Controlling system of moulded forging hydraulic press with proportional type oil controlling water

A control system and hydraulic press technology, applied to the driving device of forging press, mechanical equipment, fluid pressure actuating device, etc., can solve the problems of low precision and poor reliability, and achieve the effects of fast response, overshoot prevention and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The proportional oil control and water control system of the die forging hydraulic press of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention.

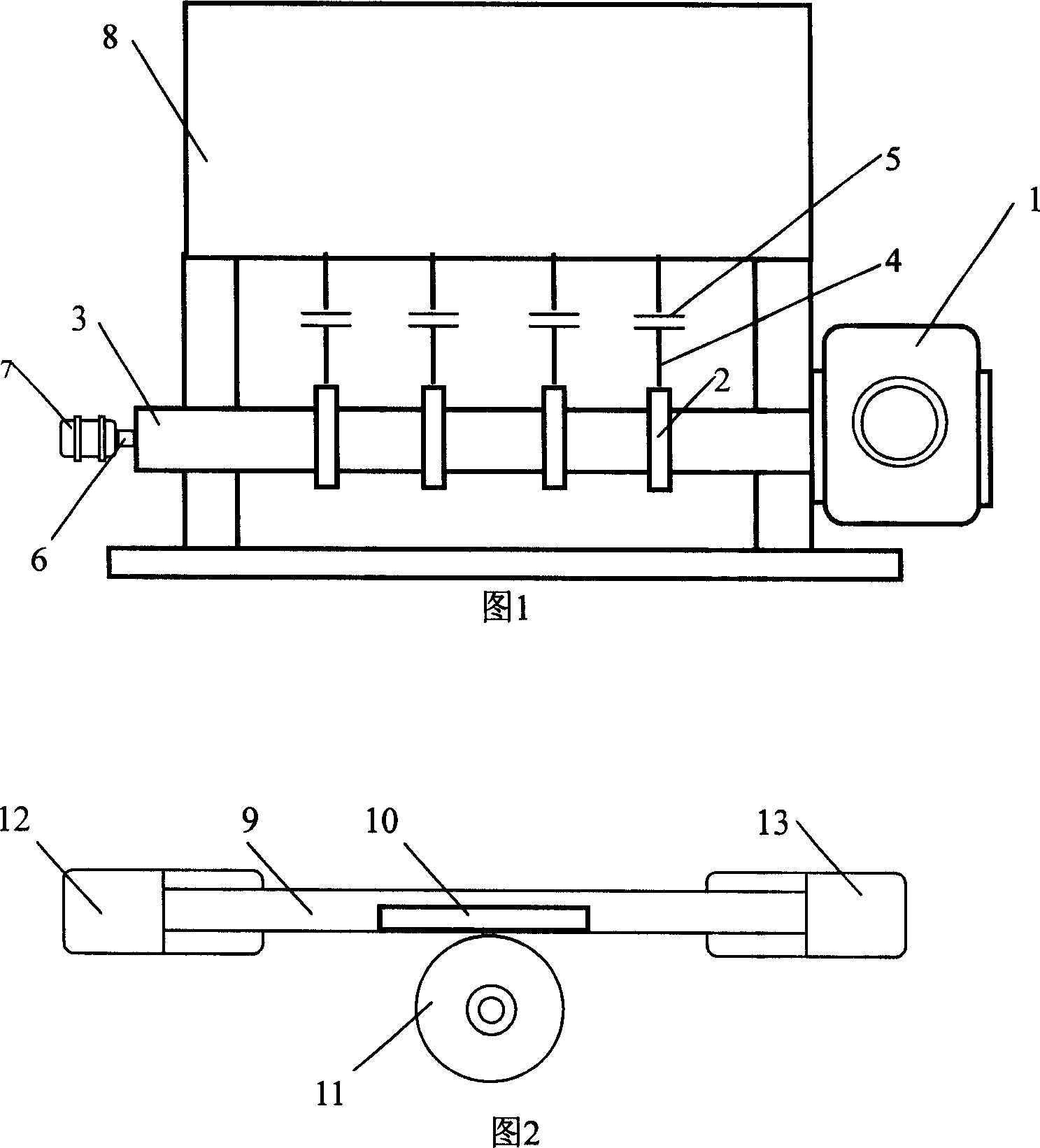

[0014] As shown in Figure 1, it is a schematic diagram of the drive mechanism of the dispenser. It includes a servomotor 1, a camshaft 3, a cam 2, a push rod 4, an adjusting nut 5, a flexible coupling 6, a rotation angle detection device 7, and a distributor valve body 8. As shown in FIG. 2 , the middle section of the piston rod 9 in the servomotor oil cylinder is made into a rack 10 , the rack 10 and the gear 11 form a rack-and-pinion transmission, and the gear 11 is installed on the camshaft 3 .

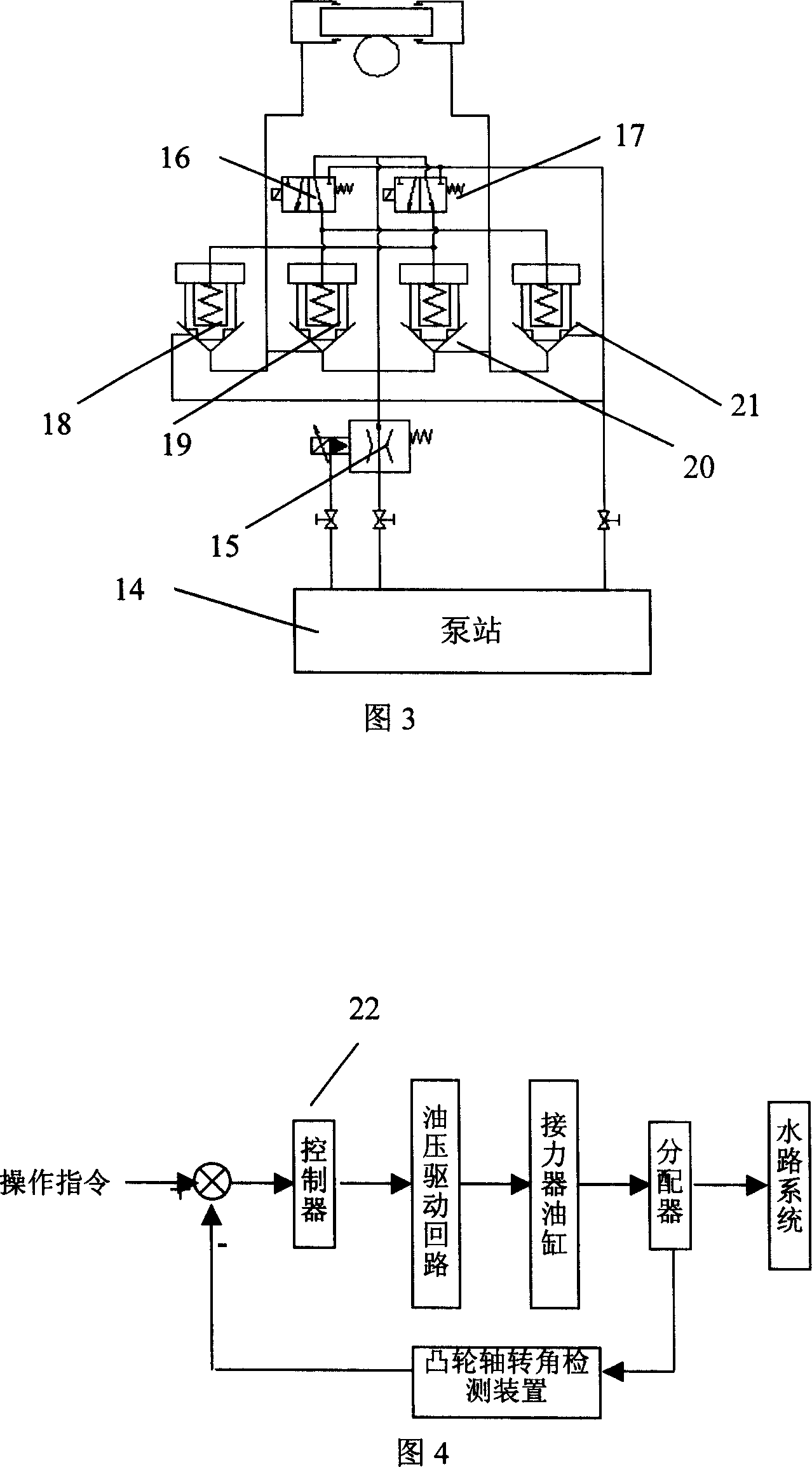

[0015] As shown in Figure 3, it is a schematic diagram of the principle of the hydraulic drive circuit. The hydraulic drive circuit is mainly composed of a pump station 14, an electro-hydraulic pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com