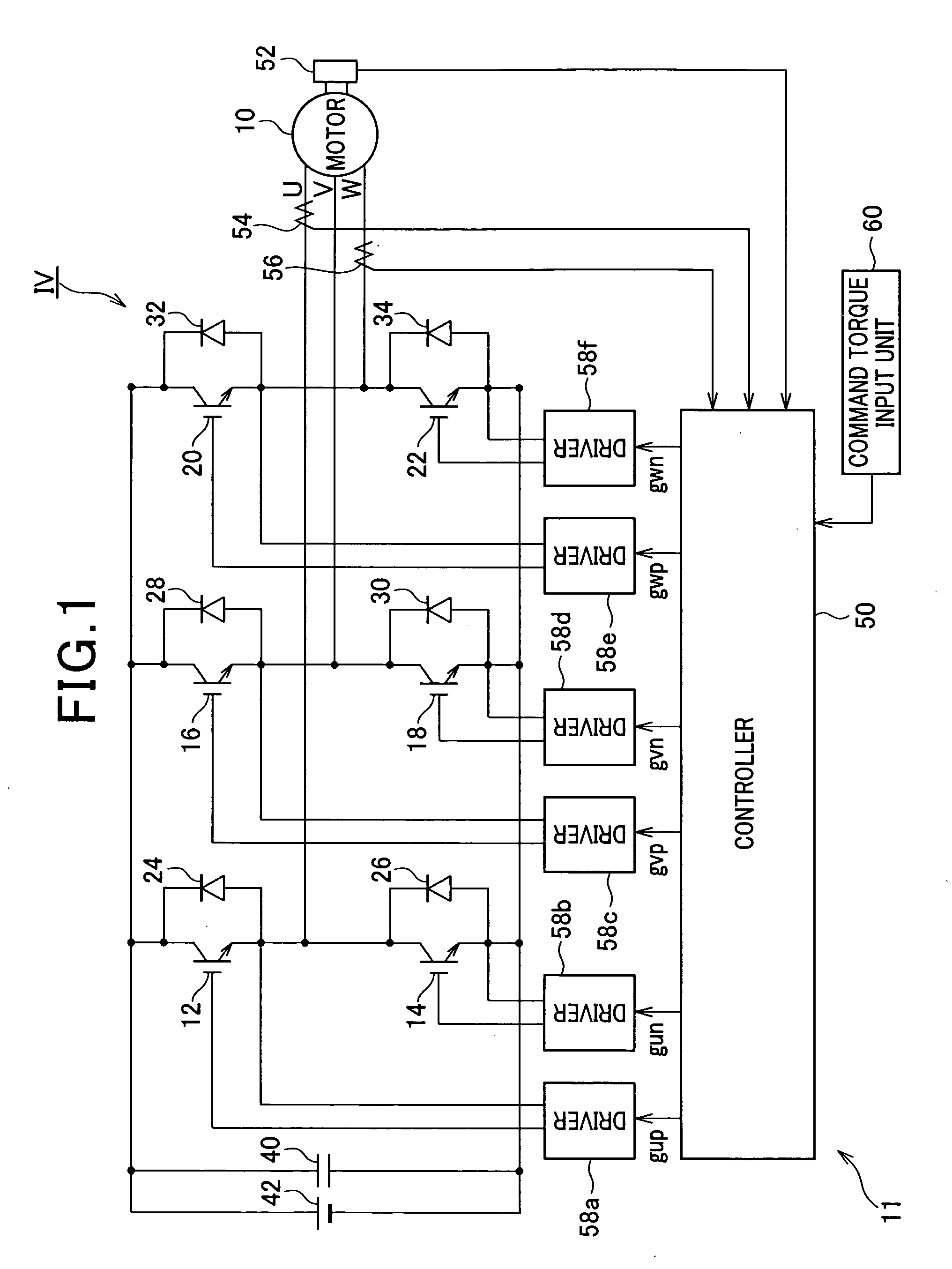

[0045]Referring to the drawings, particularly to FIG. 1, there is illustrated a three-phase brushless motor, referred to simply as “motor”, 10 and a control system 11 for controlling the motor 10.

[0046]For example, the motor 10 is provided with an annular rotor having a rotor core. The rotor core of the rotor is provided at its circumferential portion with at least one N and S pole pair. The rotor has a direct axis (d-axis) in line with a rotor N pole center line, and has a quadrature axis (q-axis) whose phase is π / 2 radian electric angle leading with respect to a corresponding d-axis during rotation of the rotor.

[0047]The stator includes a stator core with, for example, an annular shape in its lateral cross section. The stator core is for example disposed around the outer periphery of the rotor core such that the inner periphery of the stator core is opposite to the outer periphery of the rotor core with a predetermined air gap.

[0048]The stator core also has a plurality of slots. T...

second embodiment

[0374]A control system according to a second embodiment of the present invention will be described hereinafter with reference to FIG. 24.

[0375]The structure of the control system according to the second embodiment is substantially identical to that of the control system 11 according to the first embodiment. So, like parts between the control systems according to the first and second embodiments, to which like reference characters are assigned, are omitted or simplified in description.

[0376]Referring to FIG. 4, each of the modules 80, 82, and 84 according to the second embodiment includes a common logic function illustrated in FIG. 22.

[0377]Specifically, as can be seen from the comparison between the respective routines illustrated in FIGS. 7, 8, and 11, the logic structures of the respective routines illustrated in FIGS. 7, 8, and 11 are identical to each other. In other words, each of the routines illustrated in FIGS. 7, 8, and 11 has a common logic structure, individual vectors wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com