Patents

Literature

462results about How to "Compact and reasonable layout" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

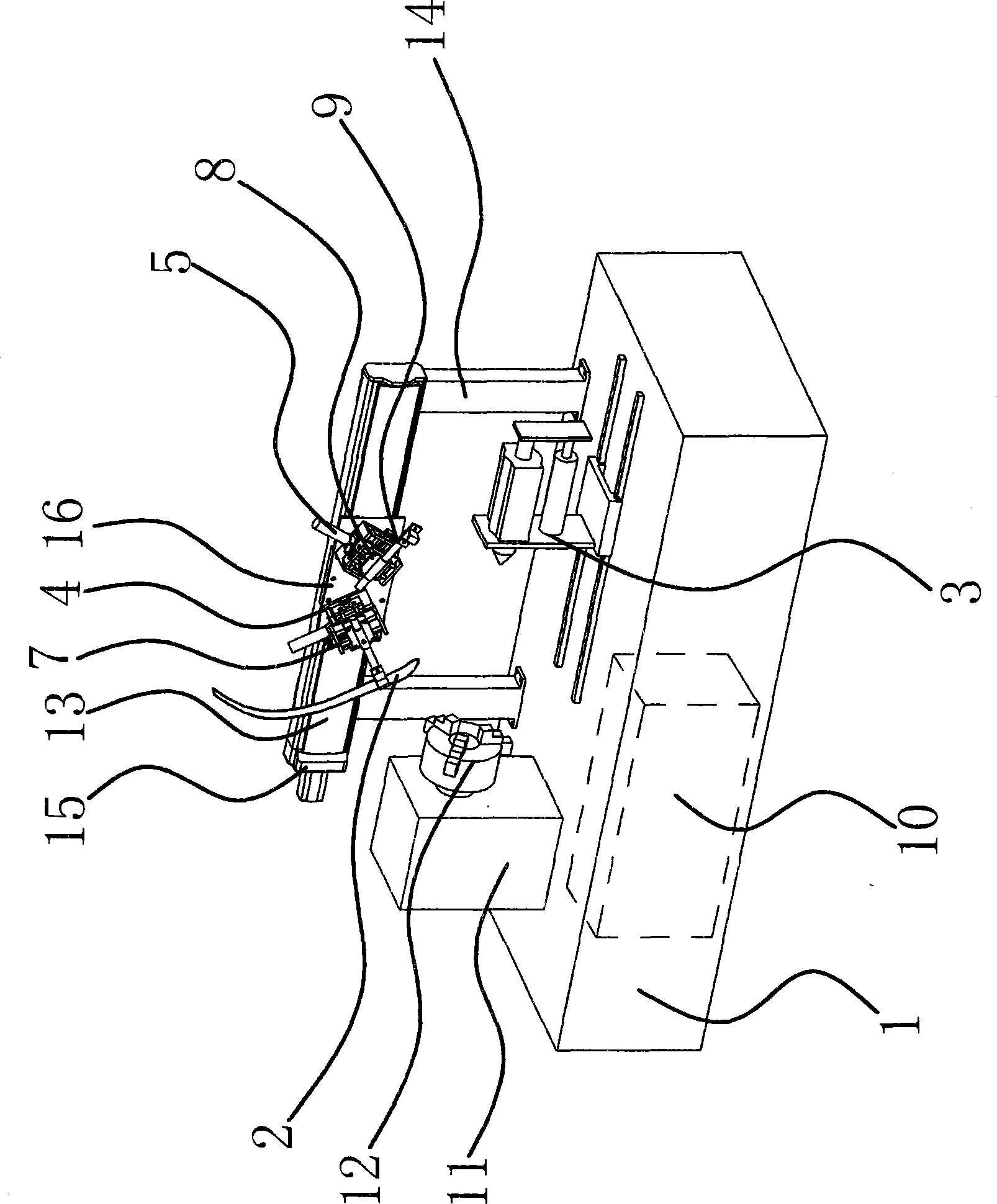

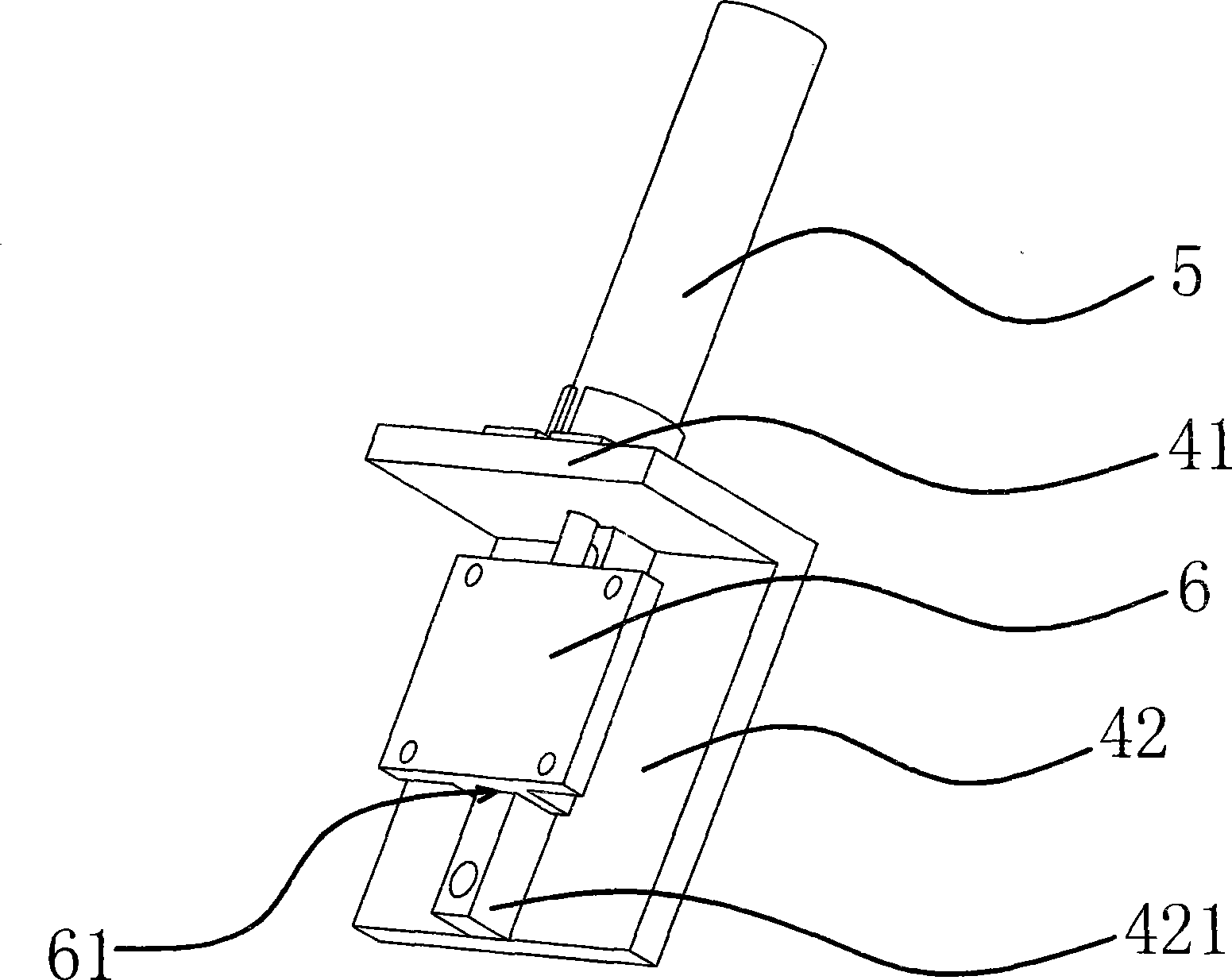

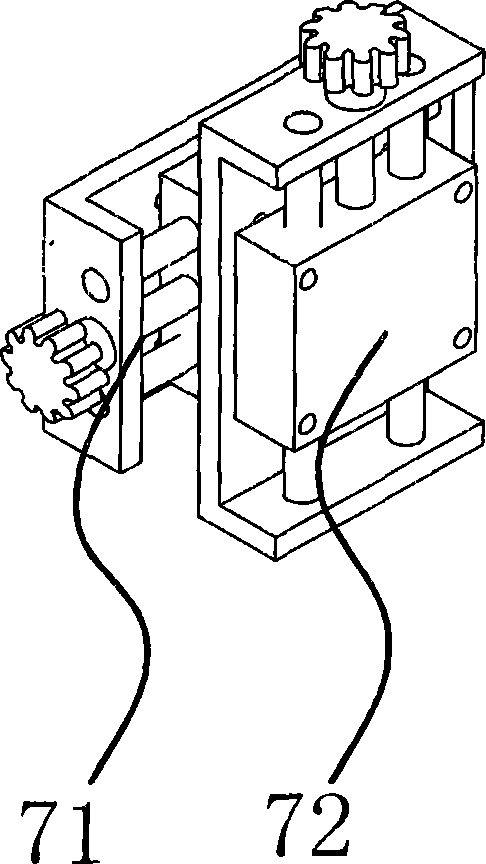

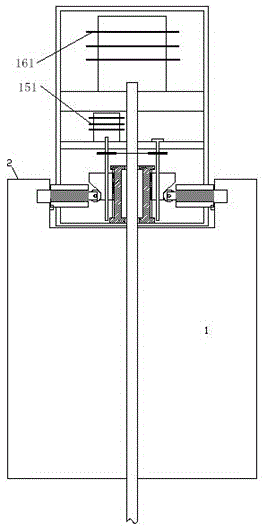

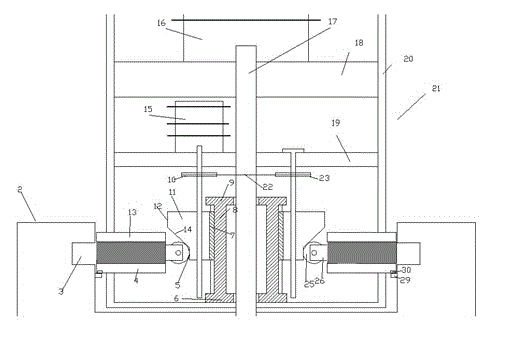

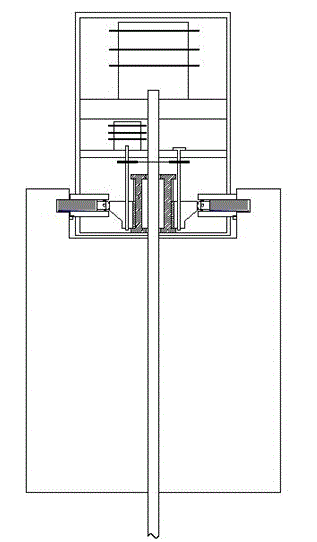

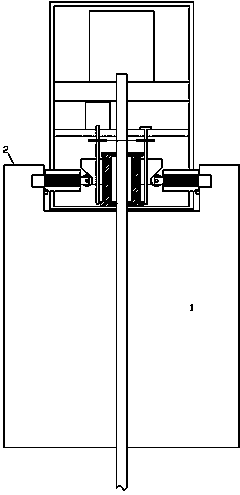

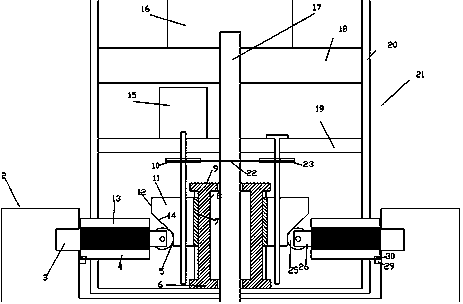

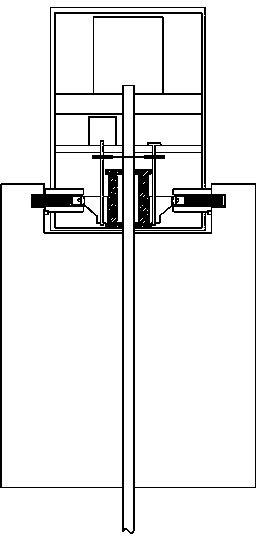

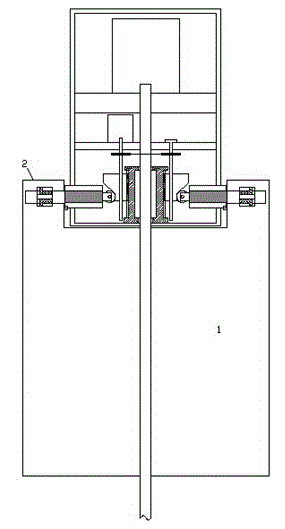

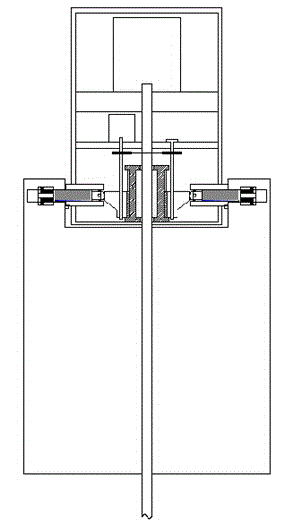

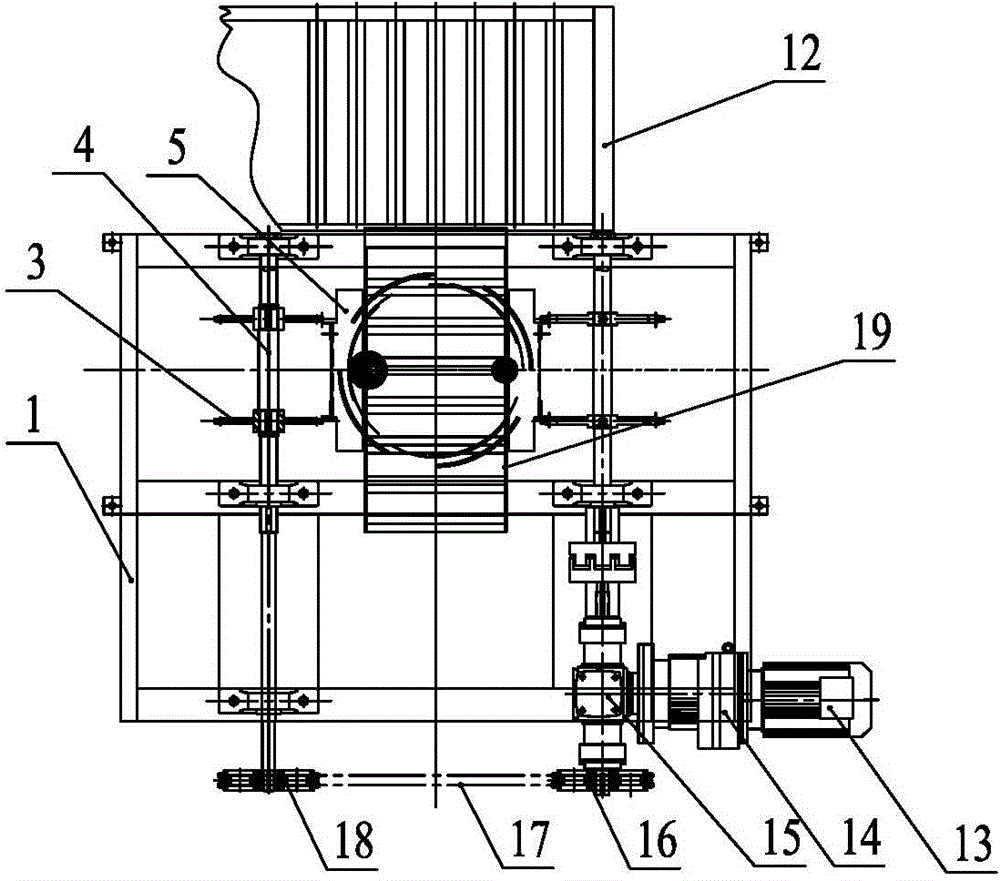

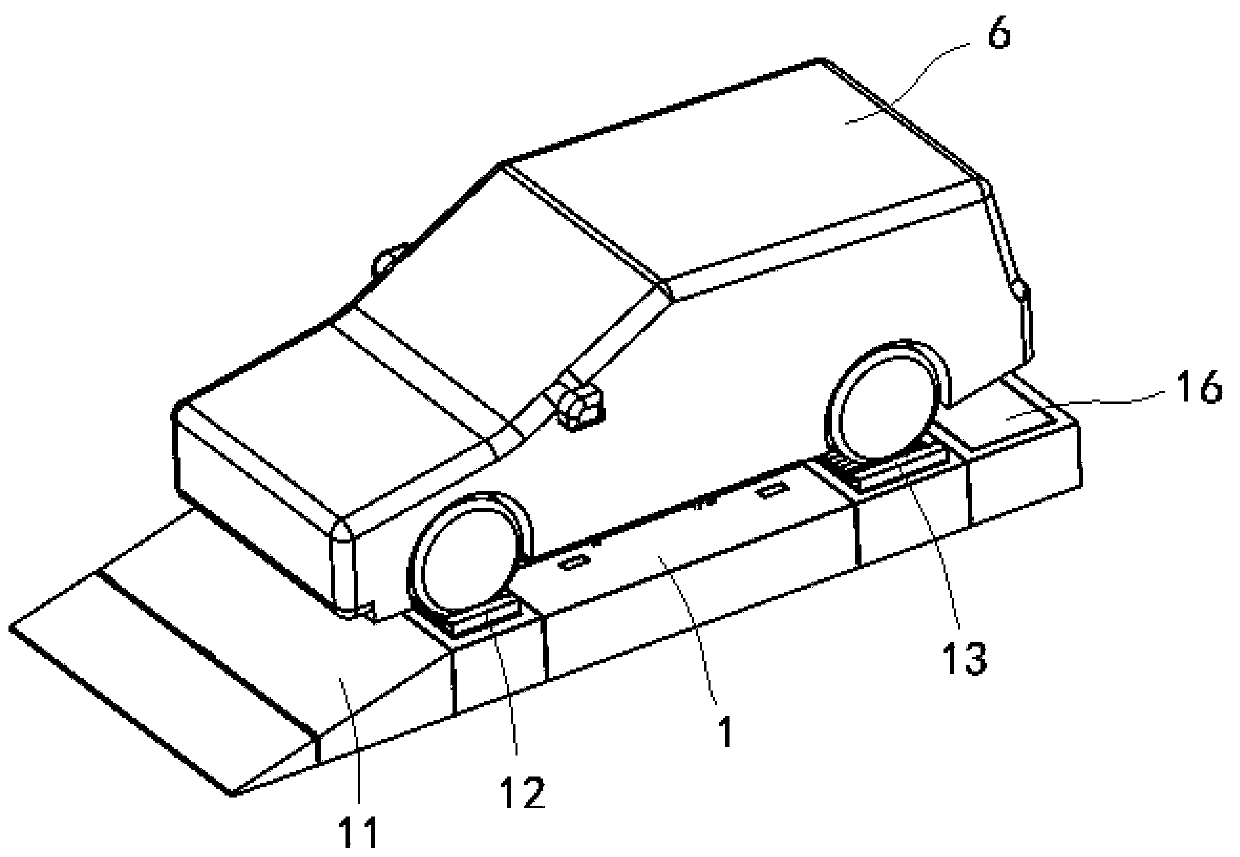

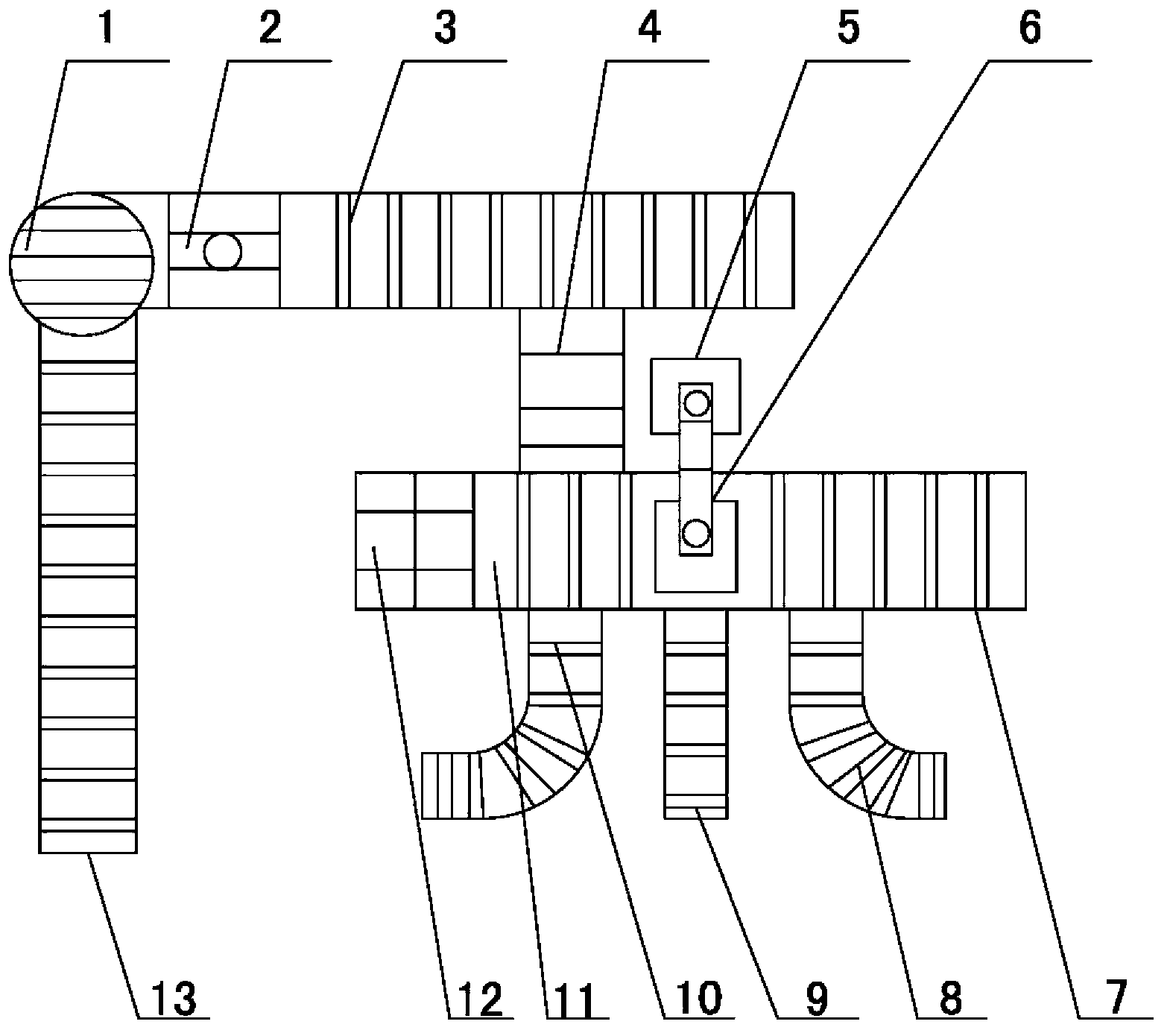

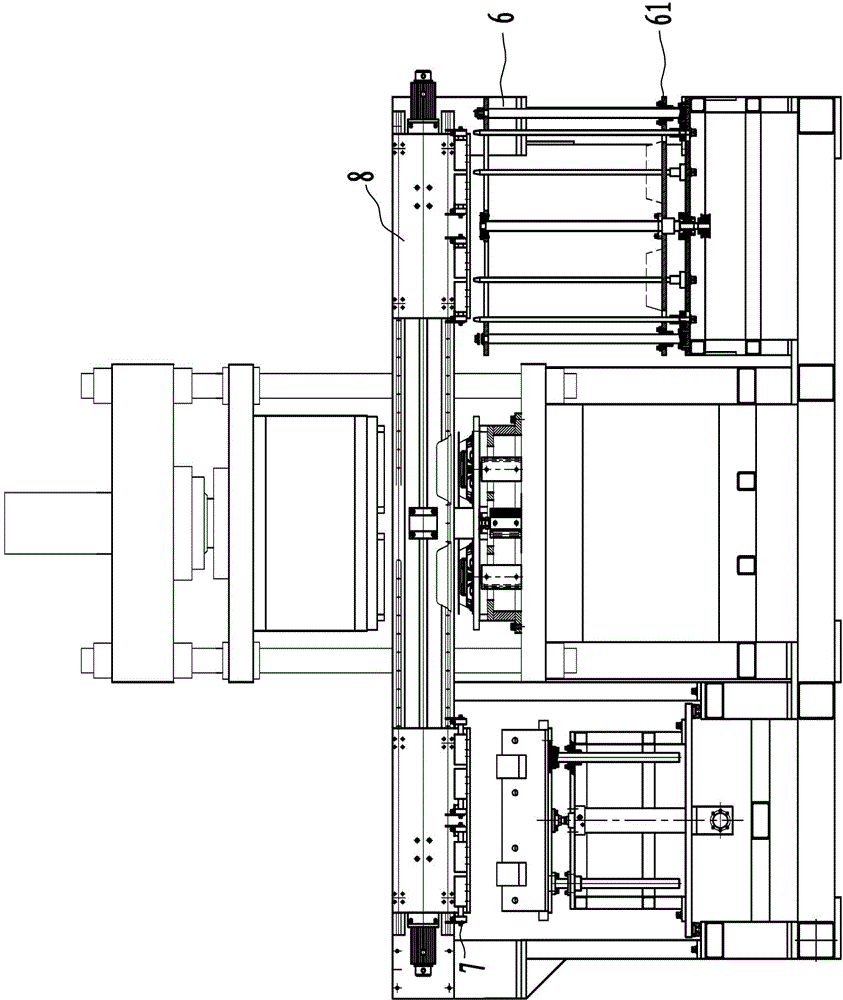

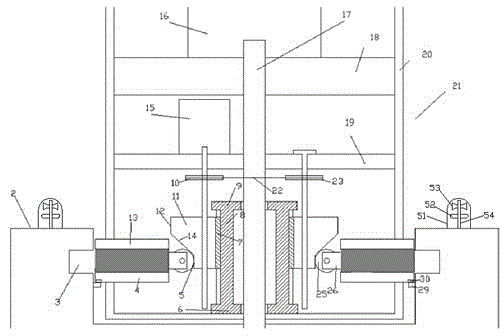

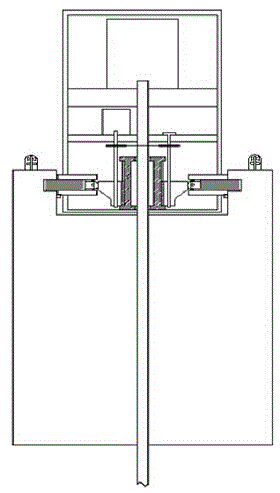

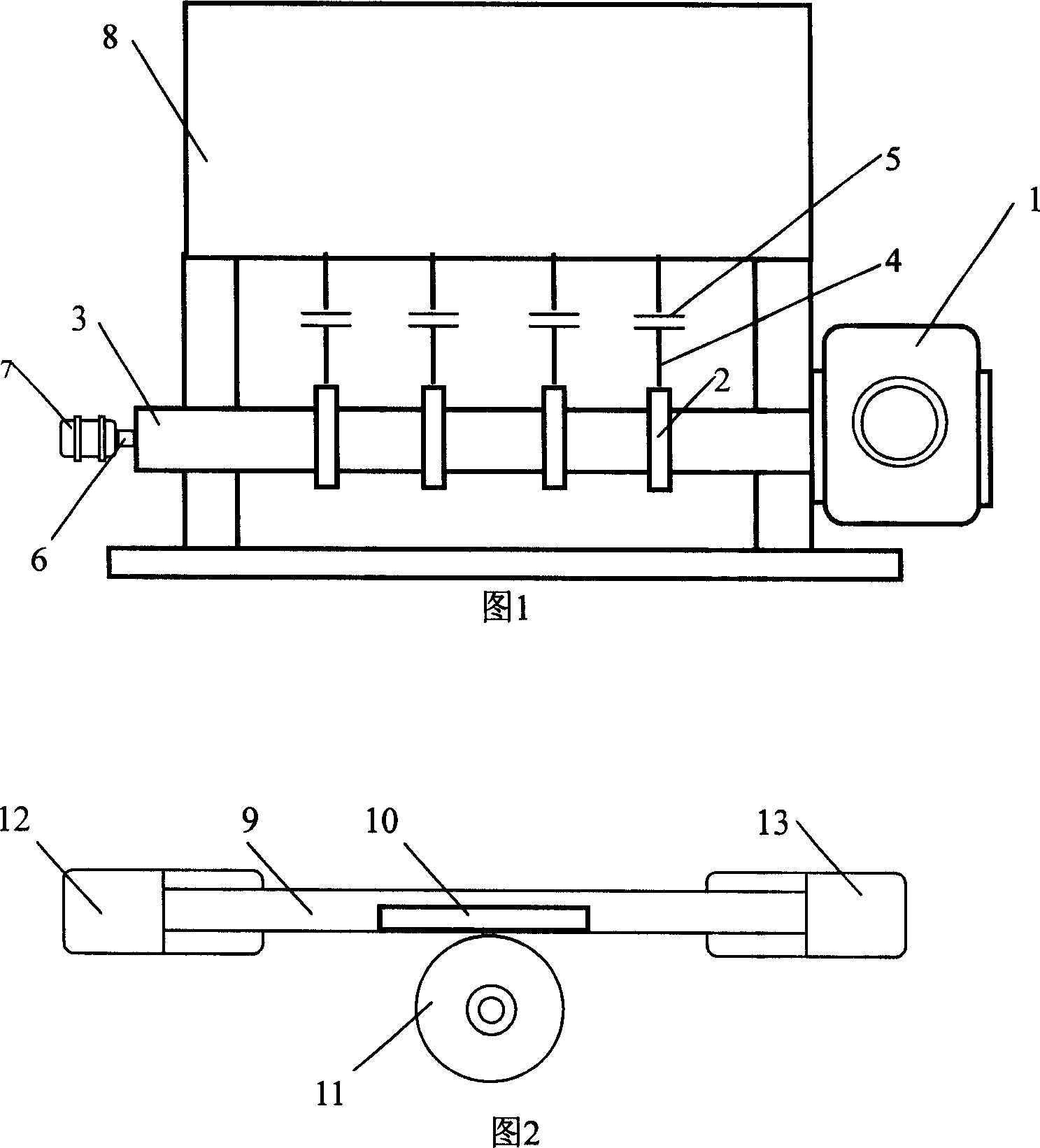

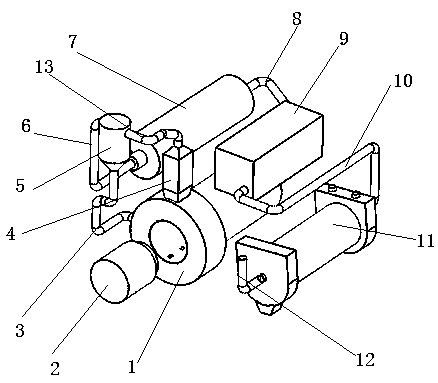

Double-circular-seam automatic welding equipment

ActiveCN103506787AEasy accessImprove efficiencyWelding/cutting auxillary devicesAuxillary welding devicesDouble loopSoldering gun

The invention relates to double-circular-seam automatic welding equipment, and belongs to the field of machines. Existing equipment can only weld a single circular seam at one time, and efficiency is low. The double-circular-seam automatic welding equipment comprises a welding gun and a machine frame, wherein the machine frame is provided with a main power pump, a speed changer, a linear guide rail, a straight guide rail driver, a three-jaw chuck and a clamping device, wherein the three-jaw chuck and the clamping device are used for clamping workpieces, the three-jaw chuck is installed on the speed changer, the linear guide rail driver is installed on the linear guide rail, the linear guide rail is provided with a rectangular plate, the rectangular plate and the linear guide rail are arranged in the same direction, one face of the rectangular plate is movably connected with the linear guide rail, the other face of the rectangular plate is vertically provided with two lifting cylinders, a piston rod of each lifting cylinder is provided with a welding gun regulating device, and each welding gun regulating device is provided with a fixing plate. By the adoption of the structure, welding can be carried out on two circular seams at the same time, not only is efficiency improved, but also the arrangement is more compact and reasonable, the double-circular-seam automatic welding equipment can be suitable for welding workpieces of various structures, and components of the equipment are also easy to obtain.

Owner:RIZHAO YUEJIANG TECH CO LTD

Automatic-locking water conservancy gate device

InactiveCN104452679AImprove lock stabilityCompact and reasonable layoutBarrages/weirsDrive motorElectrical and Electronics engineering

Owner:高承恩

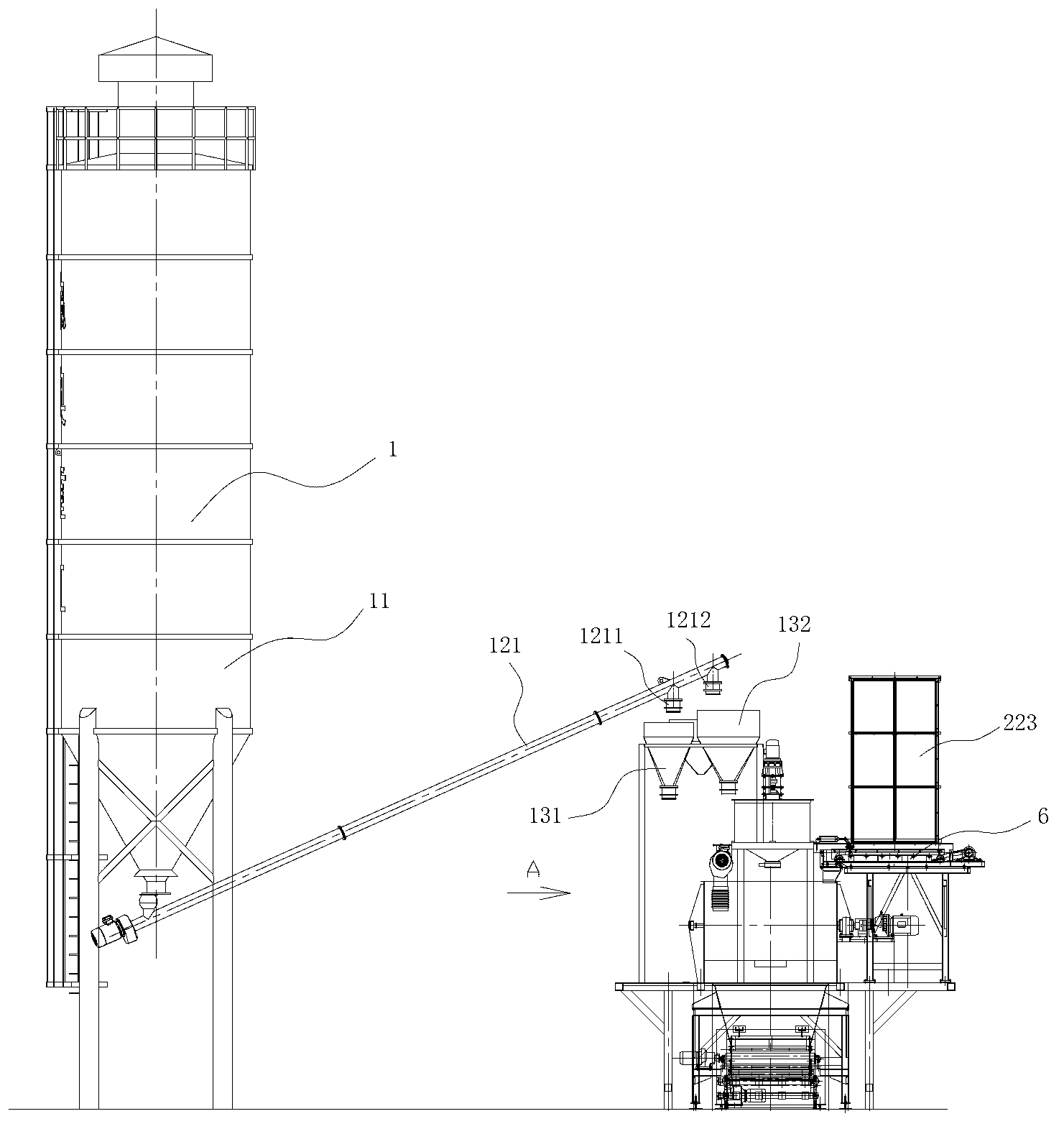

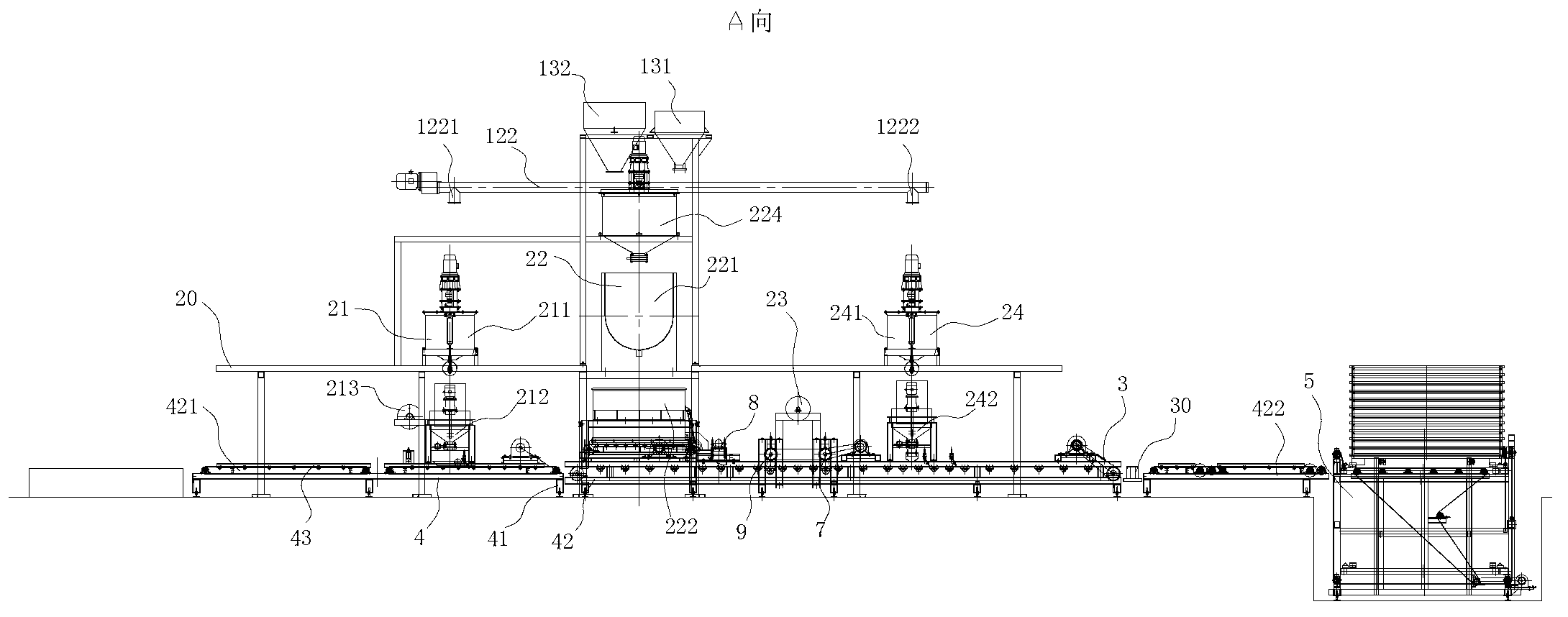

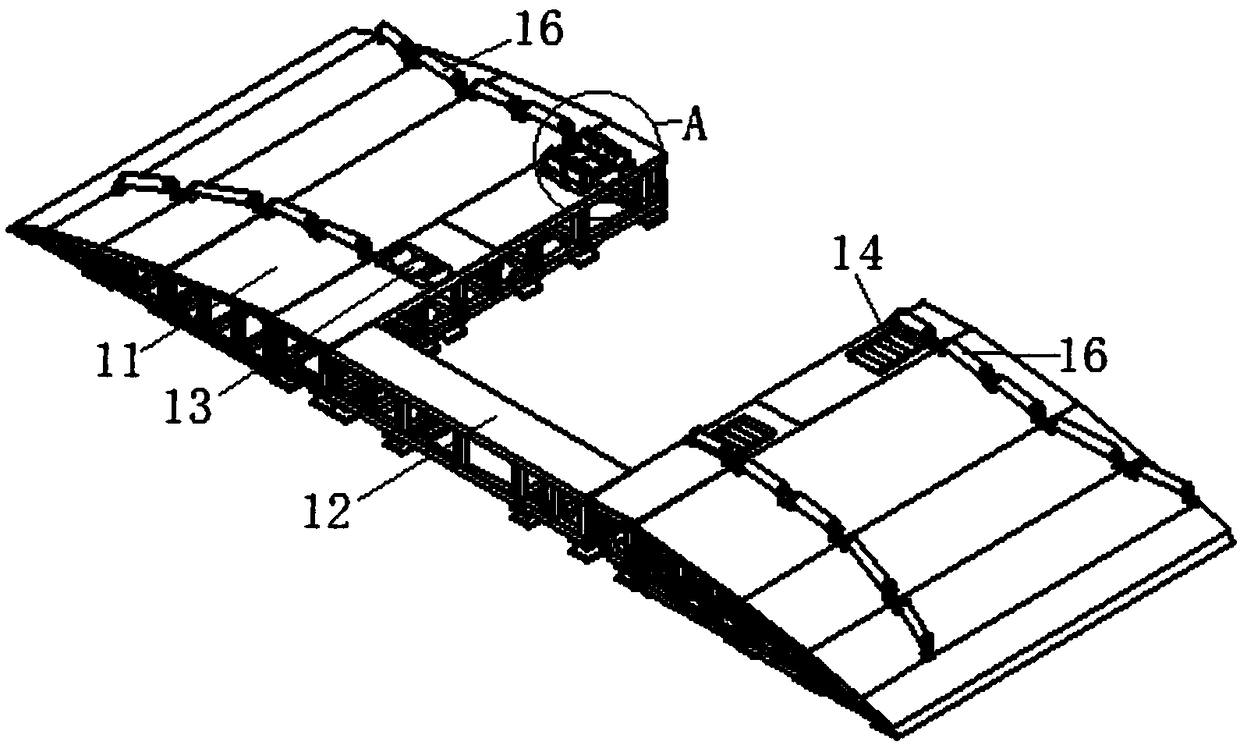

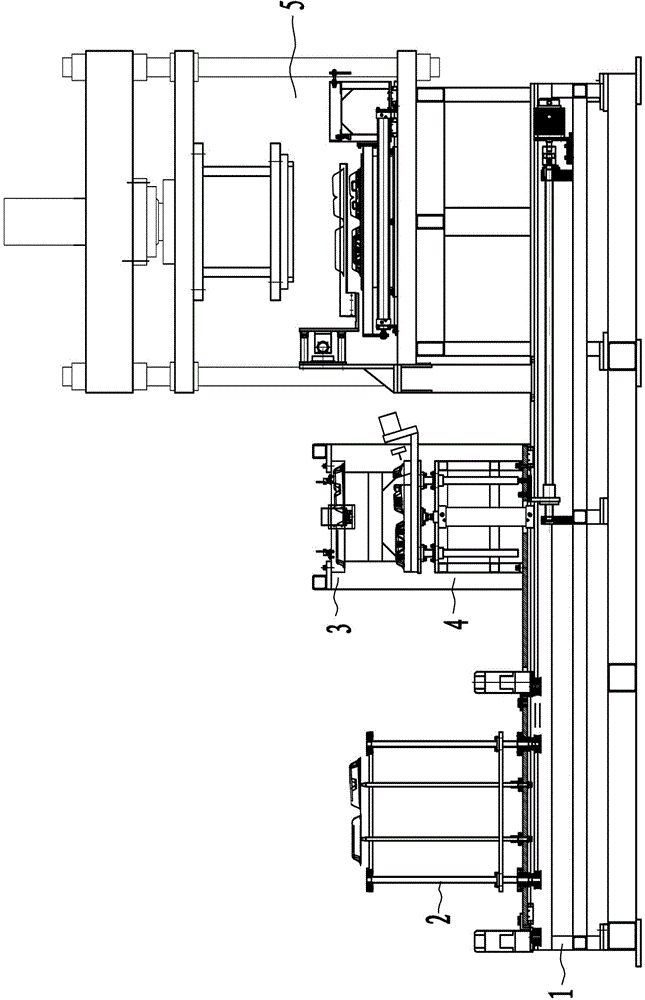

Composite insulation board production line and machining process of insulation board

InactiveCN103192451AHigh degree of automationCompact and reasonable layoutCeramic shaping plantsPress rollersProduction lineTransfer system

The invention relates to a composite insulation board production line and a machining process of an insulation board. The composite insulation board production line comprises a one-to-three material preparing system, a forming system, a transferring system, a cutting system and a plate loading system, wherein the one-to-three material preparing system comprises a raw material bin, a one-way double-outlet spiral lifting conveyor, a two-way spiral horizontal conveyor, a measuring bin I, a measuring bin II, a lower-layer pulp material preparing device, a thermal insulation material preparing device and an upper-layer pulp material preparing device, and the forming system is installed above the transferring system through a frame type workbench and comprises a lower-layer grid cloth laying device, a lower-layer pulp material feeding device, a thermal insulation mixture feeding device, an upper-layer grid cloth laying device, a rolling device and an upper-layer pulp material feeding device which are sequentially arranged. The composite insulation board production line in the invention essentially consists of five systems, namely the material preparing system, the forming system, the cutting system, the transferring system and the plate loading system, is high in degree of automation, compact and reasonable in layout, and improves the production efficiency.

Owner:扬州威奥重工机械有限公司

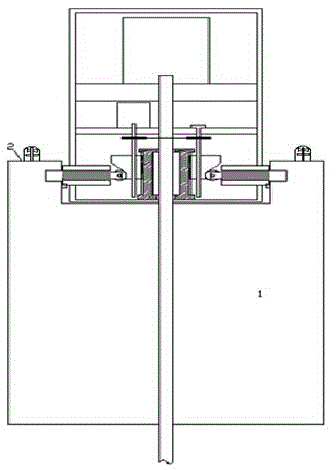

Hydraulic gate control valve capable of being automatically locked

InactiveCN104499464AImprove lock stabilityCompact and reasonable layoutBarrages/weirsMotor driveControl system

The invention discloses a hydraulic gate control valve capable of being automatically locked. The hydraulic gate control valve comprises a controller, a motor drive circuit and a hydraulic gate control device, wherein the hydraulic gate control device comprises a gate plate (1) and a gate plate lifting drive device (21); the gate lifting drive device (21) comprises a casing (20) which is fixed on a supporting base body; an upper fixing rib (18), a middle fixing rib (19) and a bottom fixing plane are arranged on the inner part of the casing (20); a gate plate lifting drive motor (16) is supported on the upper fixing rib (18) and in power connection with the upper end of a gate plate lifting drive lead screw (17) which penetrates through the upper fixing rib (18), the middle fixing rib (19) and a through hole in the bottom fixing plane, and is in screw-thread fit with the screw in the gate plate (1).

Owner:宁波市汇通生态工程建设有限公司

Water gate control system capable of automatically locking and restoring

ActiveCN104532801AImprove lock stabilityCompact and reasonable layoutBarrages/weirsMotor driveControl system

The invention discloses a water gate control system capable of automatically locking and restoring. The water gate control system includes a controller, a motor driving circuit an a water gate controller, wherein the water gate controller includes a gate plate (1) and a gate plate lifting driving device (21); the gate plate lifting driving device (21) includes a shell (20) which is fixed on a support base; an upper fixing rib (18), a middle fixing rib (19) and a bottom fixing surface are arranged in the shell (20); a gate plate lifting driving motor (16) is supported by the upper fixing rib (18), and linked with a gate plate lifting driving lead screw (17); the gate plate lifting driving lead screw (17) passes through the through holes in the upper fixing rib (18), the middle fixing rib (19) and the bottom fixing surface; the gate plate lifting driving lead screw (17) is in threaded cooperation with a screw hole in the gate plate (1).

Owner:邯郸市源沃肥业科技有限公司

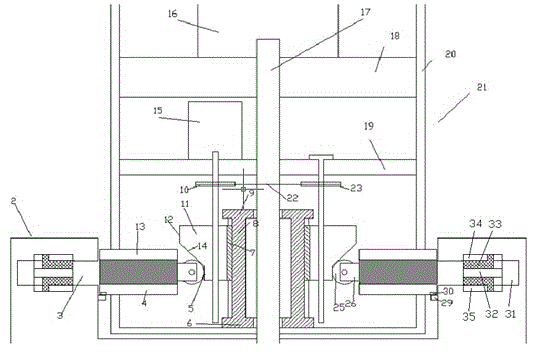

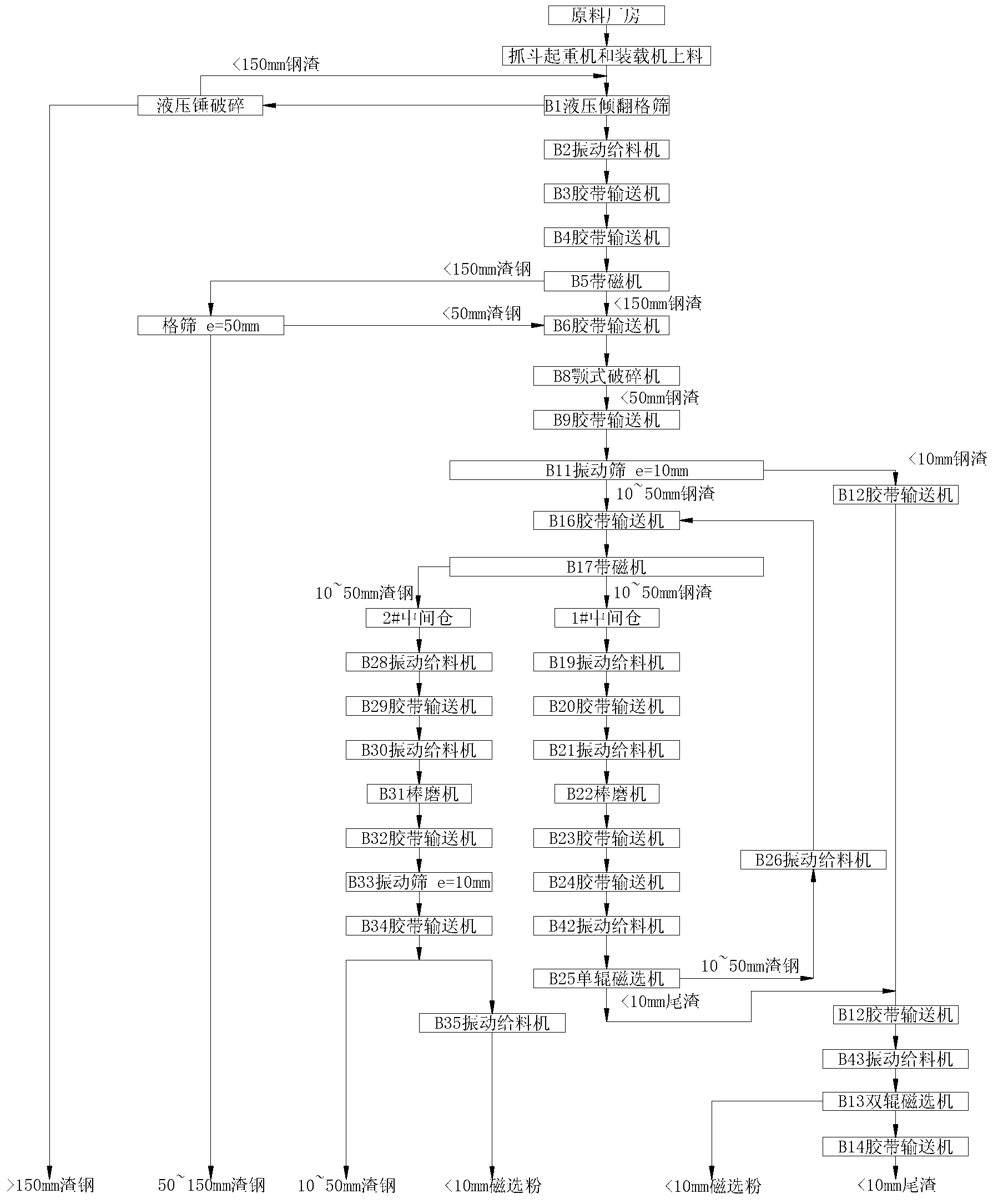

Steel slag treating technology

ActiveCN103290153AIncrease added valueFor subsequent useRecycling and recovery technologiesSteelmakingClosed loop

The invention relates to a steel slag treating technology which can be used for treating steel slag after which is stabilized by adopting a hot and stuffy method. According to the technology, the steel slag is treated by the procedures of screening, crushing, magnetic separation, purification and the like through utilizing the mode of combining an open loop and a closed loop circulation to obtain five high-value-added high-quality products, namely first-type bulk slag steel with the grade of more than or equal to 80% and particle size of 150mm, a second-type bulk slag steel with the grade of more than or equal to 80% and particle size of 50-150mm, slag steel with grade of more than or equal to 85% and particle size of 10-50mm, magnetic separation powder with grade of more than or equal to 42% and particle size of 10mm, and metal iron content (2% of tailings with the particle size of 10mm), wherein the first-type bulk slag steel and the second-type bulk slag steel and the slag steel with the grade of more than or equal to 85% can be returned for steelmaking, the magnetic separation powder can be used for sintering, and the tailings can be used for producing steel slag micropowder as high-activity admixture of cement and concrete and the like. Through the technology, the zero emission of the steel slag can be realized, the defects that the steel slag stored occupies a large area and pollutes the environment can be solved, and the economic benefits of a steel mill can be increased.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

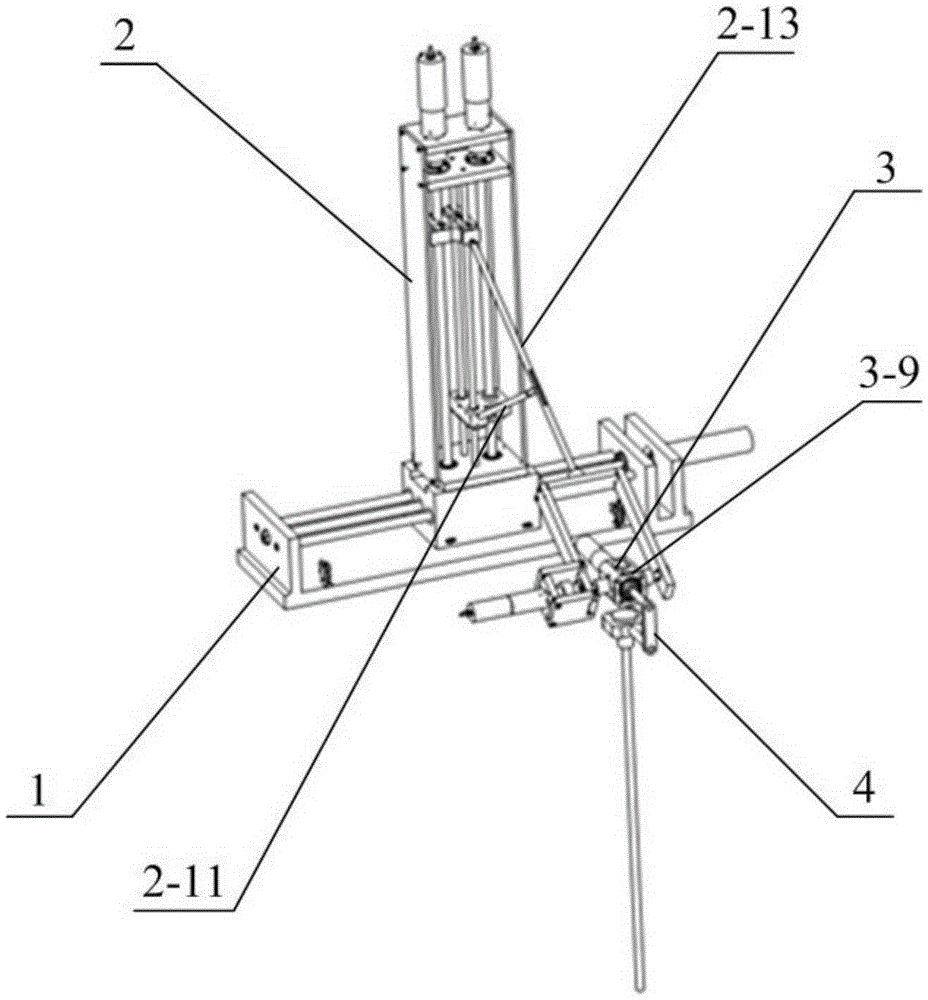

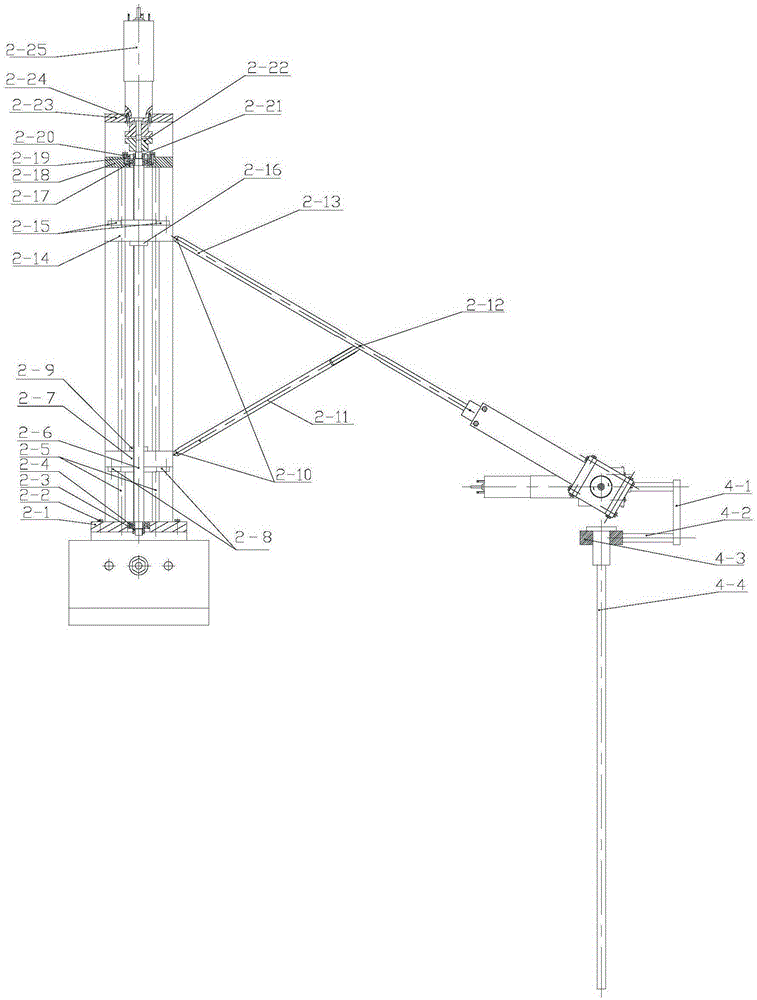

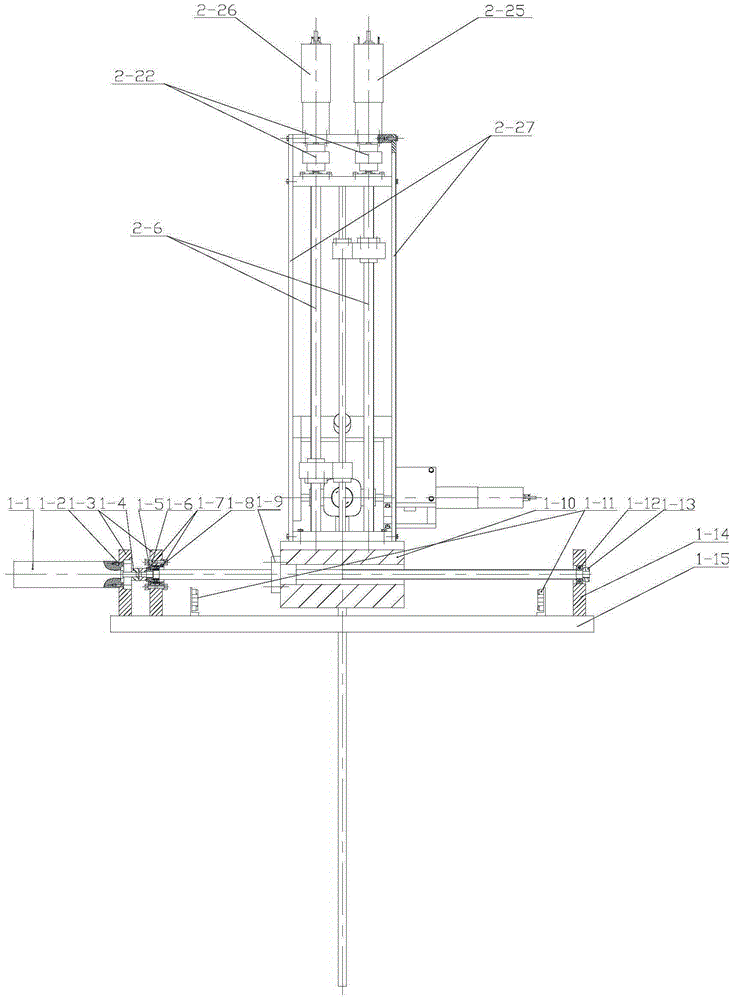

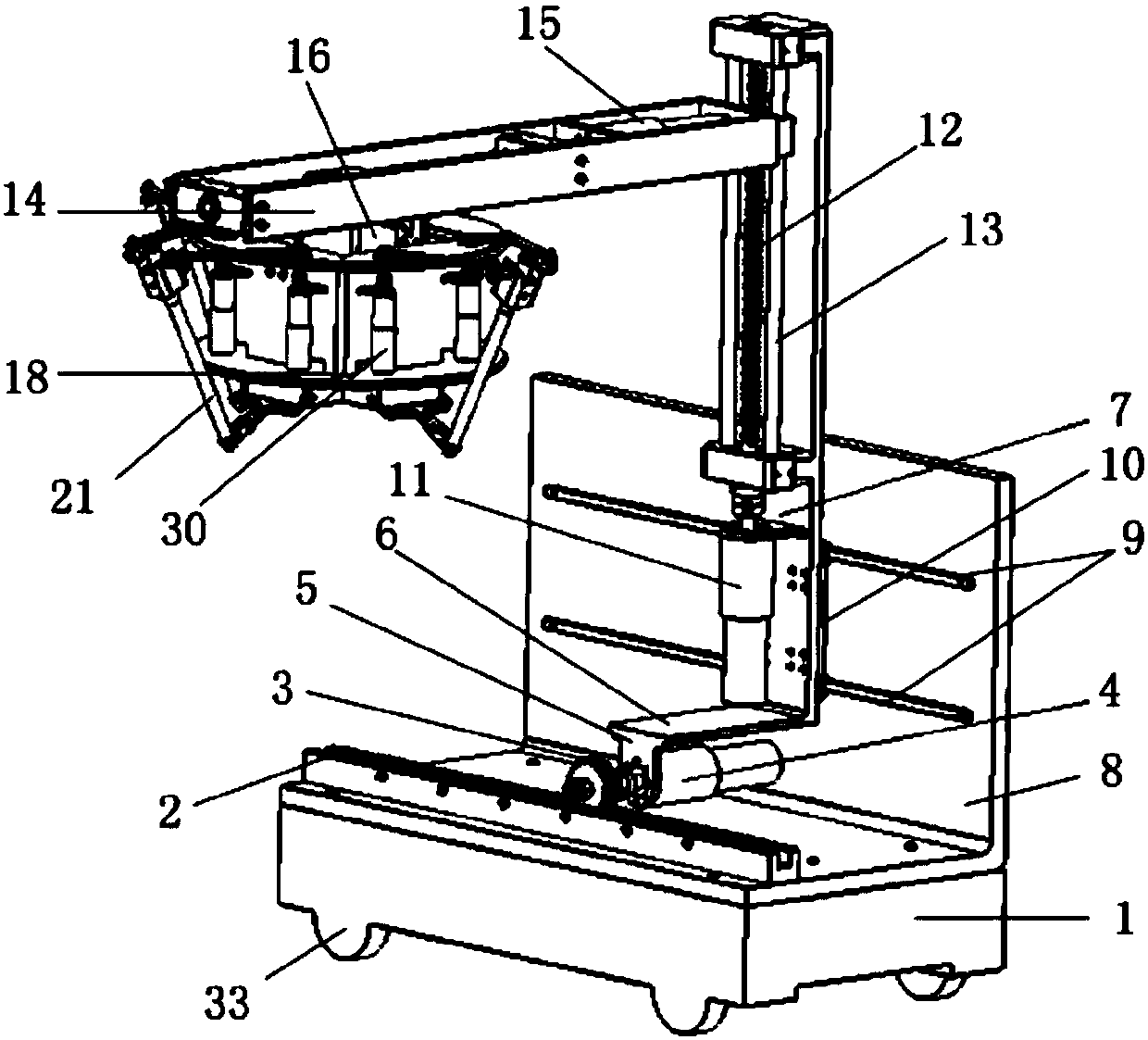

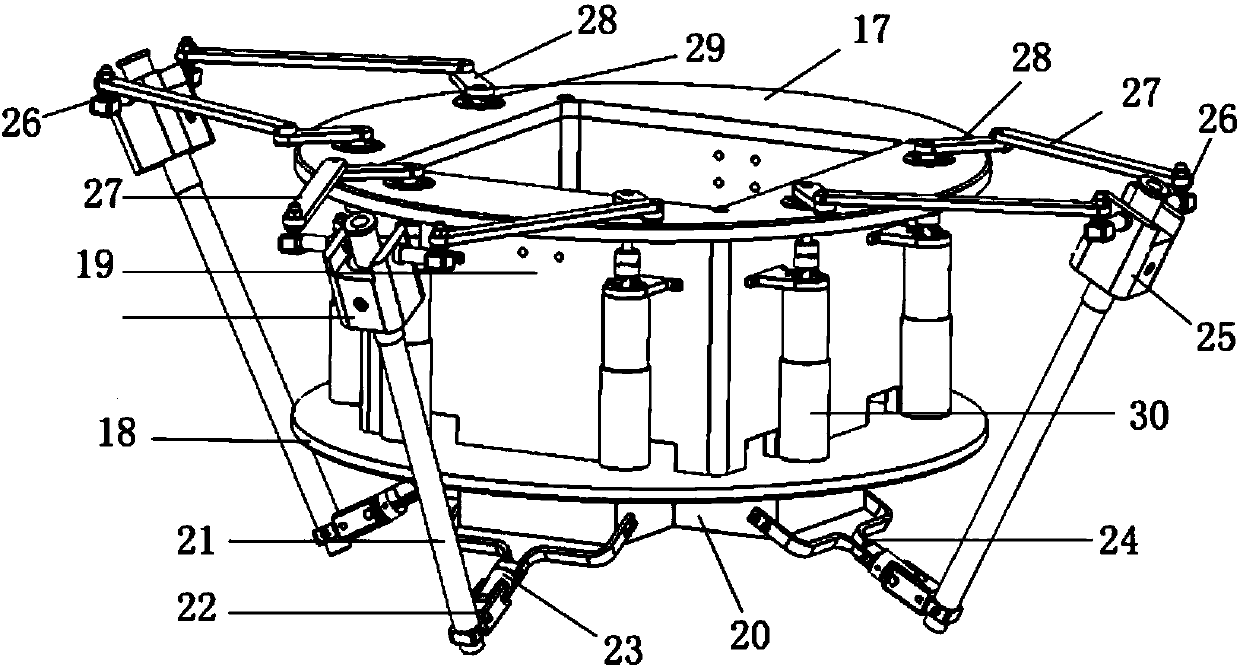

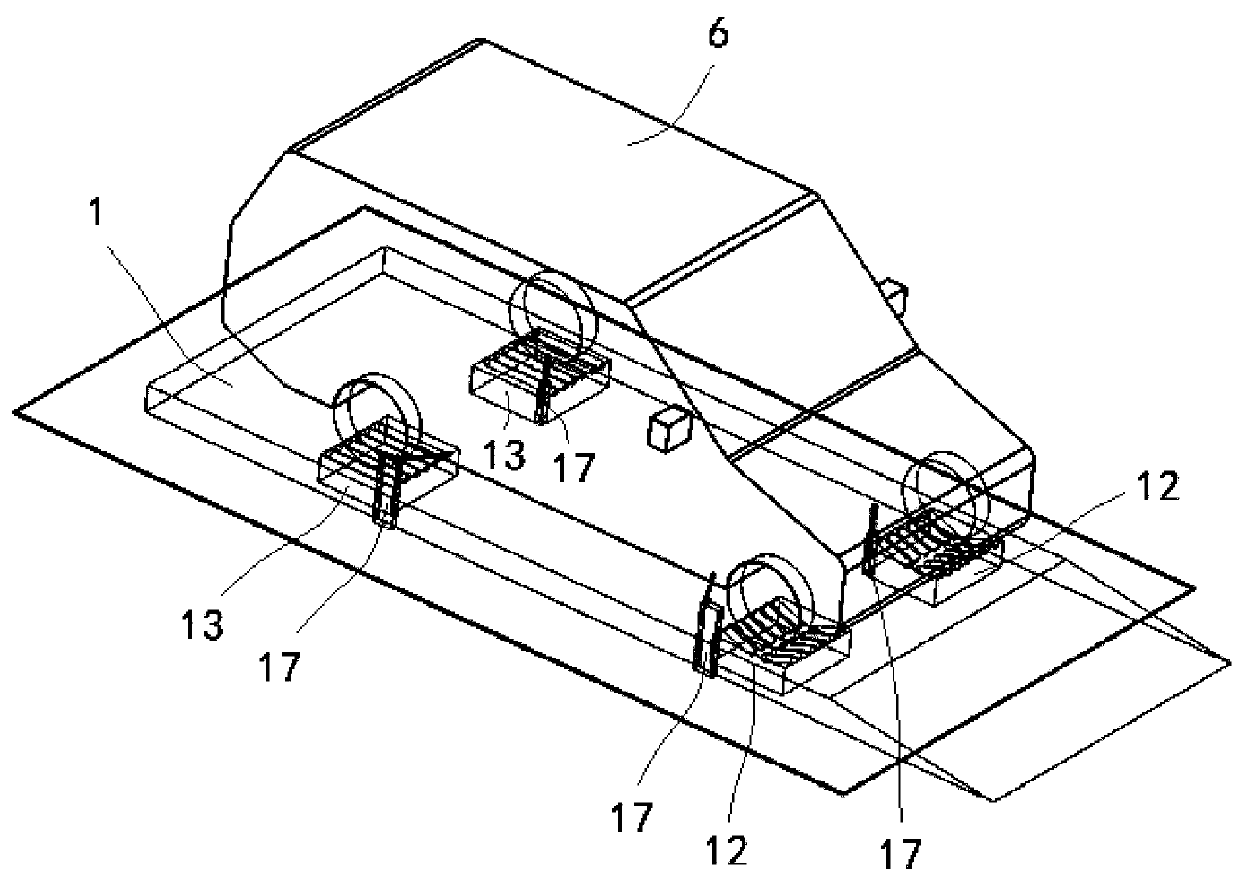

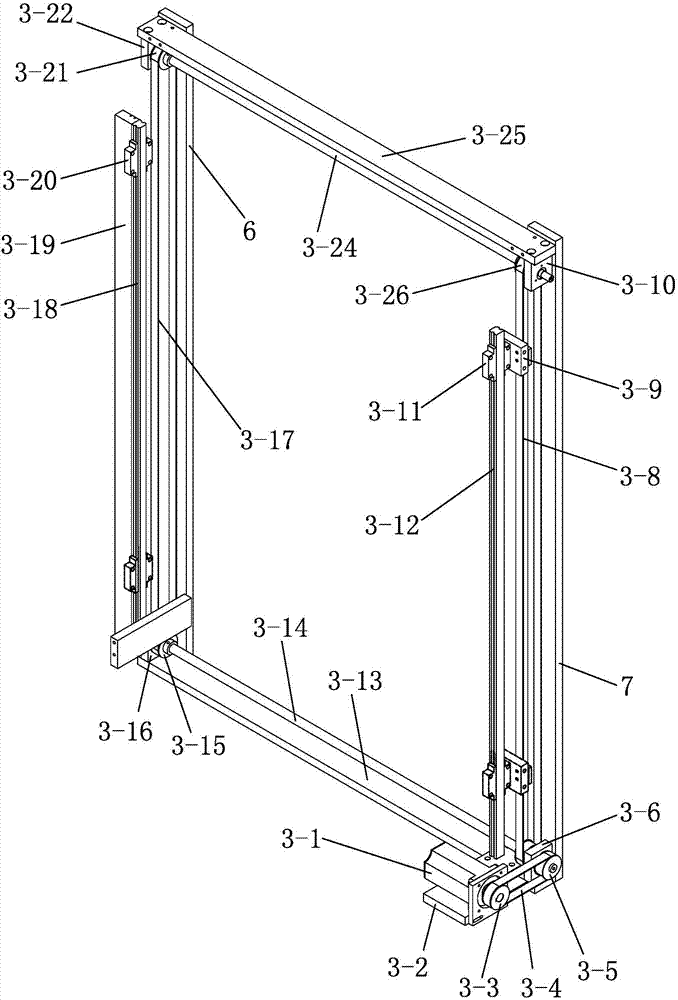

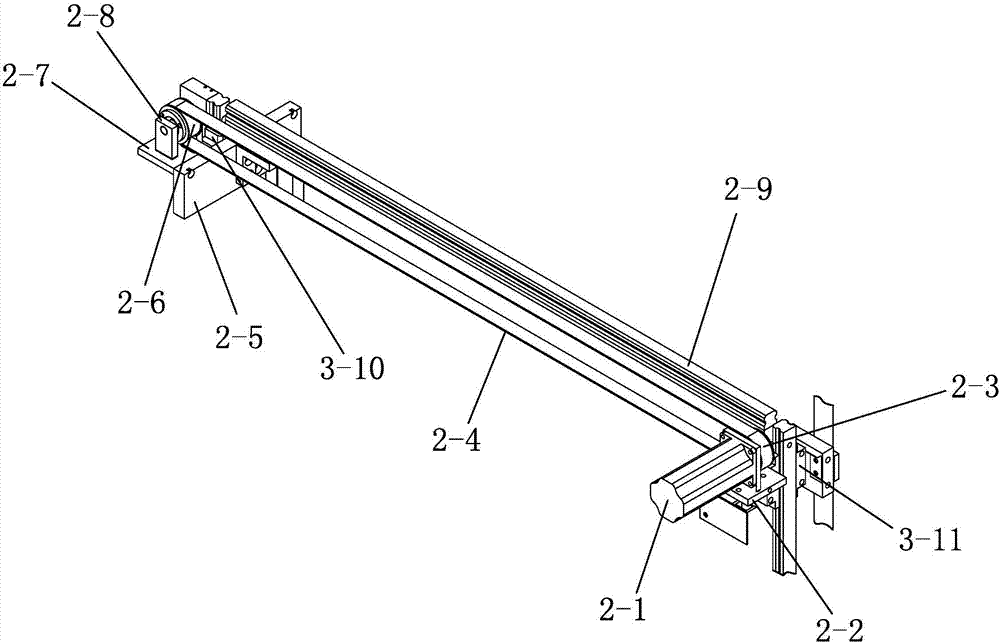

Endoscope-holding robot for minimally invasive abdominal operation

ActiveCN105361951ASimple structureCompact and reasonable layoutVaccination/ovulation diagnosticsSurgical robotsAbdominal cavityEngineering

The invention discloses an endoscope-holding robot for a minimally invasive abdominal operation. The endoscope-holding robot comprises a horizontal moving mechanism, a vertical moving mechanism, an endoscope gesture adjusting mechanism and an endoscope holding rack, wherein the horizontal moving mechanism is a dual-guide-rail and single-screw lead screw sliding platform which is arranged in a horizontal direction; the vertical moving mechanism is a dual-guide-rail and single-screw lead screw sliding platform which is arranged in a vertical direction, and the vertical moving mechanism is integrally installed on a sliding block of the horizontal moving mechanism and is driven to move left and right by virtue of the sliding block; the endoscope gesture adjusting mechanism comprises a link mechanism and a cross rotary base; an endoscope is clamped by a clamp on the endoscope holding rack; the endoscope is distributed in a vertical direction; and an extension line of the axis of the endoscope passes through the central point of the cross rotary base. The robot disclosed by the invention is simple in integral structure, compact and reasonable in layout, large in motion space, good in action coordination among various moving parts and flexible to operate and control; and especially, the robot has the characteristics of being high in precision and good in sensitivity and coordination when various actions are implemented during running.

Owner:SHANDONG UNIV OF SCI & TECH

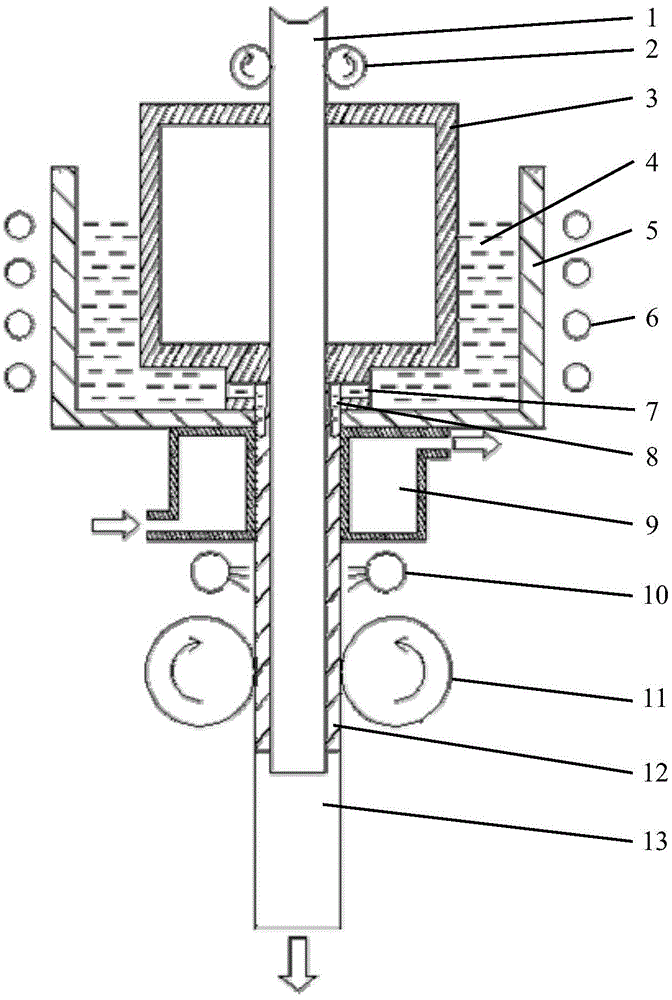

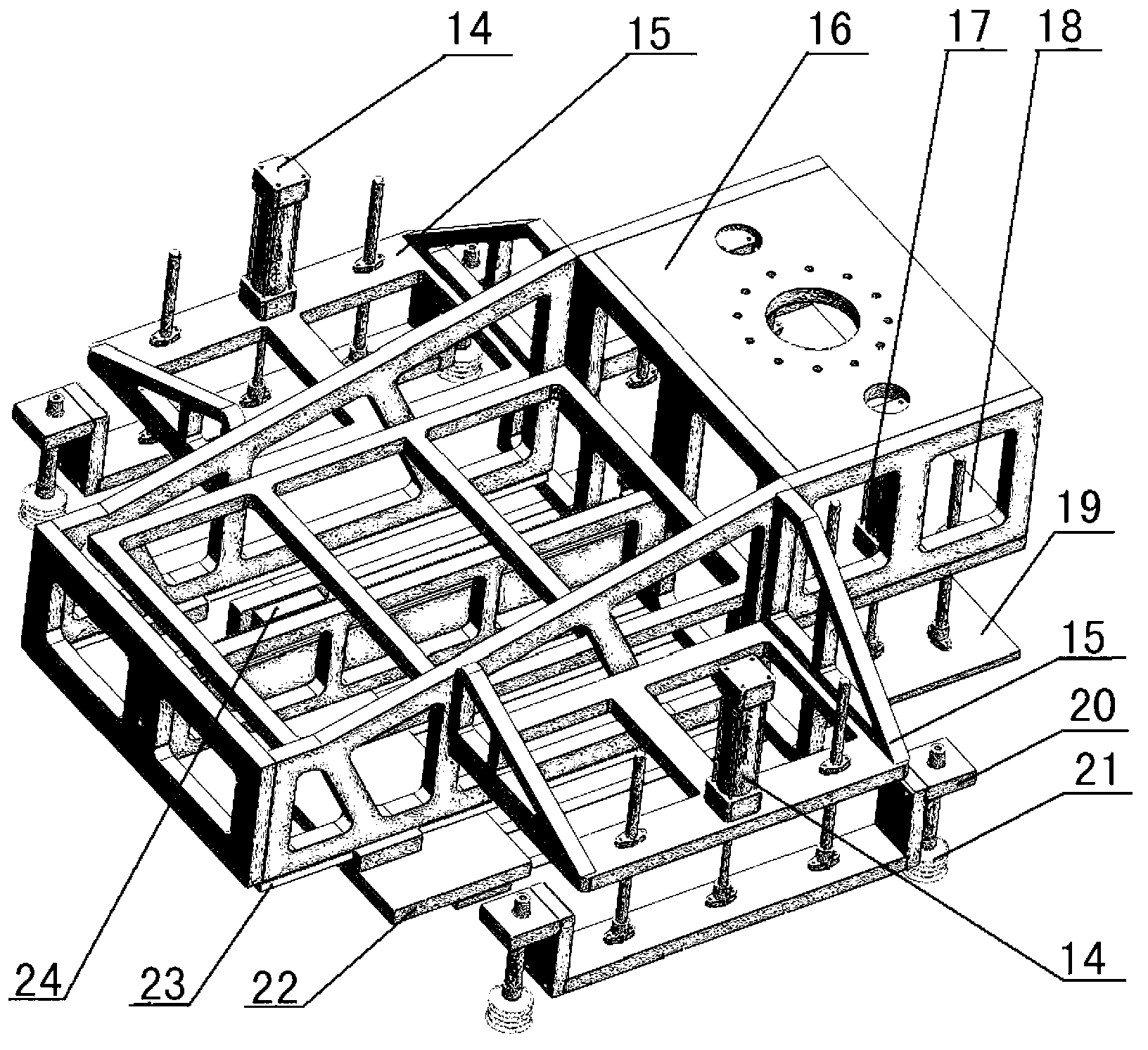

Clad material solid/liquid composite dual-solidification continuous casting and forming equipment and method

The invention belongs to the technical field of clad material continuous casting, in particular to clad material solid / liquid composite dual-solidification continuous casting and forming equipment and method. The clad material solid / liquid composite dual-solidification continuous casting and forming equipment and method are characterized in that inversion solidification and forward solidification continuous casting and forming are combined, the measures that core materials are not heated in advance, an inversion solidification device with small capacity is designed, the core materials are prevented from penetrating through clad layer melt metal for a long time, the melt metal flows out from the bottom of a crucible by relying on self-weight, and the size of the inversion solidification device and the size of a water-cooled crystallizer are controlled effectively are taken, the high quality clad materials of needed shapes and sizes are formed through continuous casting, and the equipment and the method are especially suitable for continuous casting forming of the high quality clad materials with the melting point of the clad layer metal lower than that of the core material metal. The equipment and method have the advantages that the equipment is simple in structure, parts are easy to replace, operation and maintenance are convenient to carry out, layout is reasonable and compact, investment is small, industrialized application and popularization are facilitated, the procedure of the forming process is short, energy is saved, environment is protected, cost is low, the combination freedom of the clad layer metal and the core material metal is large, and the prepared clad materials are good in quality and performance.

Owner:UNIV OF SCI & TECH BEIJING

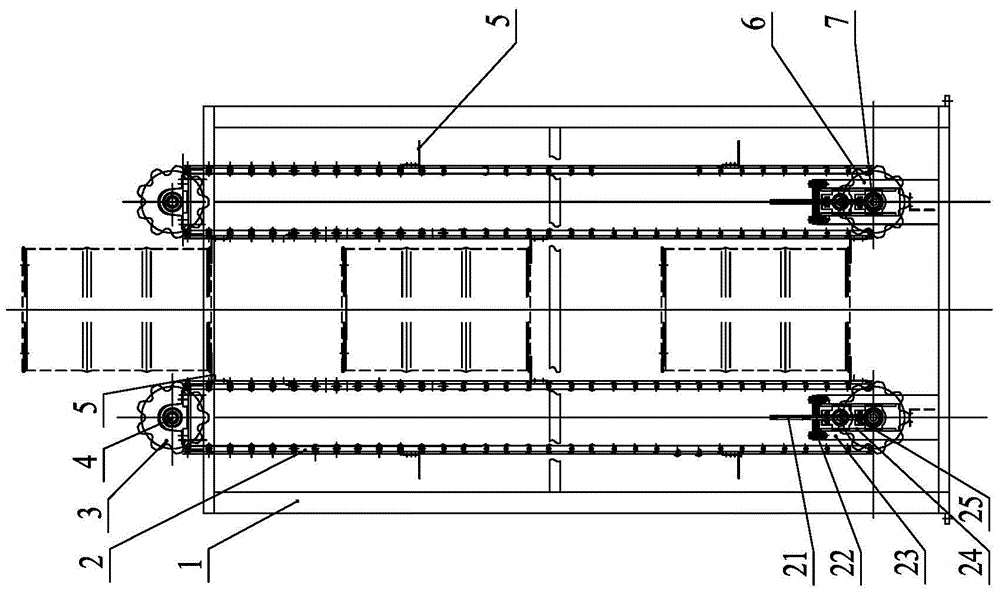

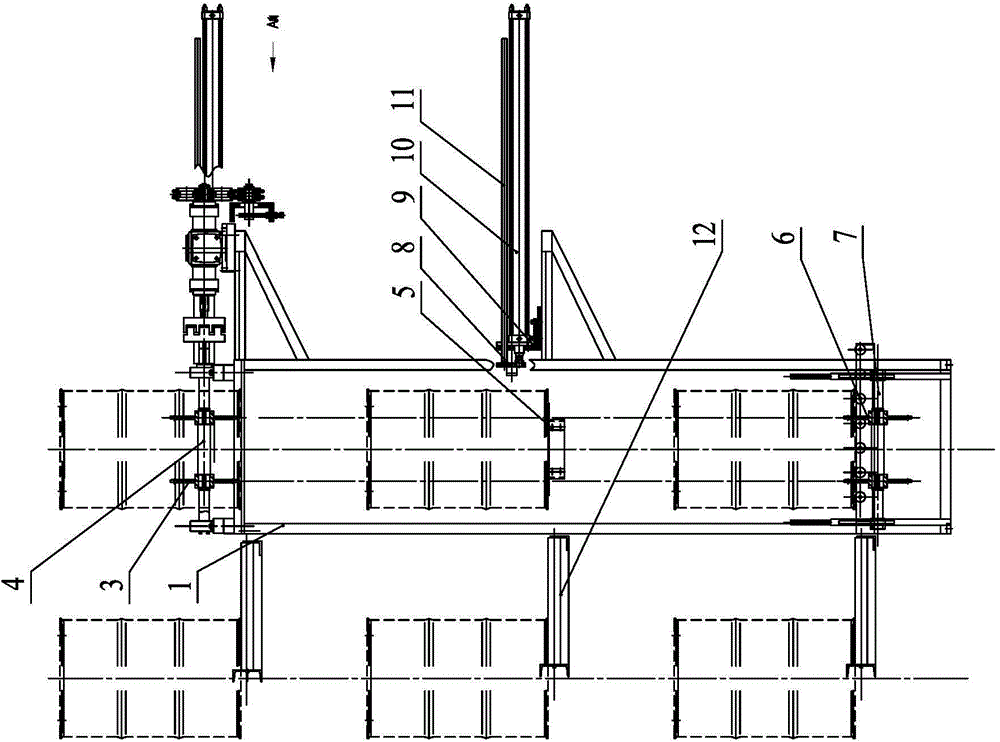

Vertical conveyer for steel drum stereoscopic warehouse

ActiveCN104444000ACompact and reasonable layoutOptimize layoutStorage devicesConveyor partsSprocketChain link

The invention relates to a vertical conveyer for a steel drum stereoscopic warehouse. According to the vertical conveyer for the steel drum stereoscopic warehouse, a steel drum lifting and conveying channel is arranged in the middle of a machine frame, a layer of conveyance rolling way is arranged below the steel drum lifting and conveying channel, the two sides of the steel drum lifting and conveying channel are each provided with a steel drum lifting device, and the two steel drum lifting device are symmetrically arranged; in each steel drum lifting device, an upper chain wheel is installed on an upper shaft on the upper portion of the machine frame, a lower chain wheel is installed on a lower shaft on the lower portion of the machine frame, the upper chain wheel and the lower chain wheel are sleeved with a lifting chain, the upper chain wheel and the lower chain wheel are driven by a driving mechanism to drive the lifting chain to rotate in a circulating mode, multiple L-shaped supporting plates which are distributed at equal intervals are installed on the lifting chain, a steel drum conveyed in place is supported by the L-shaped supporting plates and are lifted, a drum pushing device is installed on the machine frame and is arranged on the side opposite to a storage and conveyance rolling way, and the drum pushing device is used for pushing the steel drum lifted in place to the storage and conveyance roller way. The vertical conveyer for the steel drum stereoscopic warehouse is simple in structure, convenient to operate and capable of achieving automatic lifting and conveyance of the steel drum in the height direction.

Owner:TAICANG SIFANG YOUXIN DRUM-MFG CO LTD

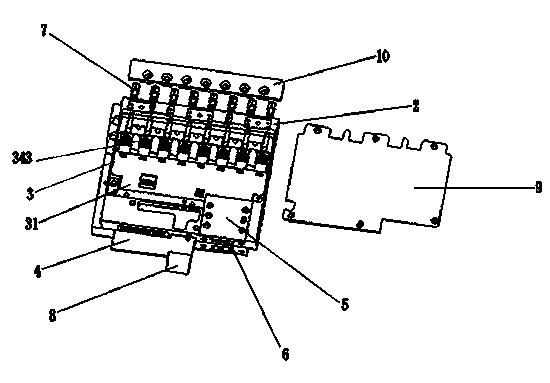

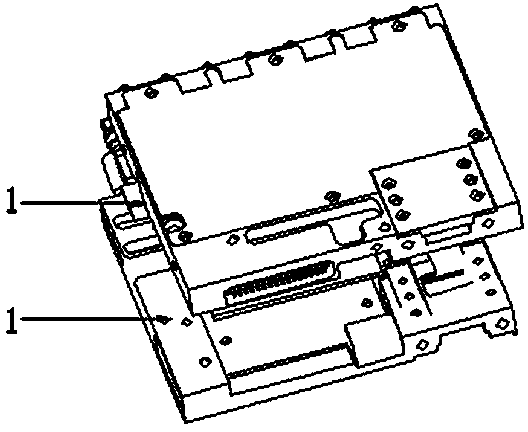

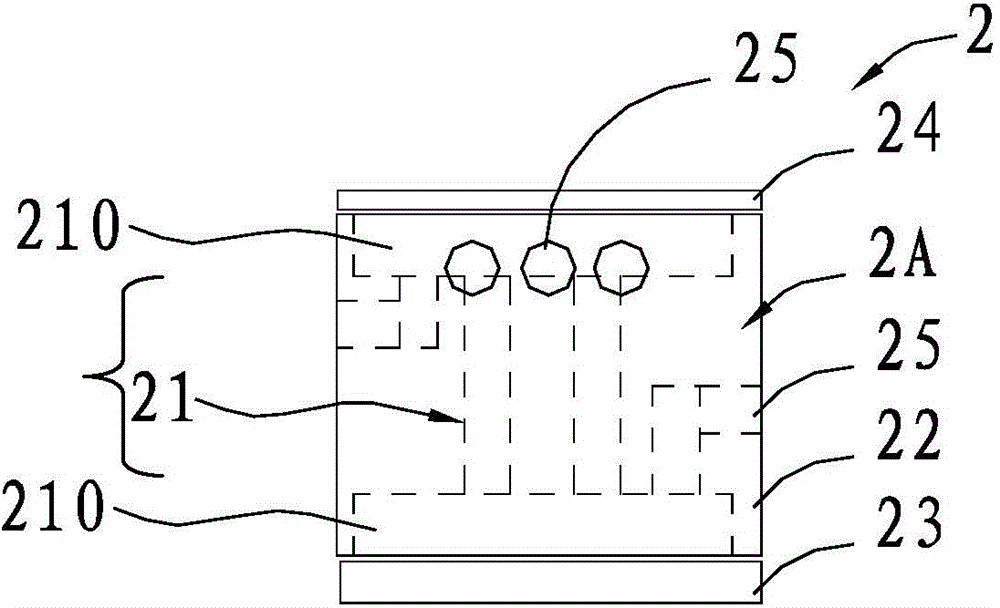

High-integrity TR radio frequency module

The invention relates to the technical field of design of TR assemblies in active phased array radar, in particular to a high-integrity TR radio frequency module. The high-integrity TR radio frequency module is formed by buckling and combining two 1X8 modules, each 1X8 module mainly comprises a box, an LTCC integrated circuit, a waveform control daughter board, a waveguide-micr0-strip conversion structure, a radio frequency input interface and an output interface are arranged in the box, the waveform control daughter board and the LTCC integrated circuit are connected through golden wire binding, an LTCC substrate serves as a carrier of the LTCC integrated circuit, and a front-end drive chip, a power divider, an 8-path TR channel and a DAC control chip are integrated on the LTCC substrate. The chips and a multifunctional circuit are integrated on the basis of the LTCC multi-layer substrate, and then by means of interconnection achieved through micro-electrons, the high-integrity TR radio frequency module is small in size and high in integrity and has an amplitude and phase controlling function.

Owner:成都雷电微力科技股份有限公司

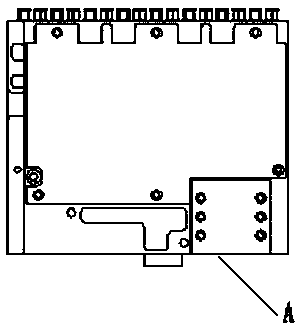

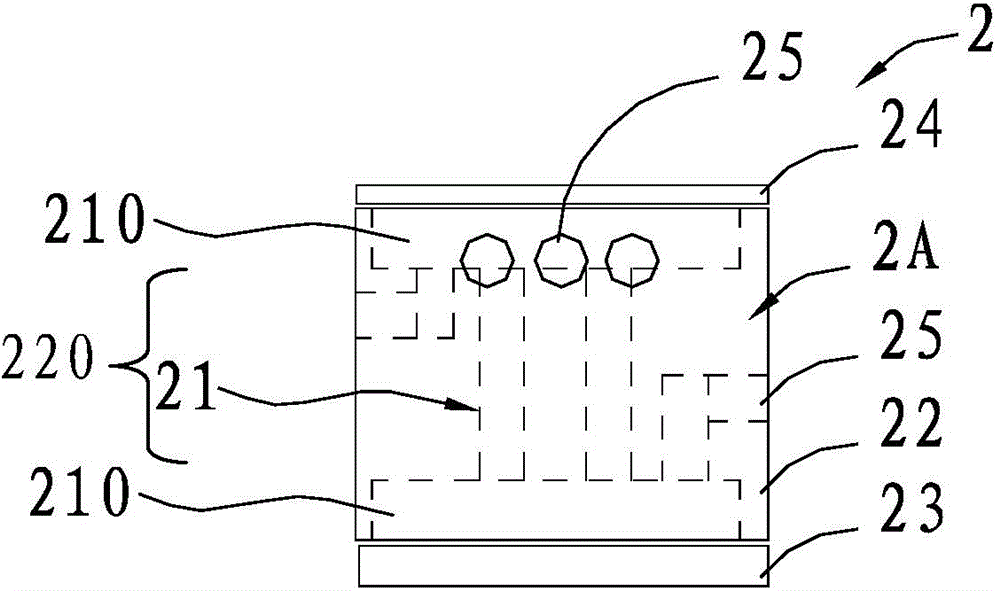

Water purifying equipment, integrated waterway module thereof and production method of integrated waterway module

ActiveCN104944608AGood flow channel sealingImprove pressure resistanceMultistage water/sewage treatmentEngineeringBiggest Problem

The invention relates to water purifying equipment, an integrated waterway module thereof and a production method of the integrated waterway module. A plurality of runners are formed in the integrated waterway module. The integrated waterway module comprises at least a body and at least a cover body, wherein a plurality of grooves are formed in the bodies and / or cover bodies respectively; the bodies and the cover bodies are hermetically connected by injection molded rubber coated structures; the bodies and the cover bodies jointly surround a part of the plurality of runners. The water purifying equipment has the beneficial effects that an integral waterway part is used instead of various tangible pipelines and connectors, thus completely eradicating the biggest problem that water leakage is caused due to failure of connection and sealing of pipes and the connectors; the interior of the water purifying equipment is more concise; design of a plurality of connector interfaces is capable of facilitating arrangement of a plurality of connectors, so that all the parts in the equipment are arranged more compactly and reasonably.

Owner:FOSHAN VIOMI ELECTRICAL TECH +2

Semi-dry rice field for imitating eel cultivating system and cultivating method thereof

ActiveCN105210969AAvoid eel escapesPrevent eels from escapingPisciculture and aquariaHorticultureCultural methodsMaggot

The invention discloses a semi-dry rice field for imitating eel cultivating system and a cultivating method thereof, wherein the semi-dry rice field comprises a rice field body; an external circle fence and an internal circle fence are set inside the rice field body; a field-surrounding fish ditch and a separating fish ditch are set inside the internal circle fence; the rice field body is divided by the separating fish ditch into a plurality of rearing units; an outer side of the rice field body is provided with a maggot auto generating collector; after the rice field body is disinfected and tested with water, rice is planted on each of the rearing units according to the semi-dry planting technology; in addition, aquatic plants and aquatic animals are put in the field-surrounding fish ditch and the separating fish ditch; and eels are cultivated while intercropping fish, escargots and loaches, thus providing rich live bait fodder; and maggots are also cultivated for providing fodder for the eels. By adopting the semi-dry rice field for cultivating eels, the beneficial effects are that the mutual beneficial relationship between the aquatic plants and the aquatic animals is fully utilized; various waste material can be used in circulation; and the quality of the produced eels and fish is the same with that of the wild eels and fish, thus the whole cultivating system and cultivating method are ecological and environmental-friendly and the economic benefits are high.

Owner:滁州市雪山粮油机械制造有限公司

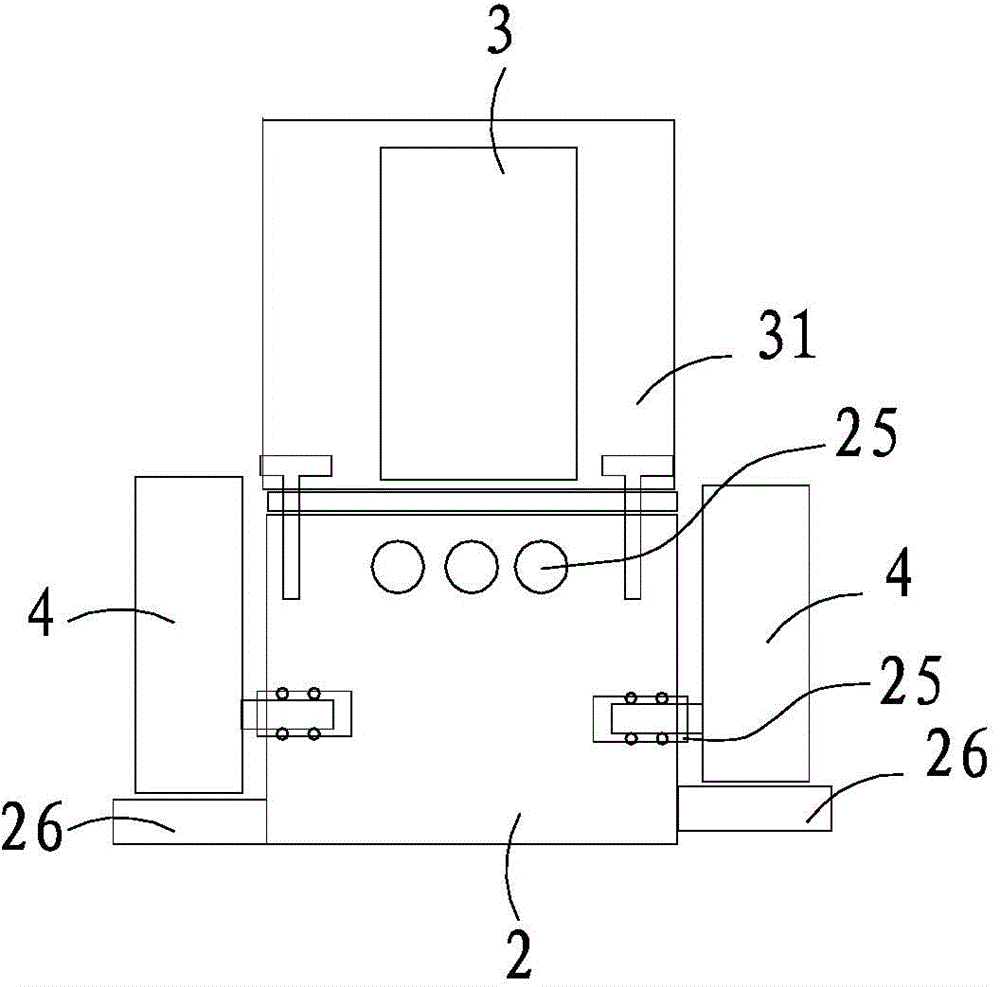

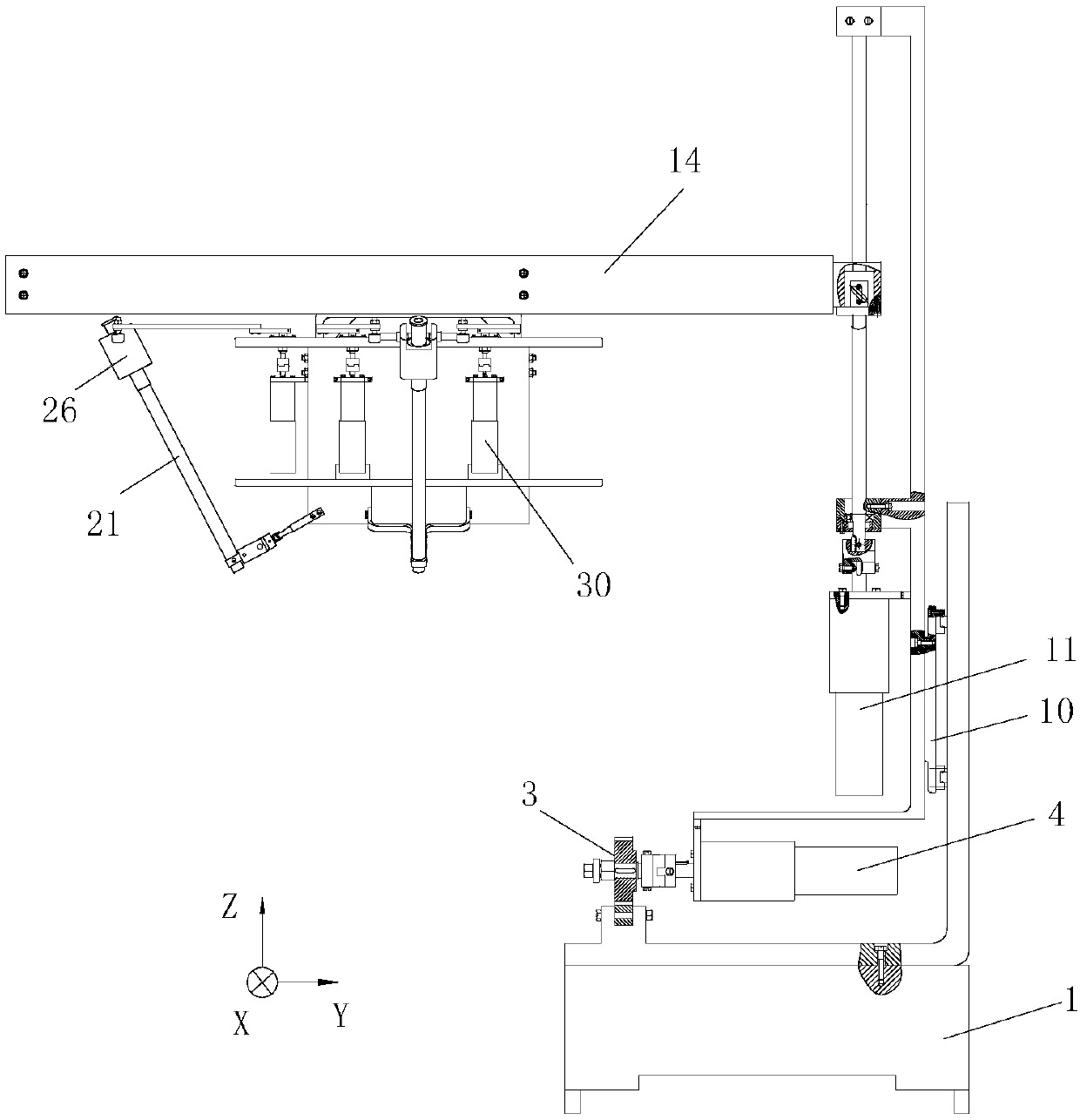

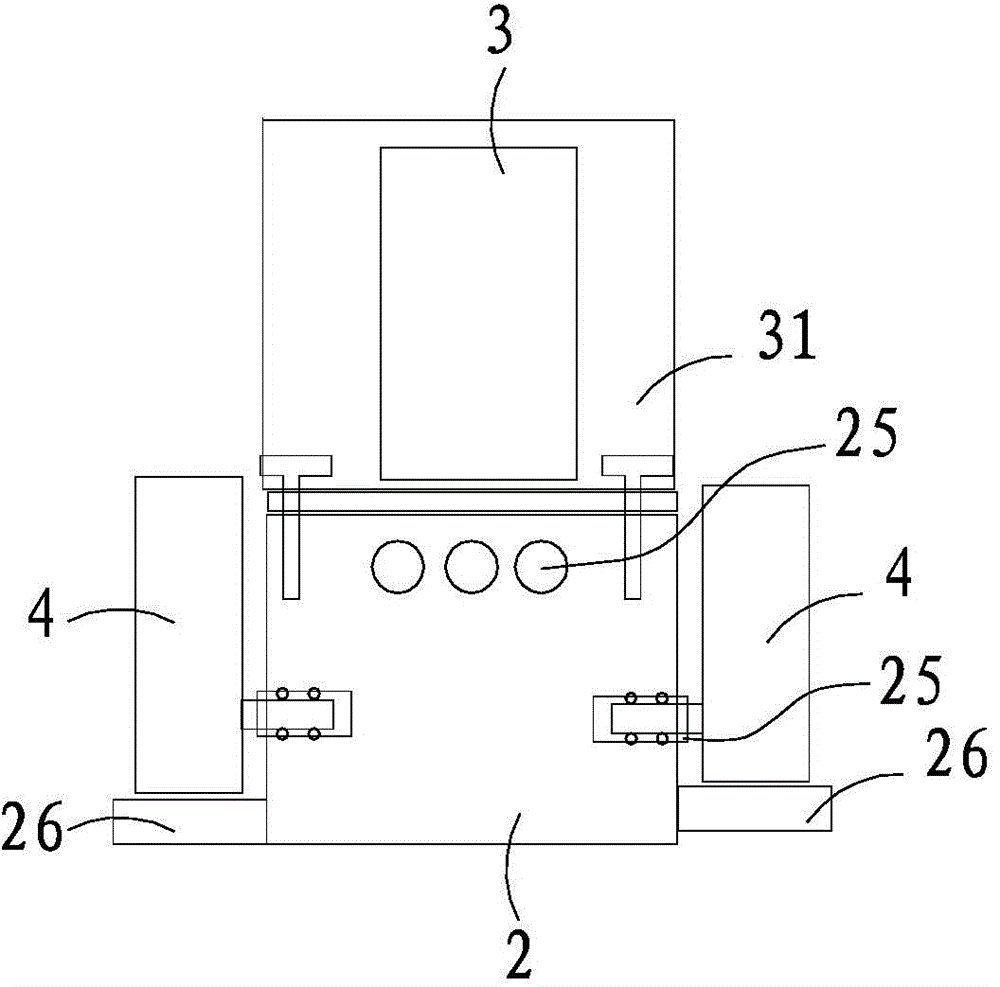

Minimally invasive celiac surgery robot

ActiveCN107789059AImprove coordinationImprove efficiencyProgramme-controlled manipulatorSurgical manipulatorsLinear motionEngineering

The invention discloses a minimally invasive celiac surgery robot. The minimally invasive celiac surgery robot comprises a base, a surgery mechanical box and a driving system. The surgery mechanical box and the driving system are arranged above the base. The driving system comprises an X-direction translational driving device, a Y-direction translational driving device and a Z-direction elevatingdriving device. The X-direction translational driving device is used for driving the Z-direction elevating driving device, the Y-direction translational driving device and the surgery mechanical box to perform reciprocating linear motion along an X-axis direction. The Z-direction elevating driving device is used for driving the Y-direction translational driving device and the surgery mechanical box to perform reciprocating elevating motion along a Z-axis direction. The Y-direction translational driving device is used for driving the surgery mechanical box to perform reciprocating linear motionalong a Y-axis direction. With outstanding strengths in stability, safety and feasibility, the minimally invasive celiac surgery robot helps improve accuracy of surgery operation and surgery quality.

Owner:SHANDONG UNIV OF SCI & TECH

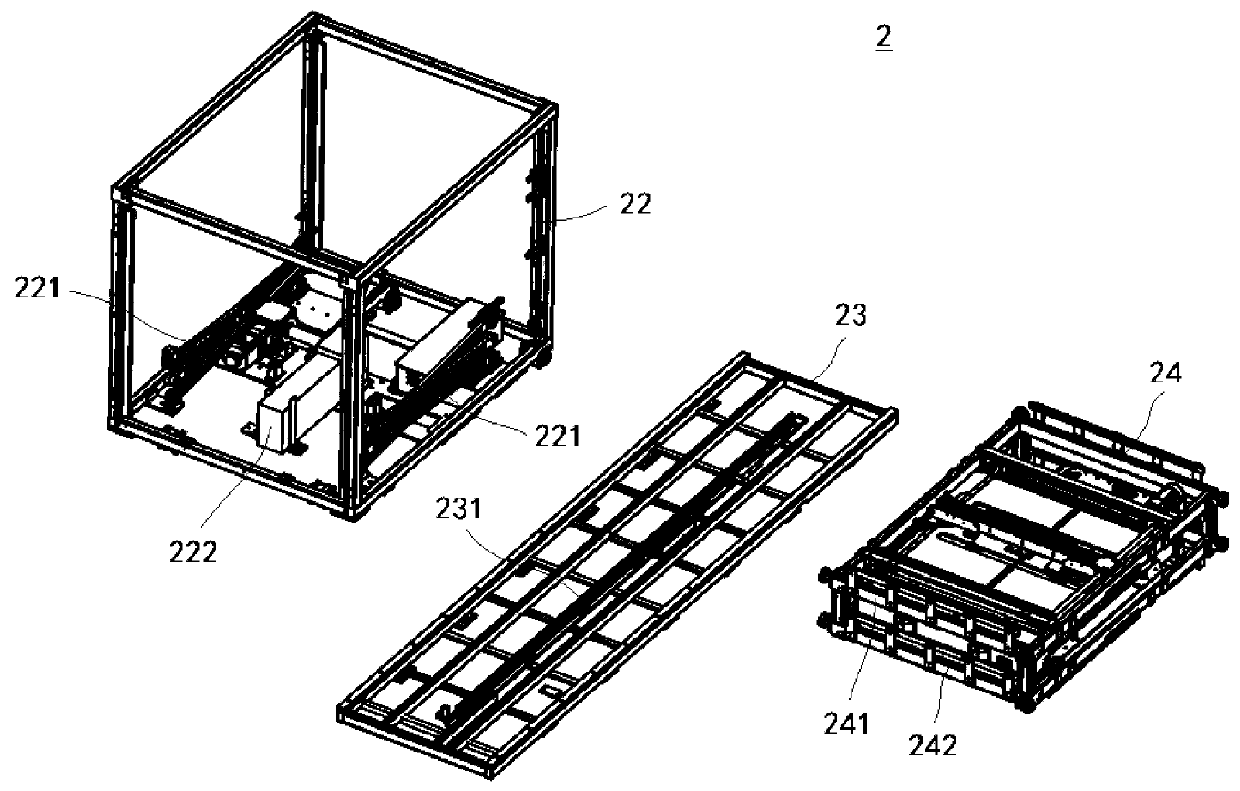

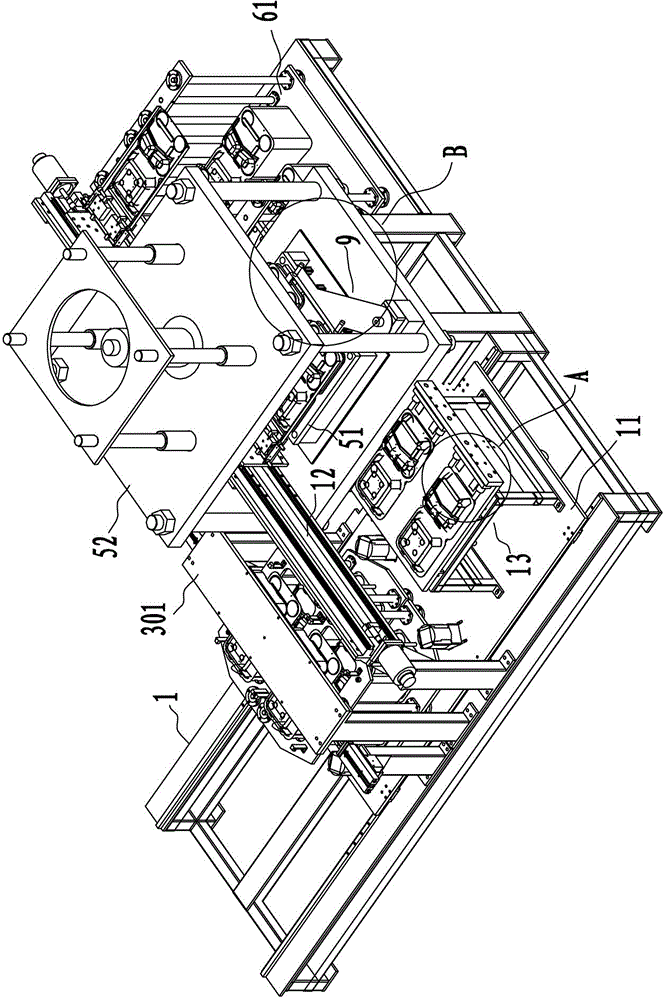

Rapid battery replacing system and method

ActiveCN110001600AReduce accumulationImprove battery swapping experienceElectric propulsion mountingVehicle servicing/repairingElectricityBattery storage

The invention discloses a rapid battery replacing system and method. The rapid battery replacing system comprises a battery replacing platform and a battery storage and transportation assembly, wherein the battery storage and transportation assembly comprises a battery compartment and a battery connection device, and the battery connection device is arranged between the battery replacing platformand the battery compartment and is used for conveying batteries; the battery replacing platform comprises a lifting mechanism, a disassembling and assembling mechanism and a conveying mechanism, wherein the lifting mechanism is used for lifting a vehicle parked on the battery replacing platform to a preset height and is capable of lowering the vehicle to the battery replacing platform; the disassembling and assembling mechanism is used for disassembling and assembling a battery of the vehicle which is lifted to the preset height; the conveying mechanism is used for conveying the battery whichis disassembled from the vehicle to the battery connection device, or conveying a recharged battery which is moved out of the battery connection device to the vehicle so that the battery can be installed on the vehicle through the disassembling and assembling mechanism. The rapid battery replacing system has the advantages that the overall layout is quite compact, the battery replacing speed is high, the success rate is high, the cost is saved, the space heat accumulation is small, and leveling operation is not needed.

Owner:NIO ANHUI HLDG CO LTD

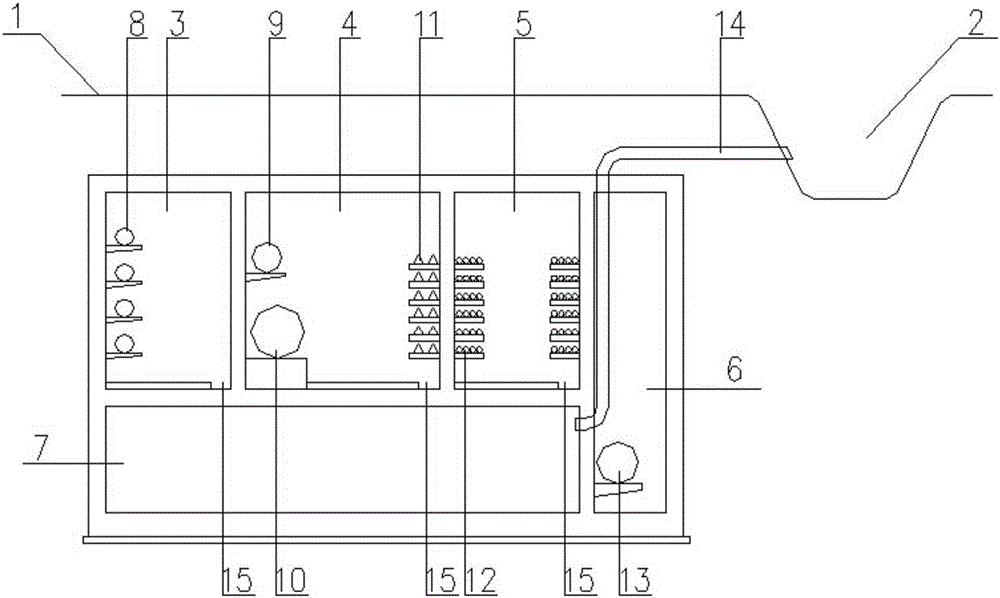

Underground comprehensive pipe gallery with water storage function

InactiveCN106013236ACompact and reasonable layoutEasy to layArtificial islandsUnderwater structuresStormwaterSewage

The invention relates to an underground comprehensive pipe gallery with a water storage function. The underground comprehensive pipe gallery with the water storage function comprises a comprehensive pipe gallery chamber which is arranged below a municipal road surface. A comprehensive green gallery is arranged on the municipal road surface. The comprehensive pipe gallery chamber comprises a natural gas chamber, a comprehensive chamber, a strong current chamber, a sewage pipeline chamber and a rainwater chamber. The natural gas chamber, the comprehensive chamber and the strong current chamber are arranged on the rainwater chamber and the sewage pipeline chamber is arranged on one side of the rainwater chamber. Natural gas pipelines are arranged in the natural gas chamber; a water supply pipeline, a recycled water pipeline and communication optical cables are arranged in the comprehensive chamber; electrical cables are arranged in the strong current chamber; a sewage pipeline is arranged in the sewage pipeline chamber. Drainage ditches are arranged on the inner bottom surfaces of the natural gas chamber, the comprehensive chamber and the strong current chamber. The rainwater chamber is connected with the comprehensive green gallery by a drainage pipe. According to the underground comprehensive pipe gallery, the problems of urban traffic congestion and inconvenient maintenance and inspection of public facilities such as electricity, communication, fuel gas and water supply and sewage can be solved, the pressure of urban inland inundation can be relieved and the rainwater can be collected and used at the same time.

Owner:SHANGHAI BAOYE GRP CORP

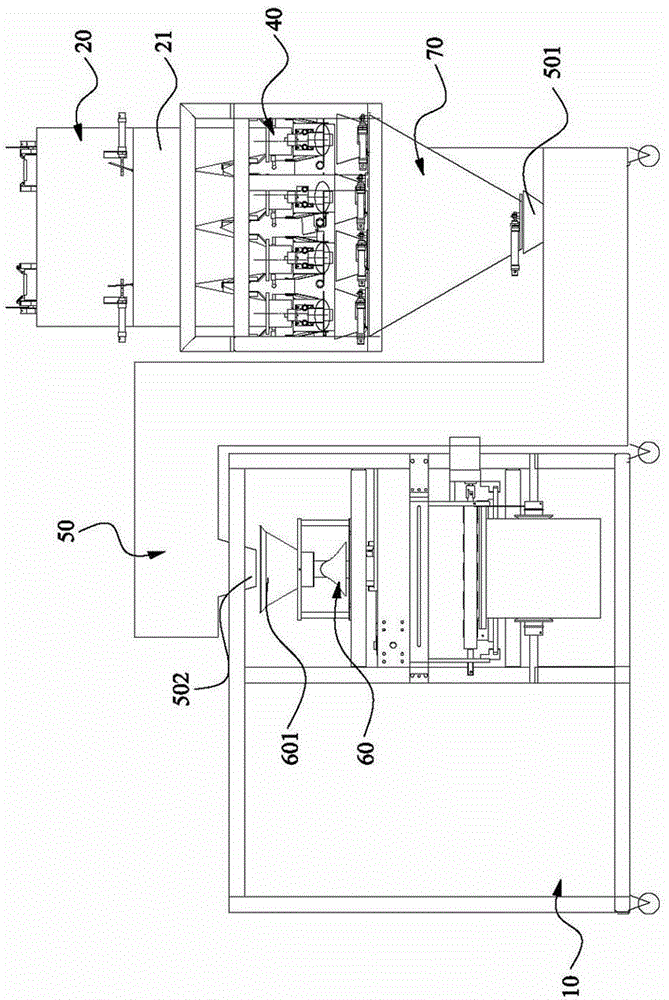

Vehicle battery replacement station

PendingCN109334628ACompact and reasonable layoutImprove securityElectric propulsion mountingVehicle servicing/repairingPower batteryElectricity

The invention discloses a vehicle battery replacement station which comprises a position-fixing platform, a battery replacement mechanism, a battery temporary storage mechanism and a capacity-expansion-type charging bin, wherein the position-fixing platform is arranged on one side of the battery temporary storage mechanism; the battery replacement mechanism is arranged at the middle of the position-fixing platform; the capacity-expansion-type charging bin is arranged on the other side of the battery temporary storage mechanism; the capacity-expansion-type charging bin comprises a lifting-and-lowering transferring mechanism and charging frames; the charging frames are arranged on two sides of the lifting-and-lowering transferring mechanism; the battery replacement mechanism is used for removing a low-power battery of a vehicle, transferring the low-power battery to the battery temporary storage mechanism and mounting a fully-charged battery; and the lifting-and-lowering transferring mechanism is used for conveying the low-power battery in the battery temporary storage mechanism into one of the charging frames for charging, and conveying the charged battery to the battery temporary storage mechanism. The vehicle battery replacement station has the advantages of realizing a full-automatic working process, enabling the layout to be reasonable and compact, improving the safety, enabling the battery mounting and dismounting and the battery storage to be operated independently and simultaneously, saving the battery replacement time and improving the work efficiency. The vehicle battery replacement station is provided with telescopic forks to realize multi-directional conveying of the batteries, and the use is flexible and convenient. The number of the charging frames can be increased or decreased according to actual use requirements, and the practicality is high.

Owner:BOZHON PRECISION IND TECH CO LTD

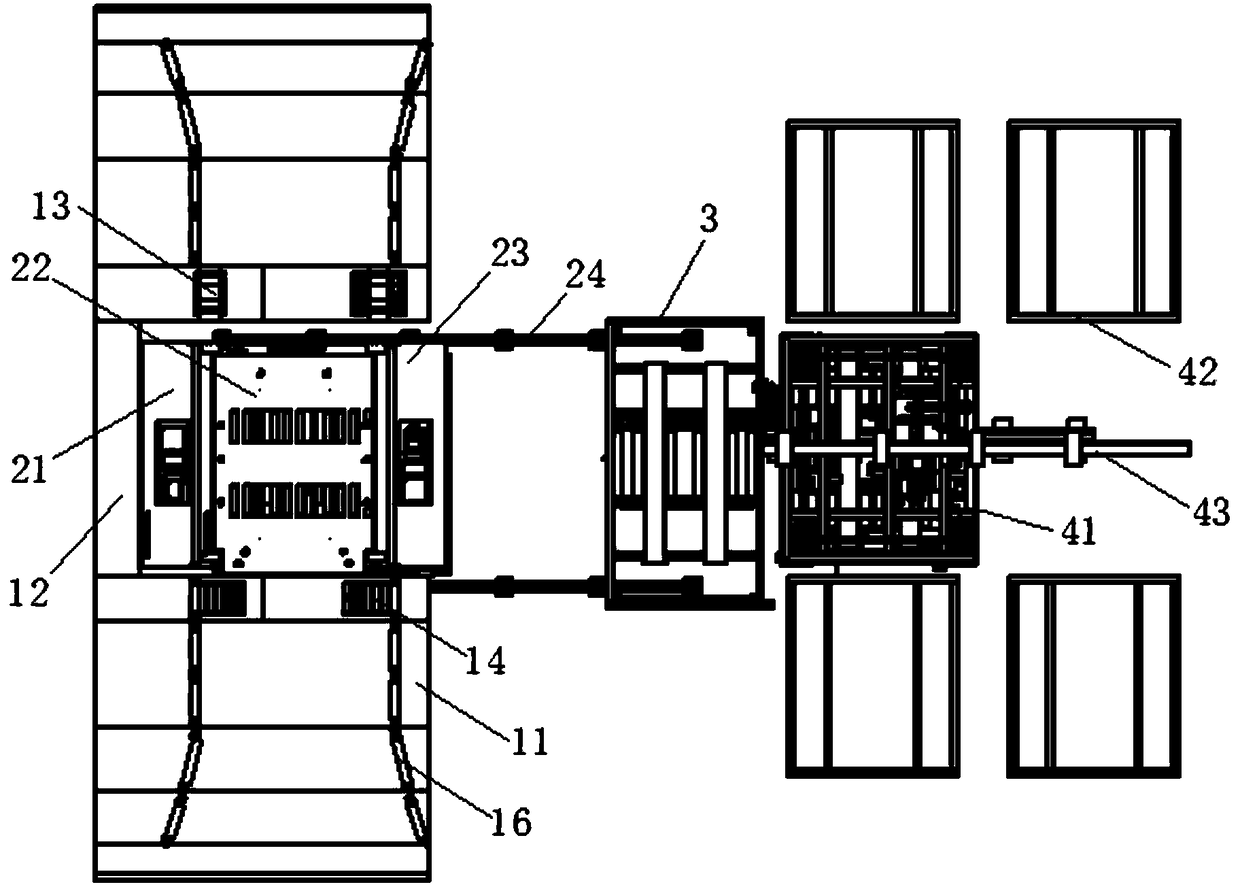

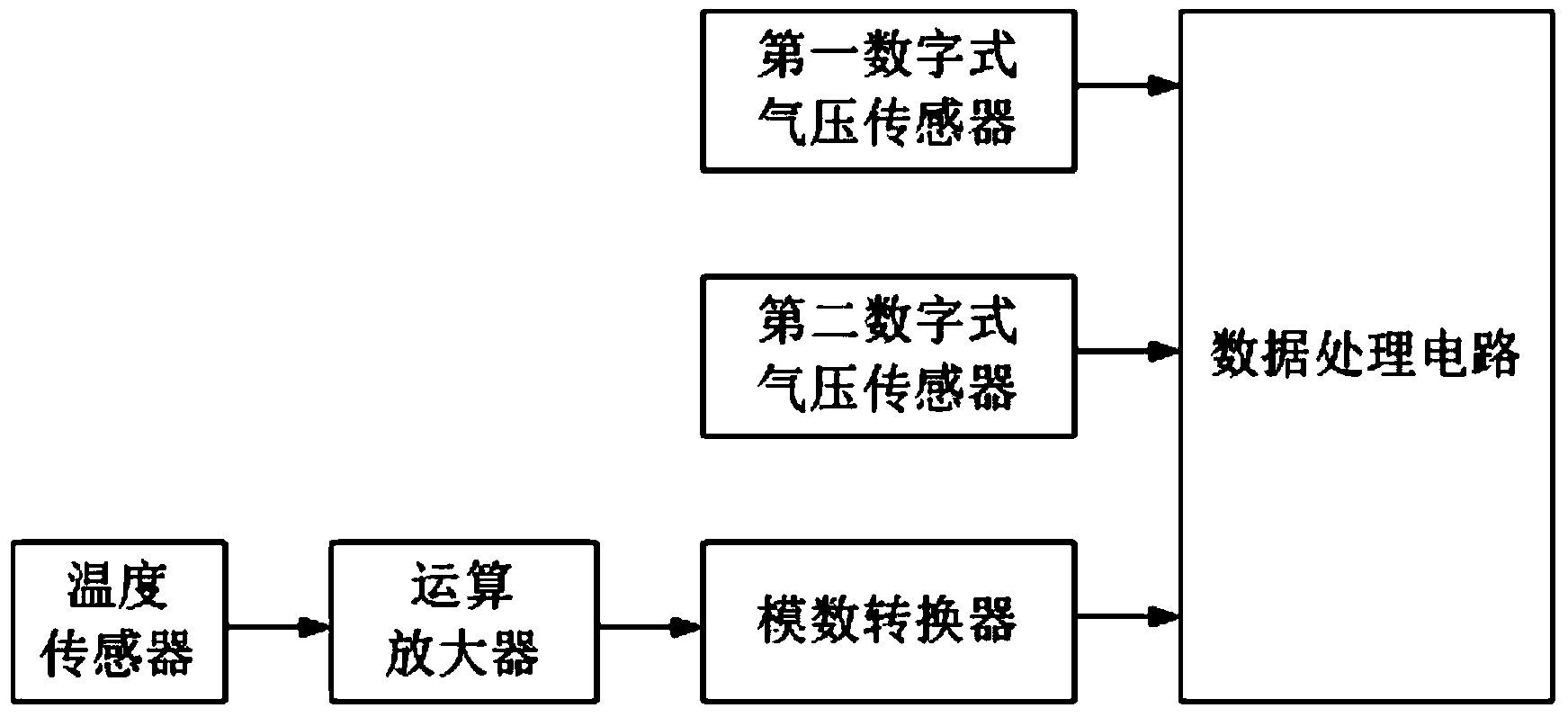

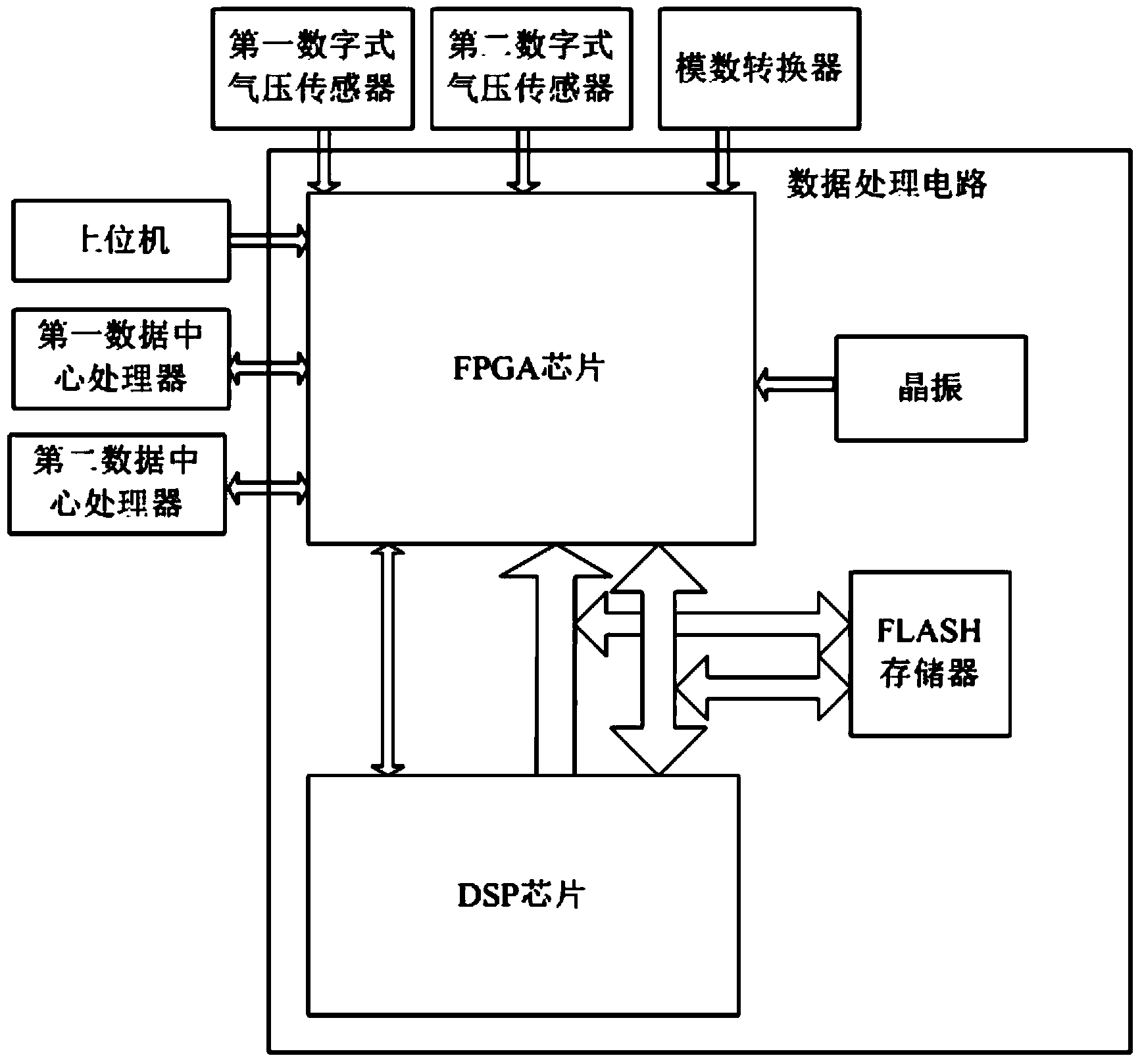

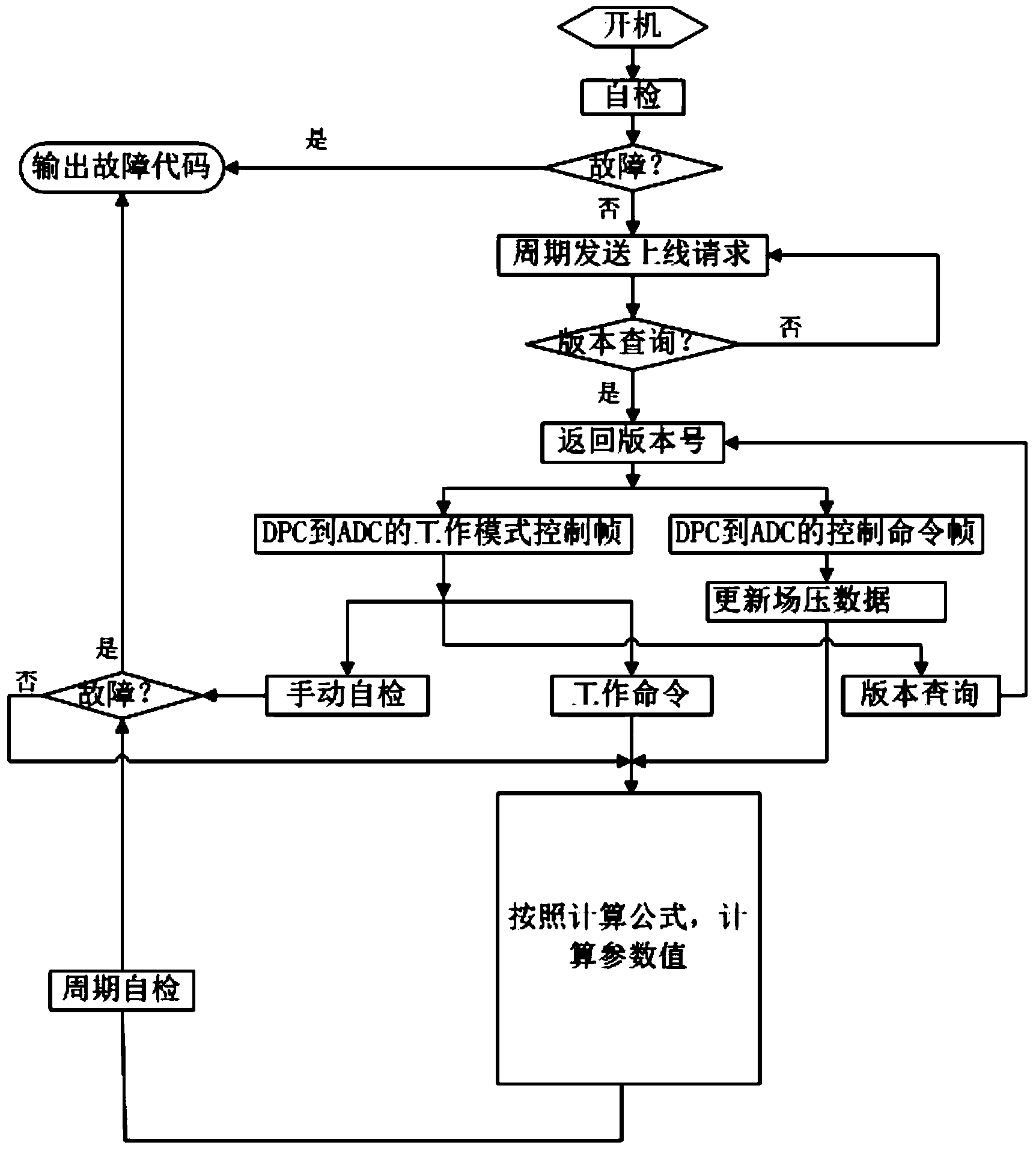

Digital atmosphere data computer and implementation method thereof

InactiveCN104238417AImprove portabilityLogicalProgramme controlMeasurement devicesDigital down converterSignal processing circuits

The invention belongs to the technical field of aviation atmosphere data detection and discloses a digital atmosphere data computer and an implementation method thereof. The digital atmosphere data computer comprises a pitot tube and a temperature sensor, and a total pressure tube and a static pressure tube are arranged on the pitot tube. A first digital barometric sensor is arranged at an outlet of the total pressure tube, and a second digital barometric sensor is arranged at an outlet of the static pressure tube. The digital atmosphere data computer further comprises an operation amplifier, an analog-digital converter and a signal processing circuit, the input end of the operation amplifier is electrically connected with the signal output end of the temperature sensor, and the output end of the operation amplifier is electrically connected with the input end of the analog-digital converter. The signal processing circuit comprises an FPGA chip and a DSP chip, the input end of the FPGA chip is electrically connected with the first digital barometric sensor, the second digital barometric sensor and the analog-digital converter, and the FPGA chip is electrically connected with the DSP chip.

Owner:XIDIAN UNIV

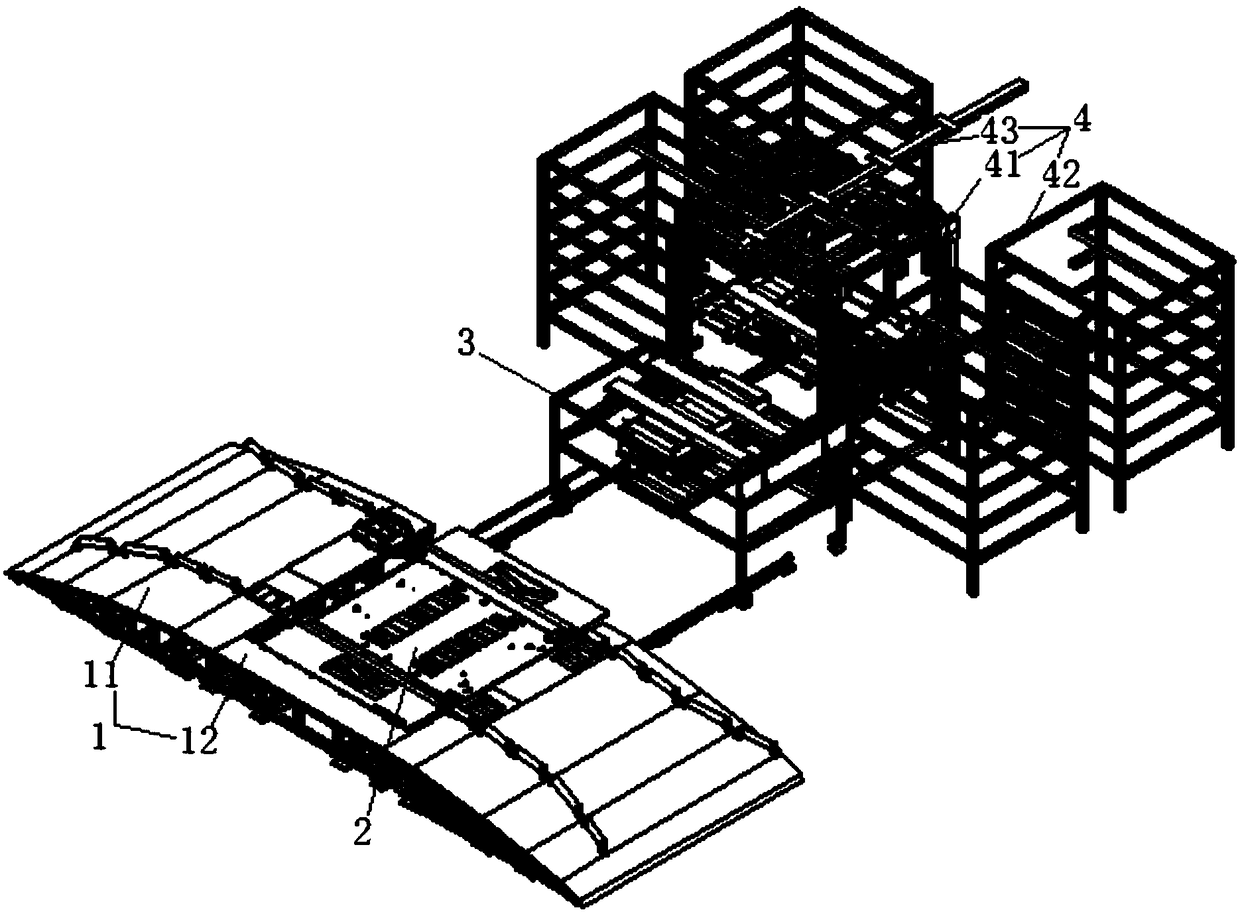

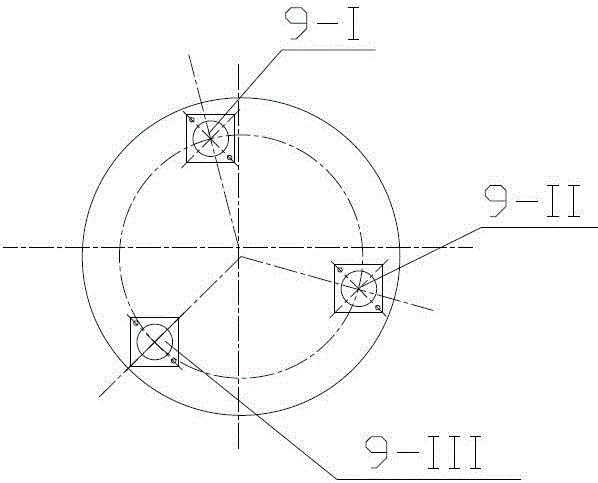

Automatic pharmaceutical glass packaging and integrating system

ActiveCN103057770ACompact and reasonable structureLess investmentStacking articlesDe-stacking articlesProgrammable logic controllerMechanical equipment

The invention belongs to the field of mechanical equipment and particularly relates to an automatic pharmaceutical glass packaging and integrating system. The automatic pharmaceutical glass packaging and integrating system is characterized by comprising a transfer robot, a pallet conveying line, a backing plate conveying line, a cover plate conveying line, a capturing line, a heavy tray conveying line and a stacking area, wherein the pallet conveying line, the backing plate conveying line, the cover plate conveying line, the capturing line, the heavy tray conveying line and the stacking area are distributed around the transfer robot. The pallet conveying line is connected with a pallet supply machine, the capturing line is connected with a hot pack conveying line, a full-automatic rotary packing machine is arranged on the heavy tray conveying line, and a composite manipulator is mounted on the mechanical arm of the transfer robot and is connected with a PLC (programmable logic controller) system. The integral automatic pharmaceutical glass packaging and integrating system can be monitored in all around by the PLC system during running. Hot packs can be conveyed and stacked automatically, backing plates can be added automatically, cover plates can be automatically captured and placed, and trays can be automatically packed. The automatic pharmaceutical glass packaging and integrating system is convenient and quick to operate, labor intensity is reduced, extra equipment investment is reduced and economic and practical purposes are achieved. The conveying lines distributed within a circumference taking the gravity center of the transfer robot as a circle center are reasonable and compact in arrangement.

Owner:SHANDONG PHARMA GLASS

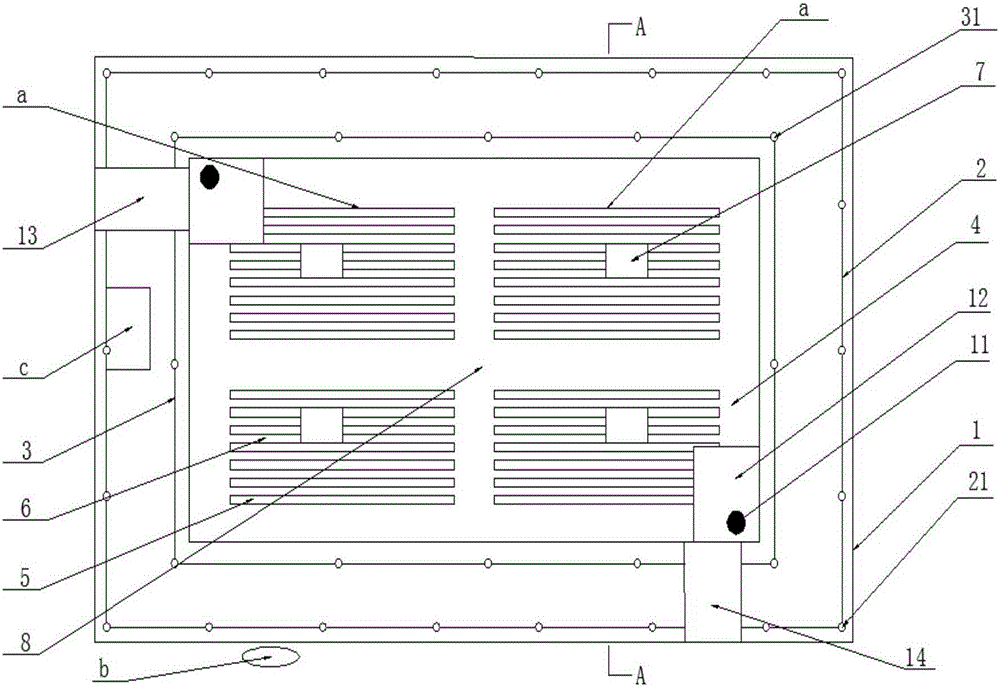

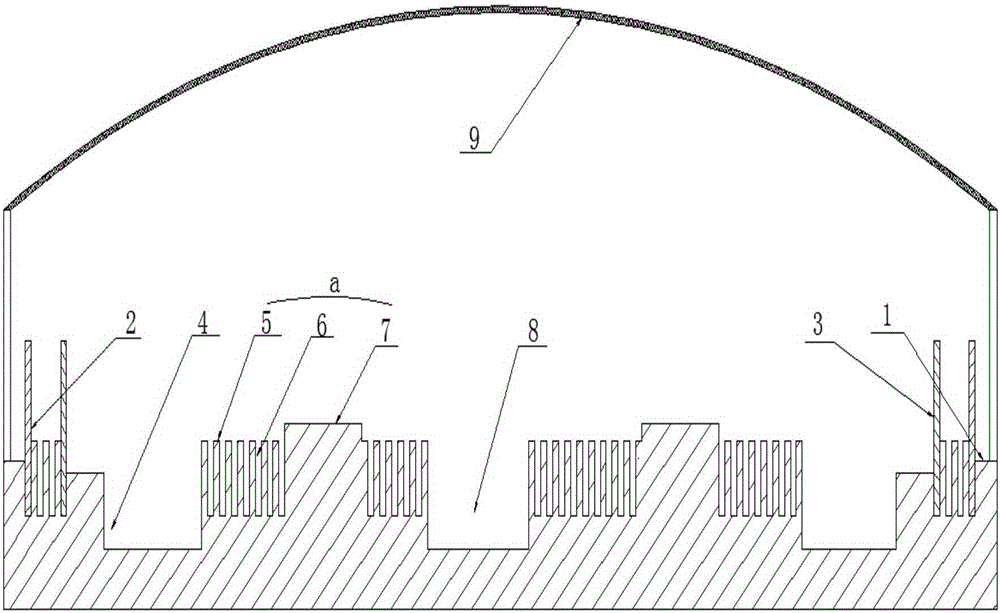

Two-way long-line pedestal method production process of prestressed concrete track slab

InactiveCN101780691AEasy to operateImprove efficiencyCeramic shaping plantsPre stressPrestressed concrete

The invention relates to a two-way long-line pedestal method production process of a prestressed concrete track slab. The invention discloses the two-way long-line pedestal method production process of the prestressed concrete track slab, which comprises relevant equipment and concrete production flows. The invention solves the problems of stretching and loosening of a two-way pretensioning track slab, enables molds to be continuously arranged tightly in both a longitudinal direction and a transverse direction and realizes the batch production of the two-way pretensioning track slab.

Owner:郭志杰

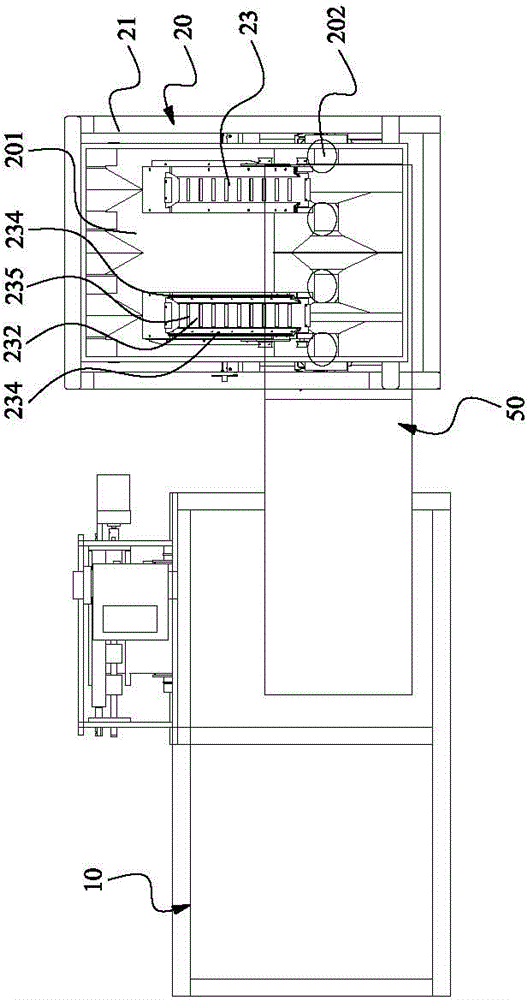

Disposable square box automatic punching and trimming integrated machine and punching and trimming method thereof

ActiveCN104552434AImprove effectivelyRealize automated productionMetal working apparatusPunchingEngineering

The invention provides a disposable square box automatic punching and trimming integrated machine, which has the advantages of rational design, high production efficiency and capability of automatically punching and trimming a square box. The integrated machine comprises a body, a square box storage cabin, an automatic distribution module, an automatic punching module, an automatic trimming module, an automatic stacking module, a first manipulator and a second manipulator; the first manipulator is used for transferring the square box which is subjected to punching action of the automatic punching module to the automatic punching module; the second manipulator is used for transferring the square box which is subjected to the trimming action of the automatic trimming module to the automatic stacking module. Because of the structure, the entire punching, trimming and discharge process of the square box can completely realize automatic production, and the production of the square box is effectively improved; beside, the entire equipment is compact and rational in layout.

Owner:广州市浩洋新材料有限公司

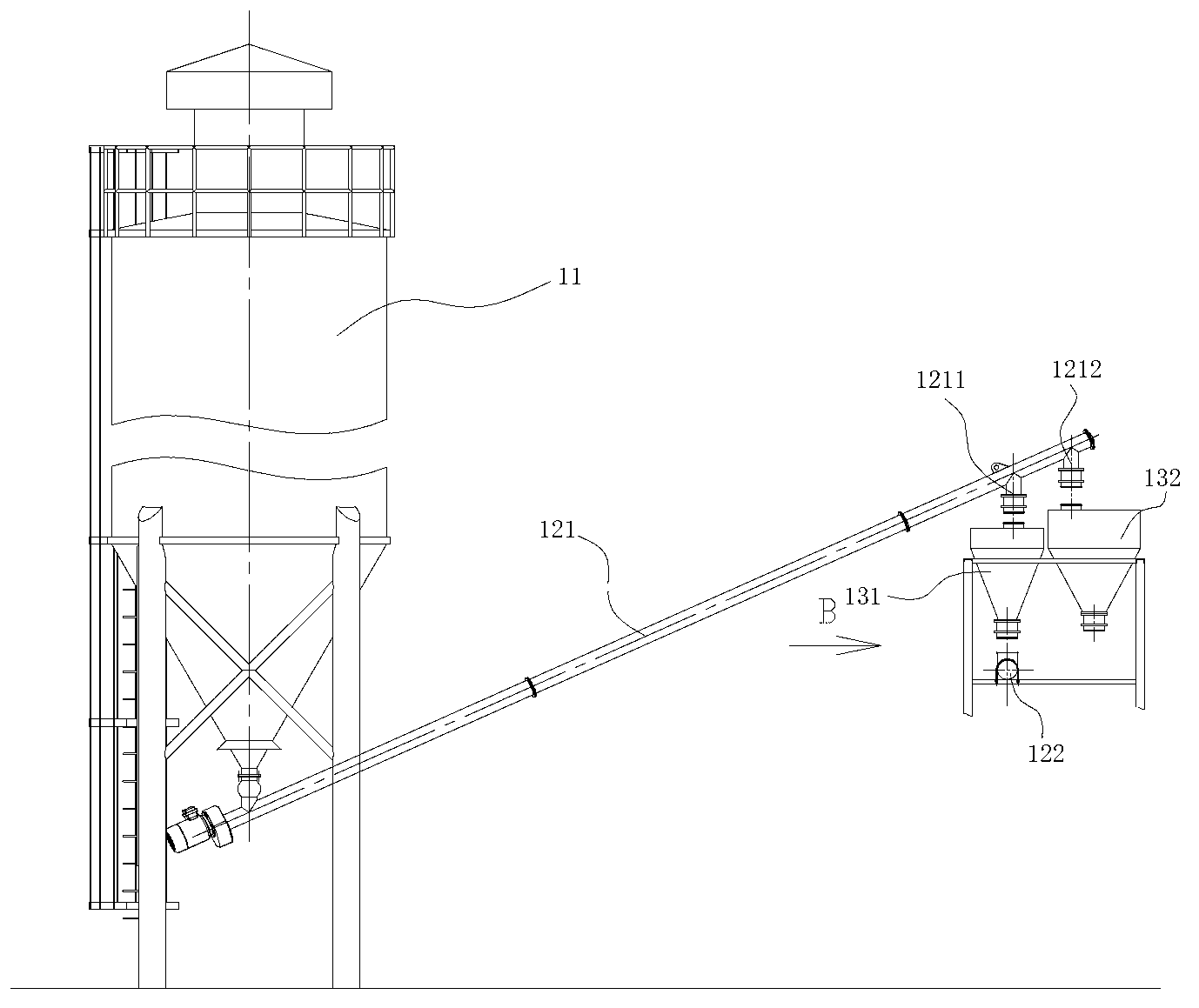

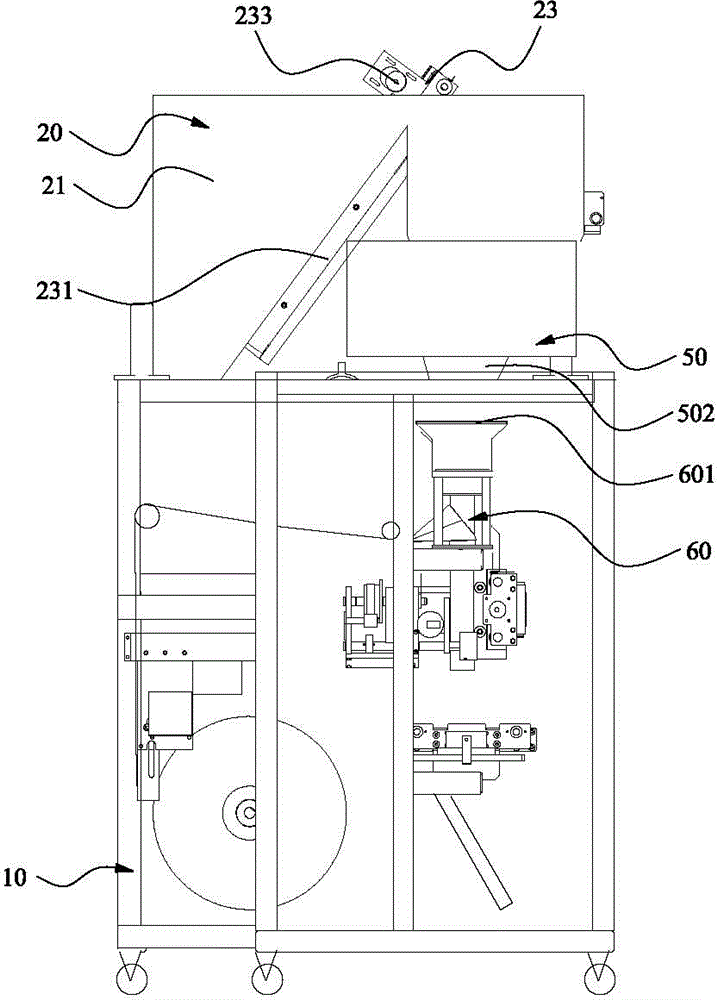

High speed automatic weighing packing machine

ActiveCN102975896APrecise quantitative cuttingHigh precisionPackagingMechanical engineeringEngineering

The invention discloses a high speed automatic weighing packing machine. The high speed automatic weigh packing machine comprises a rack, a blanking device, a weighing mechanism, a rejecting mechanism, a conveying mechanism and a bag packing mechanism. The blanking device comprises a main material hopper and a feeding mechanism. The main material hopper is provided with a first holding cavity and a second holding cavity. The first holding cavity is provided with a rough feeding mechanism. The feeding mechanism is arranged below the main material hopper. The weighing mechanism comprises a weighing hopper. The weighing hopper is arranged below the feed outlet of the feeding mechanism. The rejecting mechanism is arranged below the weighing hopper. A transitional hopper is arranged below the rejecting mechanism, and therefore, by cooperatively utilizing the rough feeding mechanism to conduct most feed to the weighing hopper of the weighing mechanism and by utilizing the feeding mechanism to conduct the compensating feed to the weighing hopper of the weighing mechanism until the default value, the high speed automatic weighing packing machine enables the quantitative blanking with particles easily controlled to become more accurate, thereby being beneficial for improving the accuracy for irregular material packing and meanwhile improving the operation efficiency of the weighing and packing.

Owner:GUANGZHOU V PACK IND CO LTD

Water conservancy gate device provided with warning lamp and capable of being automatically locked

ActiveCN104594302AImprove lock stabilityCompact and reasonable layoutBarrages/weirsArchitectural engineeringDrive motor

Owner:NANTONG HUANAITE GRAPHITE EQUIP

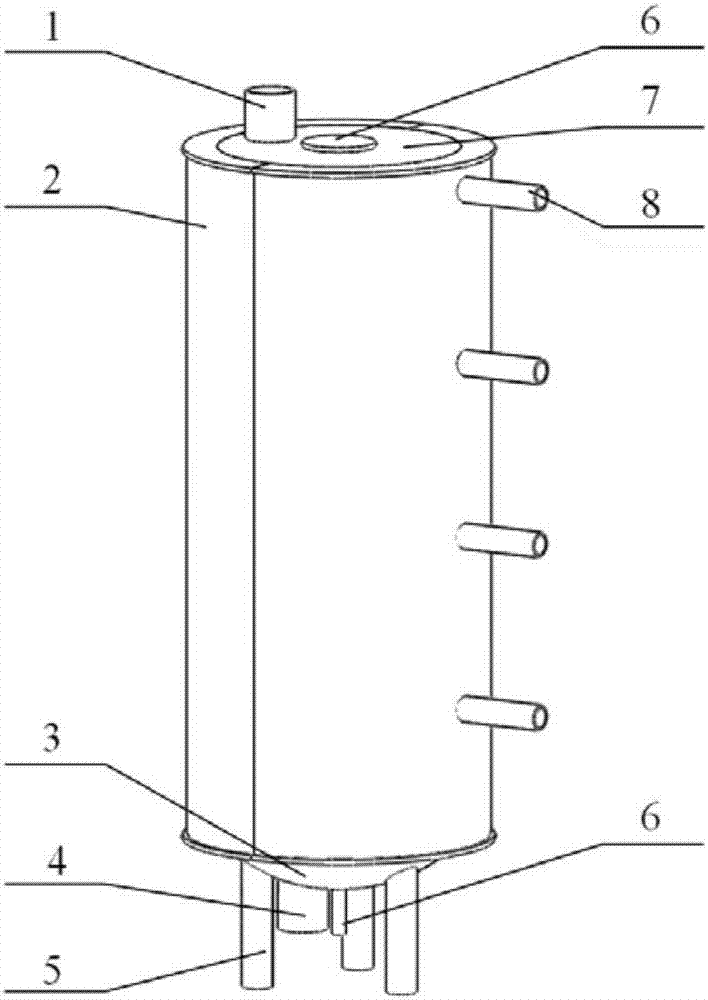

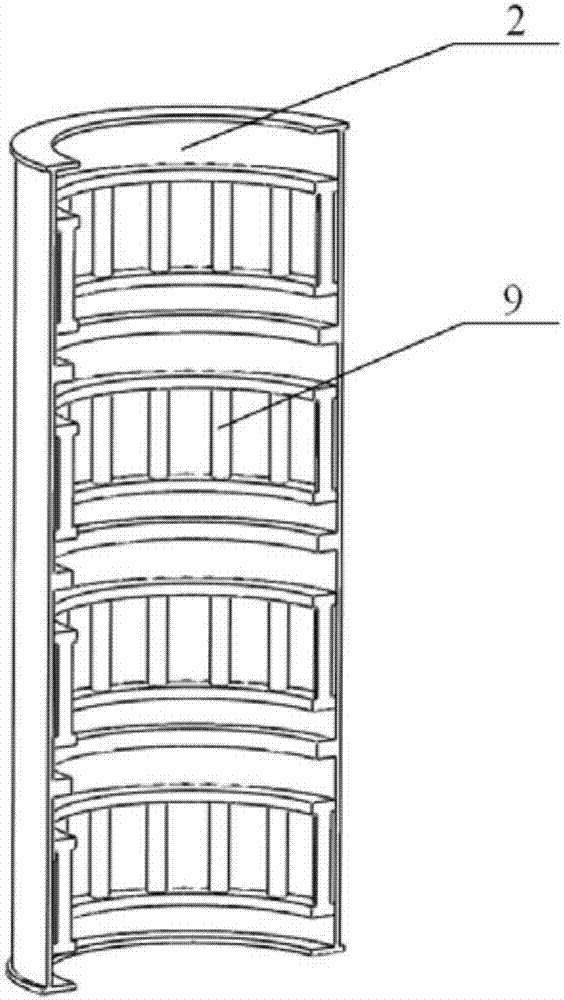

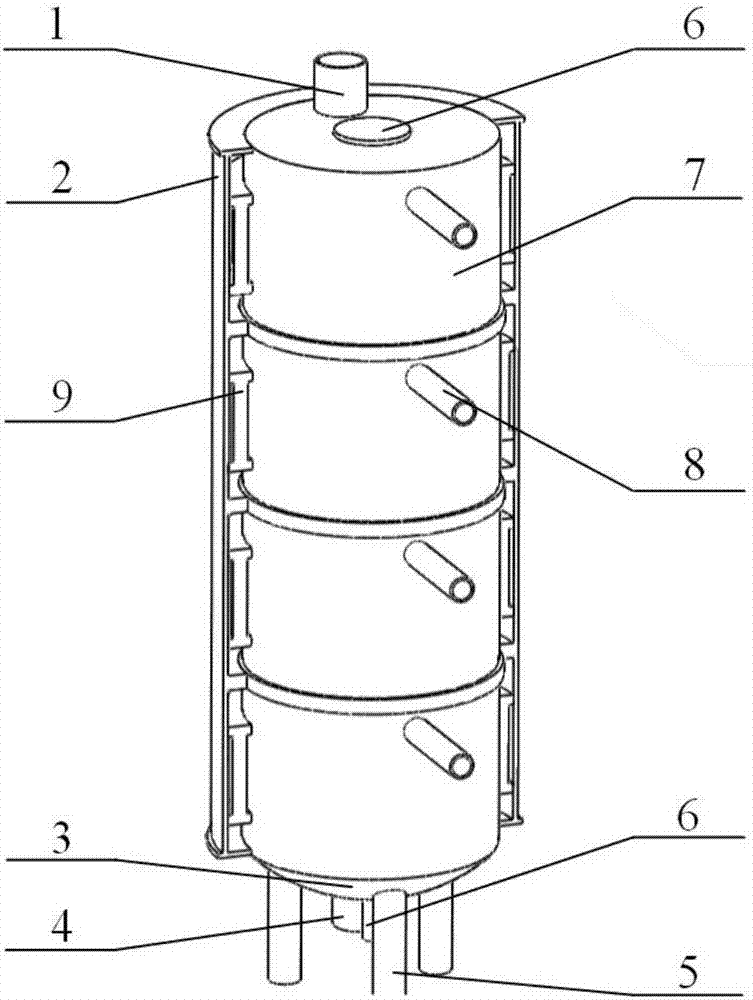

Vertical type pyrolysis device for solid organic waste

ActiveCN107446599ASmall footprintSuitable for places with high space requirementsOven incrustations prevention/removalIndirect heating destructive distillationThermal insulationDrive shaft

The invention relates to a vertical type pyrolysis device for a solid organic waste, and belongs to the technical field of pyrolysis of organic matters. The vertical type pyrolysis device for the solid organic waste comprises a furnace wall, a thermal insulation layer, a transmission shaft, a resistor disc, scraping plates, trays, guide plates, guide canopies, a feed port, a discharge port and a pyrolysis gas outlet; the resistor disc is arranged on the inner wall of the thermal insulation layer of the furnace wall; the feed port is formed in the upper part; the scraping plates arranged in a layered manner are fixed on the transmission shaft and on the trays arranged in a layered manner; the guide plates are fixed on the inner sides of the trays; the guide canopies are arranged on the lower sides of the guide plates; the pyrolysis gas outlet is formed in the furnace wall; and a residue produced after the pyrolysis is discharged from the discharge port in the bottom part. The vertical type pyrolysis device for the solid organic waste adopts a vertical structure, has the advantages of small occupied area, and is suitable for the working place having high space requirements, the multi-stage shearing is adopted, the heat transfer rate is high, coking is not caused easily, the distribution of heat is even, the heat loss is low, and the pyrolysis cost is lowered.

Owner:中海石油环保服务(天津)有限公司

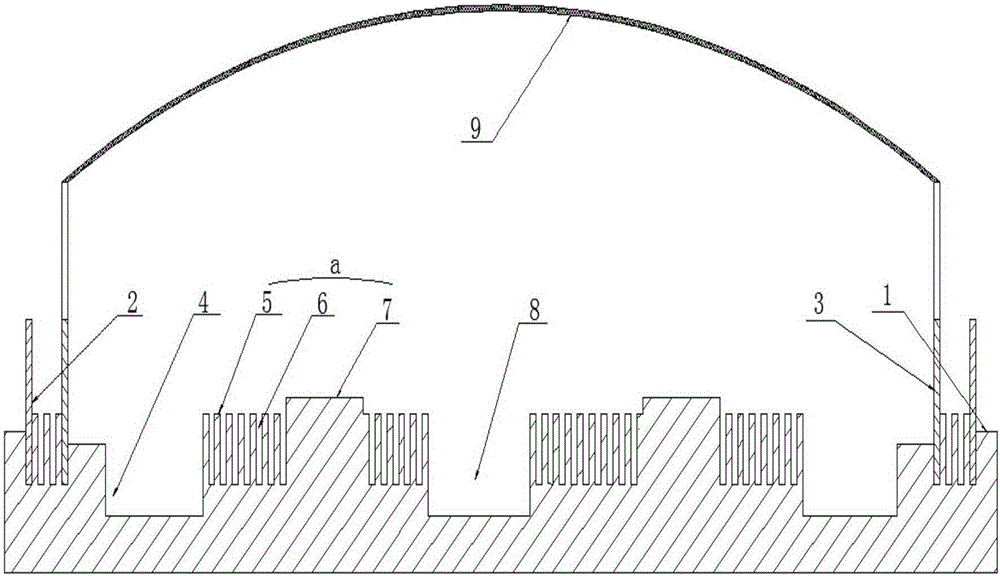

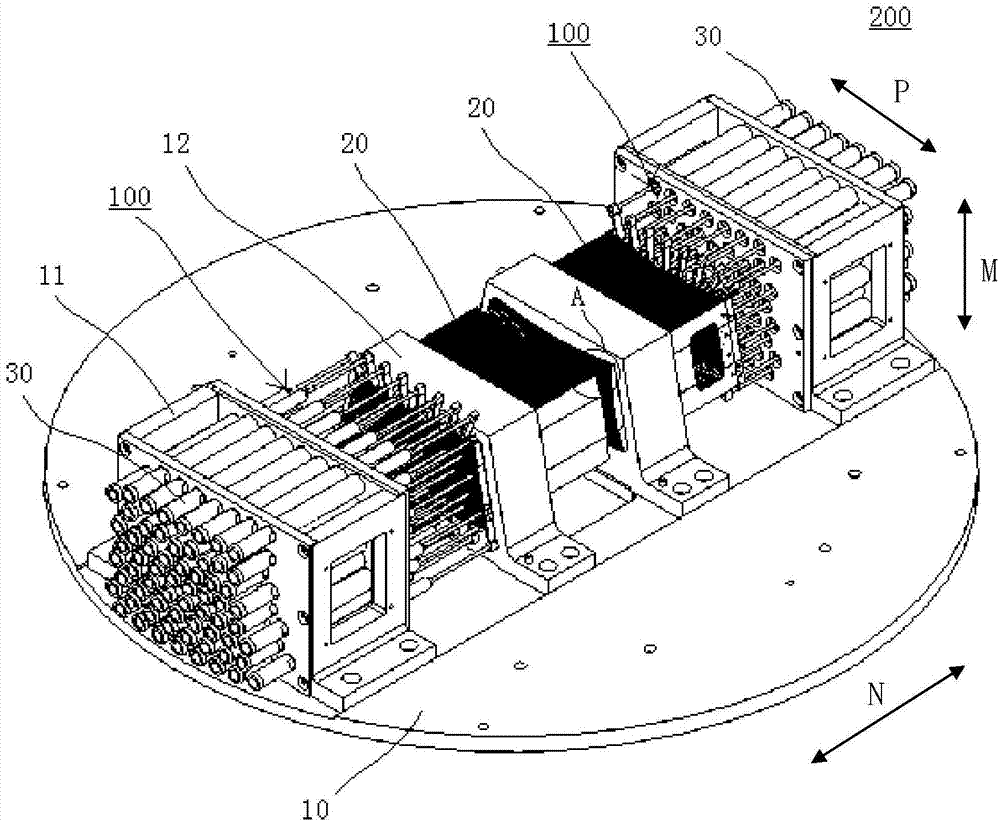

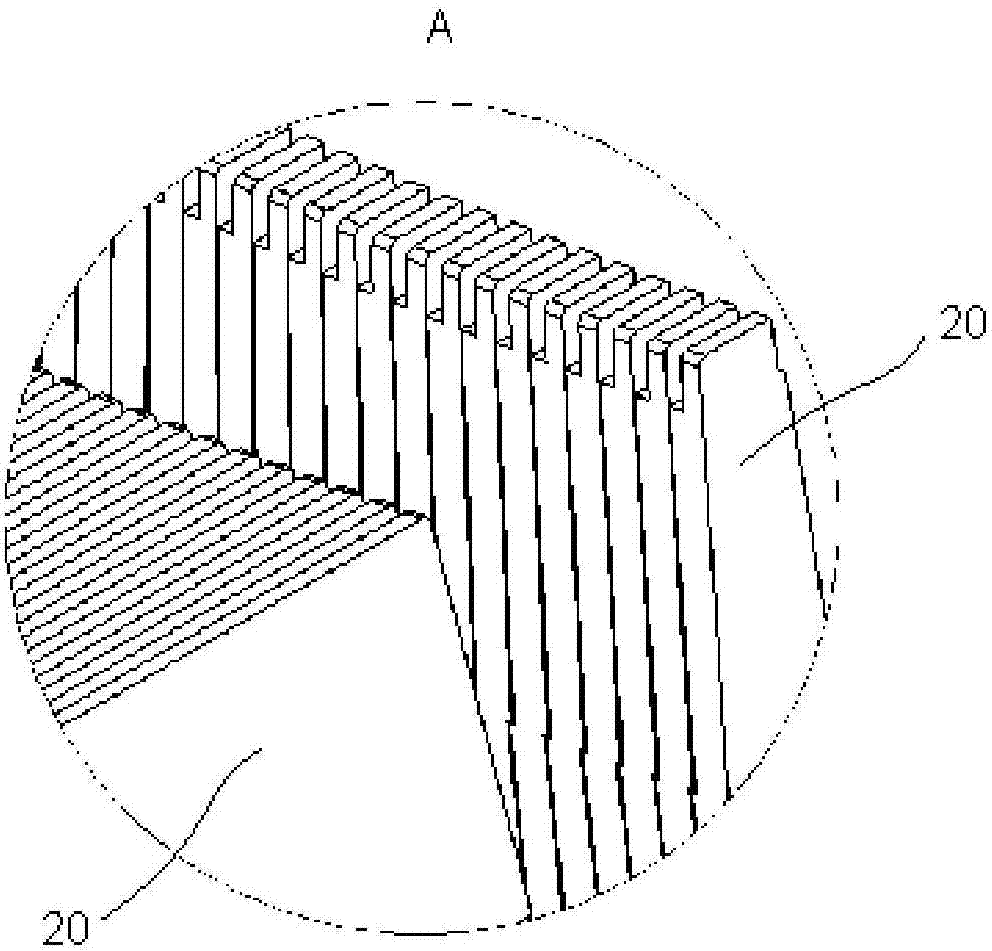

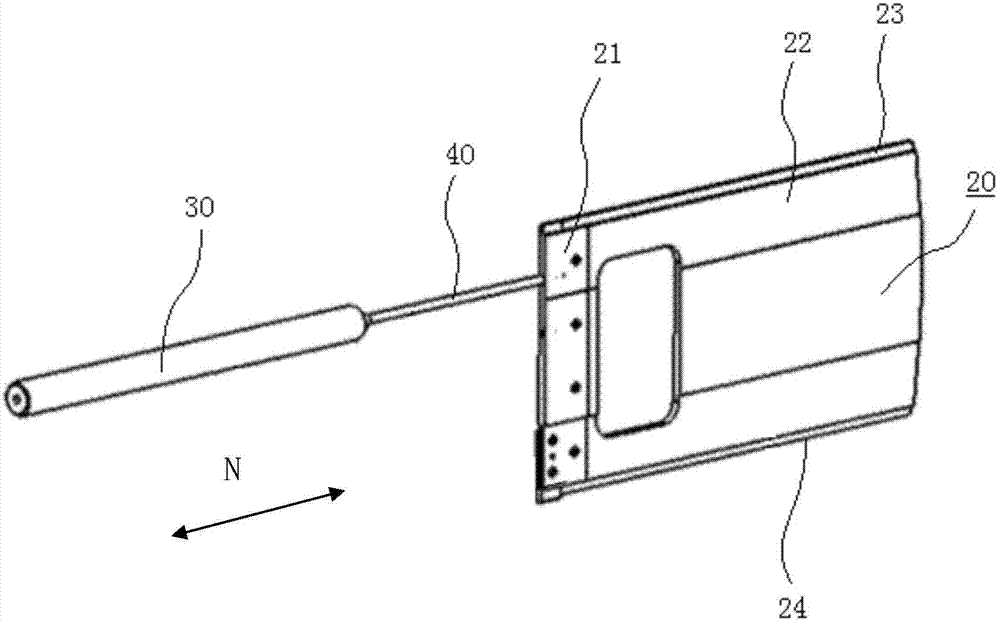

Multi-leaf collimator for tumor radiotherapy and tumor radiotherapy apparatus

ActiveCN104771838AHigh speedHigh positioning accuracyHandling using diaphragms/collimetersX-ray/gamma-ray/particle-irradiation therapyMulti leaf collimatorEngineering

The invention discloses a multi-leaf collimator for tumor radiotherapy and a tumor radiotherapy apparatus. The multi-leaf collimator for the tumor radiotherapy comprises two leaf assemblies which are arranged oppositely in the frontward-and-backward direction, wherein each leaf assembly comprises a base, multiple leaves arranged side by side in the leftward-and-rightward direction as well as multiple linear motors, the multiple linear motors are arranged on the base and connected with the leaves in a one-to-one correspondence manner so as to drive the corresponding leaves to move, each of part of the linear motors is connected with the corresponding leaf through a direct-connection push rod for enabling the linear motor and the corresponding leaf to correspond to each other in the frontward-and-backward direction, and each of the rest linear motors is connected with the corresponding leaf through a bending push rod for enabling the linear motor and the corresponding leaf to be biased in the frontward-and-backward direction. The multi-leaf collimator for the tumor radiotherapy is high in running speed and positioning precision and compact and reasonable in layout.

Owner:江苏高同装备有限公司

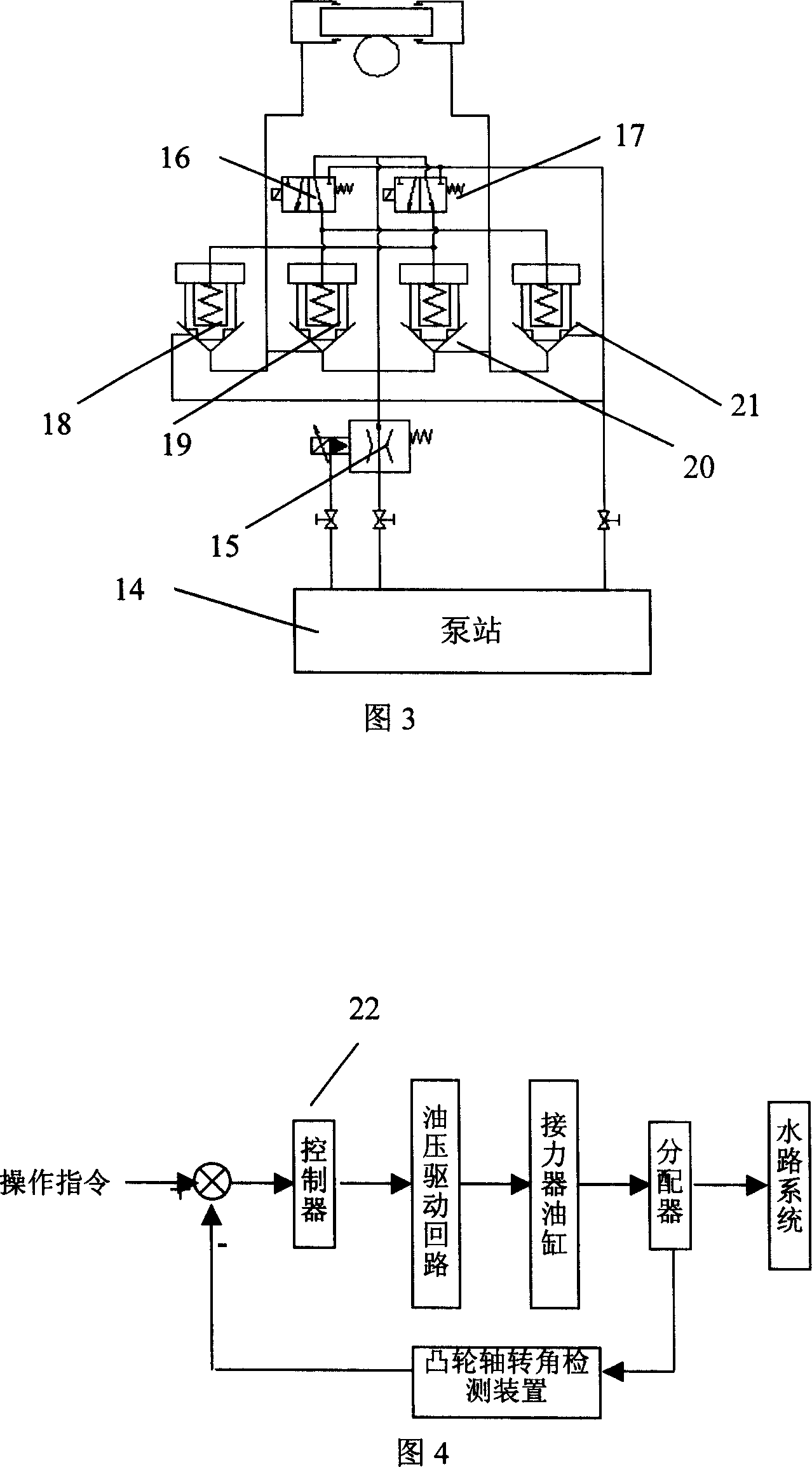

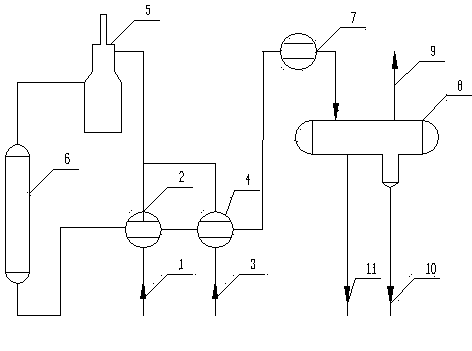

Controlling system of moulded forging hydraulic press with proportional type oil controlling water

InactiveCN101007334AImprove reliabilityAvoid oscillationServomotor componentsForging press drivesHydraulic cylinderControl system

The invention discloses a die forging hydraulic machine proportional oil-control-water operate system. It includes hydraulic drive loop, servomotor cylinder, ram, cam, rotate angle detection device and controller; said hydraulic drive loop consists of main oil way and control oil way which is composed by pumping plant, one electrohydraulic ratio choke valve and two two-position three-way valves and four plug-in cone valve; the input of said controller is connected with said rotate angle detection device, the output of controller is connected with electrohydraulic ratio choke valve to adjusting the quantity of hydraulic drive loop basing the input signals and according rate and connected with two two-position three-way valves to control the big flow direction of hydraulic cylinder through the control of make and break of two-position three-way valves. The die forging hydraulic machine proportional oil-control-water operate system has advantages of high precision and good stability.

Owner:SOUTHWEST ALUMINUM GRP +1

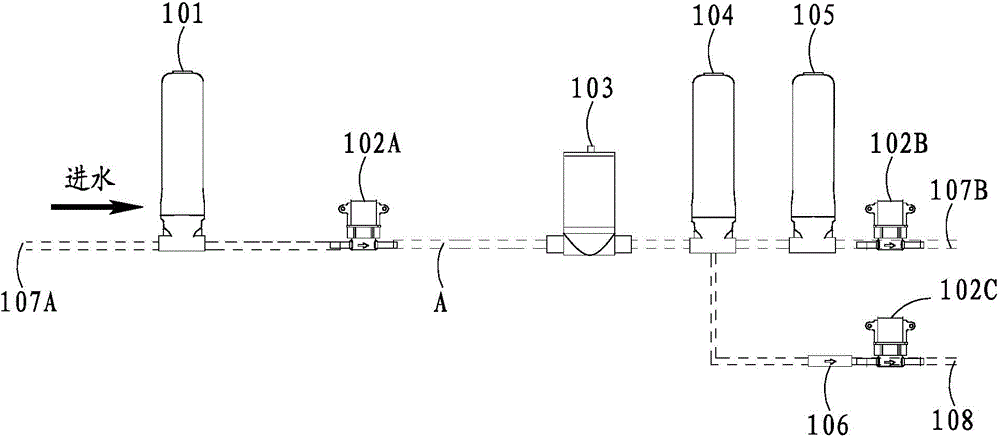

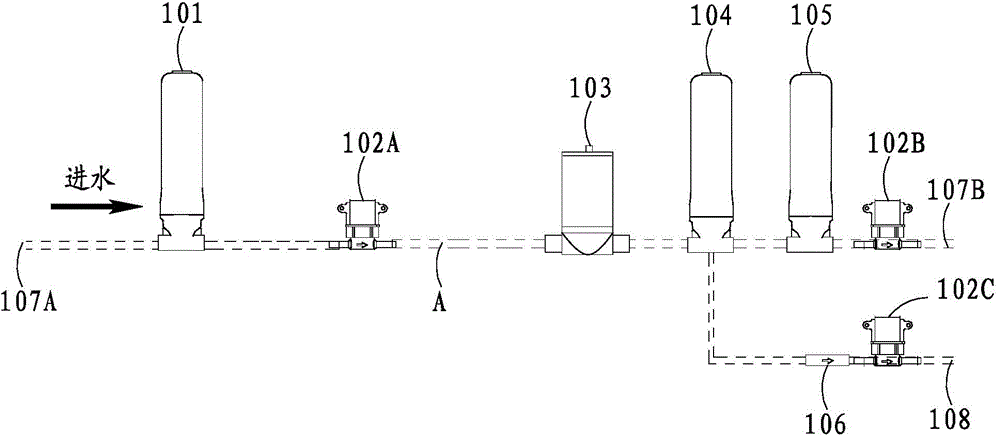

Technology for preparing high-cleanliness and high-octane gasoline from methanol through one-step catalysis method

InactiveCN104130796AEasy to adjustPrecise temperature controlLiquid hydrocarbon mixture productionBio-feedstockGas compressorComponents of crude oil

The invention relates to a technology for preparing high-cleanliness and high-octane gasoline from methanol through a one-step catalysis method. The process of preparing gasoline from methanol is a strong heat release process, and existing technologies for preparing gasoline from methanol at home and abroad all adopt recycle gas (which mainly contains mixed methane, ethane, hydrogen, propane, butane, pentane, carbon monoxide, carbon dioxide and the like) as a heat taking medium to take away heat generated in a reactor, so as to control the outlet temperature of the reactor; liquefied gas (mainly containing propane and butane) produced by a device per se is adopted in the technology to substitute the recycle gas and enters the reactor to serve as a heat removal medium, and the liquefied gas rarely participates in reaction under the same reaction condition, the reaction product is basically unchanged. The technology has the advantages that a recycle gas compressor is not needed, the equipment investment is greatly reduced, the running power consumption of the device is reduced, the heat exchange flow of the device is optimized, the device is simple, stable and reliable in operation, and meanwhile, the public engineering grade is also reduced, so that the technology has significant practicability, huge economic benefits and wide application prospect.

Owner:张永魁

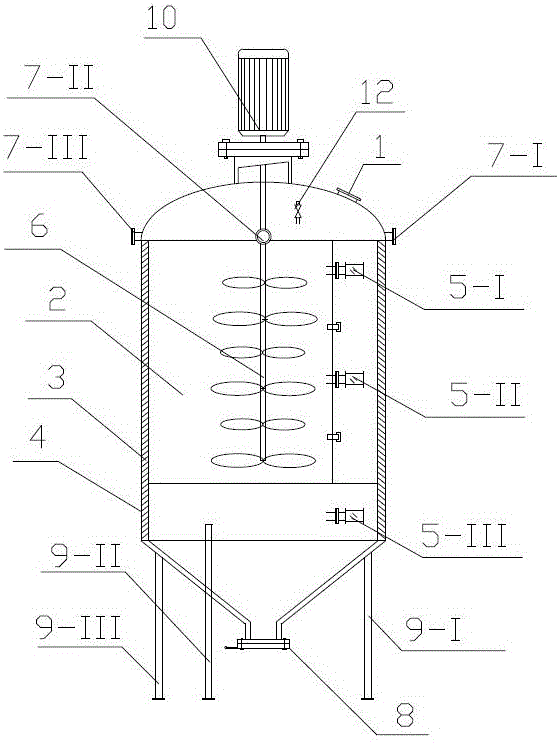

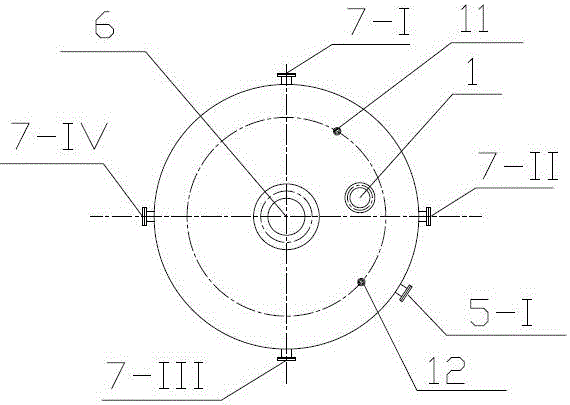

Anaerobic fermentation device and application thereof

InactiveCN106834108AReduce energy consumptionLow costBioreactor/fermenter combinationsBiological substance pretreatmentsGreen wasteMethane production

The invention provides a continuous-operation anaerobic device integrated with small-size gas producing, gas collecting and deslagging functions according to medium / high temperature anaerobic digestion principle. The device is composed of a feed inlet, a tank, a heating device, an insulating layer, an observation holes, a stirring device, an online detection device, an exhaust hole, a discharge hole and a methane collector. Raw materials of the device can be organic waste materials of agriculture waste, poultry excrement, sludge, landscape and greening waste, urban kitchen waste and the like, and the maximum methane production of 450ml / g TS can be realized; the anaerobic device has the advantages of good fermentation effect due to unique design and simpleness in operation.

Owner:NANKAI UNIV +1

Water purifying equipment and integrated waterway module thereof

ActiveCN104944607ASolve the problem that the mold cannot be divided normallyImprove sealingMultistage water/sewage treatmentWater leakageComputer module

The invention relates to water purifying equipment and an integrated waterway module thereof. The water purifying equipment comprises the integrated waterway module and a plurality of functional parts, wherein waterways among the plurality of functional parts are communicated via the integrated waterway module; the outside surface of the integrated waterway module is a plurality of connector interfaces; a plurality of runners are integrally formed in the integrated waterway module; at least part of the plurality of runners respectively extend in a three-dimensional direction; a plurality of connectors are respectively formed on the connector interfaces; the connectors are respectively access connectors of the plurality of functional parts; the plurality of runners are respectively communicated with the connectors. The water purifying equipment has the beneficial effects that an integral waterway part is used instead of various tangible pipelines and connectors, thus completely eradicating the biggest problem that water leakage is caused due to failure of connection and sealing of pipes and the connectors; the interior of the water purifying equipment is more concise; design of the plurality of connector interfaces is capable of facilitating arrangement of the plurality of connectors, so that all the parts in the equipment are arranged more compactly and reasonably.

Owner:FOSHAN VIOMI ELECTRICAL TECH +2

Phosphogypsum calcining system

A phosphogypsum calcining system belongs to the field of phosphorous gypsum calcination, and includes a calcining furnace, a fire spraying furnace, a front deduster material returning tube, a settlingchamber, a front deduster, an air duct from the front deduster to a preheating furnace, the preheating furnace, an air duct from the preheating furnace to a rear deduster, the rear deduster, an air duct form the rear deduster to a reducing furnace, the reducing furnace, a material discharging air duct, an air duct from the settling chamber to the front deduster, and an induced draft fan. The phosphogypsum calcining system has the characteristics of compact structure, energy reuse, small occupied area and high thermal efficiency.

Owner:ZHENGZHOU SUNDY BUILDING TECH

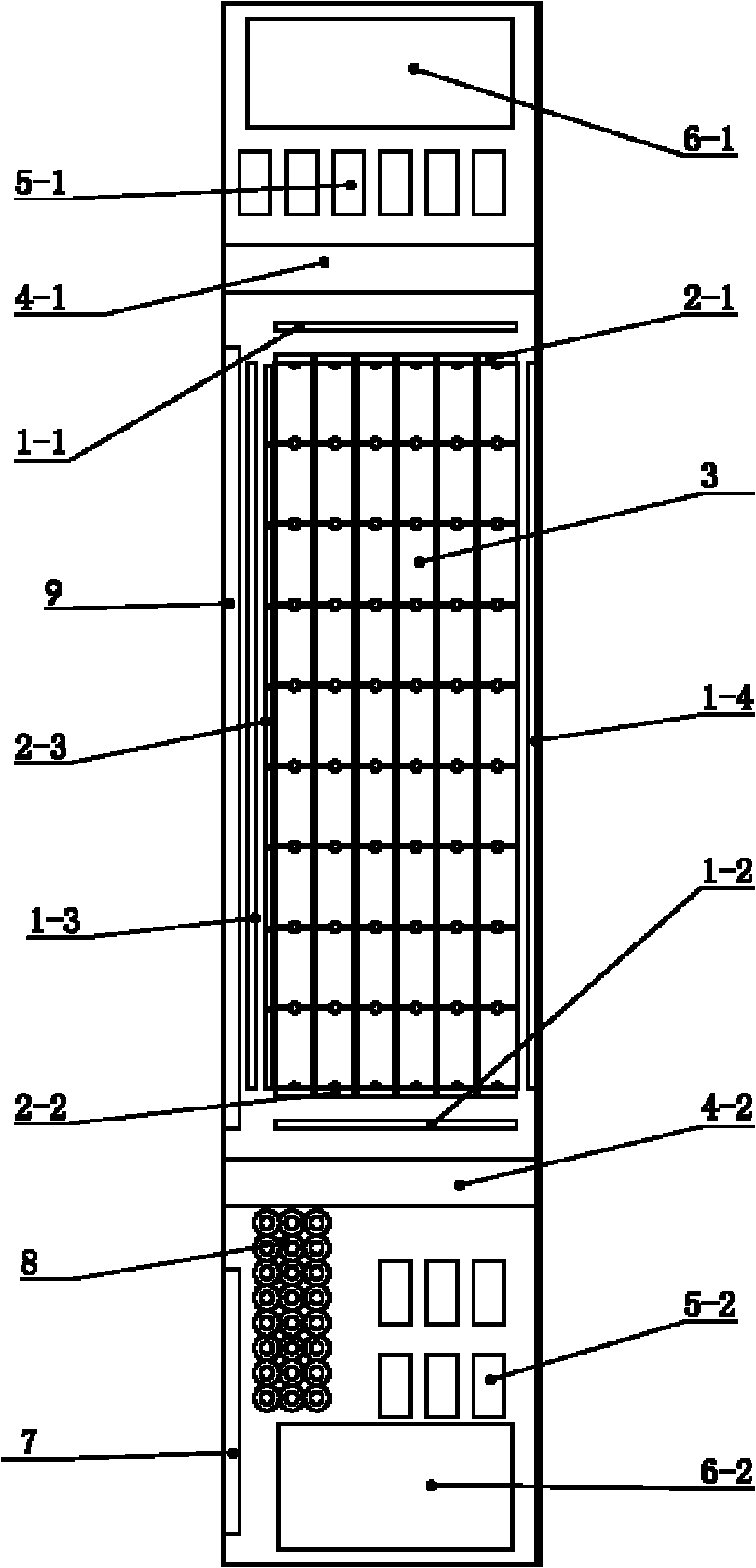

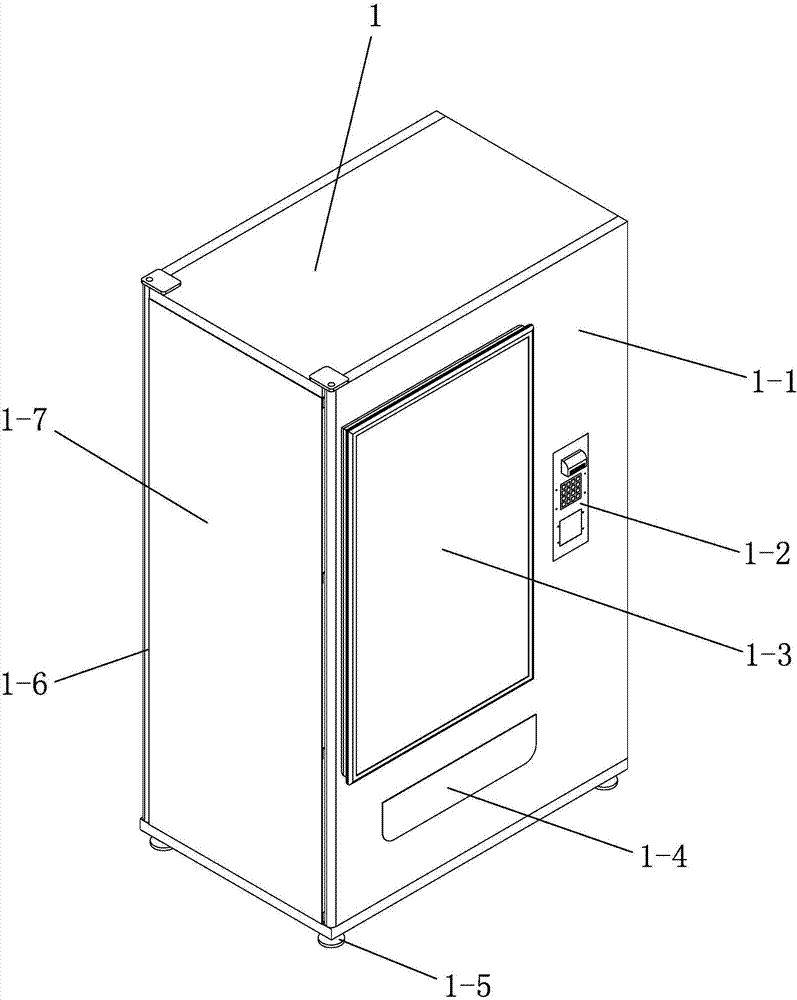

Swimsuit vending machine and operating method thereof

InactiveCN106960512ANovel structureCompact and reasonable layoutCoin-freed apparatus detailsApparatus for dispensing discrete articlesElectrical controlEngineering

The invention provides a swimsuit vending machine and an operating method thereof, and belongs to the technical field of retail auxiliary equipment. The swimsuit vending machine is novel in structure, compact and reasonable in layout, and clear in working principle, and structurally consists of a vending machine casing, and a horizontal movement mechanism, a vertical movement mechanism, a code-scanning ejection mechanism, a storage mechanism and an electric control module arranged in the vending machine casing. The swimsuit vending machine can complete code-scanning recording and ejection selling operations, the actions of code scanning and ejection are fast, and the ejection position is accurate, so that vending actions of swimsuit products are effectively assisted, and the vending efficiency is improved.

Owner:扬州弈姿户外运动服饰有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com