Double-circular-seam automatic welding equipment

An automatic welding and circular seam technology, applied in the mechanical field, can solve the problems of low efficiency and low failure rate of automatic welding machines, and achieve the effect of compact and reasonable layout, easy access, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

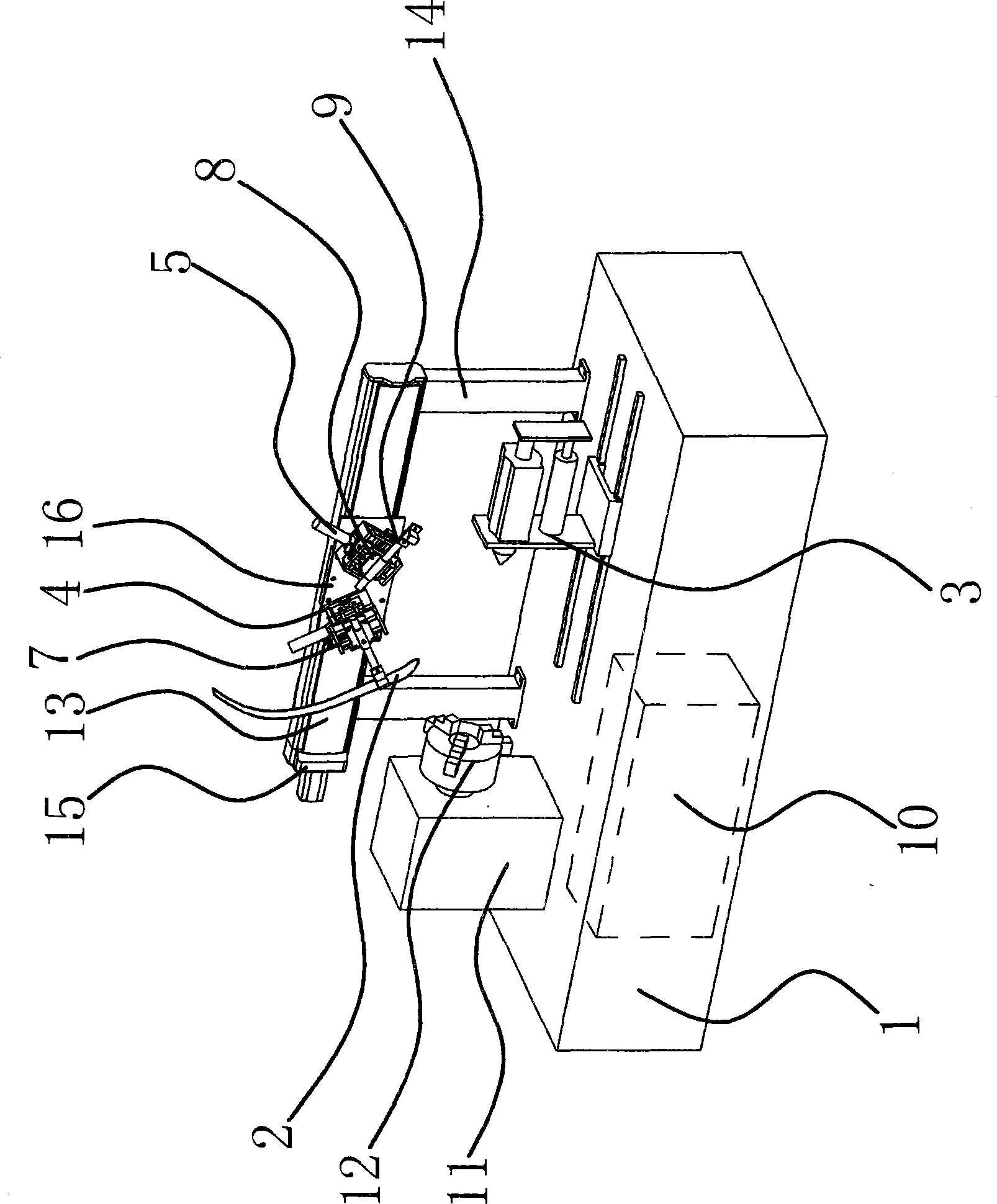

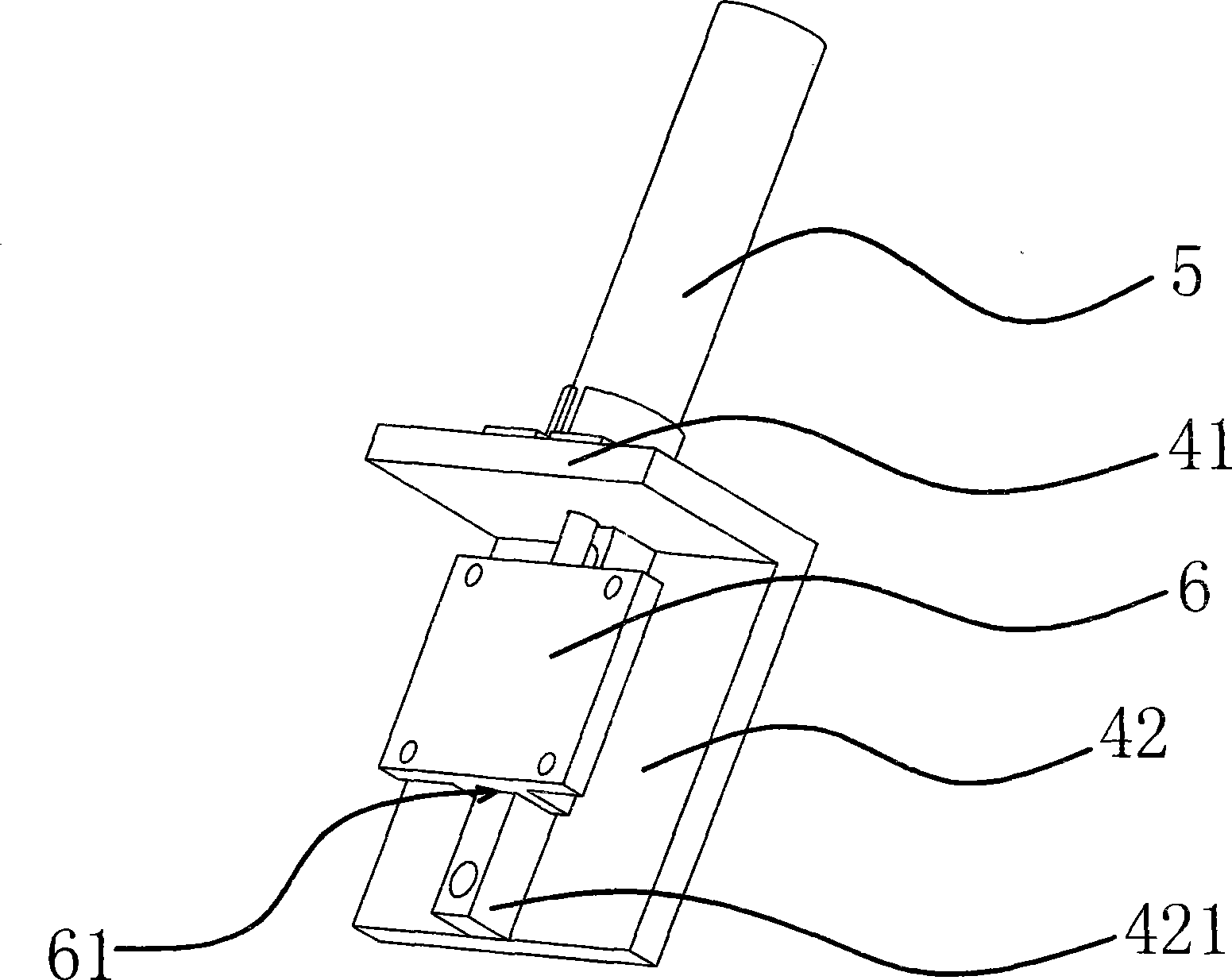

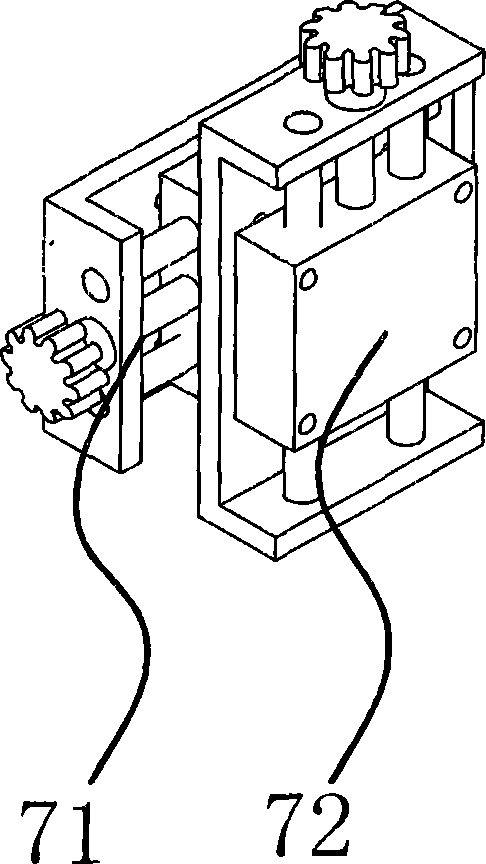

[0023] Such as figure 1 As shown, a double circular seam automatic welding equipment includes a welding torch 2 and a frame 1, an active power pump 10 is installed in the frame 1, a transmission 11 is installed on the left side of the frame 1, and a three-jaw chuck 12 is connected to the transmission 11 On the right side of the frame 1, the clamping device 3 is installed on the right side of the frame 1, opposite to the three-jaw chuck 12 and on the same center line, and the linear guide rail 13 is installed laterally on one side of the frame 1 through the column 14, And between the three-jaw chuck 12 and the clamping device 3 , the linear guide driver 15 is an electric motor installed on the left end of the linear guide 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com