Hub structure

A hub and shell technology, which is applied in the field of bicycle hub structures, can solve the problems of less meshing bonding area, loss of structural bonding stability, and low meshing force, and achieve good structural strength of components, smooth and stable rotation, and meshing large area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in conjunction with the accompanying drawings.

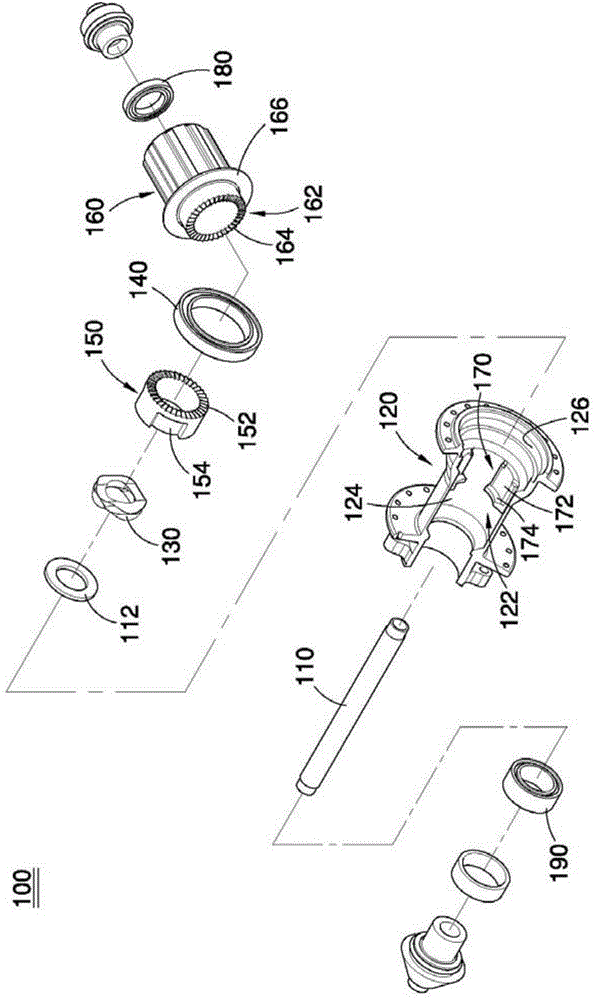

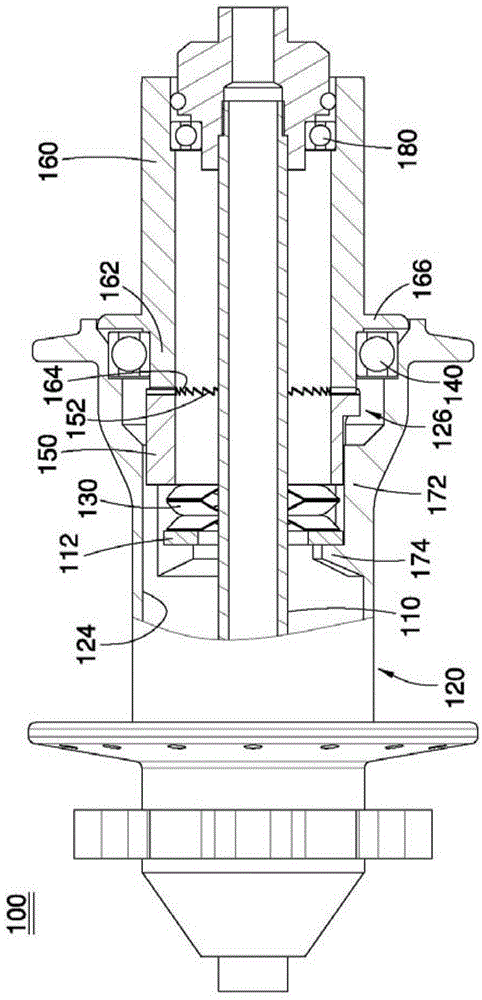

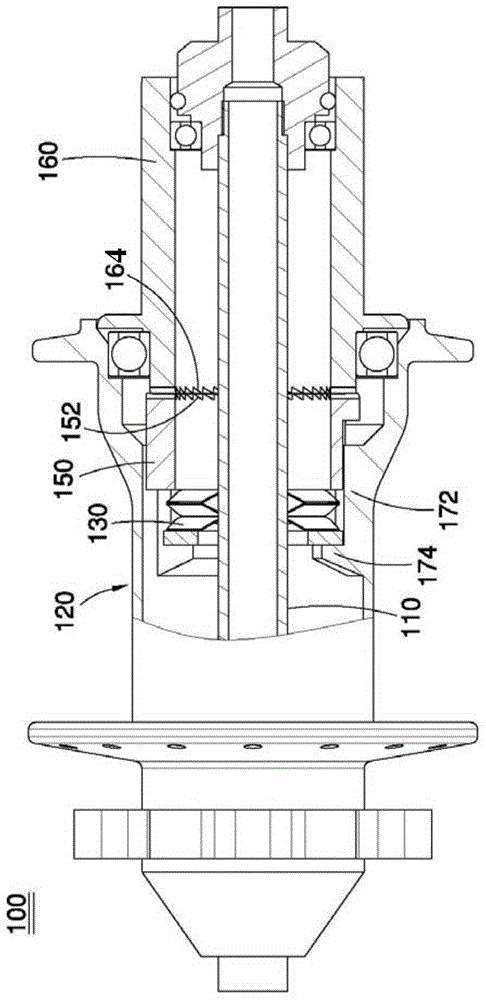

[0027] figure 1 It is a three-dimensional exploded schematic diagram of a hub structure of a bicycle in an embodiment of the present invention. figure 2 It is a combined cross-sectional schematic diagram of an embodiment of the present invention. image 3 It is a schematic cross-sectional view of a push-away idling state of an embodiment of the present invention. The hub structure 100 mainly includes a spindle 110 , a casing 120 , an elastic member 130 , a first bearing 140 and a transmission device.

[0028] The mandrel 110 extends along an axis, and the mandrel 110 axially passes through the housing 120 , and its two opposite ends are respectively pivotally connected to the bicycle frame. The casing 120 is substantially h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com