High speed automatic weighing packing machine

An automatic and heavy-packing technology, which is applied in packaging and other directions, can solve the problems of low accuracy and efficiency, unsuitable quantity, small and multiple varieties of irregular bulk packaging, etc., and achieve improved operating efficiency, improved accuracy, and compact layout. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

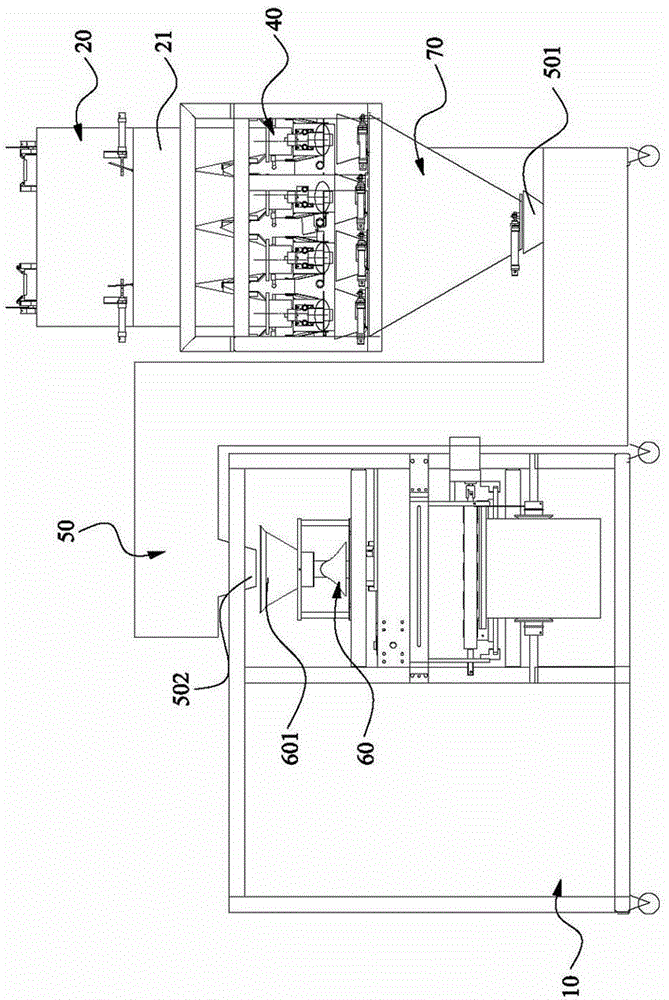

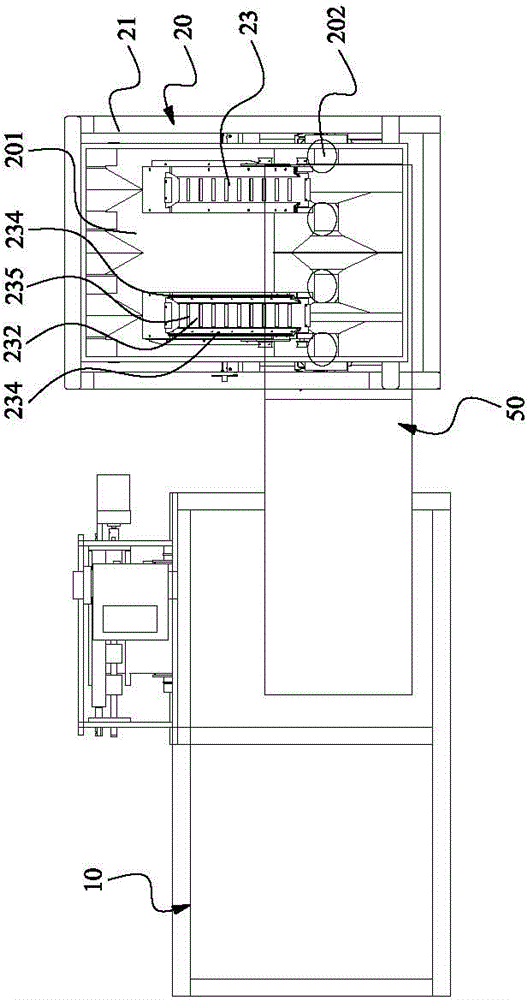

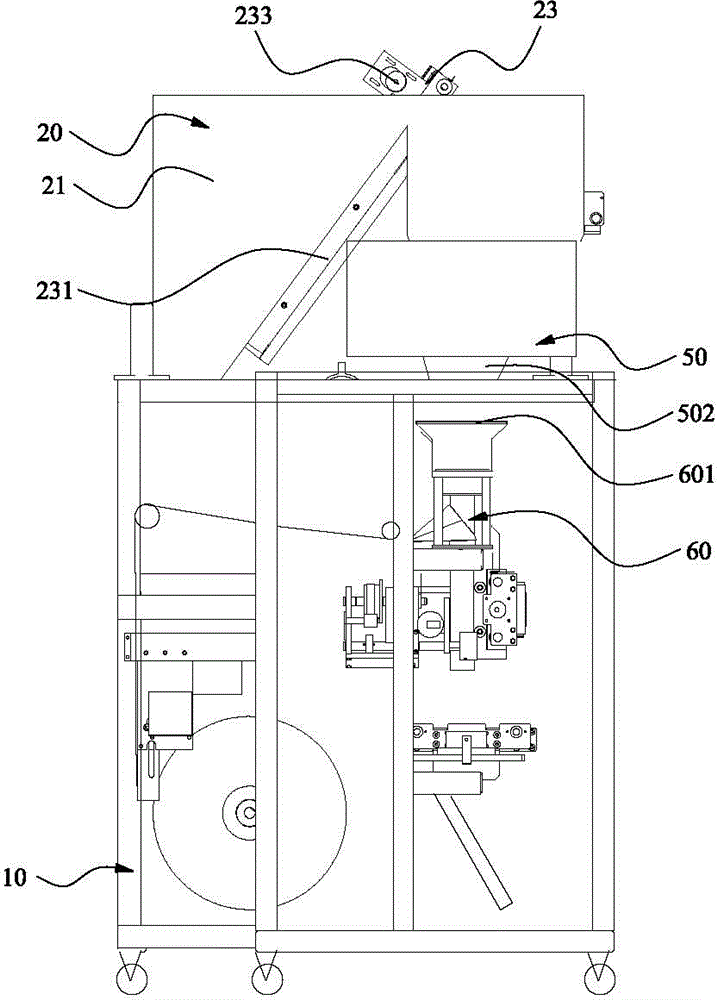

[0044] Please refer to Figure 1 to Figure 5 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a frame 10 and a feeding device 20, a weighing mechanism 30, a rejecting mechanism 40, a feeding mechanism 50 and 袋包装机构60.

[0045] The feeding device 20 includes a main hopper 21 and a feeding mechanism 22. Wherein, the main hopper 21 has a first accommodating cavity 201 and a second accommodating cavity 202, the bottom of the first accommodating cavity 201 is provided with a first outlet, and the first accommodating cavity 201 is provided with The material in the first accommodating cavity 201 is transported to the coarse feeding mechanism 23 in the second accommodating cavity 202. In this embodiment, the main hopper 21 is provided with two aforementioned second accommodating cavities 202, correspondingly, The first accommodating cavity 201 is provided with two aforementioned coarse feeding mechanisms 23. The coarse feeding mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com