Automatic production line system for coating and maintaining buoys and application method thereof

An automatic production line and buoy technology, applied in buoys, devices for coating liquid on the surface, coatings, etc., can solve the problems of long daily processing capacity recoating time, difficult to achieve, difficult to overhaul, etc., to achieve compact structure, replacement The effect of convenient spare parts and low vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

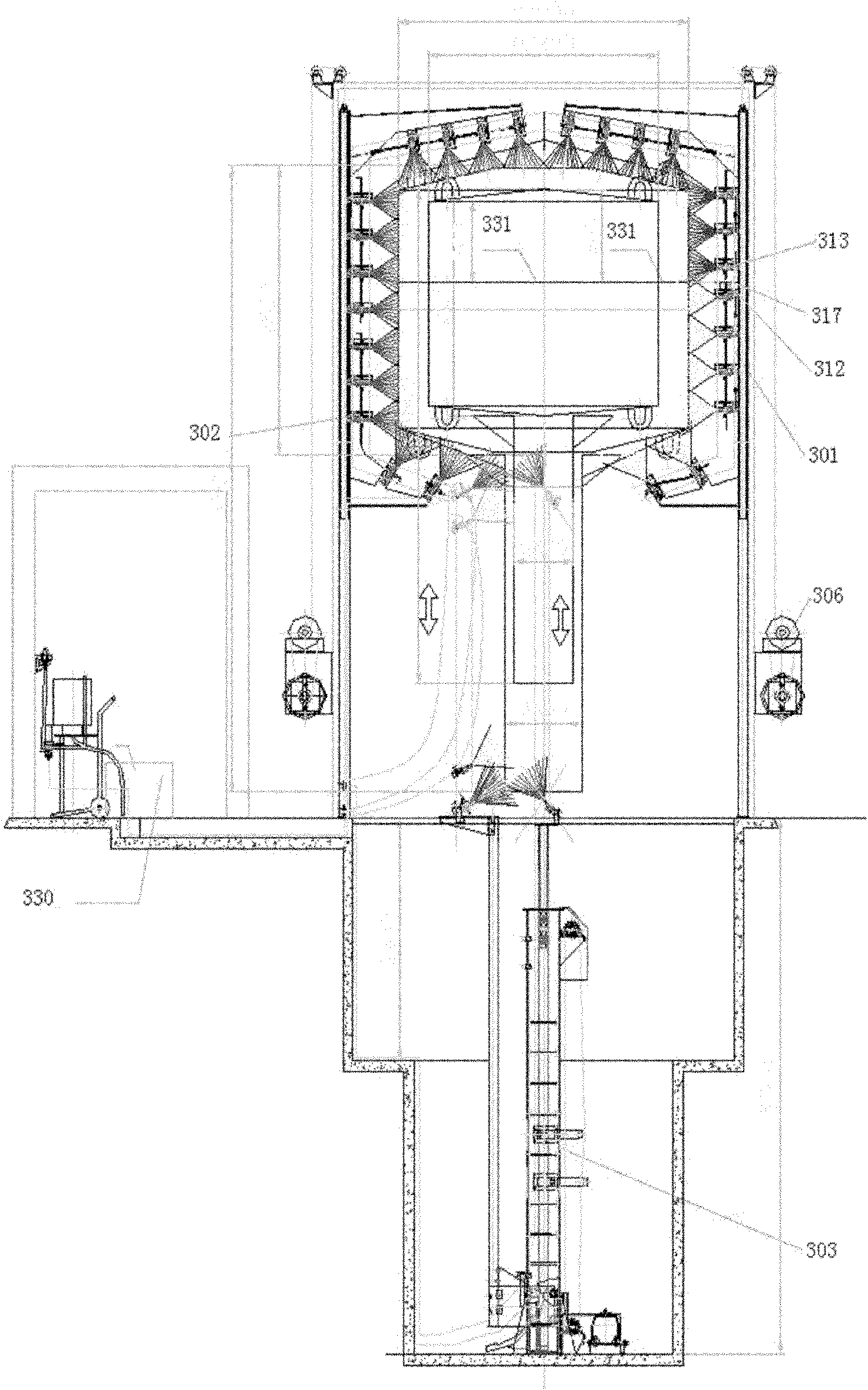

[0041] Shot blasting cleaning and strengthening process is to carry out abrasive cleaning and strengthening treatment on related parts, castings and overall parts, so as to eliminate the rust, rolling scale, etc. of the workpiece, and make the workpiece obtain the original metal color and certain surface roughness , and get the corresponding stress strengthening to improve and enhance the paint adhesion and fatigue strength of the workpiece.

[0042] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples, so as to fully understand and implement the process of how to apply technical means to solve technical problems and achieve technical effects in the present invention.

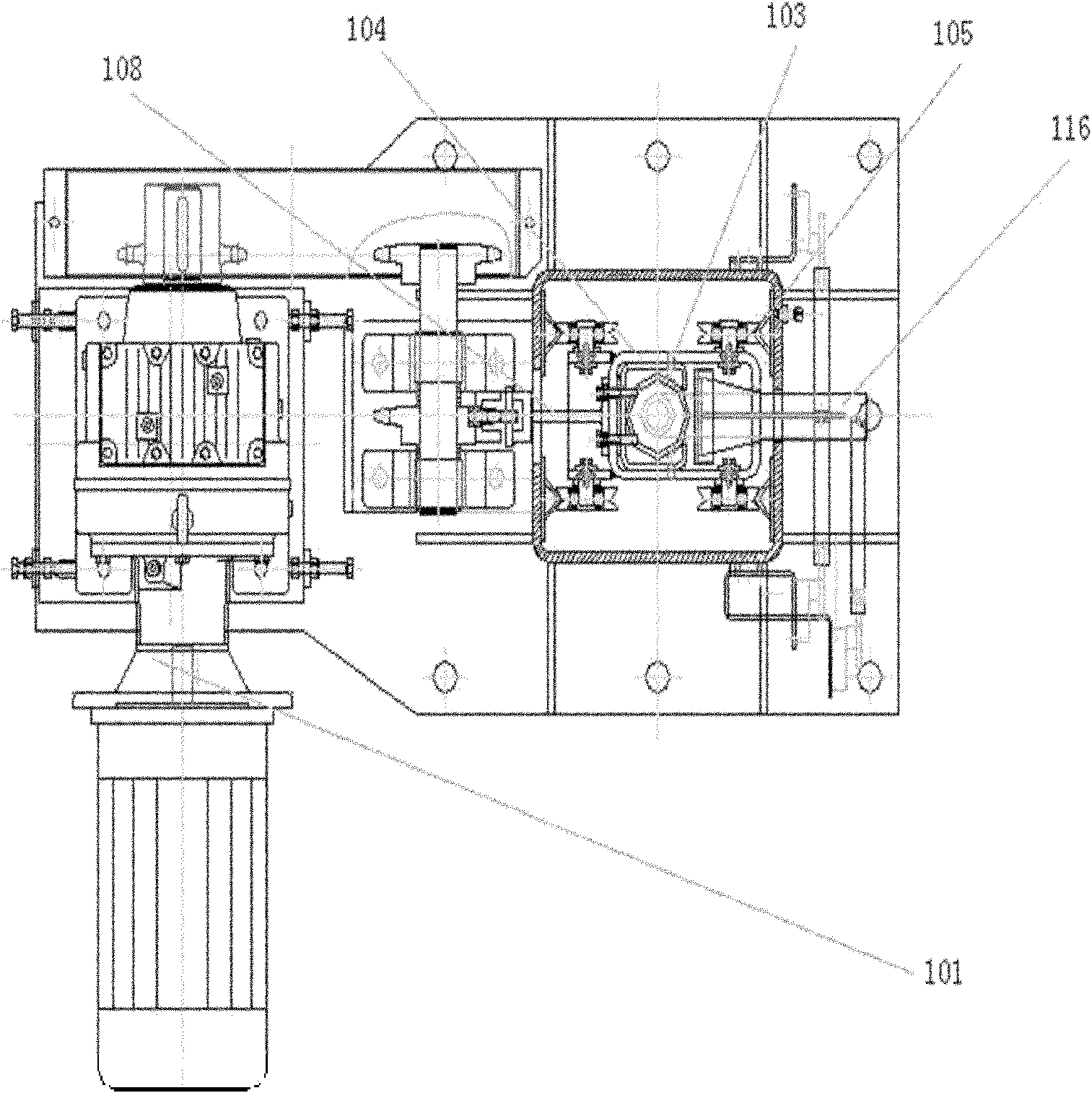

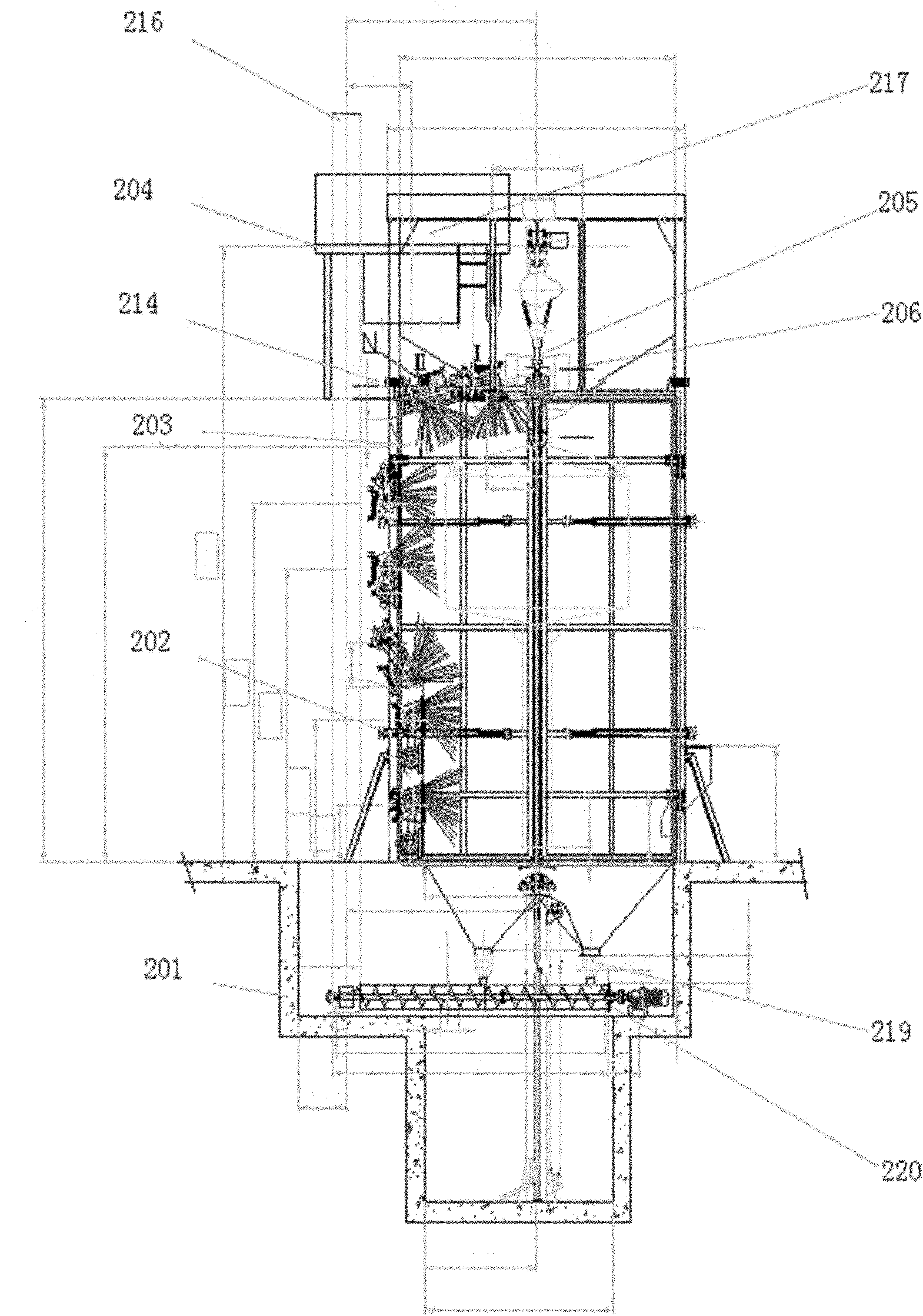

[0043] Such as figure 1 As shown, it is a general structure diagram of the buoy coating and maintenance automatic production line according to the embodiment of the present invention. Among them, the various components are: 101...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com