Factory intelligent scheduling method

An intelligent scheduling and factory technology, applied in the direction of comprehensive factory control, comprehensive factory control, control/adjustment system, etc., can solve the problems of no standardized unified standard, low production efficiency, heavy pollution, etc., and achieve human-computer friendly interaction Effects of Apps and Experiences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

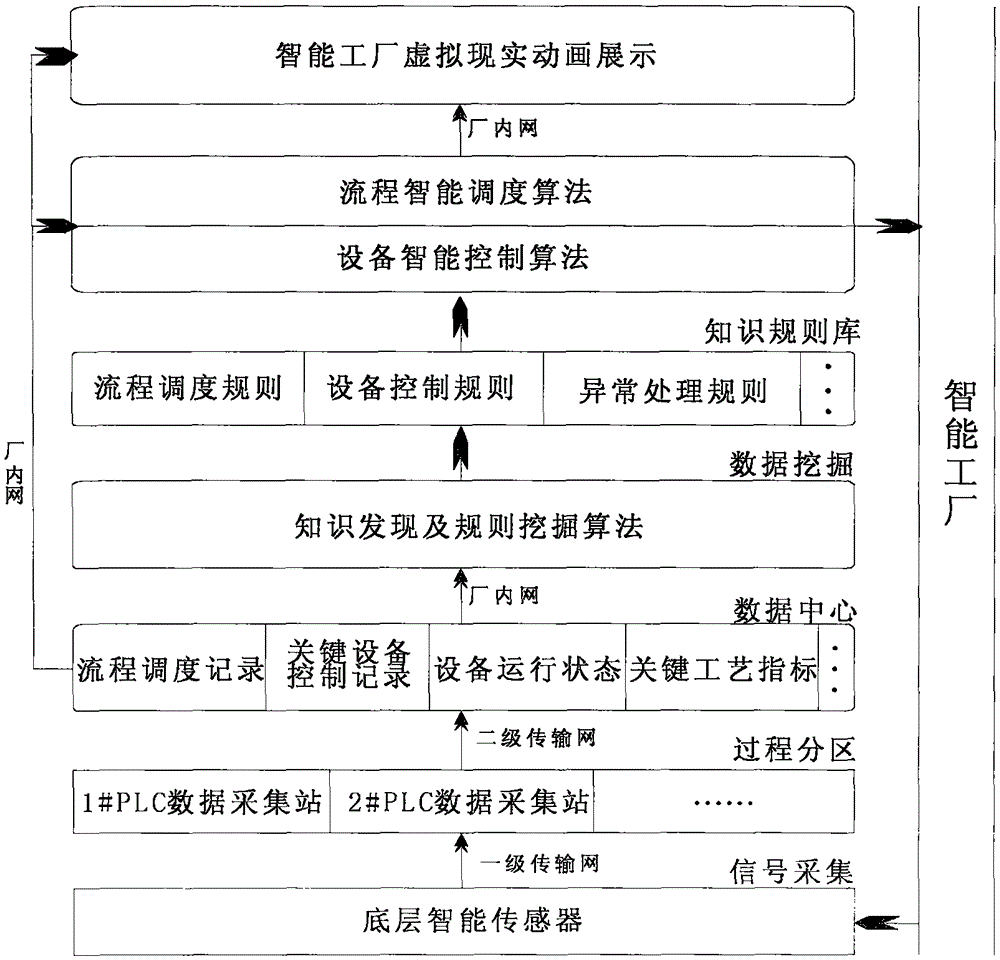

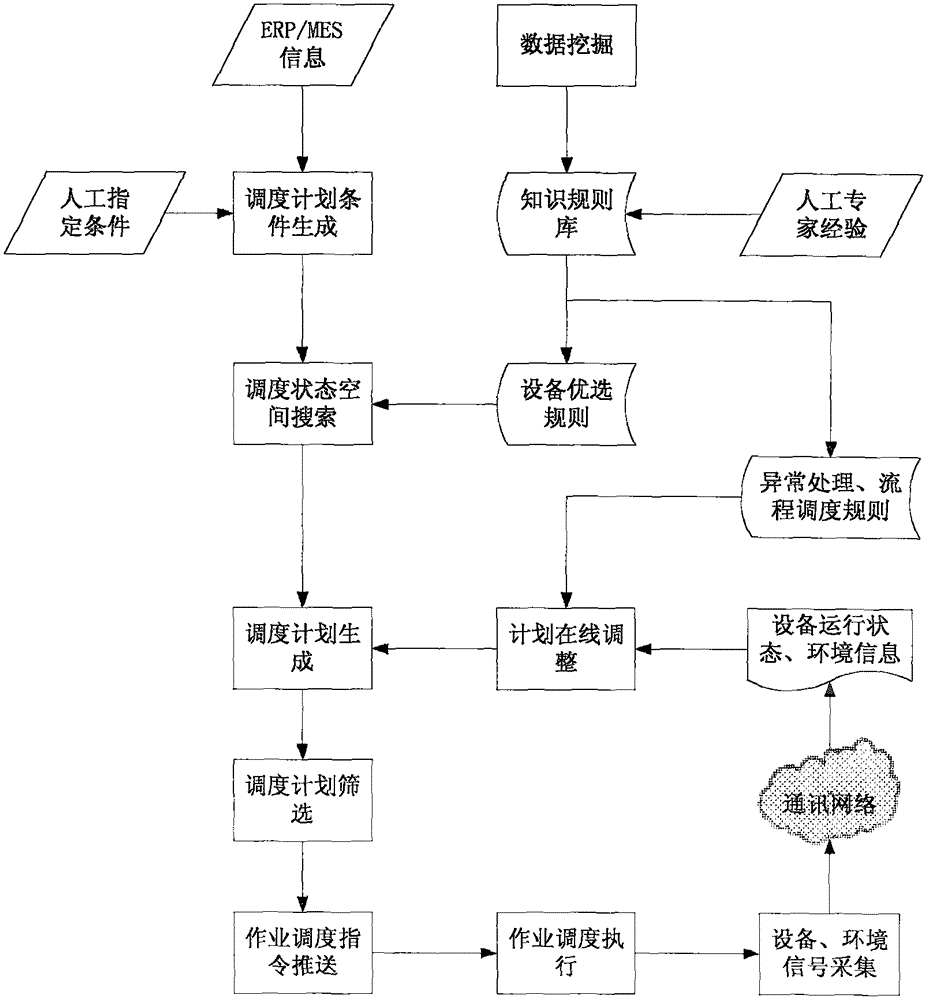

[0075] Such as figure 1 As shown, a factory intelligent scheduling method, the scheduling method mainly includes the following steps:

[0076] a. According to the needs of smart factories for information collection, smart sensors are installed inside the factory, and equipment status information and factory environment information are collected through smart sensors;

[0077] b. Send the equipment status information and environmental information to the corresponding PLC data collection station respectively;

[0078] c. After data preprocessing, each PLC data collection station divides the data into process scheduling record data, key equipment control record data, equipment operation status data, and key process index data and uploads them to the data center;

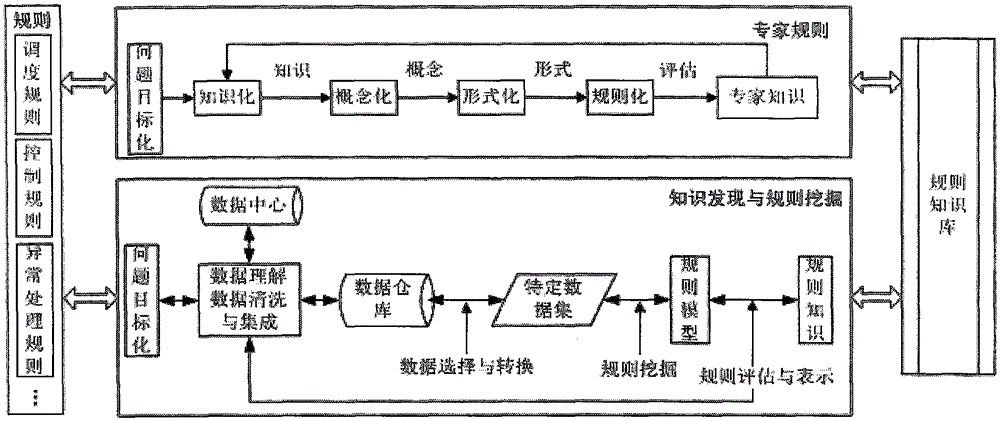

[0079] d. The data center extracts k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com