Robot system with visual servo and detection functions

A robot system and visual servo technology, applied in the field of robot systems, can solve the problems of low precision requirements of robot models, difficult to achieve integration, occupying production time, etc., and achieve the effect of improving motion control efficiency, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] This embodiment is a robot system with visual servoing and detection functions.

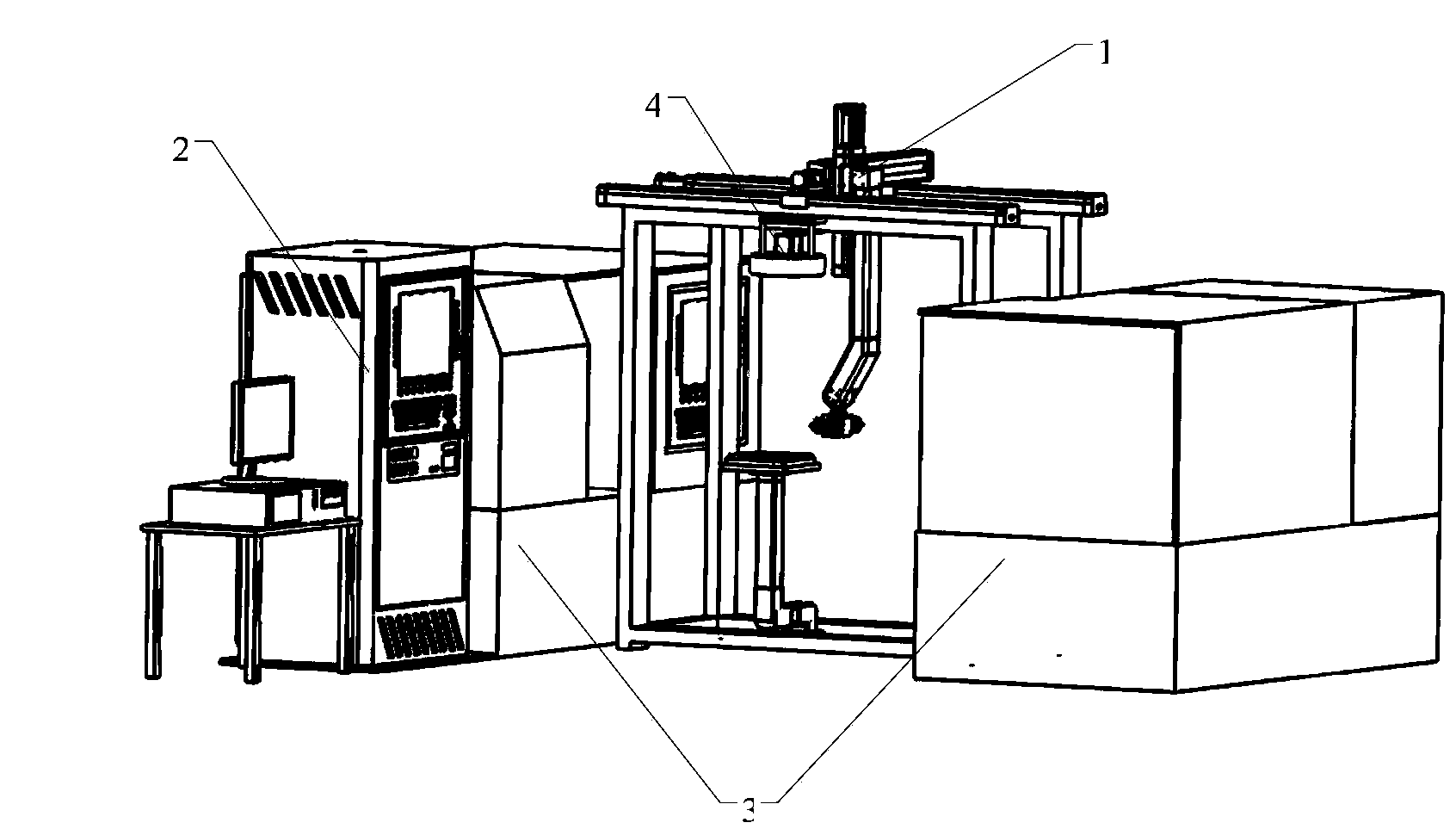

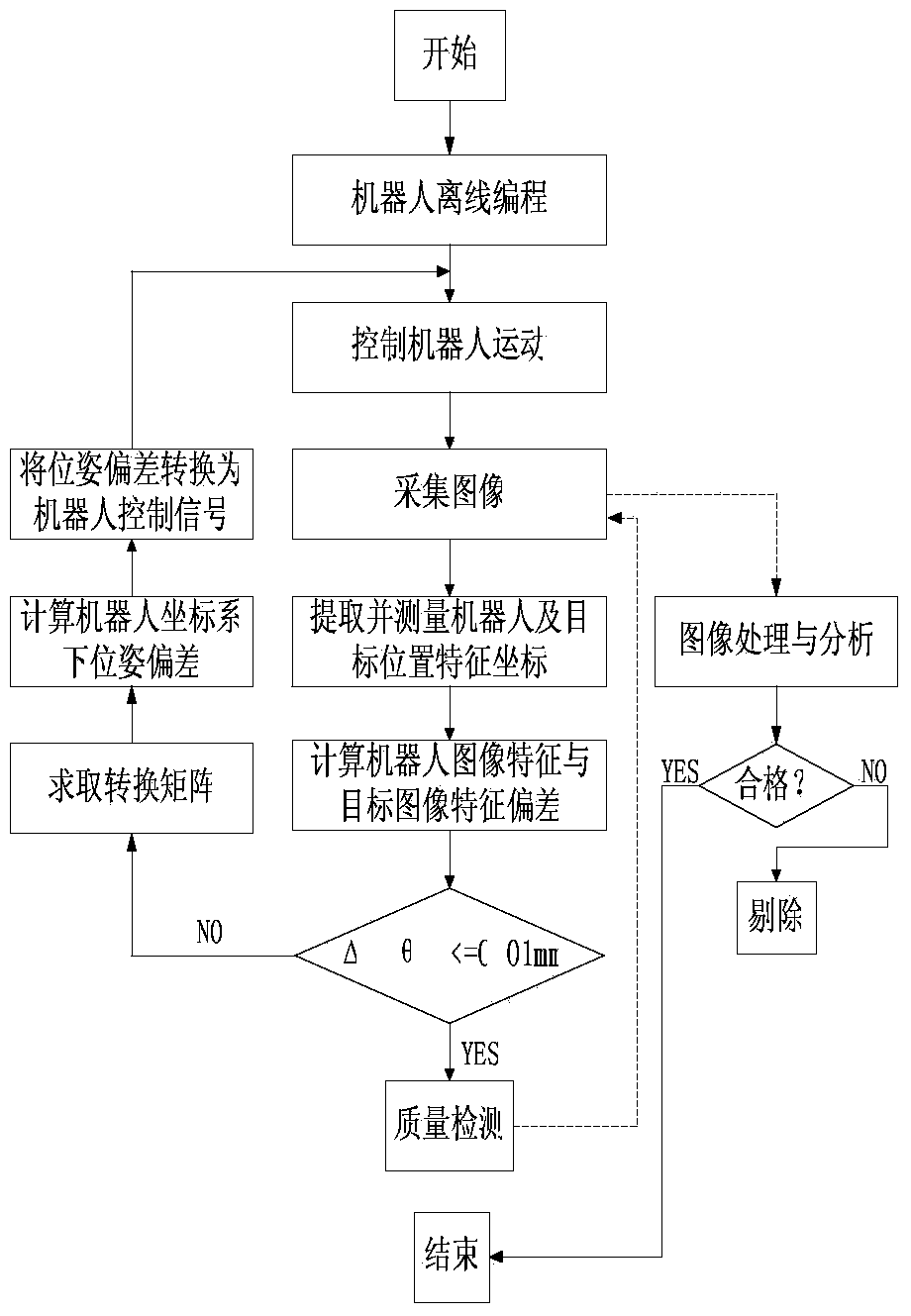

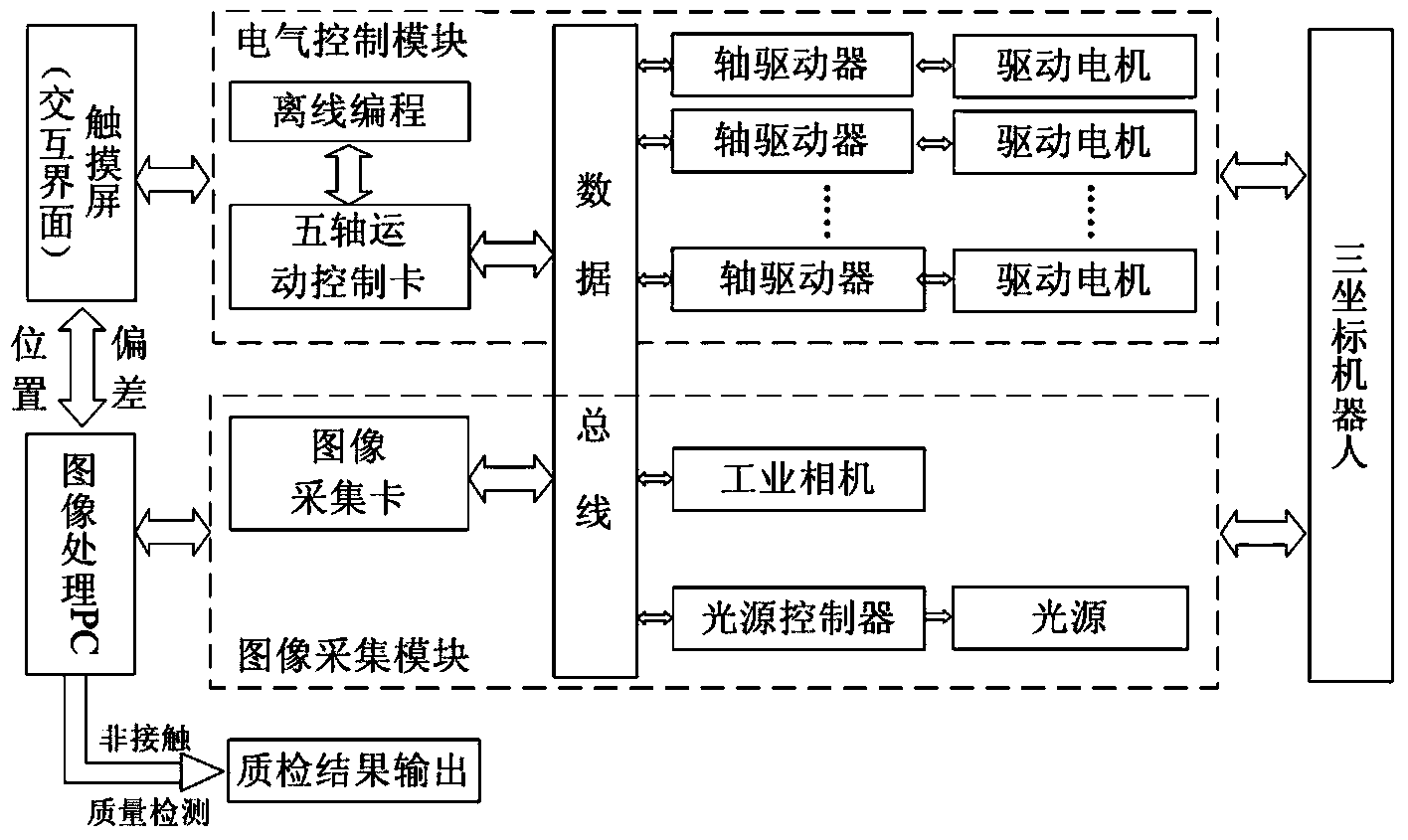

[0024] refer to figure 1 , figure 2 The overall structure of the automatic loading and unloading three-coordinate robot unit and processing unit includes four parts, namely robot 1, robot visual servo control unit and communication network unit 2 connecting each module, CNC machine tool 3, image acquisition and image processing unit 4 . The robot 1 is installed between two CNC machine tools 3, and the robot 1 completes the task of loading and unloading the CNC machine tools 3; the robot visual servo control unit and the communication network unit 2 connecting each module are installed next to the CNC machine tools 3, and control the three Coordinate the movement of the robot 1, and the CNC machine tool 3 completes the processing of the workpiece; the image acquisition and image processing unit 4 is placed above the bracket 1 on the machine, and is used to photograph the robot’s work sit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com