Method for converting PLC program into common Petri net

A technology of program conversion and programming logic, which is applied in the field of mathematical modeling of programmable logic controller programs, and can solve problems such as the increase in scale and structural complexity of industrial control systems, tedious program design and debugging workload, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

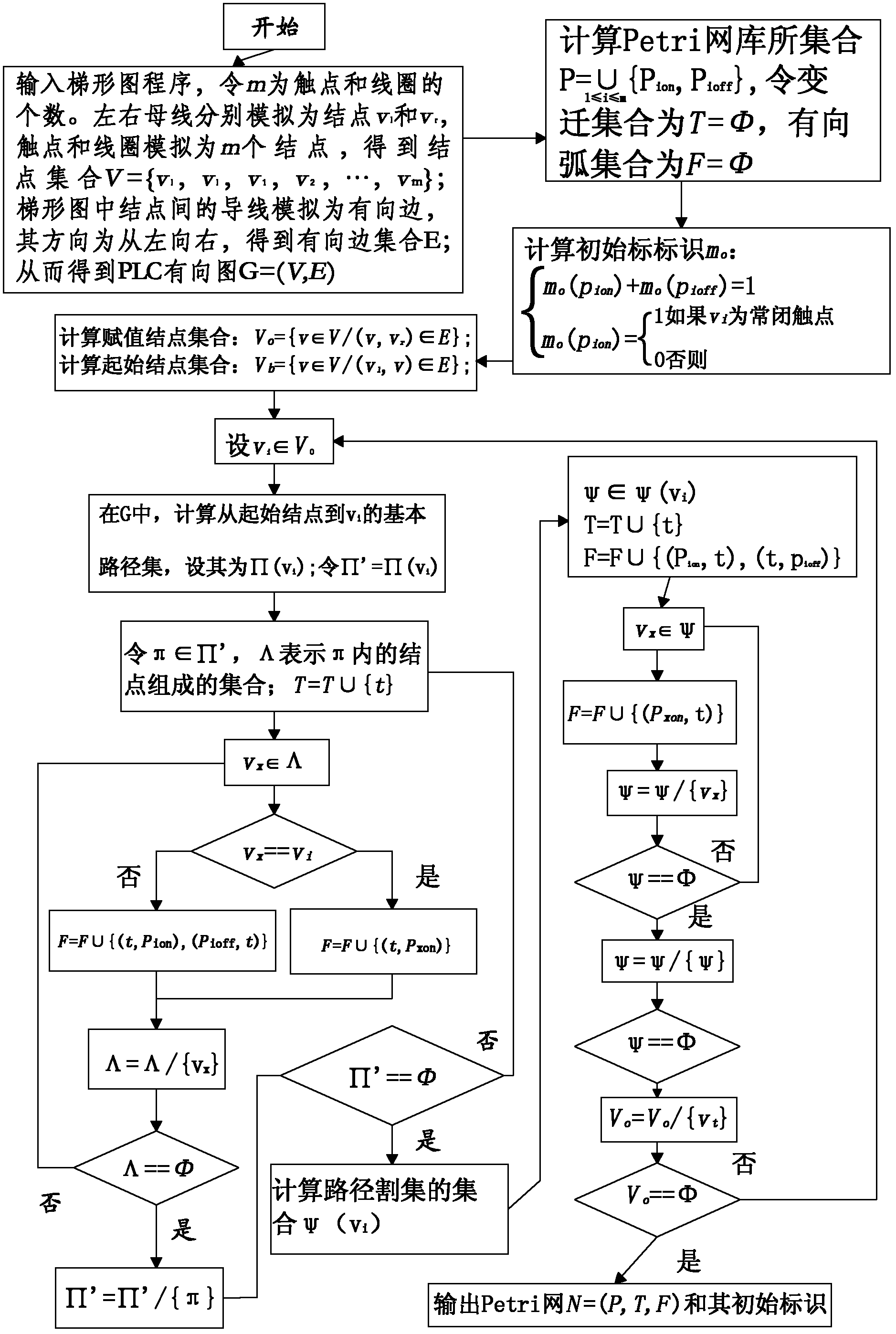

Method used

Image

Examples

Embodiment 2

[0080] The present invention is described in detail with the second embodiment "motor forward and reverse circuit".

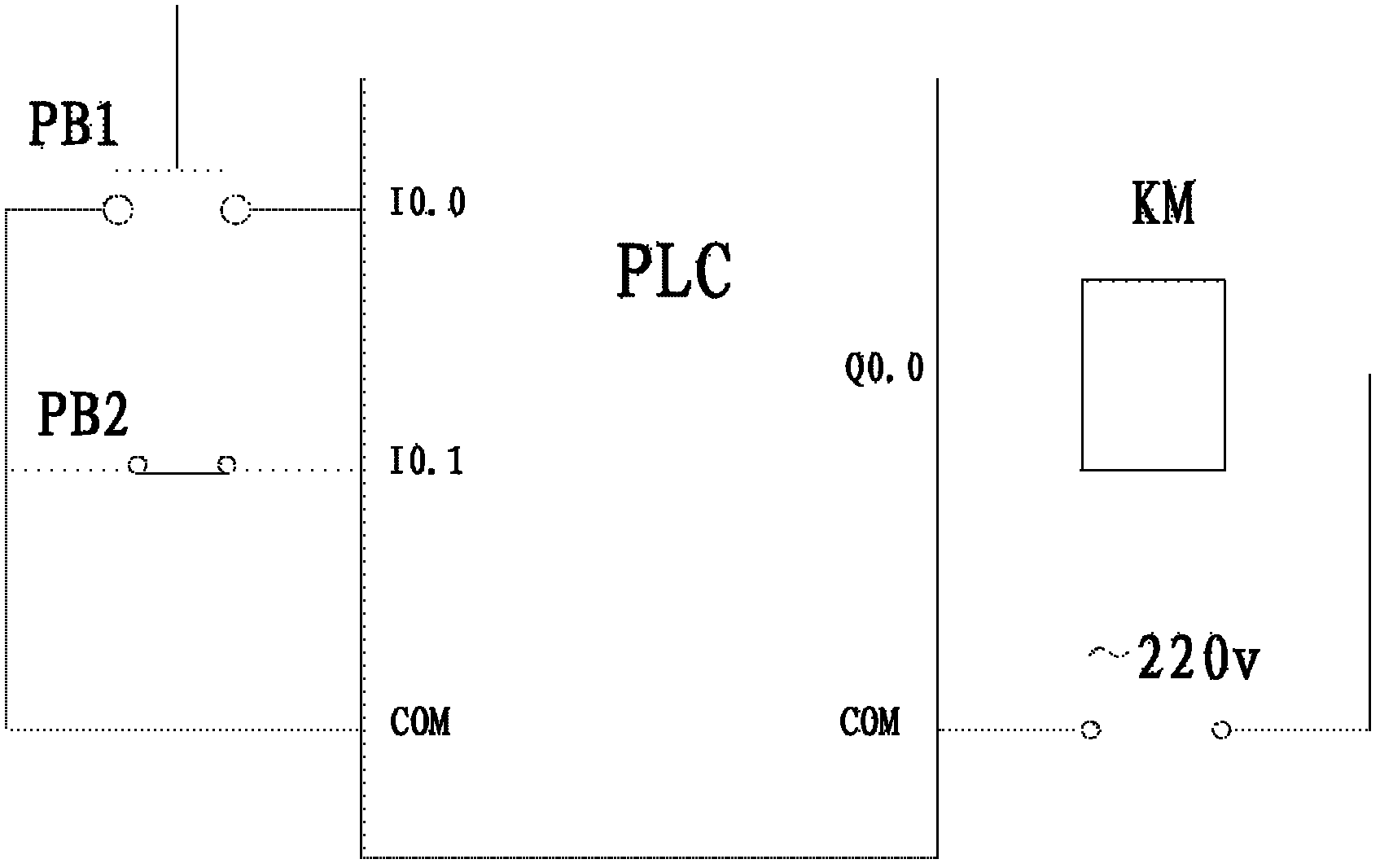

[0081] like Figure 7 As shown, SB1 and SB2 are manual switches, and KM1 and KM2 are relay coils, respectively indicating the forward and reverse working states of the motor. Figure 8 It is the external wiring circuit diagram controlled by PLC. The input terminal I0.0 of one PLC chip is connected to SB1, the output terminal Q0.0 is connected to relay coil KM1, the input terminal I0.1 of the other PLC chip is connected to SB2, and the output terminal Q0.1 is connected to Relay coil KM2. from Figure 9 It can be seen from the PLC ladder diagram program, which illustrates a simple method of interlocking program outputs. When the manual switch SB1 is pressed, the I0.0 contact is closed, the relay KM1 is energized, and the motor rotates forward; when the manual switch SB2 is pressed, the I0.1 contact is closed, the relay KM2 is energized, and the motor rotates f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com