Programmable control valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

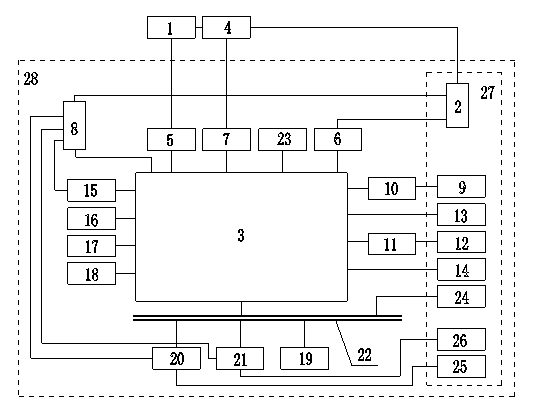

[0024] figure 1 It is a schematic diagram of the circuit structure of the present invention, and the present invention includes a valve main body 1, a power input terminal 2, a main processing unit 3, an actuator 4, an opening detection unit 5, a working state detection unit 6, a control conversion unit 7 and a power conversion unit 8 , the valve main body 1 is connected to the actuator 4 and the opening detection unit 5 respectively, the power input terminal 2 is connected to the actuator 4, the working state detection unit 6 and the power conversion unit 8 respectively, and the main processing unit 3 is respectively It is connected with the opening detection unit 5 , the working state detection unit 6 , the control conversion unit 7 and the power conversion unit 8 , and the actuator 4 is connected with the control conversion unit 7 .

[0025] The above-mentioned opening detection unit 5 is used to detect the switch state and the opening degree of the valve main body 1, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com