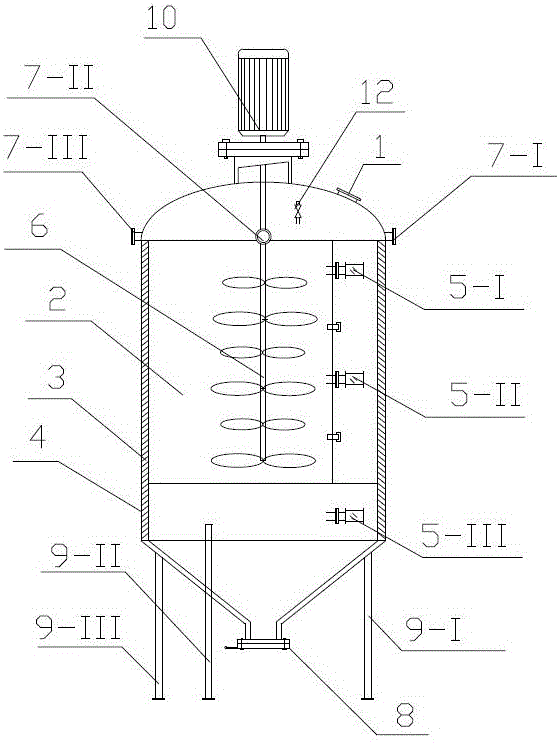

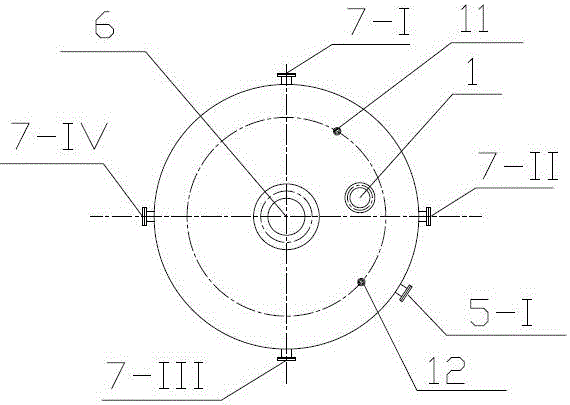

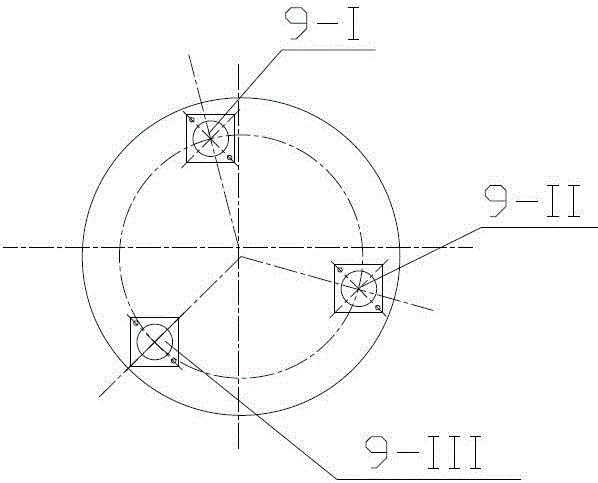

Anaerobic fermentation device and application thereof

A technology of anaerobic fermentation and heating device, applied in fermentation, biochemical cleaning device, enzymology/microbiology device, etc., can solve the secondary pollution of biogas slurry and biogas residue, long operation cycle of digestion device, and cannot adapt to low temperature environment and other problems, to achieve the effect of considerable economic benefits, small footprint, compact and reasonable device layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0028] 1) Using cow dung as biomass, process dry cow dung to a particle size of 2mm;

[0029] 2) Add the cow dung together with the domesticated anaerobic active sediment into the fermentation bin of the fermentation device to 300L from the feed port, the TS is 5%, start the motor to continuously heat and maintain the temperature at 45°C, and turn on the stirring device Forward rotation, continuous fermentation for 15 days;

[0030] 2) The daily production of biogas is measured by the flow meter at the biogas tank, and the maximum can reach 390ml / g TS;

[0031] 3) When the biogas production starts to decline on the 15th day, open the discharge port located under the fermentation device, set the stirring device to reverse mode, discharge 80% of the fermented product in the tank, feed again and repeat the above process.

Embodiment 3

[0033] 1) Using kitchen waste as biomass, treat kitchen waste to a particle size of 3mm;

[0034] 2) Add kitchen waste and acclimated anaerobic active sediment into the fermentation chamber of the fermentation device from the feed port to 350L, its TS is 8%, start the motor to continuously heat and maintain the temperature at 55°C, and start stirring The device was rotated forward and fermented continuously for 13 days;

[0035] 2) The daily production of biogas is measured by the flow meter at the biogas tank, and the maximum can reach 430ml / g TS;

[0036] 3) When the biogas production starts to decline on the 10th day, open the discharge port located under the fermentation device, set the stirring device to reverse mode, discharge 80% of the fermented product in the tank, feed again and repeat the above process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com