High-precision five-phase stepping motor driving and controlling device and method

A stepper motor and control device technology, applied in the direction of motor generator control, control system, electrical components, etc., can solve the problems of submerged five-phase motor application advantages, low drive circuit accuracy, difficult to purchase in large quantities, etc. The effect of mass production, avoiding chattering, and reducing R&D costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

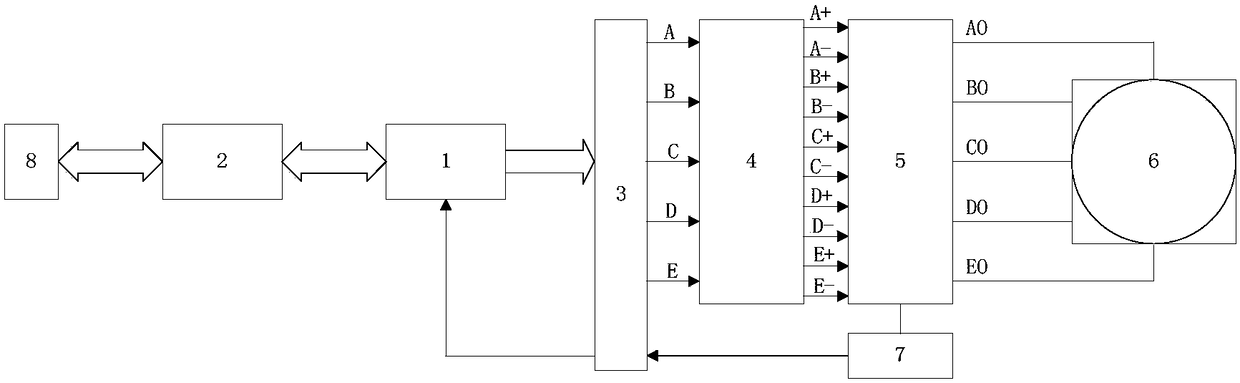

[0048] Such as figure 1As shown, the present invention consists of a host PC 8, a single-chip microcomputer circuit 1, a serial port communication circuit 2, a high-speed optocoupler isolation circuit 3, a MOSFET high-side / low-side drive circuit 4, a MOSFET circuit 5, and an overcurrent alarm circuit 7. It is used to control and drive a five-phase stepper motor 6 .

[0049] The specific circuit structure of the device is:

[0050] The upper PC is connected to the single-chip microcomputer circuit 1 through the serial port communication circuit 2, and the single-chip microcomputer circuit 1 sends the power-on phase sequence signal to the MOSFET high-side / low-side drive circuit 4 after passing through the high-speed optocoupler isolation circuit 3;

[0051] MOSFET high side / low side drive circuit 4 generates 5 groups of high / low side drive signals; each group of high / low side drive signals includes 1 high side drive signal and 1 low side drive signal; 5 high side drive signals ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com