Current-controlled permanent magnet speed controller

A technology of permanent magnet governor and current control, which is applied in electric brakes/clutches, permanent magnet clutches/brakes, and connected to control/drive circuits, etc., which can solve the problem of large eddy current power consumption, poor torque transmission capability, and waste of rare earth Resources and other issues, to achieve the effect of reducing electric heat loss, improving torque transmission capacity, and saving rare earth materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

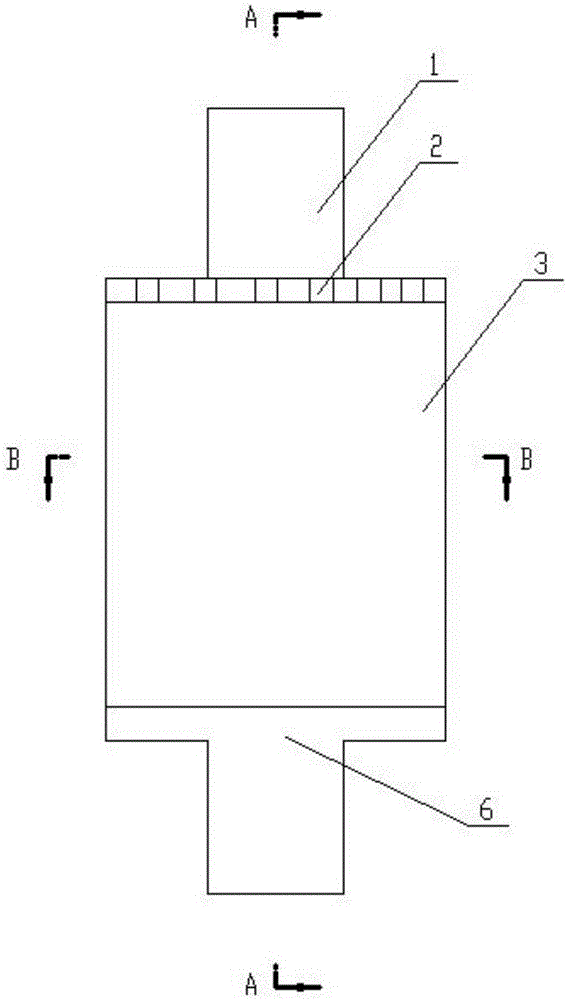

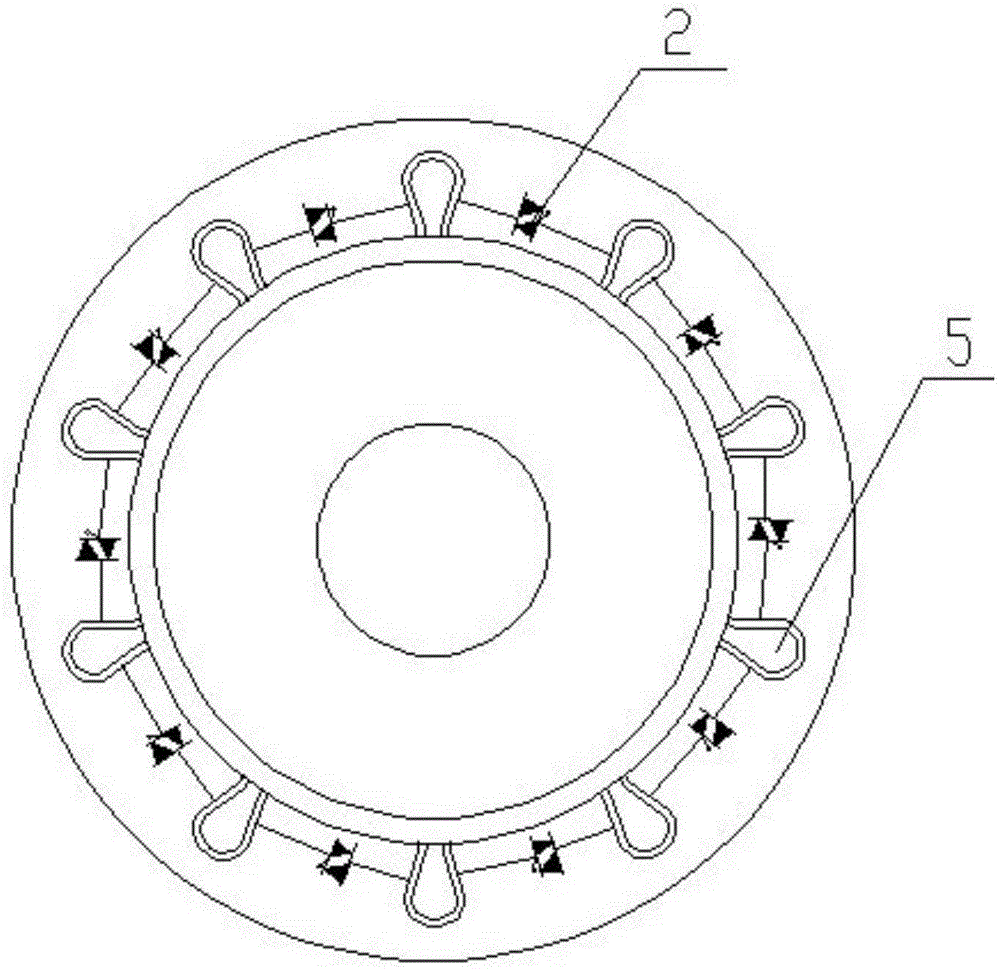

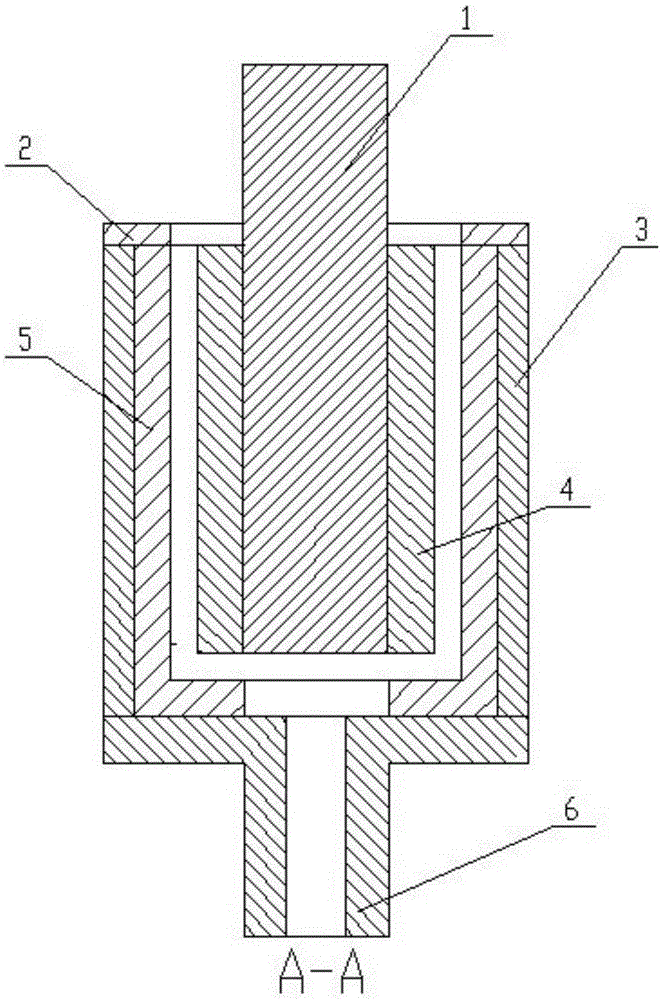

[0017] A current-controlled permanent magnet governor, comprising a squirrel-cage conductor rotor 3 connected to a drive shaft 6 and a permanent magnet rotor 4 connected to a driven shaft 1, the inner surface of the squirrel-cage conductor rotor 3 is inlaid with a squirrel cage The conductor 5, the ends of all the squirrel-cage conductors 5 are connected by setting end rings and form a squirrel-cage structure; every two adjacent squirrel-cage conductors are connected with thyristors 2 .

[0018] Such as Figure 5 As shown, the circuit for controlling the on-off of the thyristor is as follows: the potentiometer RB, the potentiometers R1 to R2n and the capacitor C1 form a phase-shift trigger network, and the potentiometer R2n-1 and the potentiometer R2n each take one end and connect to the two ends of the thyristor VTn respectively; The other end of the potentiometer R2n-1 is connected to one end of the capacitor C1, and the other end of the capacitor C1 is connected to the othe...

Embodiment 2

[0020] Such as Figure 6 As shown, the circuit for controlling the on-off of the thyristor includes a pulse generator composed of 555 and potentiometers R1 to R2n, thyristors VT1 to VTn connected to the potentiometer R2n-1 and one end of the potentiometer R2n, and the potentiometer R2n-1 is another One end is connected to the signal output end of the pulse generator, and the ground end of the pulse generator is connected to the other end of the potentiometer R2n.

[0021] The pulse generator composed of 555 provides bidirectional photoelectrically isolated pulses. The trigger power of the triac VT1 to VTn comes from the coil itself, which is isolated from the external circuit. The isolated pulse triggers the conduction of the bidirectional thyristor VT1 to VTn. All the other parts are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com