Composite insulation board production line and machining process of insulation board

A composite thermal insulation and production line technology, which is applied in manufacturing tools, ceramic molding workshops, supply devices, etc., can solve problems such as not being able to adapt to processing requirements, achieve high automation, compact and reasonable layout, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

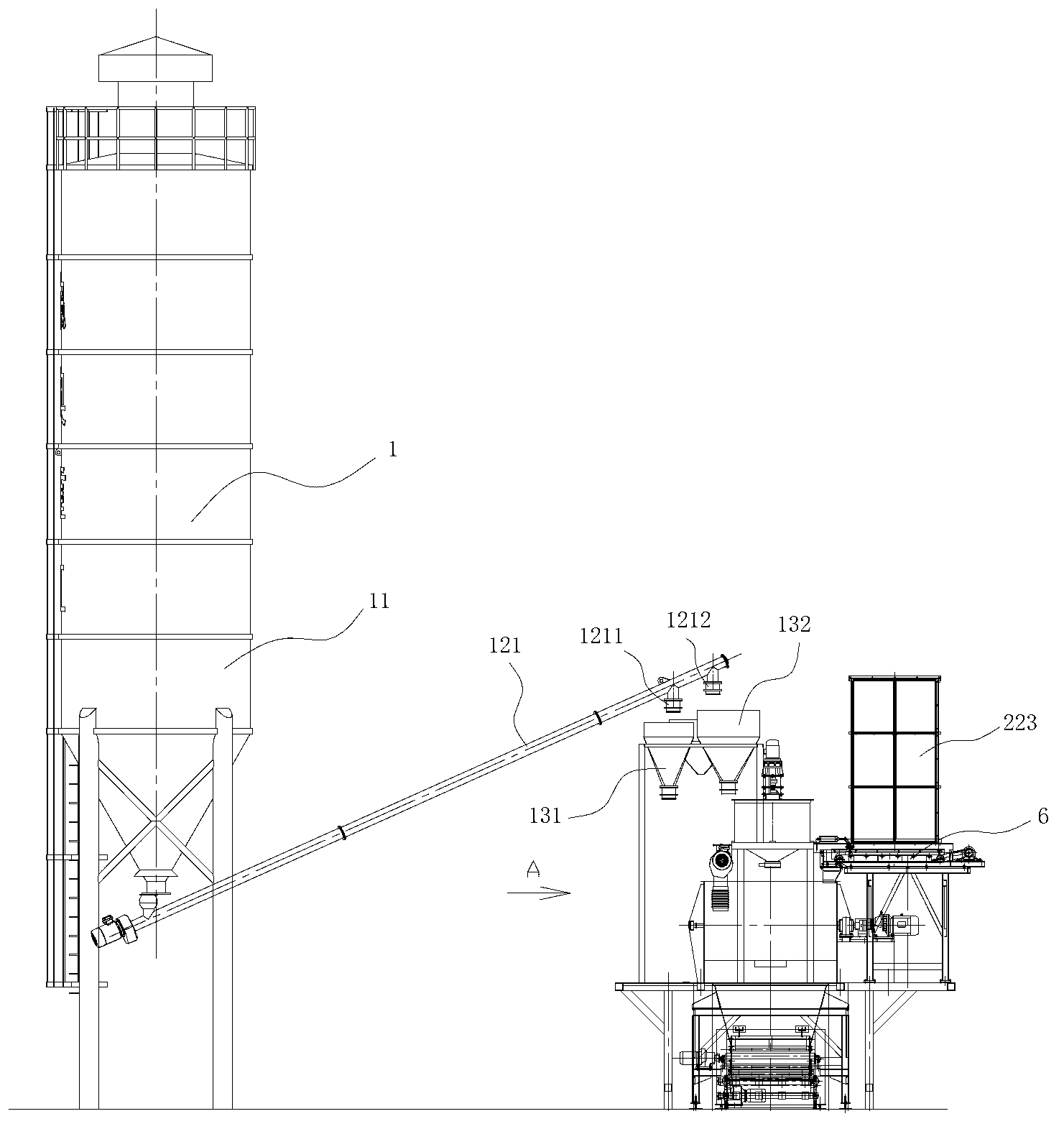

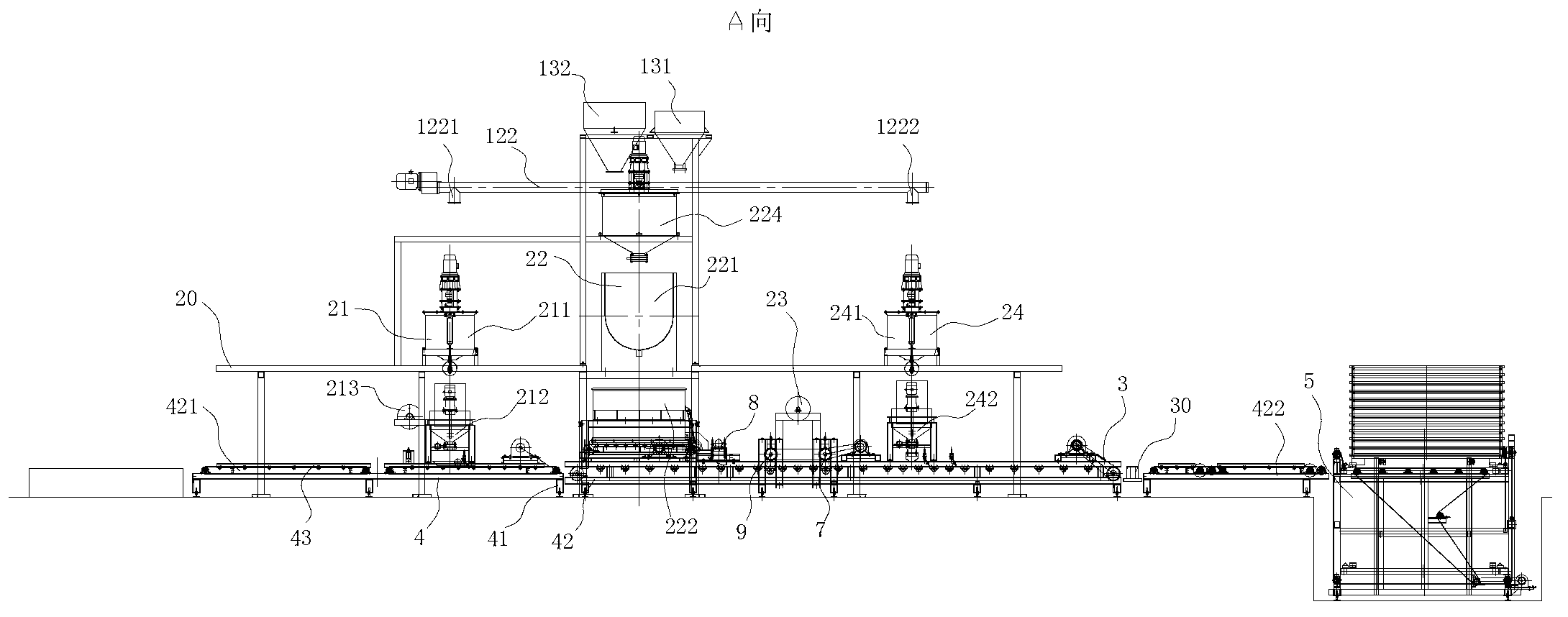

[0061] The present invention as Figure 1-10 As shown, it includes a one-to-three material preparation system 1, a forming system 2, a transfer system 4, a cutting system 3 and a loading system 5;

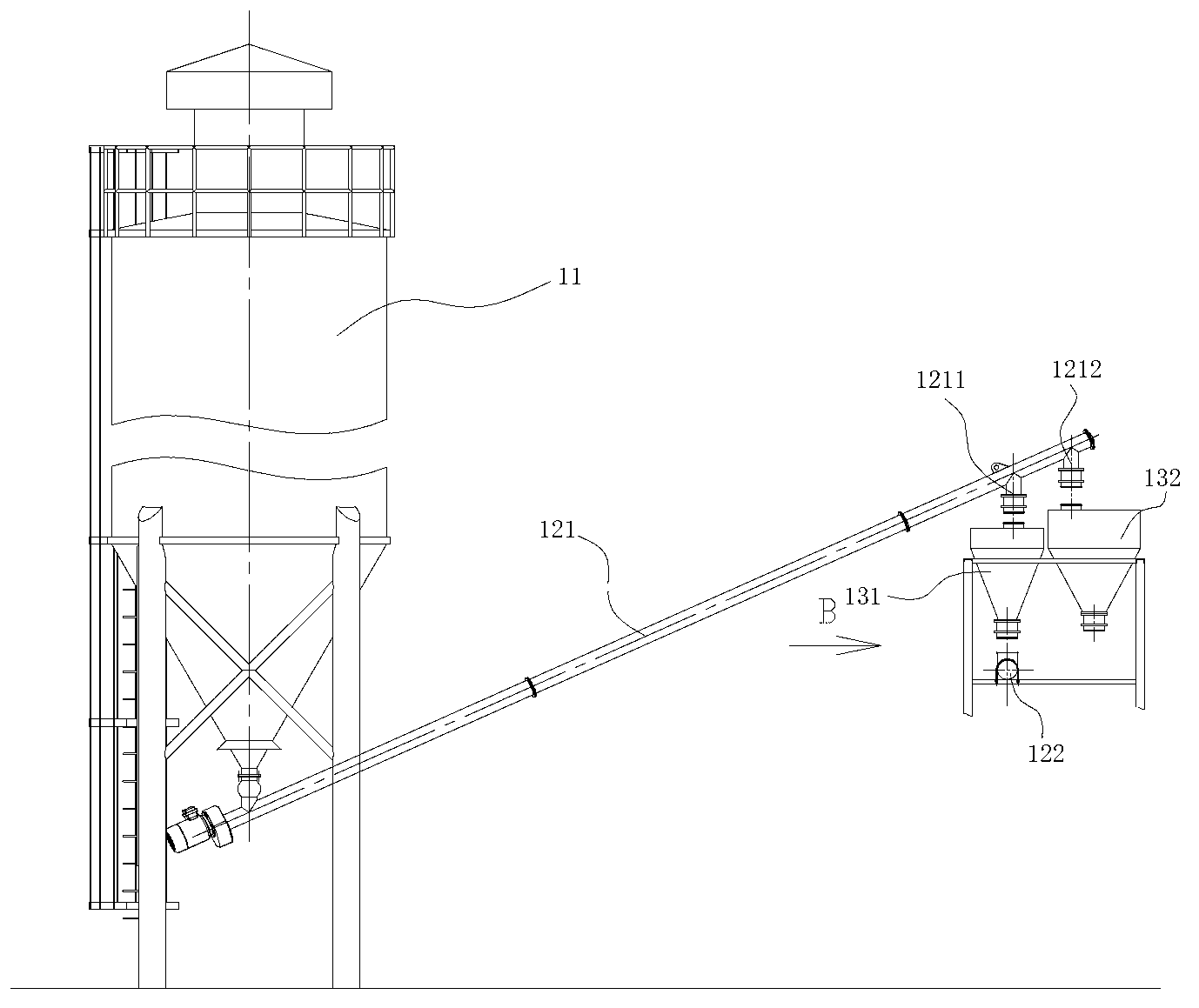

[0062] The one-to-three material preparation system 1 includes a raw material warehouse 11, a one-way double-exit screw elevator conveyor 121, a two-way screw horizontal conveyor 122, a metering bin 131, a metering bin 2 132, a lower layer slurry preparation device 21, and an insulation material preparation Device 22 and upper layer slurry preparation device 24;

[0063] The one-way double-export screw elevator conveyor 121 has a discharge port A1211 and a discharge port B1212. In practical applications, butterfly valves can be installed on the discharge port A1211 and the discharge port B1212 for control. The two-way screw horizontal conveyor 122 has a discharge port C1221 and a discharge port D1222, the discharge port of the raw material bin 11 is connected to the feed port of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com