Patents

Literature

44results about How to "Realize program control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antineoplastic drug evaluation and screening method based on cell microscopic image information

InactiveCN101149327ARealize program controlRealize control program controlMicrobiological testing/measurementIndividual particle analysisMicroscopic imageFluorescence

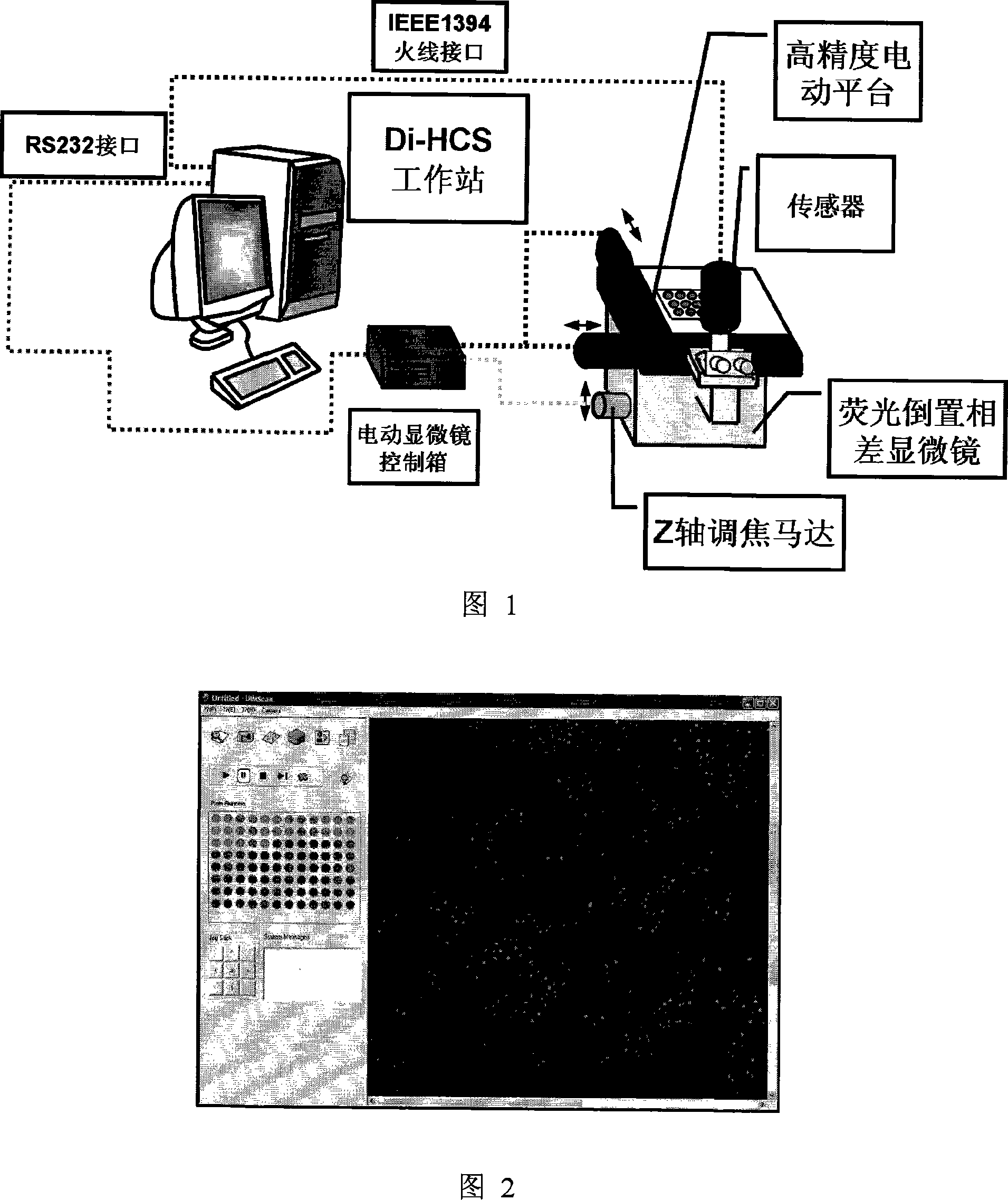

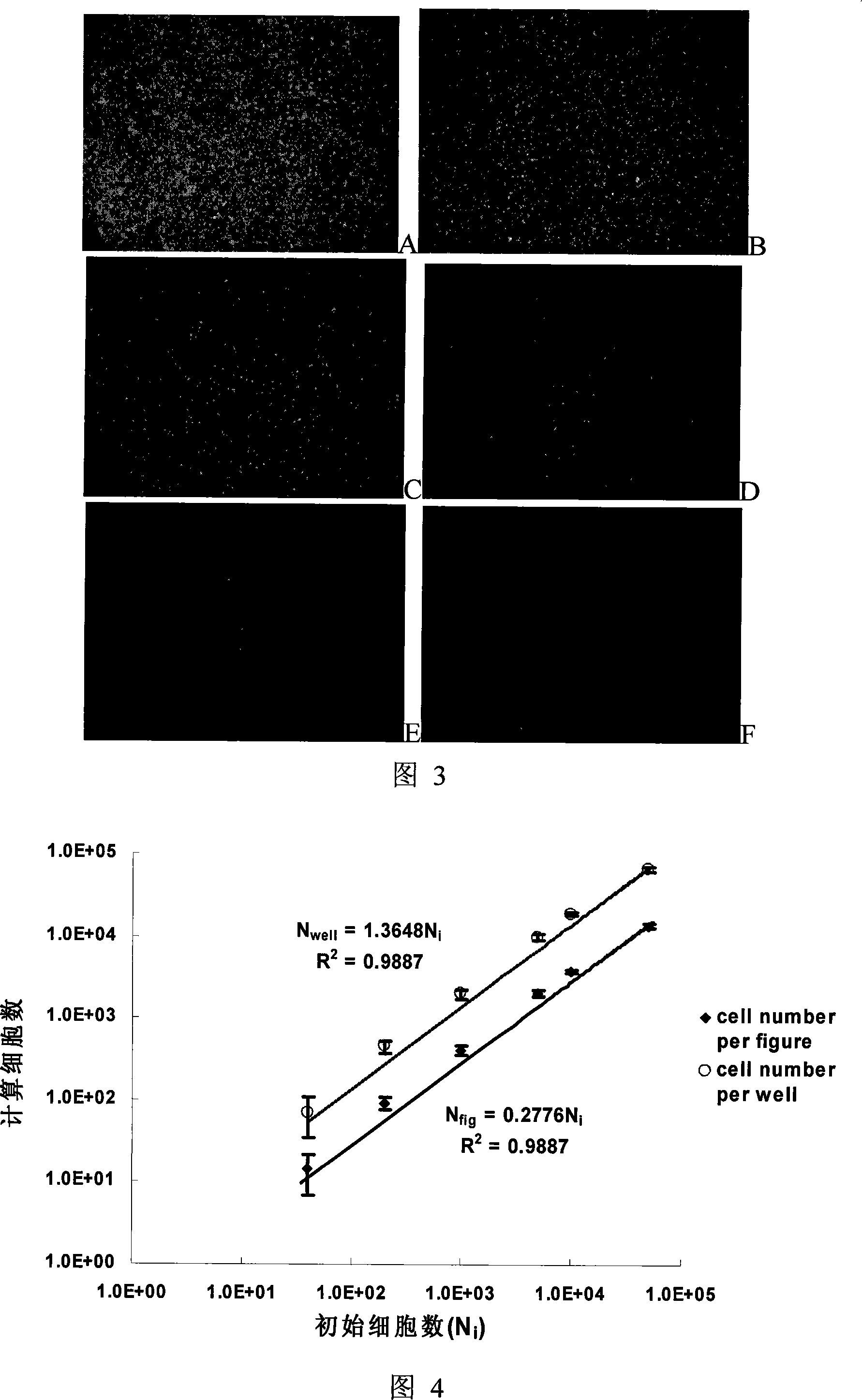

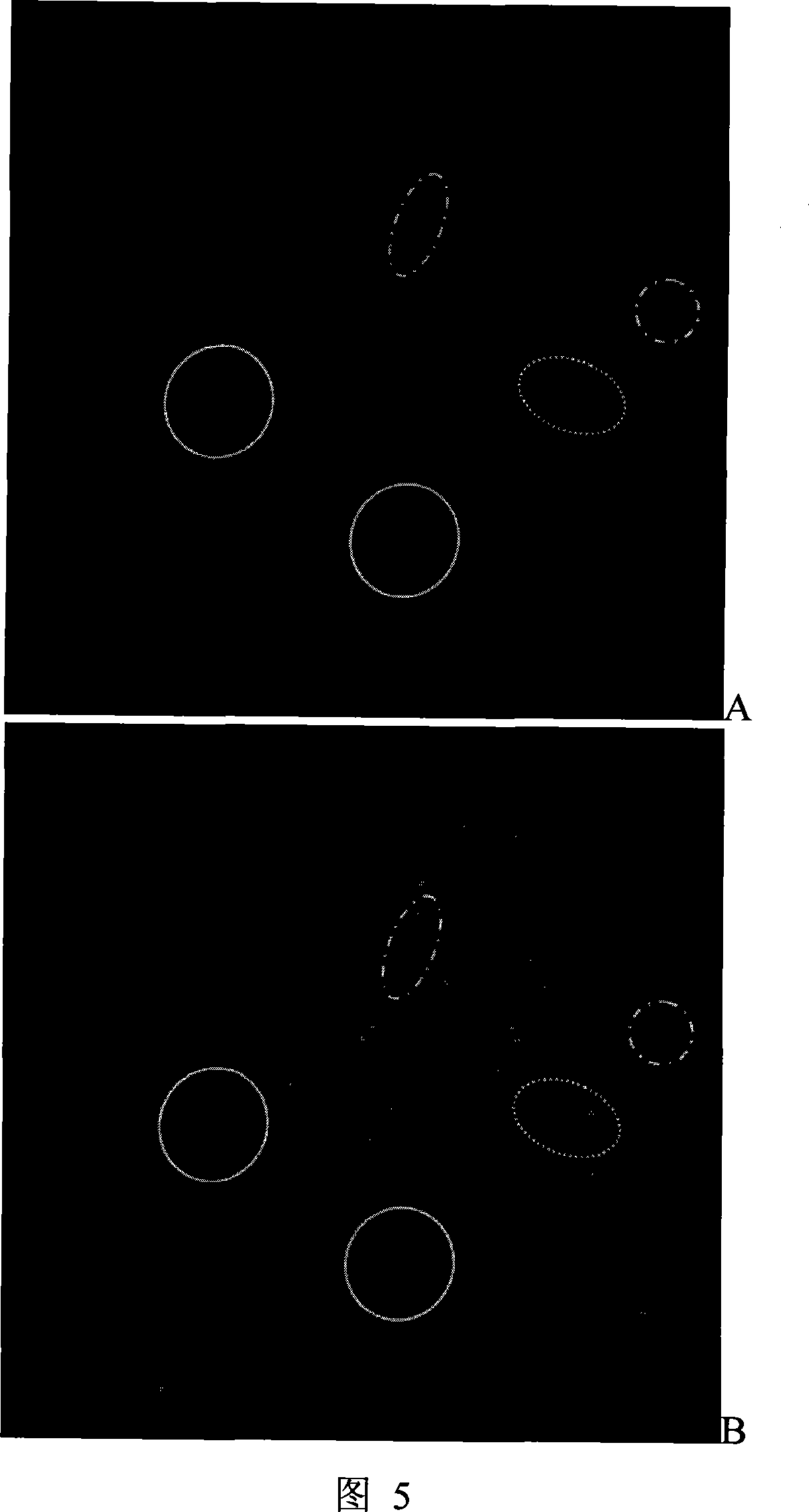

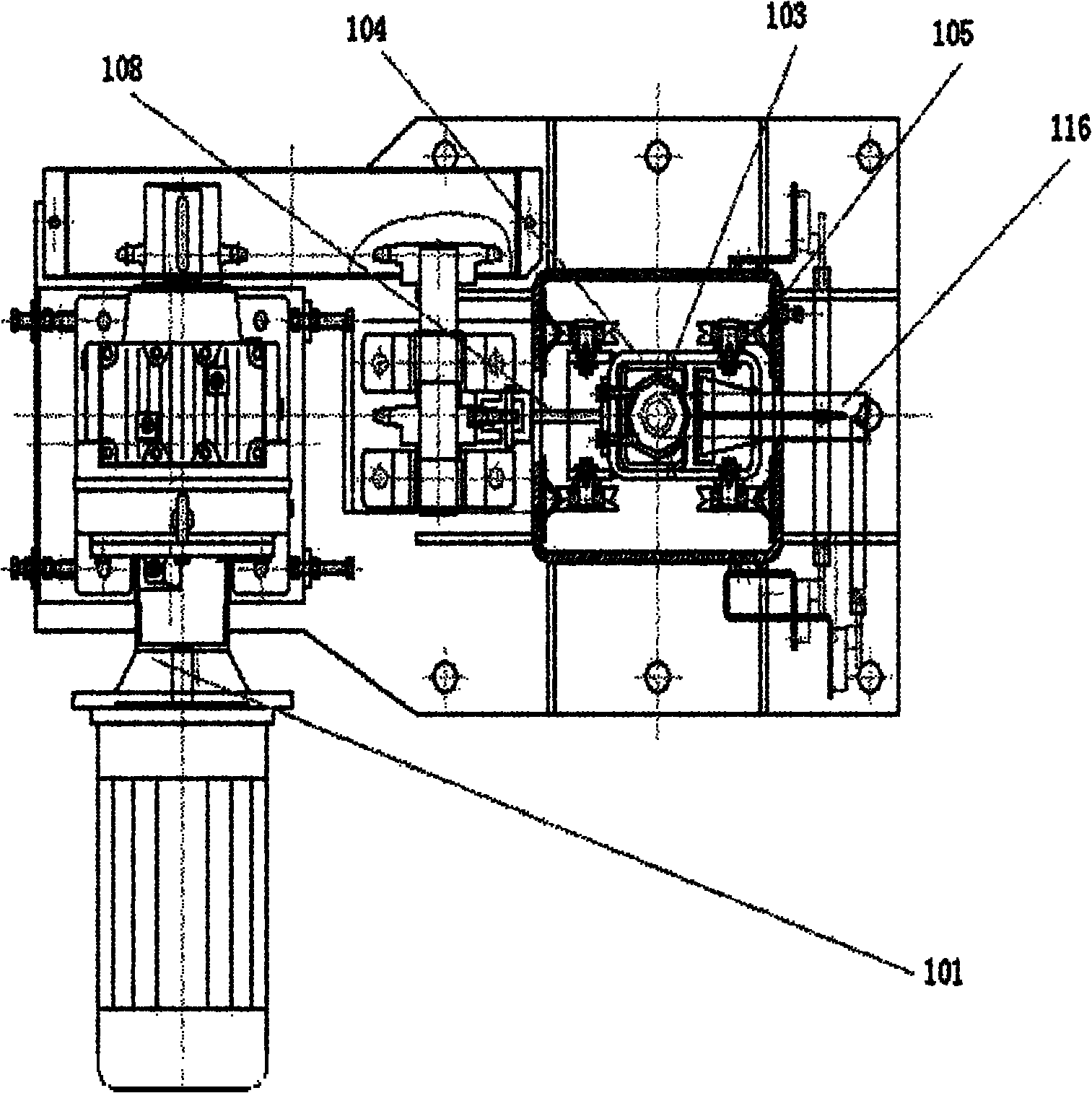

The invention provides the appraisal and selective method for the antineoplastic drug based on the cell micrograph information, which uses a sort of selection and appraisal hardware system to appraisal and select the antineoplastic drug by different fluorescence dye marking and measuring the multicellular parameter change in cell. The hardware system is made up of the high precision electric hydrous platform, the fluorescence vision system, the image collecting and processing system and working station. The diacetoxyl fluoresceine dyeing measures the active cell number; the double dyeing method of Hoechst33342 and iodized pyridine appraise the drug inducing the cell die; the three dyeing method of FDA, Hoechst33342 and PI analyzes the die mode induced by drug. The invention can measure at least two kinds of single cell or cell subgroup which expresses different drone cell organ. The method is in reason and can be used in study of drug action mechanism and selecting the high hedonic drug and toxicity analyzing, which can be used in selecting drug and appraising the drug toxicity.

Owner:ZHEJIANG UNIV

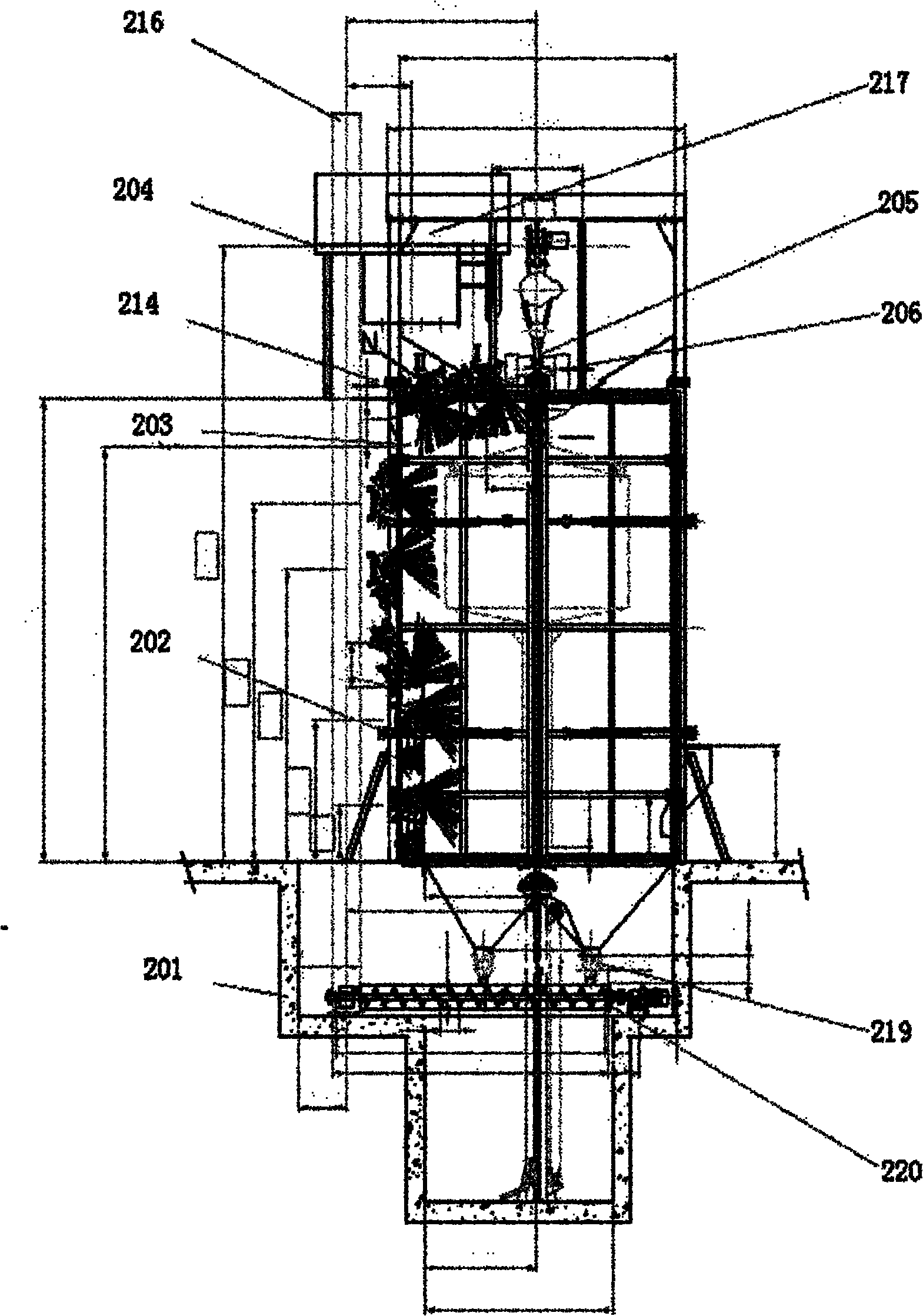

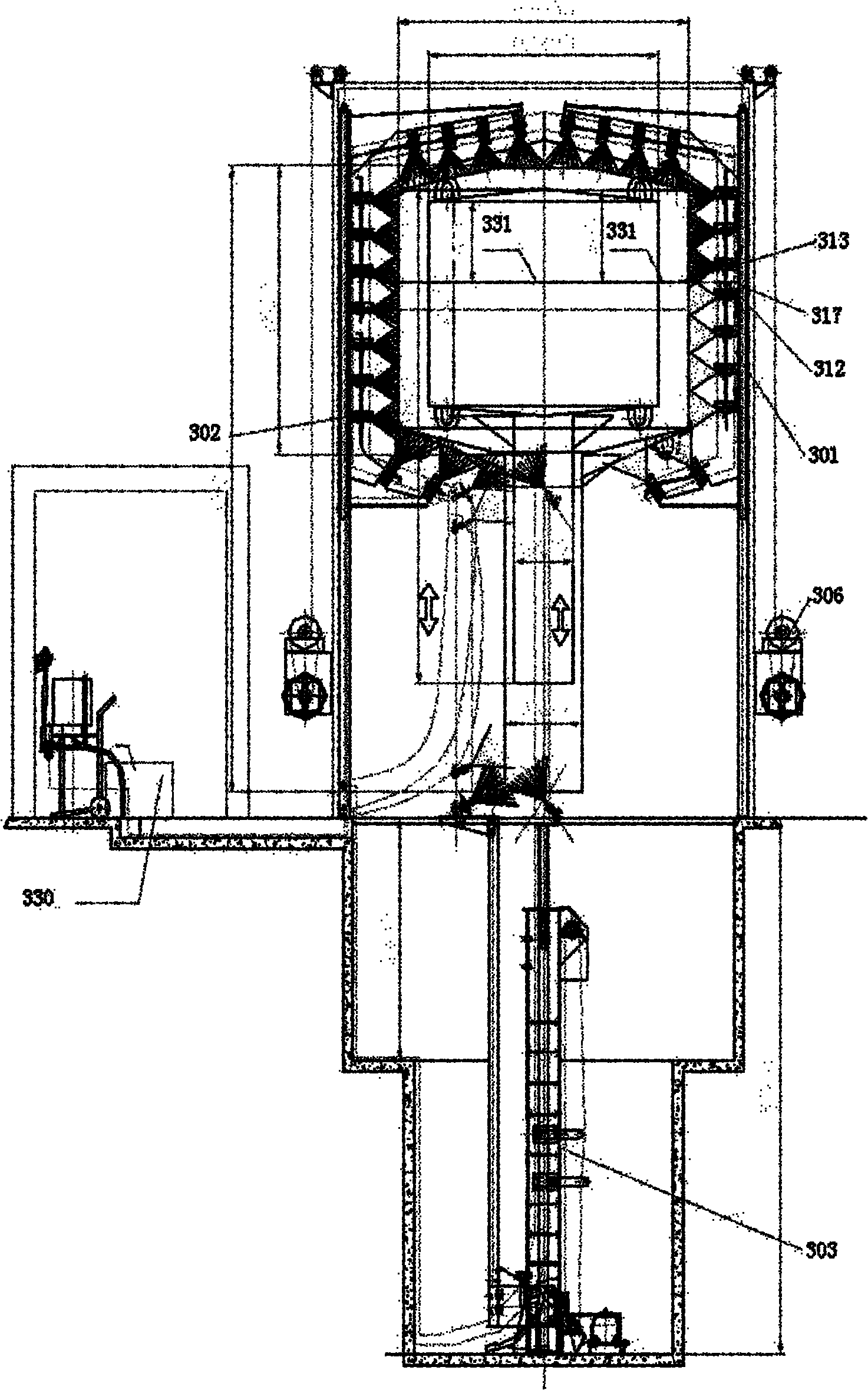

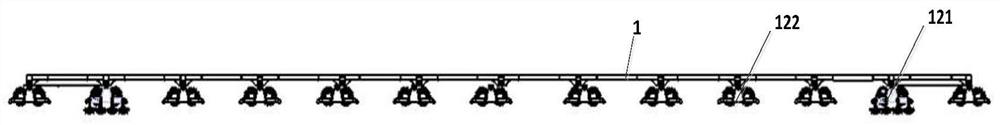

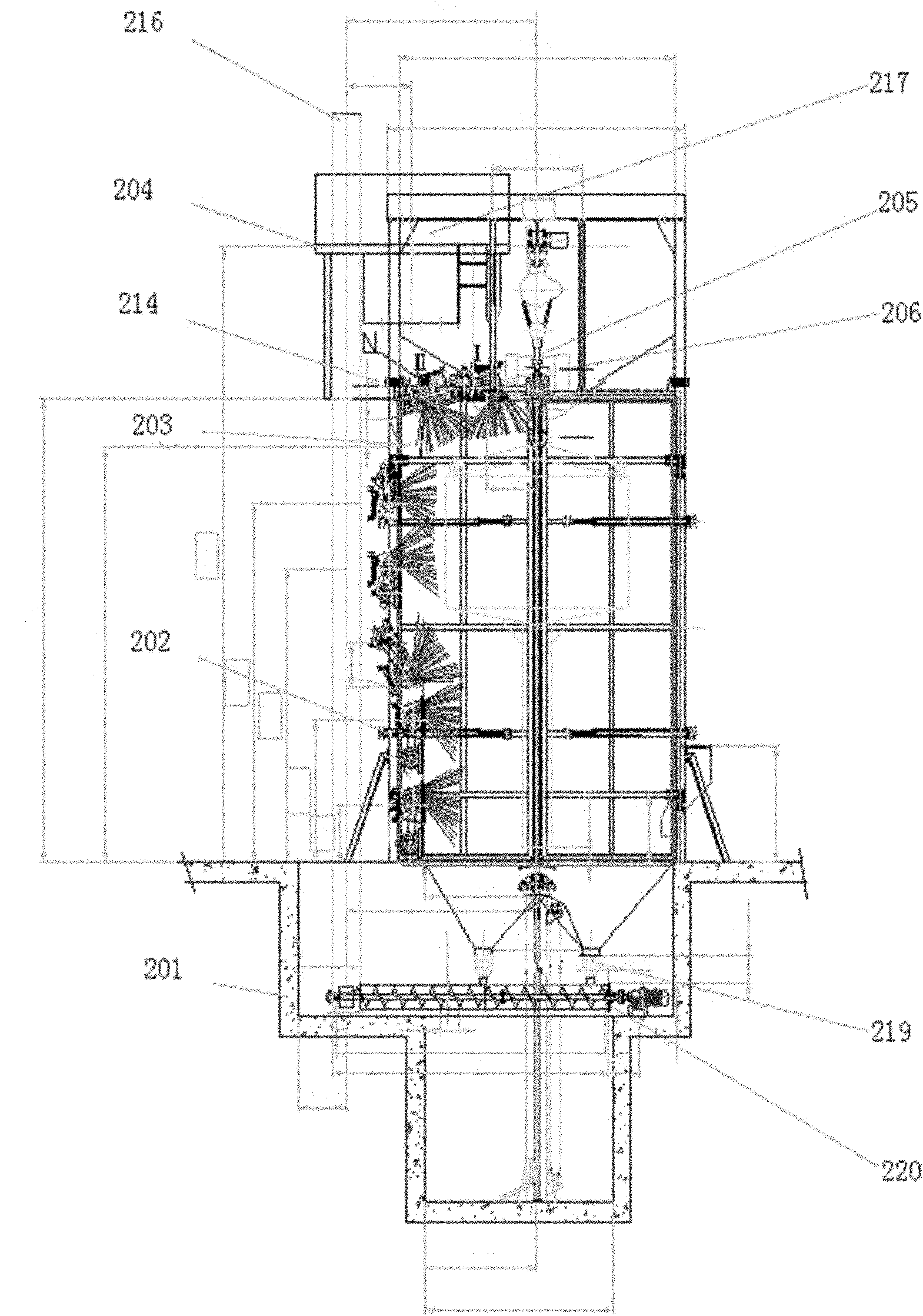

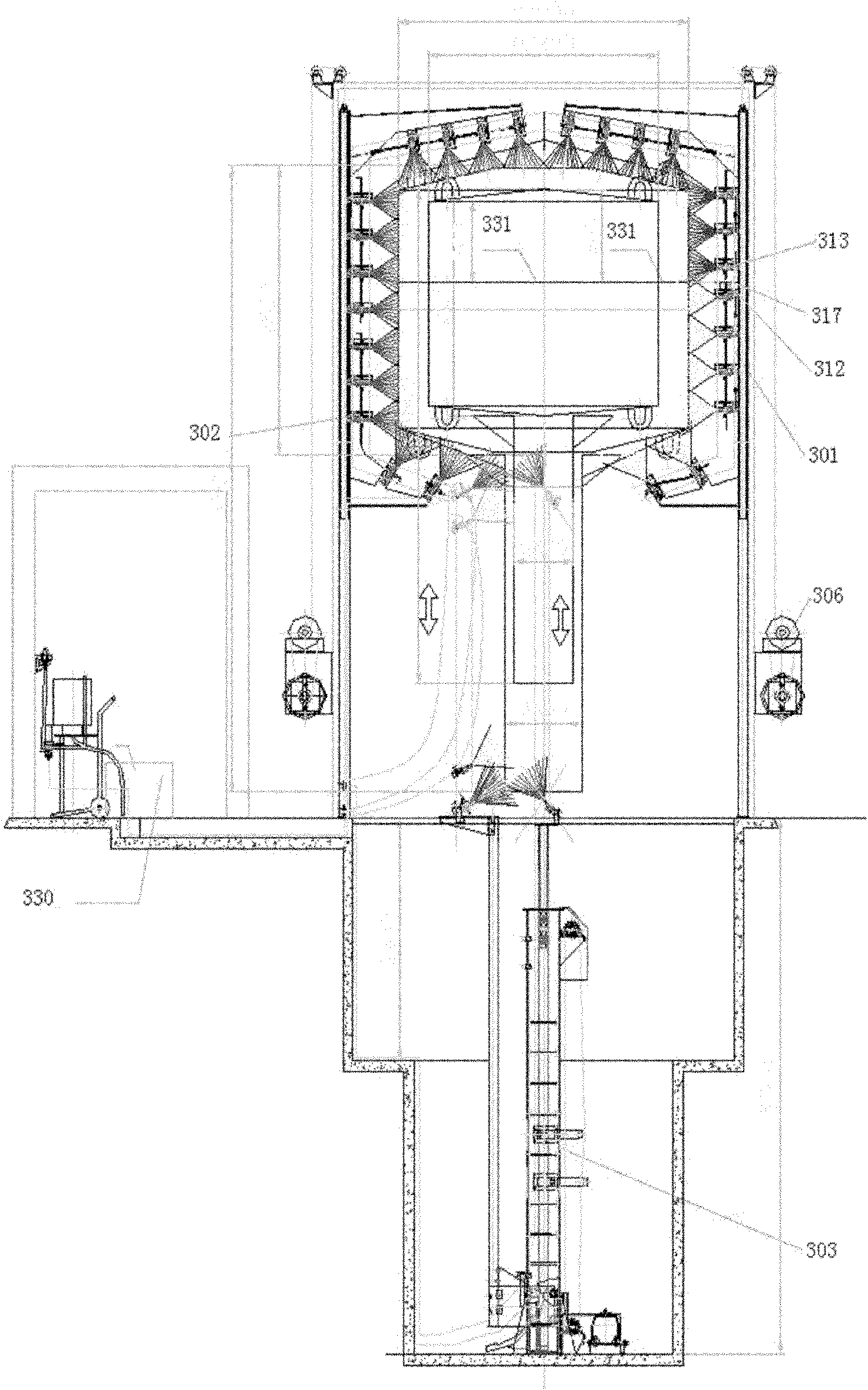

Automatic production line system for coating and maintaining buoys and application method thereof

InactiveCN102173309AAdvanced technologyCompact structureWaterborne vesselsSpraying apparatusProduction lineEngineering

The invention discloses an automatic production line system for coating and maintaining buoys and an application method thereof. The system comprises a hanging and conveying device, a blasting cleaning plant, a shot blasting cleaning plant and a drying unit; all the devices are provided with hanging type loading workpieces; the hanging type loading workpieces are used for realizing ascending and descending, walking and autorotation of the buoys in the process of cleaning the blasting and shot blasting, spraying painting and drying.The application method comprises: a. a trolley is moved to a ring-shaped rail to hoist buoys; b. the buoys enter a cleaning room to carry out blasting and shot blasting; c. the buoys enter a spray room to be painted; d. the buoys enter a drying room to be dried; e. the buoys once again enter the spray room to be painted once again; f. the buoys are dried once again. In the invention, the workpieces are loaded in a hanging manner, the lifting appliances can ascend and descend, walk and automatically rotate. Blasting and shot blasting cleaning, paint spraying, three-station drying are completed respectively to form an automatic coating processing production line; and in addition, program control is realized and a high degree of automation is enjoyed.

Owner:青岛铸造机械集团公司 +1

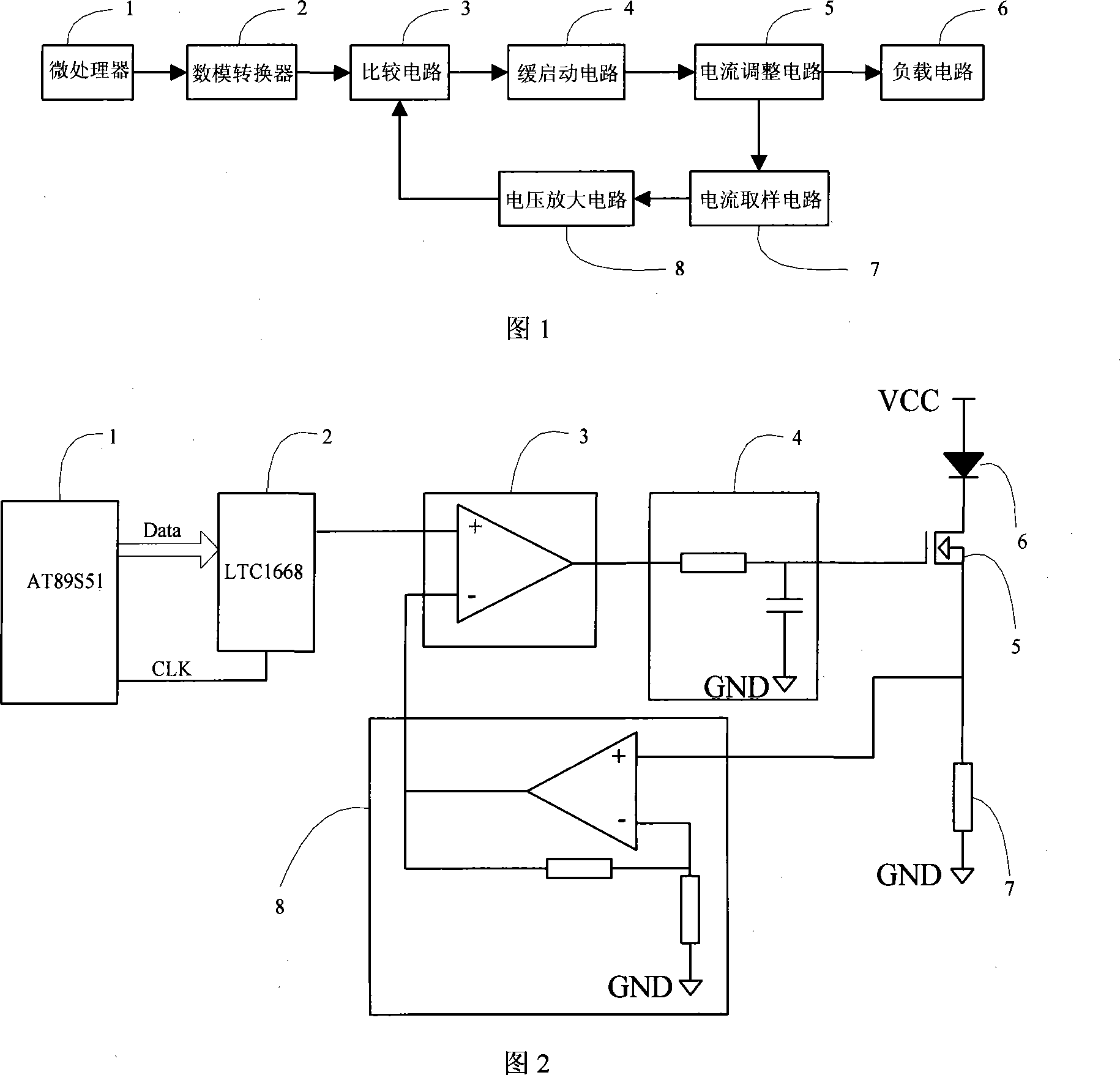

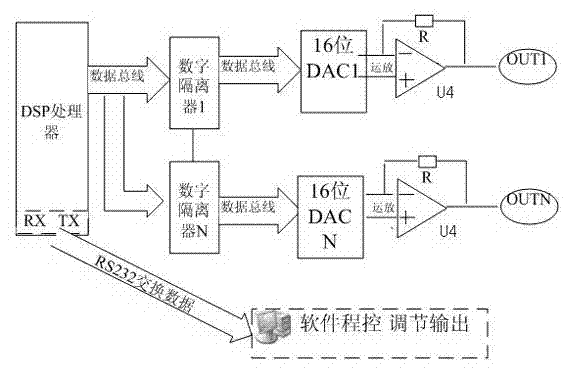

Programmed control slow-starting high stabilization great current drive device

InactiveCN101226342ARealize program controlReduce feverPhotomechanical exposure apparatusMicrolithography exposure apparatusLow voltageCurrent driver

The invention discloses a program-control delay startup high-stability large-current driver, which can control the output voltage of a high-precision digit / analogue converter via a microprocessor, control the output current of load, control a current adjustment circuit via a MOS tube to improve the output current and efficiency. The invention adds a delay startup circuit to slowly increase the load output current without abrupt change. The driver adds a high-precision sampling resistance in load to measure the current fluctuation on the load and connects the control voltage of the output current and the voltage on the sampling resistance with two inputs of a comparator via voltage amplification to form a close-loop negative feedback technique to stabilize the output current with high reliability. The invention has simple circuit, while the output drive current can reach 2A, with continuous program control and adjustable property. The invention has stable and reliable output current and low voltage impact, under the connection with different loads. The invention has wide application in constant-current control and high power LED luminous technical fields.

Owner:HEFEI ADVANTOOLS SEMICON

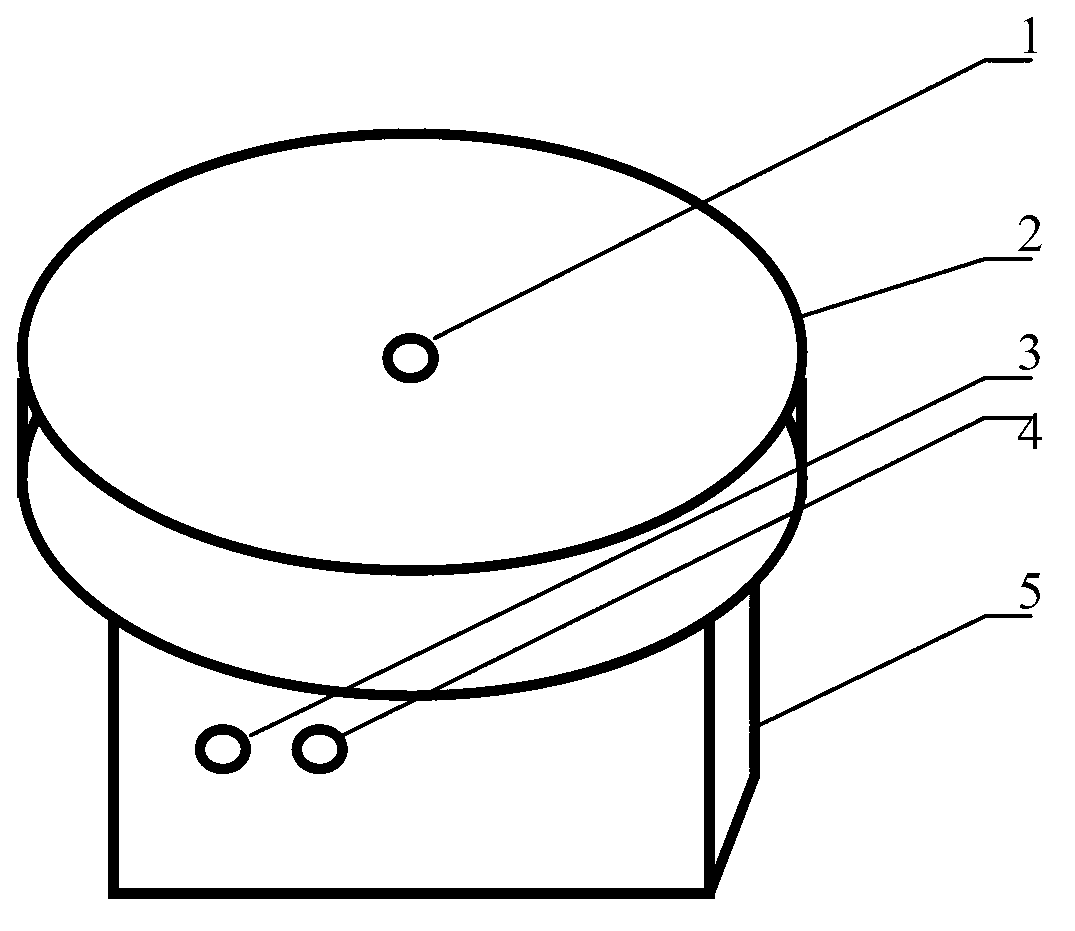

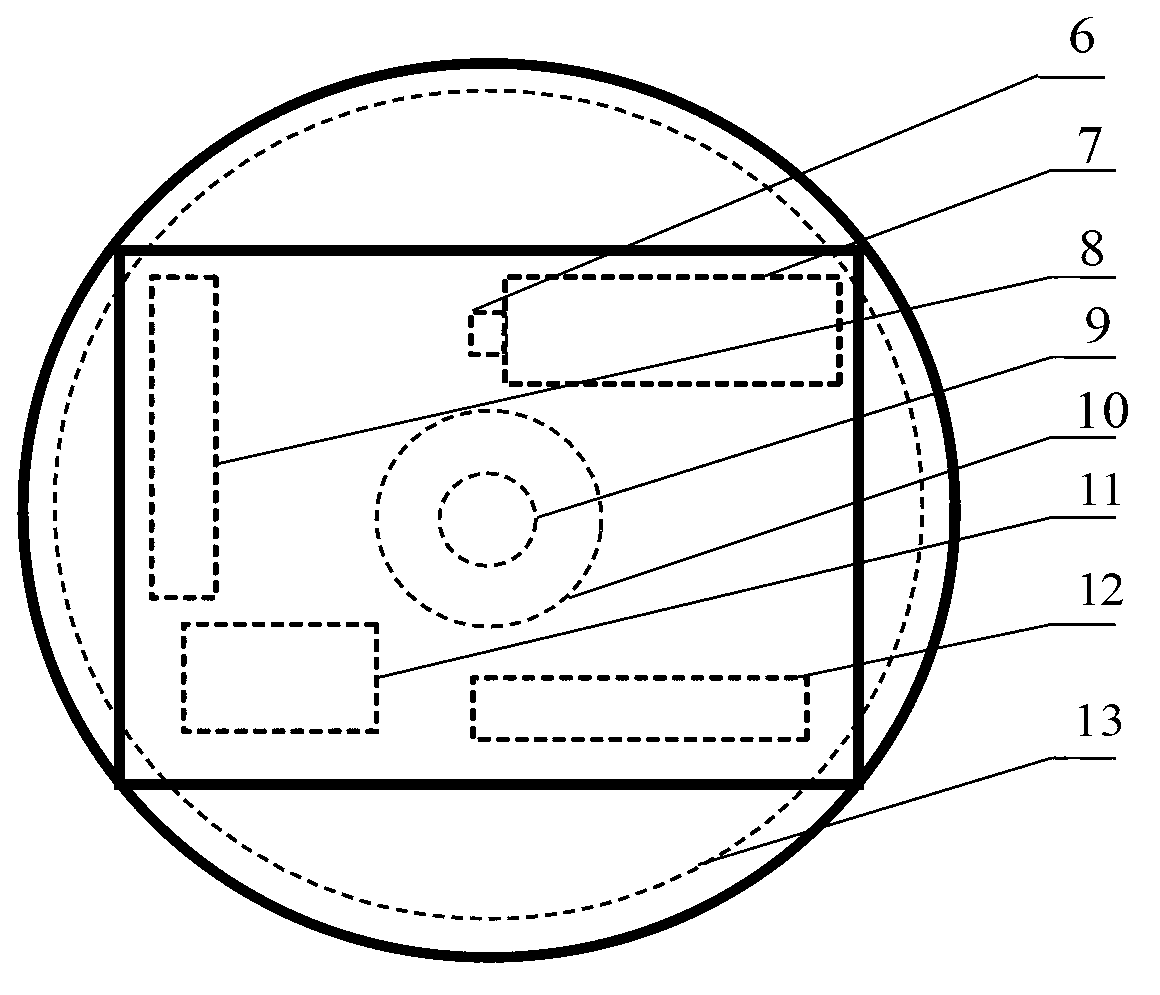

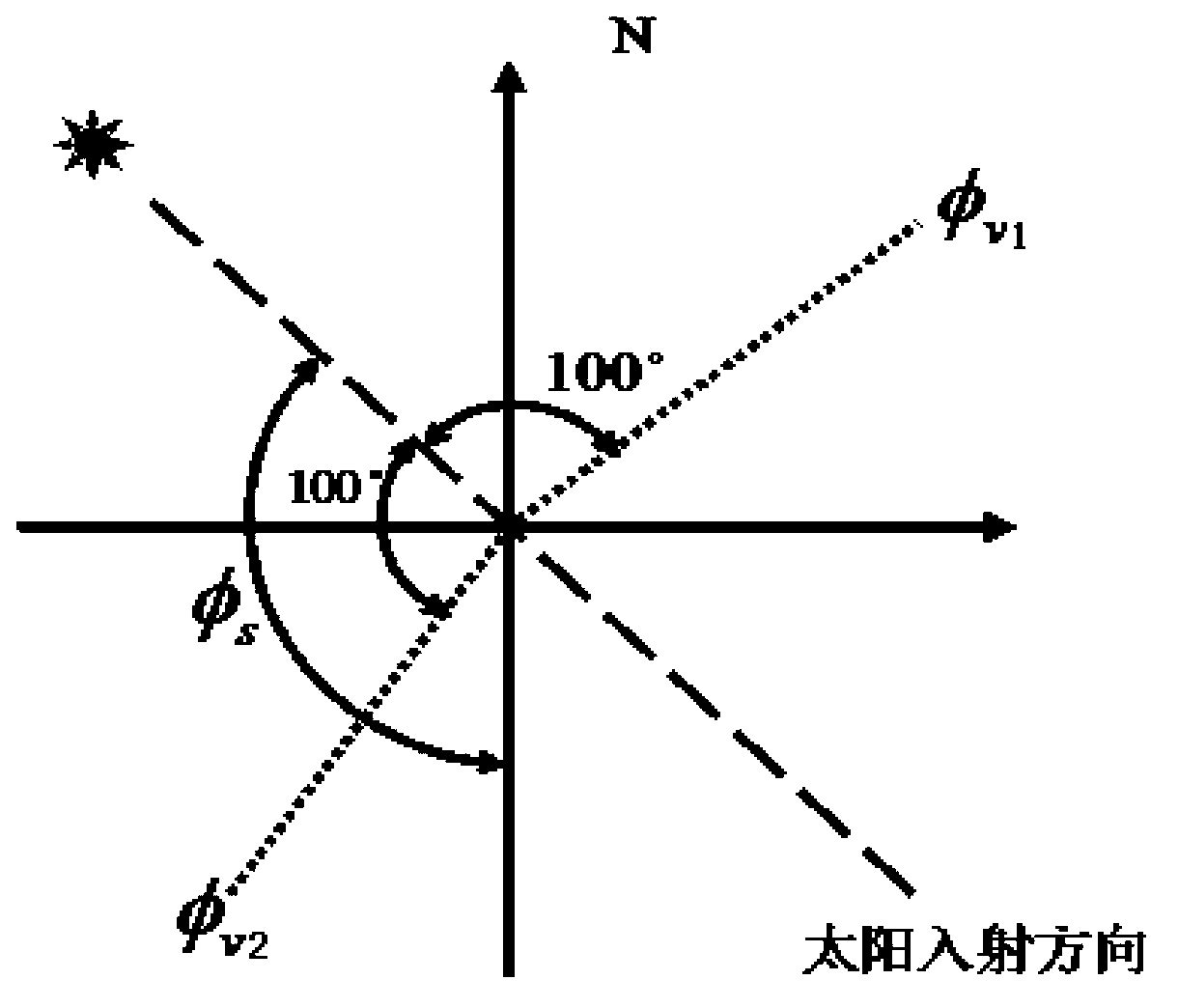

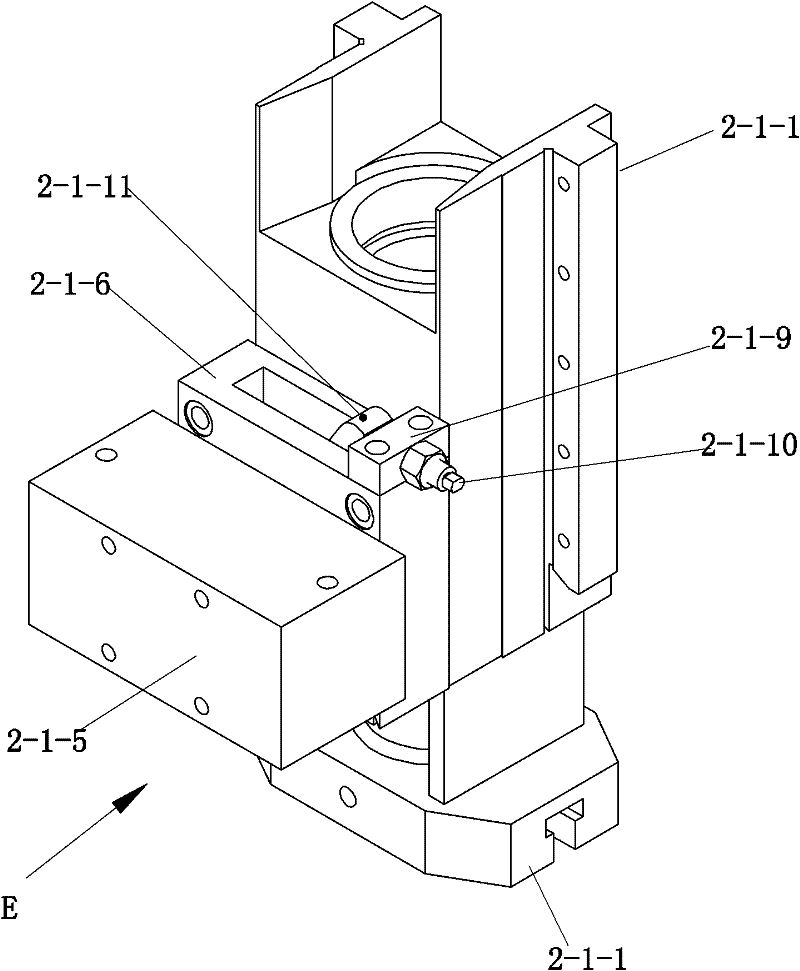

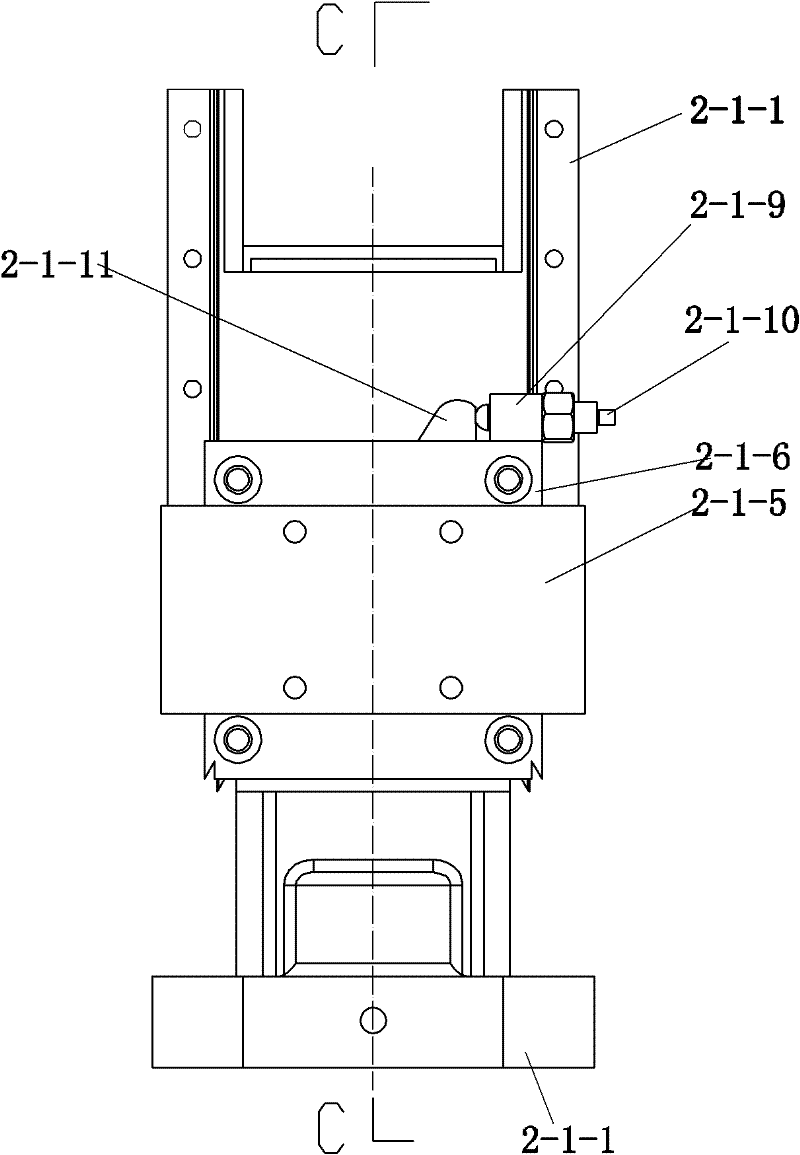

Device for automatically adjusting observation directions of on-water spectrograph

InactiveCN103279135AImprove accuracyRealize program controlPosition/direction controlSpectrographLongitude

The invention discloses a device for automatically adjusting observation directions of an on-water spectrograph. The device comprises a base and a rotating platform, wherein the rotating platform is located above the base, and a base supporting rotating shaft is connected with a rotary bearing of the rotating platform and drives the rotating platform to rotate through the rotary bearing. The on-water spectrograph is installed above the rotating platform, a single-chip microcomputer in the base controls the rotating platform according to observation azimuth angles, confirmed by the incidence direction of the Sun, of the on-water spectrograph, drives the on-water spectrograph installed above the rotating platform to automatically adjust the observation directions, keeps ideal observation geometry with a certain included angle formed between the on-water spectrograph and the incidence direction of the Sun, and improves accuracy of measuring optical parameters of water surface appearance. A method for adjusting the observation directions of the on-water spectrograph comprises the steps: calculating the incidence azimuth angle of the Sun, confirming the observation azimuth angles of the on-water spectrograph, and adjusting the observation directions of the on-water spectrograph, wherein the incidence azimuth angle of the Sun is calculated and confirmed through time and longitude and latitude of a position where the Sun is located in a real-time mode, and the relative included angle of observation orientation of the on-water spectrograph and the incidence direction of the Sun is 100 degrees.

Owner:STATE OCEAN TECH CENT

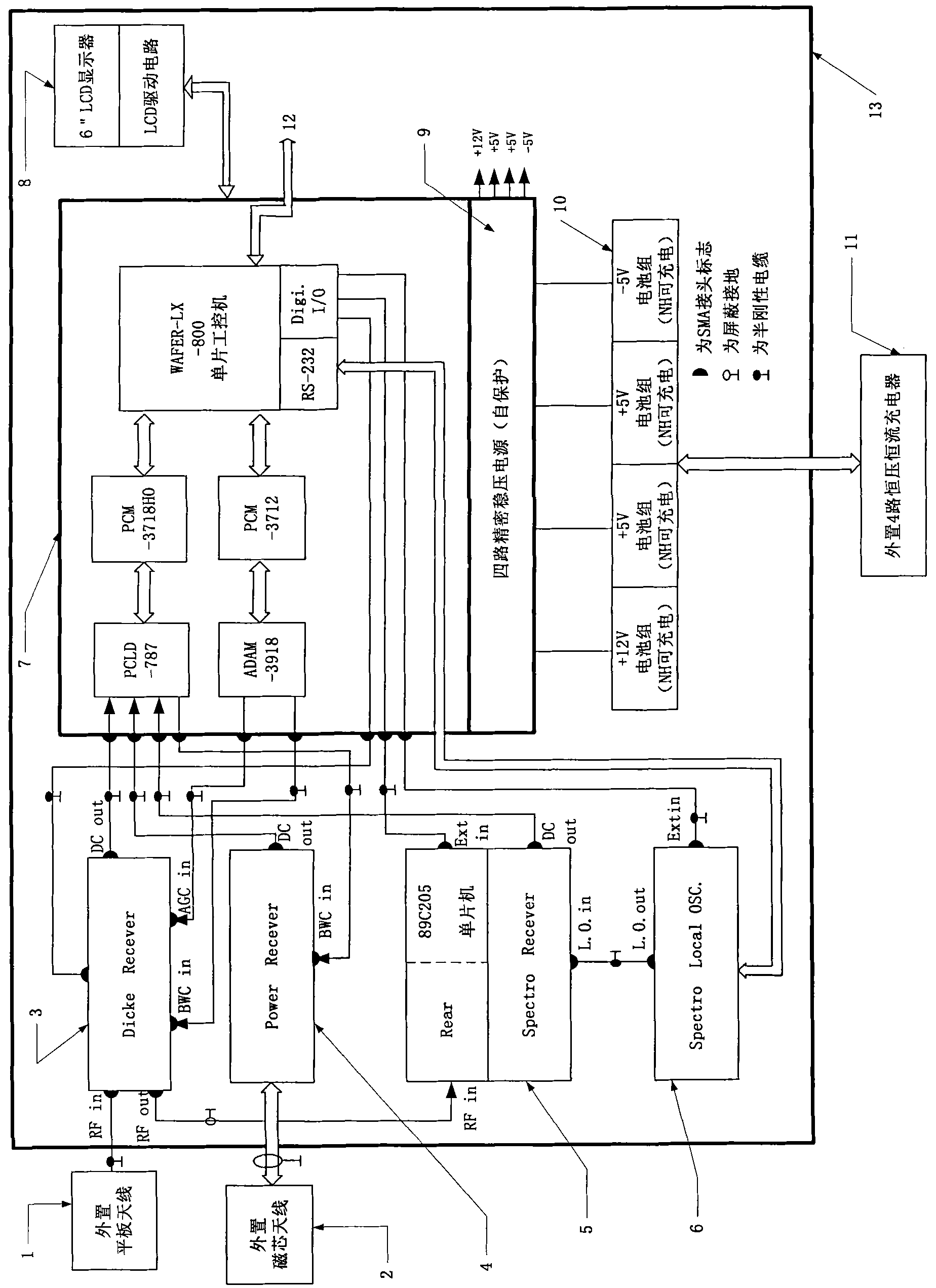

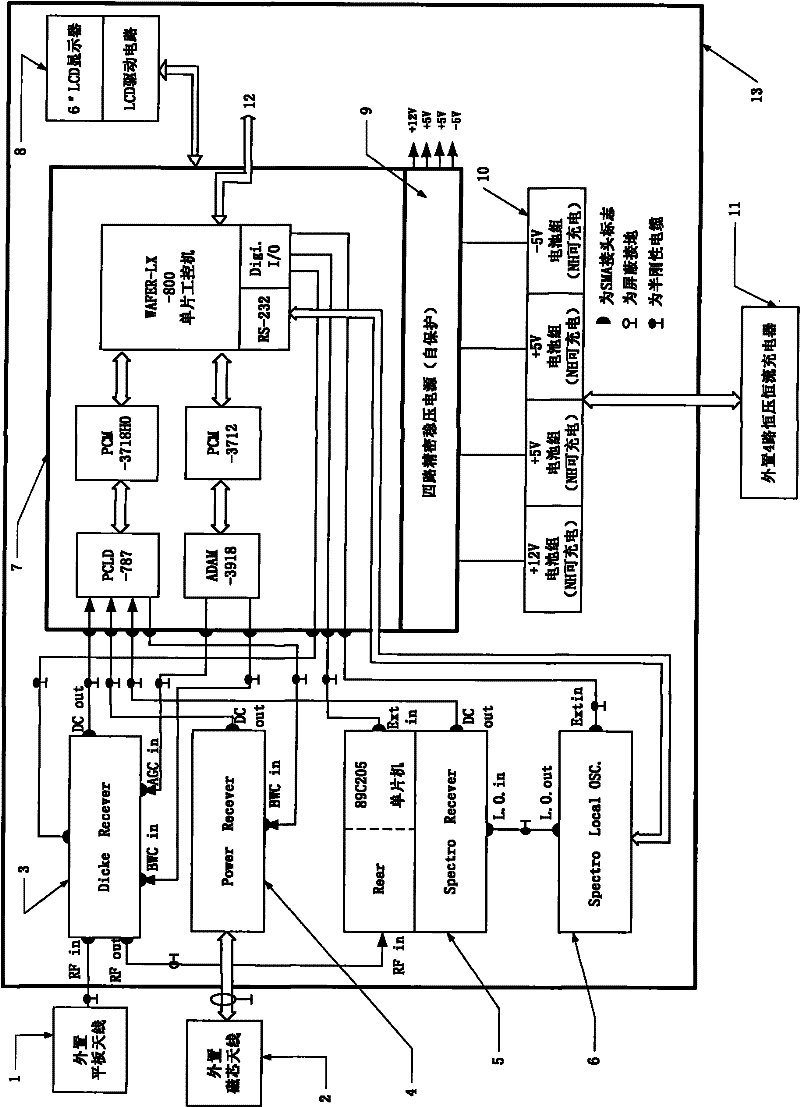

Coal bed gas radio spectrum direction-finding early warning system

InactiveCN101806228AGood for direction findingImprove discriminationSurveyMining devicesEarly warning systemFrequency spectrum

The invention discloses a coal bed gas radio spectrum direction-finding early warning system. A radio astronomy modulation radiation receiving system is used to receive gas radio steady state and unsteady state radiation temperature signals in a gas enriched region in a coal bed so as to indirectly measure the coal bed gas pressure; a radio astronomy full-power radiation receiving system is used to receive gas radio unsteady state and quickly variable radiation intensity and form signals in the gas enriched region in the coal bed so as to judge the gas radio radiation type and variation rate; and a radio astronomy spectrum radiation receiving system is used to receive gas radio unsteady state and quickly variable radiation spectrum peak and frequency drift in the gas enriched region in the coal bed so as to early warn the coal gas outburst. Due to the fit of the maximum values of the three signals under different antenna bearings and elevations, and the trigonometry measurement, the direction and normal distance of the gas enriched region are measured.

Owner:南京紫淮矿用电子高科技有限公司 +2

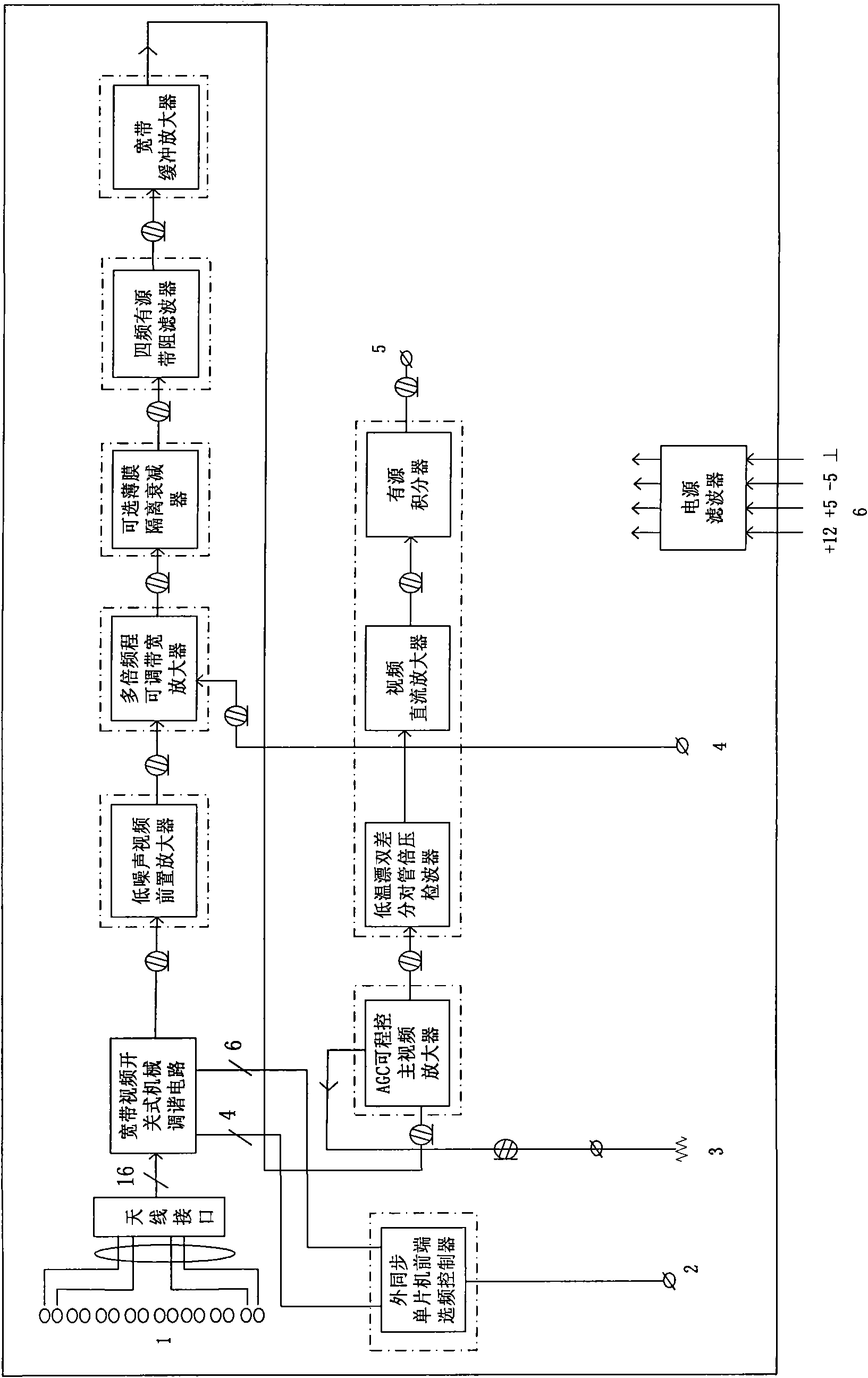

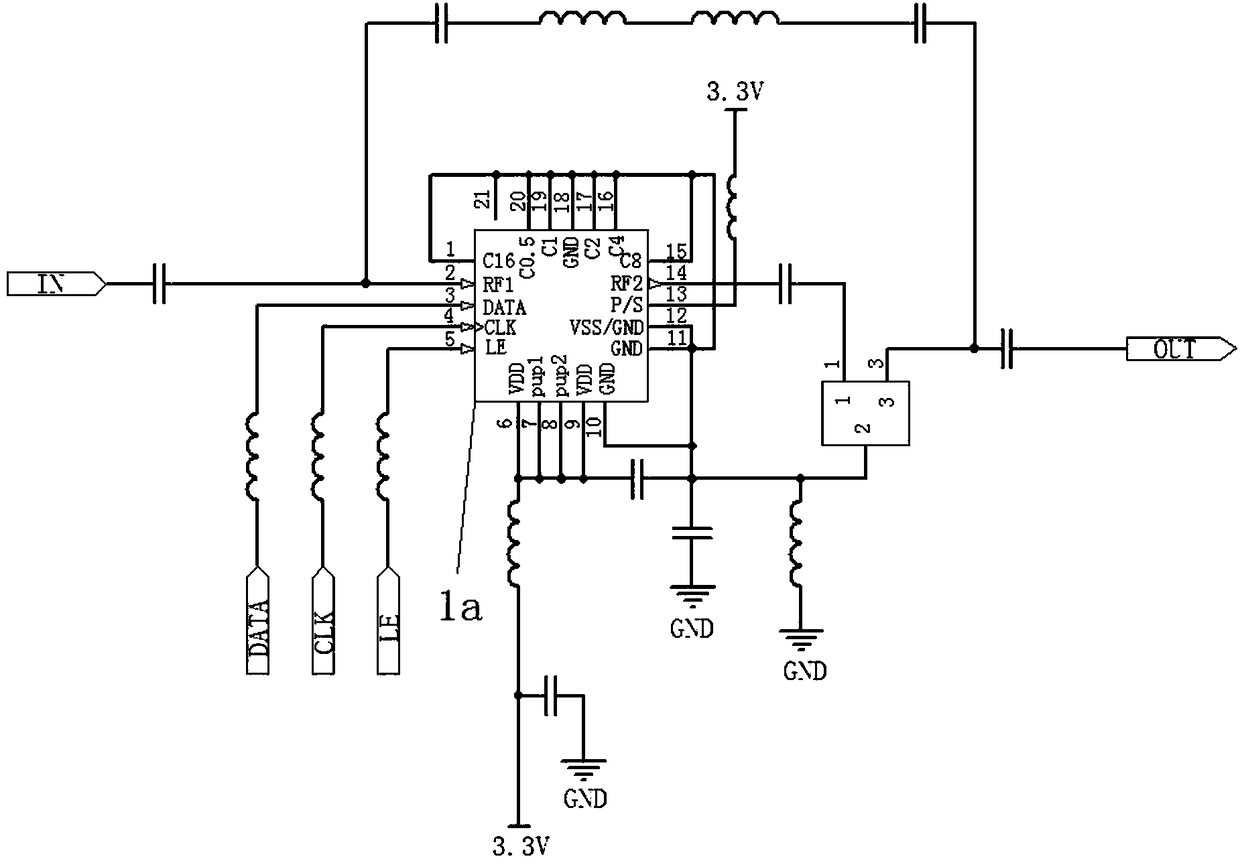

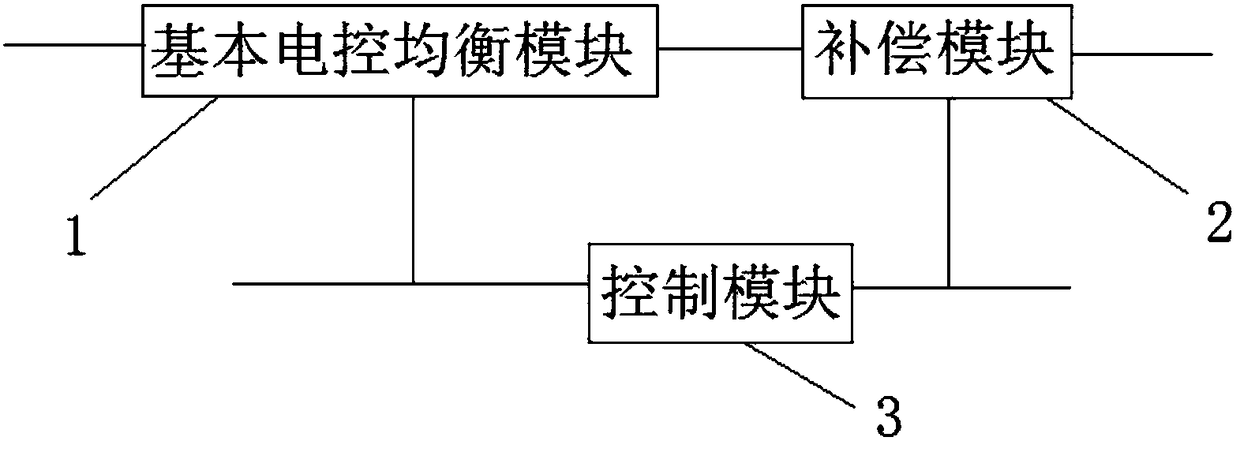

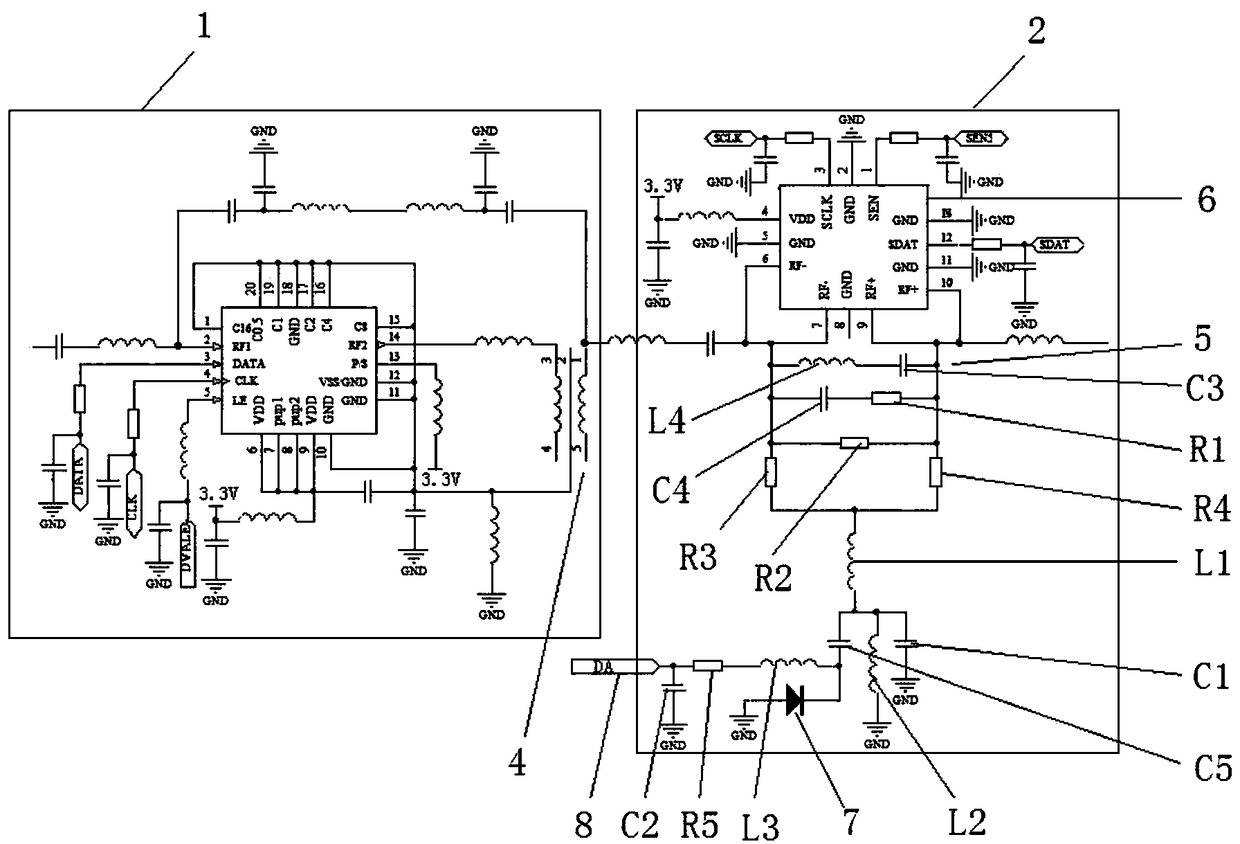

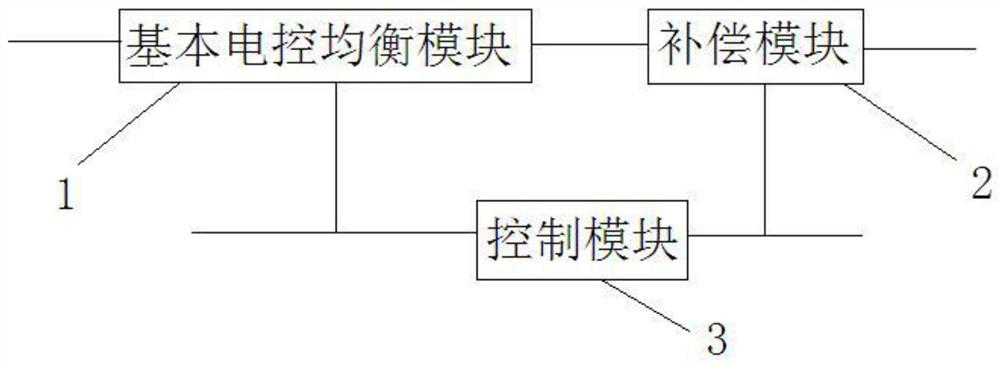

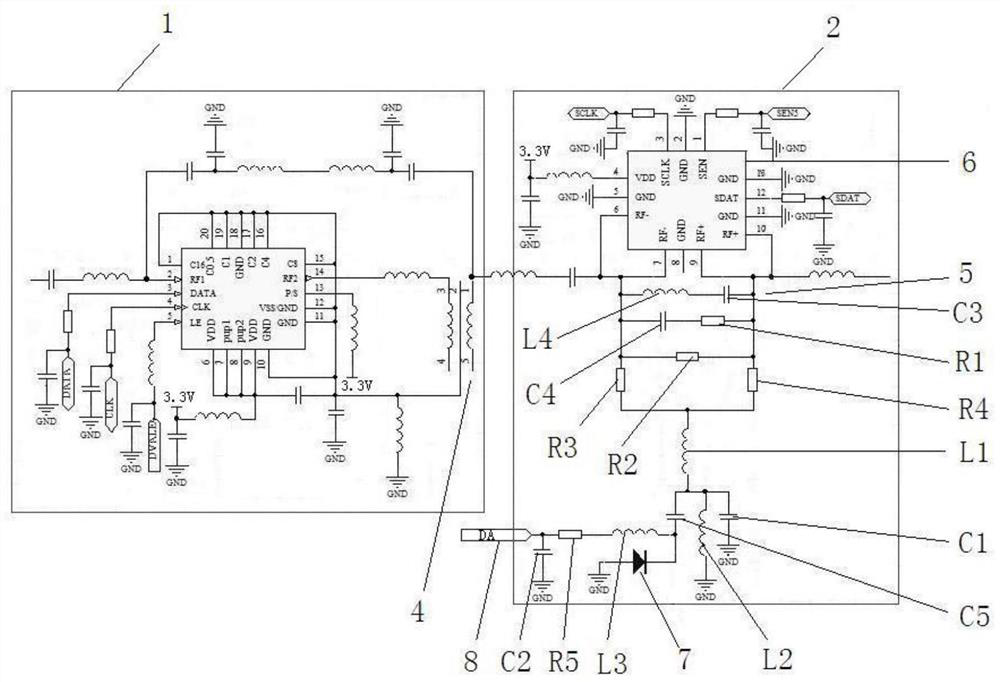

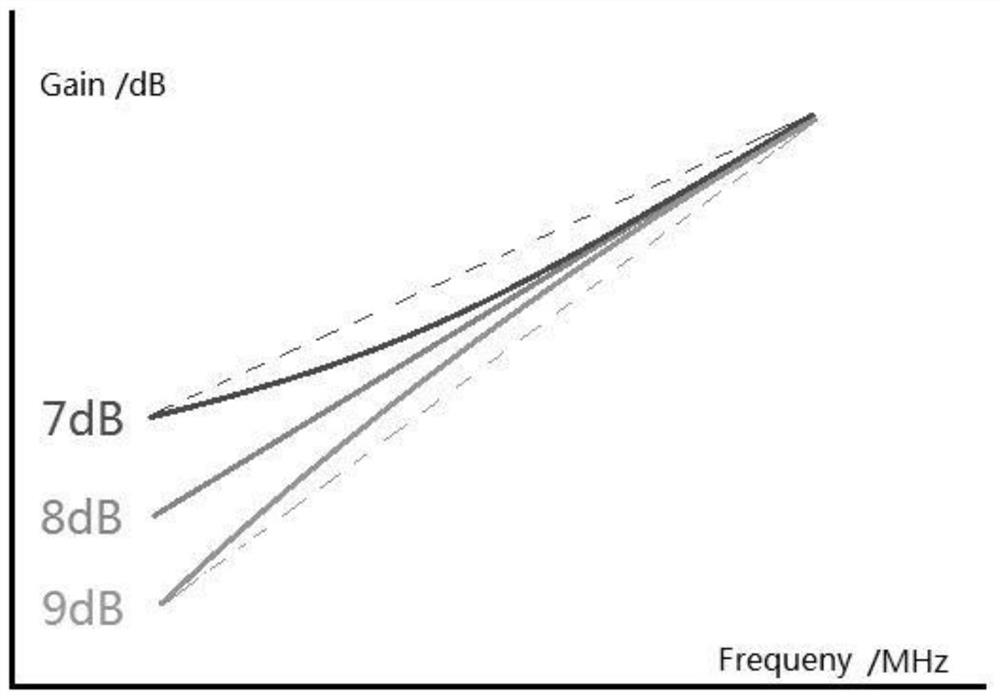

High-precision adjustable electric control equalization circuit of cable television network

ActiveCN108200368AImprove frequency response characteristicsImprove featuresImpedence matching networksTelevision system detailsElectricityComputer module

A high-precision adjustable electric control equalization circuit of a cable television network comprises one or more basic electric control equalization modules with an adjustable slope. The circuitalso comprises a control module and one or more compensation modules. The control module is electrically connected to the basic electric control equalization modules so as to control the slope changesof the basic electric control equalization modules. The control module is electrically connected to the compensation modules so as to generate a compensation signal according to the slope changes ofthe basic electric control equalization modules. The output of the basic electric control equalization modules is electrically connected to the input of the compensation modules so as to output a complete signal after the two are overlaid. The high-precision adjustable electric control equalization circuit of the cable television network can obtain good signal waveform flatness at each slope.

Owner:APPLIED OPTOELECTRONICS INC

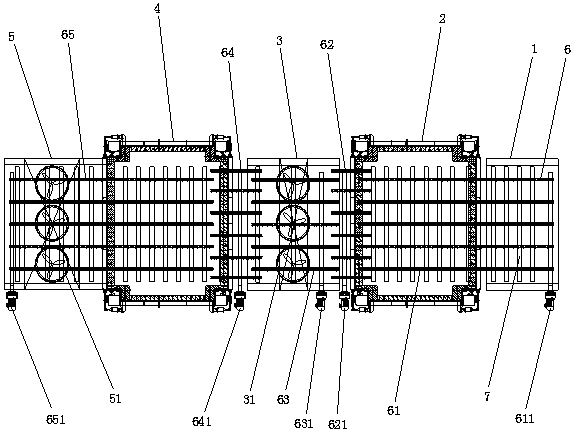

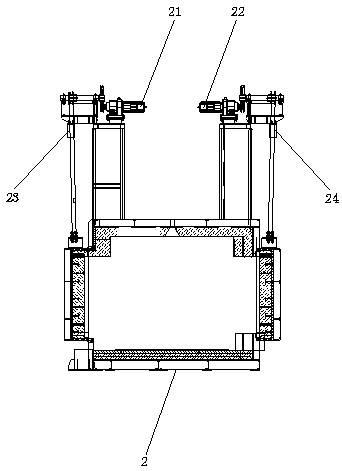

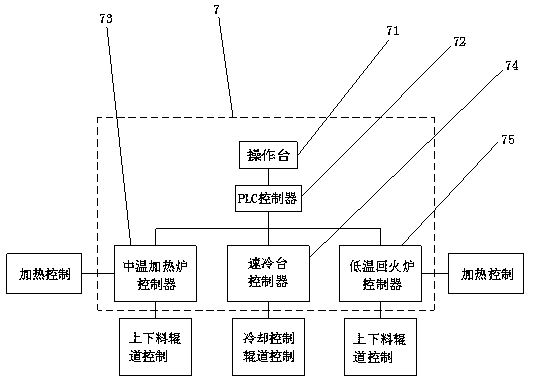

Continuous heat treatment production line and heat treatment method thereof

PendingCN111500845ACompact and reasonable layoutTaking into account the quality of quick coolingFurnace typesHeat treatment process controlTemperingProcess engineering

The invention relates to a continuous heat treatment production line and a heat treatment method thereof. The continuous heat treatment production line comprises a feeding table, a medium temperaturenormalizing furnace, a quick cooling table, a low temperature tempering furnace and a discharging table; a medium temperature feeding furnace door is arranged at the feeding end of the medium temperature normalizing furnace, a medium temperature discharging furnace door is arranged at the discharging end of the medium temperature normalizing furnace, the quick cooling table is arranged on one sideof the discharging end of the medium temperature normalizing furnace in a matched mode, the low temperature tempering furnace is arranged on one side of the discharging end of the quick cooling tablein a matched mode, a low temperature feeding furnace door is arranged at the feeding end of the low temperature tempering furnace, and a low temperature discharging furnace door is arranged at the discharging end of the low temperature tempering furnace; and the discharging table is arranged on one side of the low temperature tempering furnace in a matched mode, and the feeding table, the mediumtemperature normalizing furnace, the quick cooling table, the low temperature tempering furnace and the discharging table are connected to one other through material transfer roller ways to transportworkpieces. Normalizing heating and rapid and uniform cooling of bainite alloy steel point rails are achieved, normalizing residual heat is used for entering the furnace for tempering, the layout of the production line is compact and reasonable, automatic furnace installing and discharging are achieved, and production efficiency and product quality are improved.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP +1

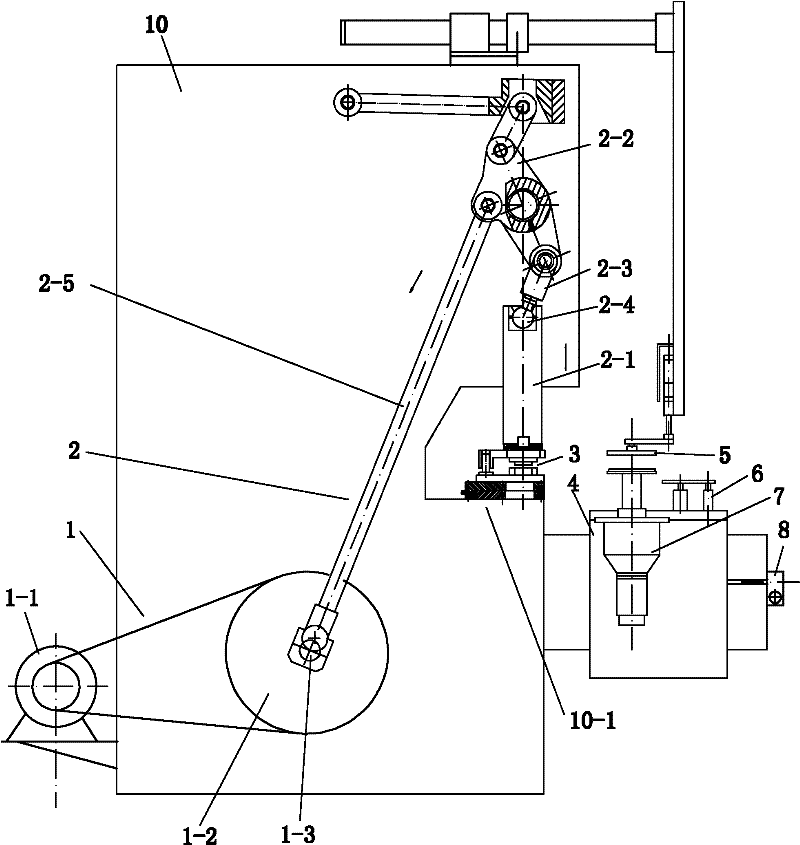

Numerically controlled notching press and method for controlling notching process by using computer program

The invention discloses a numerically controlled notching press, which comprises a machine body, a power mechanism, a toggle rod mechanism, a die, a chip pressing device, a chip unloading device, a dividing apparatus, a radial feeding device, a pressure system and a lubricant system, wherein a slider of the toggle rod mechanism consists of a slider body and a sliding core; the sliding core is provided with an eccentric shaft which is connected with an oscillating cylinder; the platform surface of the machine body is fixed with a lower die guiding rail; the bottom surface of a lower die is fixed with a lower die sliding rack; the lower die slides on the lower die guiding rail through the lower die sliding rack; the top surface of an upper die is fixed with an upper die guide frame in whicha guide plate capable of relatively sliding is arranged; the top part of the guide plate is fixed with a positioning column connected with the slider of the toggle rod mechanism; and the lower die sliding rack is connected with a tangent feeding device. The numerically controlled notching press is suitable for intermittent notching, ordinary chip notching, conical groove chip notching, spiral groove chip notching and slant and straight groove chip notching, and has a wide application range. A notching process of the notching press is controlled by adopting a computer program.

Owner:常州市耀华电机设备有限公司

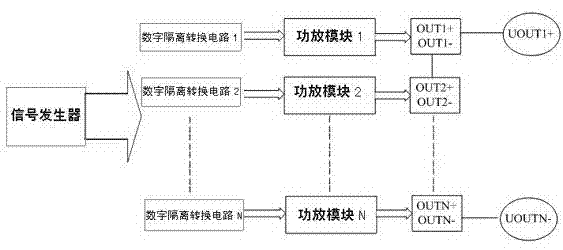

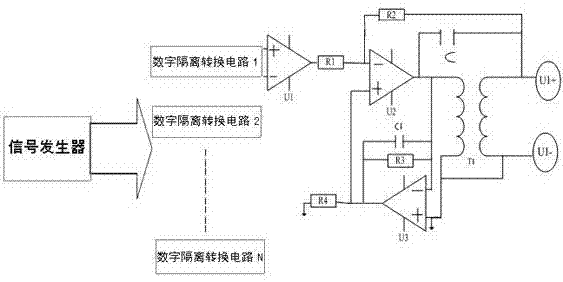

High-voltage large-power frequency conversion adjustable constant voltage source

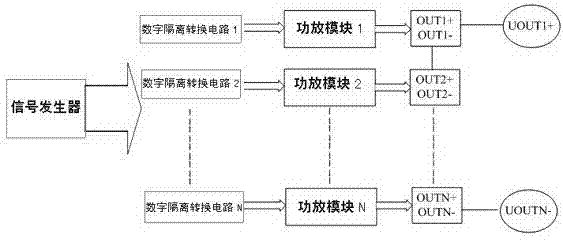

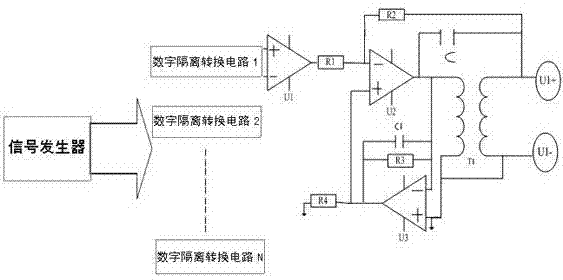

ActiveCN102955486AIncrease output powerExpand the output rangeElectric variable regulationSignal processing circuitsLow voltage

The invention relates to a high-voltage large-power frequency conversion adjustable constant voltage source which comprises a signal generator and N signal processing circuits, wherein power sources for inner components of any two signal processing circuits are not grounded; each signal processing circuit is composed of a digital isolation switching circuit and a power amplifier module; a signal generated by the signal generator is synchronously output to all the signal processing circuits; after the signal is firstly processed by the digital isolation switching circuits of all the signal processing circuit, N high-precision isolated low-voltage alternate current signals are output, wherein N is an integer which is not less than 1; all the low-voltage alternating current signals are the same in amplitude, frequency and phase, and the amplitude and frequency of all the low-voltage alternating current signal can be synchronously adjusted; and all the low-voltage alternating current signals are output to the corresponding power amplifier modules treatment be amplified; and output ends of N power amplifier modules are sequentially connected in series so as to be utilized as the total output of the constant voltage source. The constant voltage source provided by the invention has the advantages that the output voltage and power accuracy is high, and the amplitude regulating range is large.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

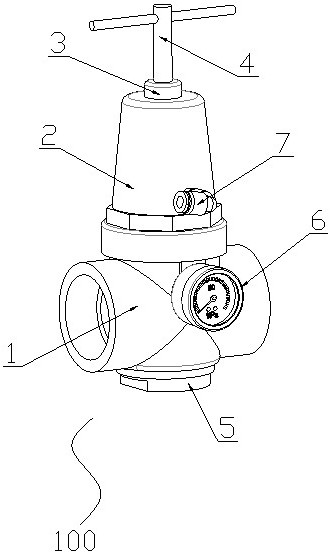

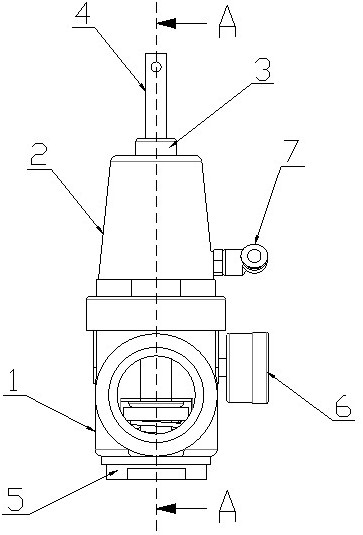

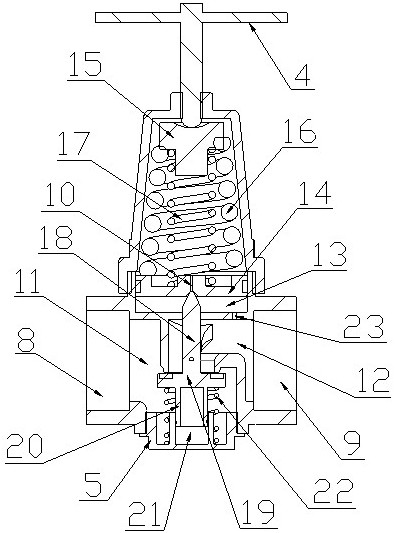

Programmable control valve

InactiveCN103343830ARealize functionRealize network operationOperating means/releasing devices for valvesMain processing unitTransformation unit

The invention belongs to the technical field of valve control, and discloses a programmable control valve. The programmable control valve is flexible in operation, stable, reliable, simple to maintain, good in expansion and low in cost. According to the technical scheme, the programmable control valve comprises a valve body, a power supply input end, a main processing unit, an executing mechanism, an opening degree detection unit, a work state detection unit, a control converting unit and a power supply transformation unit, wherein the valve body is respectively connected with the executing mechanism and the opening degree detection unit, the power supply input end is respectively connected with the executing mechanism, the work state detection unit and the power supply transformation unit, the main processing unit is respectively connected with the opening degree detection unit, the work state detection unit, the control converting unit and the power supply transformation unit, and the executing mechanism is connected with the control converting unit.

Owner:TAIYUAN UNIV OF TECH

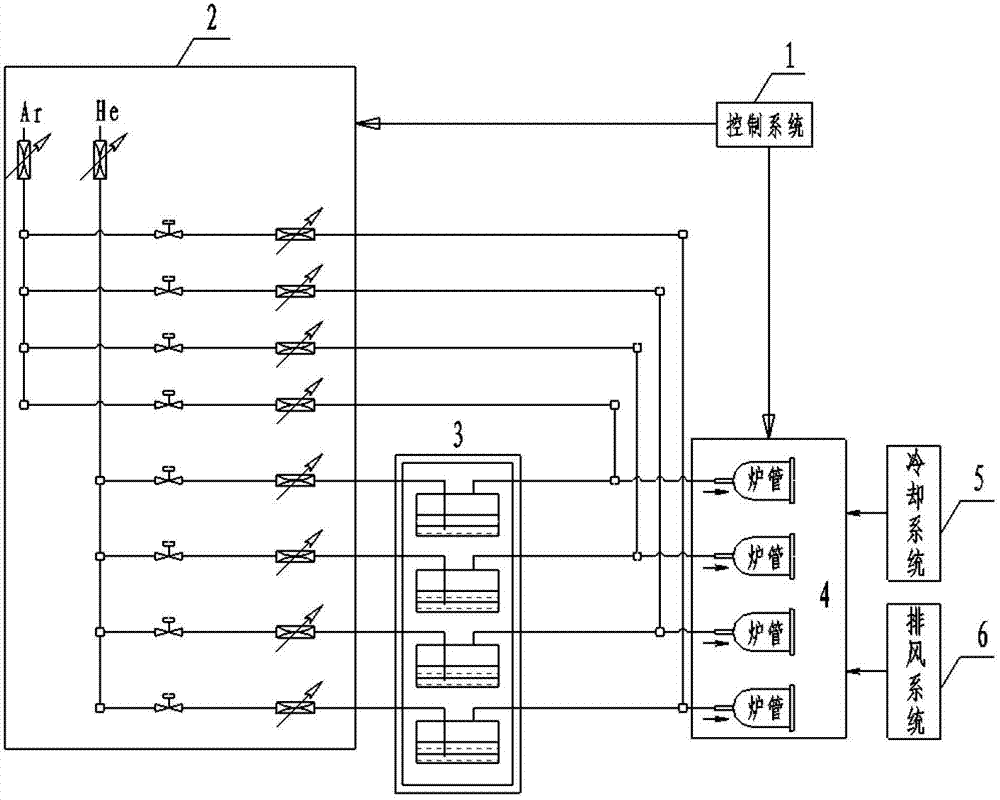

Oxidation resistance testing equipment

ActiveCN102768222ACreate a Human-Machine InterfaceRealize program controlMaterial thermal analysisControl systemShielding gas

The invention provides oxidation resistance testing equipment which comprises a control system, a gas circuit system, a thermostatic waterbath system, a thermal diffusion furnace, a cooling system and an exhaust system, wherein the control system is used for displaying and alarming the control temperature, gas flow and vapor content in the gas; the gas circuit system is connected with the control system, the thermostatic waterbath system and the thermal diffusion furnace, and is used for filling the working gas or protective gas into the thermal diffusion furnace; the thermostatic waterbath system is connected with a working gas circuit of the gas circuit system, and is used for enabling the working gas to carry vapor into the thermal diffusion furnace; the thermal diffusion furnace is connected with the gas circuit system and the thermostatic waterbath system, and is used for heating a solid element to a set experimental temperature and keeping the temperature for a certain time; the cooling system is connected with the thermal diffusion furnace, and is used for cooling a thermal diffusion furnace end flange and a furnace body; and the exhaust system is positioned at the tail part of the gas control system, and is used for collecting and discharging the tail gas. The oxidation resistance testing equipment provided by the invention can accurately and conveniently control the gas switching and flow, automatically executing temperature rise curves and displaying the operating conditions of all the components in real time, and the intelligence and safety of the equipment are improved.

Owner:TSINGHUA UNIV

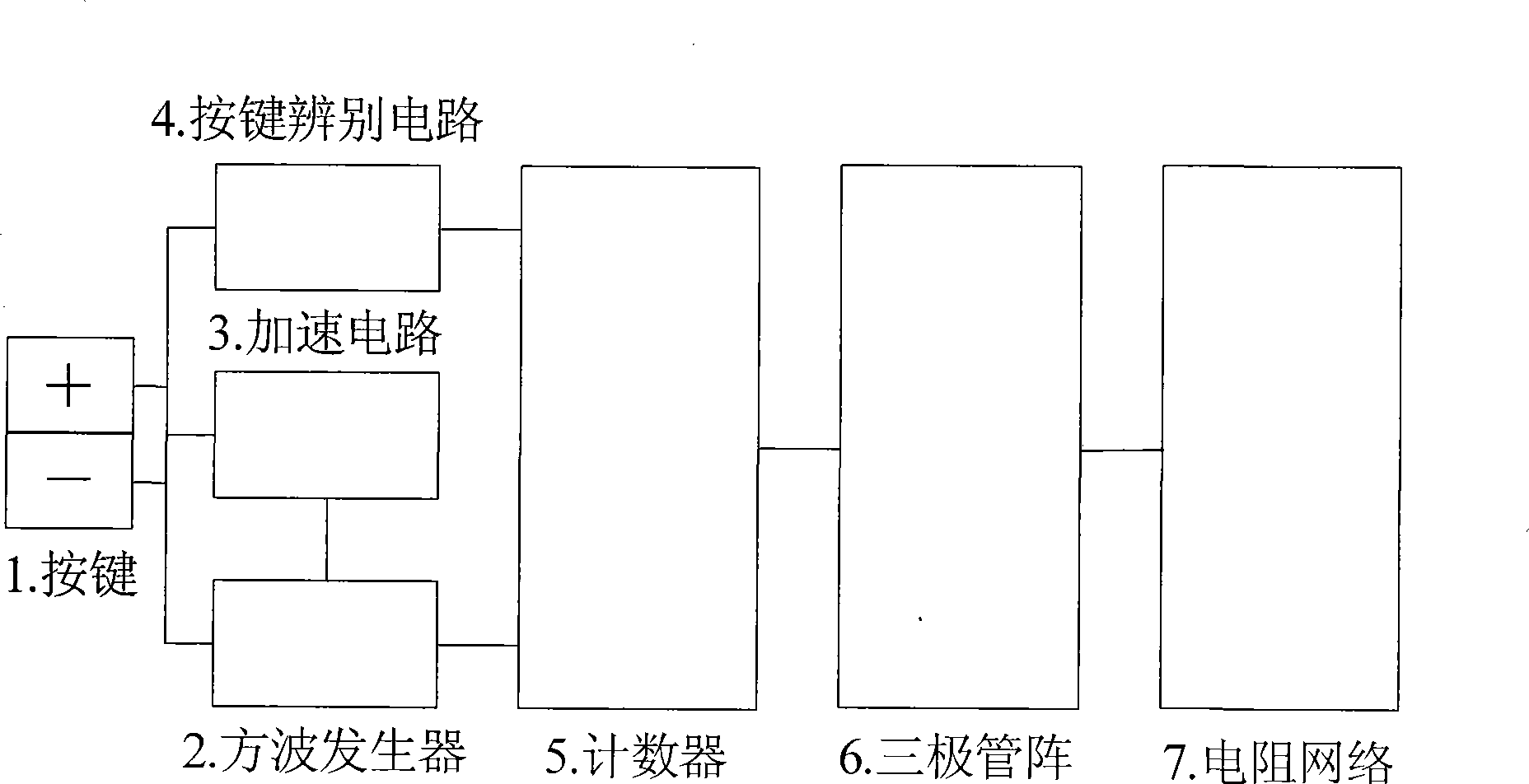

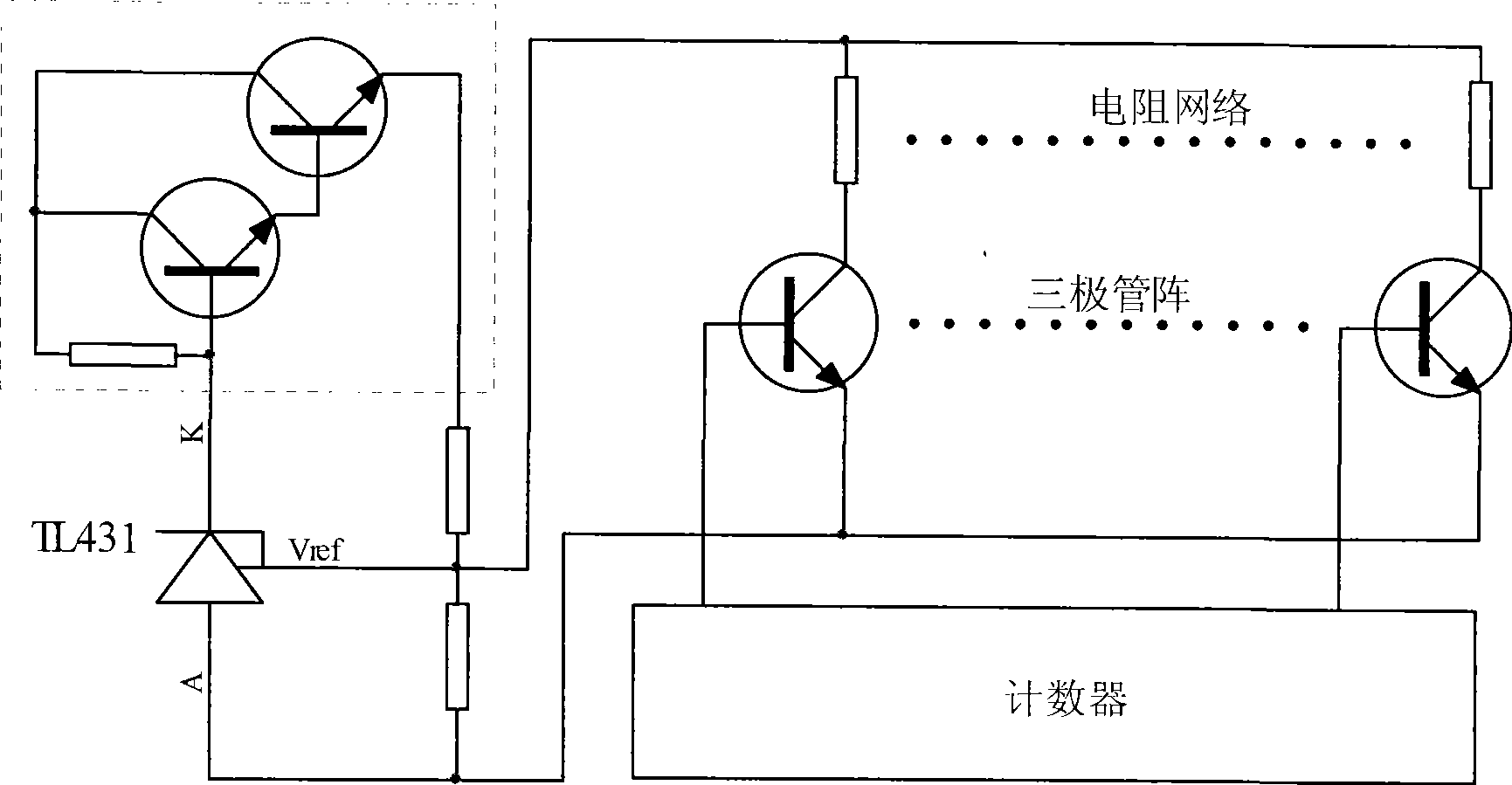

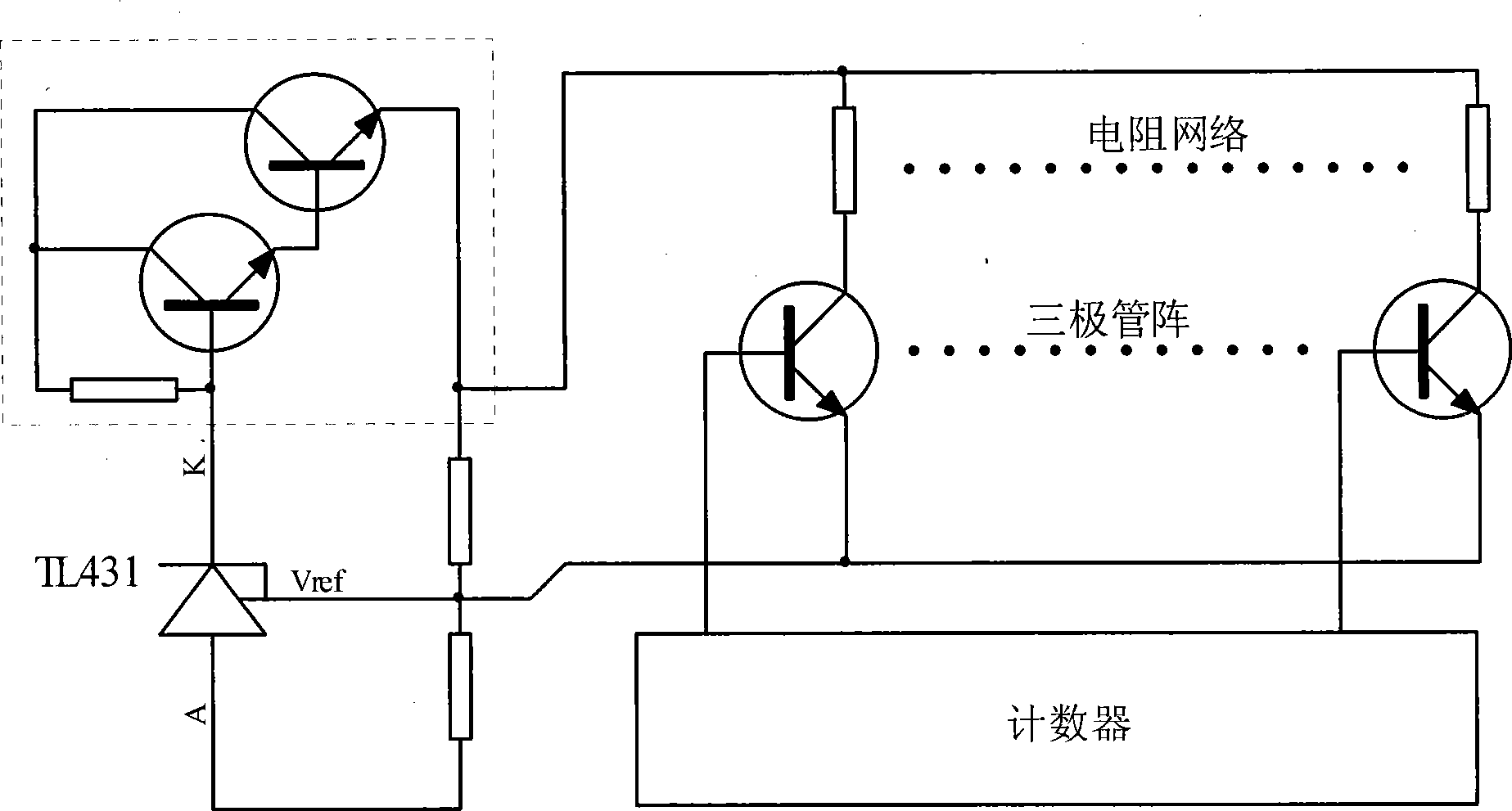

Universal electronic potentiometer module

InactiveCN101447776AFunctional implementation and extensionExtended service lifeFrequency-independant attenuatorsElectrical resistance and conductanceMicrocontroller

The invention discloses a universal electronic potentiometer module. Functional circuits such as a key switch, a square generator, an accelerating circuit, a keystroke distinguishing circuit, a counter, an NPN-typed triode array with the collector open and a resistance network and the like are electrically connected to form a complete electronic potentiometer apparatus which outputs a passive power to realize the function of a common potentiometer and expand new functions. The invention has a resistance output mode and a voltage output mode, can also lead an output value to be passively adjusted or reversely adjusted; the modes and functions can lead the module to be very easily and directly connected with other various external active circuits, and are broadly applied to various electronic fields. The technical principle construction realizing method of the invention is as follow: 1) using separated elements and small scale integrated circuits; 2) using the singlechip like AT89C2051 as a core; 3) integrating the function components and elements which can be integrated.

Owner:武汉市创佳源电子有限公司

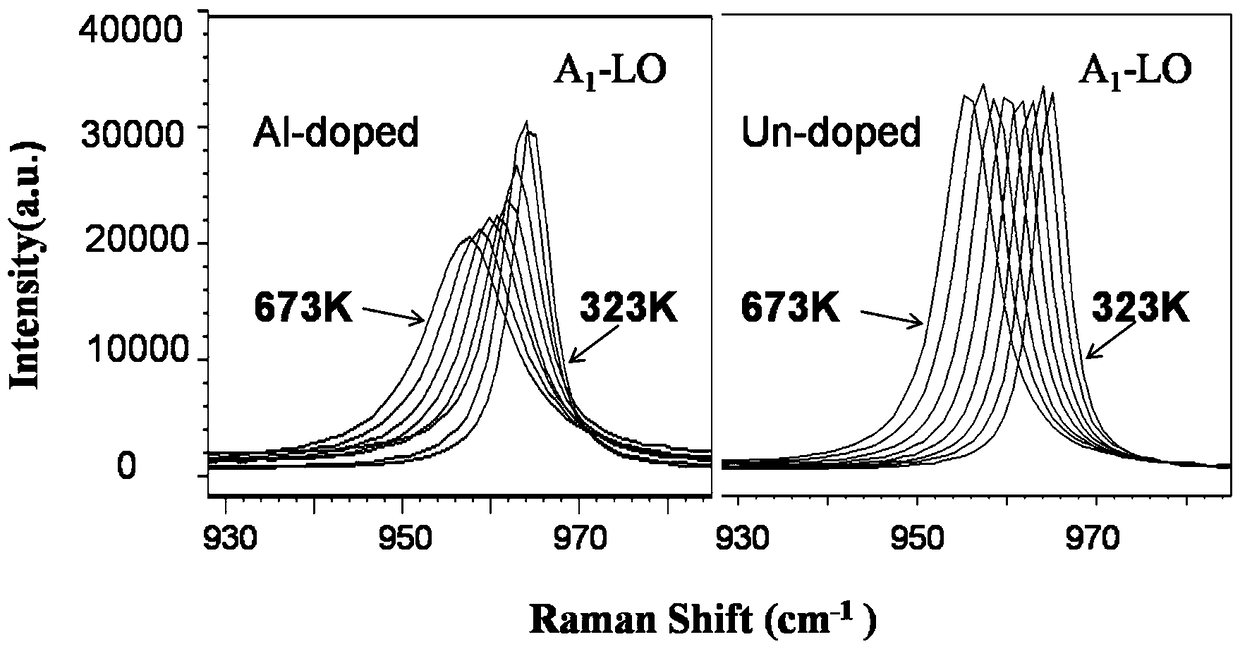

A nondestructive evaluation of p-type silicon carbide crystals

InactiveCN109065466ANo damageNo dimensions requiredSemiconductor/solid-state device testing/measurementP type siliconWafer Product

The invention relates to a non-destructive judgment of p-type silicon carbide crystal, which uses a variable temperature Raman spectrum to carry out spectral measurement on a p-type silicon carbide crystal sample, wherein the incident direction of the detection light is along the (000-1) direction of the silicon carbide wafer, the variable temperature measurement is a temperature range from room temperature to 800 K, and the temperature interval is 50 K. By analyzing and comparing the carrier-sensitive A1 longitudinal optical modes, whether the sample is p-type doped or not can be determined according to the change of the intensity and the peak position of A1 longitudinal optical modes. As the spectroscopic analysis method is adopt, carrier concentration of p-type silicon carbide crystal can be measured and analyzed without electrodes plated like Hall measurement. The detection process can be automated and programmed. The outgoing products can be inspected comprehensively. The detection process can also be used in the inspection of 2, 3, 4, 6 inches wafer products in the market.

Owner:NANTONG UNIVERSITY

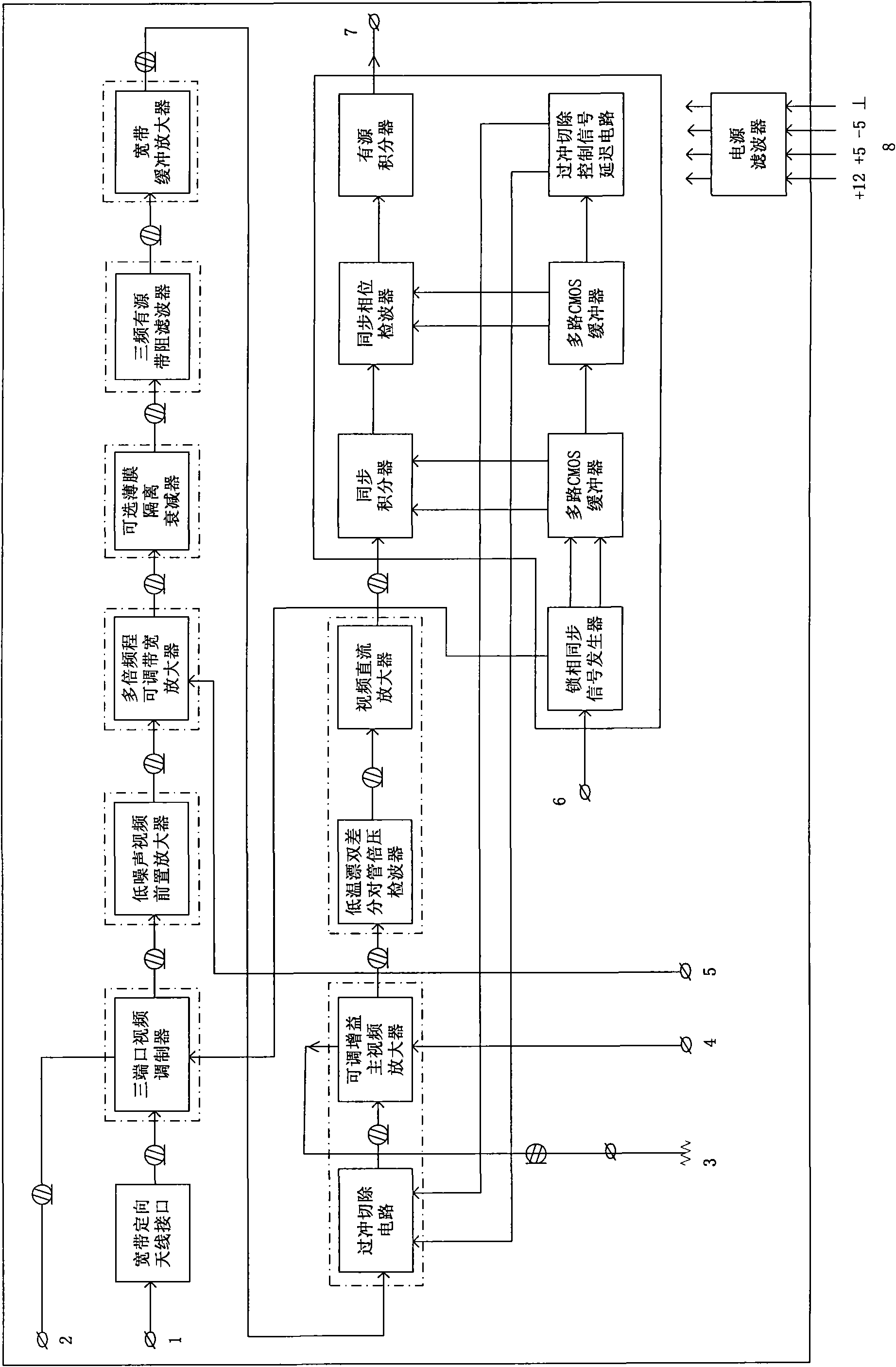

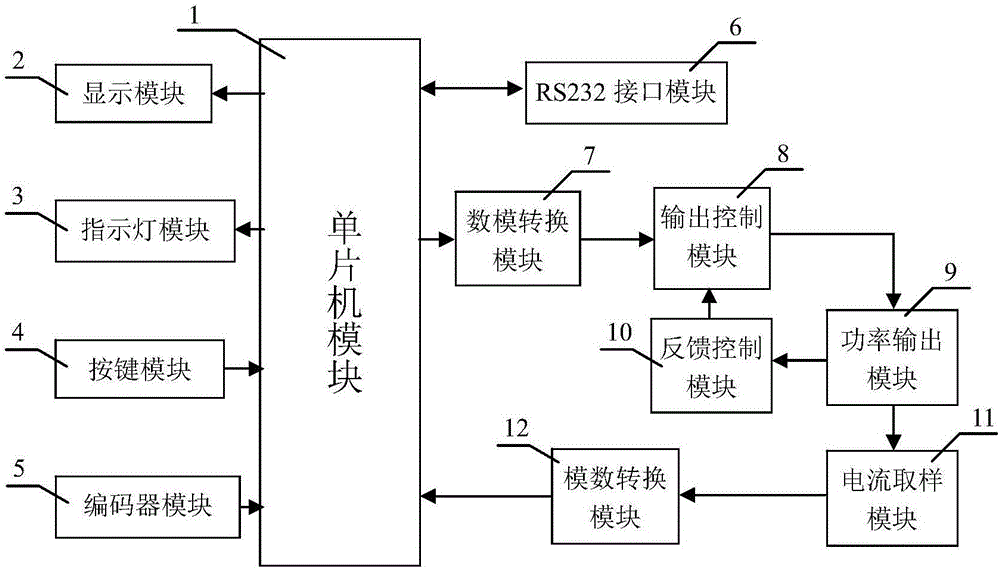

Digital bidirectional constant current source

The invention belongs to the technical field of electronic equipment, and provides a digital bidirectional constant current source. The digital bidirectional constant current source structurally comprises an output control module (8), a power output module (9), a feedback control module (10) and a front panel (13), and is characterized by further structurally comprising a single chip microcomputer module (1), a display module (2), an indicator light module (3), a key module (4), an encoder module (5), an RS232 interface module (6), a digital-to-analog conversion module (7), a current sampling module (11) and an analog-to-digital conversion module (12). The digital bidirectional constant current source is based on control of a single chip microcomputer, and has the advantages of rich function, high convenience in upgrading, high programmable controllability, and the like, and has the function of controlling both analog negative feedback and digital negative feedback, high stability and wide application occasions.

Owner:JILIN UNIV

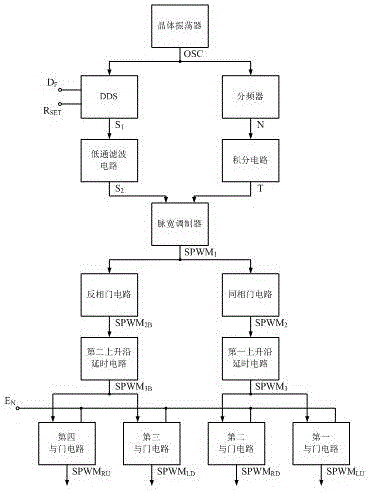

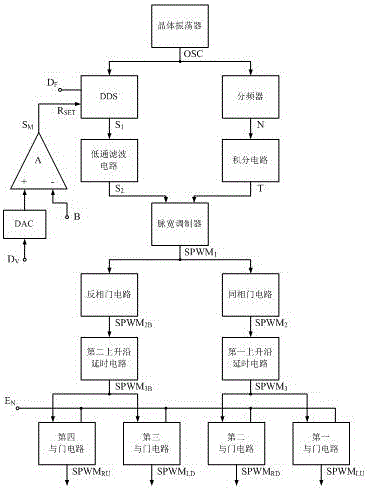

spwm signal generating circuit based on direct digital frequency synthesizer

ActiveCN104617931BSmall distortionAchieve stabilizationPulse duration/width modulationEngineeringVIT signals

The invention provides an SPWM signal generation circuit based on a direct digital frequency synthesizer. The SPWM signal generation circuit adopts the direct digital frequency synthesizer to generate sine-wave signals of a SPWM circuit, combines the synthesizer with triangular wave signals generated by an integral circuit, obtains bipolar SPWM signals through natural sampling, enables the distortion of the inverted restored sine-wave signals to be minimum, overcomes the defects that SPWM signals are generated by adoption of pure artificial circuits and pure software programming in the prior art by utilization of the characteristics of the direct digital frequency synthesizer, remains the advantages of the pure artificial circuits and the pure software programming in the prior art, enables the output SPWM signals to meet the technical requirements that the wave form distortion is low, the accuracy of the frequency and amplitude of signals is high, the adjustable range of the signal frequency is large, the stability is good and the frequency resolution is small, and effectively helps the development of the performance of the SPWM application technology.

Owner:重庆希诺达通信有限公司

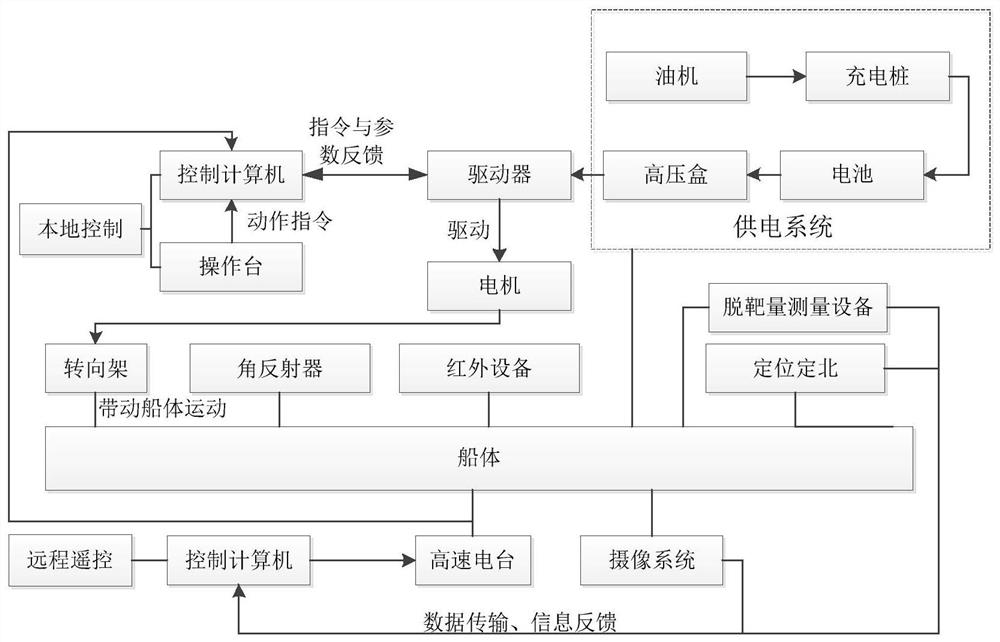

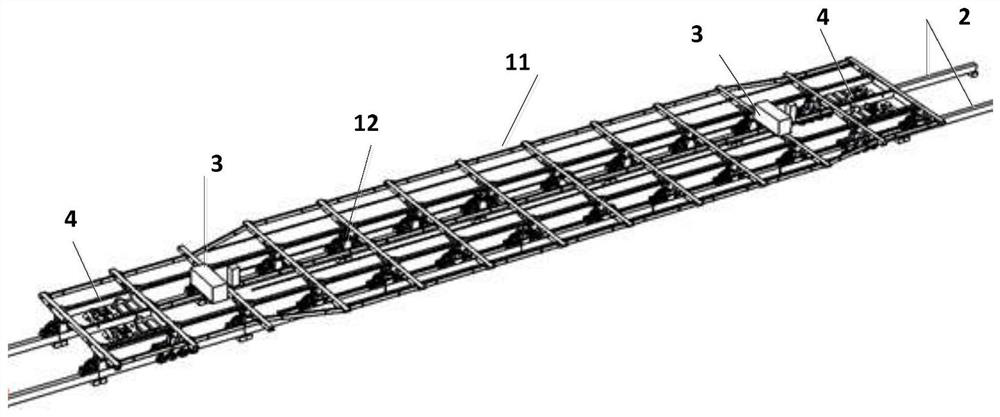

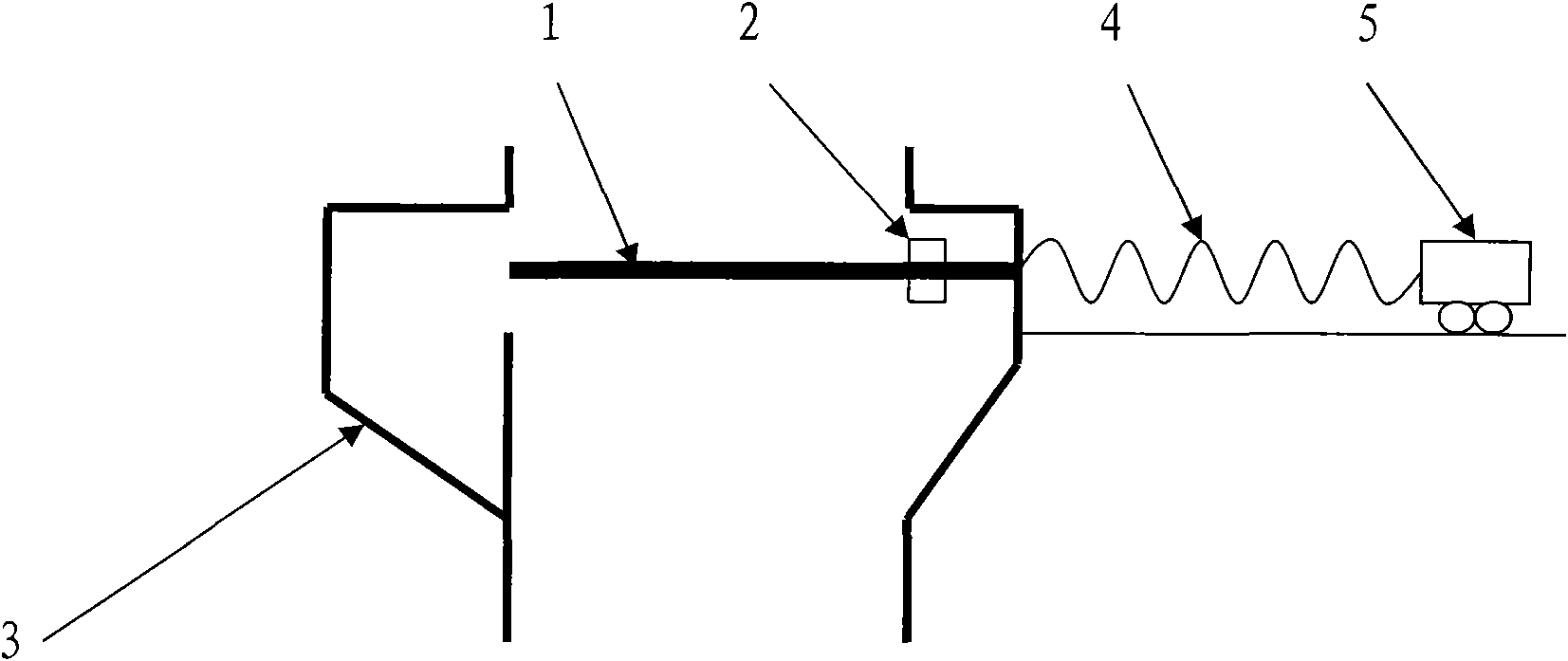

Land ship system for simulation test

ActiveCN112706884AReal motion characteristicsRealistic simulation of motion characteristicsAmmunition testingWaterborne vesselsHullTest preparation

The invention aims to overcome the defects in the prior art, and provides a land ship system for a simulation test, which is used for simulating the motion characteristics of a target ship on the land, and comprises a control subsystem and a land ship subsystem in signal connection with the control subsystem, the control subsystem is used for controlling the operation of the land ship subsystem and receiving the feedback of the land ship subsystem; and the land ship subsystem is used for realizing simulation of a target ship according to the command of the control subsystem. A land ship for simulating the target ship is arranged on the land, so that the land ship can be separated from the water environment for testing, does not need to coordinate a test water area and block the water surface, is relatively small in test preparation and coordination workload, is easy to recover the ship body, and can flexibly travel on the land at a high speed according to a preset track through the control subsystem; and the motion characteristics of the target ship are truly simulated.

Owner:NANJING CHANGFENG AEROSPACE ELECTRONICS SCI & TECH

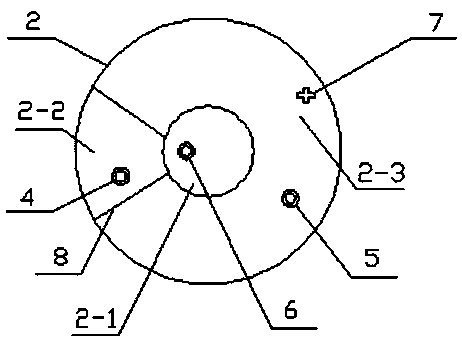

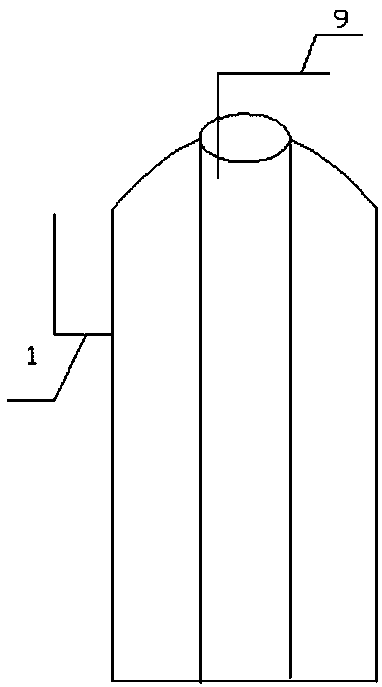

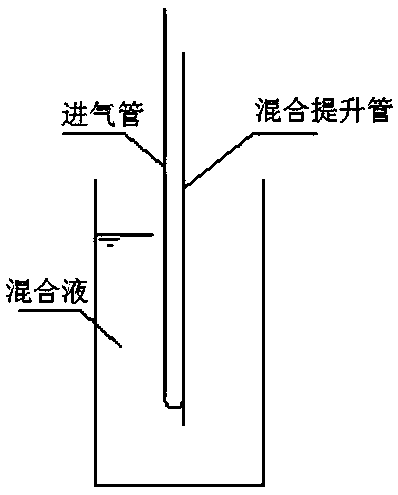

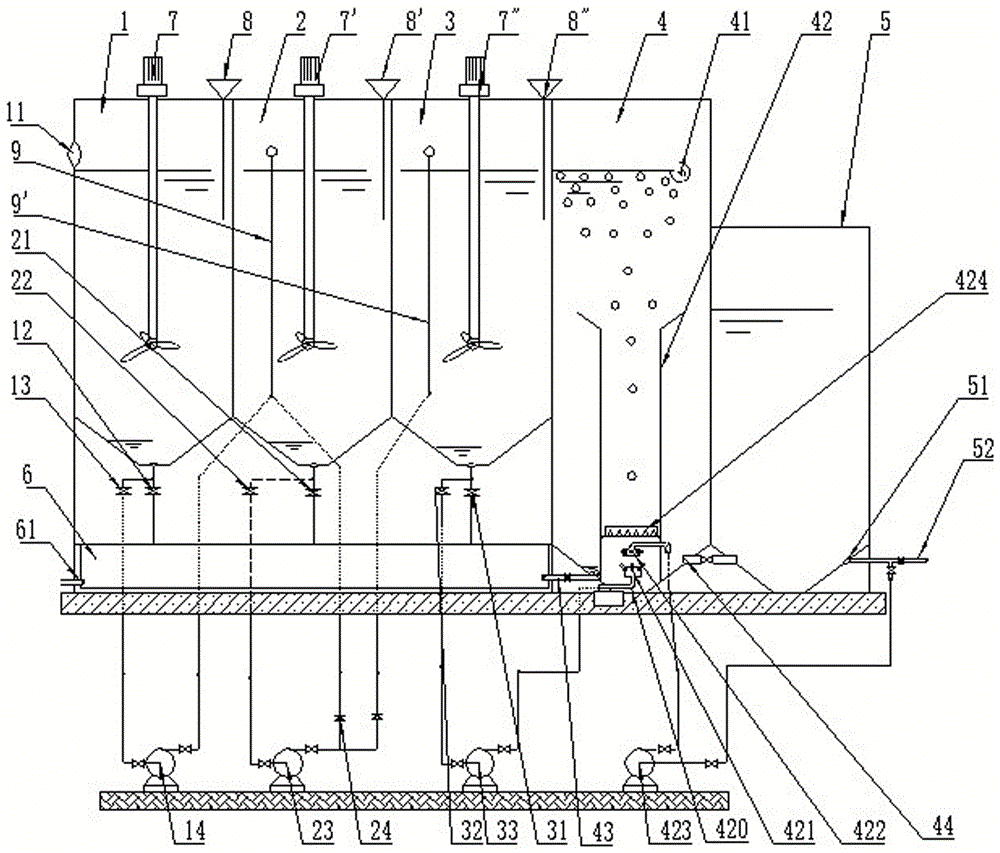

Air pump driven sewage reactor based on program control, and treatment method thereof

PendingCN110127954AMeet emission standardsSolve the technical needs of near-zero maintenanceWater treatment parameter controlSpecific water treatment objectivesPipingSewage

The invention discloses an air pump driven sewage reactor based on program control, and a treatment method thereof. The air pump driven sewage reactor comprises a water inlet tube, a sewage treatmentreactor, a PLC control cabinet and a water outlet tube, wherein an air pump and a PLC are arranged in the PLC control cabinet; the air pump is divided into a first air lifting tube, a second air lifting tube, a third air lifting tube and an aeration tube from the PLC control cabinet, and each air pipeline is opened by a PLC controlled solenoid valve; the sewage treatment reactor comprises an innercylinder and an outer cylinder, the inner cylinder is provided with a outlet water disinfecting zone, and the outer cylinder is divided into a water inlet zone and a main reaction zone by a partitionplate; a high liquid level gauge, a low liquid level gauge and the first air lifting tube are arranged in the water inlet zone; a bio-filler, the second air lifting tube and the aeration tube are arranged in the main reaction zone; a disinfecting tablet basket and the third air lifting tube are arranged in the outlet water disinfecting zone; and the water inlet tube is connected with effluent water from a septic tank, and is connected with the water inlet zone. The technical requirement of near zero maintenance of a small volume of sewage is met in the invention.

Owner:HARBIN INST OF TECH

A high-voltage, high-power, variable-frequency, adjustable constant-voltage source

ActiveCN102955486BIncrease output powerLarge adjustment rangeElectric variable regulationSignal processing circuitsLow voltage

The invention relates to a high-voltage large-power frequency conversion adjustable constant voltage source which comprises a signal generator and N signal processing circuits, wherein power sources for inner components of any two signal processing circuits are not grounded; each signal processing circuit is composed of a digital isolation switching circuit and a power amplifier module; a signal generated by the signal generator is synchronously output to all the signal processing circuits; after the signal is firstly processed by the digital isolation switching circuits of all the signal processing circuit, N high-precision isolated low-voltage alternate current signals are output, wherein N is an integer which is not less than 1; all the low-voltage alternating current signals are the same in amplitude, frequency and phase, and the amplitude and frequency of all the low-voltage alternating current signal can be synchronously adjusted; and all the low-voltage alternating current signals are output to the corresponding power amplifier modules treatment be amplified; and output ends of N power amplifier modules are sequentially connected in series so as to be utilized as the total output of the constant voltage source. The constant voltage source provided by the invention has the advantages that the output voltage and power accuracy is high, and the amplitude regulating range is large.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Sundry separating device

InactiveCN102366744AIncrease cleaning driveGuaranteed continuitySievingScreeningPower stationEngineering

The invention discloses a sundry separating device, which comprises a bar screen, a clearing mechanism, a shell, a transmission screw rod and an electric executing device, wherein the shell of the sundry separating device is formed by deforming a material flow channel, and is partitioned into two parts; a clearing region is formed inside the material flow channel; one side of the channel is provided with a sundry storage region; the bar screen is arranged on the upper part of the shell; the clearing mechanism is arranged on one side of the bar screen, and is connected with the transmission screw rod; and the transmission screw rod is connected with the electric executing device. When the electric device is used for driving the screw rod to rotate, the screw rod is used for driving the clearing mechanism sleeved on the comb-shaped screen to move horizontally, the clearing mechanism is used for pushing sundries hung on the screen to the sundry storage region, the screw rod rotates reversely, the clearing mechanism returns to the original position, the screen is used for continually intercepting sundries, and the previous process is repeated when sundries are accumulated to a certain degree. The sundry separating device can be widely applied to industries such as firepower power stations, metallurgy, coal mines, sewage treatment and the like.

Owner:CHINA PETROCHEMICAL CORP +1

Coal bed gas radio spectrum direction-finding early warning system

InactiveCN101806228BGood for direction findingImprove discriminationSurveyMining devicesEarly warning systemFrequency spectrum

The invention discloses a coal bed gas radio spectrum direction-finding early warning system. A radio astronomy modulation radiation receiving system is used to receive gas radio steady state and unsteady state radiation temperature signals in a gas enriched region in a coal bed so as to indirectly measure the coal bed gas pressure; a radio astronomy full-power radiation receiving system is used to receive gas radio unsteady state and quickly variable radiation intensity and form signals in the gas enriched region in the coal bed so as to judge the gas radio radiation type and variation rate; and a radio astronomy spectrum radiation receiving system is used to receive gas radio unsteady state and quickly variable radiation spectrum peak and frequency drift in the gas enriched region in the coal bed so as to early warn the coal gas outburst. Due to the fit of the maximum values of the three signals under different antenna bearings and elevations, and the trigonometry measurement, the direction and normal distance of the gas enriched region are measured.

Owner:南京紫淮矿用电子高科技有限公司 +2

High Precision Adjustable Electronically Controlled Equalization Circuit for CATV Network

ActiveCN108200368BImprove frequency response characteristicsImprove featuresImpedence matching networksTelevision system detailsSignal waveElectrical connection

A high-precision adjustable electronically controlled equalization circuit for a cable television network, comprising one or more basic electronically controlled equalization modules with adjustable slopes, characterized in that it also includes a control module and one or more compensation modules, the control The module is electrically connected with the basic electronic control equalization module for controlling the slope change of the basic electric control equalization module, and the control module is electrically connected with the compensation module for generating a compensation signal according to the slope change of the basic electric control equalization module. The output of the equalization module is electrically connected to the input of the compensation module for outputting a complete signal after the two are superimposed. The high-precision adjustable electronically controlled equalization circuit of the cable TV network can obtain good signal waveform flatness at every slope.

Owner:APPLIED OPTOELECTRONICS INC

Pretreatment equipment for high concentration cutting fluid sewage

ActiveCN104843905BSatisfy the water quality conditionsImprove processing efficiencyMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationHigh concentrationFlocculation

The invention discloses high-concentration cutting liquid sewage pretreatment equipment, which comprises a demulsification pool, wherein one side of the demulsification pool is provided with a water inlet; the other side of the demulsification pool is sequentially provided with a chemical oxidation pool, a flocculation pool, an air floatation pool and a clean water pool; a mud residue collecting pool is arranged right under the demulsification pool, the chemical oxidation pool and the flocculation pool. The high-concentration cutting liquid sewage pretreatment equipment has the characteristics of reasonable structure, compact layout and good treatment effect; by aiming at the characteristics of ultrahigh concentration and little sewage quantity of metal processing cutting liquid, combined equipment integrating treatment technologies such as demulsification, chemical oxidation, flocculation, air floatation and residue discharging is adopted; the continuous operation can be adopted, and the intermittent batch operation can also be adopted; the metal processing high-concentration cutting liquid sewage can be effectively treated; therefore on one hand, the production cost of enterprises can be reduced, and on the other hand, the environment can be protected to the greatest degree, so that the environment pollution is reduced.

Owner:ZHEJIANG HONGDIAN ENVIRONMENTAL PROTECTION & TECH CO LTD

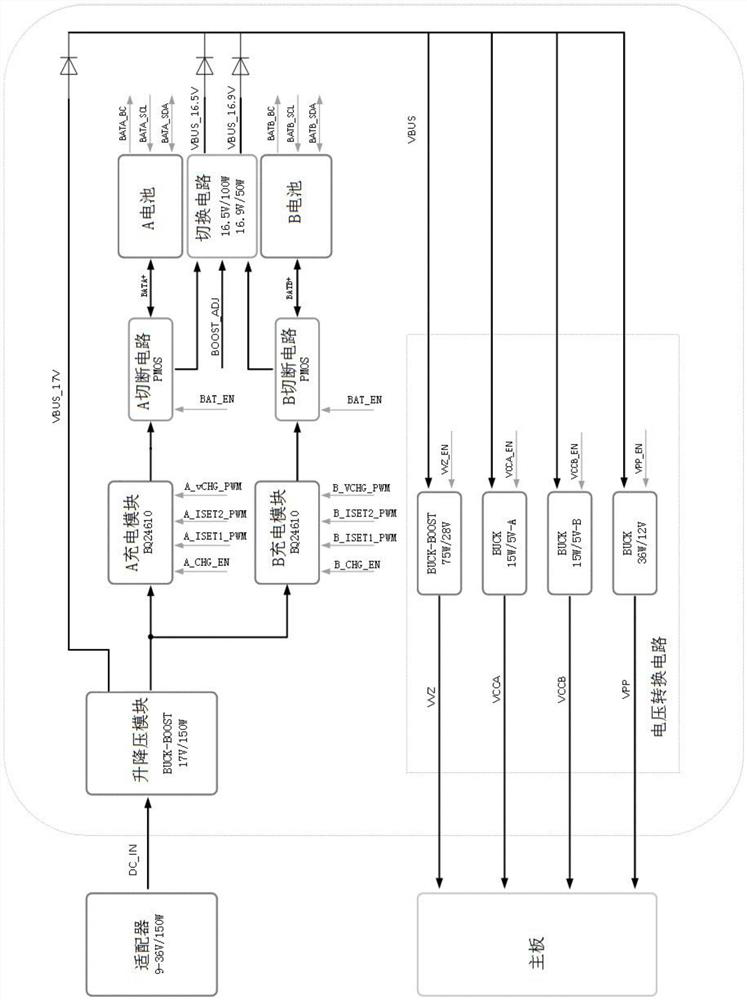

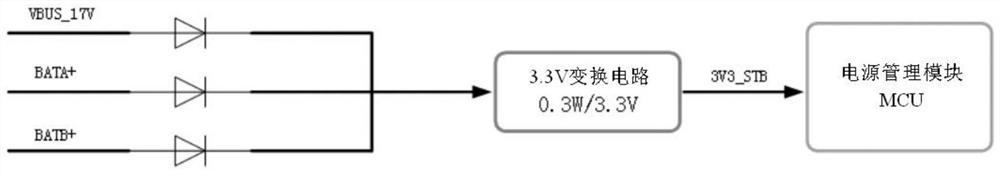

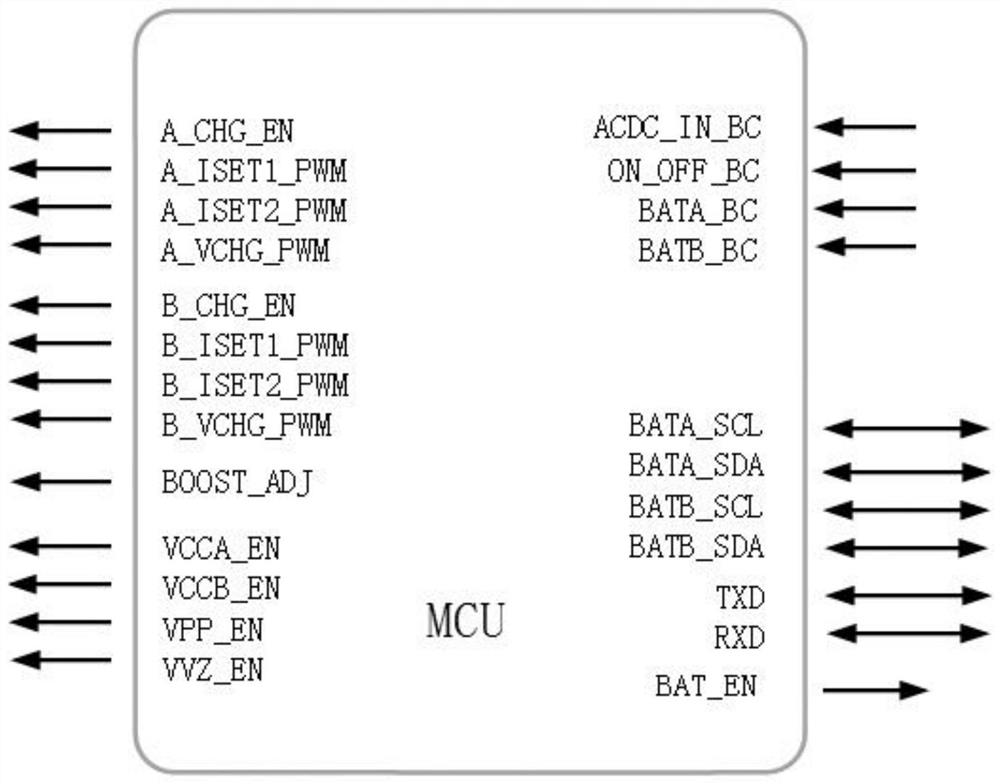

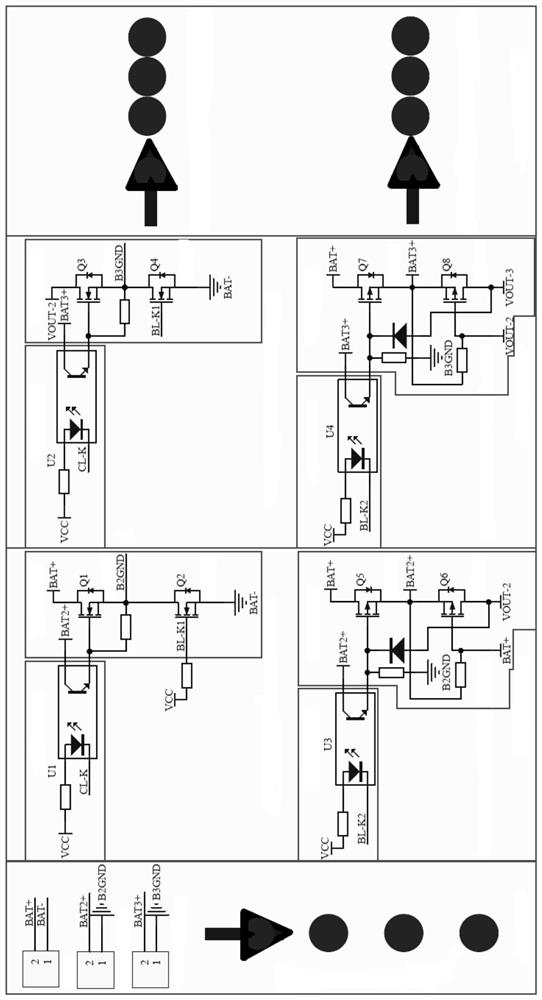

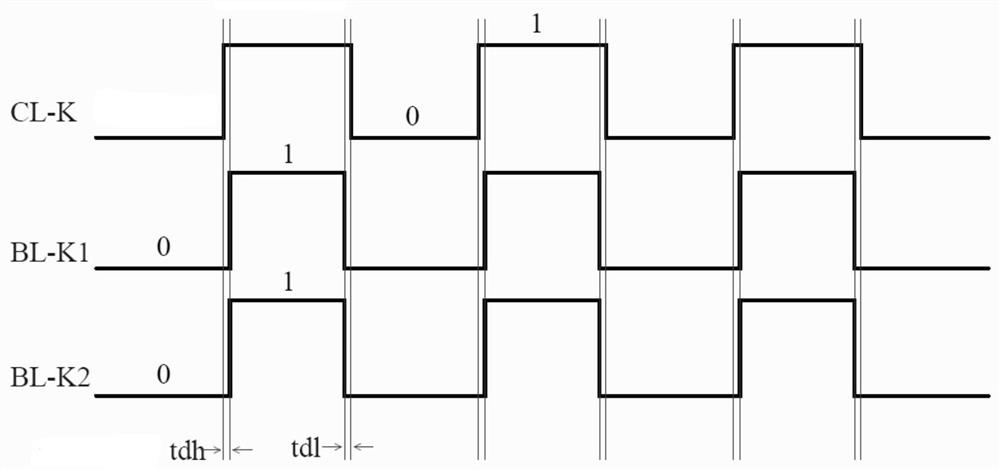

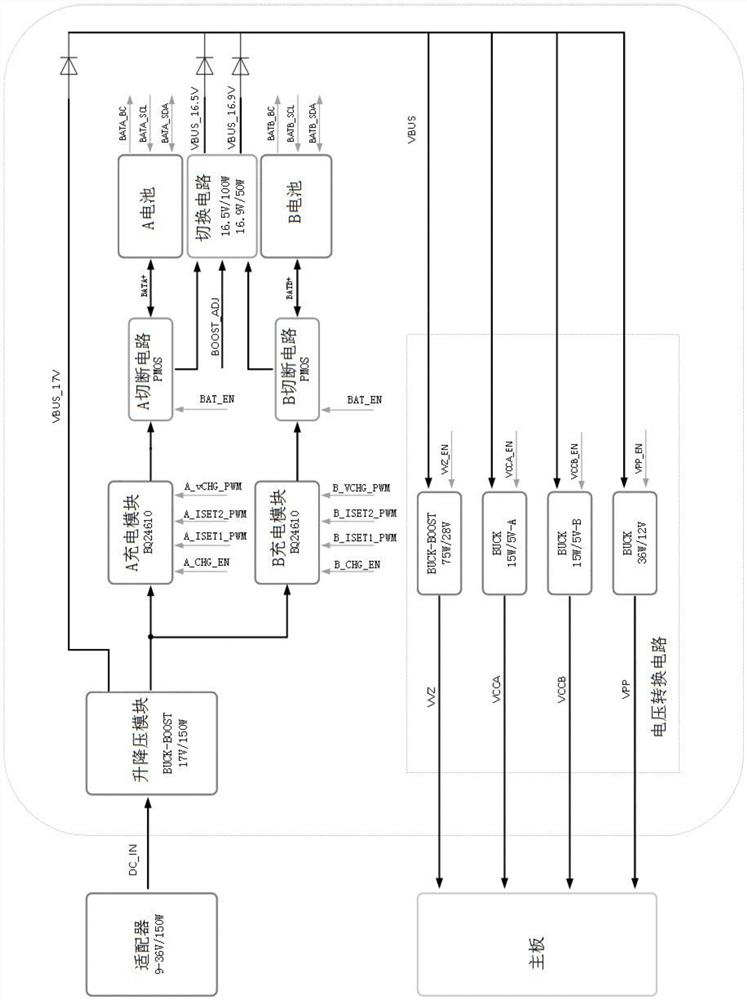

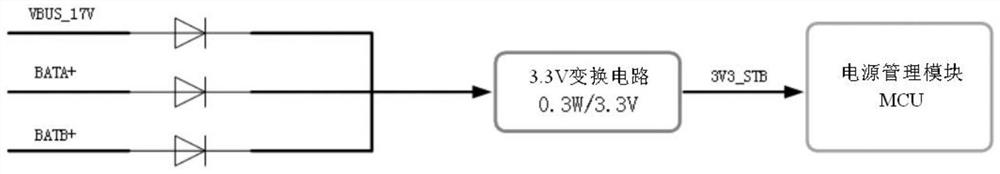

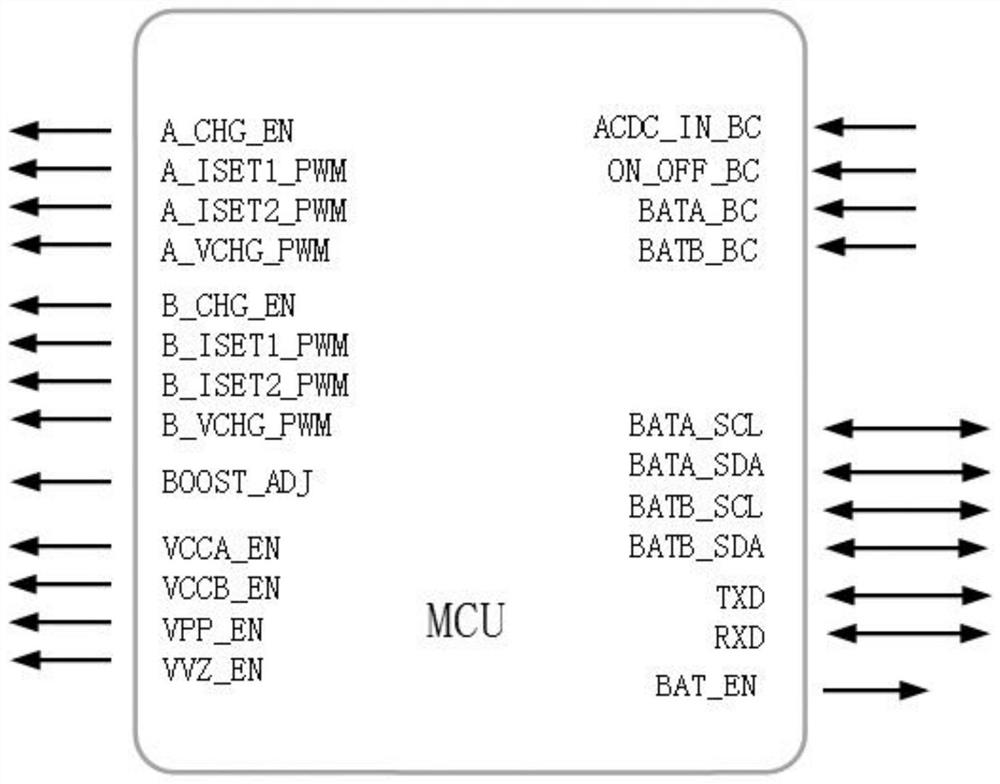

Dual-battery switching structure of portable general life support system adapted to field environment

ActiveCN113328496AAchieving charging currentProgrammable voltageCircuit monitoring/indicationDifferent batteries chargingControl engineeringSingle chip

The invention discloses a dual-battery switching structure of a portable general life support system adapted to a field environment, and the structure comprises a buck-boost module electrically connected with an external adapter, and a charging module A and a charging module B for charging a fixed battery A and a detachable battery B. The output ends of the fixed battery A and the detachable battery B are connected with a switching circuit; the output end of the switching circuit and the output end of the buck-boost module are connected with the input end of the main power supply branch and the input end of the single-chip microcomputer power supply branch, and the output end of the main power supply branch is connected with a mainboard of the portable general life support system to supply power to the portable general life support system. The output end of the single-chip microcomputer power supply branch circuit is connected with a power management module used for controlling the charging module A, the charging module B, the switching circuit and the main power power supply branch circuit to work coordinately. According to the invention, dynamic distribution of system power can be realized, power is provided to the system to supply power to the maximum, and charging power does not need to be reserved, so continuous work of the portable general life support system in a field environment is effectively guaranteed.

Owner:SANHE KEDA IND +1

Electronic proportioning valve and control system

PendingCN114151399ASimple structureHigh control precisionFluid-pressure actuator testingServomotor componentsControl systemEngineering

The invention discloses an electronic proportioning valve. The electronic proportioning valve comprises a proportioning valve body, the proportional valve body comprises a valve body and a conical upper cover; an air inlet cavity and an air outlet cavity which are communicated with each other are formed in the valve body; a valve element assembly used for controlling the opening degree of the valve body is arranged between the air inlet cavity and the air outlet cavity. A bottom cover is connected to the bottom of the valve body in an embedded mode. The valve element assembly is elastically installed on the bottom cover. A piston cavity is formed in the top of the valve body; a piston is arranged in the piston cavity in a sliding manner; one end of the valve element assembly extends into the piston cavity and is connected with the piston in an abutting mode. A pre-pressing device used for adjusting the preset threshold value of the piston is arranged in the upper cover. The side end of the upper cover is provided with an air valve with an air inlet or air outlet function; the outer side wall of the valve body is provided with a barometer used for detecting the pressure of gas in the gas outlet cavity. The electronic proportioning valve is simple in structure and high in control precision, stepless adjustment of pressure can be achieved, and the impact phenomenon during reversing of a switch type air valve is avoided.

Owner:广东鑫太自动化设备有限公司

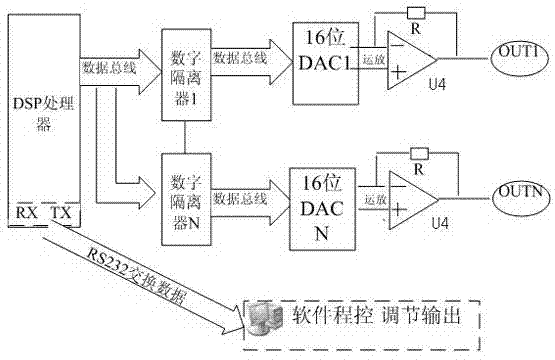

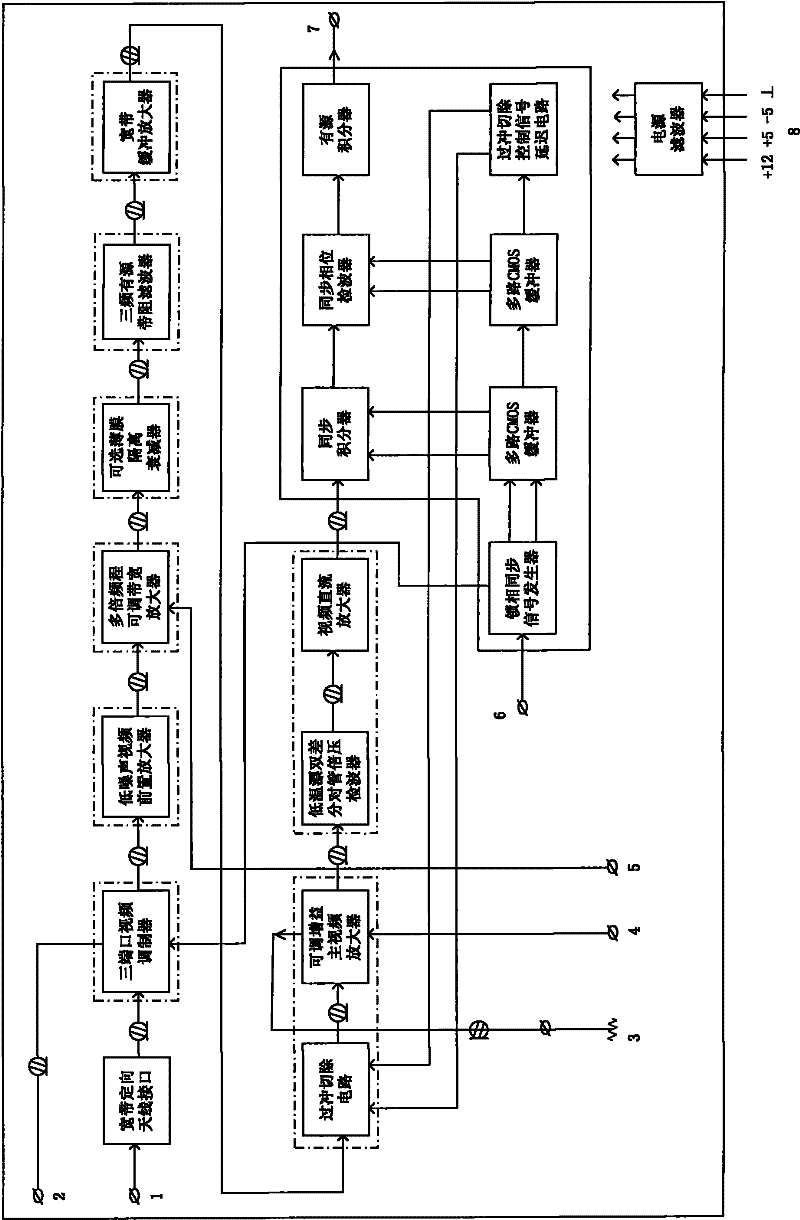

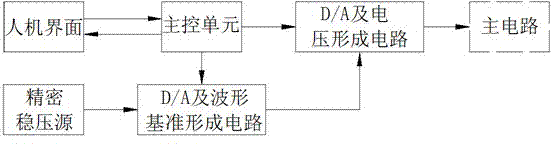

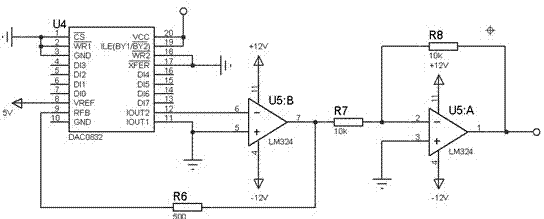

Simulated voltage generation device for inverter grid-connection experiment

InactiveCN104730299ARealize program controlElectrical measurement instrument detailsElectrical testingHuman–machine interfaceAddress generator

The invention provides a simulated voltage generation device for inverter grid-connection experiment. The simulated voltage generation device comprises a square-wave generator, a pre-value frequency divider, a phase-locked loop, a programmable address generator, a dual-port RAM, a main control unit, a D / A and voltage forming circuit, a D / A and waveform reference forming circuit, a precision voltage stabilization source, and a man-machine interface. The simulated voltage generation device is characterized in that a square-wave signal generated by the square-wave generator enters the pre-value frequency divider controlled by the main control unit and then enters the phase-locked loop controlled by the main control unit so as to generate a needed frequency signal which is then sent to the dual-port RAM by the address generator; a signal generated by the dual-port RAM enters the D / A and waveform reference forming circuit, and a waveform reference generated by the precision voltage stabilization source enters the D / A and voltage forming circuit so as to generate a needed voltage waveform; and the man-machine interface is connected with the main control unit, and comprises keys and a display.

Owner:XIAN XINWEI INFORMATION TECH

Battery for passive secondary circuit inspection source and battery management circuit

PendingCN111668907AImprove work efficiencyReduce equipment costElectric powerBattery overcharge protectionElectrical batterySecondary loop

The invention discloses a battery for a passive secondary circuit inspection source and a battery management circuit. The battery comprises a battery unit, a battery II switching unit, a battery III switching unit and a battery N switching unit, the working states from a battery I to a battery N comprise parallel connection and series connection; the switching is completed by the battery switchingunits; the battery unit comprises a plurality of batteries and battery packs; the circuit is suitable for a plurality of battery packs. The battery II switching unit comprises a battery II low-end B2GND parallel connection and series connection switching circuit and a battery II high-end BAT<2+> parallel connection and series connection switching circuit, wherein the parallel connection and series connection switching circuit of the battery II low-end B2GND comprises an isolation switch circuit and an N-type MOS tube half-bridge switching circuit, and the parallel connection and series connection switching circuit of the battery II high-end BAT<2+> comprises an isolation switch circuit and a P-type MOS tube half-bridge switching circuit. The requirement of current electrical equipment formulti-voltage power supply can be met, the working efficiency of the power supply equipment is improved, and the use cost of the equipment is reduced.

Owner:HANGZHOU PUAN TECH

Dual-battery switching structure of portable universal life support system adapted to field environment

ActiveCN113328496BRealize program controlImprove reliabilityCircuit monitoring/indicationDifferent batteries chargingMicrocontrollerControl engineering

The invention discloses a dual-battery switching structure of a portable universal life support system adapted to the field environment, including a buck-boost module electrically connected to an external adapter, and A charging modules and B charging modules for charging the fixed battery A and the detachable battery B respectively module, the output terminals of the fixed battery A and the removable battery B are connected with a switching circuit, and the output terminals of the switching circuit and the buck-boost module are connected with the input terminals of the main power supply branch and the single-chip microcomputer power supply branch, and the main power supply branch The output end of the circuit is connected to the main board of the portable general life support system to supply power for it, and the output end of the single-chip microcomputer power supply branch is connected to the power management module for controlling the A charging module, the B charging module, the switching circuit and the coordinated operation of the main power supply branch. The present invention can realize the dynamic allocation of system power, maximize the power supply to the system, and does not need to reserve charging power, thereby effectively ensuring the continuous work of the portable general life support system in the field environment.

Owner:SANHE KEDA IND +1

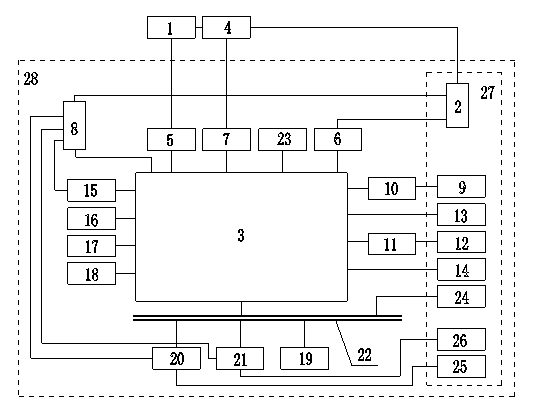

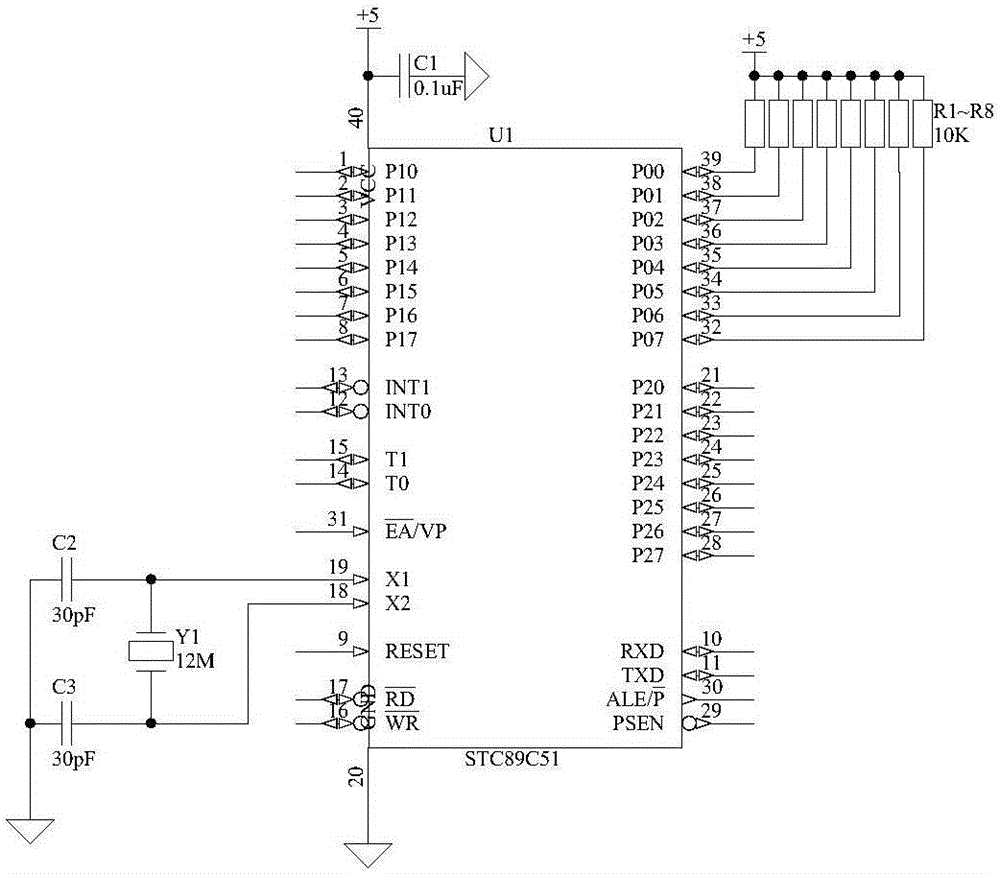

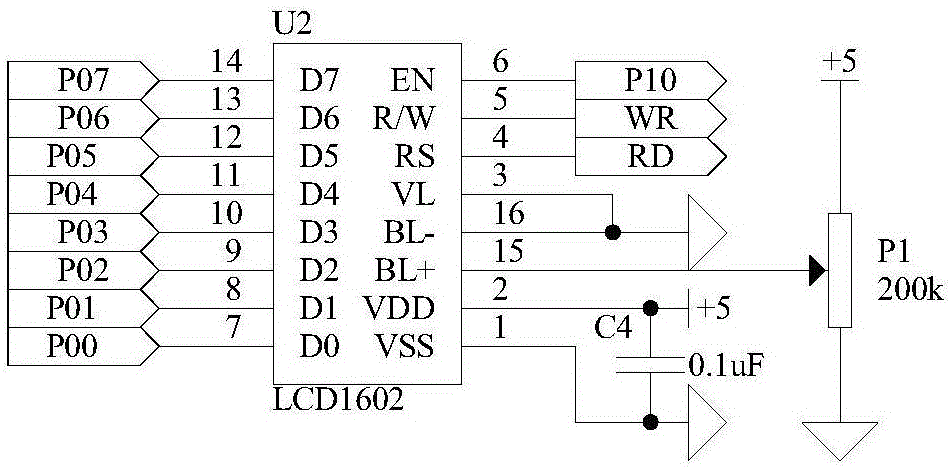

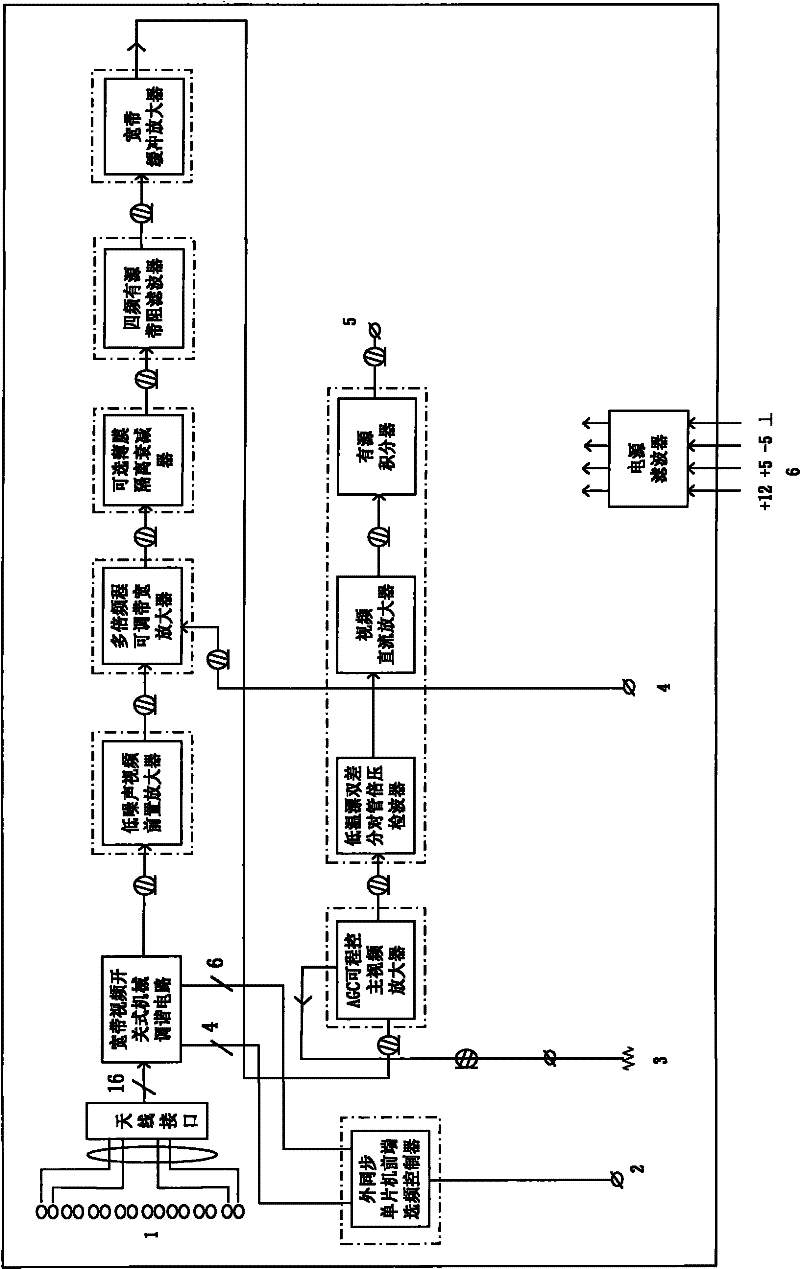

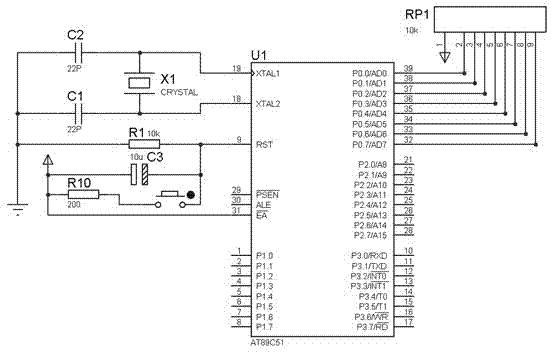

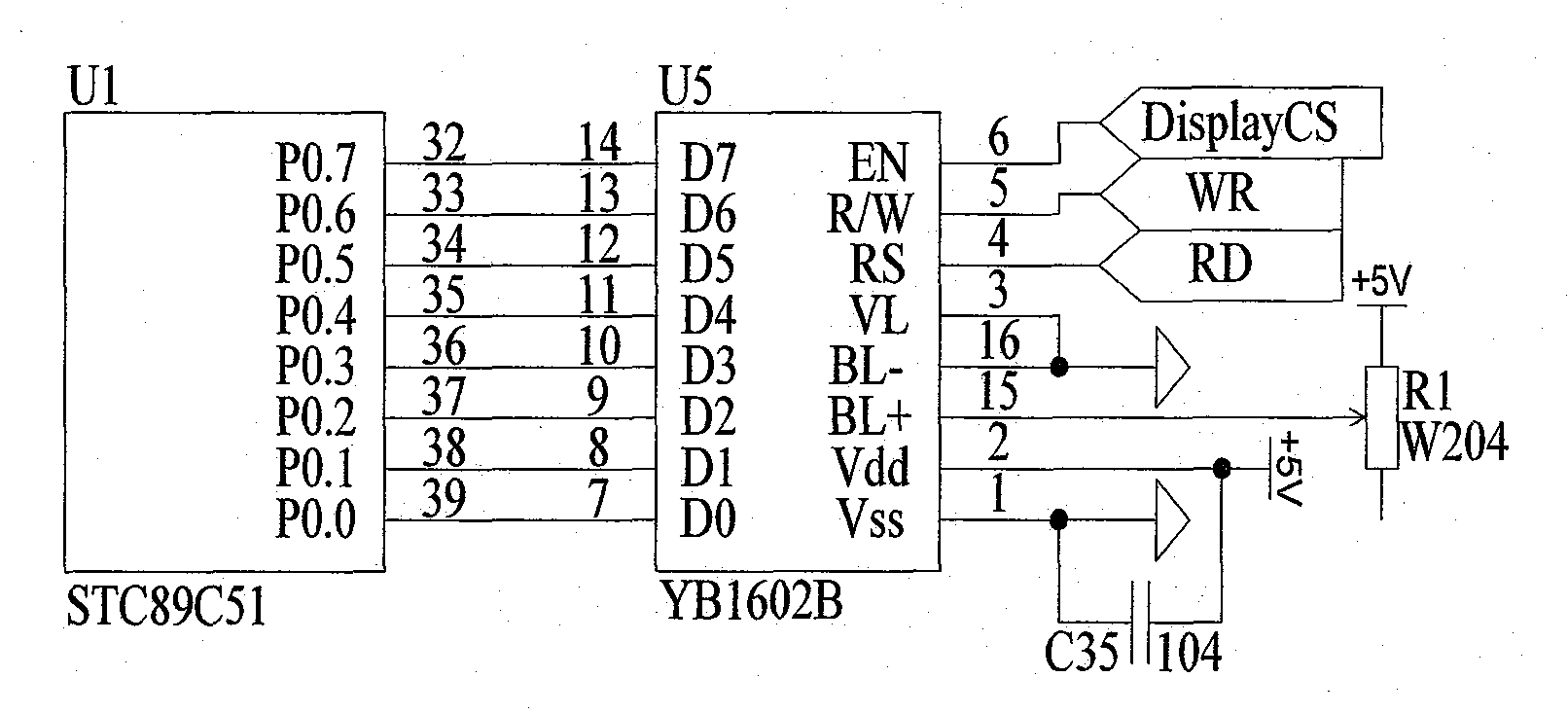

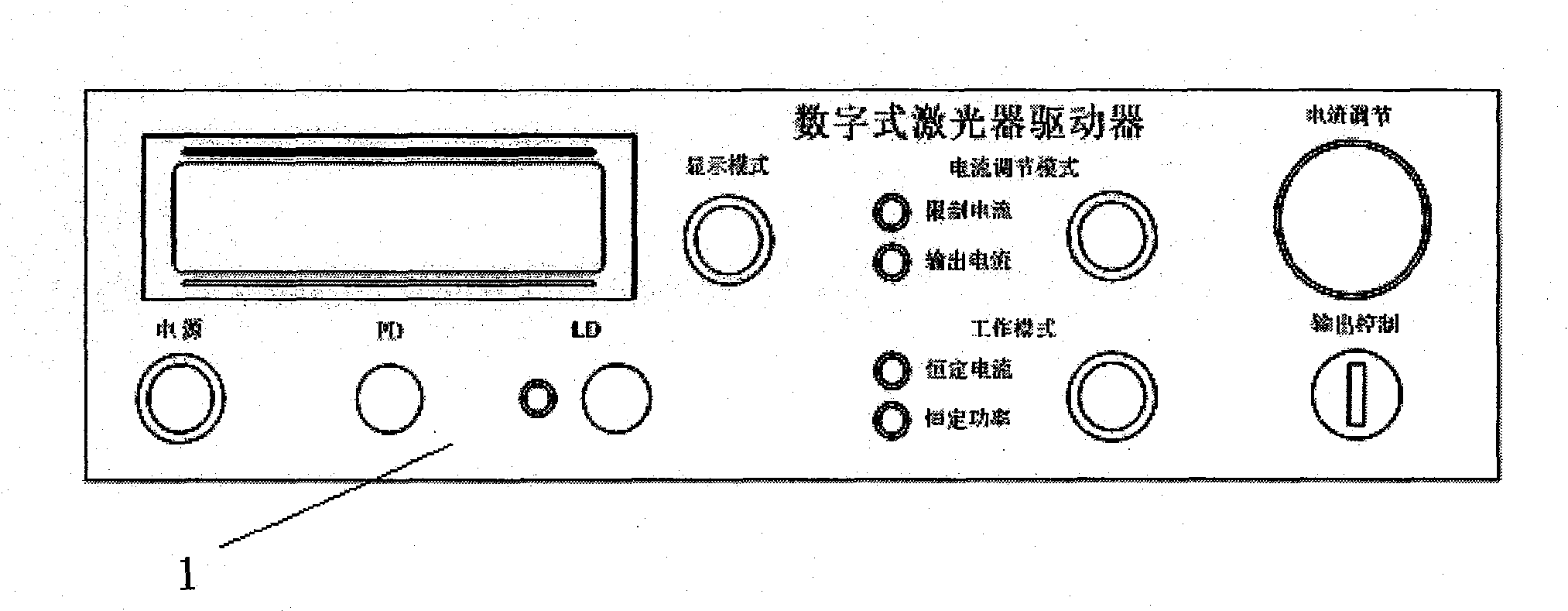

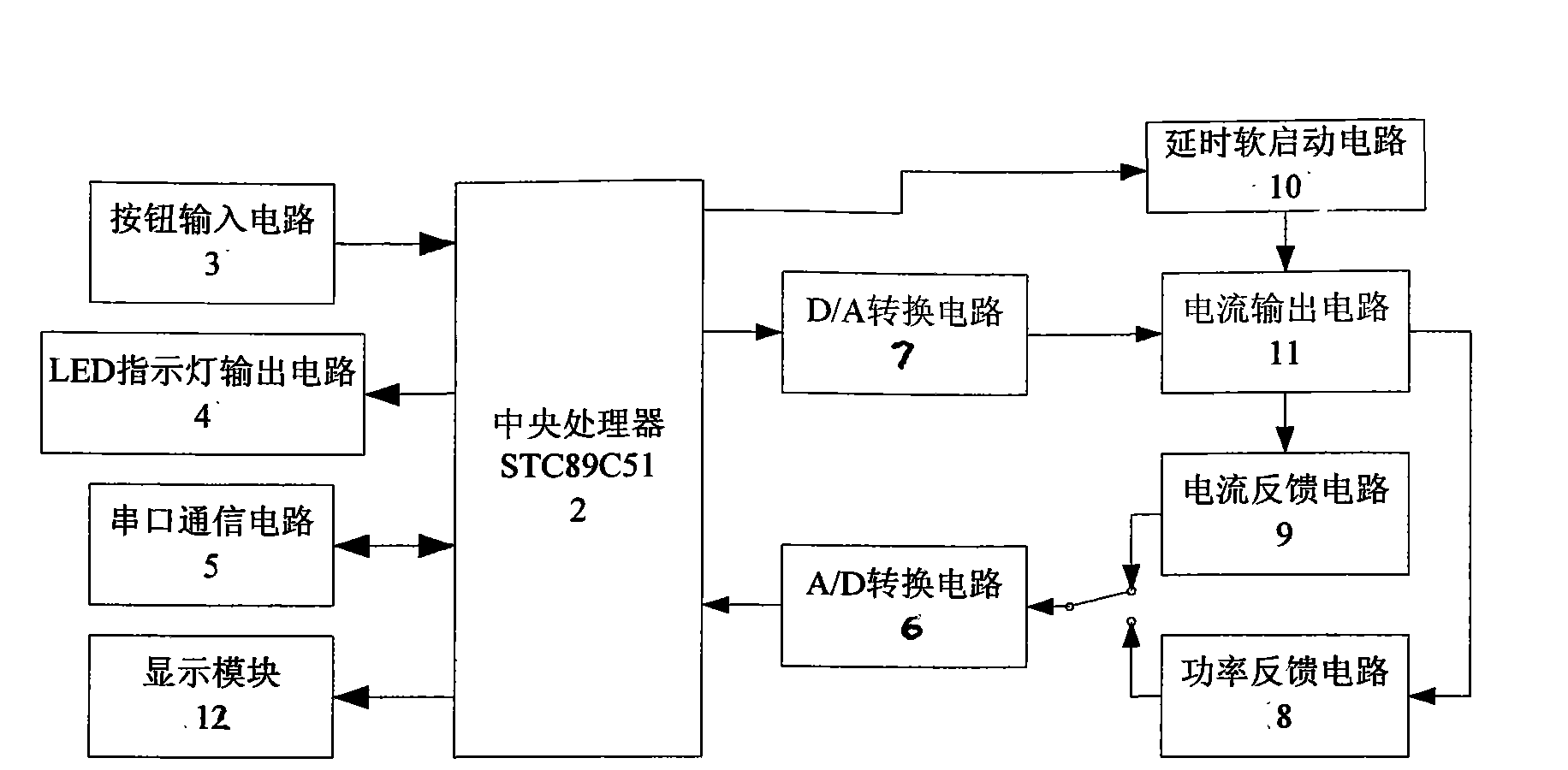

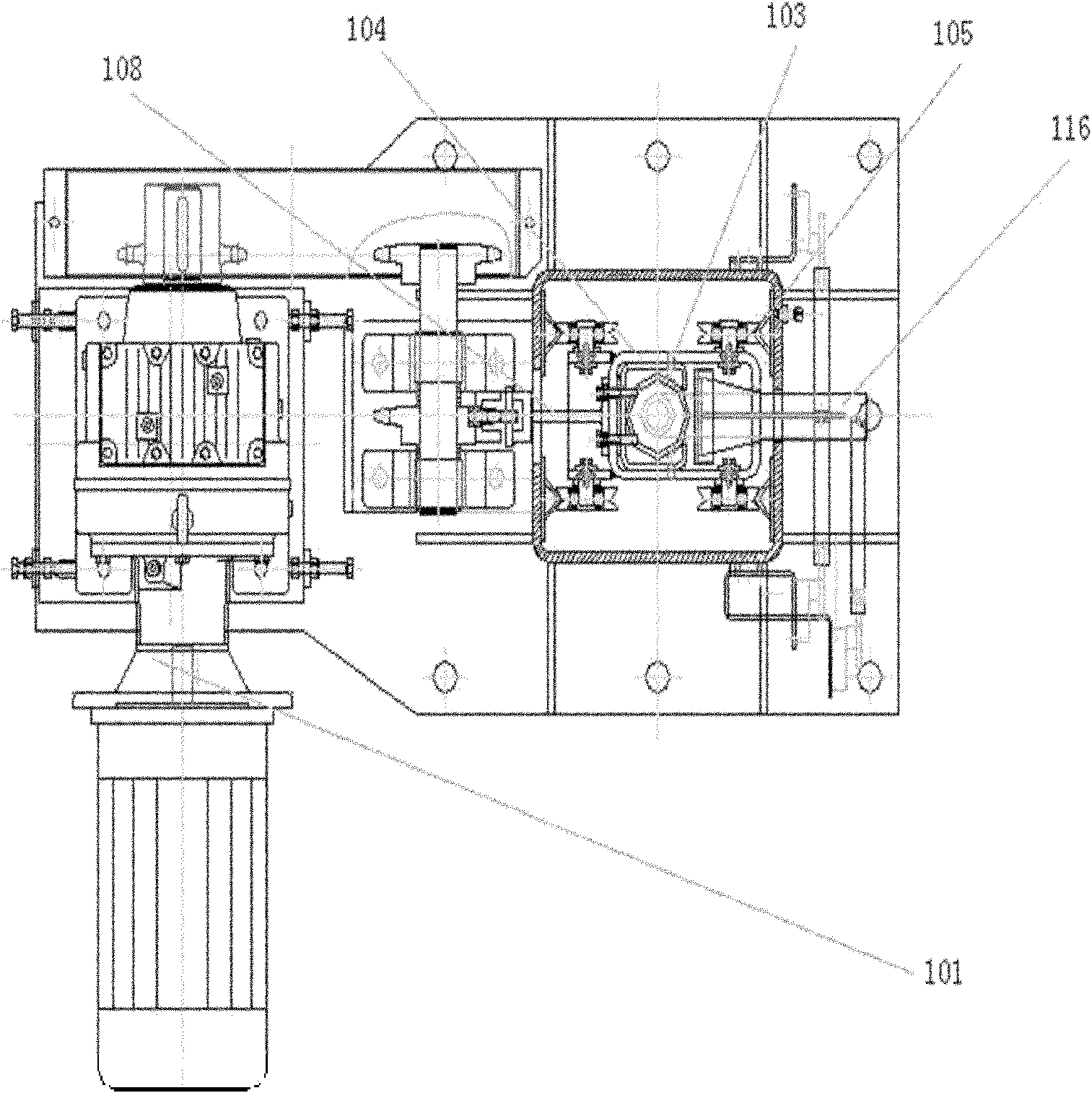

Constant current driver of digital semiconductor laser

InactiveCN101540476BProtection securityRealize program controlProgramme controlLaser detailsConstant powerTime delays

The invention relates to a constant current driver of a digital semiconductor laser, belonging to the technical field of electronic equipment. The structure of the constant current driver comprises a front panel (1), a central processing unit (CPU) STC89C51 (2), a button input circuit (3), an LED indicating lamp output circuit (4), a serial communication circuit (5), an A / D converting circuit (6), a D / A converting circuit (7), a power feedback circuit (8), a current feedback circuit (9), a time delay soft start circuit (10), a current output circuit (11) and a display module (12). The constant current driver has the output current of 0-2A, adopts negative feedback structure, effectively improves the output stability, and has the short-term stability being lower than 38ppm; two driving ways which are constant current and constant power are provided by the constant current driver, so that the constant current driver is convenient for use on different occasions; the constant current driver has the protecting functions such as current limitation, soft start, time delay and the like, so as to effectively guarantee the safety of the laser; and program can be controlled and upgraded in system.

Owner:JILIN UNIV

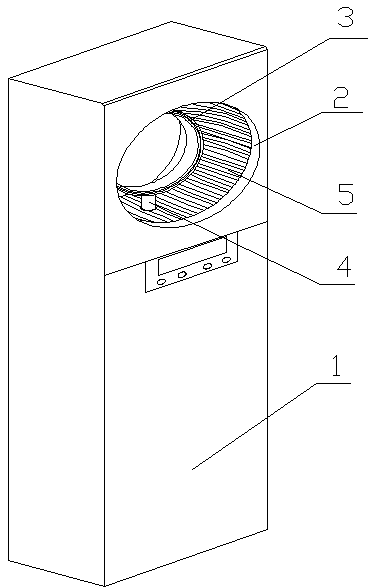

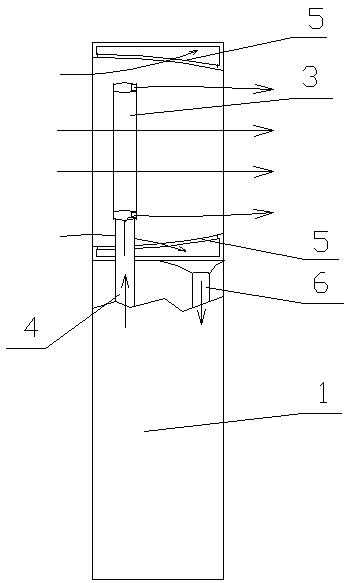

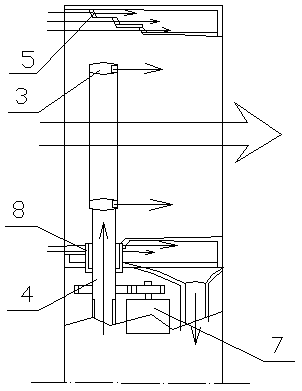

Inner air inlet wind tunnel air supply device

InactiveCN105736325BImprove air supply efficiencyEasy to moveJet pumpsPump installationsImpellerEngineering

An inward air inlet type air tunnel air supply device comprises an air tunnel. A connector connected with a host is formed in the bottom of the air tunnel, an air inlet is formed in the inner wall of the air tunnel and connected with an inner cavity of the air tunnel, and an air inlet pipe is arranged at the lower end of the inner cavity of the air tunnel. An air ring is arranged in the center of the air tunnel, and a high-pressure air outlet is formed in one side of the air ring. An air supply pipe, penetrating the inner wall of the air tunnel, in an inner cavity of the air ring is connected with a high-speed motor and an impeller which are arranged in the host. According to the inward air inlet type air tunnel air supply device, the air inlet is formed in the inner wall of the air tunnel, and when the air inlet works, air sucked into the position near the inner wall of the air tunnel serves as inflow air, flowing of the air in the air tunnel is increased, and the air supply efficiency of the air tunnel is improved; the air outlet is formed in the air tunnel rather than the inner wall of the air tunnel, so that on the one hand, the area of the air inlet is increased, and the amount of the air entering the high-speed motor is increased; and on the other hand, the air outlet is formed in the air tunnel, therefore, the air in the center of the air tunnel can flow better, a part of air between the inner wall of the air tunnel and the air ring can be utilized, and the air supply efficiency is improved.

Owner:张伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com