Two-way long-line pedestal method production process of prestressed concrete track slab

A production process and track plate technology, applied in the direction of manufacturing tools, ceramic molding workshops, ceramic molding machines, etc., to achieve the effects of reducing costs, reducing labor intensity, and solving interference problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

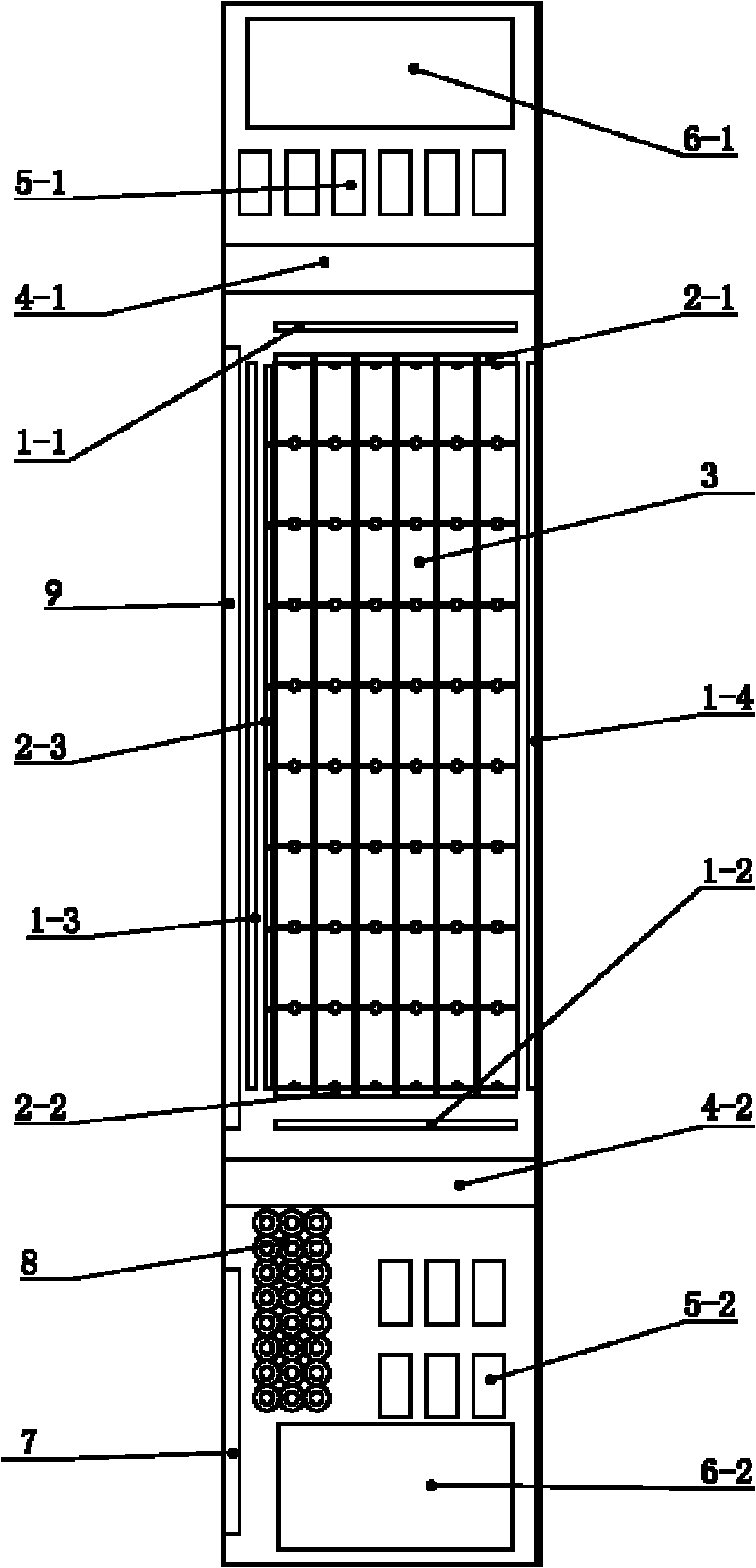

[0020] Combined with the accompanying drawings, the production process of the two-way long-line pedestal method is described in detail. The specific production steps are:

[0021] 1 Model cleaning Clean the track plate mold, side plate, and end plate. When cleaning ash and dirt, it is strictly forbidden to hammer or hit directly with hard objects to avoid pits and local deformation.

[0022] 2 Mold positioning Move the steel mold to the positioning position, insert the positioning pin, the movable end beams 2-1, 2-2 are horizontally restored to the position before stretching, and the tensioning device is adjusted to the state before tensioning.

[0023] 3. Spraying the release agent should be evenly sprayed to prevent missing coating, and not too much. Use a sponge to wipe off the accumulation of the release agent for a long time, so as not to see obvious oil stains. The side plates, end plates, and arcs can be painted with a brush.

[0024] 4 Lay out the prestressed tendons S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com