Patents

Literature

465results about How to "Logical" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

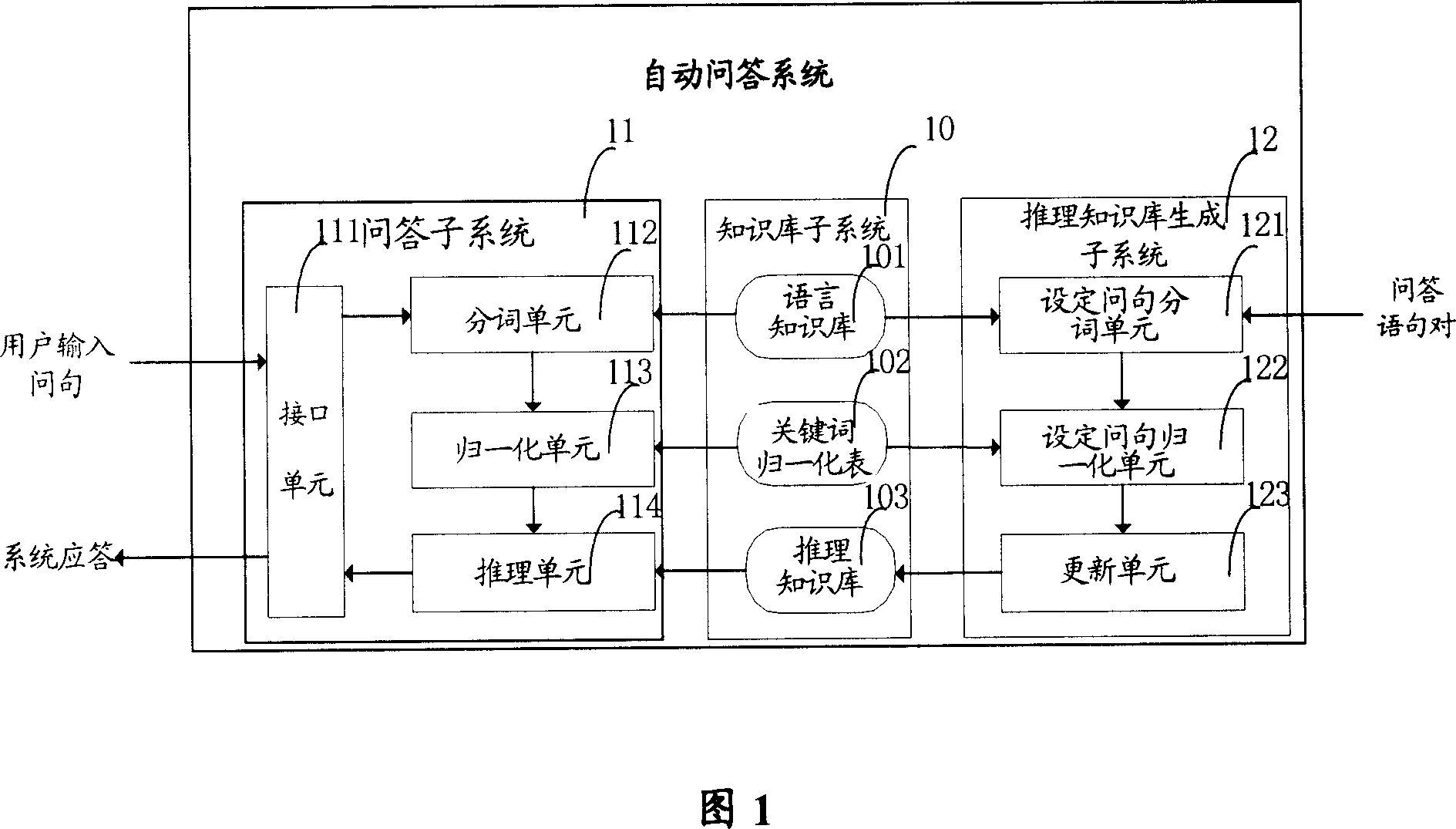

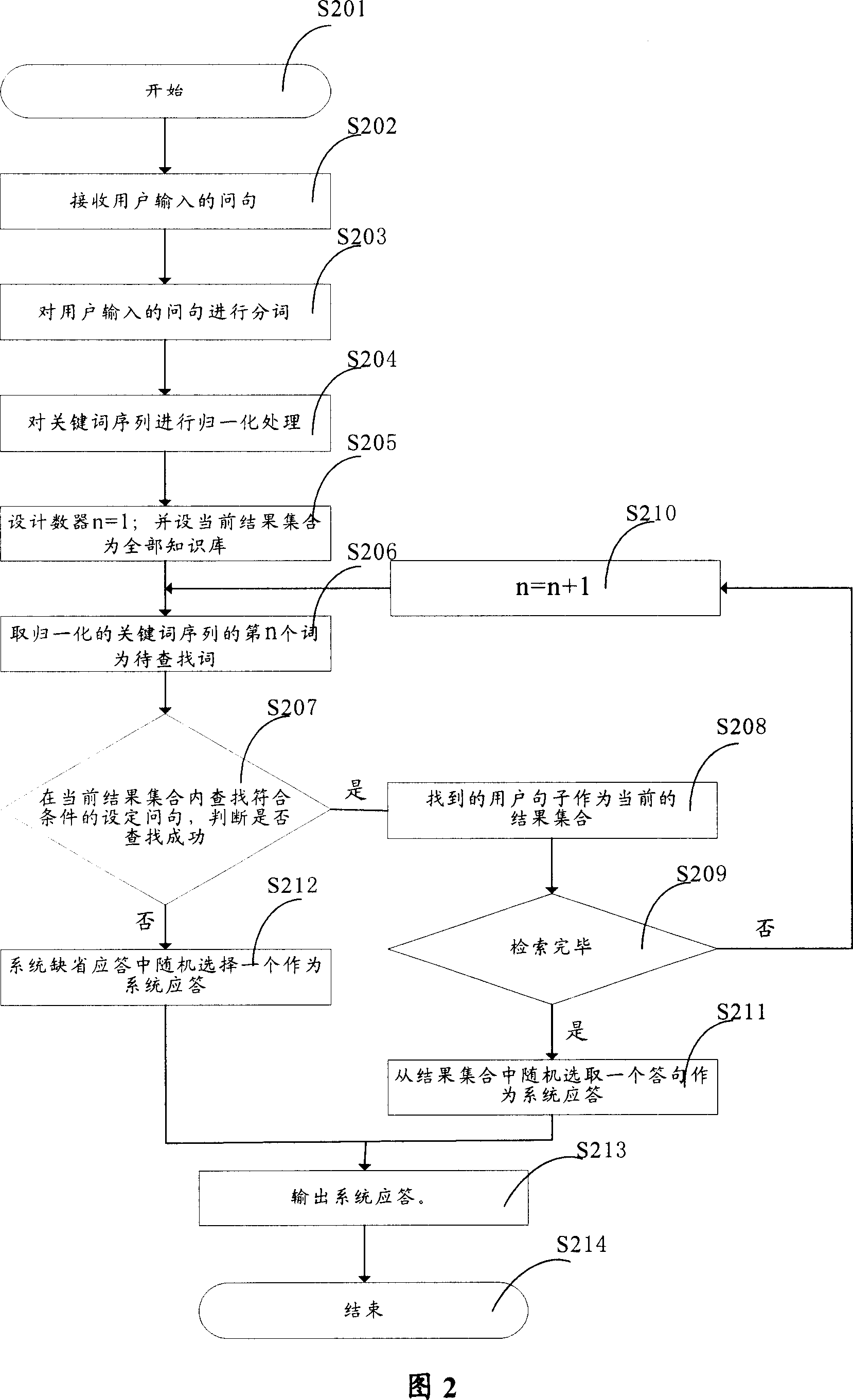

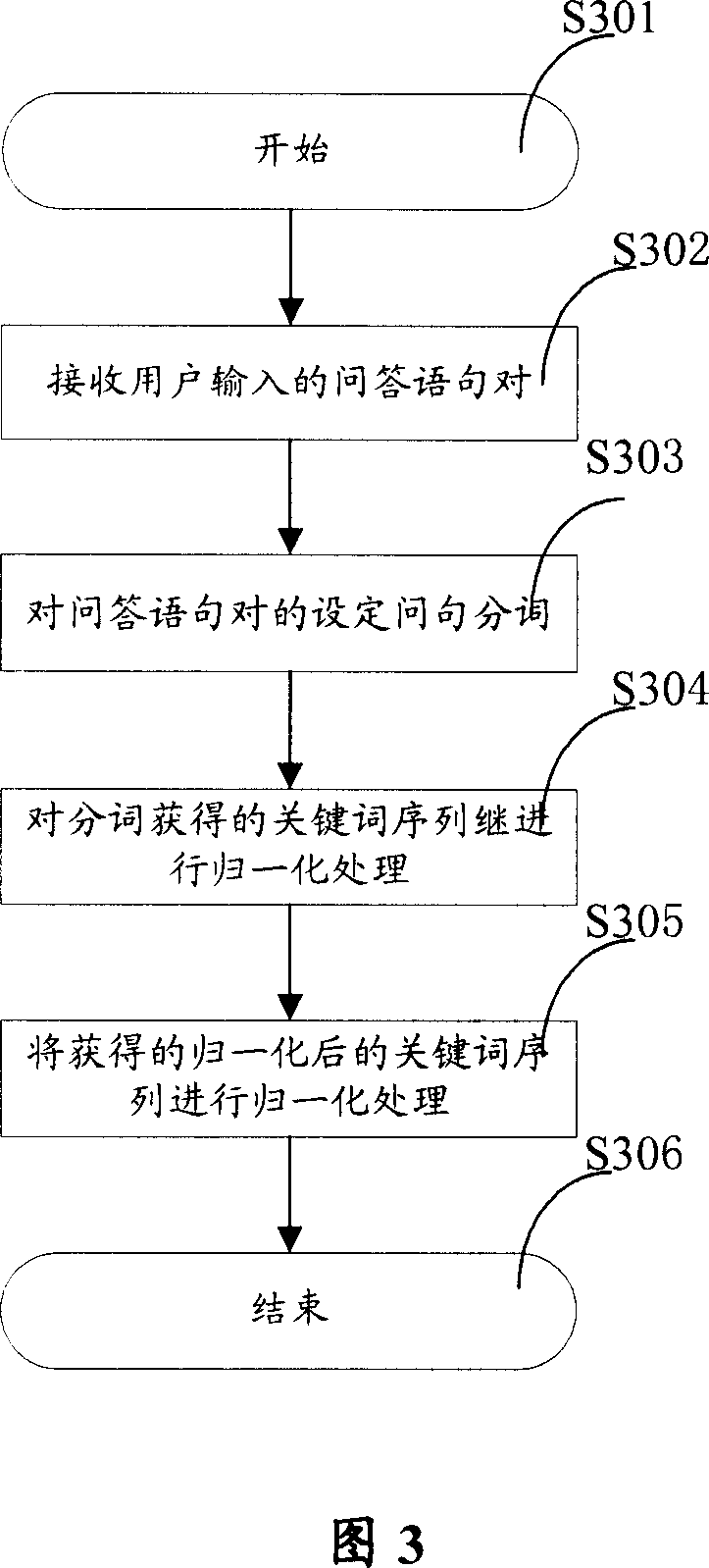

Automatically request-answering system and method

ActiveCN101097573AQ&A sentence reductionReduce workloadSpecial data processing applicationsUser inputHuman language

The invention discloses a kind of auto question-answering system, which includes interface unit, illation unit, language knowledge base, illation knowledge base, normalization table of keyword, and normalization unit, the illation unit inquires said illation knowledge base according to sequence of normalization to find the answer corresponding with the question with same sequence of keyword, and the answer is as the system response to be output by said interface unit. The invention also discloses a kind of auto question-answering method, which can be used in the system with language knowledge base, illation knowledge base, normalization table of keyword, and it can divide the input question; and the normalization is done for the sequence of keyword; and the normalized keyword can find the setting question with same keyword; and it can search the answer according to the question; and said answer is output as system response. Thee invention can reduce the working capacity for building illation knowledge base by the normalization of synonymous keywords.

Owner:TENCENT TECH (SHENZHEN) CO LTD

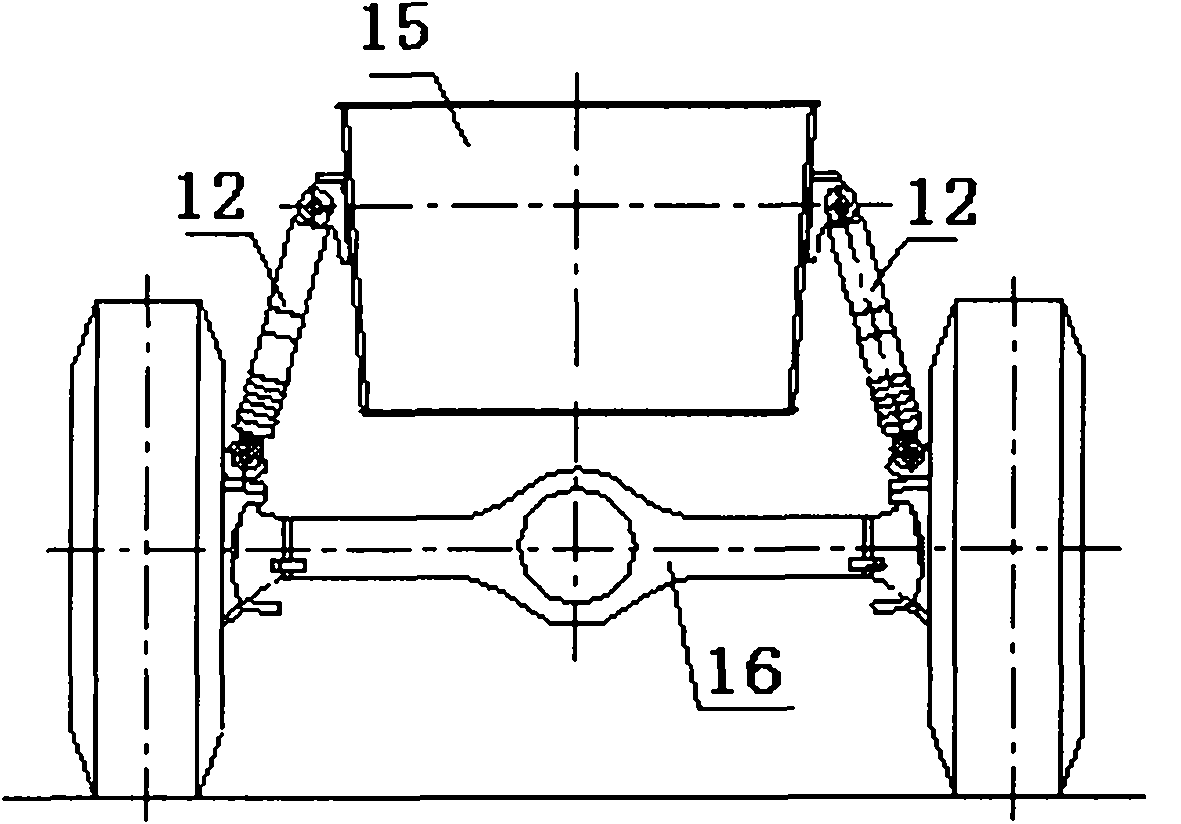

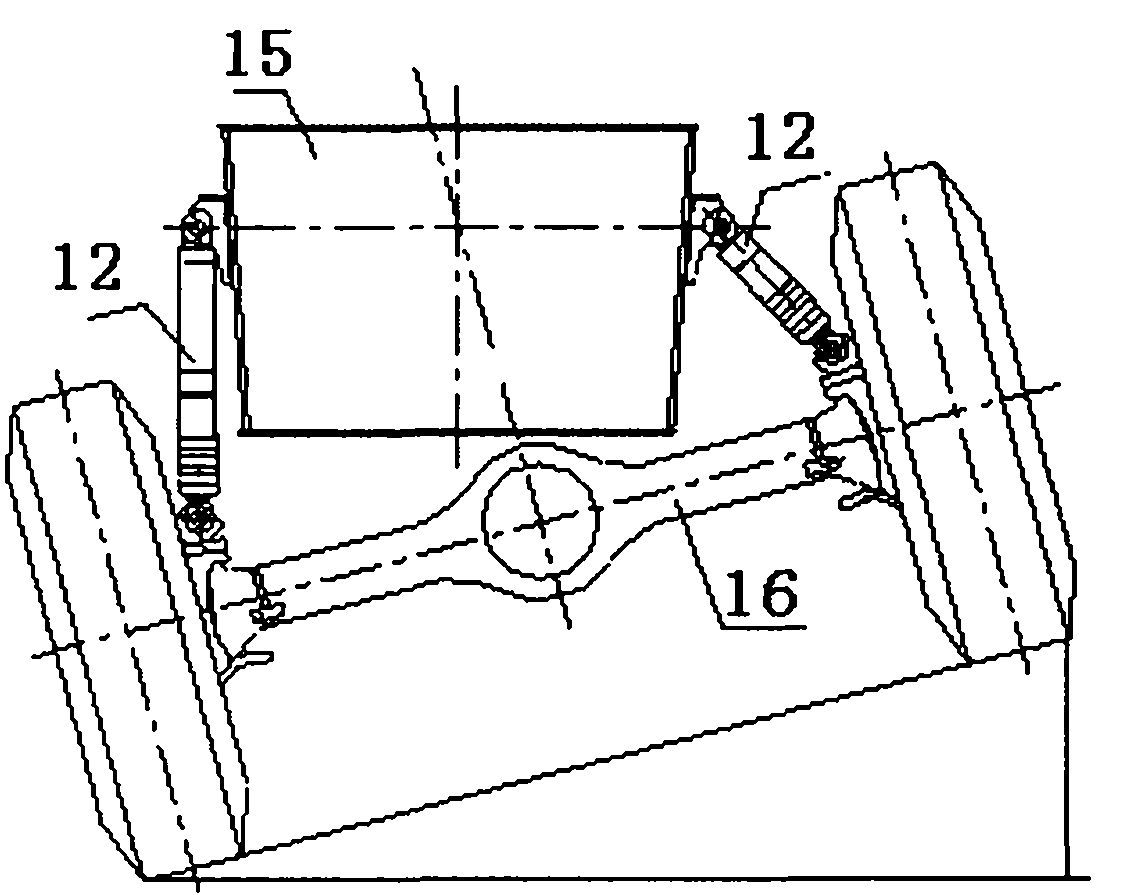

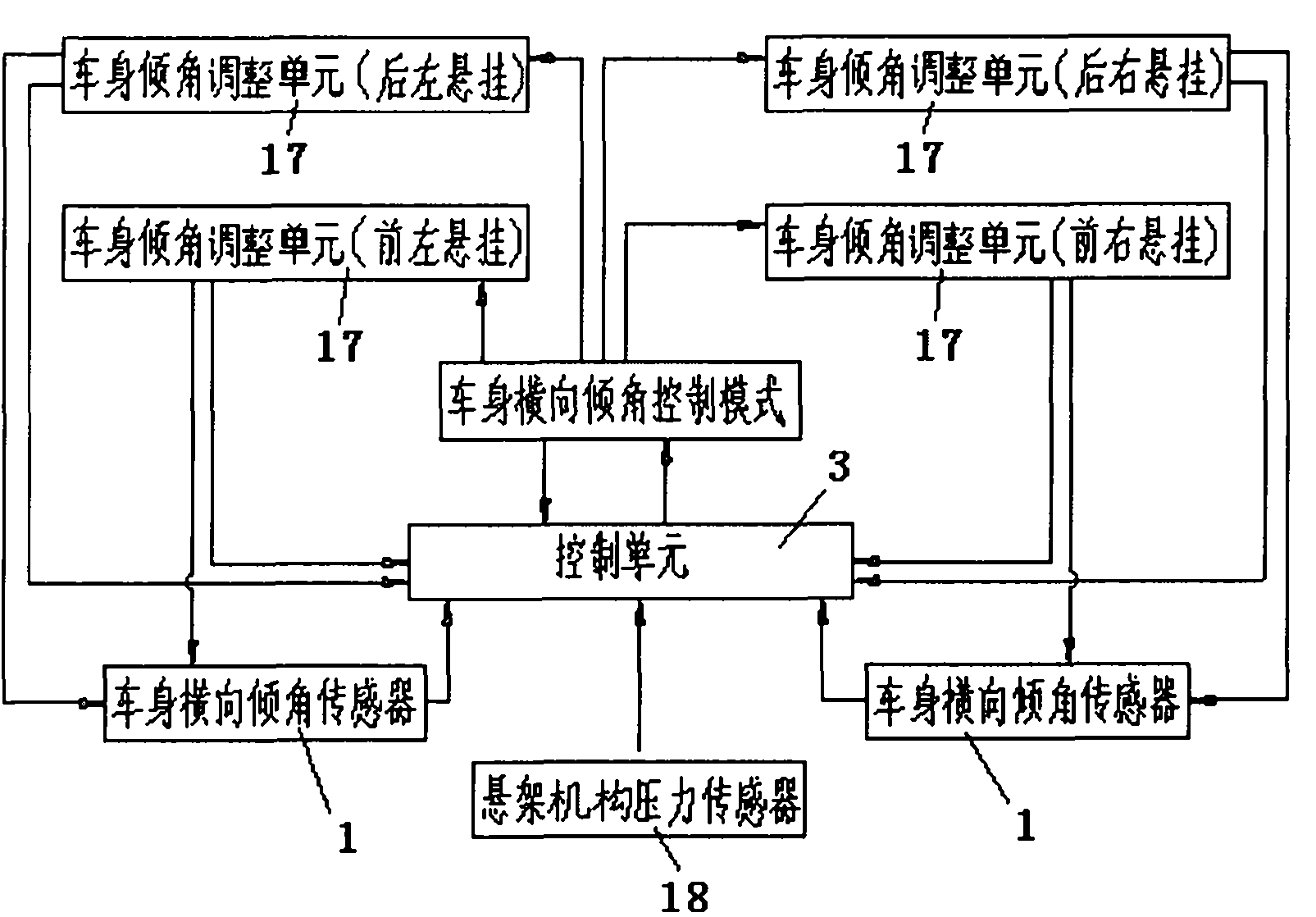

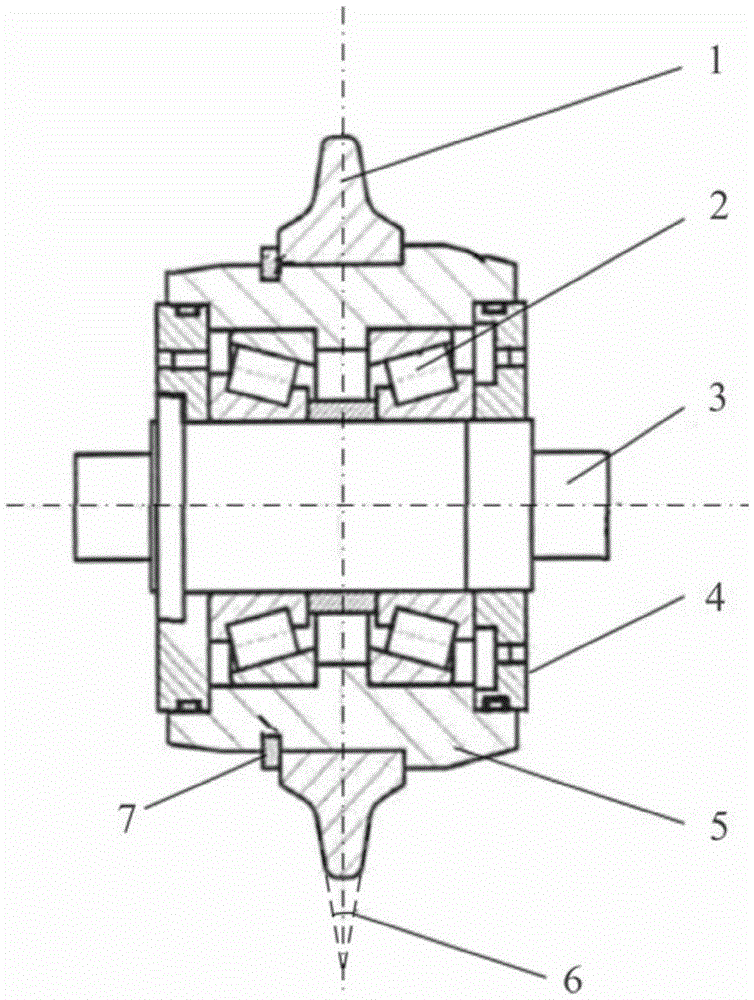

Vehicle body dip angle adjusting unit, oil gas suspension mechanism and mobile crane

ActiveCN102039791AEasy to operateLogicalFluid-pressure actuatorsInterconnection systemsHydropneumatic suspensionFuel tank

The invention relates to an automatic leveling oil gas suspension mechanism, which comprises at least two pairs of suspension oil cylinders (12), a vehicle body dip angle adjusting unit (17), a vehicle body traverse dip angle sensor and a control unit, wherein each suspension oil cylinder is provided with a vehicle body dip angle adjusting unit with a balanced oil cylinder (10) correspondingly; and one cavity of the balanced oil cylinder is connected to an oil tank (5) and a leveling operating oil source by a first one-way damper valve (8) and an electronic control switching valve (14), and the other cavity of the balanced oil cylinder (10) is connected to a rodless cavity of each suspension oil cylinder by an electronic control lockup valve (14) and a second one-way damper valve (9). In addition, the invention also provides a mobile crane with an automatic leveling oil gas suspension mechanism. The automatic leveling oil gas suspension mechanism realizes the function of dynamic leveling of various roads, particularly traverse rampways, of the mobile crane effectively, and is simple in operation and high in logicality; and the operation is completed automatically by the control unit, so the running safety is improved obviously, and accidents such as overturn and the like are prevented from occurring.

Owner:ZOOMLION HEAVY IND CO LTD

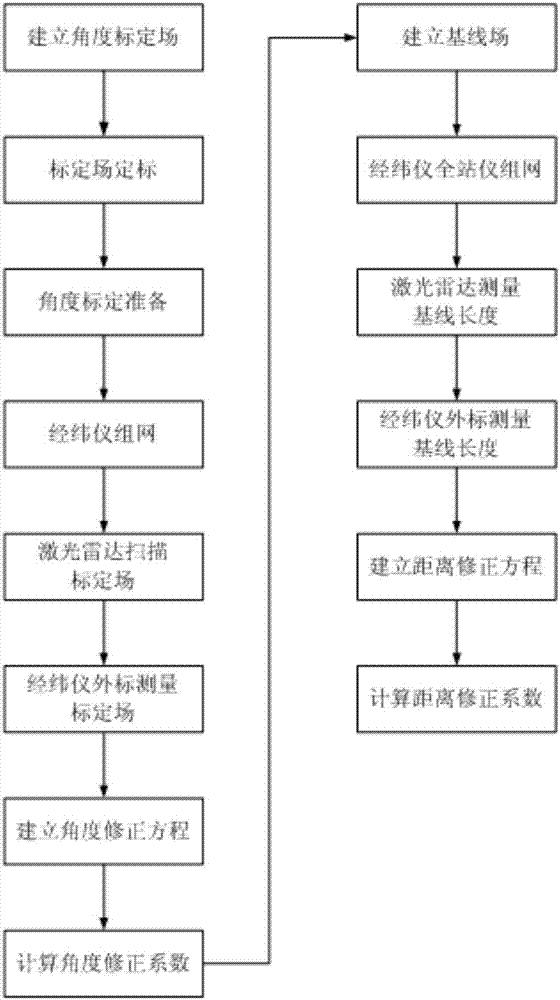

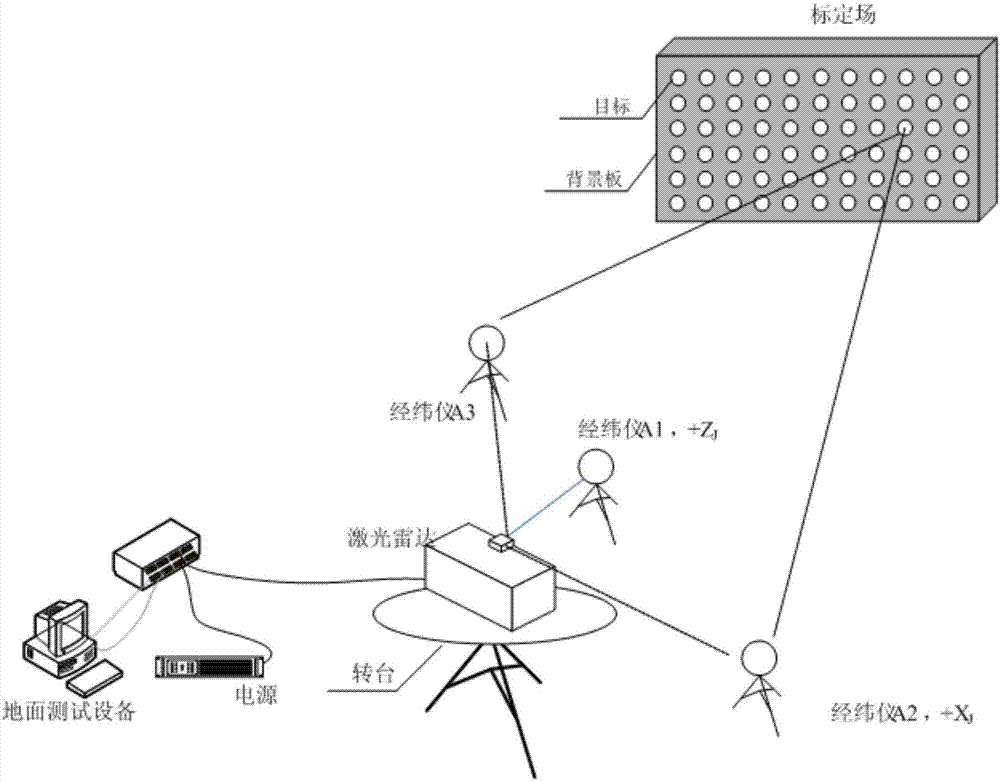

Laser radar two-step calibration method based on calibration field

ActiveCN107167790ABreaking high flatness requirementsBreak flatness requirementsWave based measurement systemsDistance correctionTheodolite

The invention discloses a laser radar two-step calibration method based on a calibration field. The method comprises steps of establishing a calibration field; carrying out calibration; preparing angle calibration; networking a theodolite; scanning a laser radar; measuring the theodolite; establishing an angle correction equation; calculating an angle correction coefficient; establishing a base line field; measuring the laser radar; measuring the theodolite; establishing a distance correction equation; and calculating a distance correction coefficient. According to the invention, rapid calibration of the laser radar is achieved without taking a precisely designed and processed calibration device as a calibration standard; a problem of too high requirements on a test place, the calibration field and the calibration device in the normal method is solved; through cooperation of a rotation bench, the whole test process is achieved, the test difficulty level is reduced and a difficulty in ensuring precision of full field-of-view angle correction in the normal method is solved; and through the test of the calibration field and the base line field step by step, effects of correcting separation distances in a calibration model are achieved and disadvantages in mutual coupling of distance parameters and angle parameters in the normal method are overcome.

Owner:BEIJING INST OF CONTROL ENG

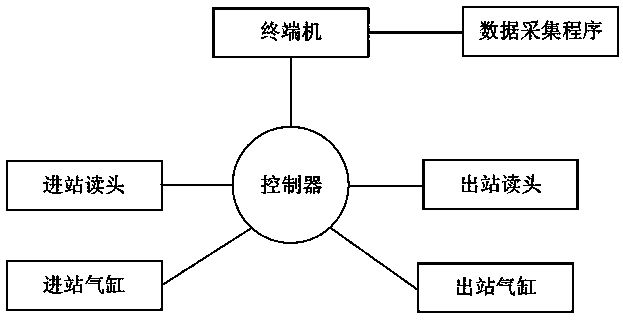

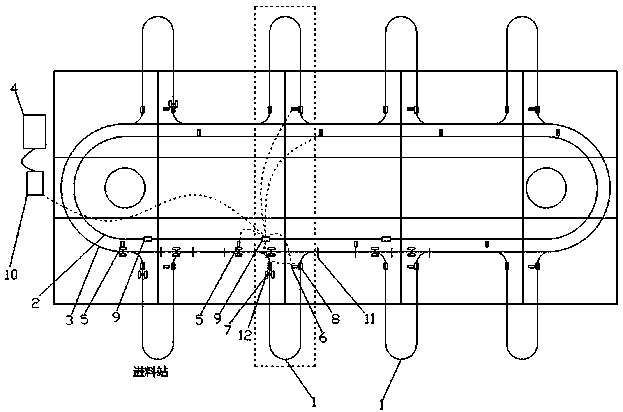

Control method of intelligent clothing suspension system

ActiveCN103734964AAvoid inefficiencies in productionSimplified logic control methodClothes making applicancesEmbedded systemAutomatic control

The invention discloses a control method of an intelligent clothing suspension system. According to the control method, the readable-writable IC card data technology is adopted, and the readable-writable IC card data technology is matched with other software / hardware control technologies to realize automatic control on circulation of clothes hangers of the intelligent clothing suspension system between various steps. The method is characterized in that the IC card information of the clothes hangers and a push rod are classified into different types, the information is collected and written in through a come-into-station read head and a come-out-of-station read head, and the circulation of the clothes hangers between a main track and each workstation is realized according to requirements under the combined action of a controller, a terminal and a data acquisition program. The control method of the intelligent clothing suspension system is high in adaptability and intellectualization degree; the complexity of the system is effectively reduced by virtue of the readable-writable technology; the system is high in safety, and the work of the whole system cannot be affected by the fault of one workstation.

Owner:HUIZHOU TECHZEN IOT SCI & TECH CO LTD

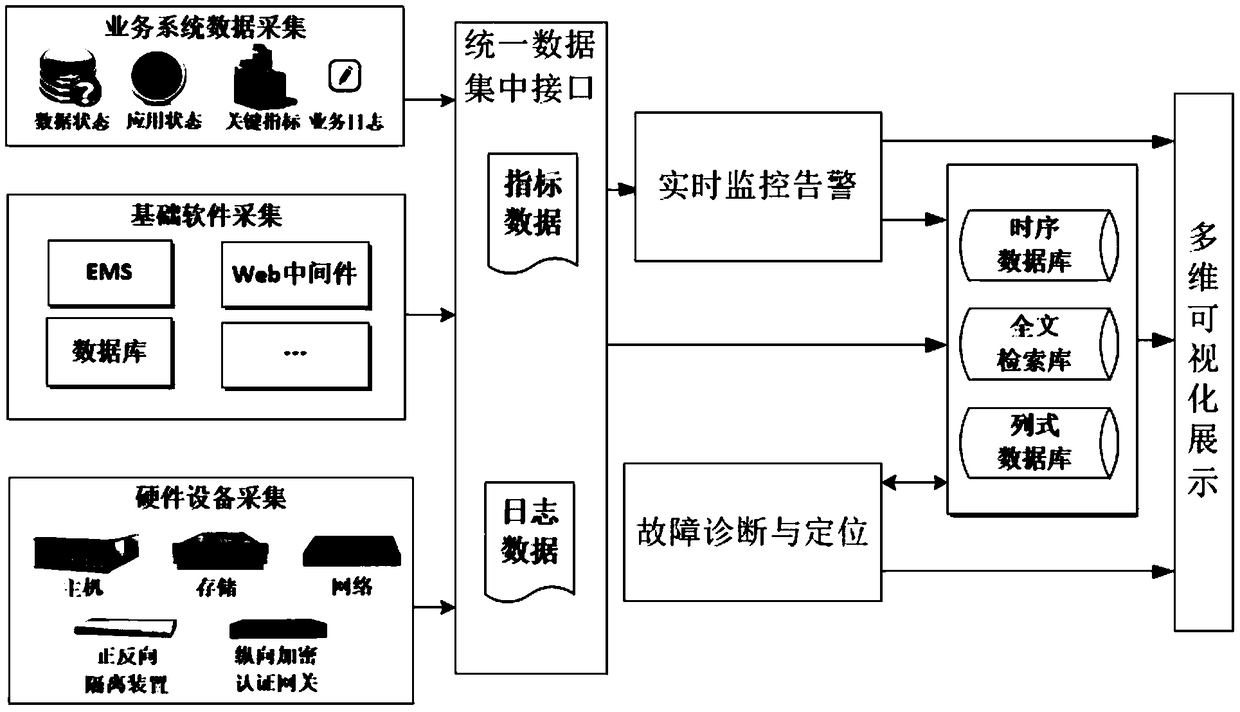

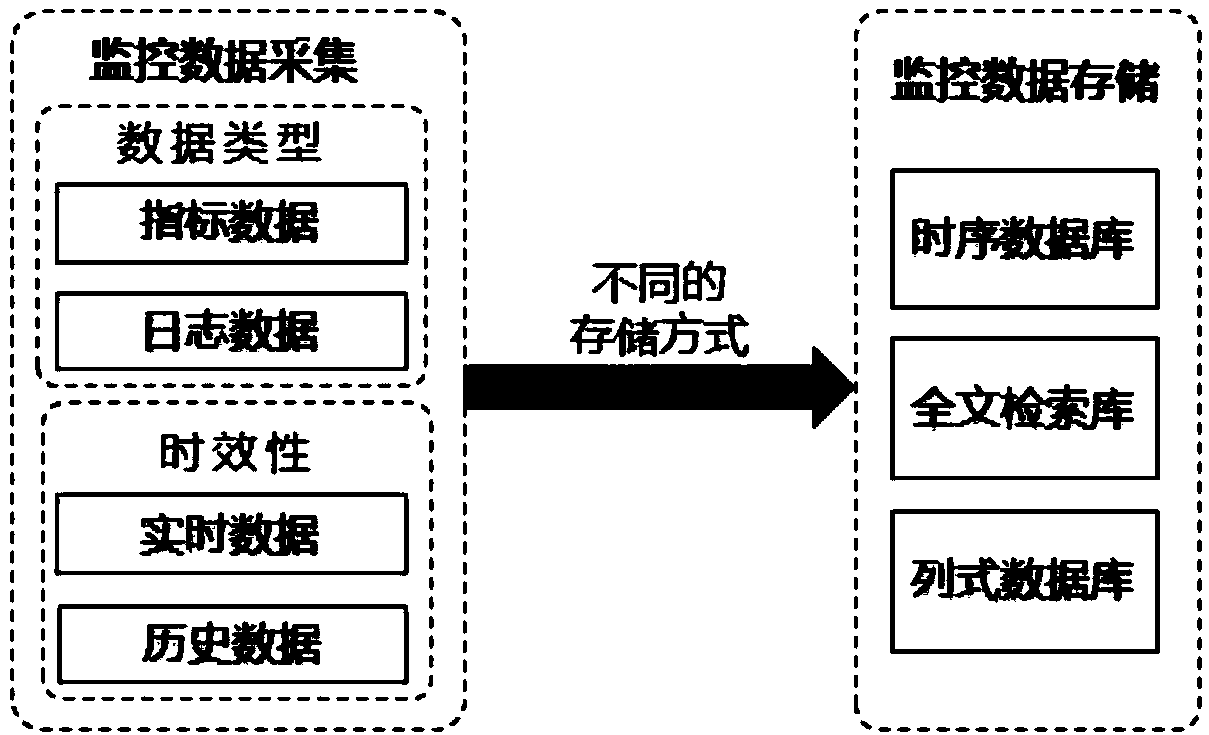

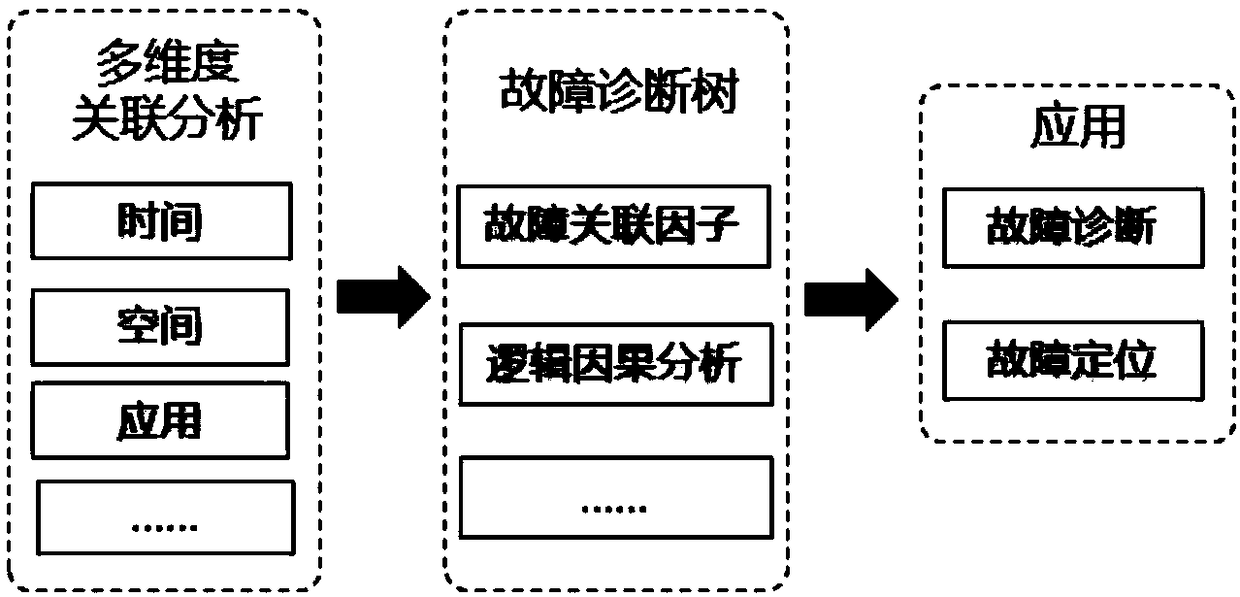

An intelligent operation and maintenance architecture design method for power grid dispatching control system

The invention discloses an intelligent operation and maintenance framework design method for a power grid dispatching control system, which includes the following steps: 1) omni-directional monitoringdata acquisition, 2) monitor data storage, 3) real-time monitoring alarm, 4) fault diagnosis and location, and 5) multi-dimensional visual display. The application can monitor the operation status ofthe whole system in real-time, evaluate the health status of the software and hardware such as the host, storage, application and the like in an effective, accurate and timely manner, and provide effective information for system optimization and fault discovery, and improve the operation and maintenance efficiency of the system.

Owner:NARI TECH CO LTD +2

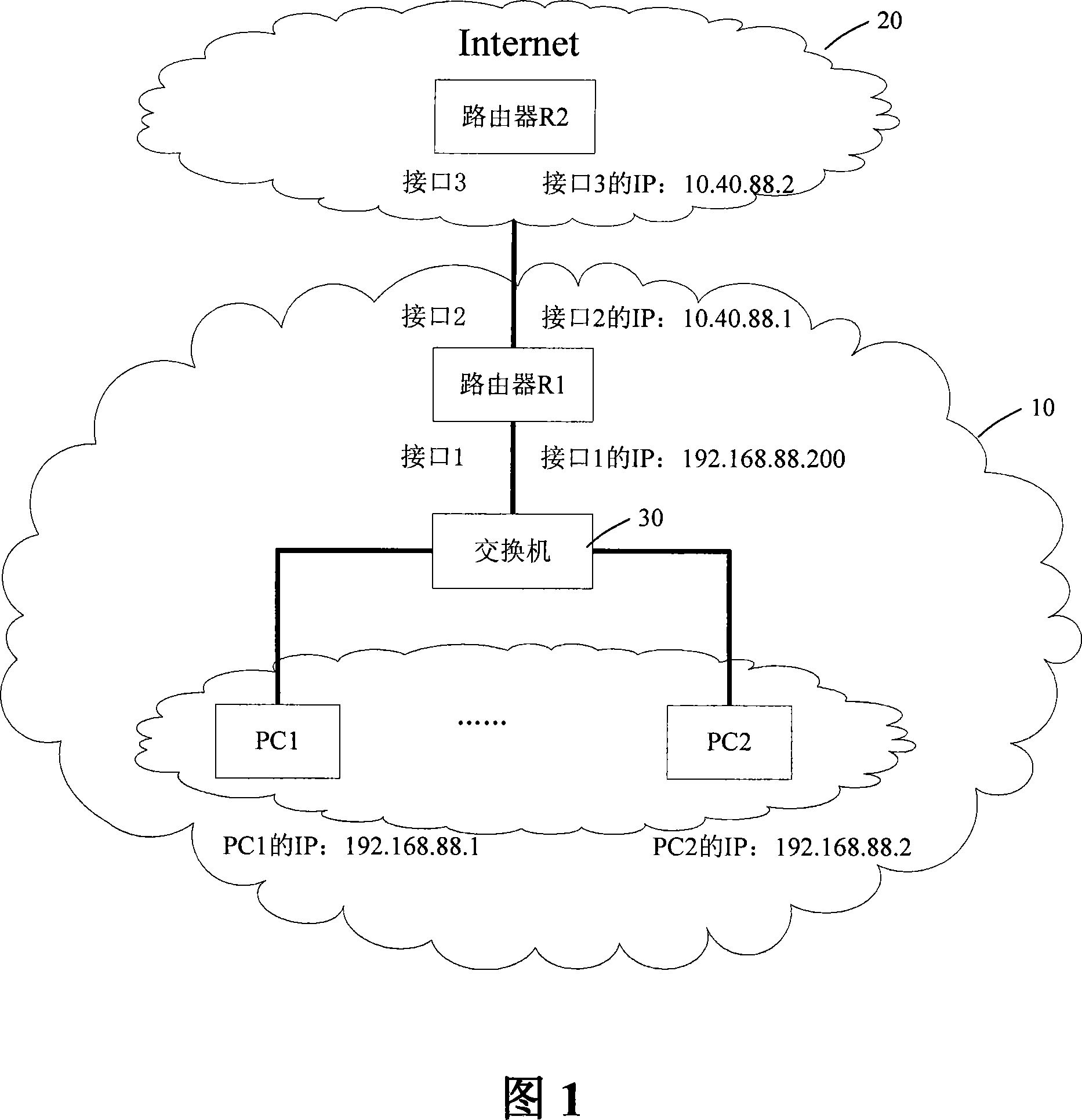

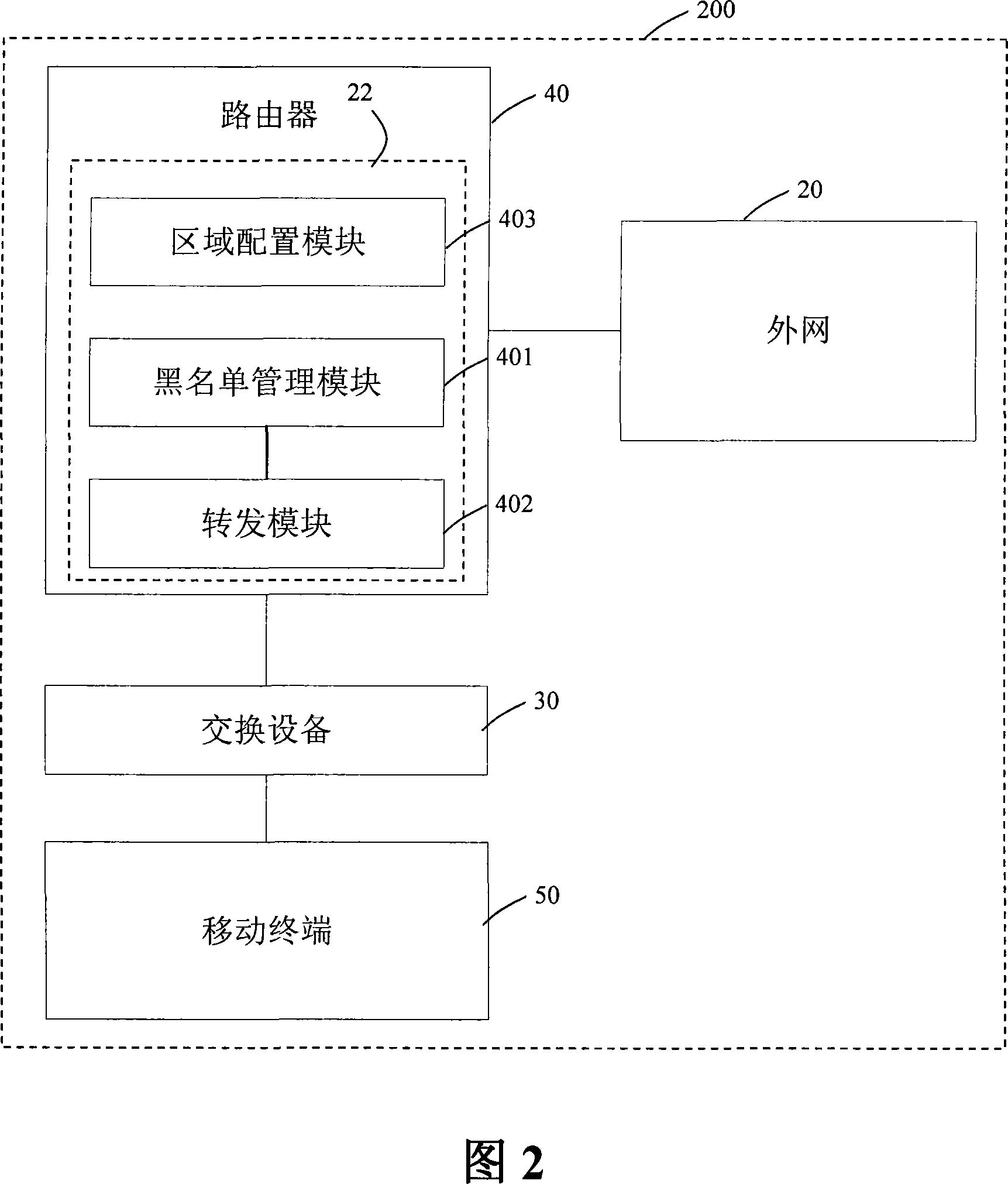

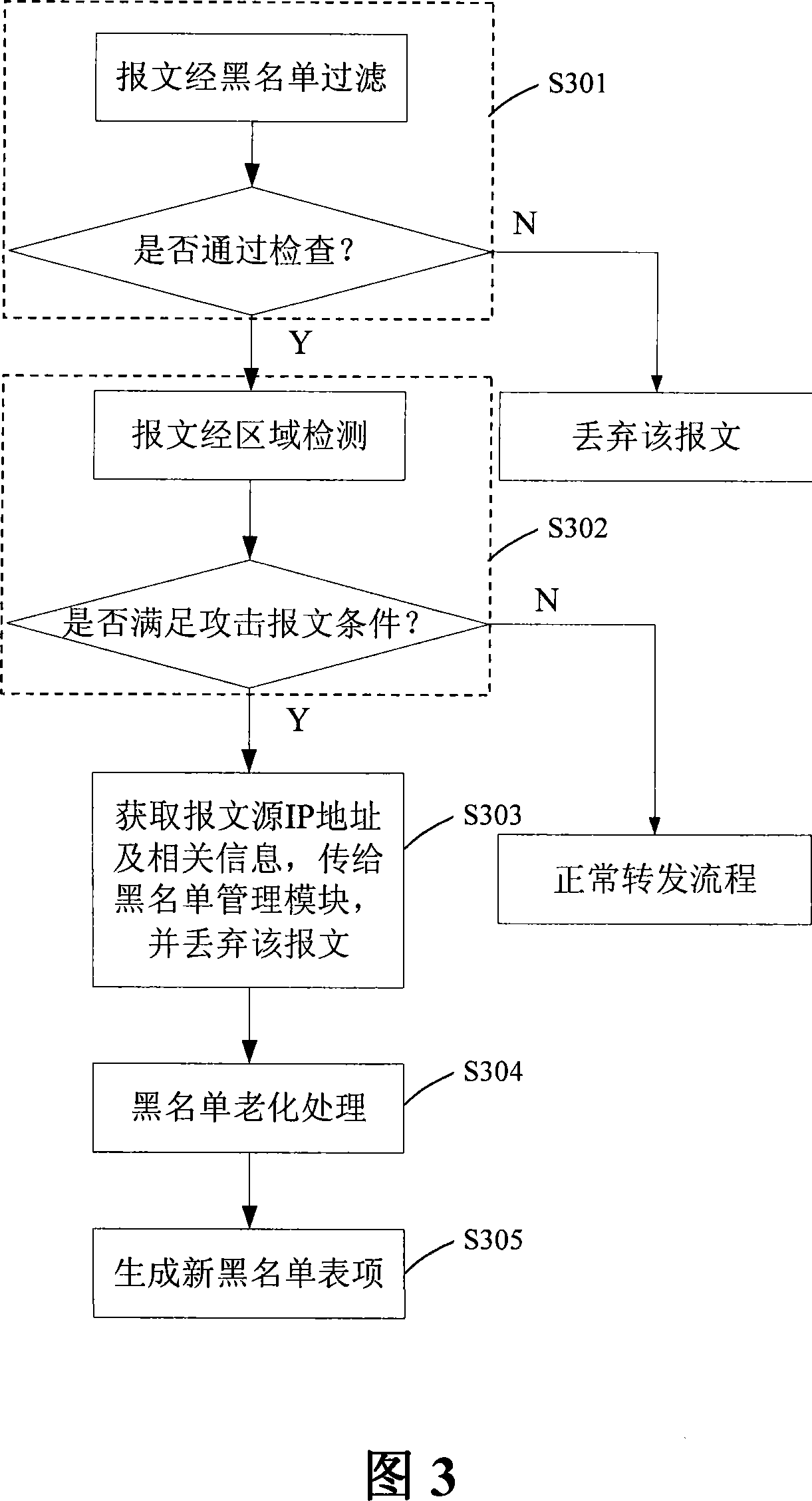

A blacklist real time management method and device

InactiveCN101188612AImprove securityImprove real-time performanceData switching networksSpecial data processing applicationsCommunications systemReal time management

The invention discloses a method for real-time blacklist management and the device thereof, wherein, the method comprise the following steps: step one, a transmission module sends detected message information with attack signature to a blacklist management module, and discards the message; step two, the blacklist management module searches all the blacklist list items in the blacklist, deletes aged blacklist list items, and adds the information into the blacklist list items. The invention adopts a module optimization treatment mode, obtains technical and security progresses, and truly achieves the effect of the real-time blacklist management. No information interaction exists between the modules, therefore the designs in the modules are required to be compactor and more logical, thereby the real time and the stability of the blacklist management are better, and the security of a communication system is higher.

Owner:ZTE CORP

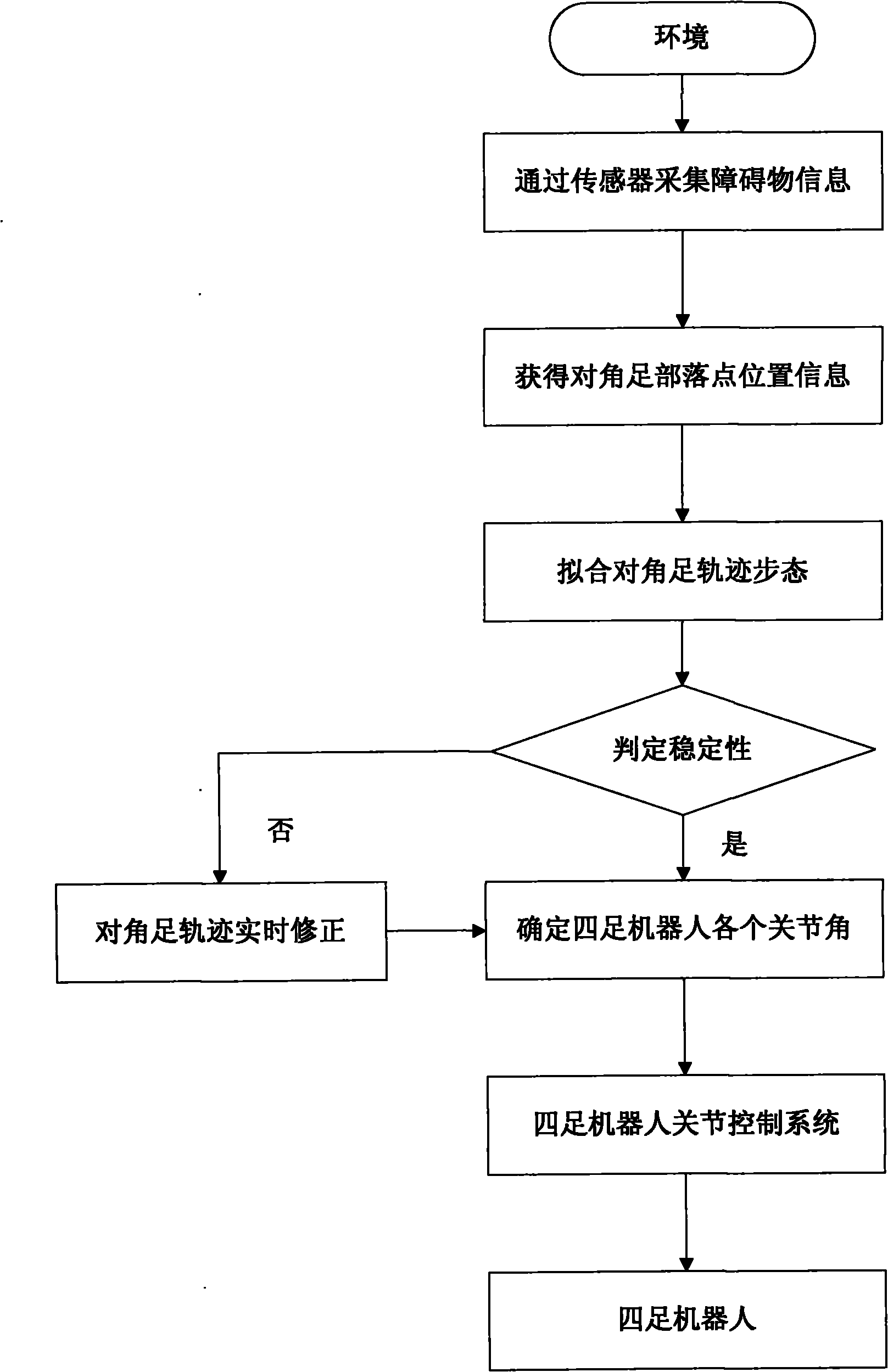

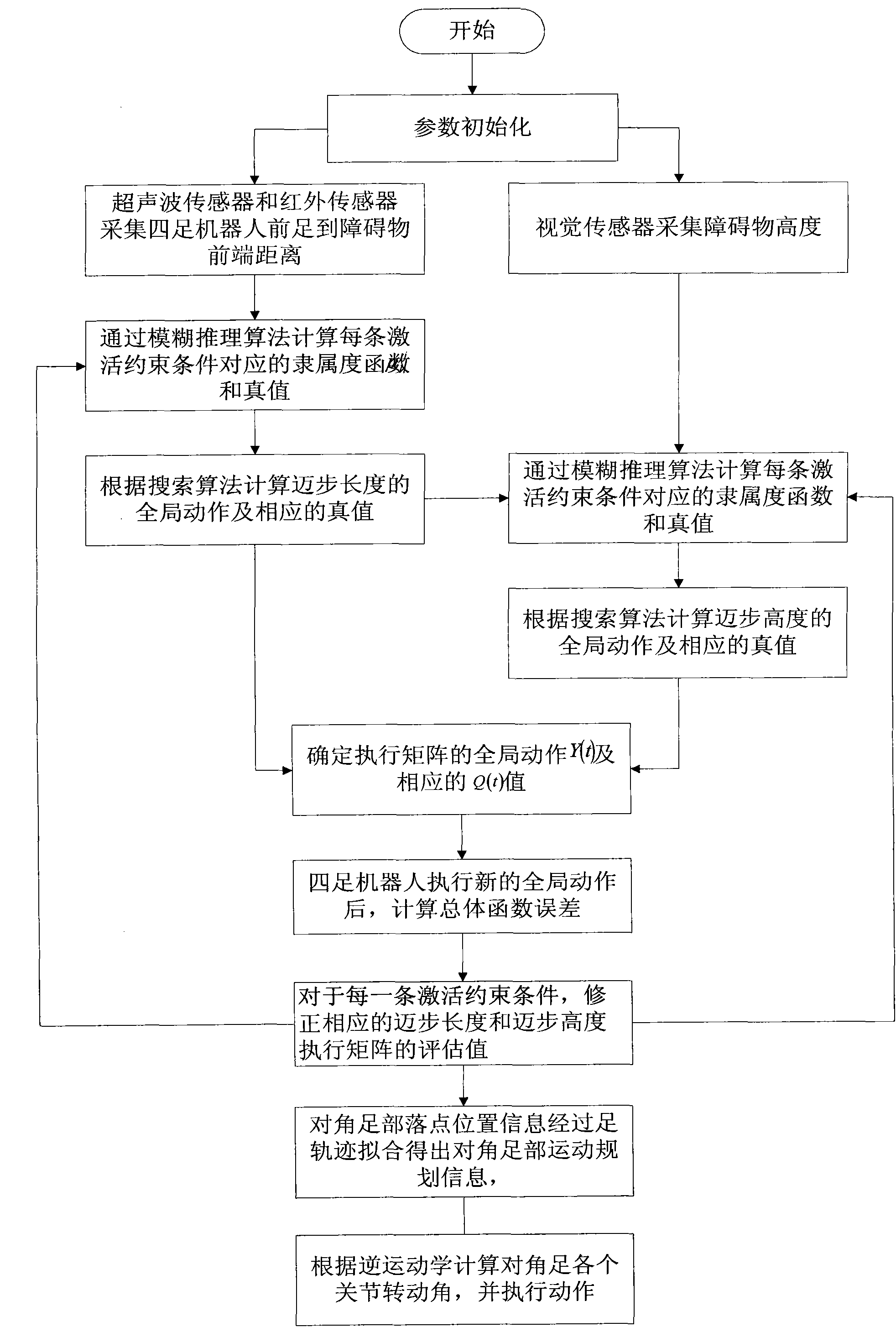

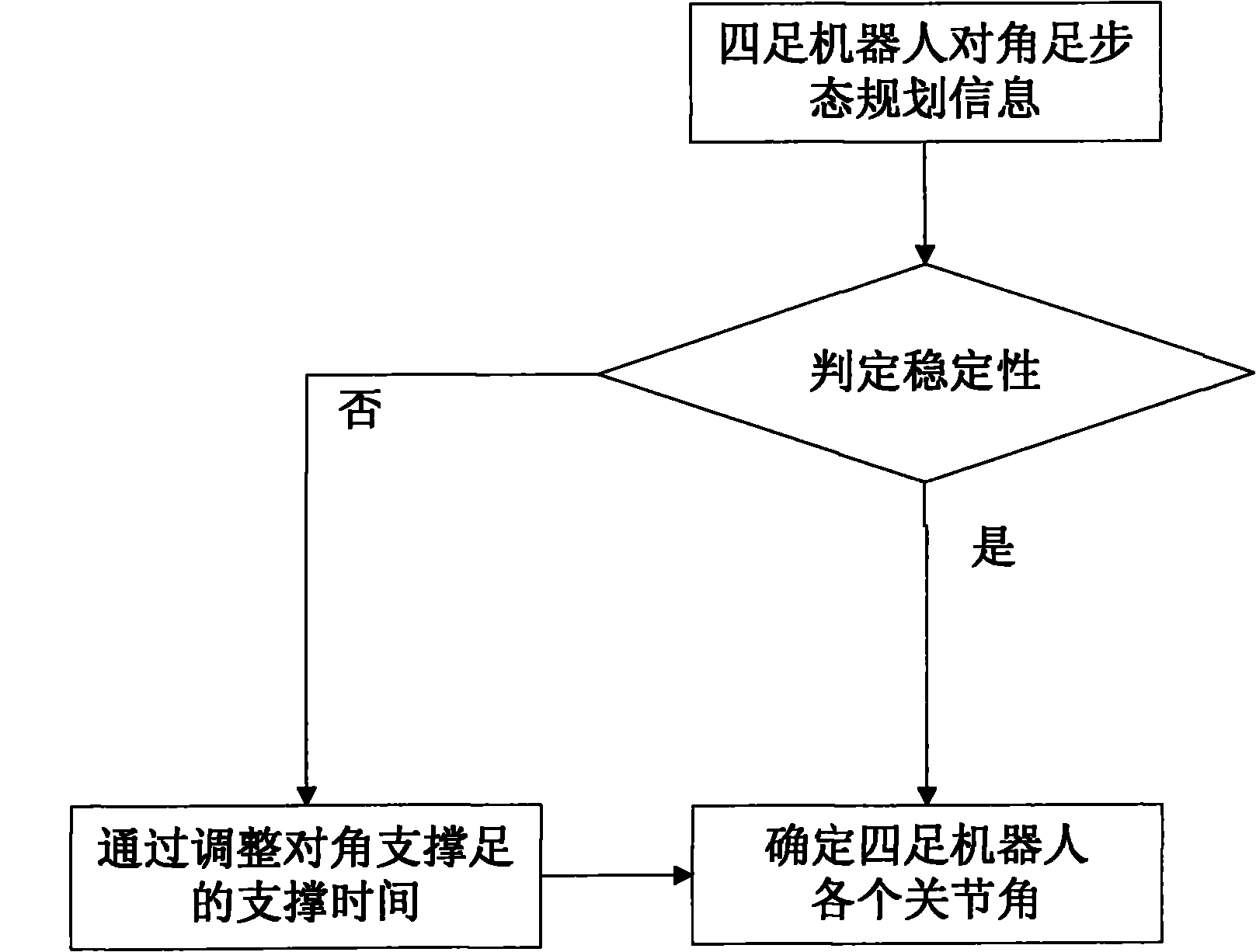

Self-adaptive control method for diagonal gait of four-footed robot

InactiveCN102156484AImprove execution efficiencyClear division of laborControl without using feedbackTerrainEngineering

The invention discloses a self-adaptive control method for diagonal gait of a four-footed robot, which is used for self-adaptively controlling the walking of the four-footed robot in the nonstructural terrain with the diagonal gait. The self-adaptive control method bases on a fuzzy reasoning learning method and a foot trajectory real-time correction method and takes the diagonal gait as the motion mode so as to comprehensively control a robot body to adapt for the nonstructural environment. The gait planning is carried out on the environmental information collected by the sensor through the fuzzy reasoning learning method; the stability judgment is carried out on the gait planning information; if the planned four-footed robot has stable diagonal gait, the joint corner information is sent to a control system; if not, the supporting time of the diagonal feet is corrected by the foot trajectory real-time correction method so that the four-footed robot has better stability when walking under the changed gait in the nonstructural terrain. The self-adaptive control method is used for correcting foot trajectory planning and walking stability under changed gait when the four-footed robot walks diagonally in a dynamic way, thus realizing the self-perception, self-correction and self-adjustment of the four-footed robot.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Velocity regulating method of speech sound self adaptive multivelocity

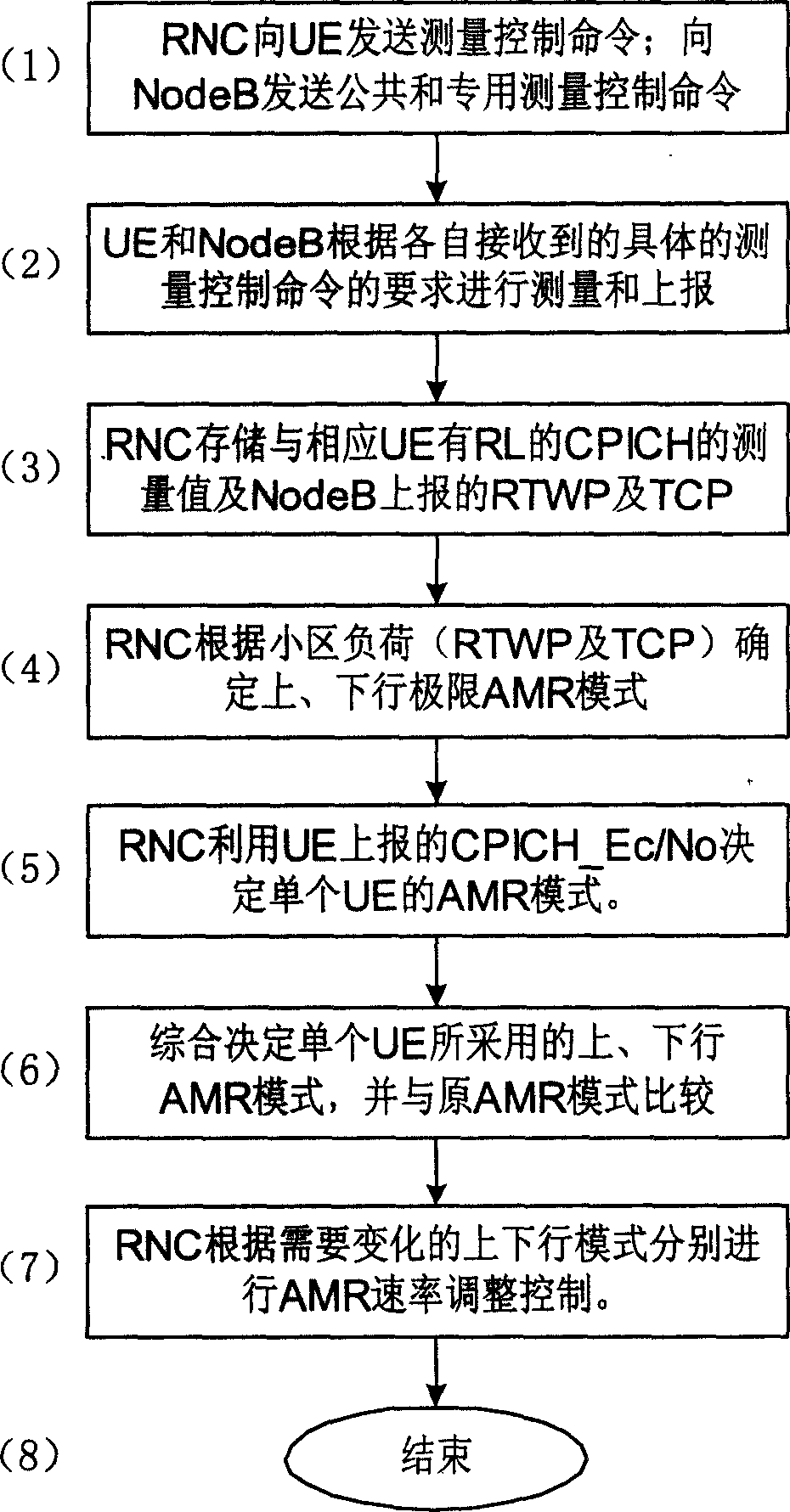

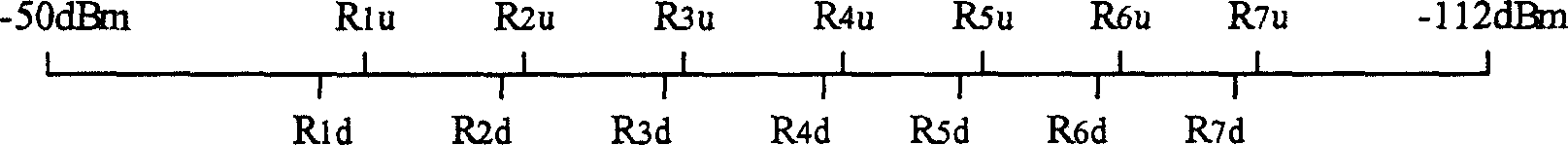

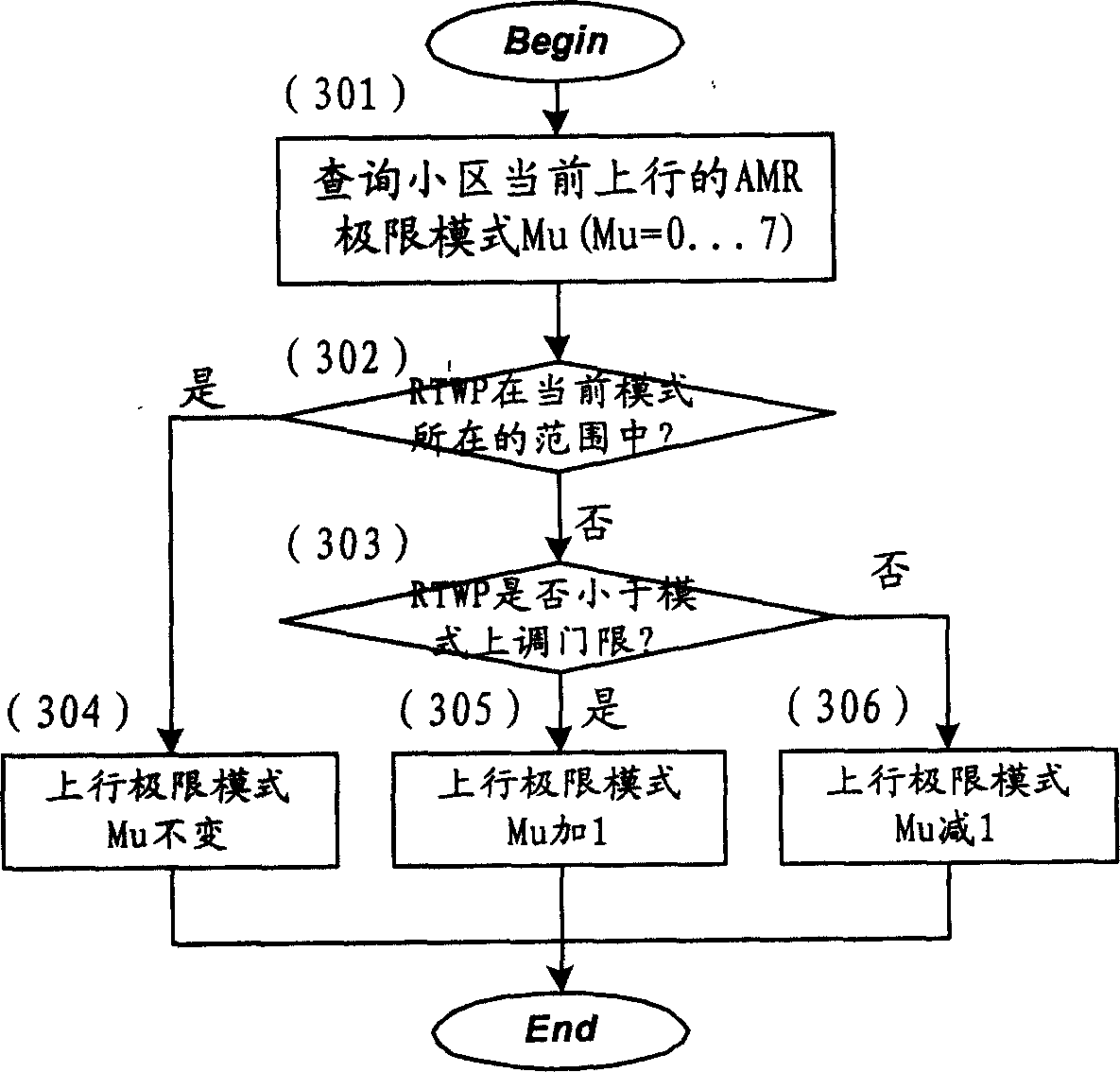

InactiveCN1514559AGuaranteed stabilityReduce transmit powerCode division multiplexRadio/inductive link selection arrangementsEngineeringSelf adaptive

The method includes following procedures: based on RTWP and TCP, RNC determines upper limit allowed in up run and downward run in AMR mode; based on measured value of CPICH-Ec / No, RNC determines AMR mode in up run and downward run the single UE expects to use; based on upper limit allowed in up run and downward run in AMR mode as well as AMR mode in up run and downward run UE expects to use, RNC determines AMR mode in up run and downward run utilized by single UE. Comparing AMR modes between UE utilized and current utilized, if they are same, then control command is not needed to send; if AMR modes in up run are different, then adjustment command is sent to UE through message for controlling transmission format; if AMR modes in downward run are different, then adjustment command is sent to side of core network through rate control frame.

Owner:ZTE CORP

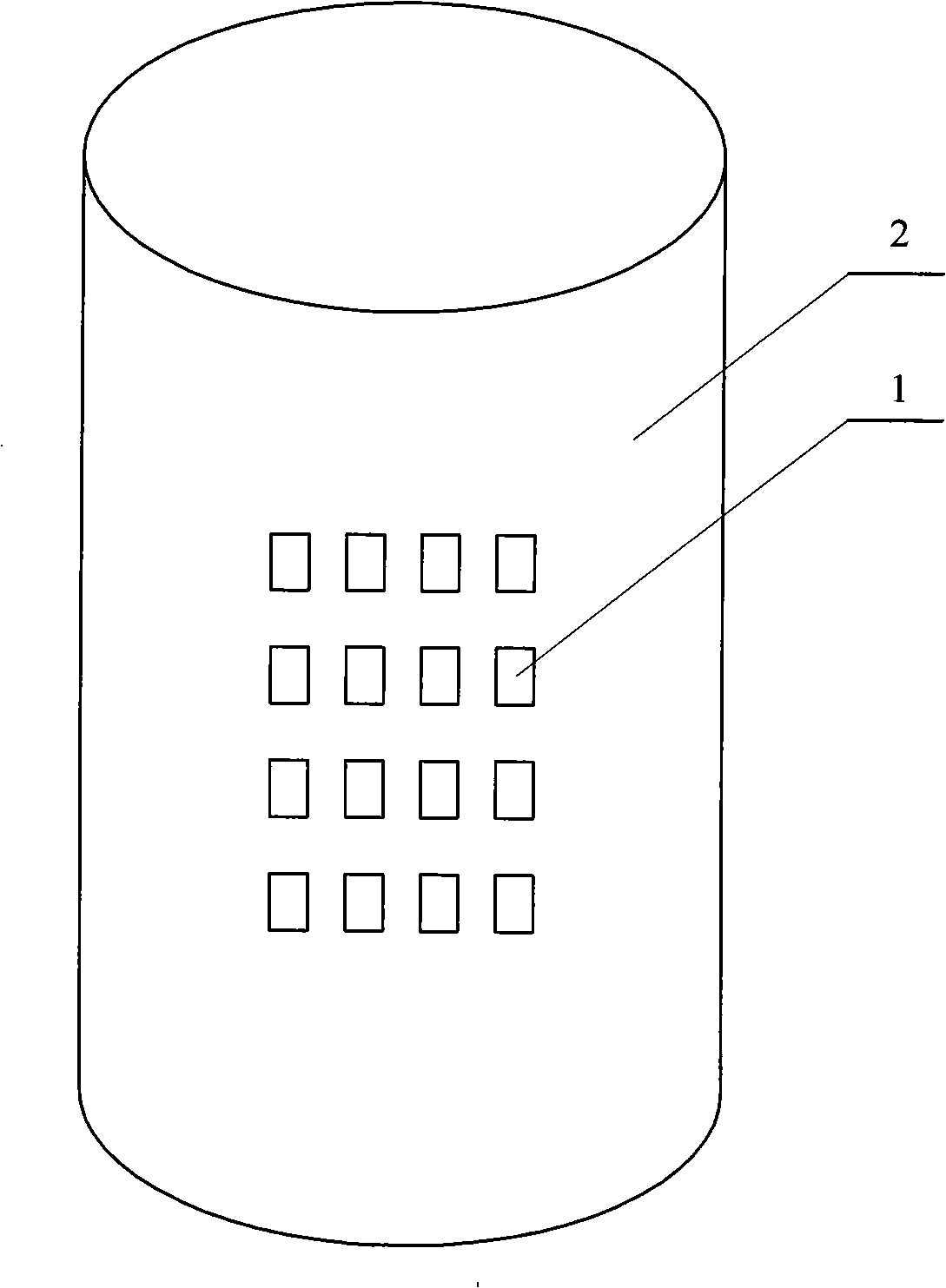

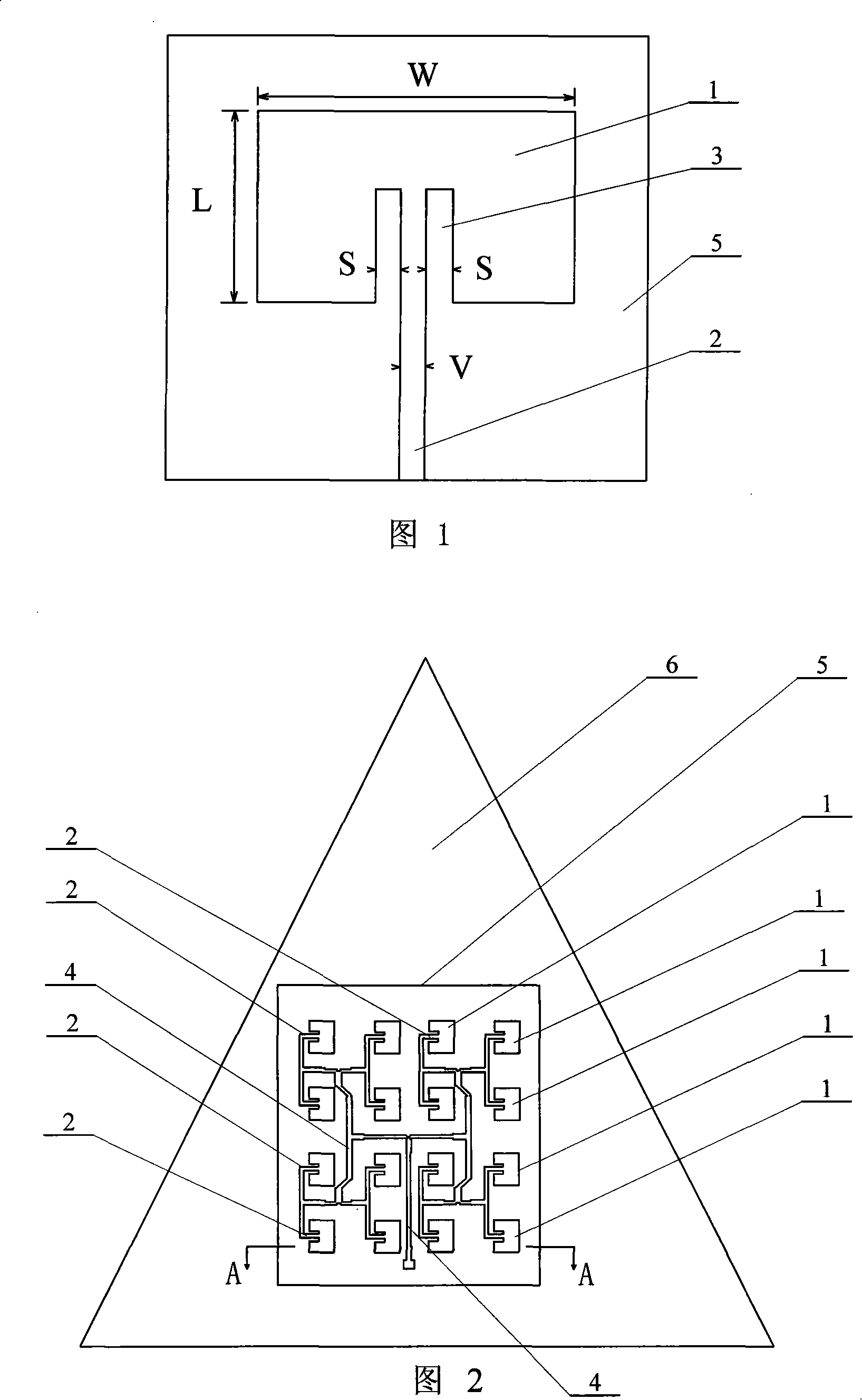

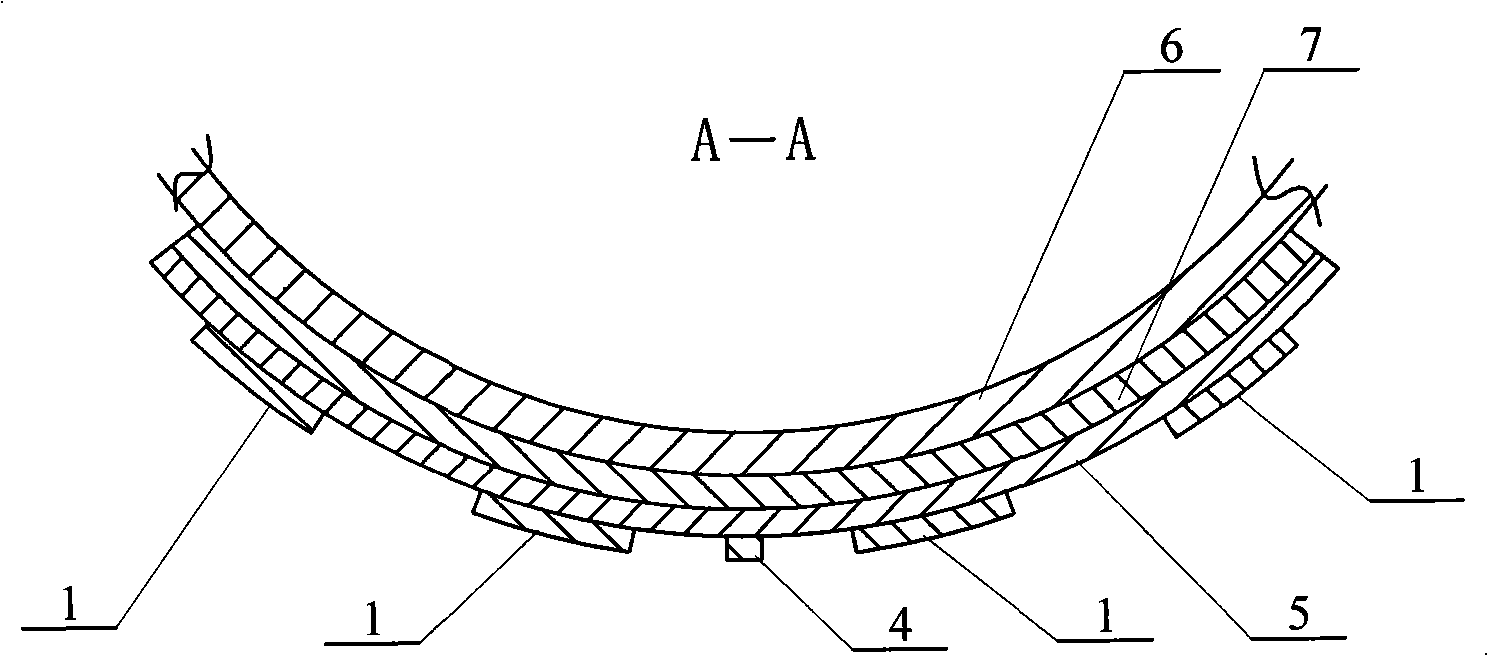

Millimeter wave band broadband cylinder conformal 4*4 microstrip antenna as well as design method thereof

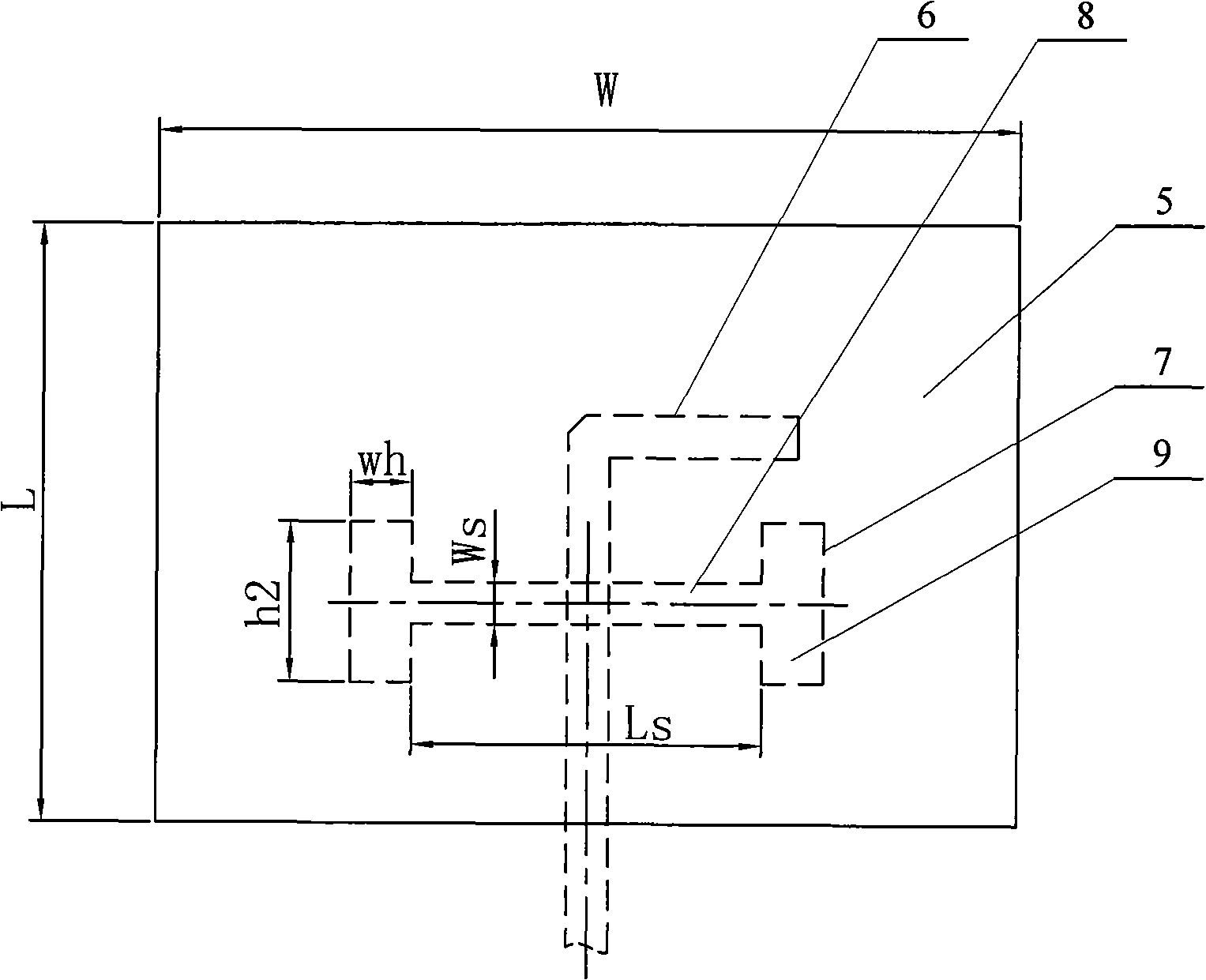

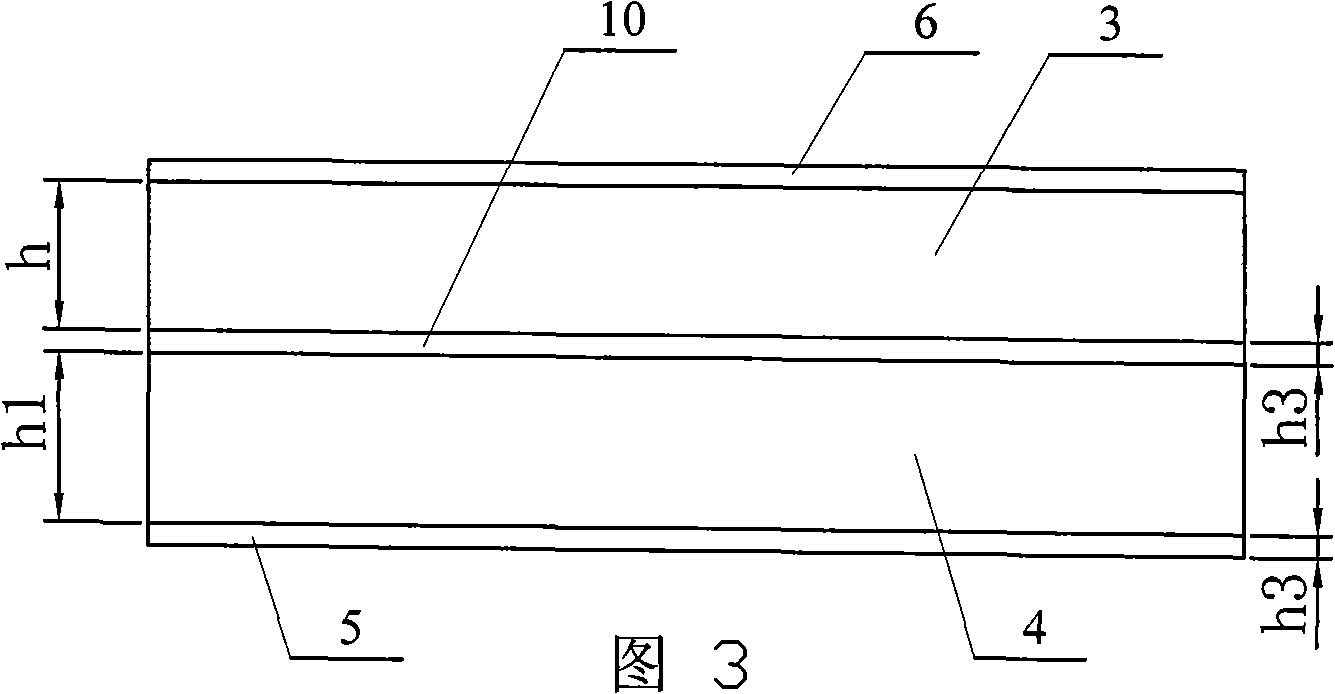

InactiveCN101281998AEasy to installAvoid radiation interferenceAntenna arraysAntenna supports/mountingsAviationSpaceflight

A millimeter wave band broad band column conformal 4*4 micro-band antenna and design method thereof relate to an antenna and design method thereof. For the purpose that the column conformal4 micro-band antenna for aviation, spaceflight, ship and surface car can stably work under frequency of 35GHz, the antenna is equipped with a sheet sticking layer(5), a first medium layer, a second medium layer, a middle floor(10) equipped with a H-shape groove(7), and a feeding network layer(6). The design method includes: designing a planar 4*4 micro-band antenna array with the H-shaped groove (7)in CST through coupling feeding micro-band antenna units by utilizing the H-shaped groove(7), drawing columns with different radius and different material, reducing column type carriers(2) with different thickness by utilizing ''substrate'' function, stretching the two medium layers, the feeding network layer(6), the middle floor(10) and the sheet sticking layer(5) to the column type carriers(2), fetching intersection of the two by utilizing ''intersect'' to conformally arrange the planar array on the column type carriers(2). The micro-band antenna for aviation, spaceflight, ship and surface car can stably work under frequency of 35GHz, and design method is simple.

Owner:HARBIN INST OF TECH

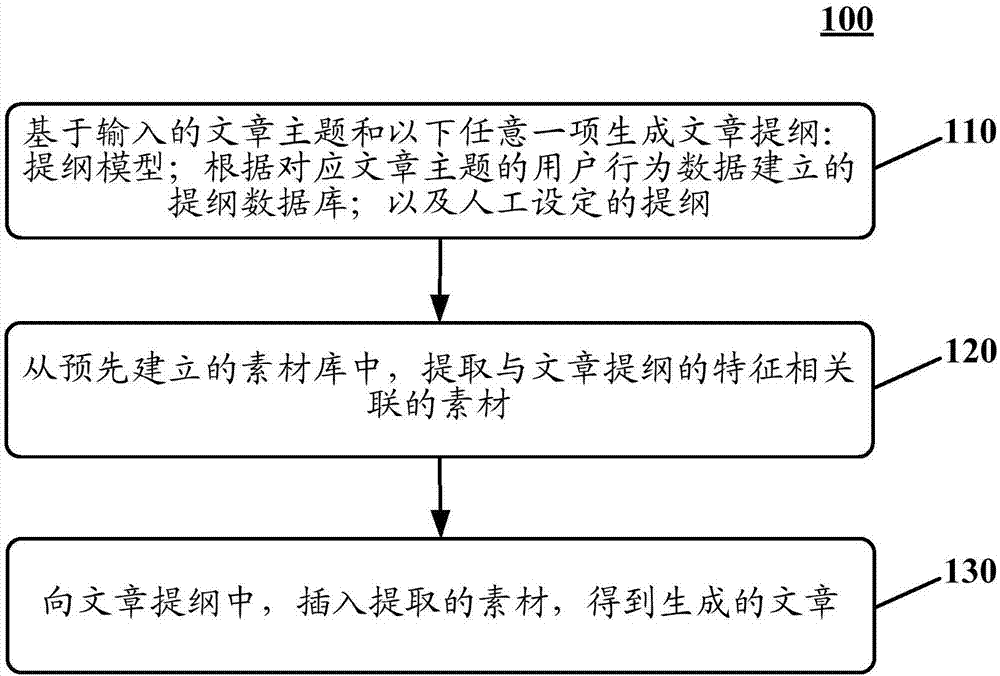

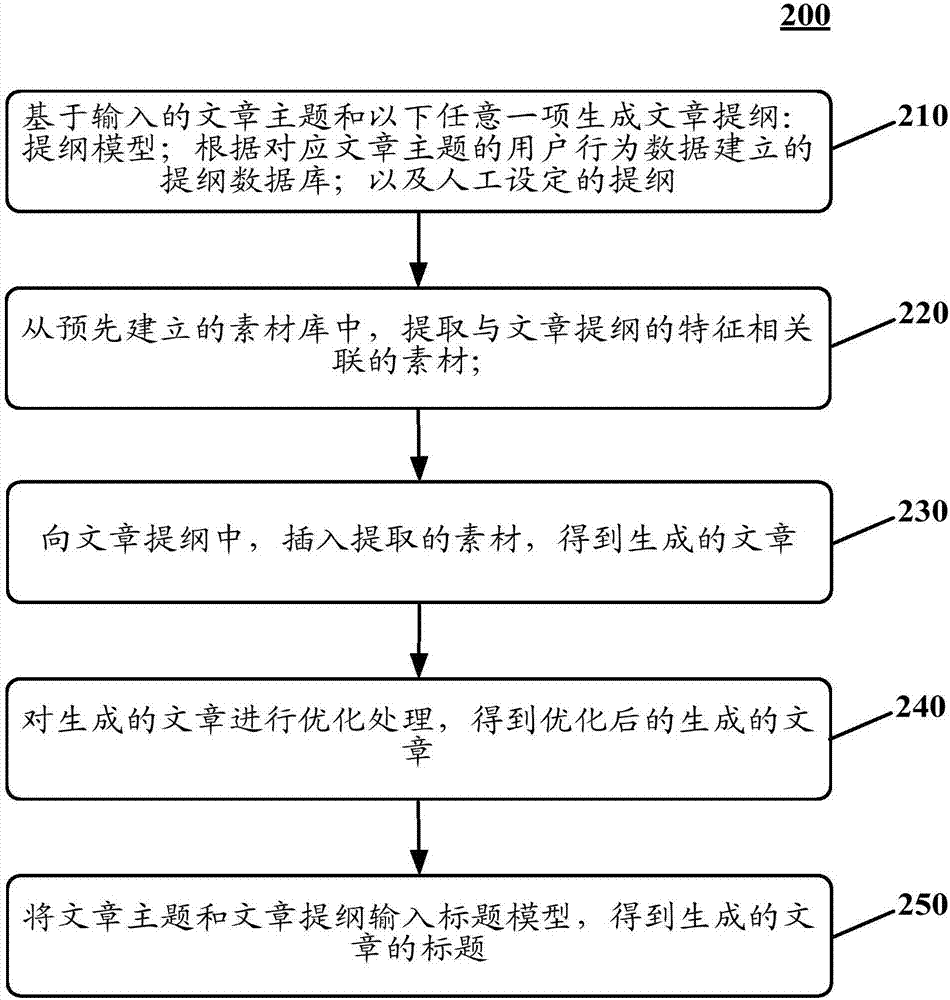

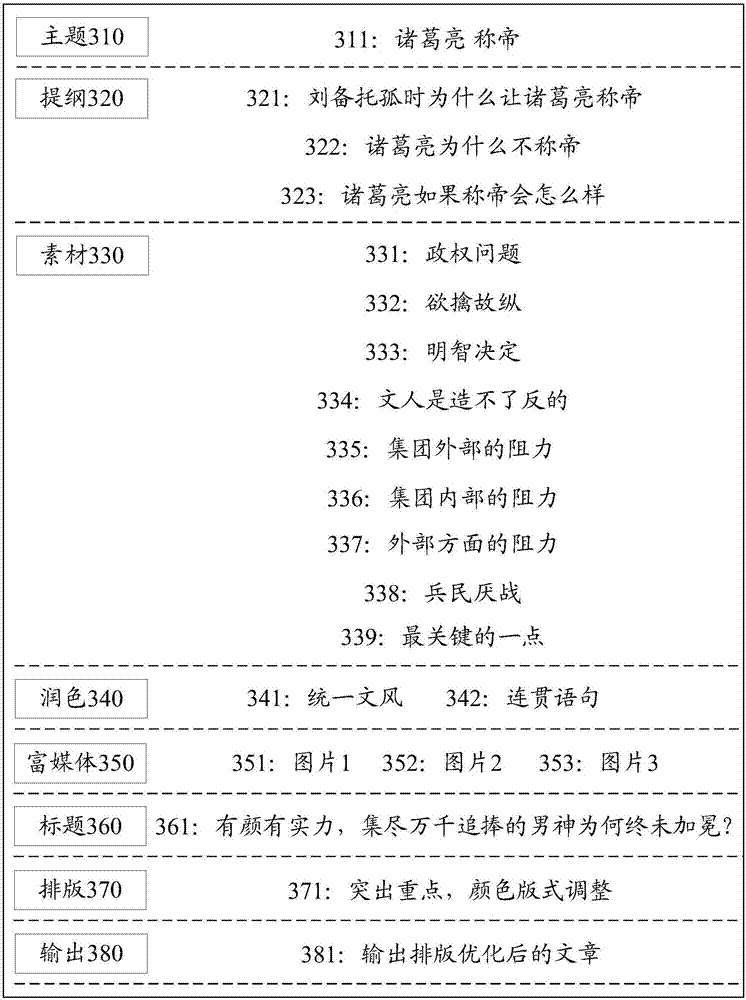

Method and device used for generating article

InactiveCN106970898AThe writing is logicalLogicalSemantic analysisOther databases indexingInformative contentSubject matter

The invention discloses a method and a device used for generating an article. One specific implementation way of the method comprises the following steps that: on the basis of an input article theme and any one of the following items, generating article outlines: an outline model, an outline database established according to the user behavior data of a corresponding article theme and an artificially set outline; from a pre-established material library, extracting a material related to the feature of the article outline; and inserting the extracted material into the article outline to obtain a generated article. By use of the implementation way, according to the input article theme, the outline is generated, the quality of the article outline is improved, the reasonable writing logic and the rich form of the generated article can be guaranteed, the material related to the feature of the article outline is inserted according to the article outline, the contents of the article are enriched, so that the generated article has the advantages of reasonable logic and rich contents.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

Method for controlling synchronous degradation of each layer of co-extrusion composite film by utilizing same biological base

ActiveCN102627013AAppearance unchangedIngenious ideaSynthetic resin layered productsComposite filmAgricultural engineering

The invention discloses a method for controlling the synchronous degradation of each layer of a co-extrusion composite film by utilizing the same biological base. Aiming at the co-extrusion composite film which is in three layers or more than three layers, a biological active additive 'EcoPure' is used as the biological base. The method is characterized by comprising the following steps of: calculating a weight proportion relationship between carbon contents of each layer of the co-extrusion composite film first, then determining the addition concentration of the biological base of each layer according to the weight proportion relationship between the carbon contents of each layer in extruded polymer of each layer before the preparation, and making the degradation rate of each layer of the co-extrusion composite film be accordant. The method disclosed by the invention has the contribution of having a predictable control ability for the biological degradation process and the degradation rate of multi-layer co-extrusion composite film which is composed of different polymers; and by balancing the concentration of the biological base, the biological degradation rate which is suitable for the final processing environment is provided, and the appearance, the function and the physical and mechanism performance of a product before being discarded are ensured to be unchanged.

Owner:圣厦药品食品包装新材料(昆山)有限公司

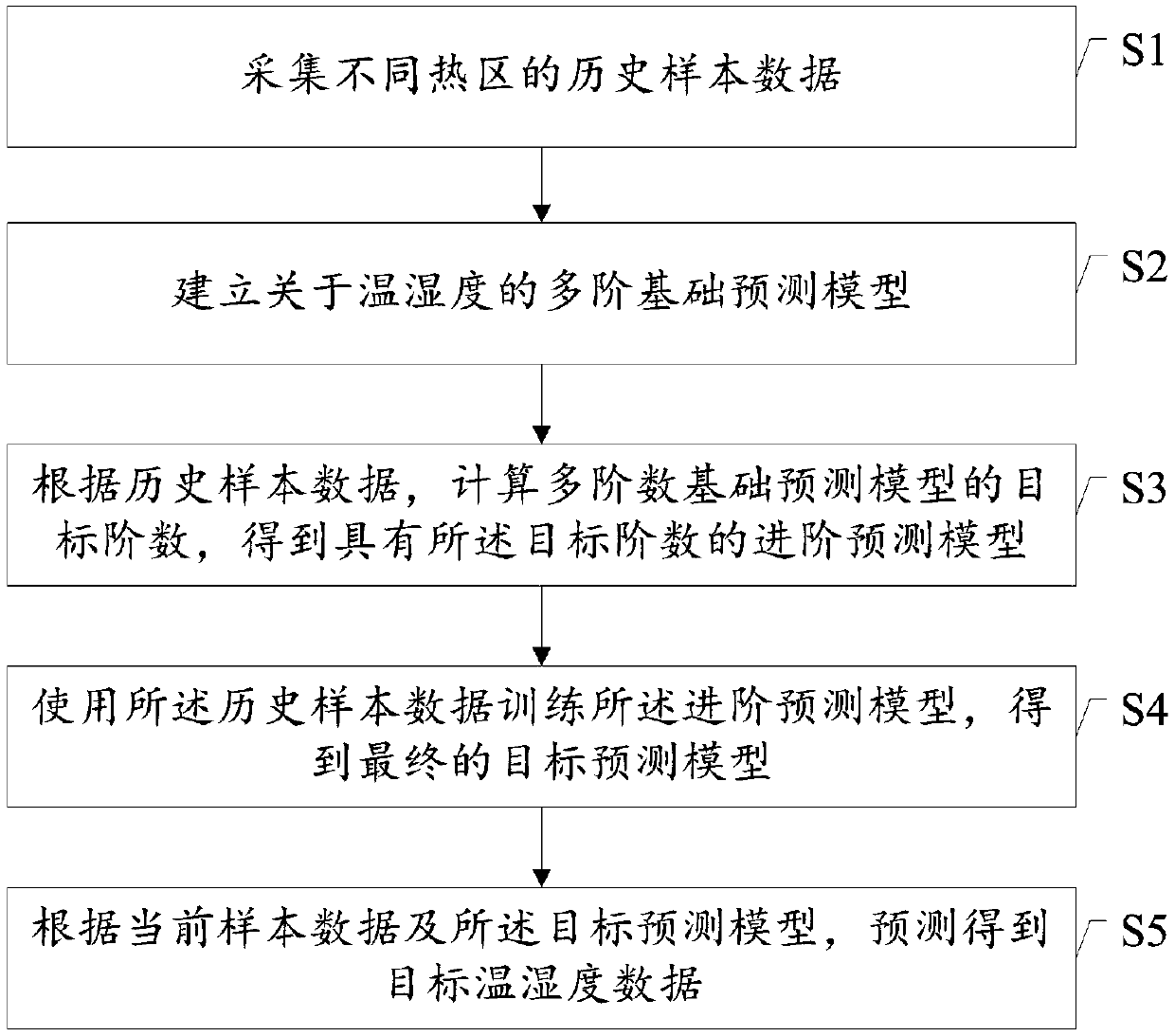

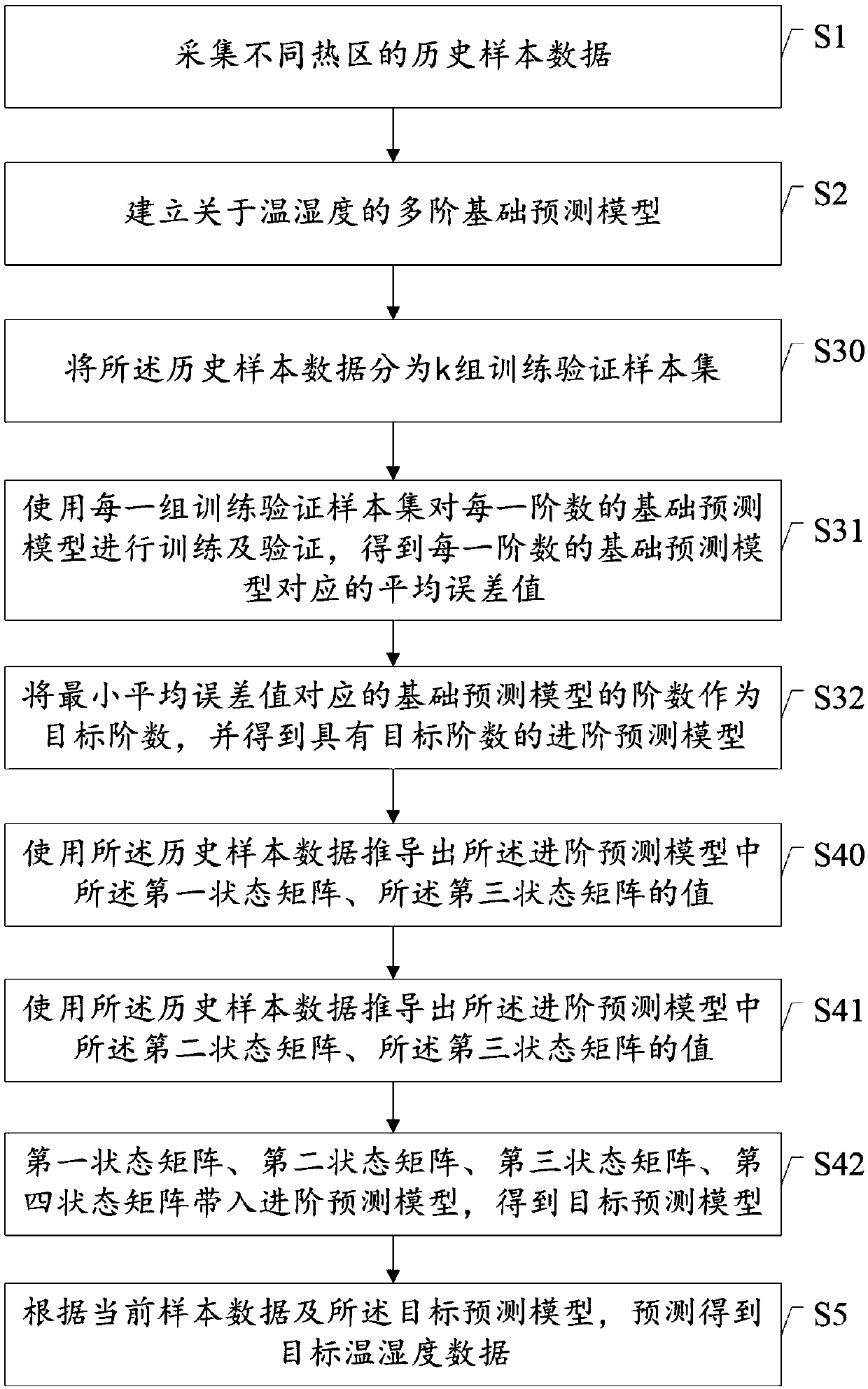

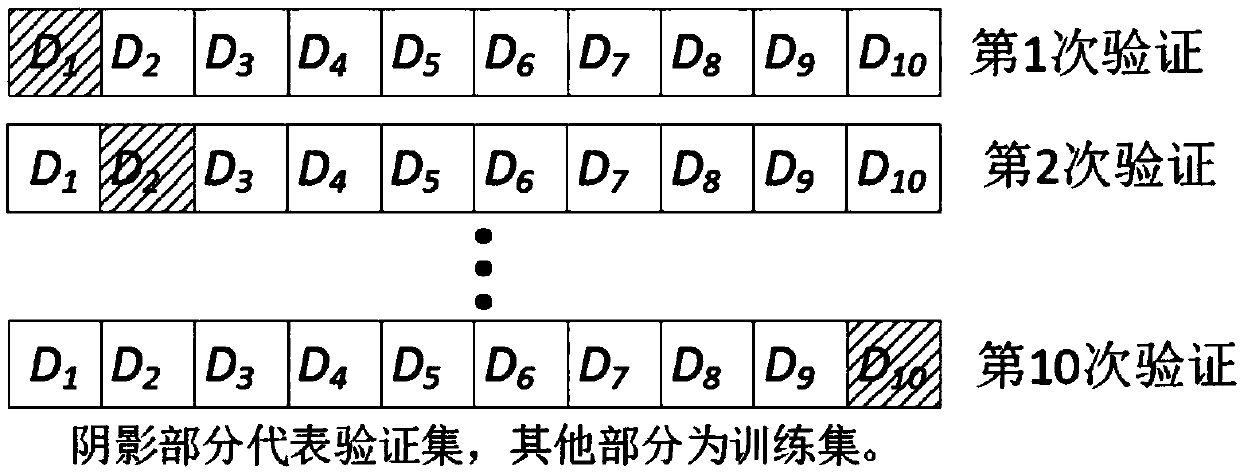

Indoor temperature and humidity prediction method and system

InactiveCN108317683ALow costSimple modeling methodMechanical apparatusSpace heating and ventilation safety systemsCurrent sampleComputer science

The invention provides an indoor temperature and humidity prediction method and system. The method comprises the steps of firstly, acquiring the historical sample data of different hot areas, whereinthe historical sample data include the indoor historical temperature data, the indoor historical humidity data, the outdoor historical temperature data, the outdoor historical humidity data and the indoor equipment energy consumption; secondly, building a multi-level basic prediction model about the temperature and the humidity; thirdly, calculating the target order of the multi-order basic prediction model according to the historical sample data to obtain an advanced prediction model with the target order; fourthly, training the advanced prediction model by using the historical sample data toobtain the final target prediction model; and fifthly, carrying out prediction to obtain the target temperature and humidity data according to the current sample data and the target prediction model.With the indoor temperature and humidity prediction method and system, the prediction on the indoor temperature and humidity is realized with the low cost and the accurate results.

Owner:SICHUAN FEIXUN INFORMATION TECH CO LTD

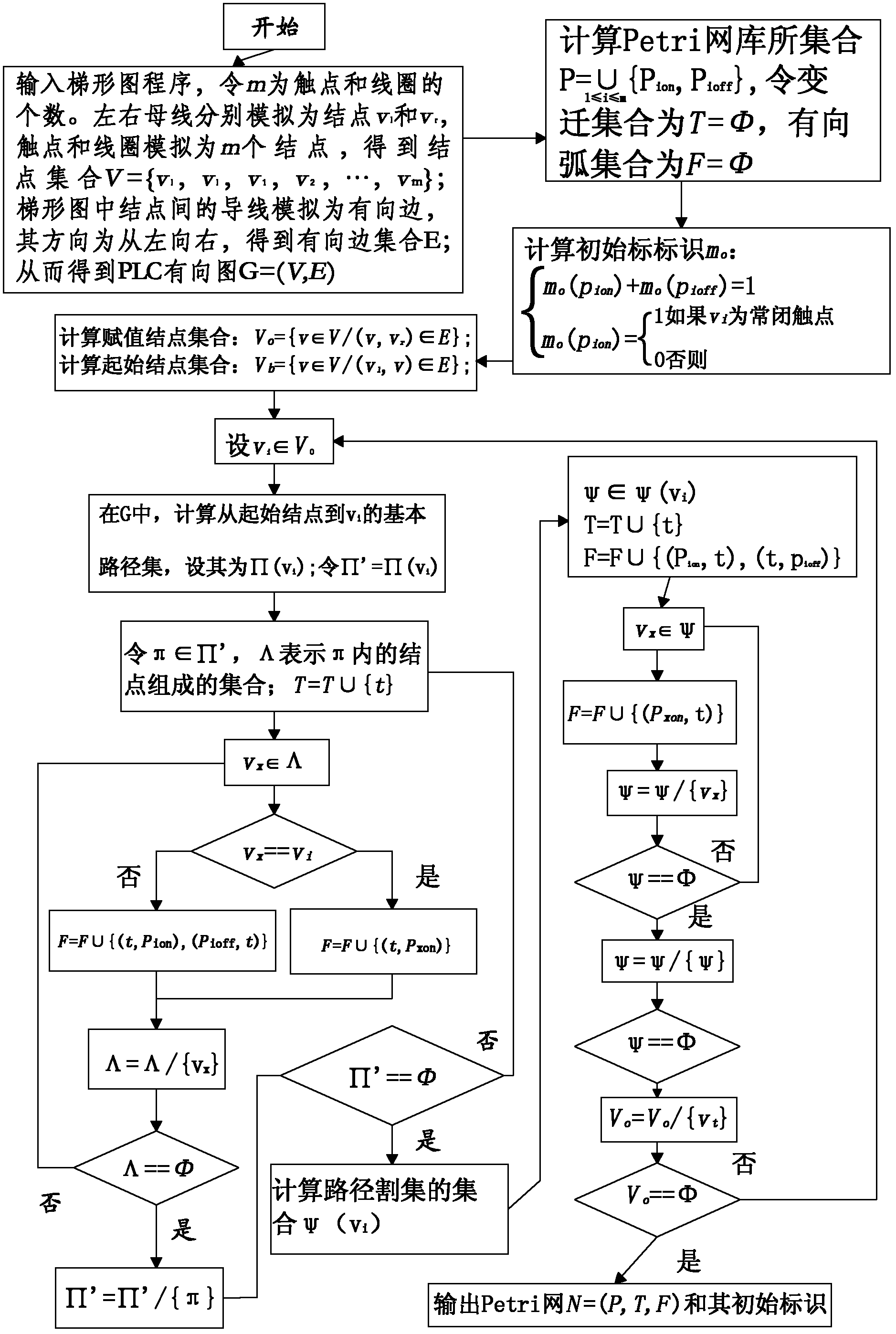

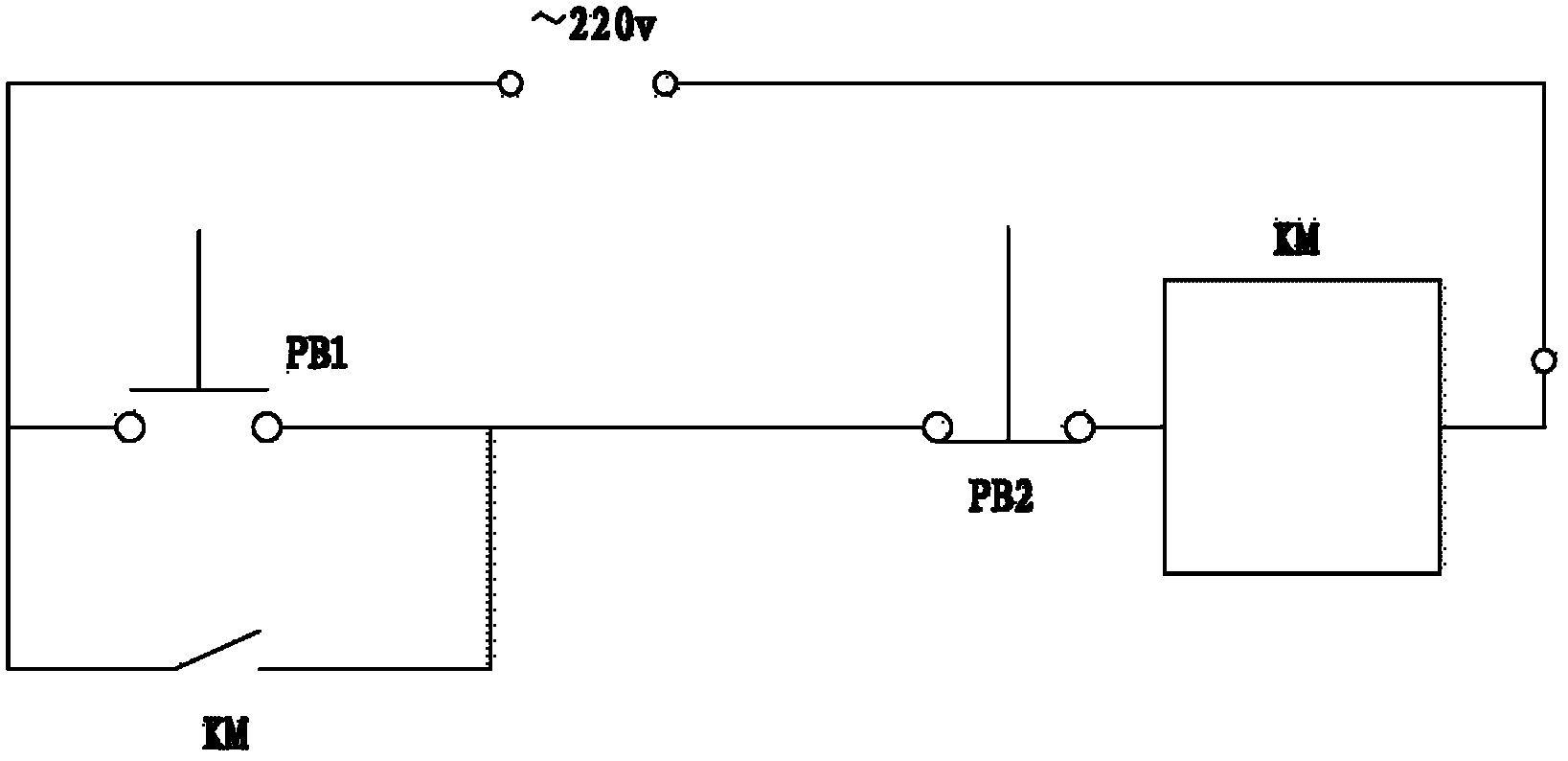

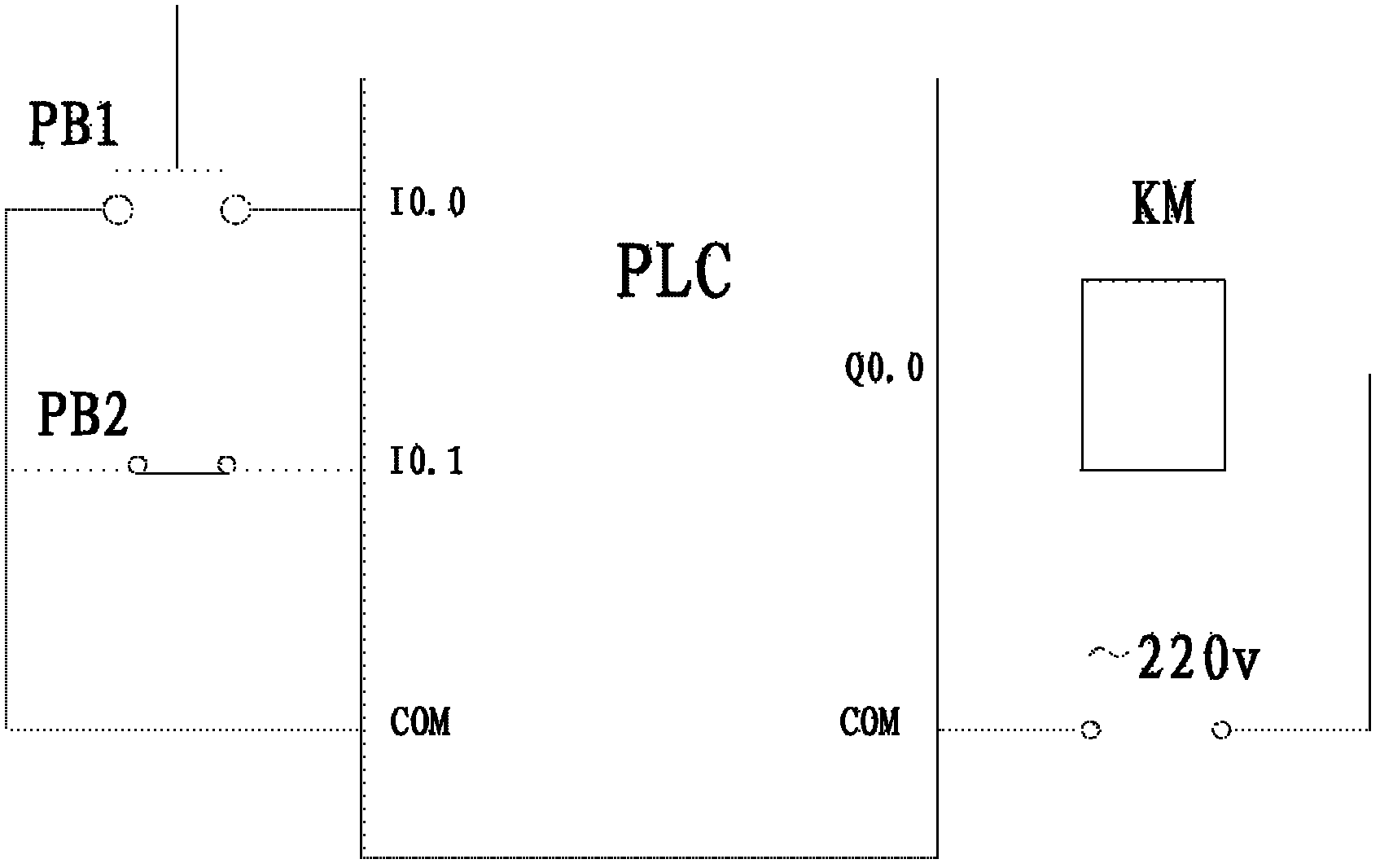

Method for converting PLC program into common Petri net

ActiveCN102411330AEasy to analyzeEasy to correctProgramme control in sequence/logic controllersDirected graphControl system

The invention provides a method for converting a PLC program into a common Petri net. The method is characterized by: aiming at a PLC ladder diagram program, simulating a ladder diagram contact and a coil as a node; simulating a lead as a directed edge; establishing a PLC directed graphical model of the ladder diagram program; defining a path in a directed graph; according to a path relation, converting the PLC directed graph into the Petri net. In the invention, automatic conversion from the PLC ladder diagram program to a common Petri net model can be realized. Because an excitation condition of the common Petri net is concise, a logic thinking mode is simple, visual and understandable and the obtained Petri net model can complete simulate a dynamic behavior of a PLC control system, PLC program analysis and error correction can be conveniently achieved and PLC program logic is more precise.

Owner:HUAQIAO UNIVERSITY

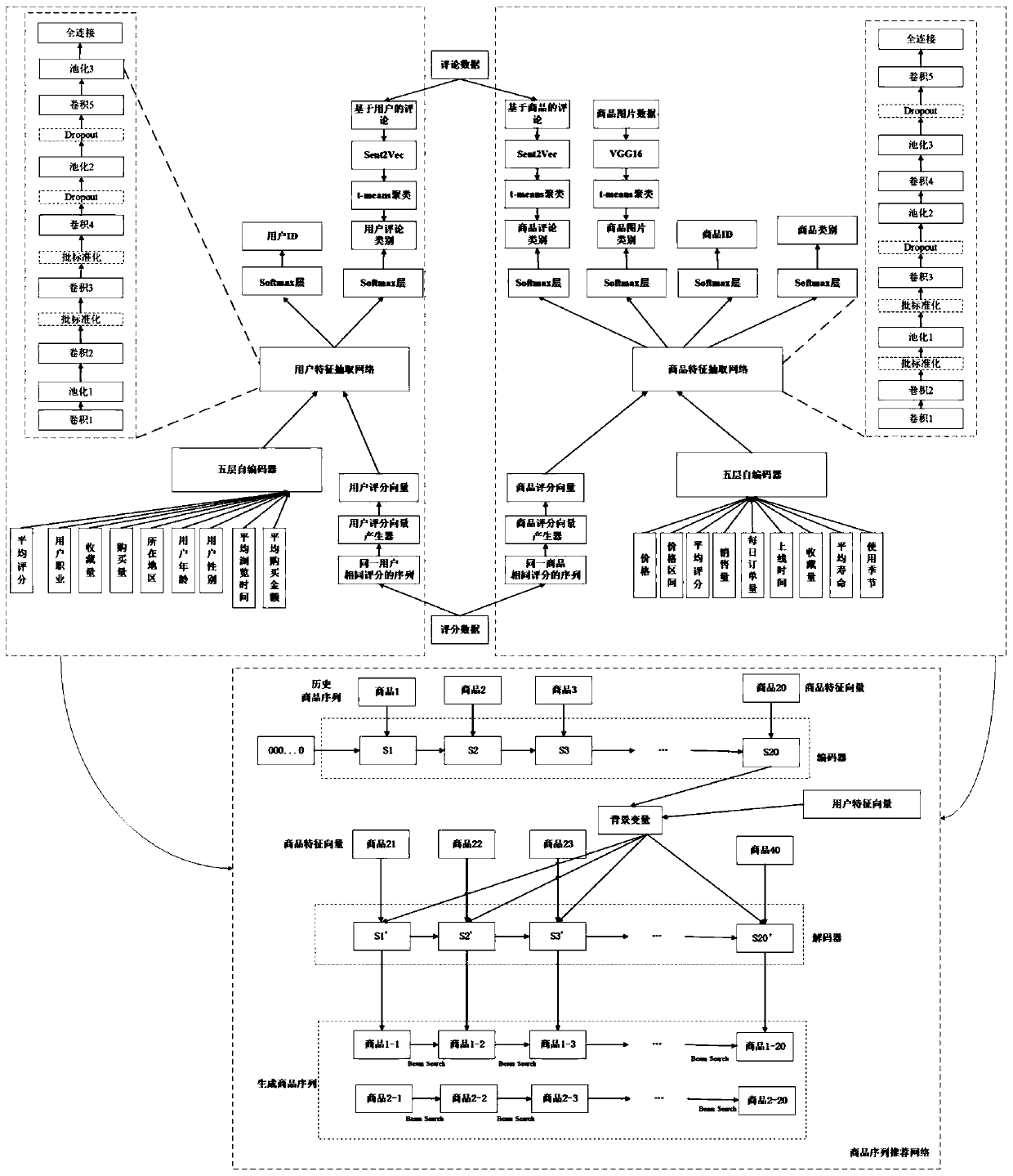

User dynamic preference oriented commodity sequence personalized recommendation method

ActiveCN110458627AEasy to useScore full useAdvertisementsCharacter and pattern recognitionFeature vectorPersonalization

The invention discloses a user dynamic preference oriented commodity sequence personalized recommendation method. The method comprises the steps of extracting a commodity sequence under the same usersimilarity score to construct a commodity score vector; extracting a user sequence of similar scores of the same commodity to obtain a user score vector; combining user personal information, commoditybasic attribute information, user and article comments and commodity pictures; achieving feature extraction of a user and a commodity based on multi-task learning, taking a user feature vector and afeature vector of a historical commodity sequence of the user feature vector as input, achieving generation of the commodity sequence by training a coder-decoder, and accurately learning recommendation of the optimal commodity sequence in combination with a search strategy. According to the invention, based on the multi-modal user-commodity data, the user features and the commodity features are highly extracted and fused, personalized recommendation of the commodity sequence for user preferences is realized, and the user experience is improved.

Owner:SOUTH CHINA NORMAL UNIVERSITY +1

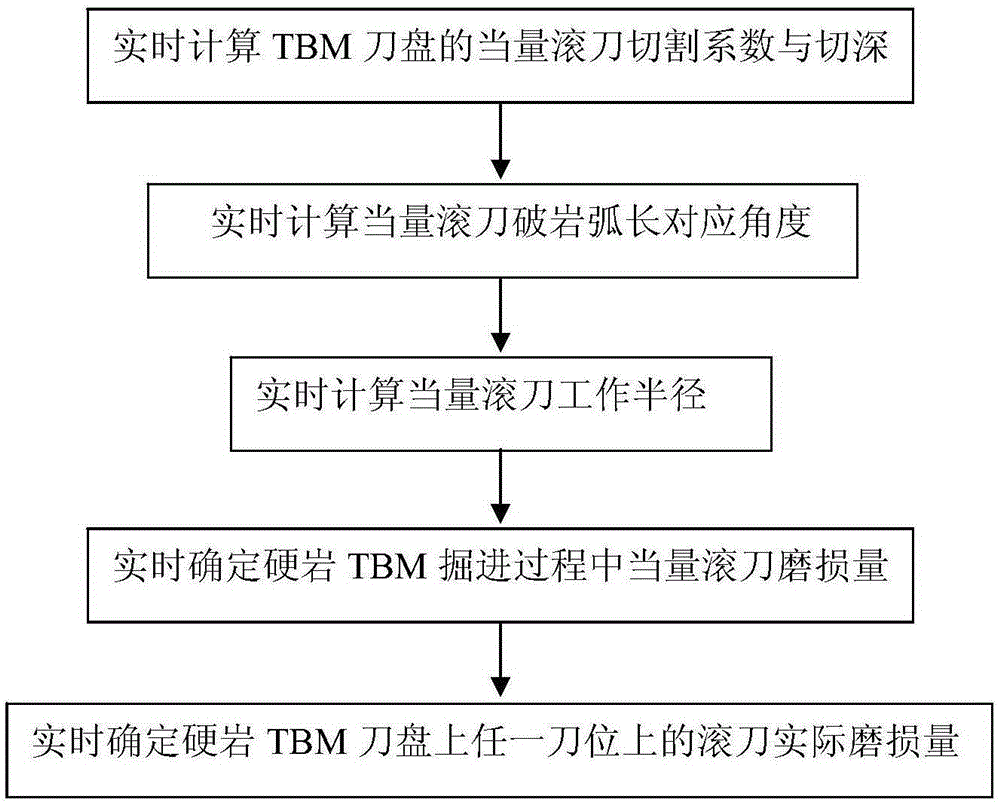

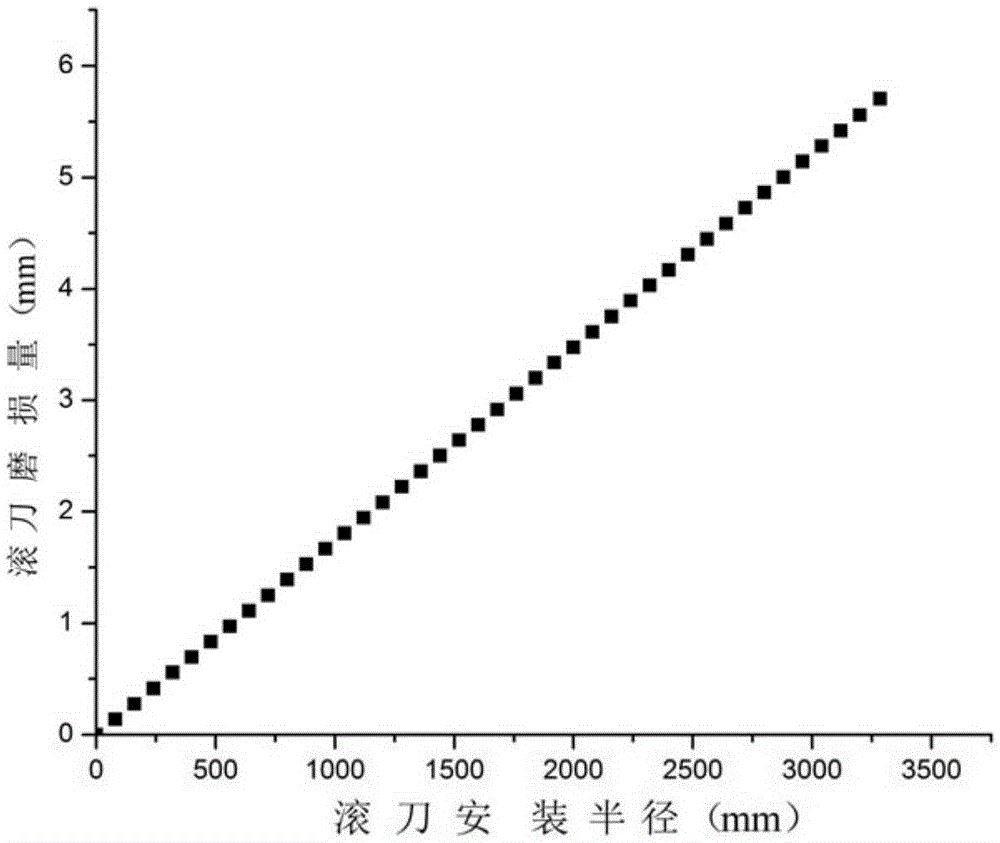

Real-time calculation method of abrasion loss of disc cutter of hard rock tunnelling boring machine

A real-time calculation method of abrasion loss of a disc cutter of a hard rock tunnelling boring machine (TBM) provided by the invention relates to a data processing method particularly suitable for specific application. From the aspect of mechanical analysis of hard rock hobbing cutter rock breaking, a relationship between a cutting coefficient and a hobbing cutter rock breaking arc length is established, and the real-time calculation method of abrasion loss of the hobbing cutter in the tunneling process of a hard rock TBM is realized through adoption of tunneling parameters automatically acquired in the work process of the hard rock TBM. The real-time calculation method comprises the steps: performing real-time calculation of an equivalent hobbing cutter cutting coefficient and a knifing of a TBM cutter; performing real-time calculation of an angle with respect to the equivalent hobbing cutter rock breaking arc length; performing real-time calculation of an equivalent hobbing cutter working radius; performing real-time determination of the abrasion loss of the equivalent hobbing cutter in the tunneling process of the hard rock TBM; and performing real-time determination of the actual abrasion loss of a hobbing cutter at any one cutter spacing on the hard rock TBM cutter. According to the invention, the real-time calculation method helps to make up the deficiencies in the prior art that abrasion of a hobbing cutter of the hard rock TBM in the tunneling process cannot be directly detected in real time and the abrasion loss of the hobbing cutter of the hard rock TBM in the tunneling process cannot be reflected.

Owner:MILITARY TRANSPORTATION UNIV PLA

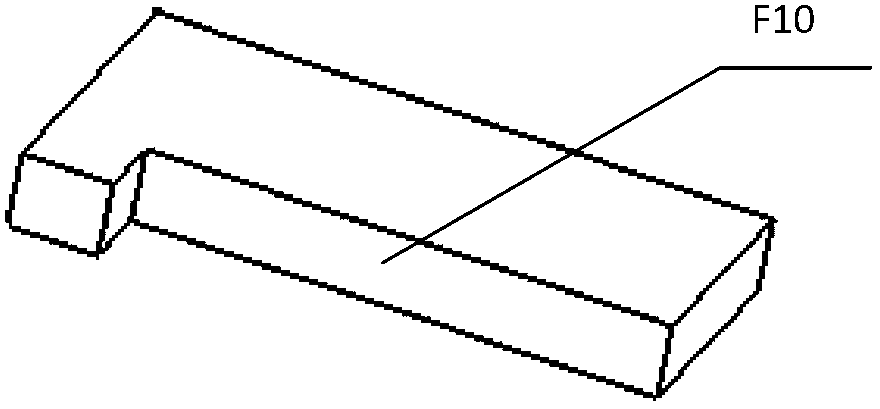

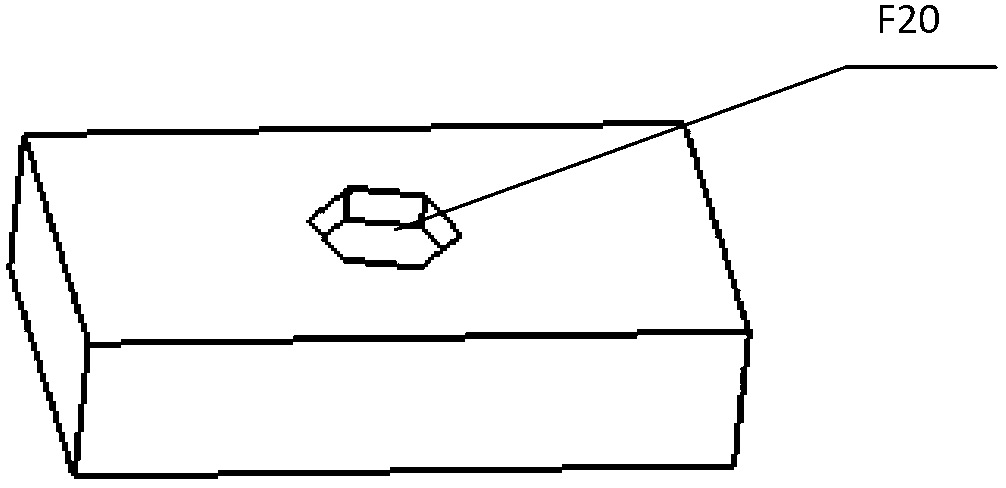

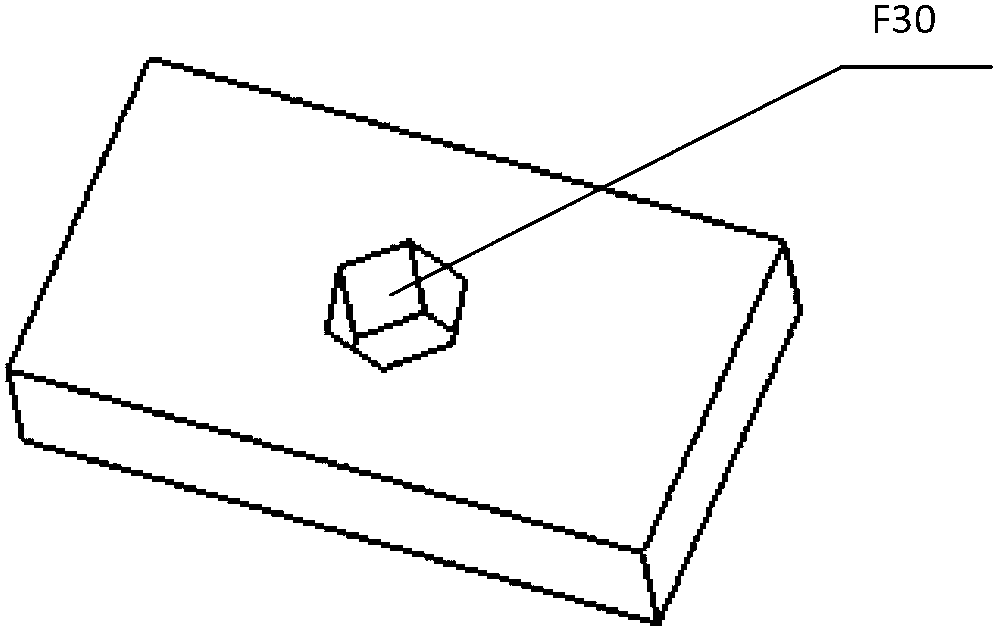

Three-dimensional mechanical in-process model sequential modeling method based on removal feature recognition

InactiveCN103020381ADifficulty of SimplificationEnsure rapid creation of requirementsSpecial data processing applicationsQuality by DesignModel order

The invention relates to a three-dimensional mechanical in-process model sequential modeling method based on removal feature recognition, which mainly aims to solve the technical problems of repetitive work and big application limitation in the prior art. In the method, first of all, the removal features are classified into boundary feature, inset feature, communication feature, thread feature and loop feature. On the basis of the classification, the method includes the steps of: 1) producing a workblank; 2) judging whether a next process is necessary, and if yes, entering the third step; 3) recognizing the removal features in the process, which includes selecting a feature type and recognizing the feature; and 4) modeling the in-process models. All the in-process models are assembled to form a whole process model and are organized by a standard structure of a process all-information model. The method makes full use of the geometrical characteristics of the original components, solves the problem of high quality requirement to the original component model design in three dimensional process design, speedily creates the in-process models according to the practical mechanical processing sequence and improves the overall efficiency of the process design system.

Owner:SHENYANG AEROSPACE UNIVERSITY

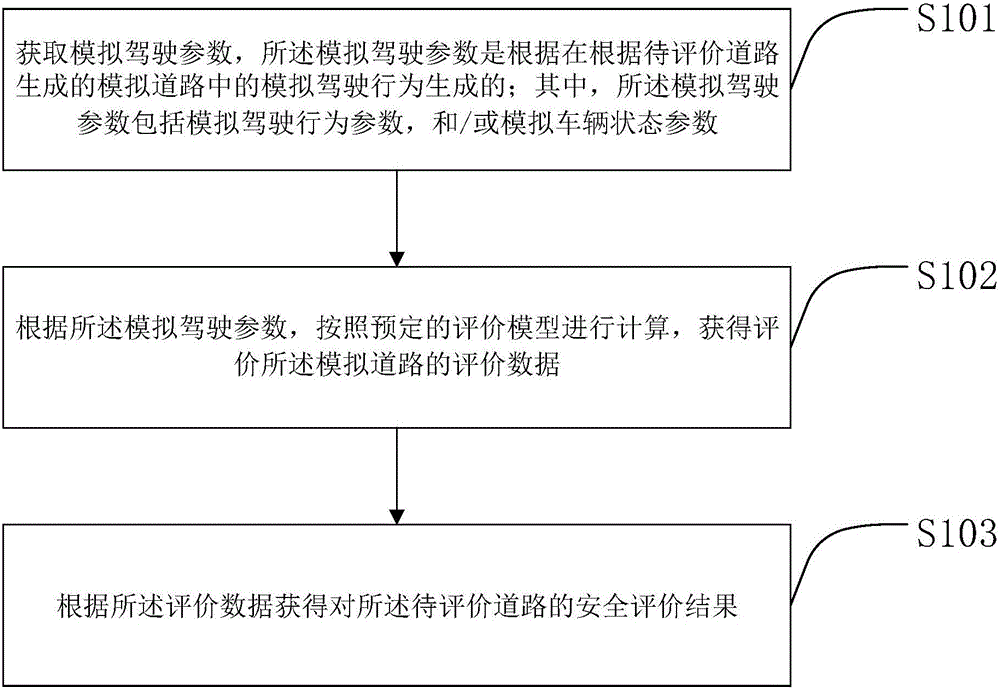

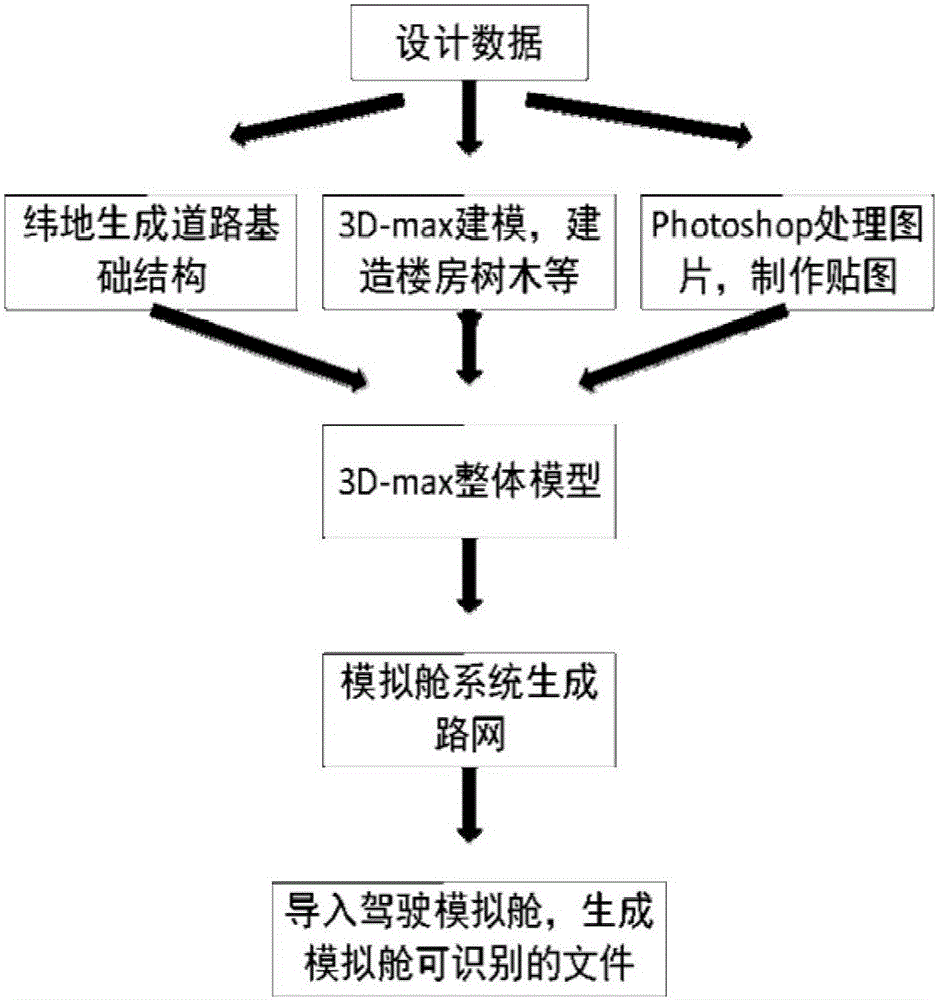

Road safety evaluation method and apparatus

InactiveCN105844384AMeet the needs of pre-evaluationImprove securityResourcesEvaluation resultState parameter

The invention provides a road safety evaluation method, which comprises the steps of first acquiring simulated driving parameters; then based on the simulated driving parameters, calculating according to a predetermined evaluation model to obtain evaluation data for evaluating a simulated road; and finally, obtaining a safety evaluation result of the road to be evaluated based on the evaluation road. Compared with the prior art, the invention obtains the simulated driving parameters based on simulated driving technology, and can present a comprehensive and true reflection of the actual traffic situation of the road. Since the simulated driving parameters include simulated driving behavior parameters and / or simulated vehicle state parameters, the application further takes a full account of the impact of vehicle and / or driver factor on road safety, establishes a systematic road safety evaluation method based on the driving simulation technology, and can meet the demand of pre-evaluation of road safety in a road preliminary design phase.

Owner:BEIJING UNIV OF TECH

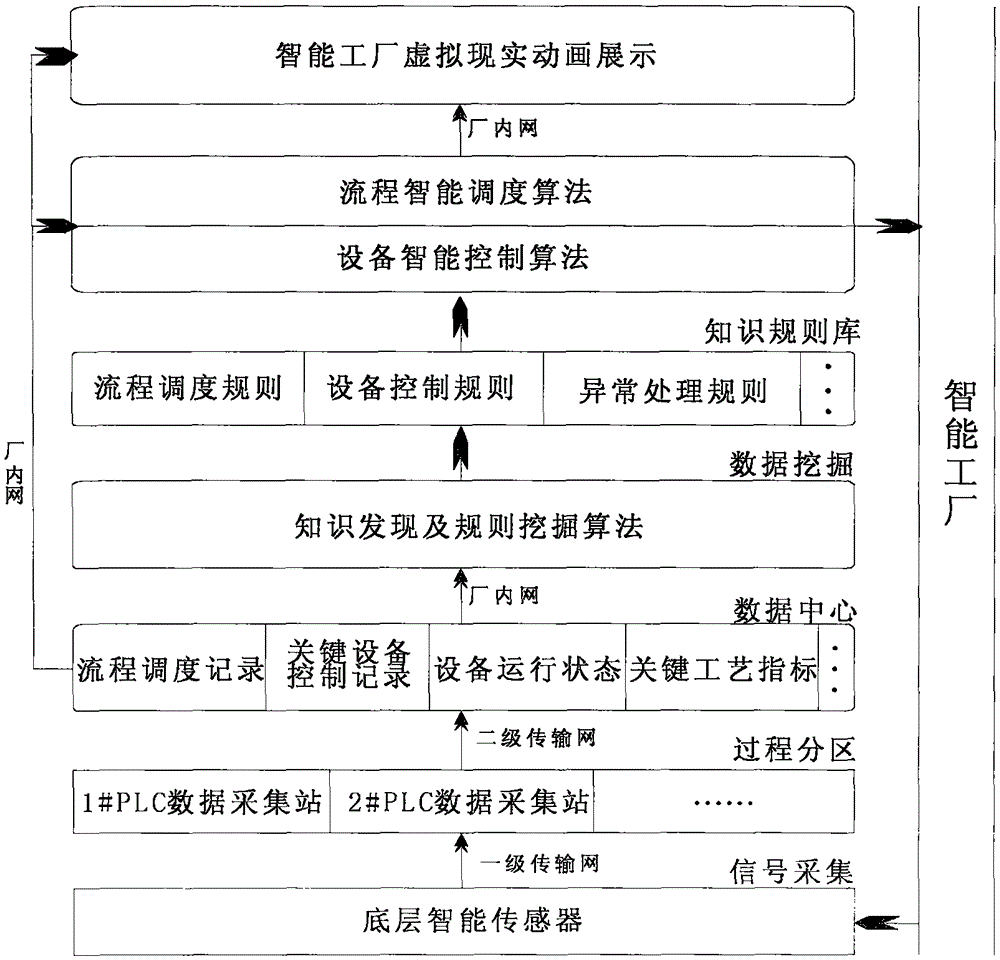

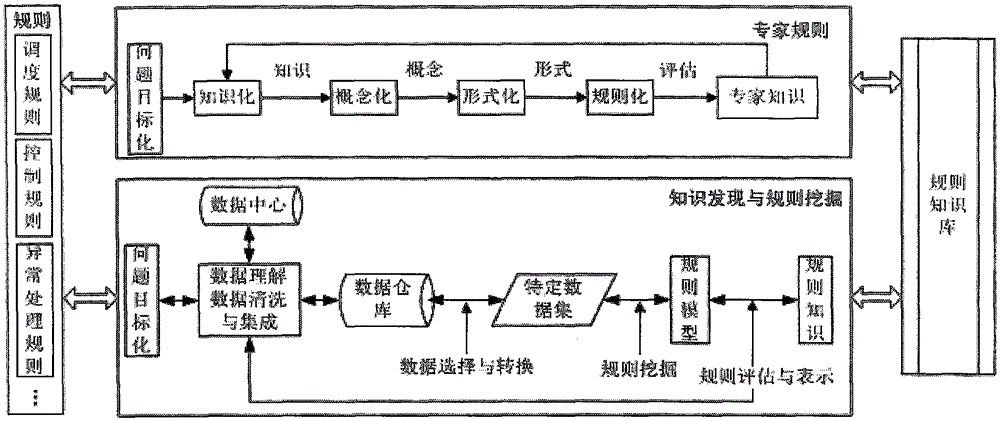

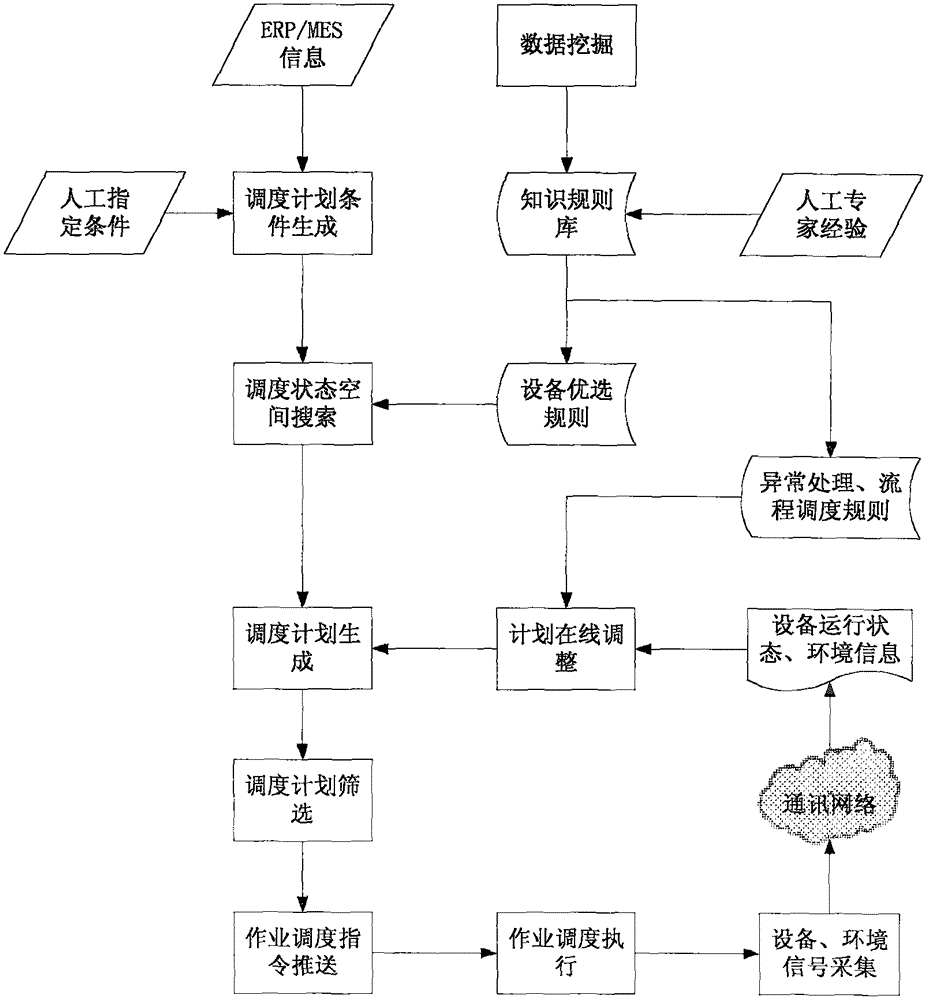

Factory intelligent scheduling method

ActiveCN105302096ARealize human-computer friendly interactive application and experienceReal, timely and reliable transmissionTotal factory controlProgramme total factory controlSmart transducerIntelligent sensor

The invention discloses a factory intelligent scheduling method which mainly comprises the following steps that equipment state information and factory environmental information are acquired via intelligent sensors; the equipment state information and the environmental information are respectively transmitted to corresponding PLC data acquisition stations; each PLC data acquisition station divides data into flow scheduling record data, key equipment control record data, equipment operation state data and key technological index data to be uploaded to a data center through data preprocessing; the data center performs extraction of knowledge rules so as to obtain a knowledge rule base formed by flow scheduling rules, equipment control rules and abnormity processing rules; and the corresponding rules are respectively read via an equipment intelligent control algorithm and a flow intelligent scheduling algorithm so that optimized configuration and scheduling of resources in an intelligent factory can be realized. Upgrading and reconstruction of conventional factory production modes can be realized so that production efficiency can be enhanced, production energy consumption can be reduced, environmental pollution can be reduced and production cost can be saved, and thus green production can be truly realized.

Owner:HUNAN CHAIRMAN IOT INFORMATION TECH CO LTD

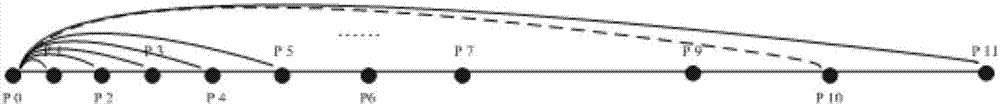

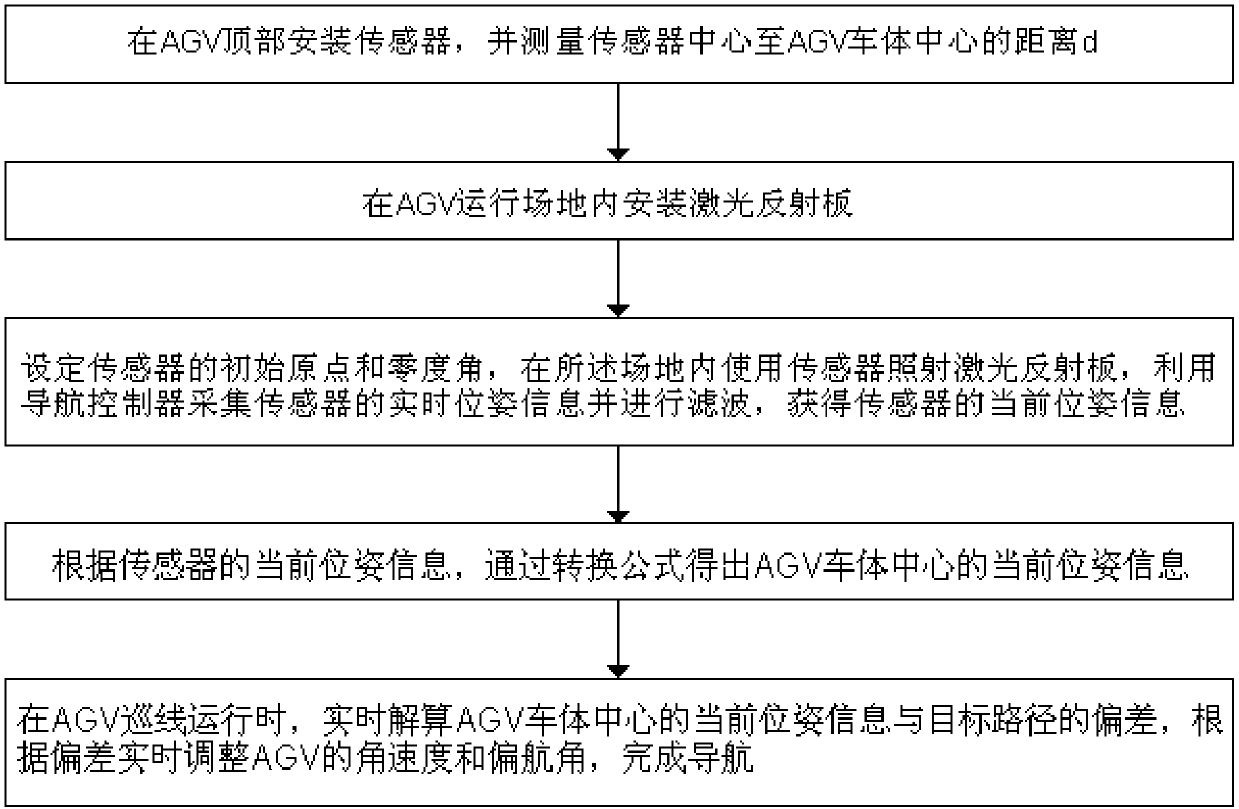

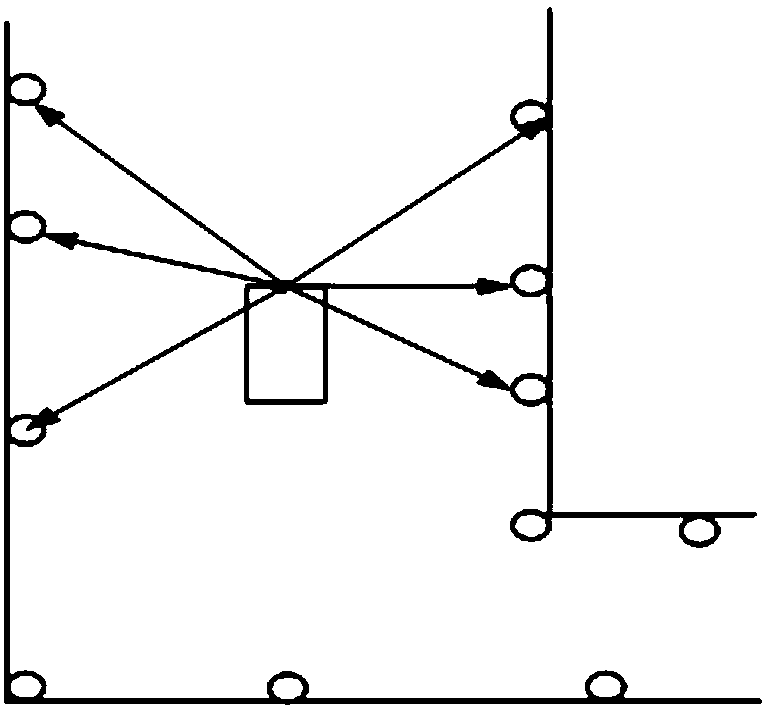

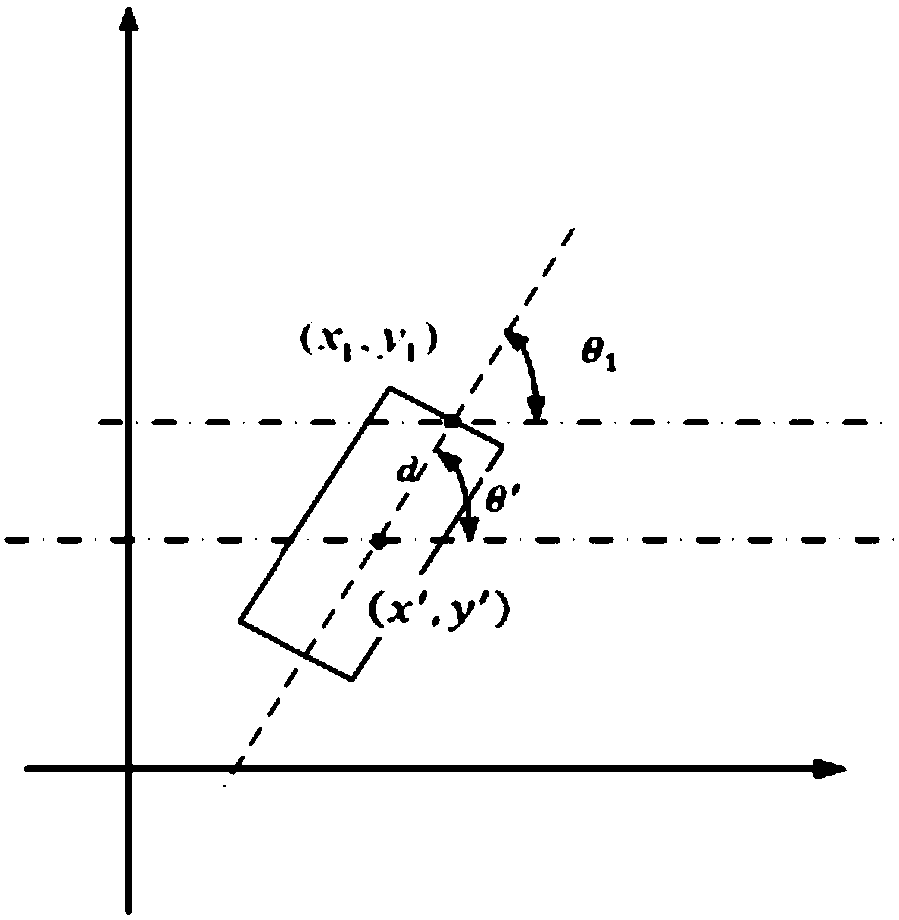

Omnidirectional intelligent mobile equipment positioning and navigation method based on laser ranging

ActiveCN108152827AEnsure accuracy andAchieve accurate positioningElectromagnetic wave reradiationLaser rangingAngular velocity

The invention discloses an omnidirectional intelligent mobile equipment positioning and navigation method based on laser ranging, which comprises the following steps: installing a sensor on an AGV, and measuring the distance from the center of the sensor to the center of the AGV; installing a laser reflector in the AGV operating site; setting the initial origin and zero angle of the sensor, usinga navigation controller to collect the real-time pose information of the sensor and filter it to obtain the current pose information of the sensor; obtaining the current pose information of the body center of the AGV through a conversion formula; and when the AGV performs patrol running, timely solving the deviation of the current pose information of the body center of the AGV from the target path, and timely adjusting the angular velocity and the yaw angle of the AGV according to the deviation to complete the navigation. The method arranges the sensor and the laser reflector, solves the deviation of the AGV pose and the target path in real time, and adjusts the AGV according to the deviation in real time, thereby realizing the flexible setting of the AGV running route and accurate navigation, and making up defects of the traditional laser navigation AGV positioning method that the path is single and the reliability is poor.

Owner:BEIJING SATELLITE MFG FACTORY

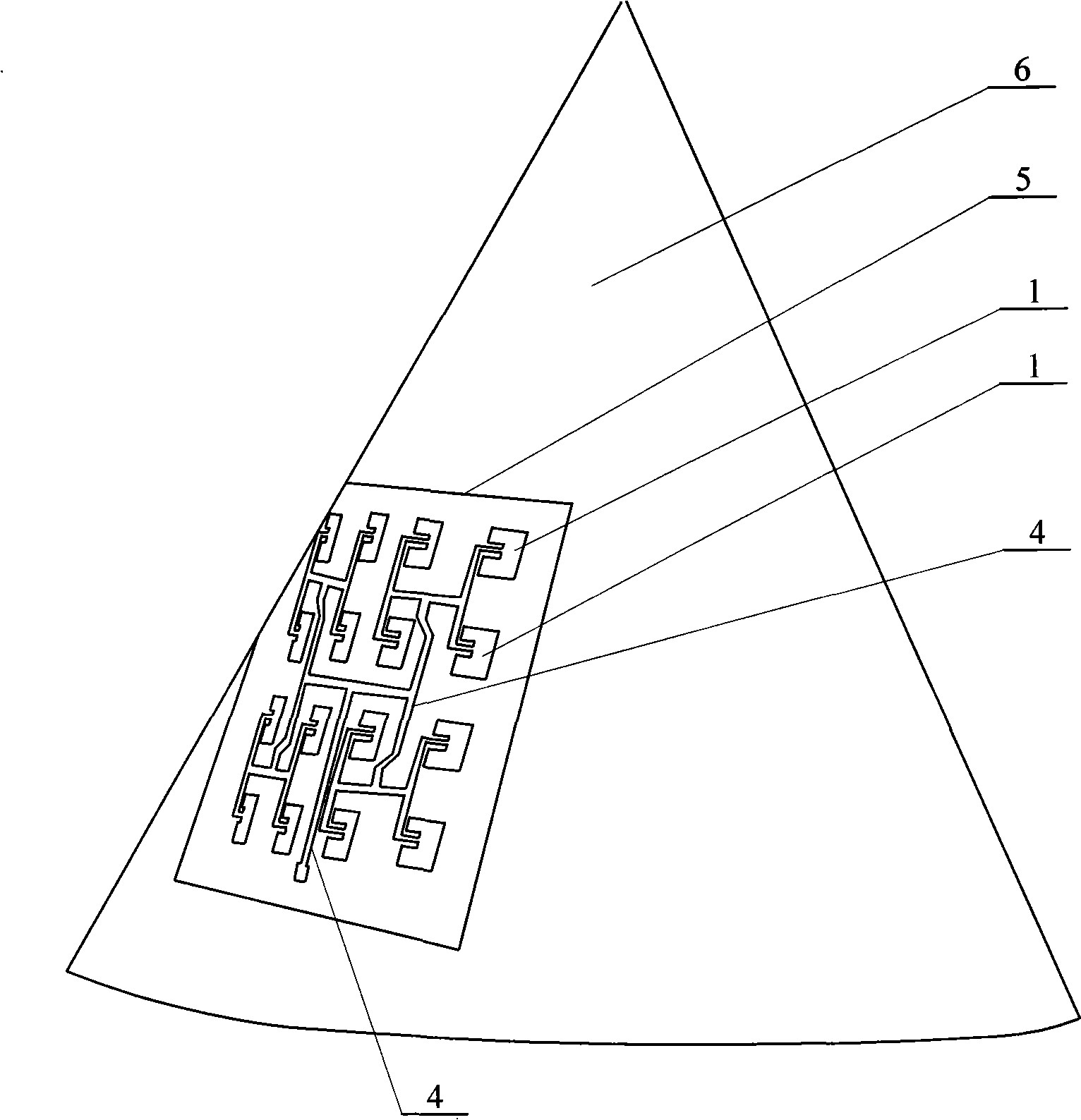

A mm wave section 4x4 cone common-shape dual-frequency micro-belt antenna and its design method

InactiveCN101267063ASimple modelSimple processing technologyAntenna arraysAntenna feed intermediatesEngineeringBand width

The present invention provides a millimeter wave band 4*4 conical conformal dual-frequency microstrip antenna and its design method, relating to a microstrip antenna and its design method. The aim of the invention is resolving the problem of the difficult design of the present conical conformal dual-frequency microstrip antenna. The whole of the antenna four-group patch units shows rectangle provided on the surface of the dielectric layer to form an array, one end of each feeder is connected with one patch unit one by one. The method of the invention includes: deducting different thickness cone layer by the object function, extending the floor layer, the dielectric layer and the patch layer of the planar antenna to the cone layer, catching the intersection by the intersection function and conforming the planar array on the cone surface. The two resonant frequencies of the antenna are all in millimeter wave band, 30.6 and 35.5GHz respectively, the bandwidth of the conformal array on the two resonance points are 315MHz and 485MHz respectively. The invention has a simple structure, clearly arrangement, strict logic, relatively ideal simulation results, simply processing technology.

Owner:HARBIN INST OF TECH

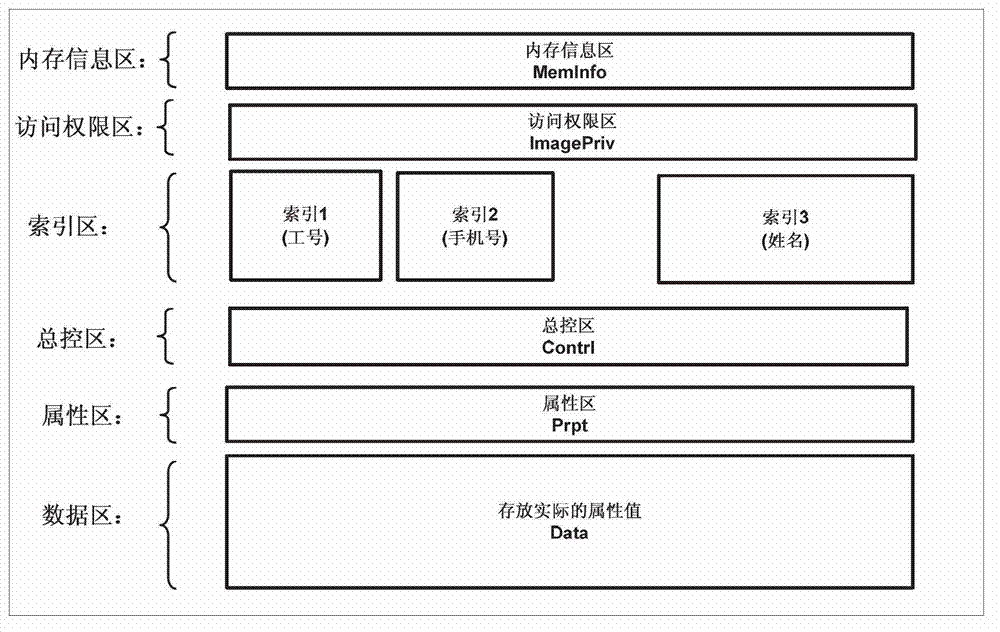

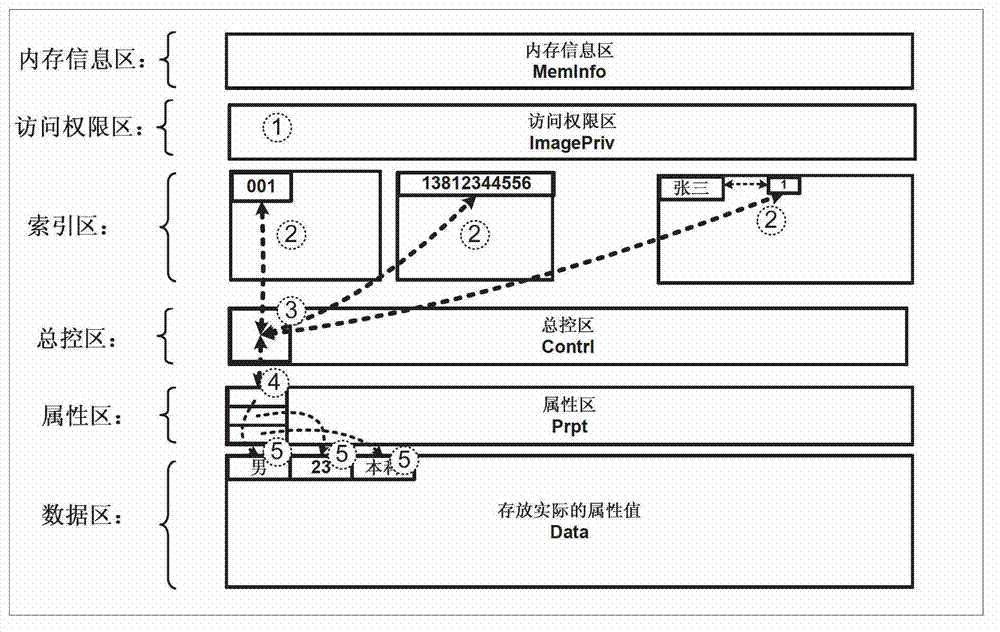

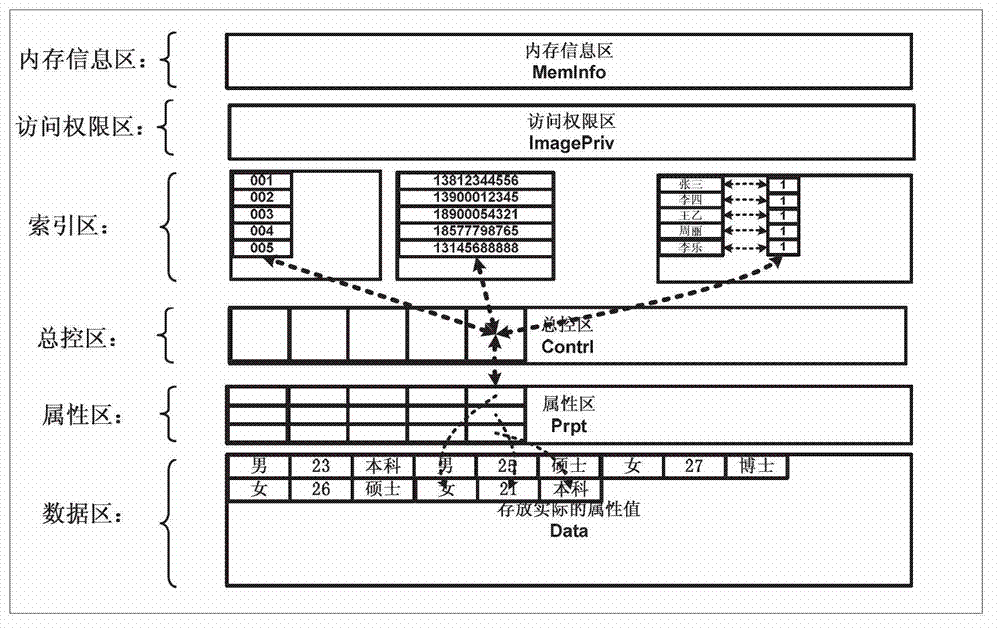

Novel concurrent memory data organization and access method

InactiveCN102880704AEnsure data consistencyFlexible designSpecial data processing applicationsWrite once read manyOrganizational form

The invention relates to the field of data processing technology, in particular to a novel concurrent memory data organization and access method. The method is characterized in that the memory data organizational form provides two types of data access methods: Key-Value accurate index method and Key-ValueList clustered index method; any attribute of each entity can be accessed according to requirements; a multidimensional index is simultaneously supported and a single entity can be retrieved through different indexes; the entire memory data can be managed in a manner of block organization; management information of different levels and different types is stored respectively in each memory block; and data access is controlled in series based on the logic of each memory block. Compared with the prior art, the method has the advantages that the memory data structure is flexibly designed and organized on the premises of data integrity and high concurrent access efficiency, an efficient data retrieval model is provided, the WORM (write-once-read-many) concurrent data access is supported, the integrity of data read and write transaction is effectively ensured, the resource consumption is effectively reduced, and the concurrent access ability is improved.

Owner:SHANGHAI STOCK EXCHANGE

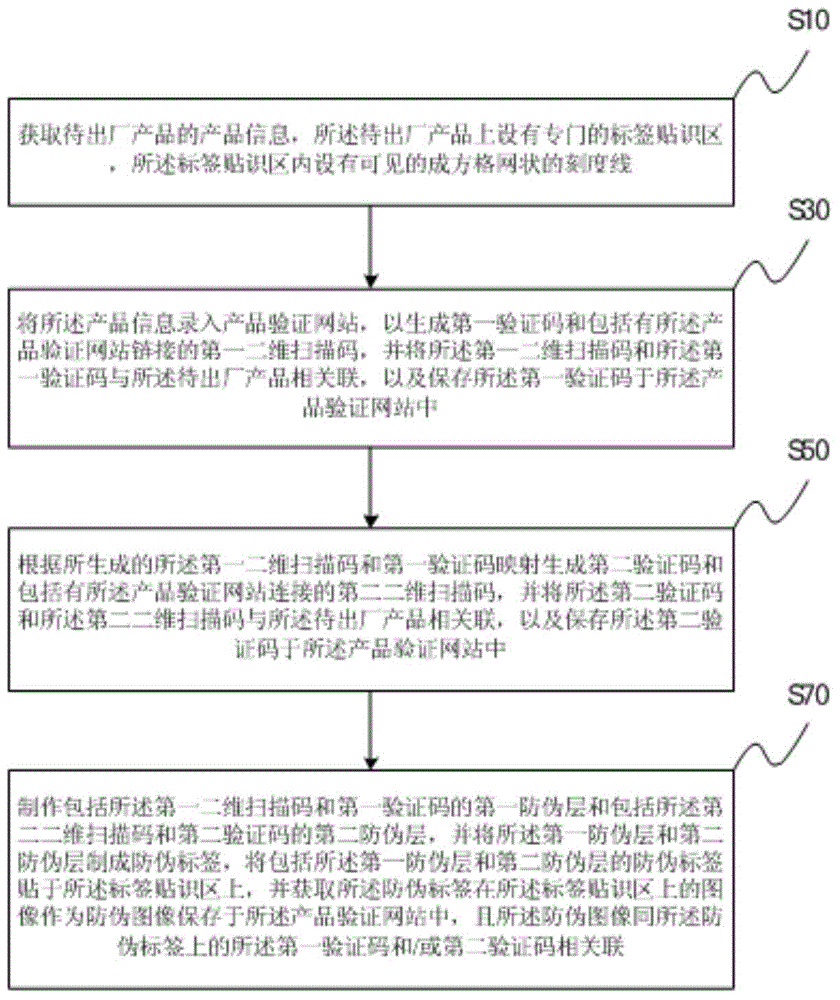

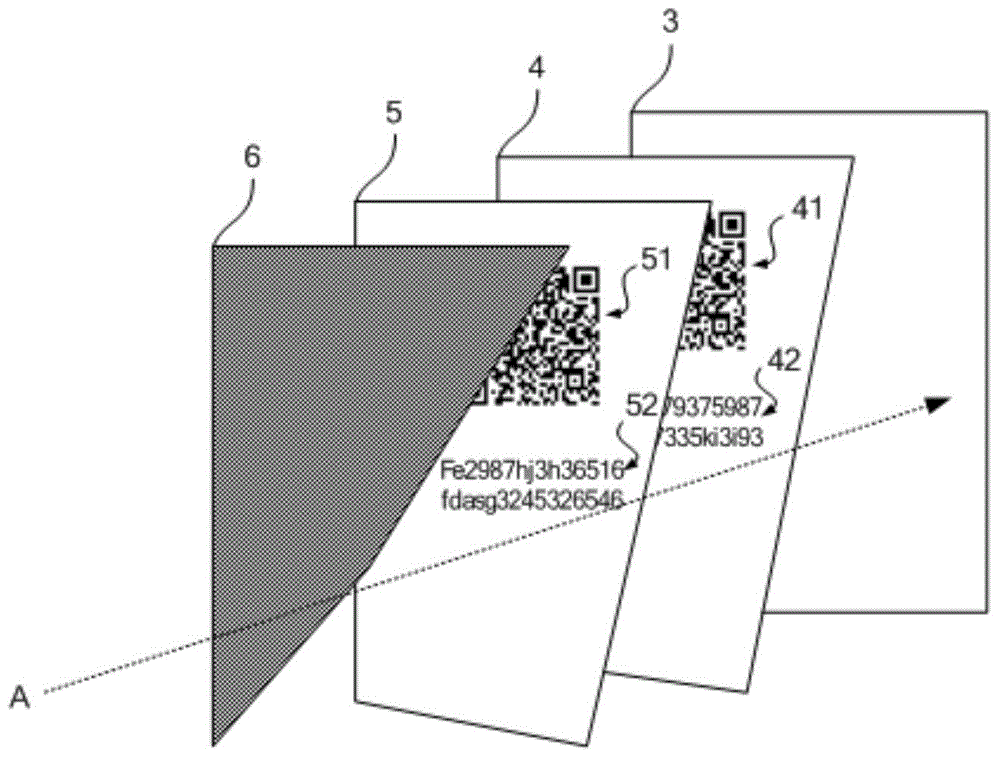

Product anti-counterfeiting method

InactiveCN104933569ARandomUniqueness guaranteedCommerceSensing by electromagnetic radiationComputer science

The invention provides a product anti-counterfeiting method used for the field of product anti-counterfeiting. According to the product anti-counterfeiting method, a two-dimensional code scanning technology and an internet technology are mainly utilized, a label pasting and identifying region is then arranged on a product which is going to leave a factory, and an image of an anti-counterfeiting label pasted in the label pasting and identifying region is obtained and used as an anti-counterfeiting image, so that the anti-counterfeiting safety of labels is enhanced, and the consistency between the anti-counterfeiting label on the product going to leave the factory and the label recorded before leaving the factory is ensured more effectively; in addition, an identifying code is arranged, and the identifying code is associated with production information of the product going to leave the factory and the anti-counterfeiting image, so that consistency and the unilateral control performance of the information associated with the product going to leave the factory are ensured. The invention further provides a product anti-counterfeiting system for realizing the method, so that an effective and safe anti-counterfeiting technology is provided to a product producer.

Owner:上海快捷科技发展有限公司

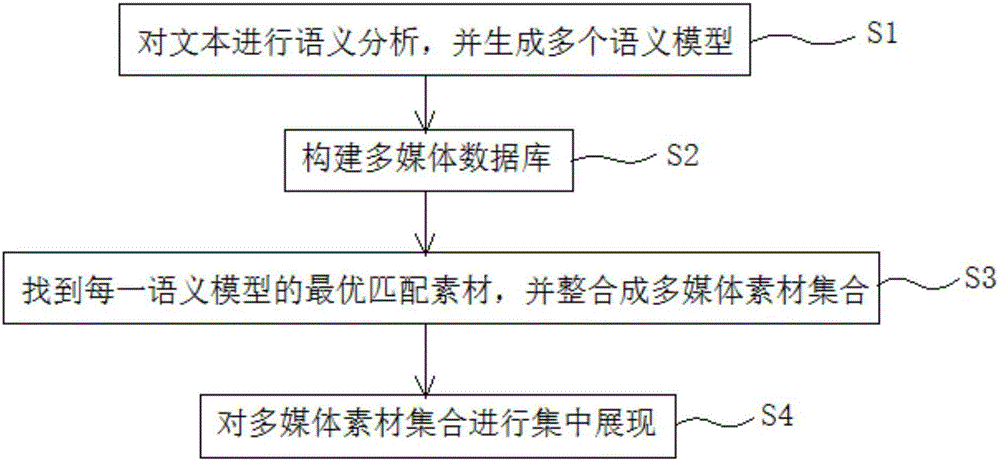

Method for achieving visualized dynamic presentation of text

InactiveCN106294666AVivid special effects experienceIntuitive special effects experienceSemantic analysisMetadata multimedia retrievalNatural language processingOptimal matching

The invention discloses a method for achieving visualized dynamic presentation of text. The method comprises the following steps that 1, semantic analysis is conducted on the specified text to generate multiple semantic models; 2, a multimedia database is constructed; 3, optimal matching materials of all the semantic models are found by retrieving the multimedia database, and the optimal matching materials corresponding to all the semantic models are integrated into a multimedia material set corresponding to the specified text; 4, concentrated presentation is conducted on the multimedia material set. According to the method, the baldness of text description is effectively improved, the text is presented in a richer form, and the reasonable logic and a wide application prospect are achieved.

Owner:上海汽笛生网络科技有限公司

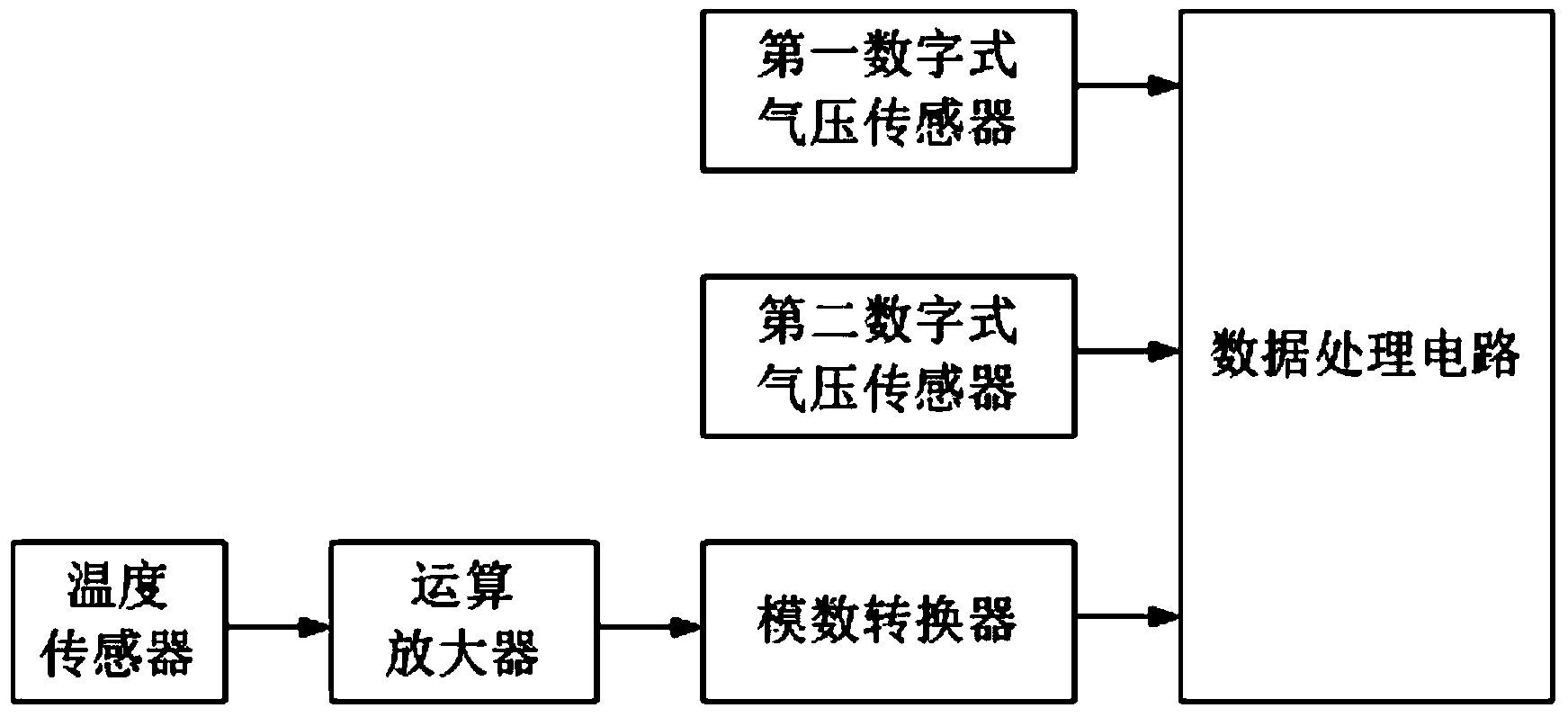

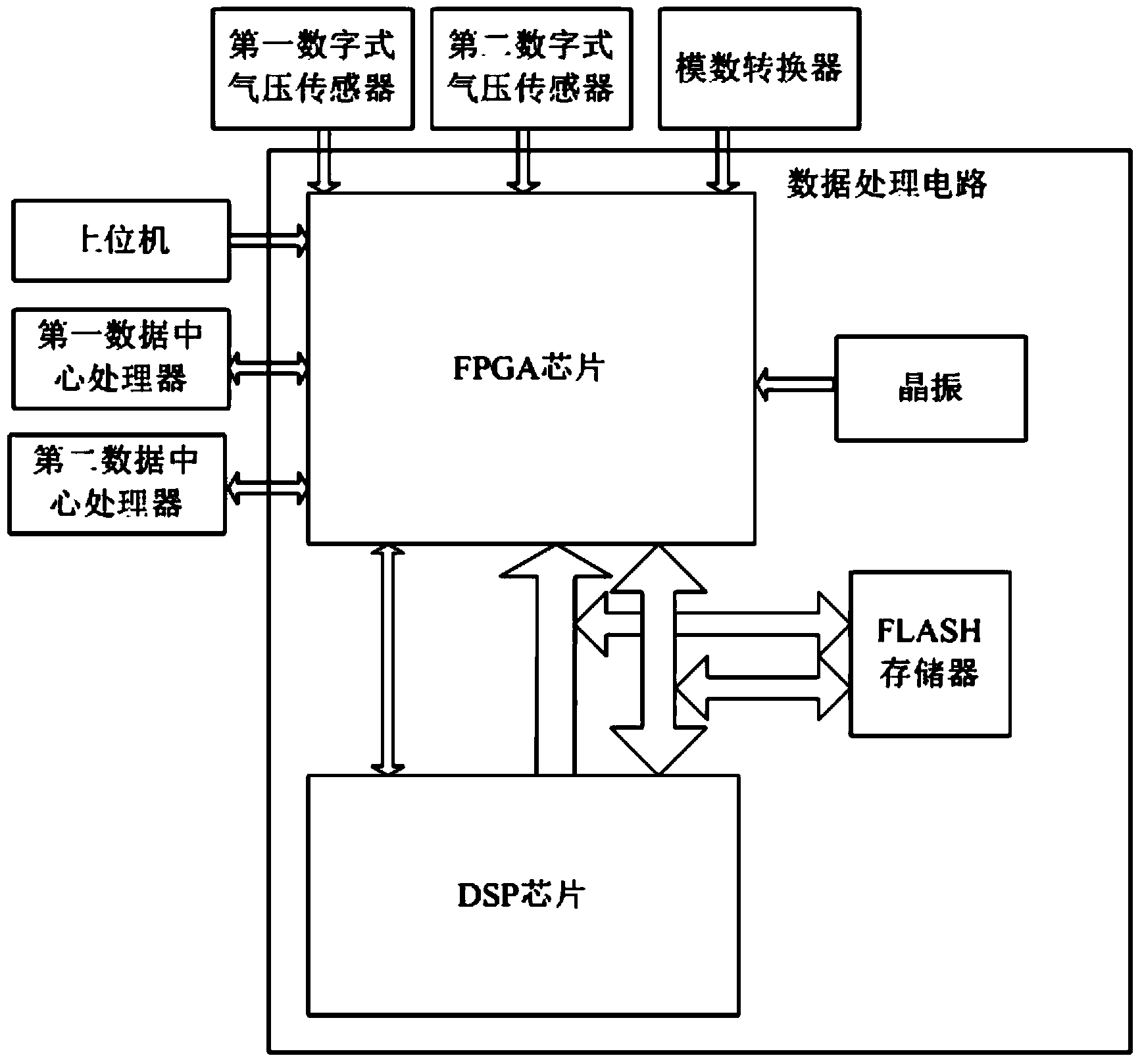

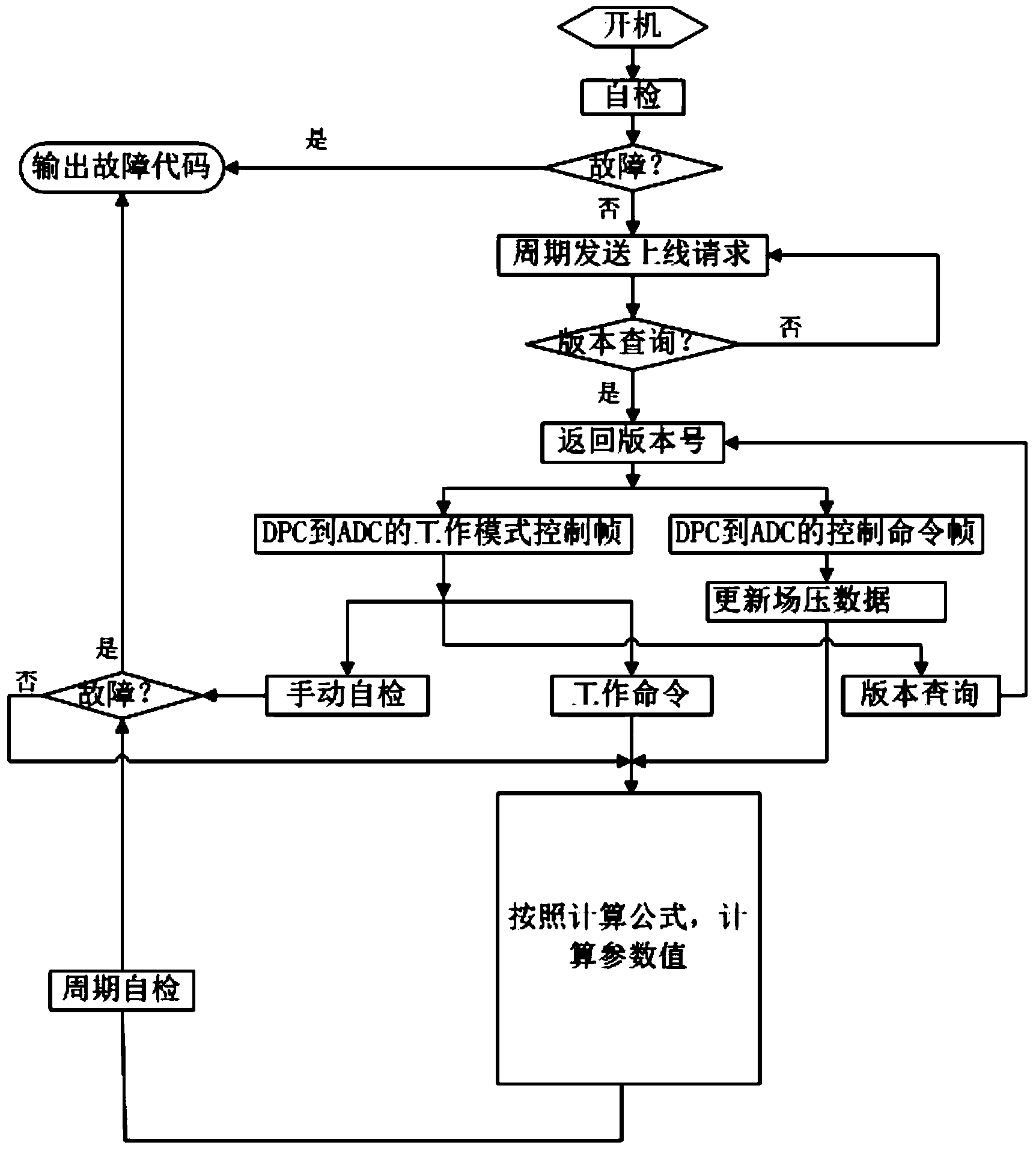

Digital atmosphere data computer and implementation method thereof

InactiveCN104238417AImprove portabilityLogicalProgramme controlMeasurement devicesDigital down converterSignal processing circuits

The invention belongs to the technical field of aviation atmosphere data detection and discloses a digital atmosphere data computer and an implementation method thereof. The digital atmosphere data computer comprises a pitot tube and a temperature sensor, and a total pressure tube and a static pressure tube are arranged on the pitot tube. A first digital barometric sensor is arranged at an outlet of the total pressure tube, and a second digital barometric sensor is arranged at an outlet of the static pressure tube. The digital atmosphere data computer further comprises an operation amplifier, an analog-digital converter and a signal processing circuit, the input end of the operation amplifier is electrically connected with the signal output end of the temperature sensor, and the output end of the operation amplifier is electrically connected with the input end of the analog-digital converter. The signal processing circuit comprises an FPGA chip and a DSP chip, the input end of the FPGA chip is electrically connected with the first digital barometric sensor, the second digital barometric sensor and the analog-digital converter, and the FPGA chip is electrically connected with the DSP chip.

Owner:XIDIAN UNIV

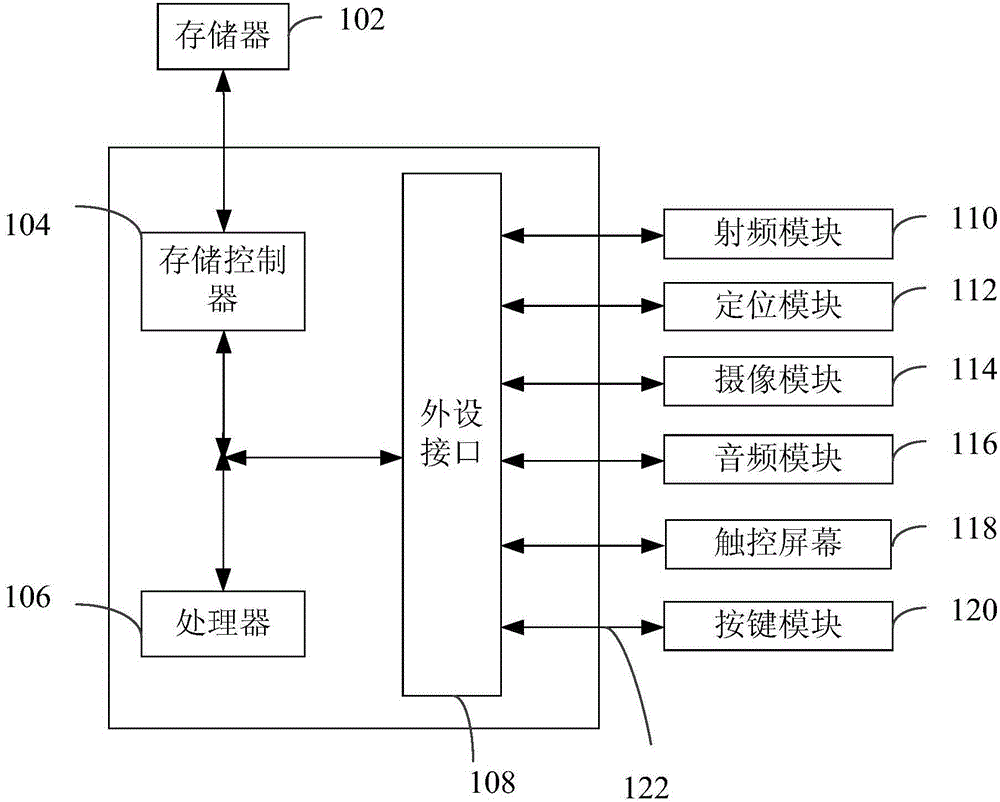

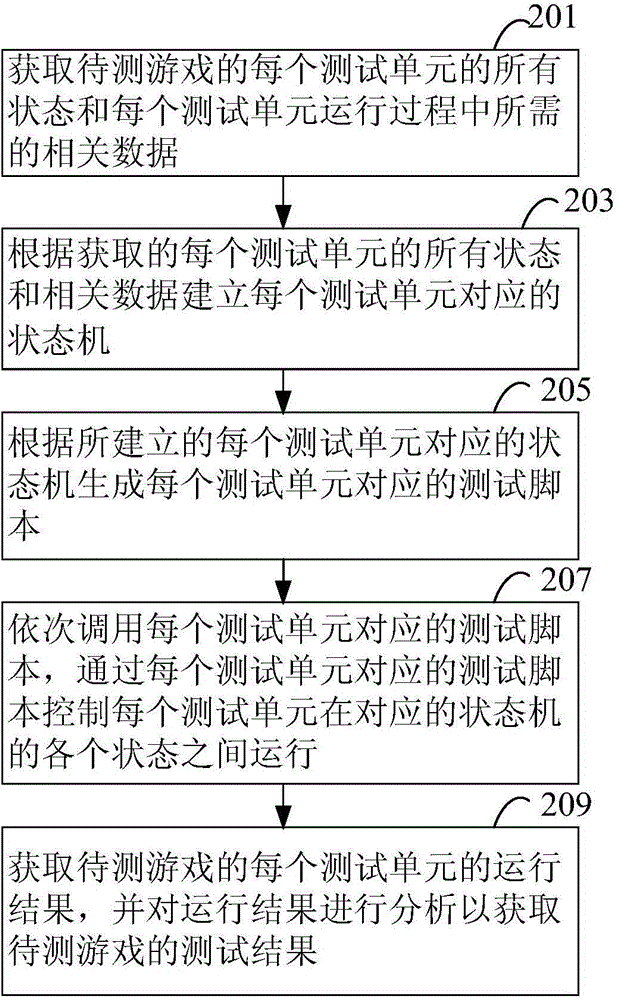

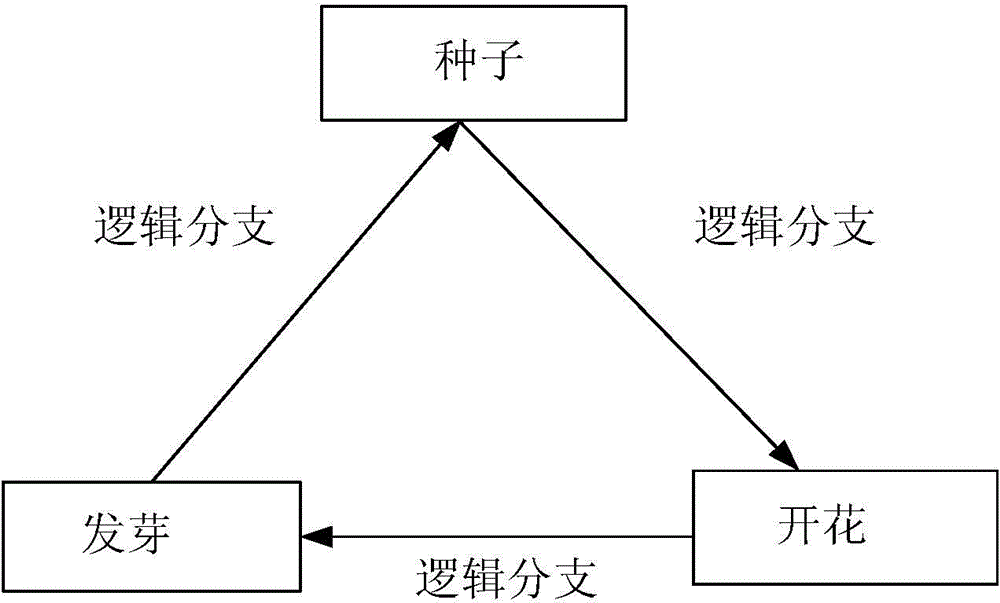

Method and device for game test

Embodiments of the invention disclose a method and a device for game tests. The method comprises: acquiring all states of each test unit of a to-be-tested game and related data required in an operating process of each test unit; according to the required all states of each test unit and the related data, establishing state machines respectively corresponding to each test unit; according to the established state machines corresponding to each test unit, generating testing scripts respectively corresponding to each test unit, and implanting the testing script corresponding to each test unit to game development environment; calling the testing script corresponding to each test unit in sequence, controlling each test unit to operate among states of the corresponding state machine; and acquiring an operation result of each test unit of the to-be-tested game, analyzing the operation result to obtain a test result of the to-be-tested game. The method and the device can be used to test games rapidly and effectively.

Owner:TENCENT TECH (SHENZHEN) CO LTD

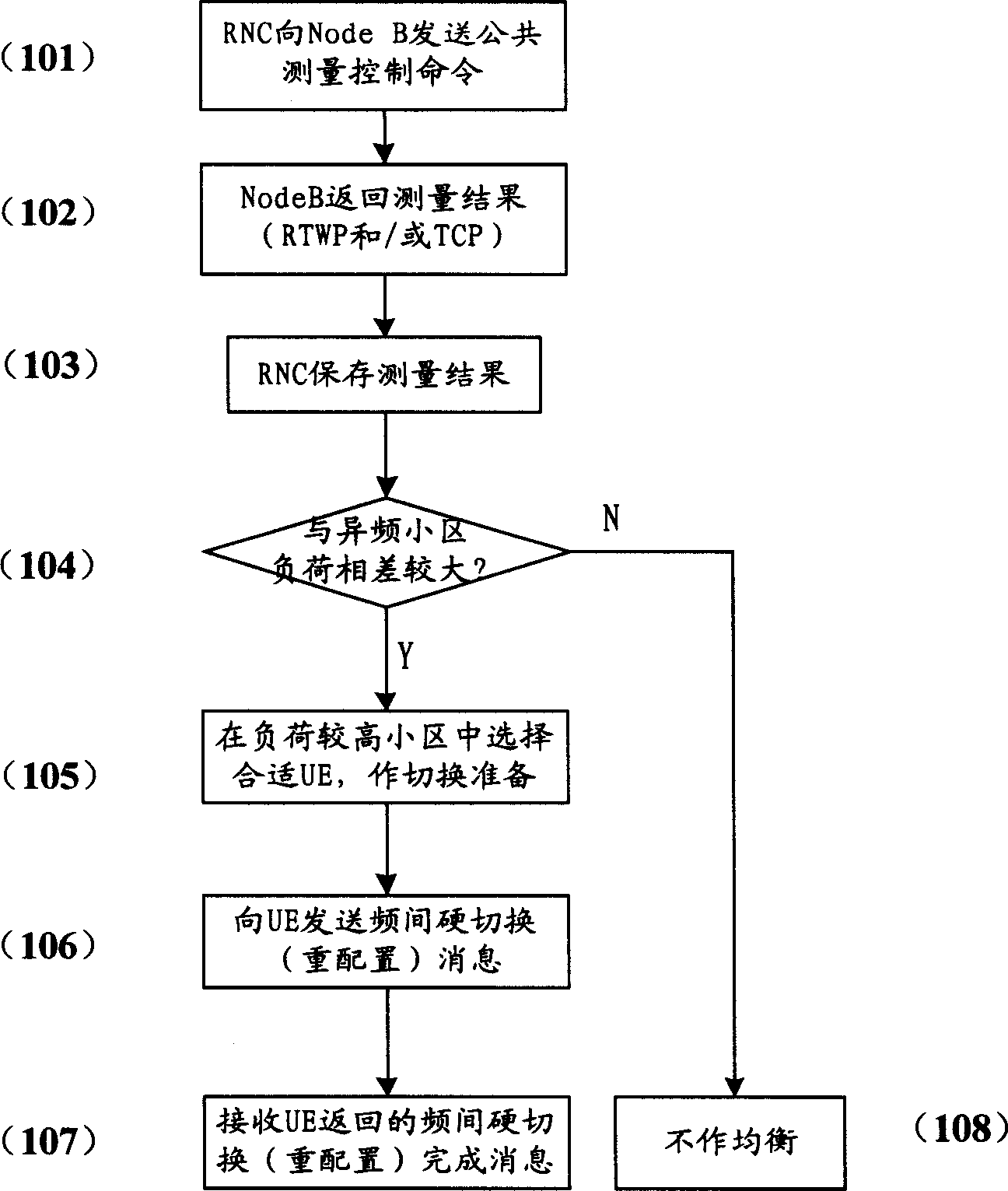

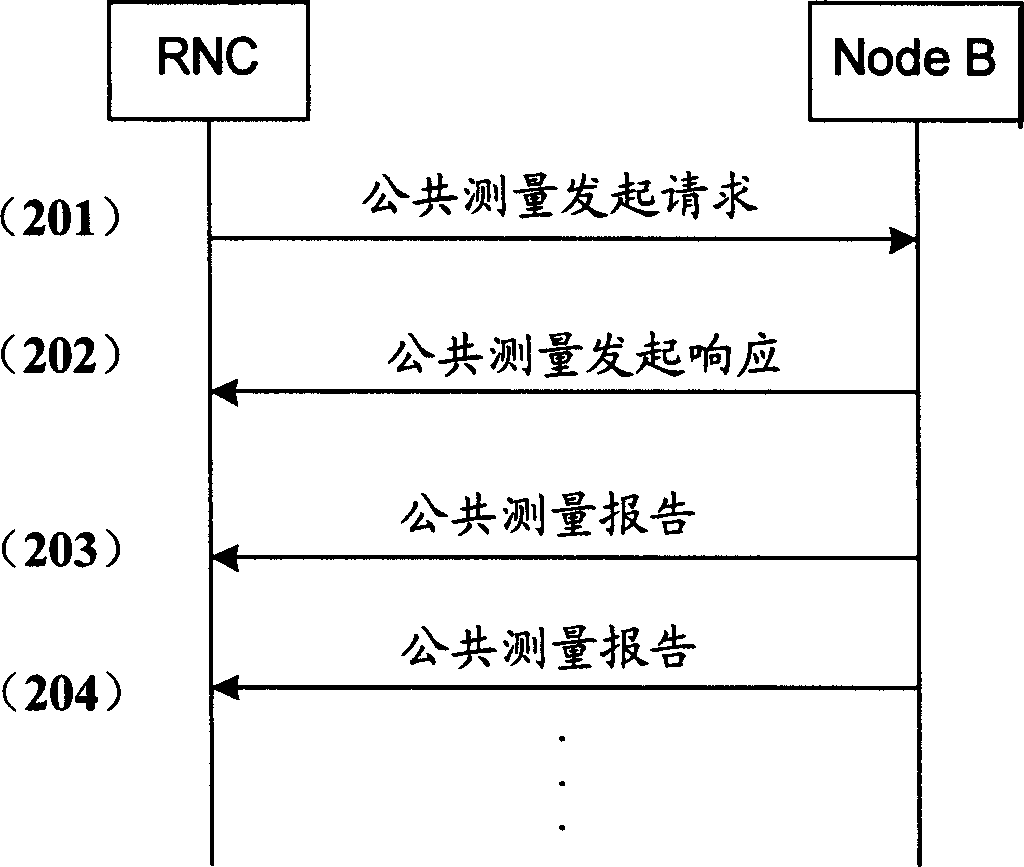

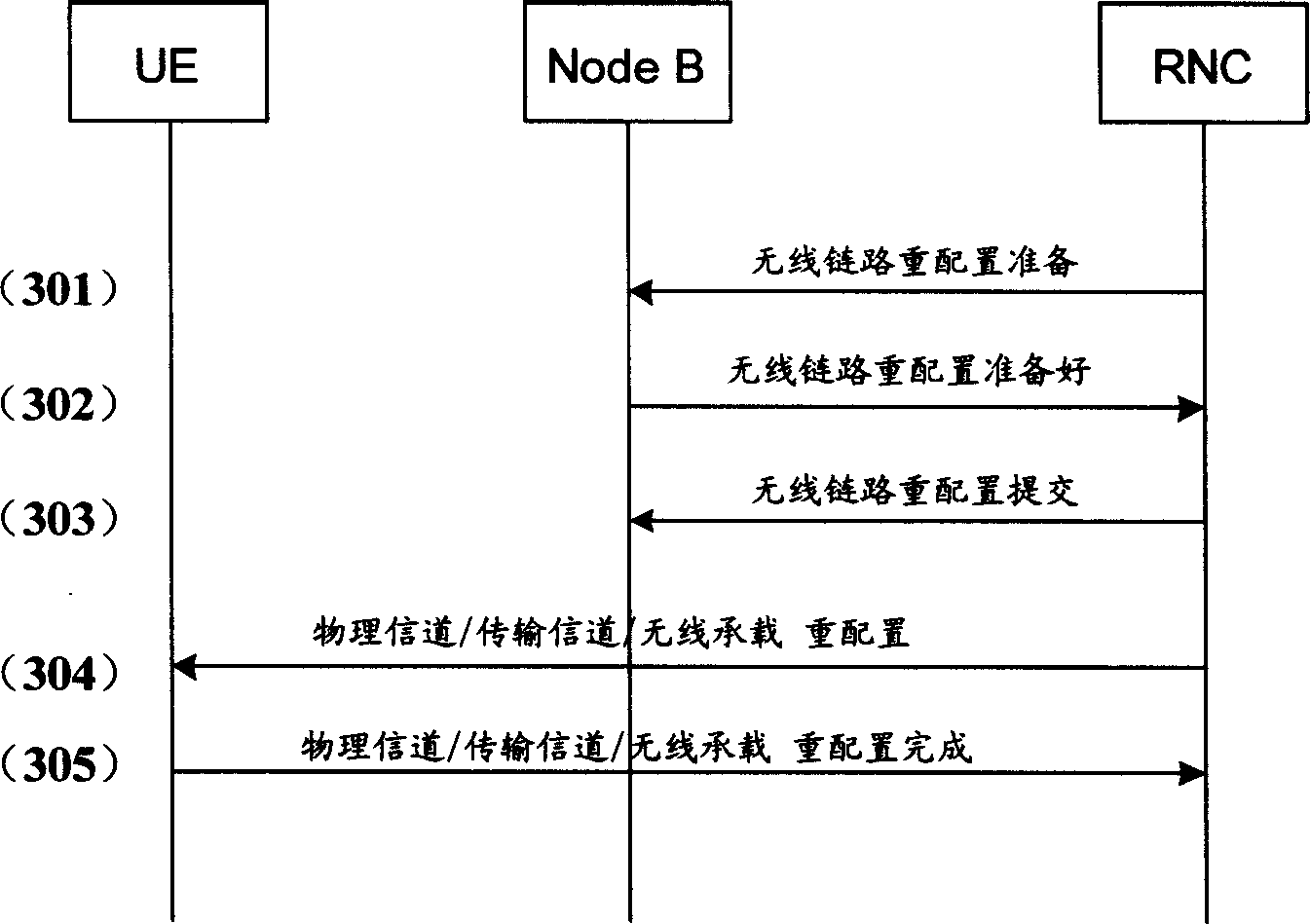

A method for controlling inter-frequency load balancing in WCDMA system

InactiveCN1571292AEasy to acceptEasy accessTransmission control/equalisingCode division multiplexComputer networkSystem capacity

The invention discloses a frequency-frequency load balance controlling method in wideband code division multiple access (CDMA) system, including the following processing steps: RNC obtains information reflecting village load status at regular intervals; RNC determines if it is necessary to execute balancing action according to preset load threshold parameters, actually-measured village load and same-covered different frequency village load: if yes, select partial UEs from the different-frequency village and send frequency-frequency hard switching command to these UEs; the UEs executing switching return finish information in the different frequency village. The invention can perfectly assure WCDMA system selects partial UEs to switch to lower- load same-covered different frequency village so as to receive service as soon as possible in the operating course, thus better realizing laod balance and maximumizing the whole system capacity and can also be convenient for the connection of follow-up UE.

Owner:ZTE CORP

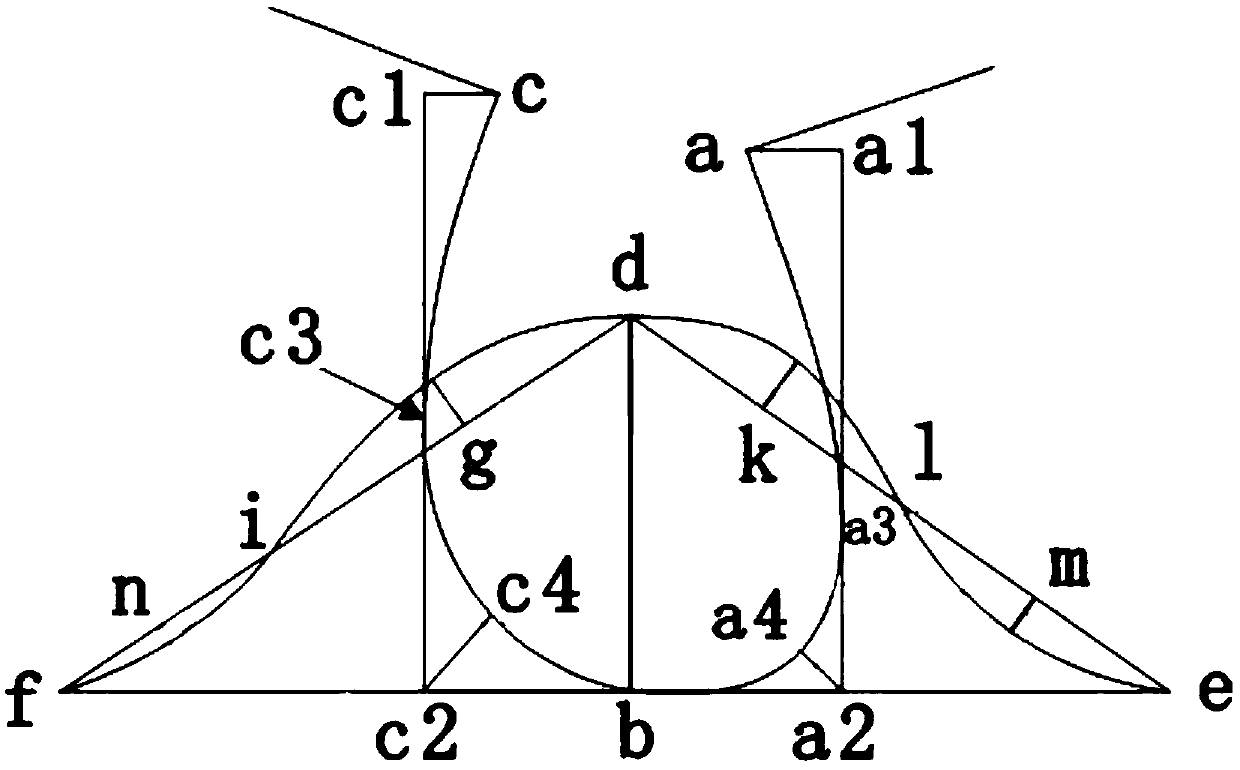

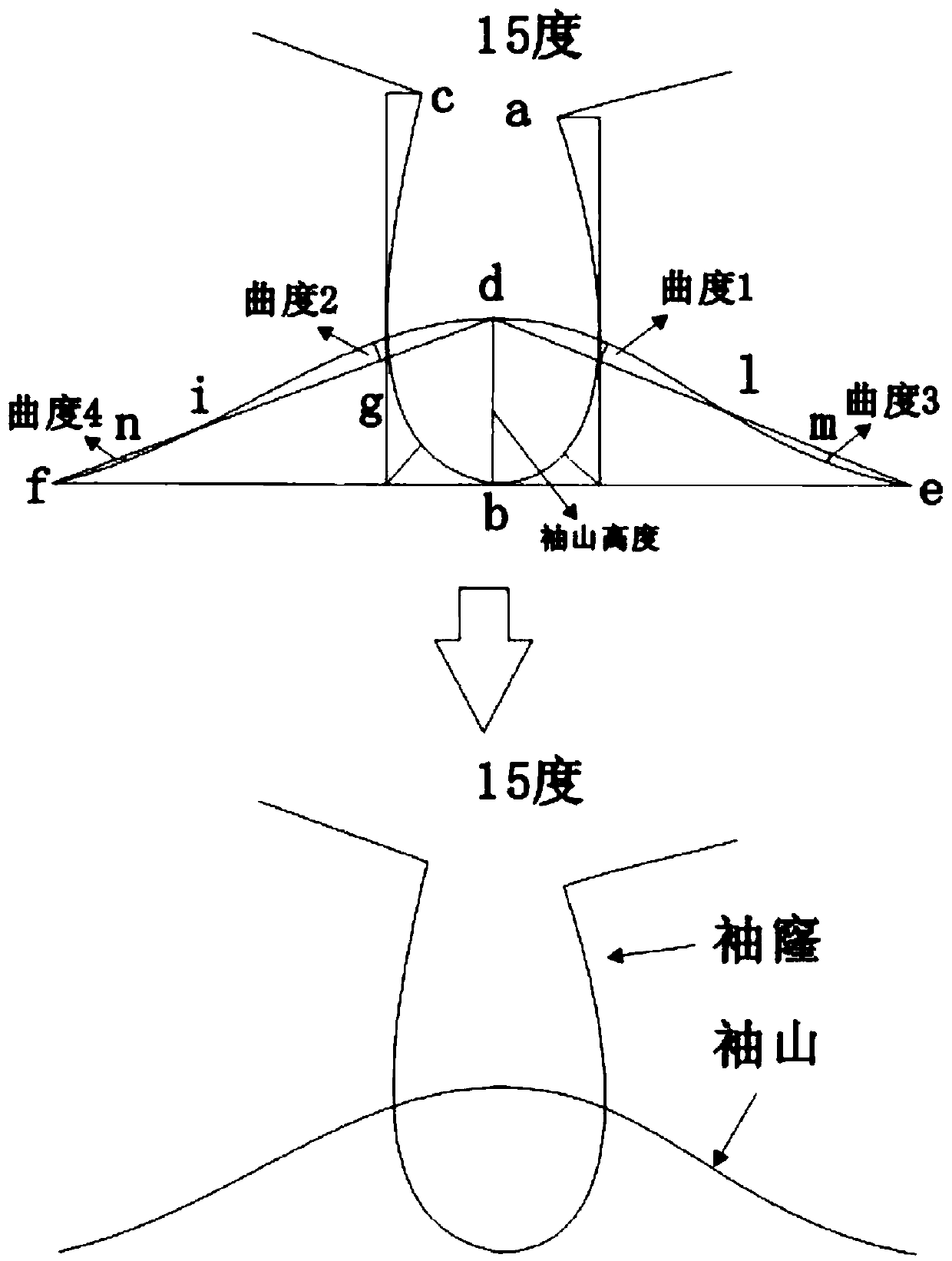

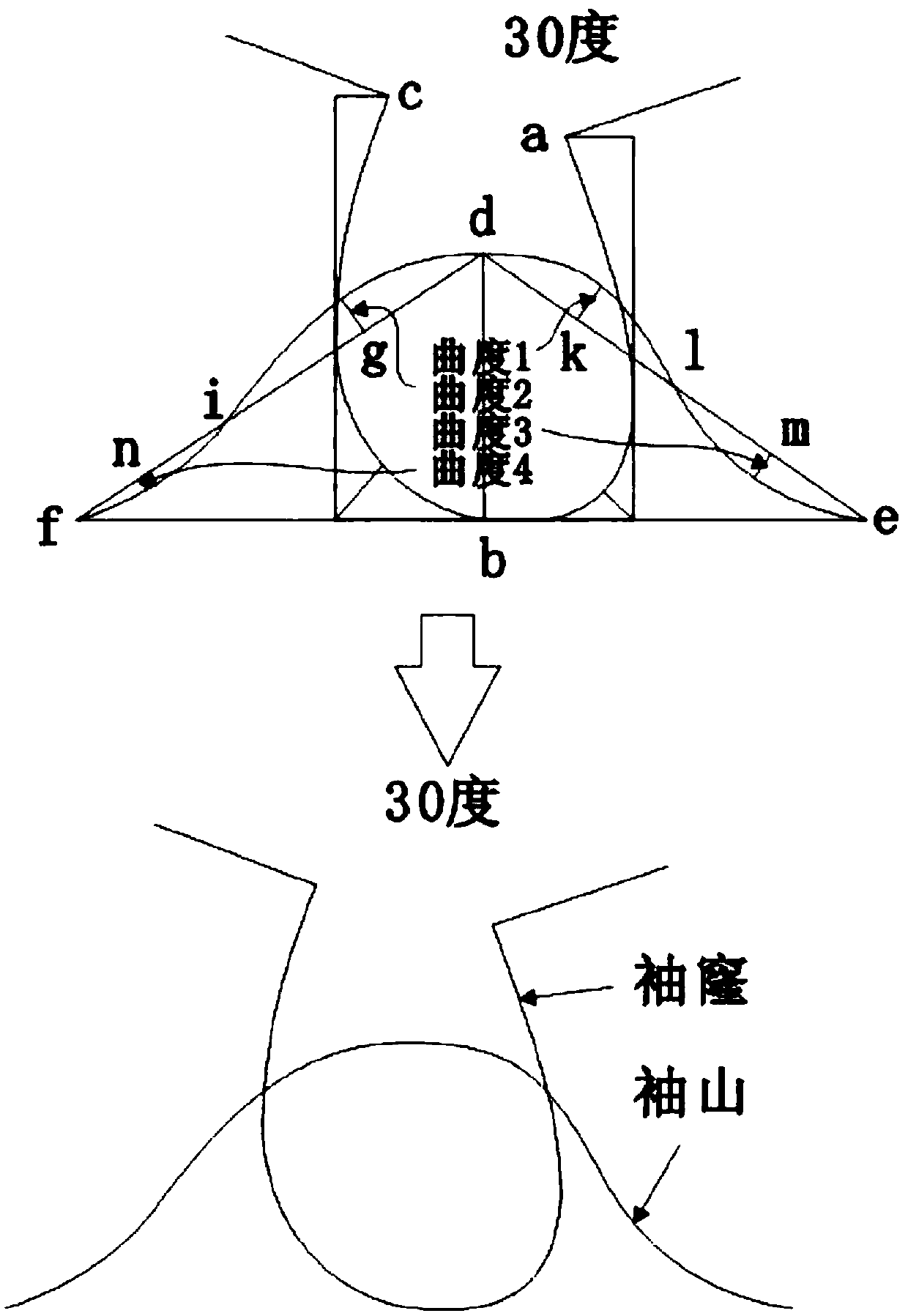

Method for drawing clothing armhole and sleeves

ActiveCN109527684ASolving the exact match problemSolve the influence curvatureClothes making applicancesBody angleAxilla

The invention discloses a method for drawing clothes armholes and sleeves, which comprises an armhole part drawing method and a sleeve part drawing method. The armhole part drawing method comprises the following steps of: (S100) drawing the width of the bottom of the armhole according to a chest circumference line on a garment piece; (S200) generating armhole base line segments c2c1 and a2a1 as arear armhole depth and a front armhole depth respectively; (S300) making vertical line segments a1a and c1c on a2a1 and c2c1, and selecting shoulder part volume according to different clothes; (S400)setting tangent points a3 and c3 on a2a1 and c2c1, and determining the end points a4 and c4 of the anterior armpit volume and the posterior armpit volume; and (S500) sequentially connecting the pointsa, a3, a4, b, c4, c3 and c to form a complete arc line according to the determined points, thereby forming an integral armhole shape. The method effectively unifies elements such as external body angle, sleeve mountain depth, sleeve width, sleeve mountain curvature, sleeve mountain inclined line, armhole structure and shape, bust size, change of big and small sleeves and the like, and improves drawing efficiency and style requirements.

Owner:惠州市木子辰科技有限公司

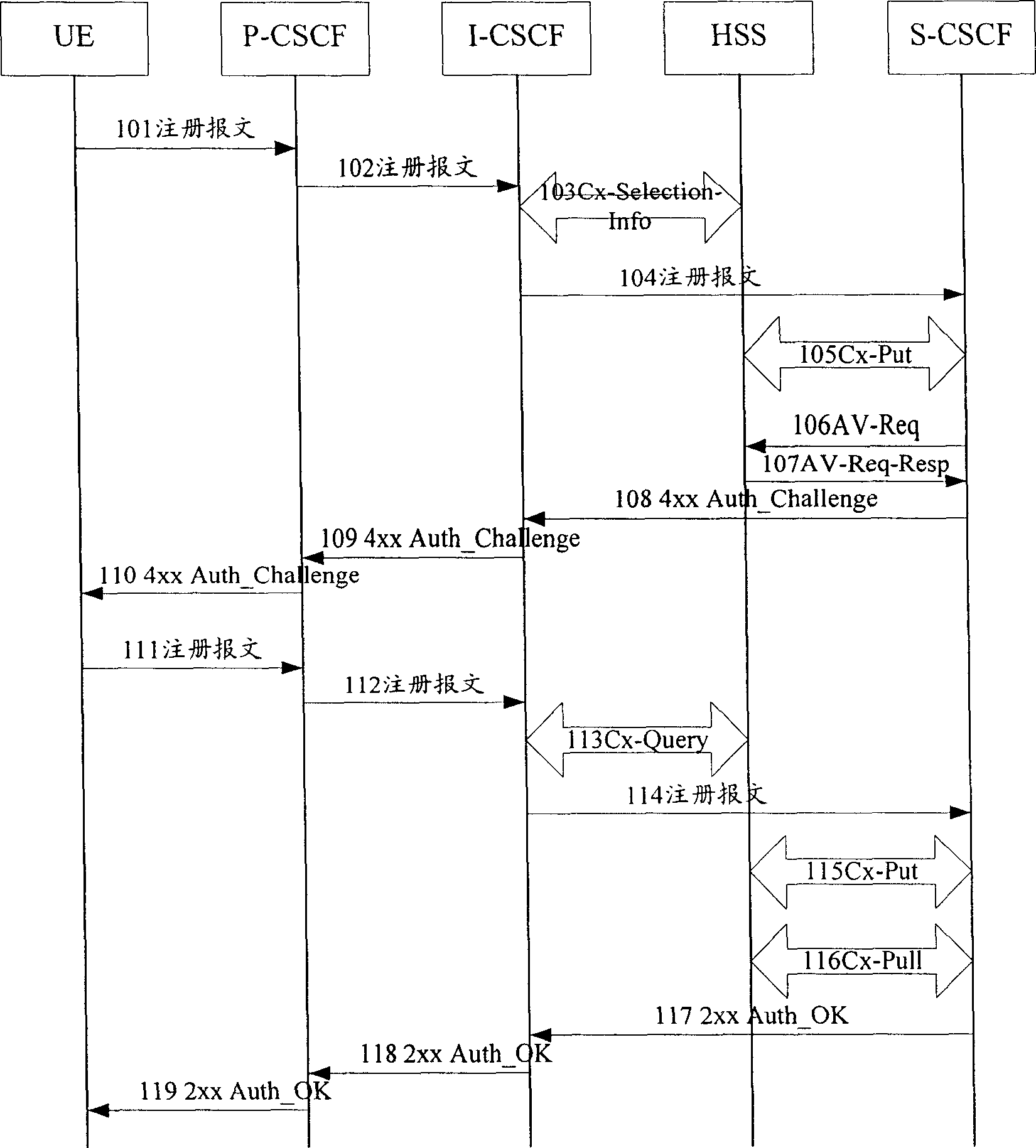

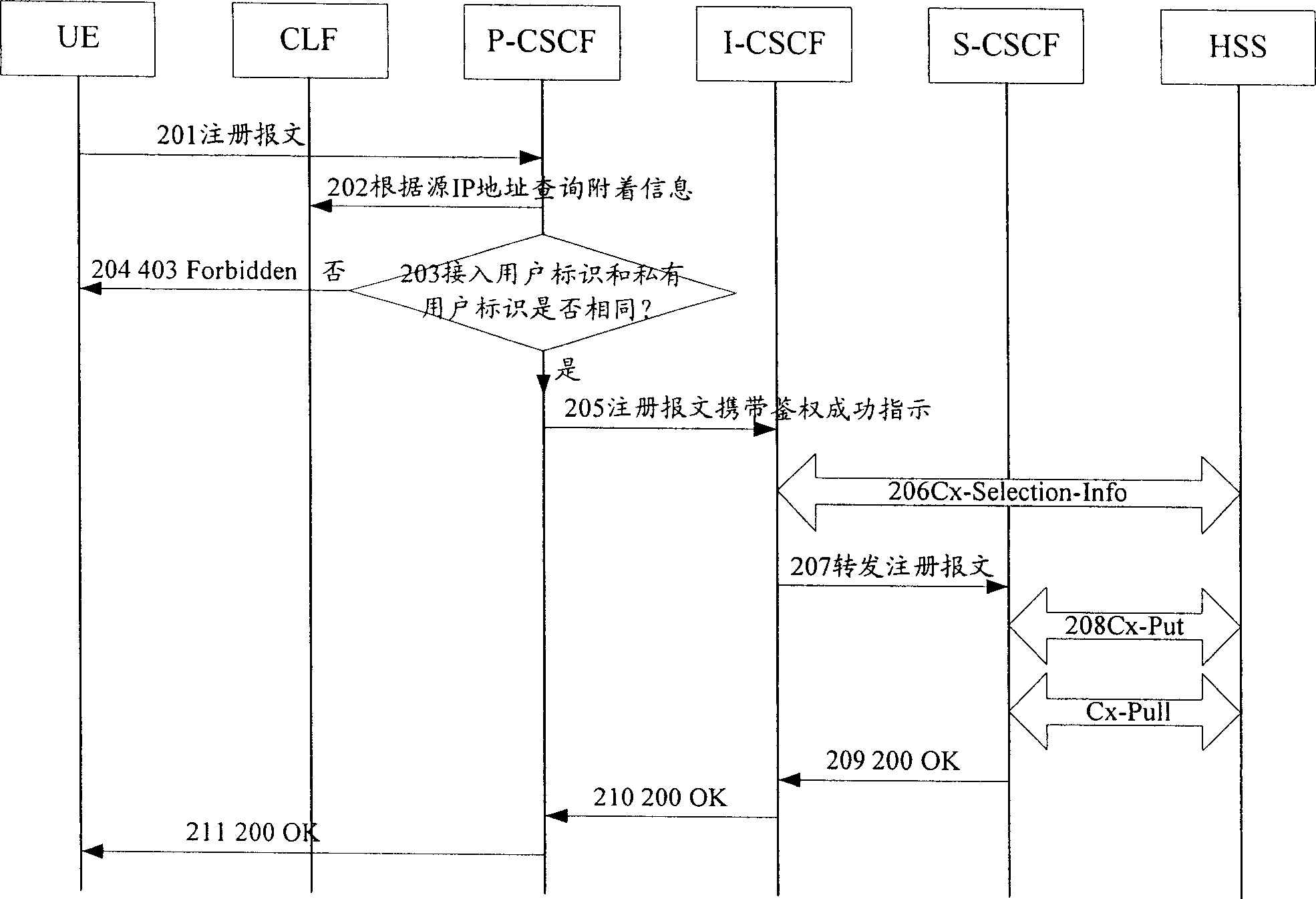

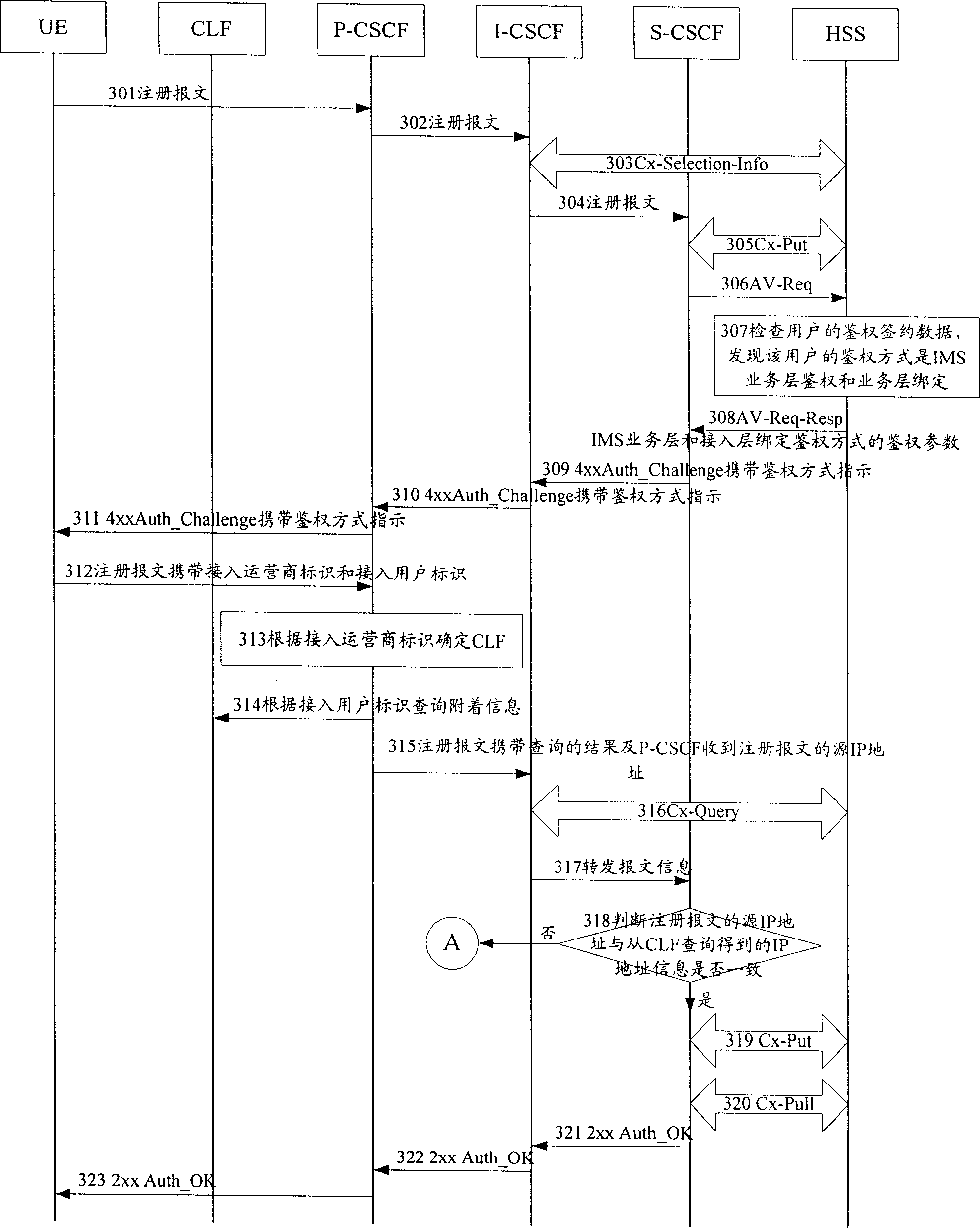

Authority-identifying method of internet protocol multi-media sub-system

ActiveCN1893352AReasonableMinor changesUser identity/authority verificationData switching networksInternet protocol suiteAccess network

The disclosed authentication method for IP multimedia subsystem includes steps: after receiving registration message sent from UE, P-CSCF queries attachment information of UE at access network from the determined CLF so as to obtain queried result, and sends registration message together with the queried result to I-CSCF; I-CSCF forwards the registration message to S-CSCF notified by HSS; based on authentication mode obtained from HSS, S-CSCF authenticates UE so as to obtain authentication result, which is sent to UE. It is reasonable that IMS service layer determines authentication mode for user, and S-CSCF accomplishes authenticating procedure. Further, the method not only discloses authentication mode of binding IMS service layer and access layer, as well as discloses the combining mode of the disclosed authentication mode with other authentication modes. Thus, if the disclosed binding authentication mode is in failure, then authentication can be carried correctly.

Owner:HUAWEI TECH CO LTD

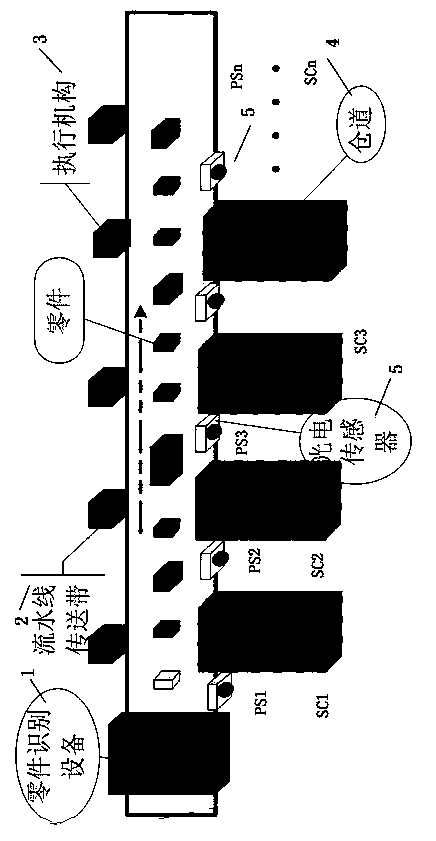

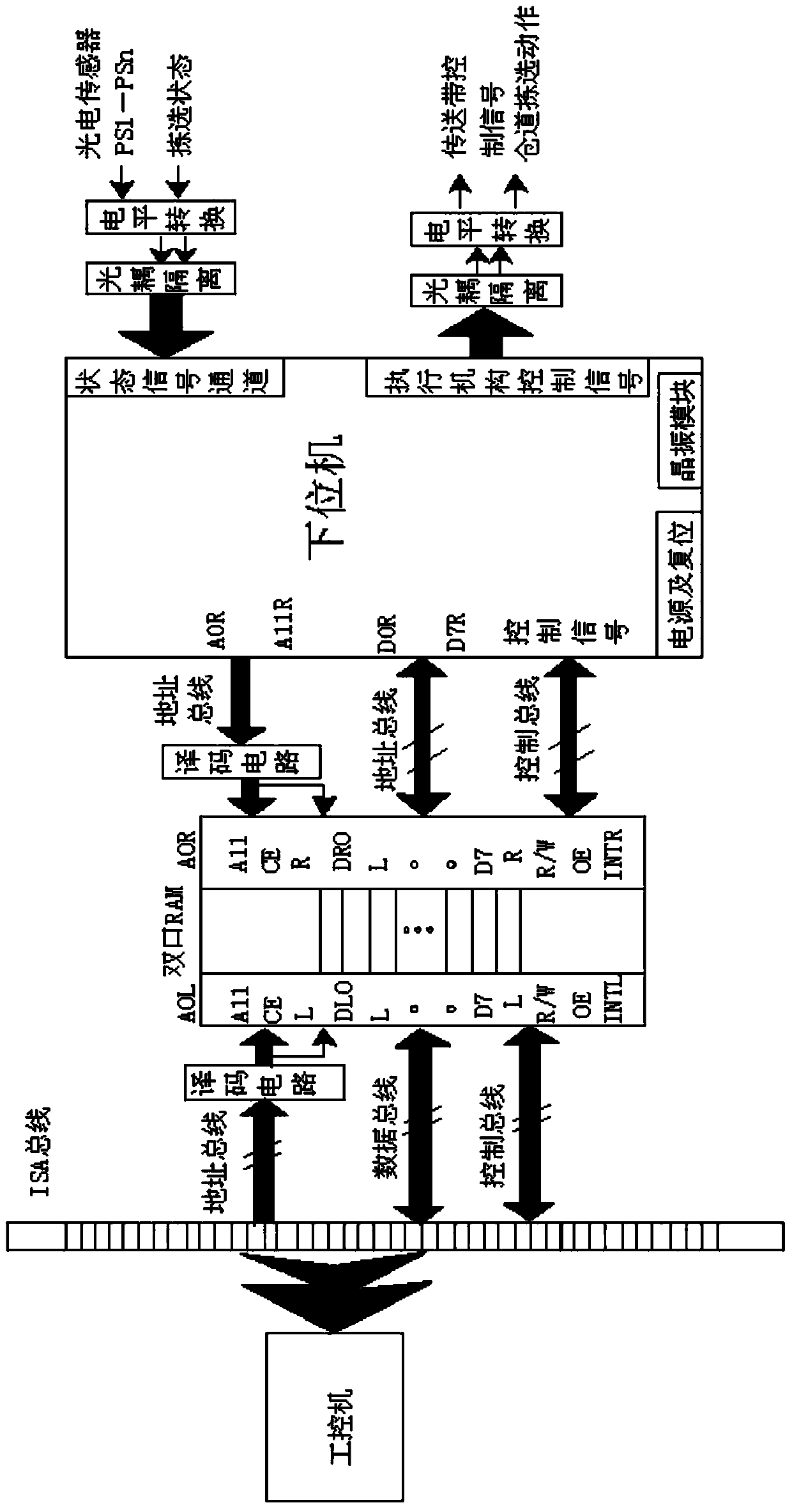

Component sorting method and sorting device for industrial production line

The invention relates to a component sorting method and sorting device for an industrial production line. The component sorting method and the sorting device classify and sort components in a counting way, the cost is reduced, and the working stability of equipment is improved. Moreover, the component sorting method and the sorting device are convenient to use andhave high cost performance, and the extended function is liable to implement. The component sorting method and the sorting device are characterized in that a plurality of equally-spaced channels are arranged on one side of a production line conveying belt along the conveying direction, and actuating mechanisms used for pushing the components into the channels and corresponding to allchannels one to one are arranged on the other side of the production line conveying belt and are mentioned in the following order: SC1, SC2, SC3...SCn; component identification equipment used for identifying the types of the components is arranged at the head end of the production line conveying belt, and the first channel is closed to the component identification equipment; a photoelectric sensor or a proximity switch type sensor used for detecting the number of the components is arranged on the front side of each channel, and the photoelectric sensors or the proximity switch type sensors are separately named PS1, PS2, PS3...PSn; and the photoelectric sensors or the proximity switch type sensors correspond to the actuating mechanisms, and the corresponding different identification and classification results are named C1-Cn.

Owner:BOHAI UNIV

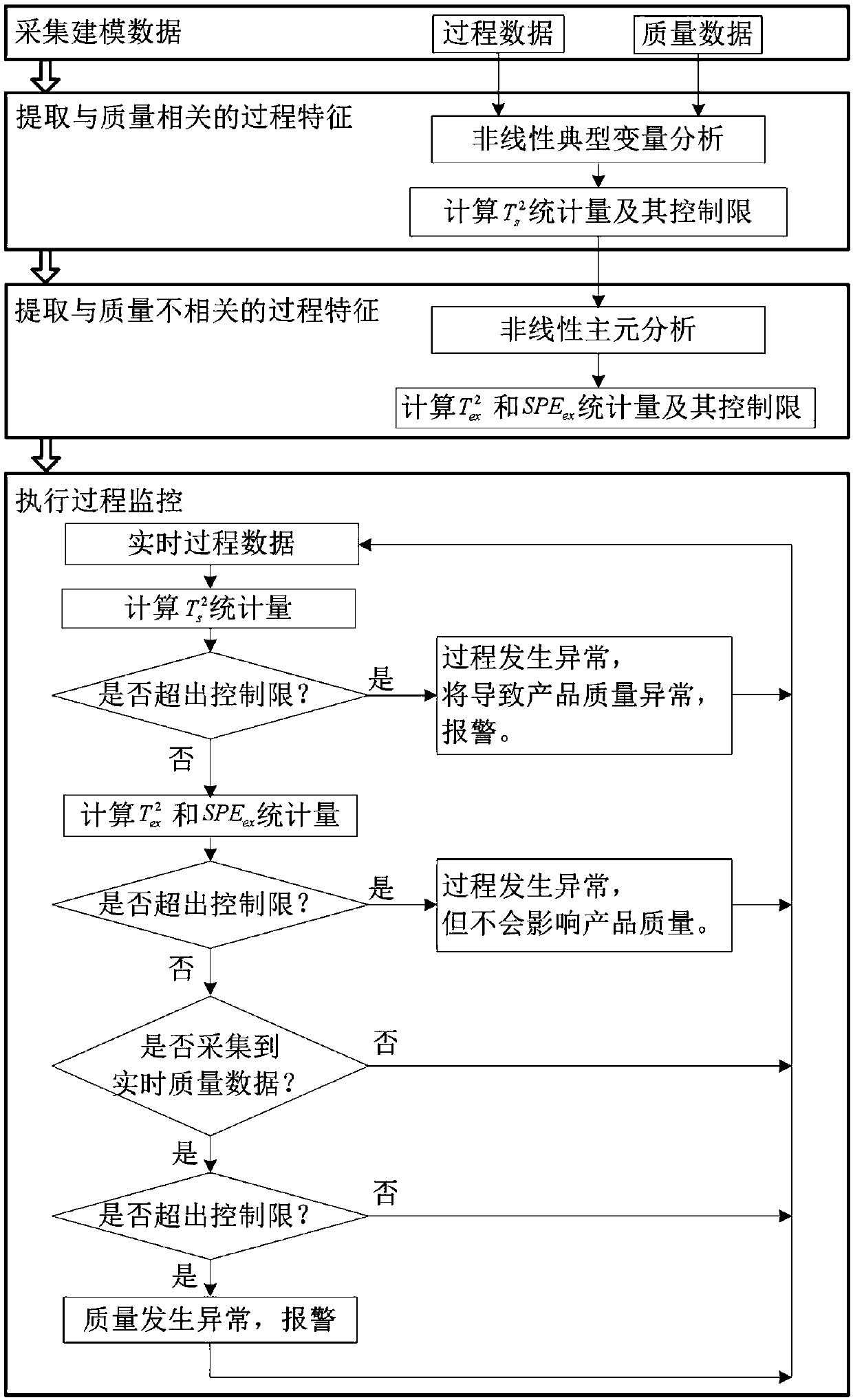

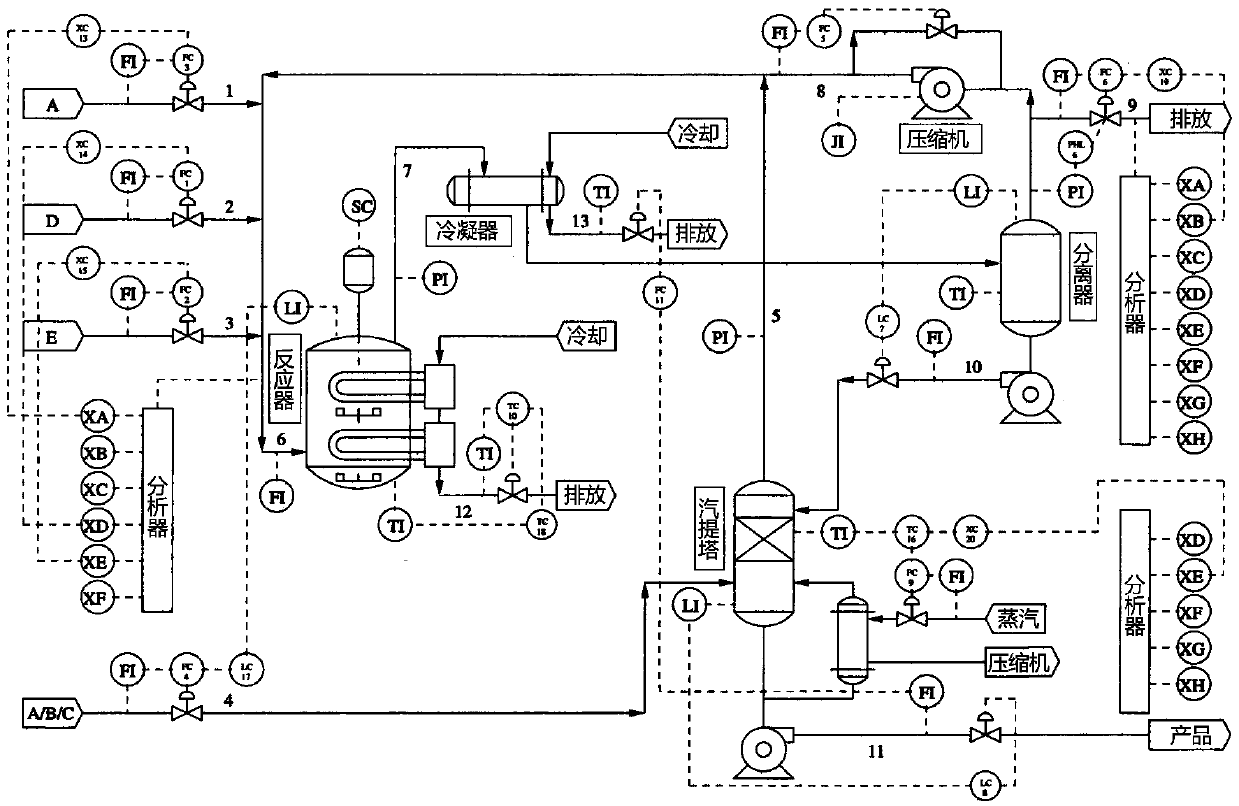

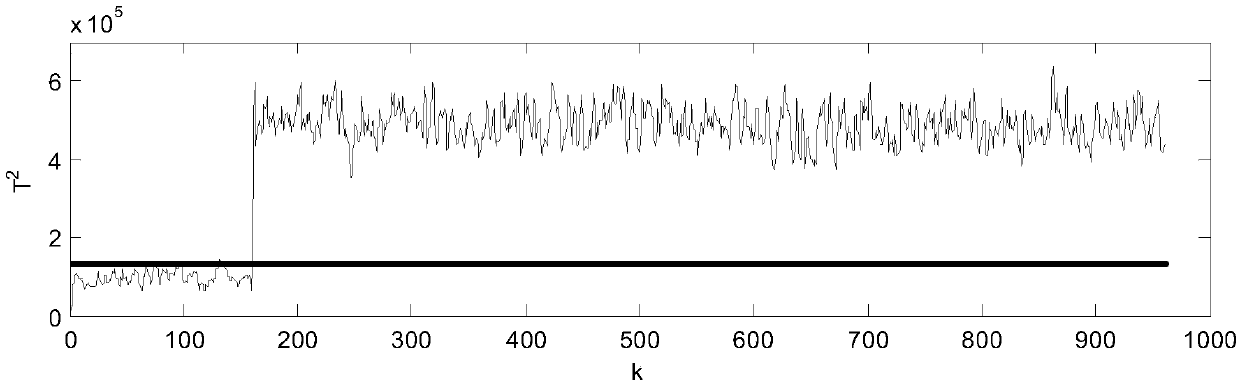

Quality-oriented nonlinear dynamic process monitoring method

ActiveCN108664002AImprove integrityImprove practicalityTotal factory controlProgramme total factory controlQuality dataMonitoring system

The invention relates to a quality-oriented nonlinear dynamic process monitoring method. The method comprises the following steps of (1) collecting process data and quality data of a nonlinear processunder normal working conditions, constructing modeling data, and standardizing; (2) calculating a standard square sum of typical vectors related to quality and control limits; (3) calculating a standard square sum of principal element vectors not related to quality, squared prediction errors SPEex and control limits; (4) monitoring process variables in the nonlinear dynamic process and quality variable data in real time, calculating standard square sums SPEex statistics, and judging whether or not a failure occurs and whether or not the process failure affects product quality. The method caneffectively filter out process failure alarms which do not affect the product quality, improve the credibility of process monitoring, enhance the logic integrity and practicability of a real-time process monitoring system, and adapt to the requirements of real-time process monitoring of a nonlinear dynamic process; a process failure diagnosis is accurate, the real-time process monitoring efficiency is high, and the adaptation range is wide.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com