Component sorting method and sorting device for industrial production line

An assembly line and parts technology, which is applied in the field of industrial assembly line parts sorting and sorting devices, can solve the problems of long image processing time of detection equipment, inaccurate sensor recognition, expensive detection equipment, etc., and achieve easy and accurate hardware circuit expansion The effect of high precision and low labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention takes the E-type magnetic material as the sorting object, and the tool capable of identifying the shape and size of the E-type magnetic material is a high-power industrial camera. High-power industrial cameras can identify the shape category and size of E-type magnetic materials, and then sort each different type of magnetic materials into different bins.

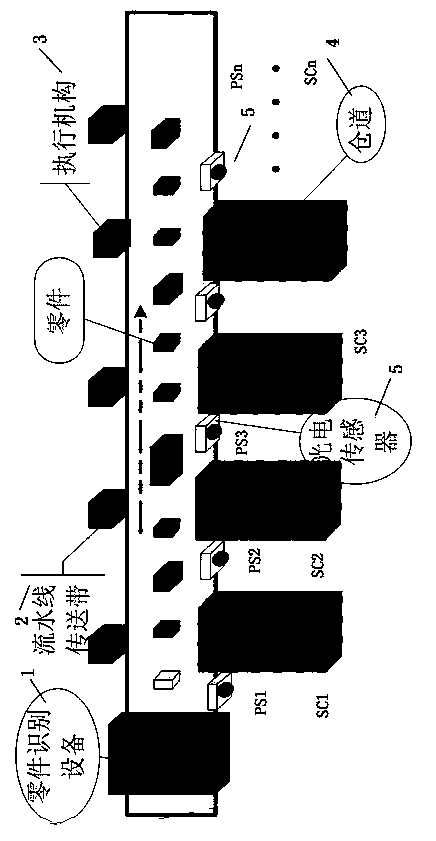

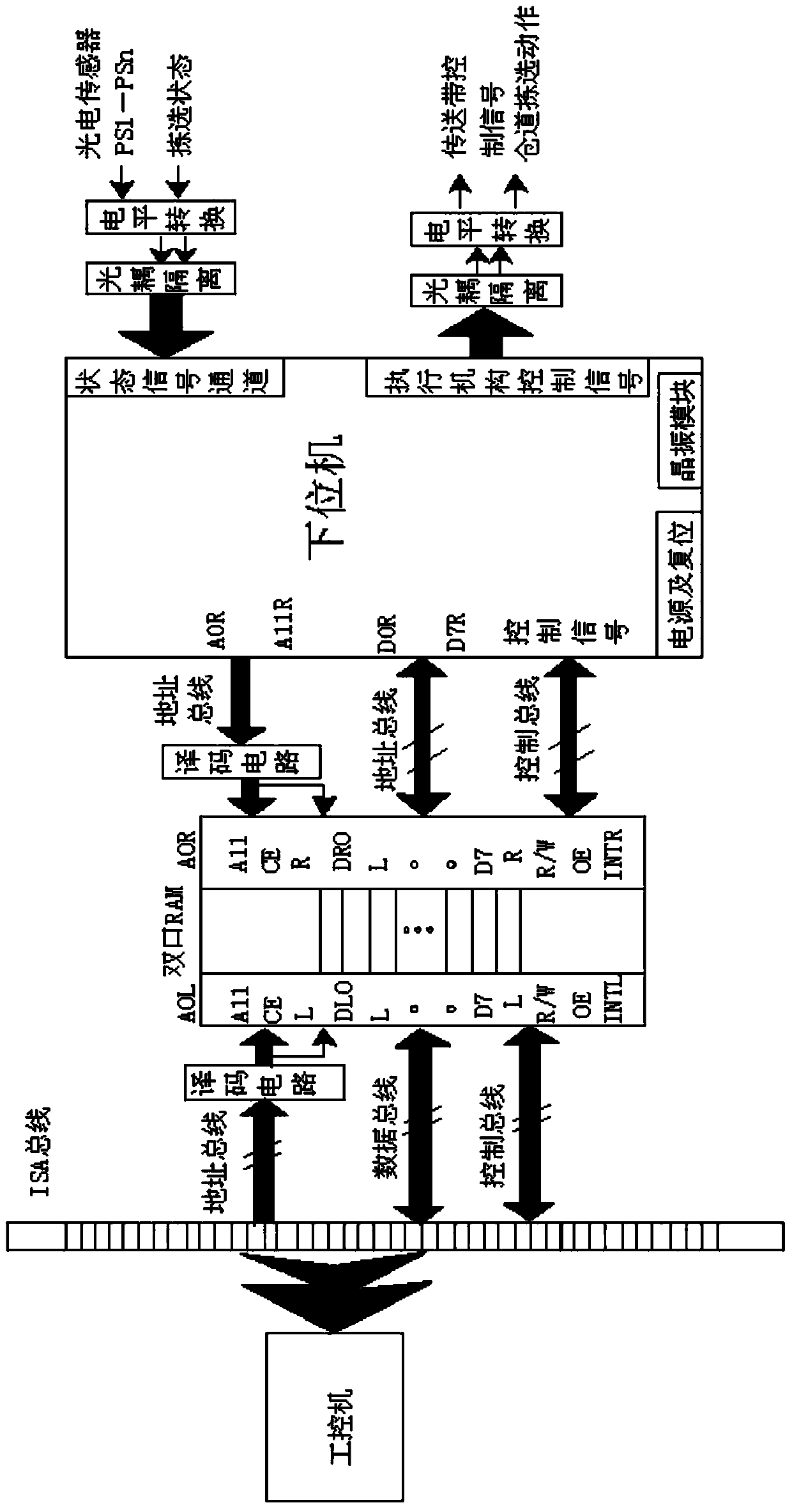

[0026] like figure 1 , figure 2 As shown, it is used for the sorting device of industrial assembly line parts. On one side of the assembly line conveyor belt 2, there are a plurality of equally spaced bins 4 along the conveying direction. Corresponding to each warehouse lane, an actuator 3 for pushing parts into the warehouse lane is respectively provided, and a parts identification device 1 for identifying the type of parts is provided at the head end of the assembly line conveyor belt 2, and the parts identification device 1 is connected to it by a host computer The recognition sensor (or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com