Patents

Literature

43 results about "Beam walking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

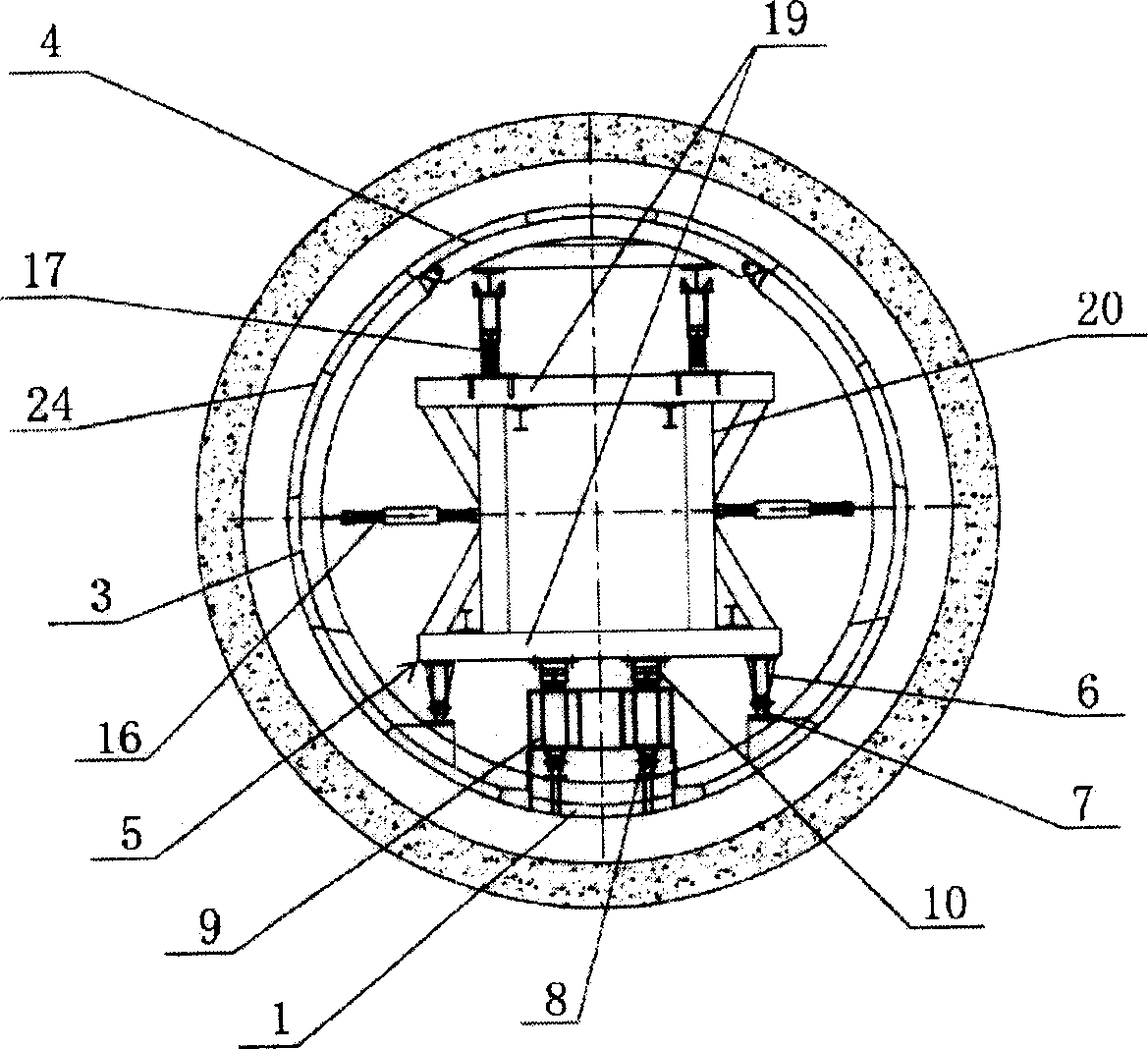

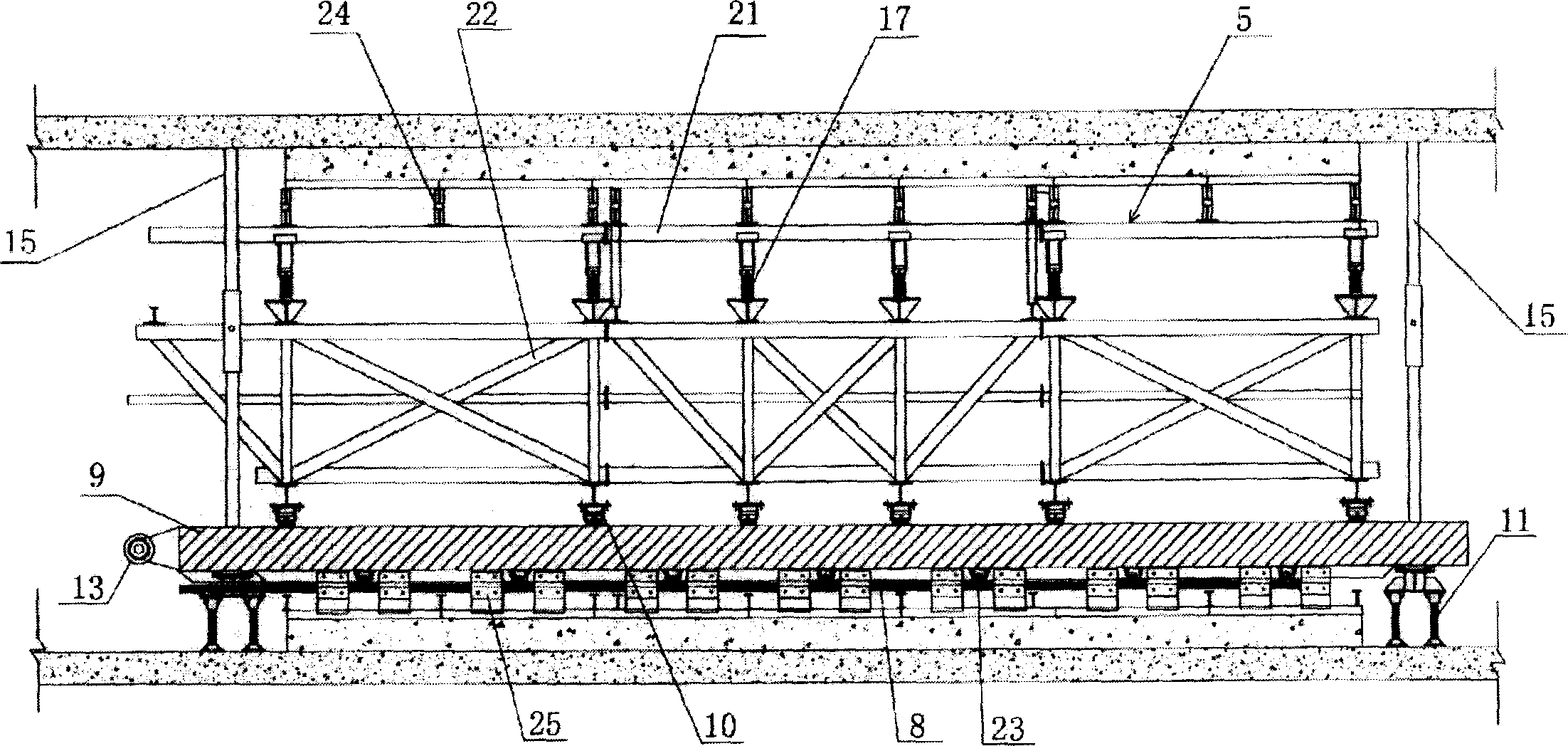

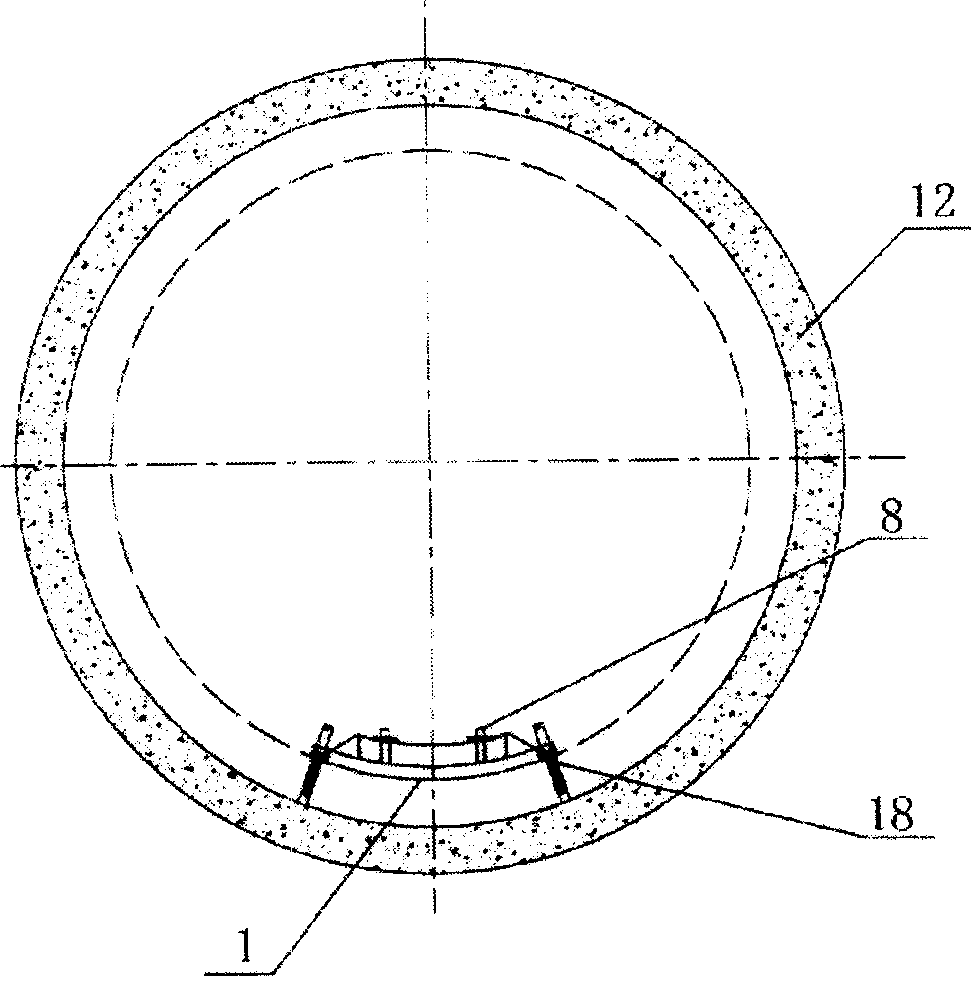

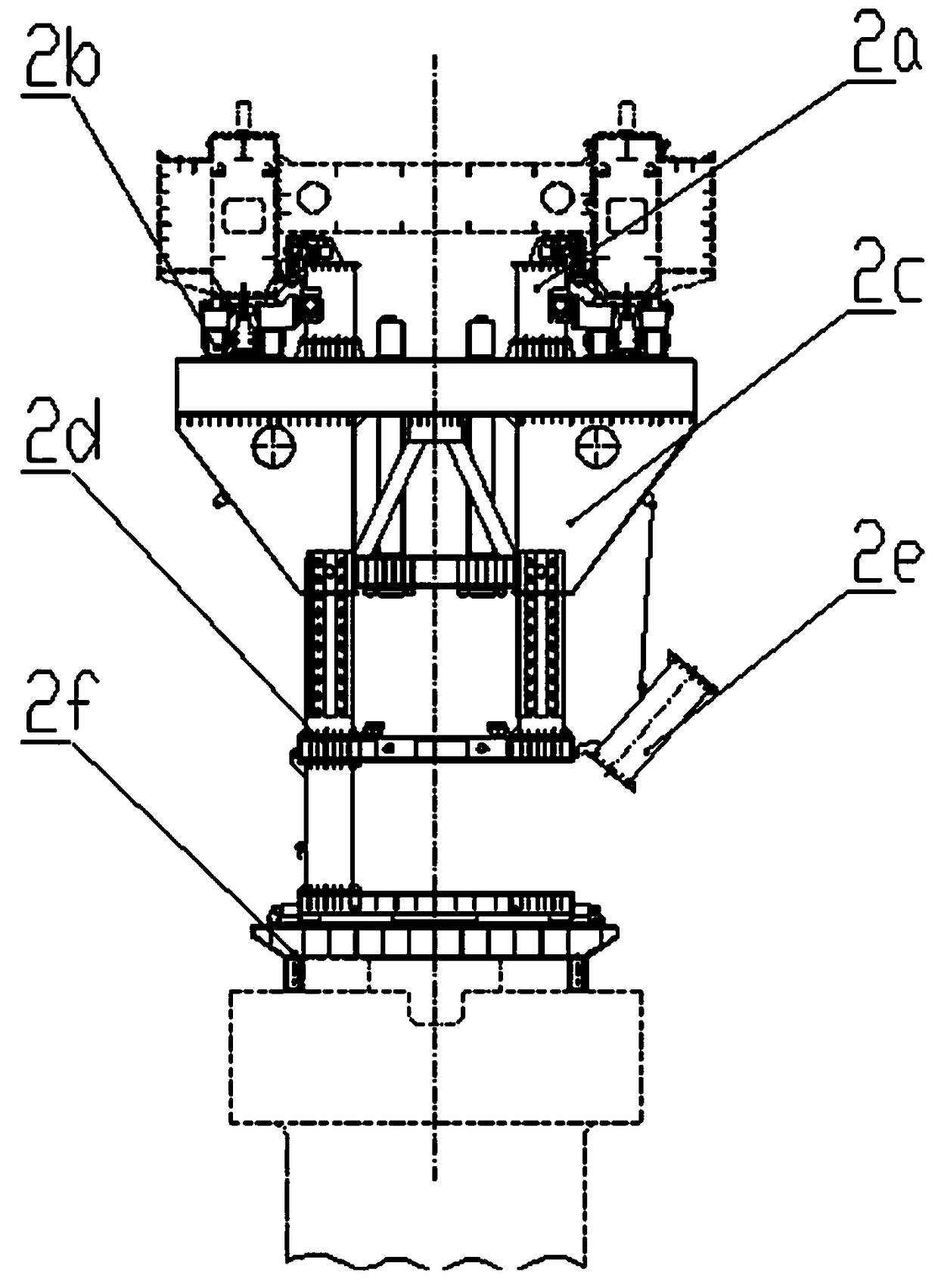

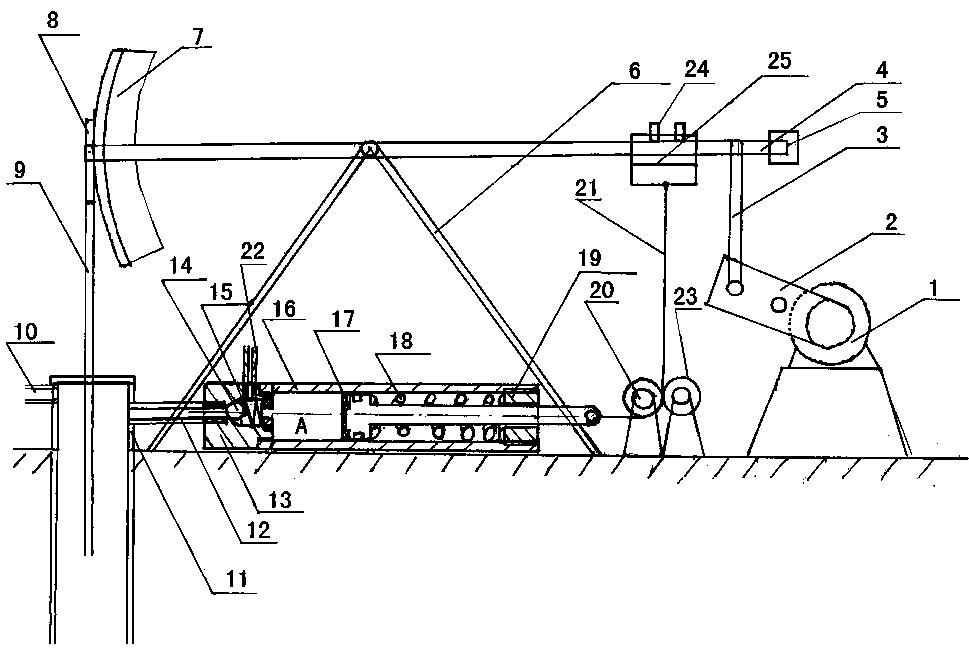

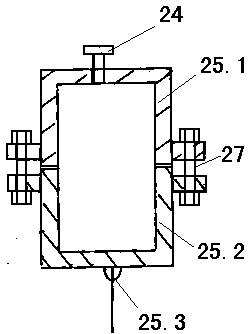

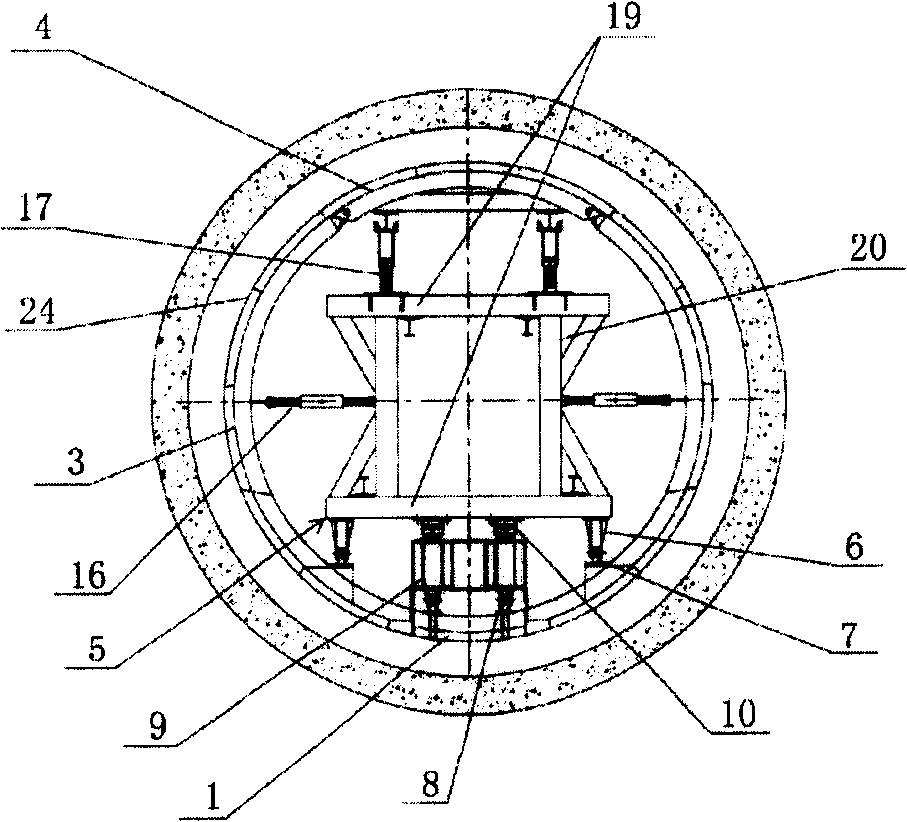

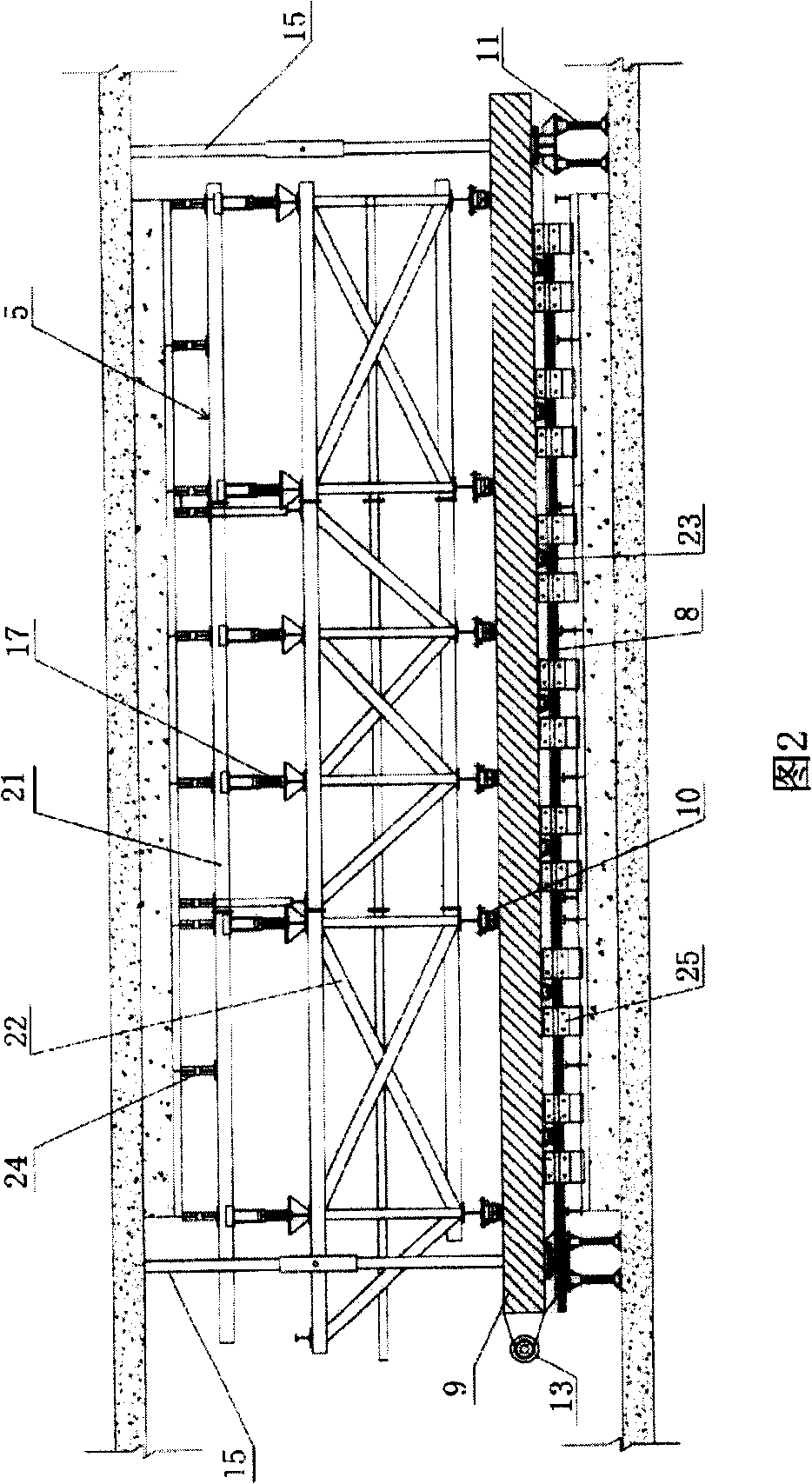

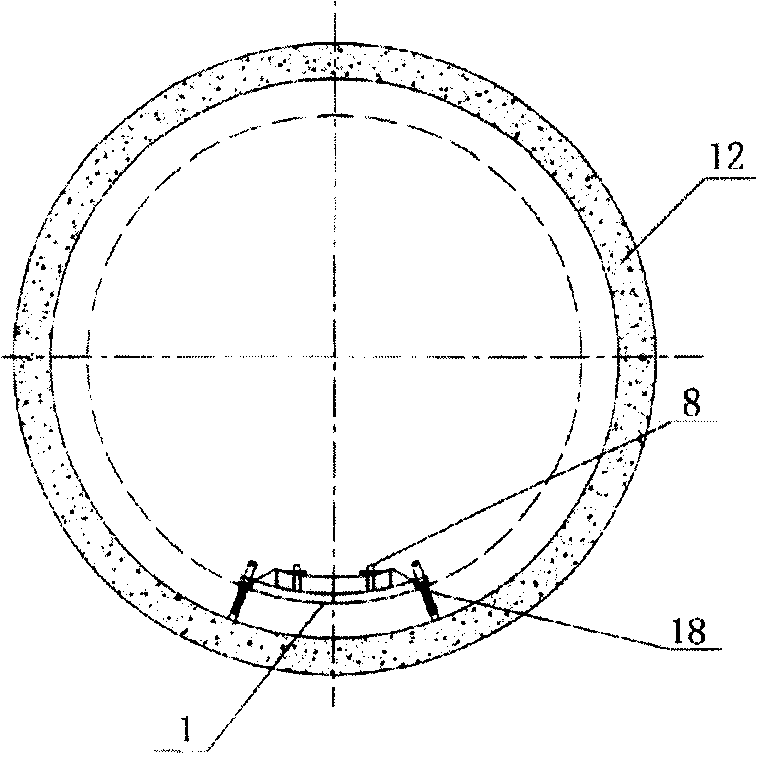

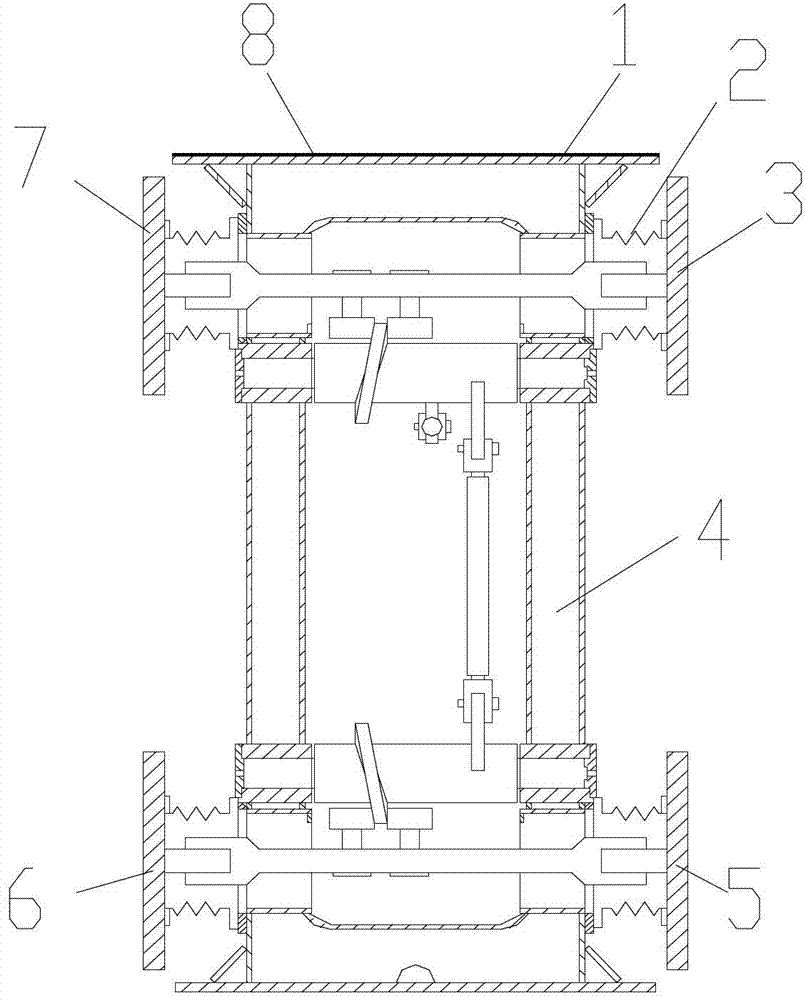

Full circle once lining segregation type nose girder module bench and its construction method

ActiveCN1908374AReduce consumptionOvercoming weightUnderground chambersTunnel liningNoseBeam walking

The invention relates to a linear separated guide beam template table, wherein its annular linear beam is connected to the inner side of template; the annular linear beam and the table support top template support screw disc, side template support lead screw and bottom template support lead screw between them; the table via walking device is supported on the table walking steel track above the bottom template; one table and two bottom templates are alternatively matched; the bottom template is fixed with guide beam walking steel track which supports the detachable support guide beam; the bottom of detachable support guide beam has walking wheel, while its top is detachably connected via adjustable base and table; the end of detachable support guide beam via the end base of guide beam is supported on the support concrete structure, while its one end is connected to the drawing system; another bottom template is at the concrete pouring position. And it can be used on the template table machine whose section diameter is 6-3m, with large operation space and lower cost.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

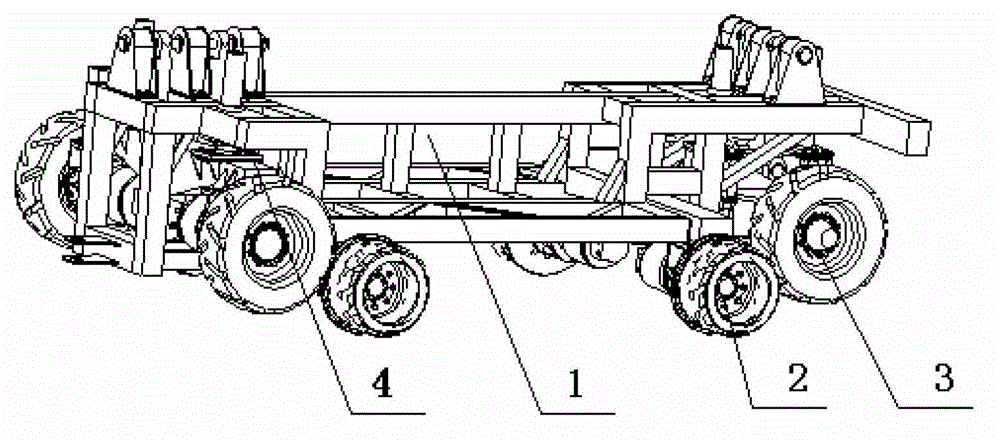

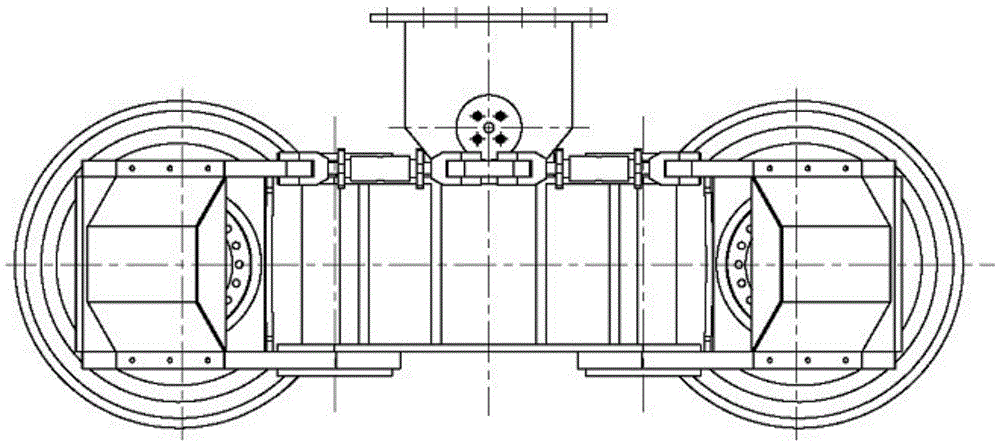

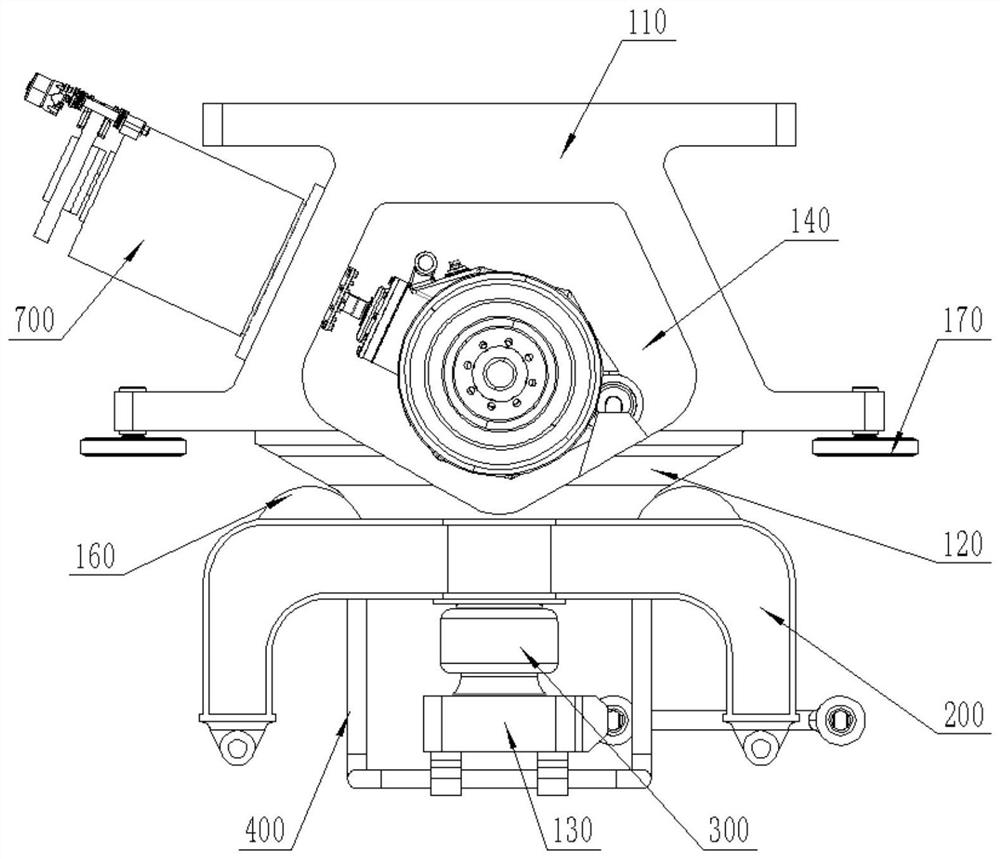

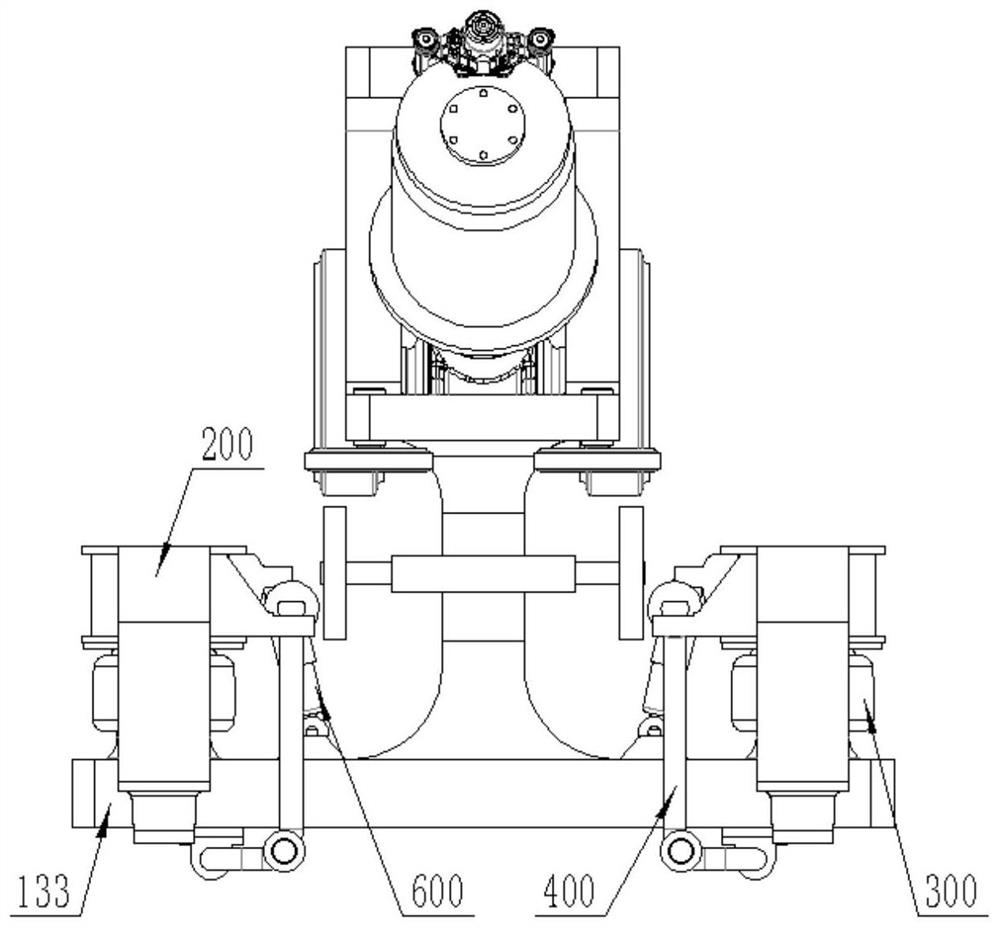

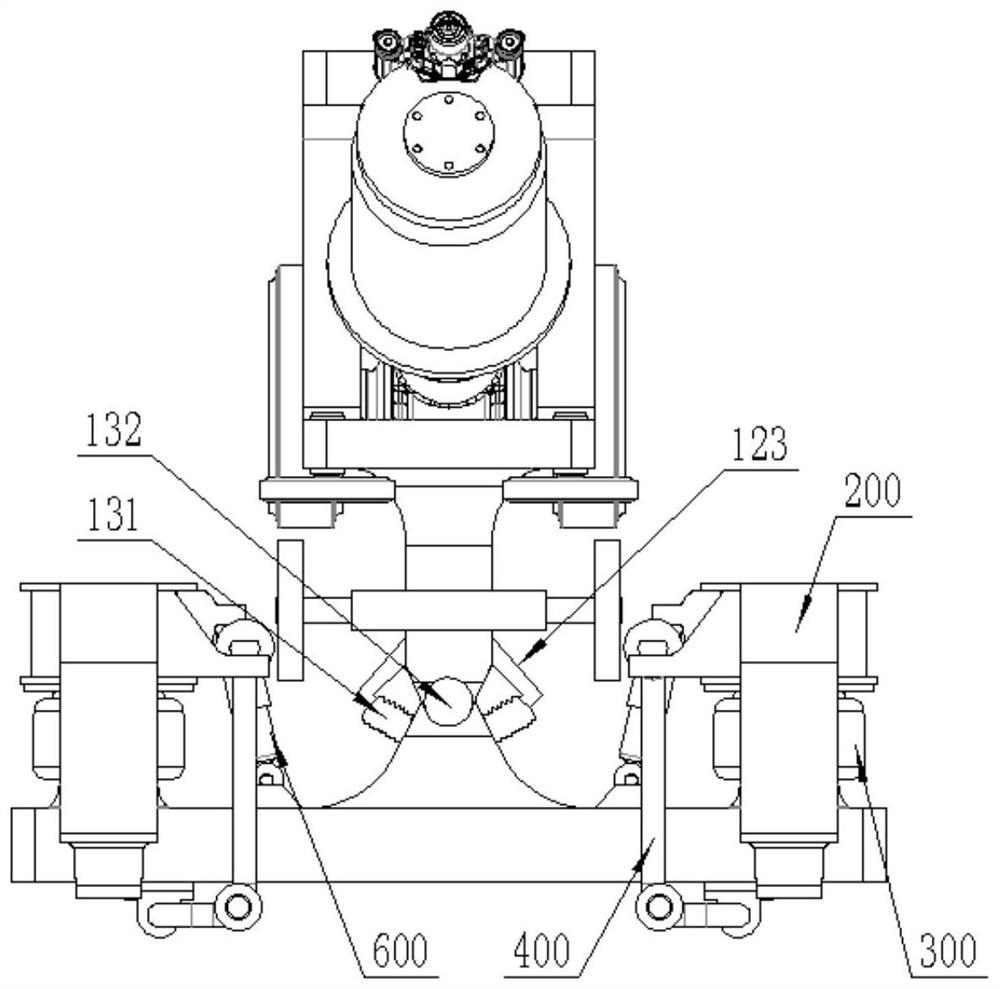

Multifunctional chassis of track tractor

The invention provides a multifunctional chassis of a track tractor. The multifunctional chassis comprises a frame, a track traveling mechanism and a road traveling mechanism, wherein the track traveling mechanism comprises a balance-beam walking mechanism at the front end and track driving mechanisms at the two sides of the rear end, wherein the balance-beam walking mechanism is mounted at the bottom of the frame through support shafts and support shaft seats, which are located at the middle of a balance beam, and the track driving mechanisms are respectively mounted at the two sides of the bottom of the rear end of the frame; the road traveling mechanism comprises a steering axle at the front end and a road driving mechanism at the rear end, wherein both the steering axle and the road driving mechanism are mounted on the frame through traveling state switching devices; the track driving mechanisms comprise hydraulic motors, bearing mounting seats, rear track wheels, a track wheel axle and a pair of tapered roller bearings, wherein the track wheel axle is fixedly arranged in the bearing mounting seats through the tapered roller bearings which are mounted in a face-to-face manner, the rear track wheels are mounted on extending ends of the track wheel axle, input ends of the track wheel axle are connected with output shafts of the hydraulic motors, the hydraulic motors are mounted on end faces of the bearing mounting seats through flange faces, and the track driving mechanisms are connected to the frame through the bearing mounting seats.

Owner:HUBEI SANJIANG AEROSPACE WANFENG TECH DEV

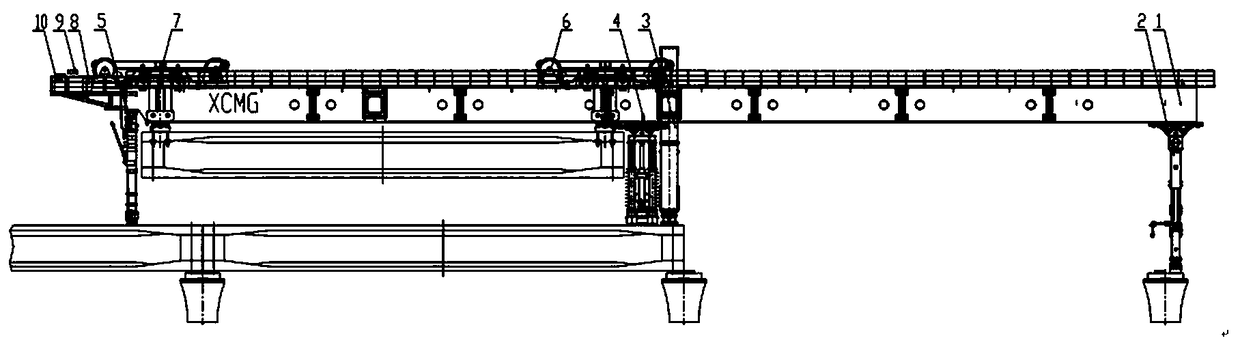

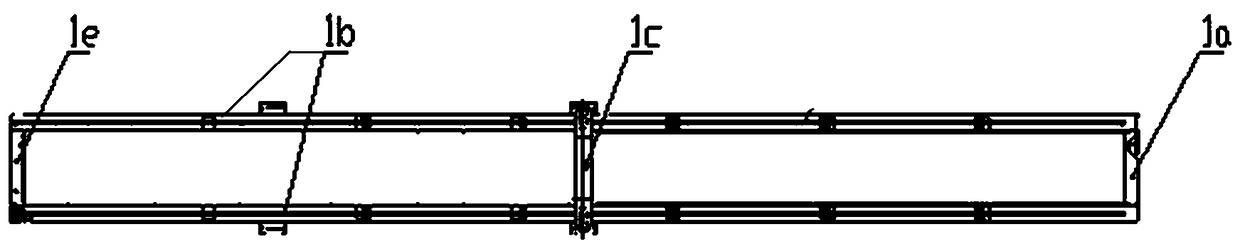

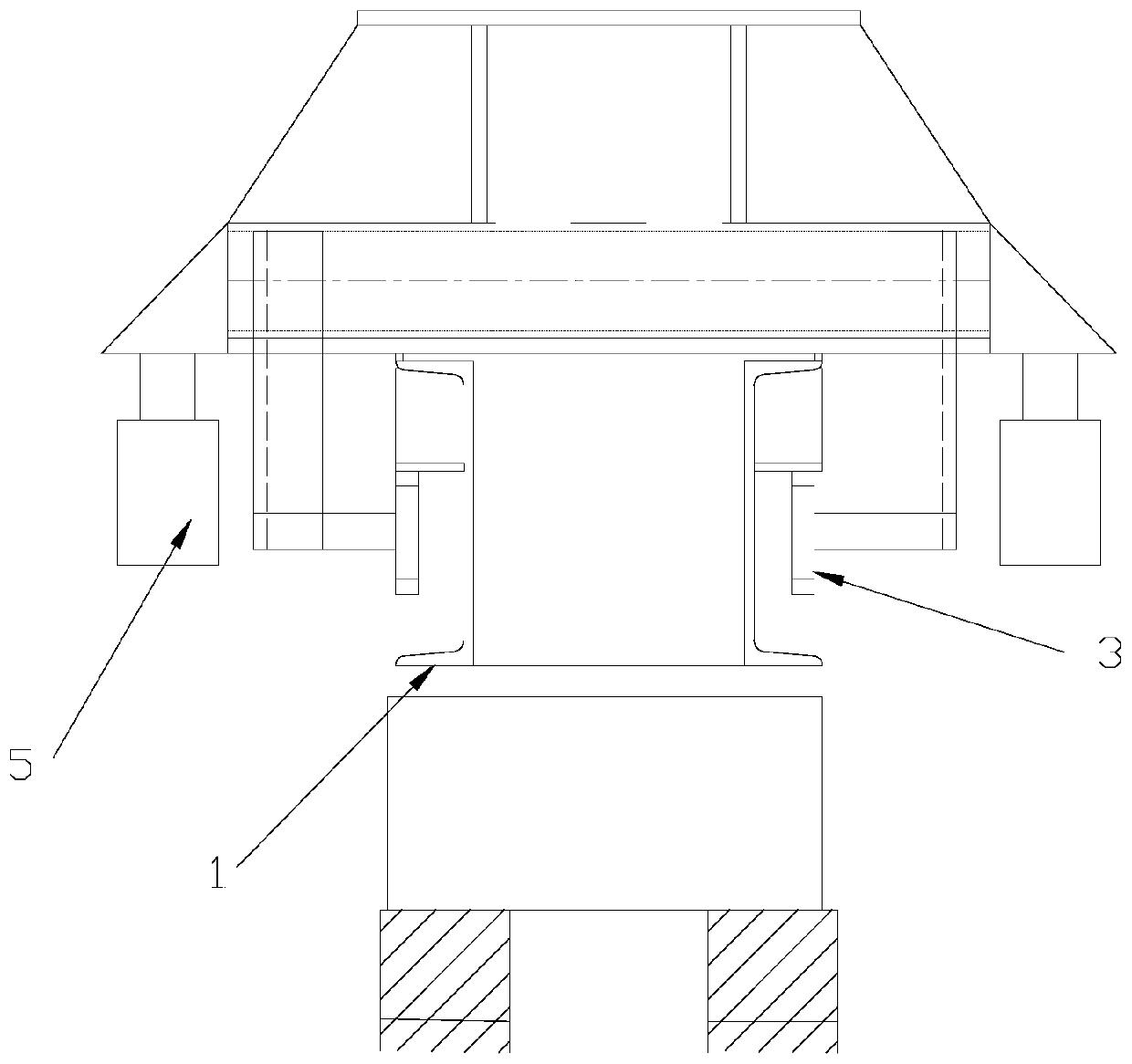

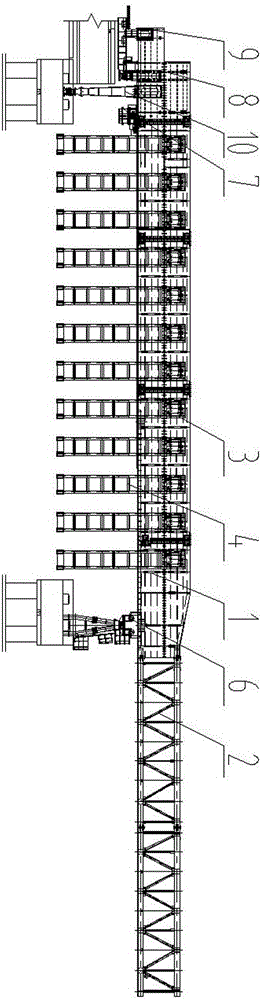

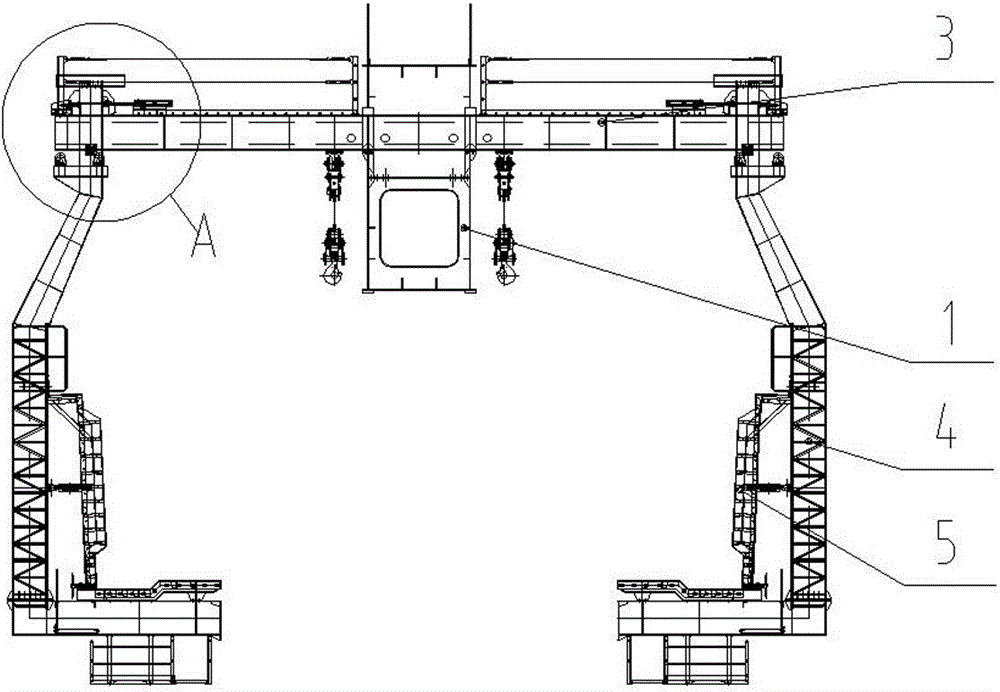

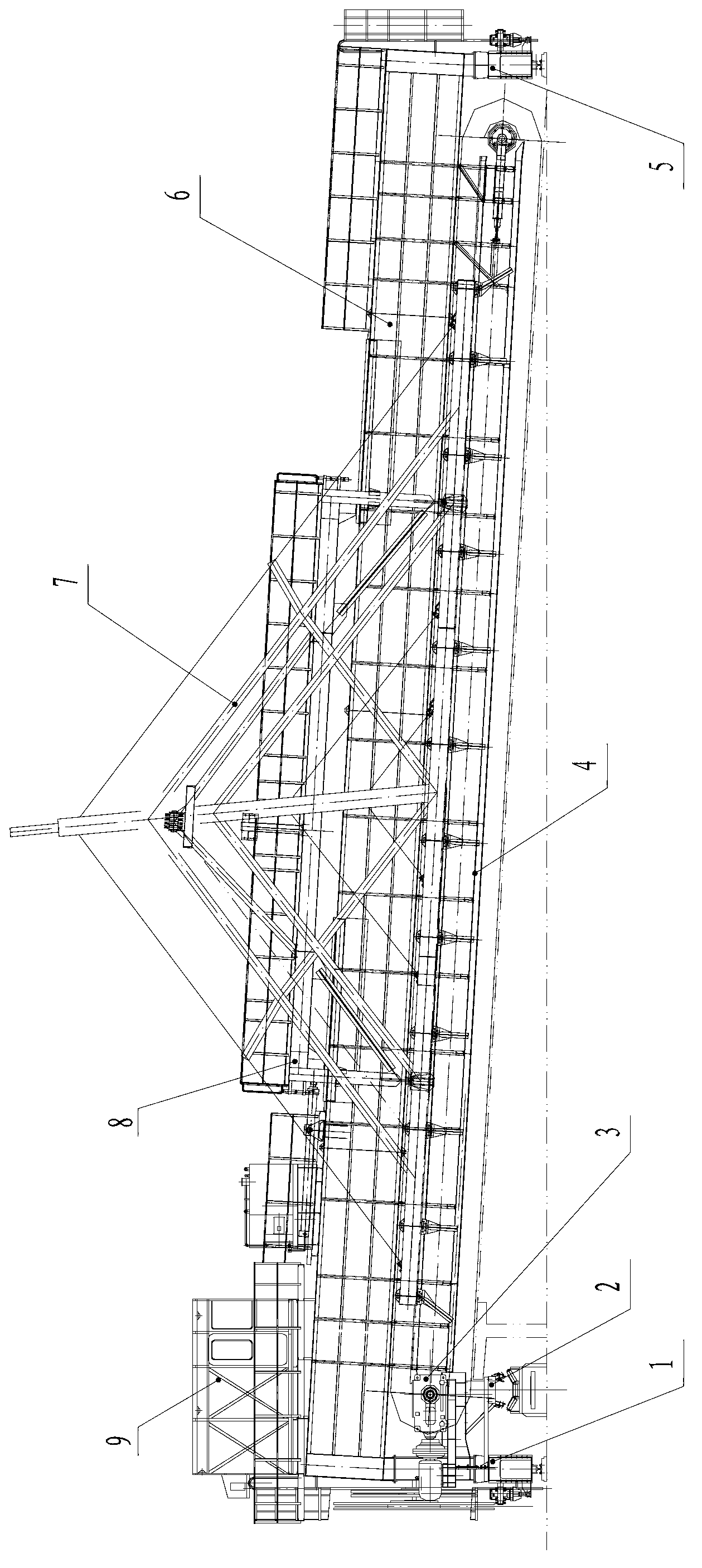

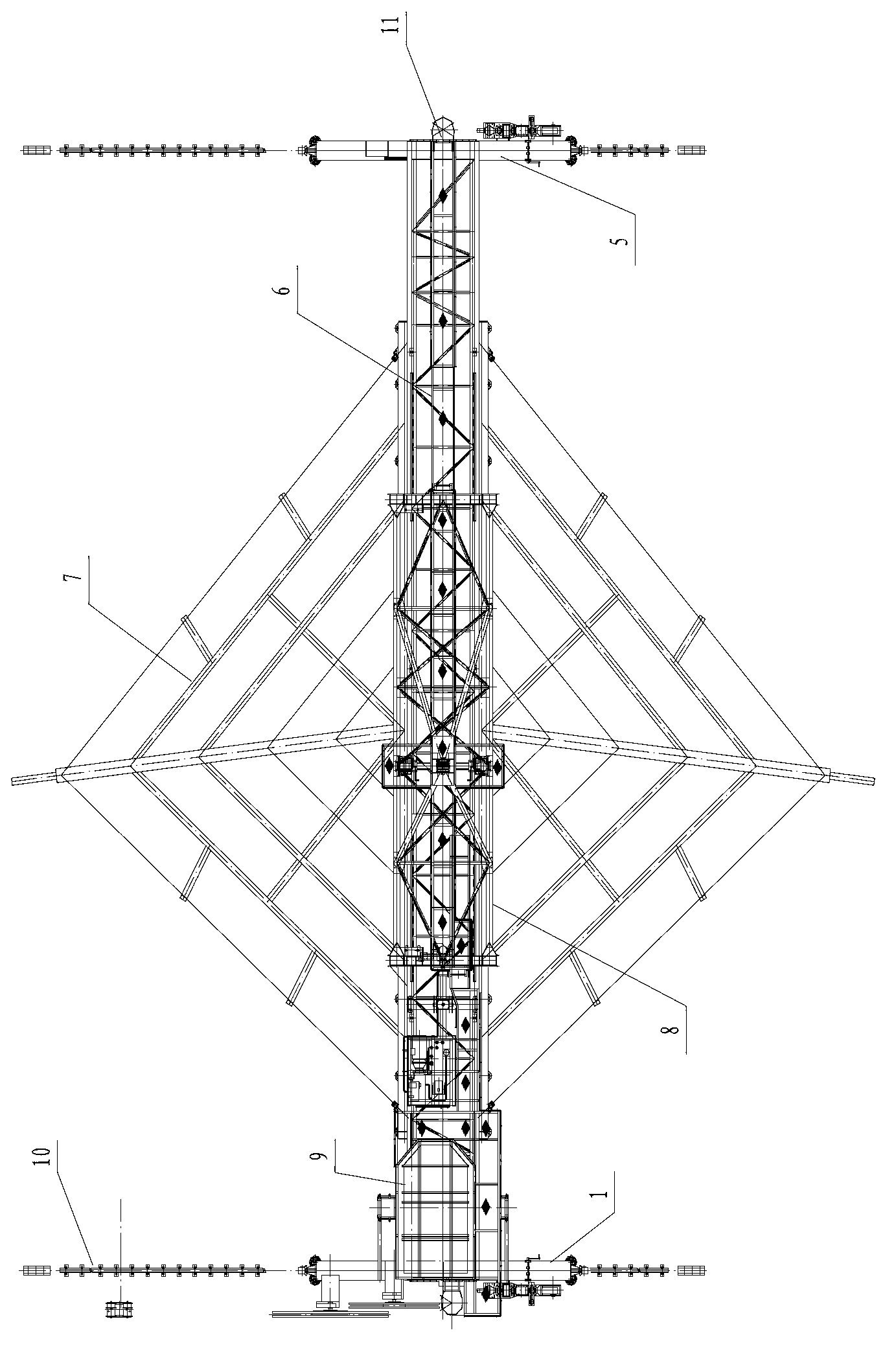

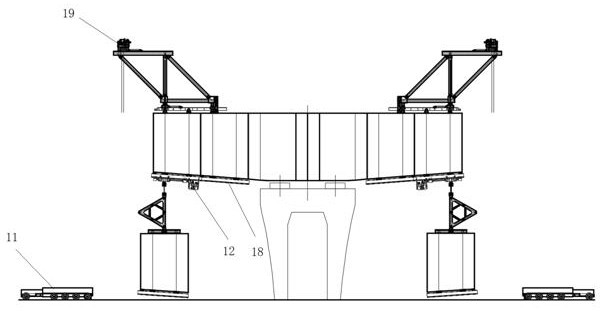

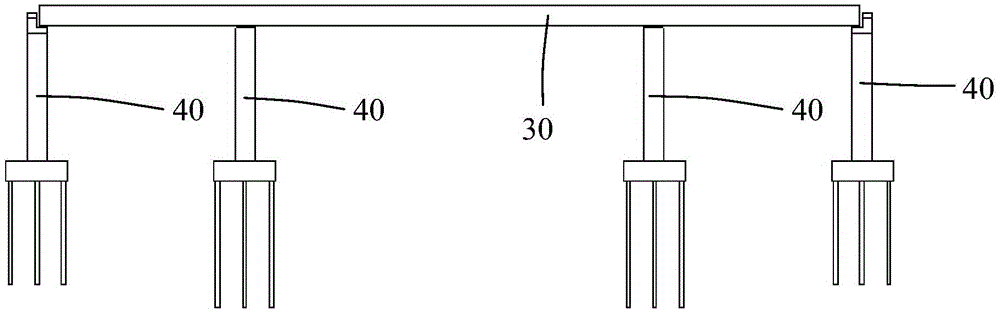

Double-beam walking-type bridge girder erection machine used for box girder erection and compatible with G-series high-speed train single-line and double-line girder erection

PendingCN108824218AGuaranteed swingAvoid constructionBridge erection/assemblyEngineeringBeam walking

The invention relates to a double-beam walking-type bridge girder erection machine used for box girder erection and compatible with G-series high-speed train single-line and double-line girder erection and belongs to the technical field of bridge girder erection machines. The bridge girder erection machine comprises main beams, supporting legs, overhead travelling cranes, an electric control system, a hydraulic system and a power system and is characterized in that the supporting legs include a front supporting leg, a middle supporting leg, a via hole supporting leg and a rear supporting leg,the overhead travelling cranes include a front overhead travelling crane and a back overhead travelling crane, the front supporting leg, the middle supporting leg and the rear supporting leg are sequentially connected and arranged at a main beam supporting leg installing position, a middle supporting leg installing position and a rear supporting leg installing position. The double-beam walking-type bridge girder erection machine has the advantages that a walking-type structure form is adopted, the construction problem under complicated working conditions is solved, and the adaptability and working efficiency of the machine are improved; the bottom of the front supporting leg and the bottom of the via hole supporting leg are both provided with transverse moving mechanisms, and constructionof a curve R smaller than 2000 m is really solved; the machine is compatible with G-series high-speed train single-line and double-line box girders, and the utilization rate of the machine is improved.

Owner:徐州徐工铁路装备有限公司

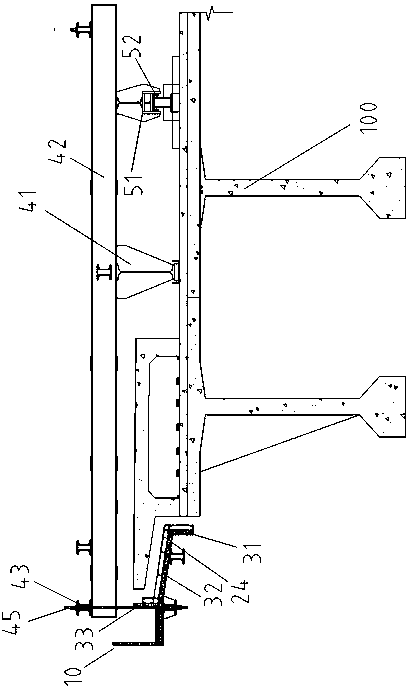

Culvert trolley

The invention provides a culvert trolley which comprises a portal, a ground beam walking device, an inner template panel, an inner template motion adjustment device, an outer template panel and an outer template motion adjustment device, wherein the portal comprises a template slide beam, a small upright, an upper longitudinal beam and a large upright; the ground beam walking device comprises a ground beam support and walking wheels; the template slide beam is fixedly connected to the upper end of the small upright; the lower end of the small upright is fixedly connected to the upper longitudinal beam; the upper longitudinal beam is also fixedly connected to the upper end of the large upright; the lower end of the large upright is fixedly connected to the ground beam support; and the walking wheels are in rotatable connection with the ground beam support. The culvert trolley provided by the invention has the beneficial effects that a culvert wall body can be manufactured easily throughadjustment of an interval between the outer template panel and the inner template panel, and the culvert trolley can walk to a next section of culvert wall body for continuous manufacture; the outertemplate panel and the inner template are stable in adjustment, and culverts with different specifications can be manufactured; and the whole structure is firm and reliable, manufacture is efficient,and use is convenient.

Owner:福建祝融工程机械有限公司

Using method of horizontal type oil production and gas exhaust synchronous production device

PendingCN108756819APrevent fallingAvoid safety accidentsConstructionsFluid removalBeam walkingReciprocating motion

The invention relates to a using method of a horizontal type oil production and gas exhaust synchronous production device. According to the technical scheme, an gas inlet pipe of a wellhead connectingshort section is connected to the horizontal type gas exhaust device, and a suction piston and a return spring are installed in an inner cavity of a horizontal type sealing cylinder liner; the outerend of the suction piston in the horizontal type sealing cylinder liner is connected to a draw cord position finding block by winding a fixed pulley through a draw cord, and the draw cord position finding block is installed at the rear end of a walking beam; the beam walking is driven by an electric motor to swing up and down, and the oil production is realized while gas exhausting. The using method of the horizontal type oil production and gas exhaust synchronous production device has the beneficial effects that the reciprocating motion of a walking beam type pumping unit is utilized to enable the horizontal type gas exhaust device to discharge natural gas in a casing in time, the weight principle of the walking beam type pumping unit and the conversion of potential energy and kinetic energy are utilized to enable a whole pumping system to be more energy-saving, and a horizontal type structure is more safe and reliable; and in addition, the discharge of the natural gas is realized synchronously, and the natural gas is subjected to preliminary removal of hydrogen sulfide to avoid the occurrence of a poisoning safety accident on field staff.

Owner:高新昀

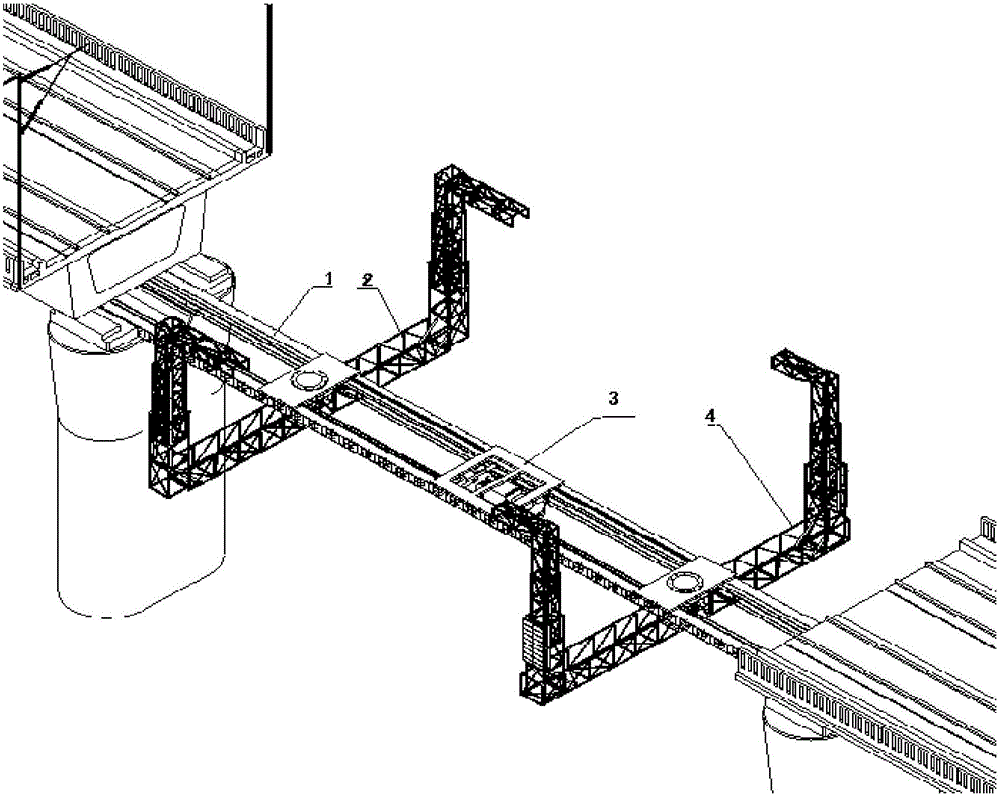

Transverse moving hoisting walking track device of bridge erecting machine

PendingCN110468731AAchieve span adjustmentAchieve angle adjustmentBridge erection/assemblyMovable tracksBeam walkingEngineering

The invention discloses a transverse moving hoisting walking track device of a bridge erecting machine. The machine comprises a connecting beam and a hoisting arm, wherein the hoisting arm is coaxially connected with the connecting beam, an electric walking hoist is arranged on the lower side of the hoisting arm, the connecting beam is connected with the bridge erecting machine through an installing device, the installing device comprises a guide rail, a first connecting body and a second connecting body, the connecting beam is clamped by the second connecting body, the guide rail is fixed onthe lower side of the connecting beam, the first connecting body is rotationally connected with the second connecting body to achieve the angle adjustment of the bridge erecting machine, and the second connecting body slides along the guide rail so as to achieve the span adjustment of the bridge erecting machine. According to the transverse moving hoisting walking track device of the bridge erecting machine, the working efficiency of the bridge erecting machine carrying out the transverse moving hoisting of a walking track beam of a front supporting leg can be accelerated, so that the problemof overall transverse moving hoisting of a wide skew bridge beam walking track can be solved in a self-propelled and timely mode.

Owner:上海宝冶市政工程有限公司 +1

Hanging basket track beam walking method

The invention discloses a hanging basket track beam walking method. Buckling wheels are arranged at the front fulcrum and the rear fulcrum of the hanging basket to drive a hanging basket track to lift, walking forward movement of the hanging basket track is realized; large special hoisting equipment is not used, evidence obtaining and approval procedures can be effectively reduced, the construction cost and the hoisting operation risk are reduced, the hanging basket track integrally travels forwards, the site assembling, disassembling and transferring procedures are reduced, track damage is avoided, the traveling efficiency is improved, and the hanging basket can be manually moved forwards only by means of rolling friction resistance of the buckling wheels in the traveling and forward moving process. The method is applied to the field of hanging basket construction.

Owner:CHINA RAILWAY GUANGZHOU ENG GRP CO LTD +1

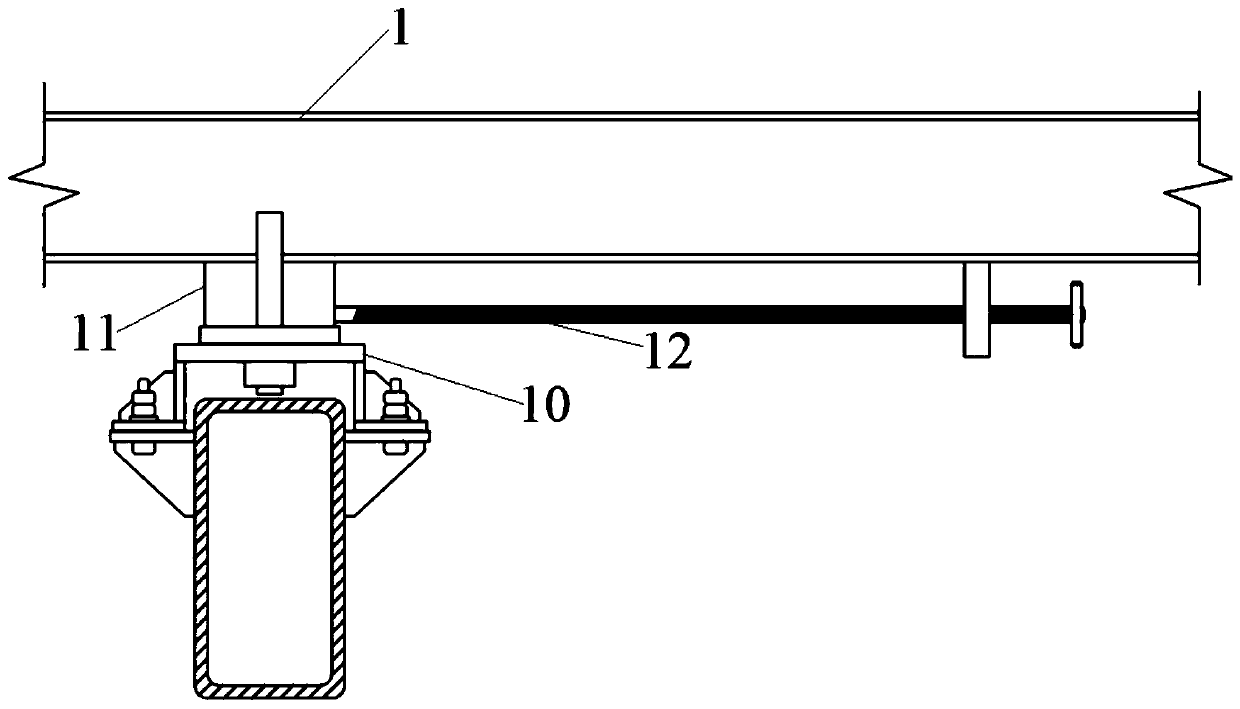

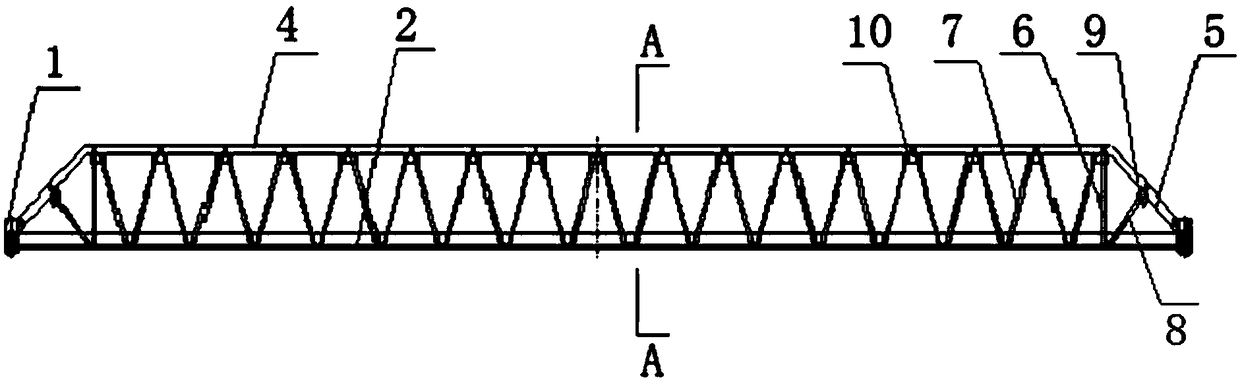

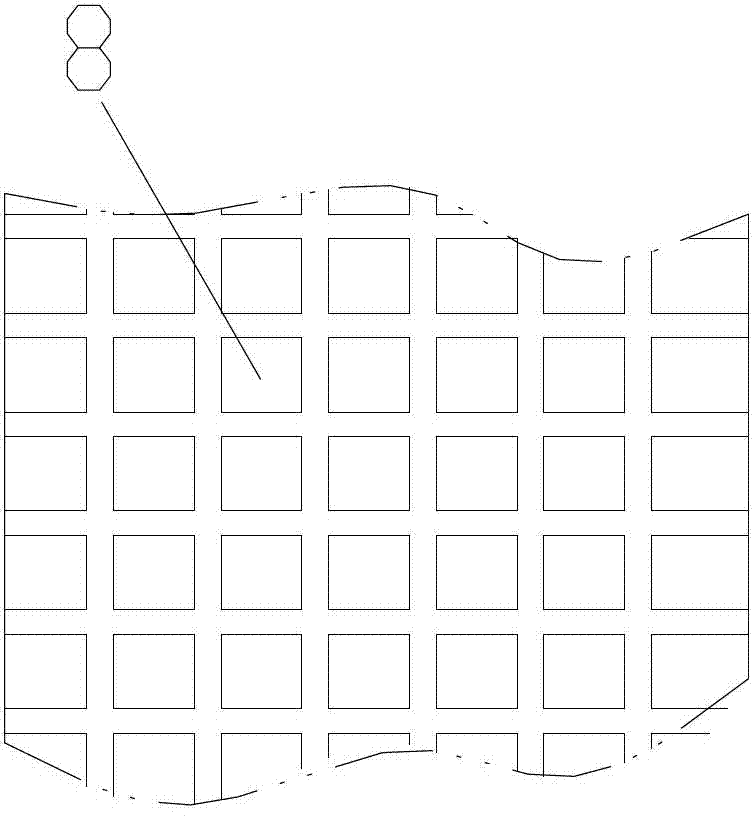

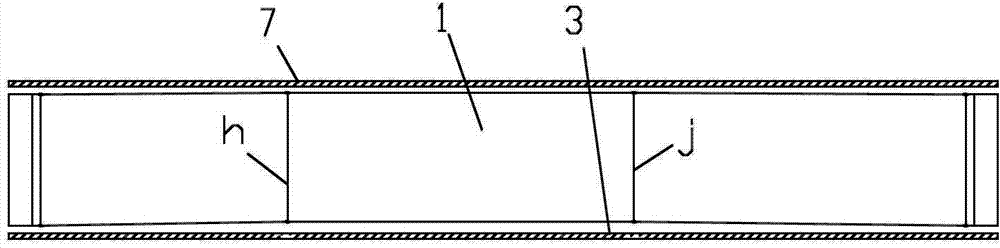

Main beam structure of electric single-beam bridge crane

InactiveCN109264574ASmall wheel pressureLower requirementLoad-engaging girdersBeam walkingEngineering

The invention belongs to the technical field of cranes, and provides a main beam structure of an electric single-beam bridge crane. The main beam structure comprises end beam walking mechanisms whichare arranged symmetrically, and further comprises a bottom plate and a top plate which are arranged horizontally in parallel. Fixing rods which are arranged symmetrically are fixedly connected to thetwo ends of the top plate, the two ends of the bottom plate are fixedly connected with the two end beam walking mechanisms respectively, the two ends of the fixing rods and the two end beam walking mechanisms are fixedly connected through inclined connecting rods, vertical straight web membranes are fixedly connected between the two ends of the fixing rods and the two corresponding ends of the bottom plate, multiple inclined web members which are arranged at intervals are fixedly connected between the fixing rods and the bottom plate, every two adjacent inclined web members are arranged symmetrically, and inclined supporting rods are fixedly connected between the connecting rods and the bottom plate. The main beam structure is small in self weight, the appearance is attractive, and the problem that an existing main beam structure of the electric single-beam bridge crane is large in self weight is solved.

Owner:HENAN SHENGHUA HEAVY CRANE

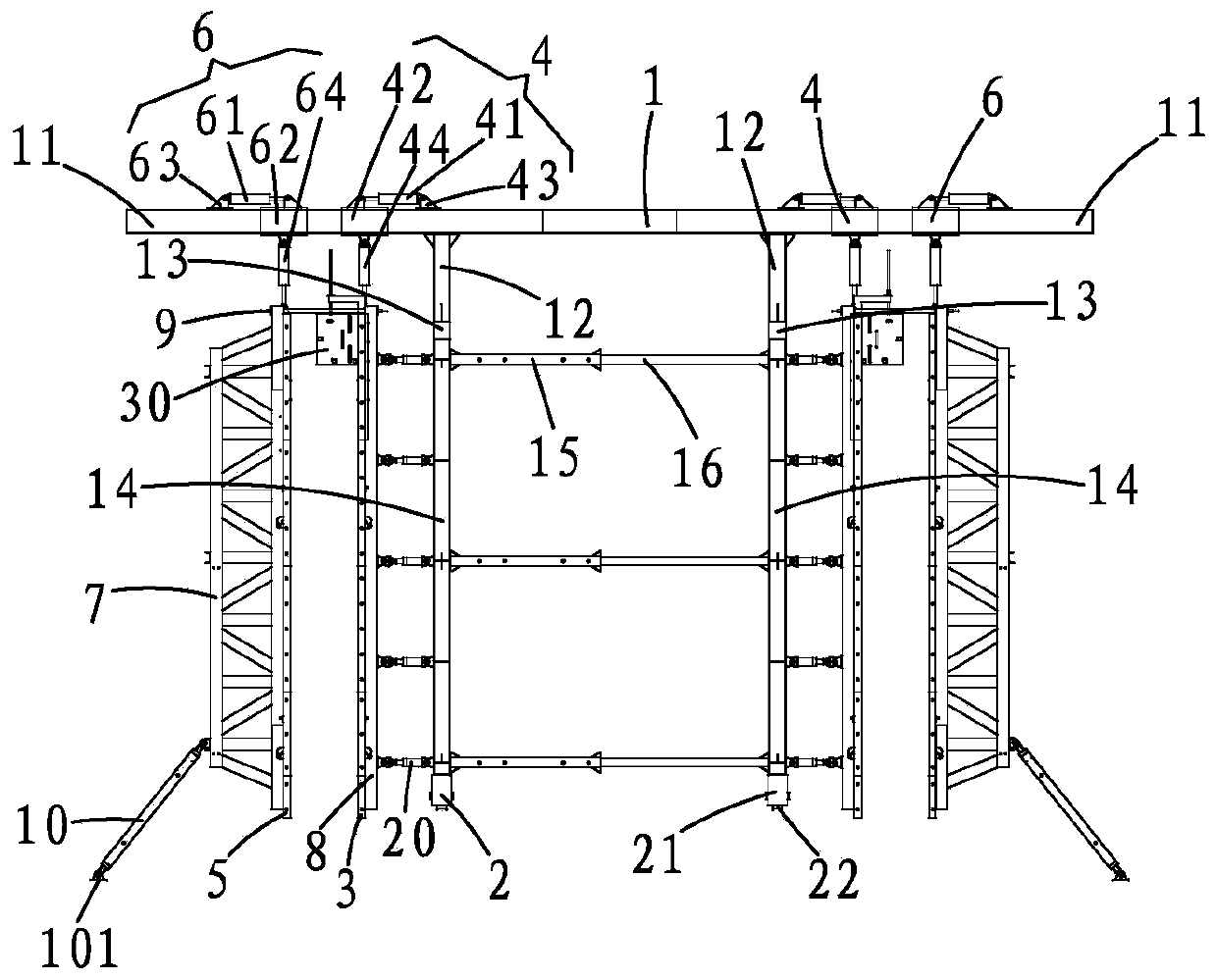

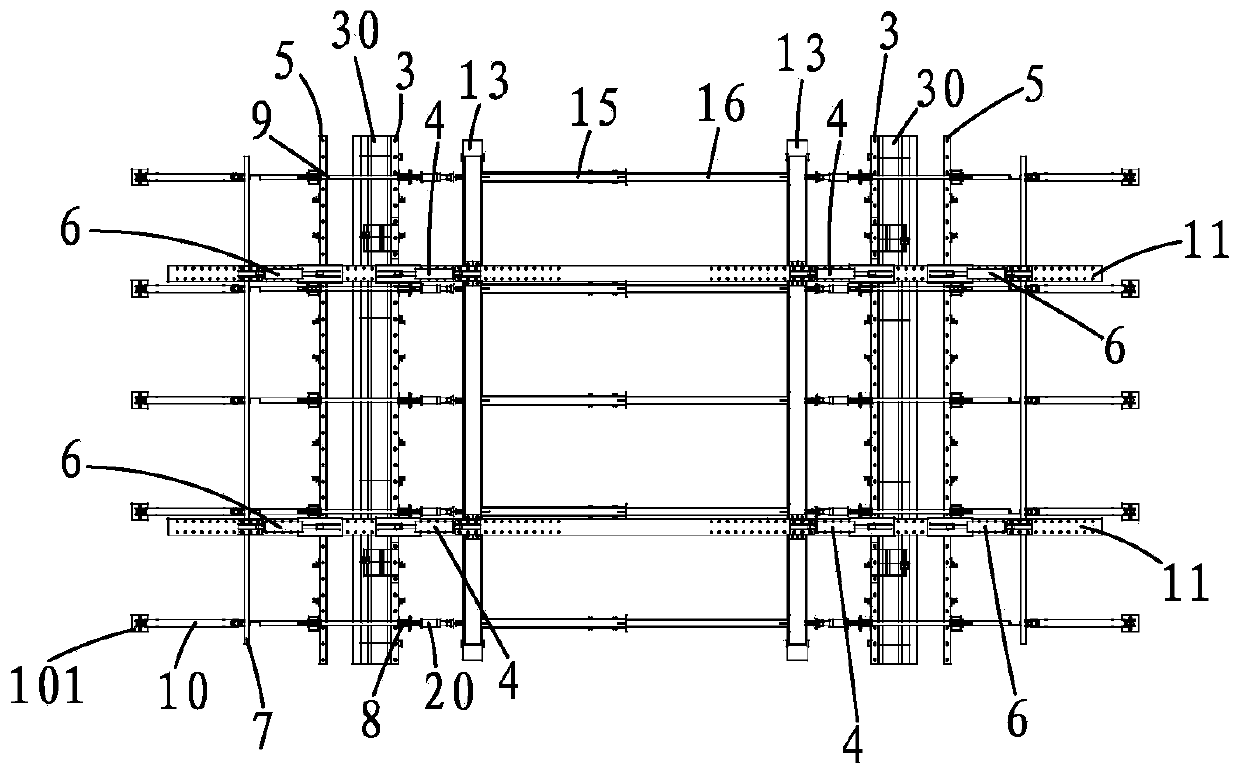

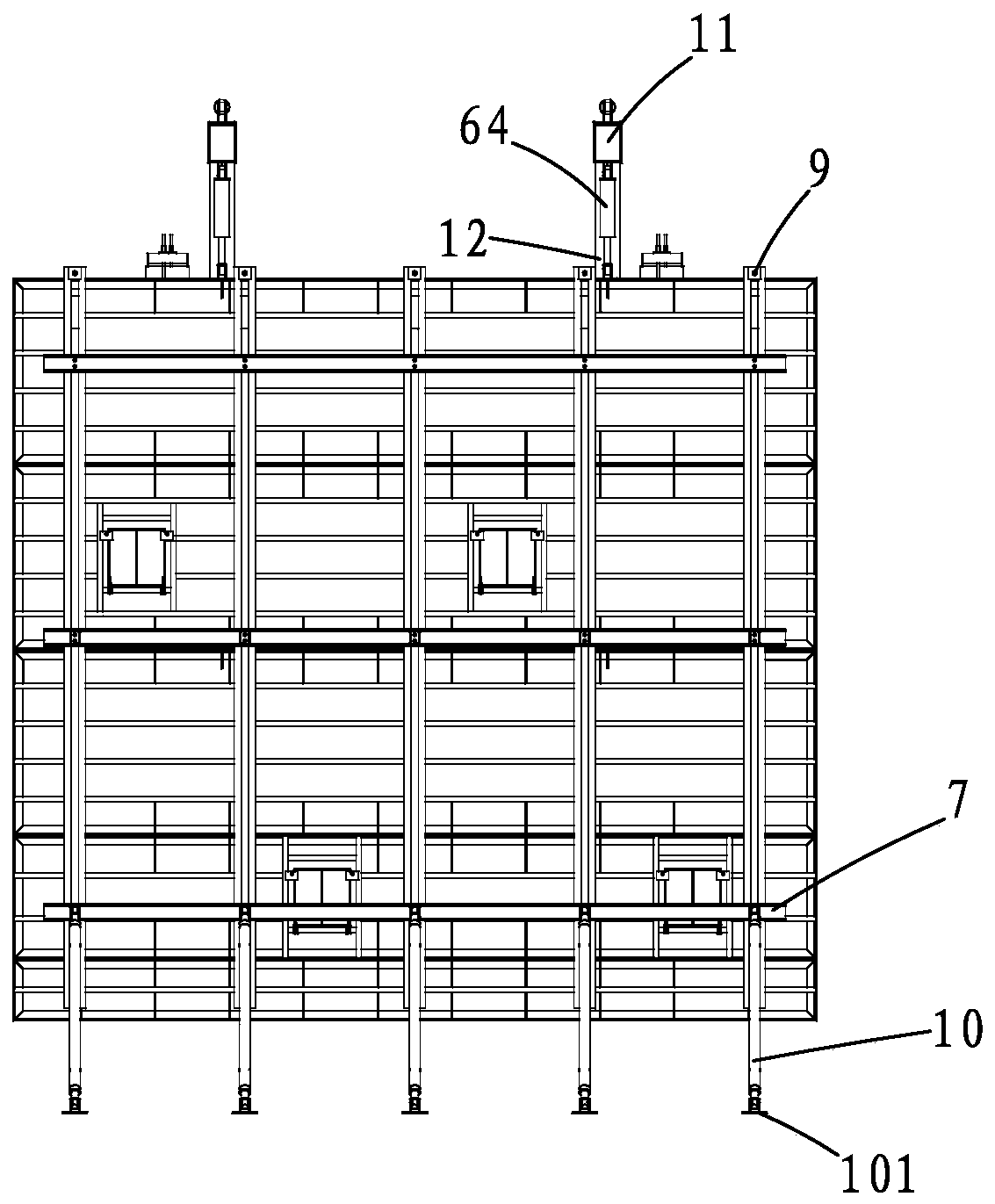

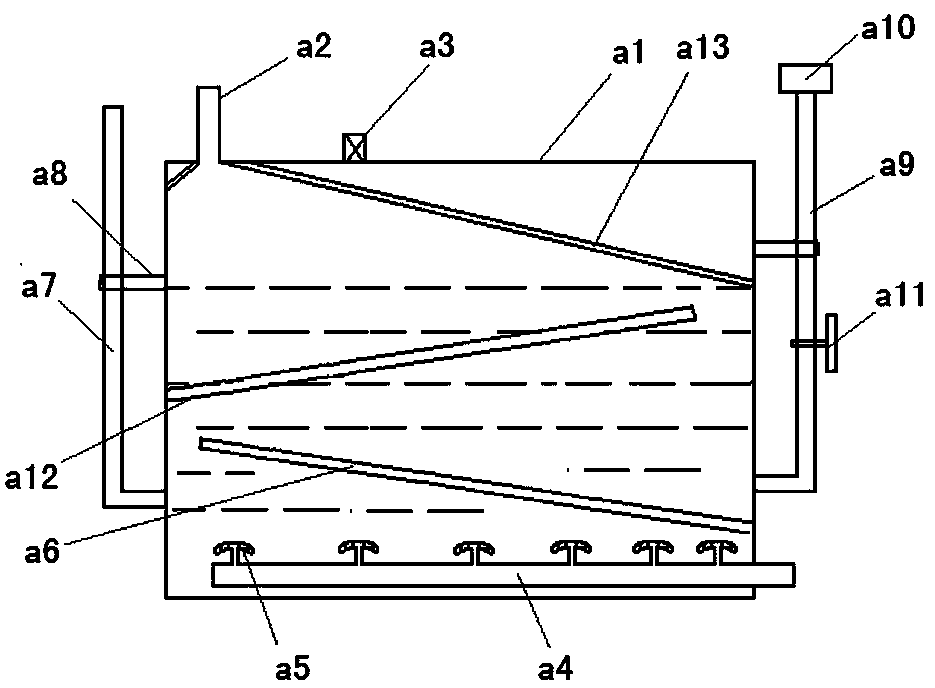

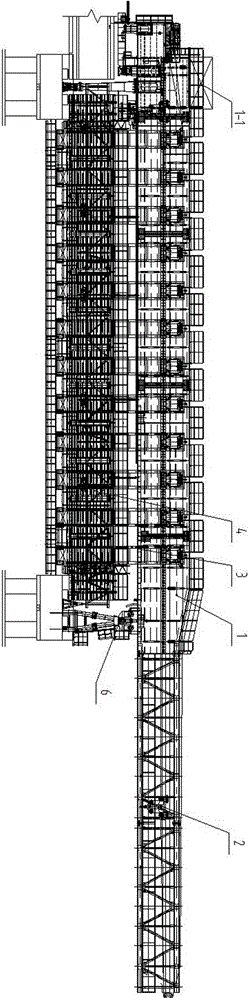

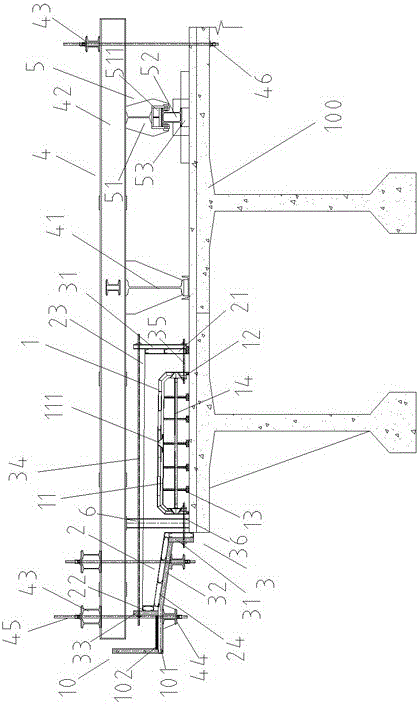

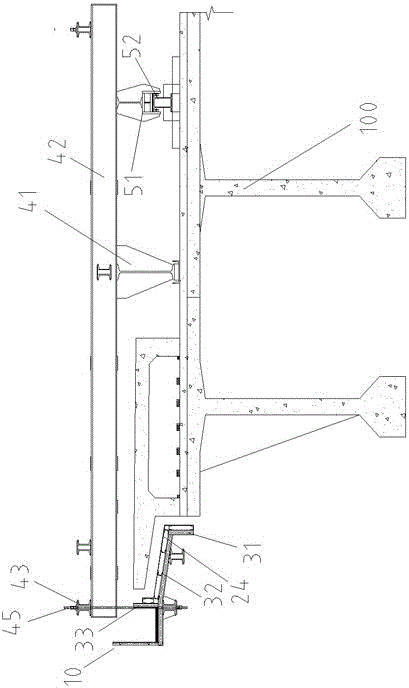

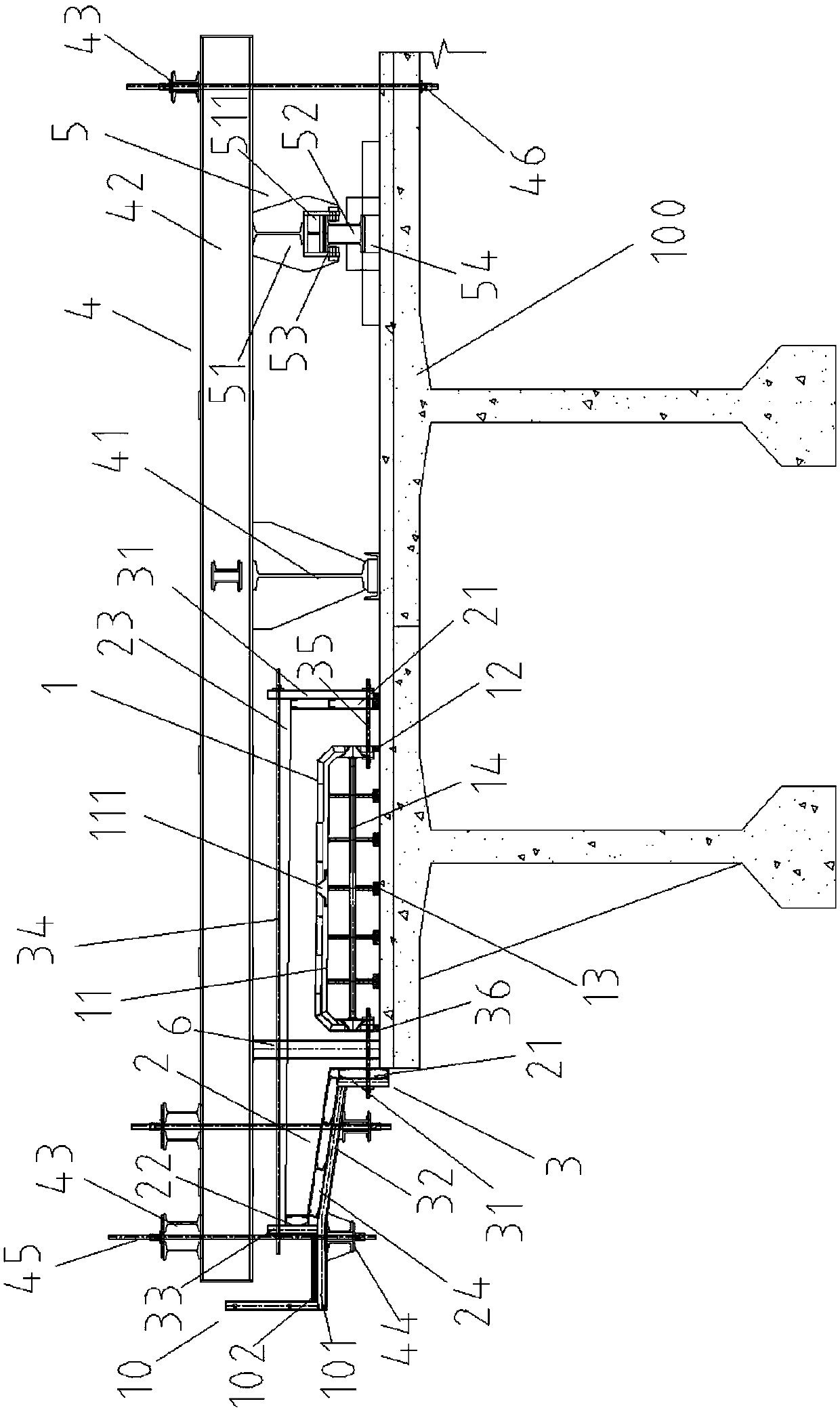

Movable formwork for single rectangular top closed type water conservancy aqueduct construction

ActiveCN106149639AReduce investmentShorten the construction periodArtificial water canalsPunchingBeam walking

The invention relates to a movable formwork for single rectangular top closed type water conservancy aqueduct construction. The movable formwork comprises an outer beam system, an inner beam system and a hoisting system, wherein the outer beam system comprises an outer beam, an outer rib, an outer formwork, a No.1 landing leg, a No.2 landing leg, a No.3A landing leg, a No.3B landing leg and No.4 landing leg; the No.2 landing leg, the No.3A landing leg and the No.3B landing leg are matched with each other so as to move the outer formwork under the driving of a girder; the inner beam system comprises an inner beam, an inner beam holding support leg, an inner beam walking support leg and an inner formwork; the inner beam has a single girder truss structure; the inner formwork is driven to move by the inner beam walking support leg; the hoisting system comprises a hauling mechanism and a hoisting mechanism; the hoisting system can drive the landing leg to move to an effective construction position. According to the invention, in the manner of striding the outer beam for a half of length, positioning the No.3B landing leg on a groove surface while pouring, driving the outer beam to walk by the hydraulic system and punching twice, the punching manner is more stable and safe and the structure form and construction mode are different from those of the previous water conservancy aqueduct machine.

Owner:ZHENGZHOU NEW DAFANG HEAVY IND & TECH

Suspended combined hydraulic beaming device

InactiveCN101761347AImprove securityImprove reliabilityProps/chocksBeam walkingStructural engineering

The invention relates to a beaming device, in particular to a suspended combined hydraulic beaming device, which is structurally characterized by comprising a main beam. The main beam is provided with a secondary beam; the upward side of a main beam support sleeve on the main beam is connected with a hanging grip cylinder by a hanging grip lift oil cylinder; the hanging grip cylinder is connected with a hanging grip by a hanging grip connecting rod; the main beam support sleeve is also connected with a main beam walking cylinder and a hanging arm walking cylinder which are arranged on the main beam; the end of the main beam is provided with a beam support arm seat; and the beam support arm seat is connected with a beam support mechanism. Compared with the prior art, the suspended combined hydraulic beaming device has the characteristics of reasonable design, simple structure, convenient operation, flexible and firm installation and the like.

Owner:刘卫平

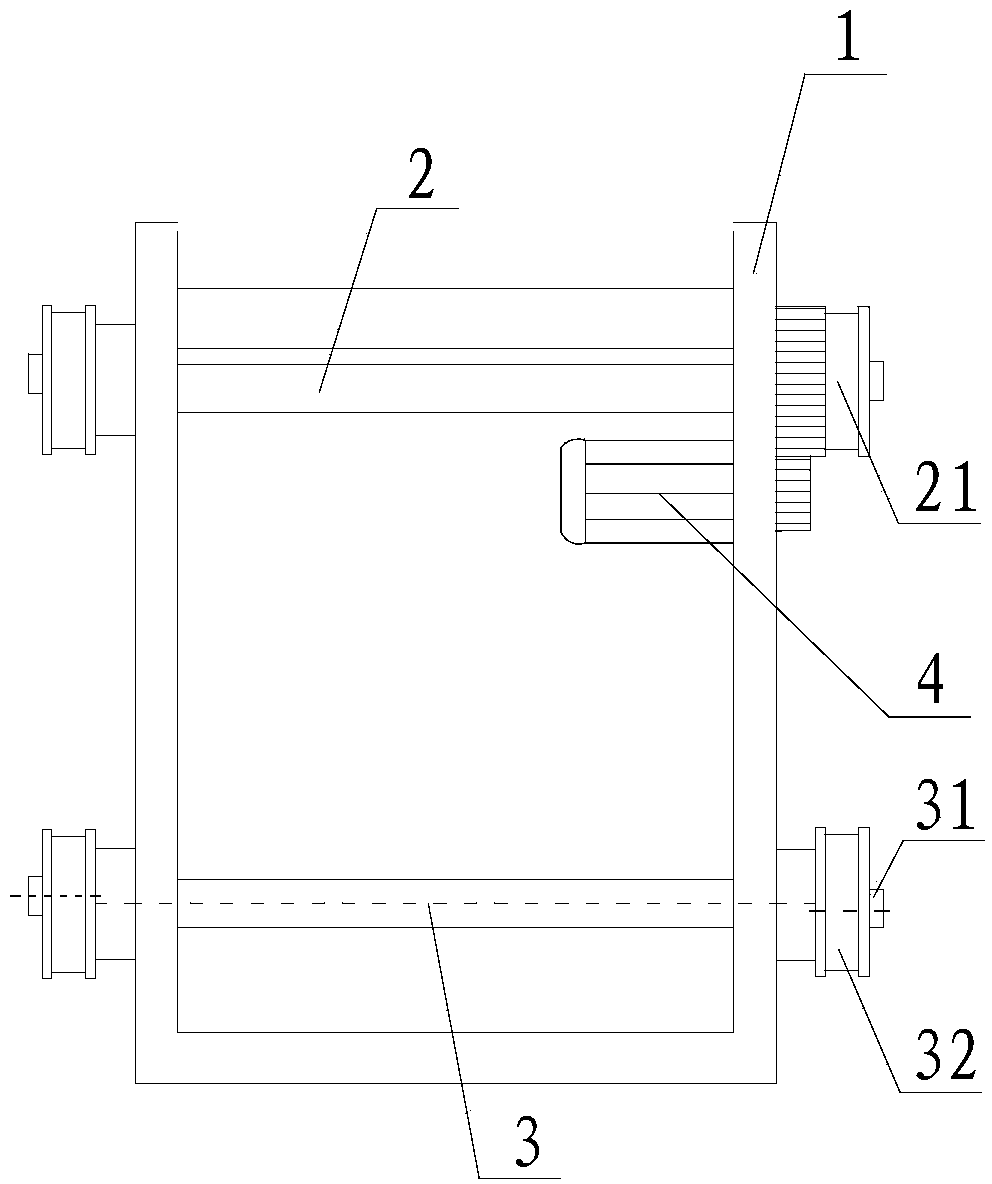

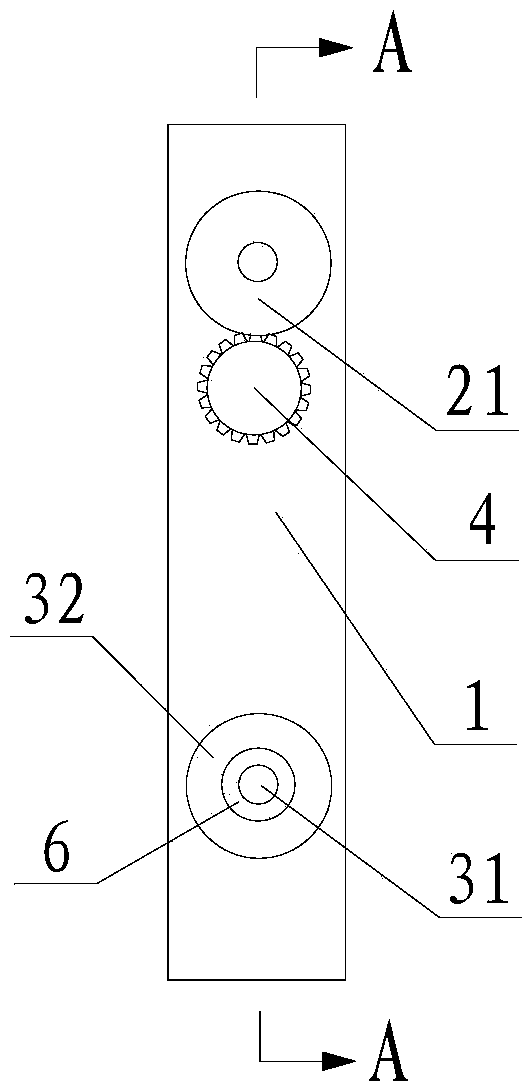

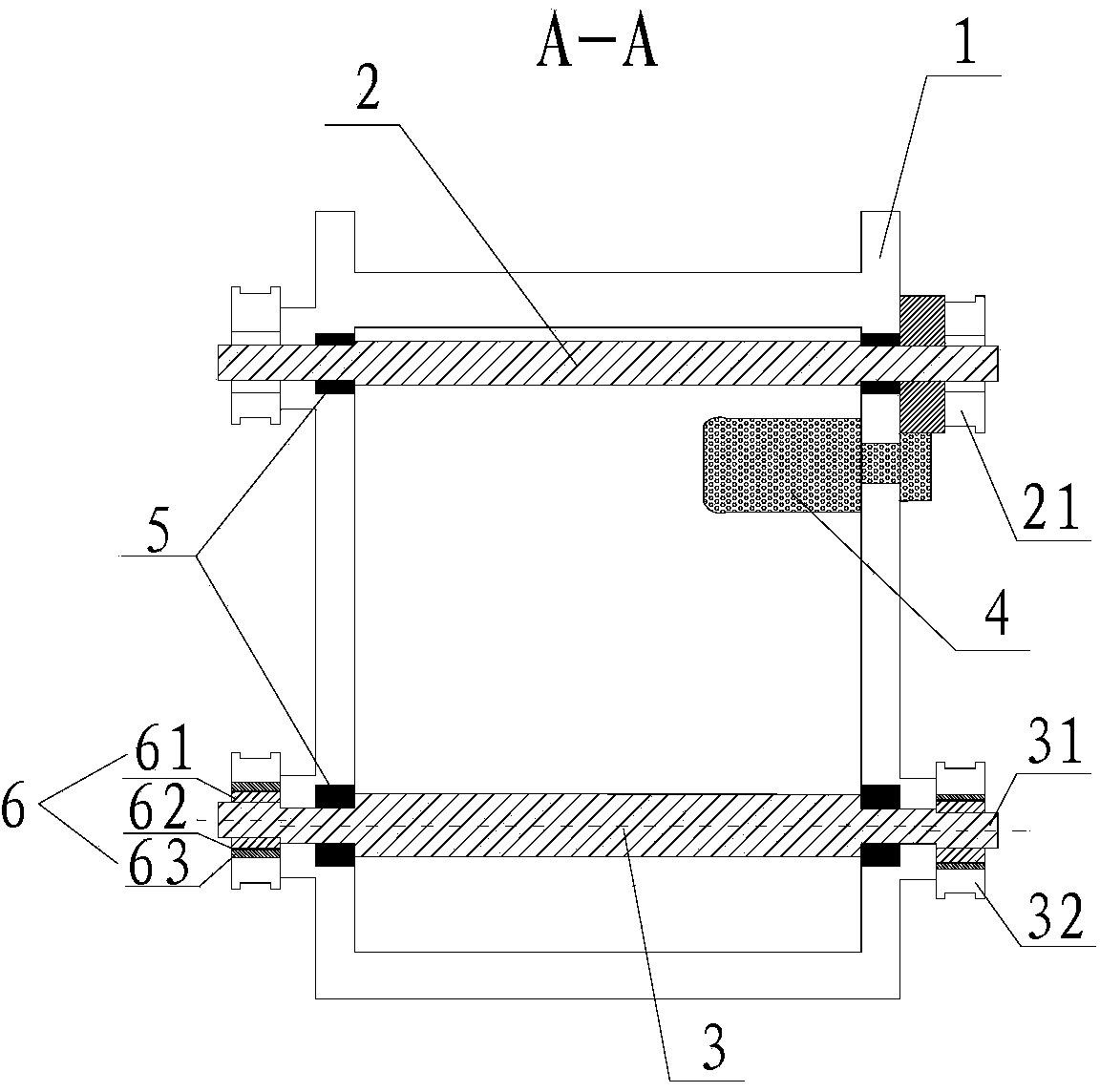

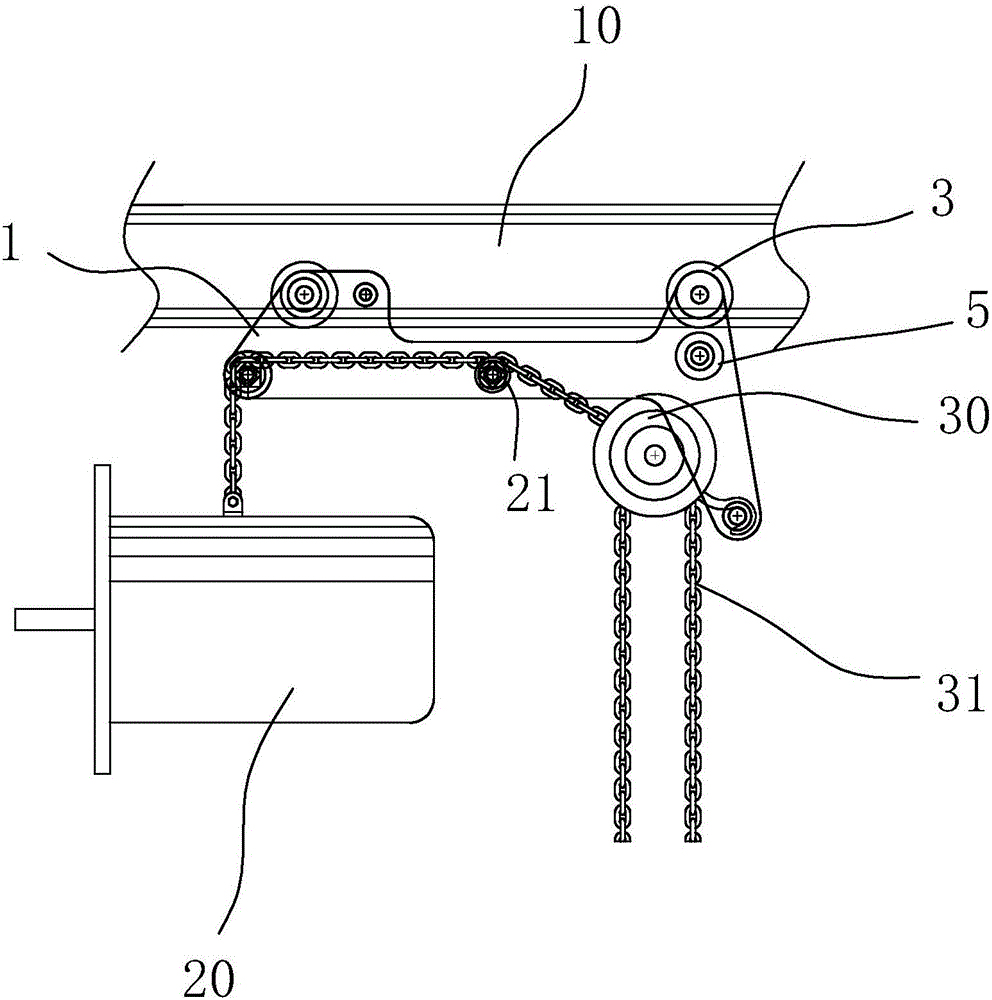

Double-beam walking trolley

The invention relates to a double-beam walking trolley, comprising a square frame body, a driving shaft and a driven shaft which can be rotatably penetrated in the square frame body, driving wheels located on the outer side of the square frame body and fixed at the two ends of the driving shaft, and a motor installed in the square frame body, wherein the driving shaft and the driven shaft are mutually parallel and form a horizontal plane, the motor is engaged with one driving wheel, columnar projections are integrally fixed at the two ends of the driven shaft, the columnar projections are located on the outer side of the square frame body, the driven wheel is installed on the columnar projections, and the axle wire of the driven shaft and the axle wires of the columnar projections at the two ends of the driven shaft are mutually parallel and are not located on the same straight line. Since the axle wire of the driven shaft and the axle wires of the columnar projections at the two ends of the driven shaft are mutually parallel and are not located on the same straight line, the three-leg phenomenon generated when the walking trolley walks on double beams is overcome, the non-uniform stress condition of the walking trolley is avoided and the service life of the walking trolley is prolonged.

Owner:SUZHOU ZHONGZHOU ANBO CRANE

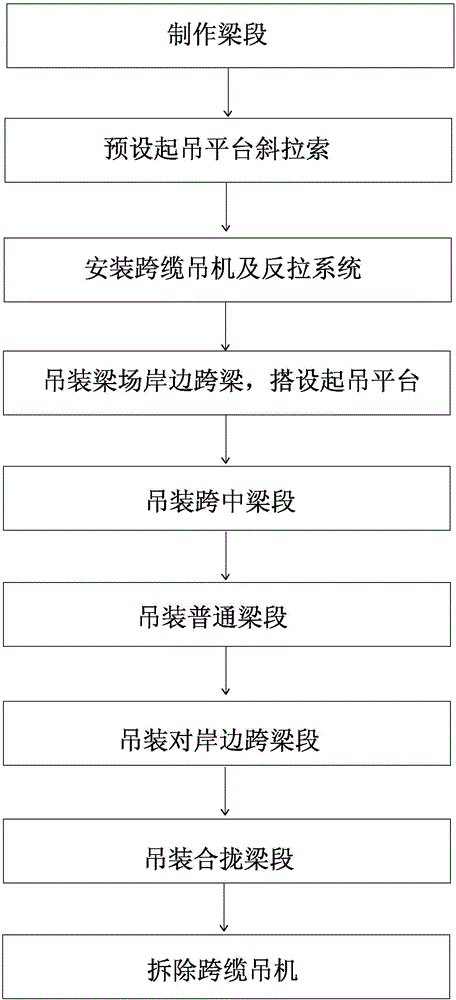

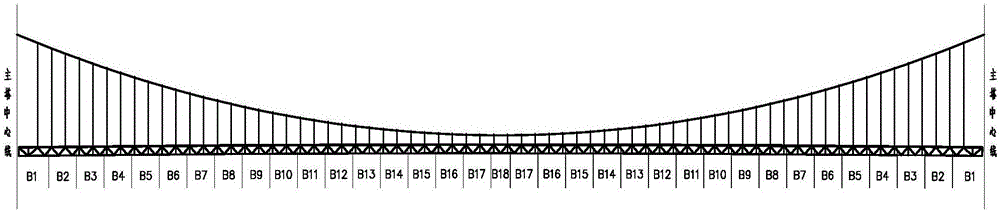

The construction method of hoisting the stiffening beam of suspension bridge with cross-cable crane walking with beam

ActiveCN105839537BSimple processImprove construction efficiencyBridge erection/assemblyBeam walkingCable stayed

The invention provides a construction method for hoisting a stiffening girder of a suspension bridge by adopting girdle-carrying traveling of a deck erection gantry. Firstly, a side span girder segment is mounted through cooperation of reverse pulling systems and the deck erection gantry, is fixed by a prearranged prestress cable-stayed beam and is taken as a hoisting platform for hoisting of other girder segments; a girder field is arranged on one bank, hoisting of all the girder segments is realized through girdle-carrying traveling of the single deck erection gantry, little equipment investment is consumed, the process is simple, the construction efficiency is high, and the cost is low.

Owner:CCCC FOURTH HIGHWAY ENG +1

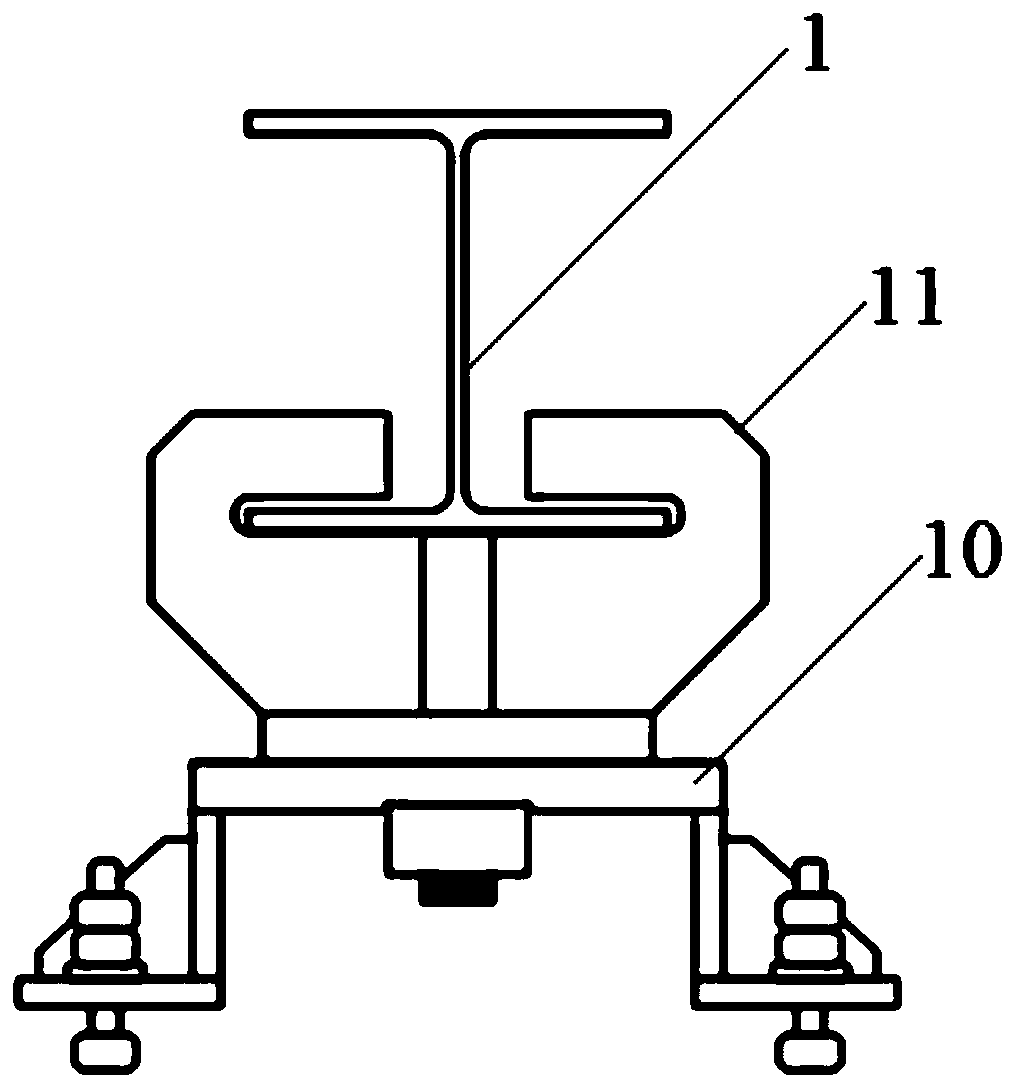

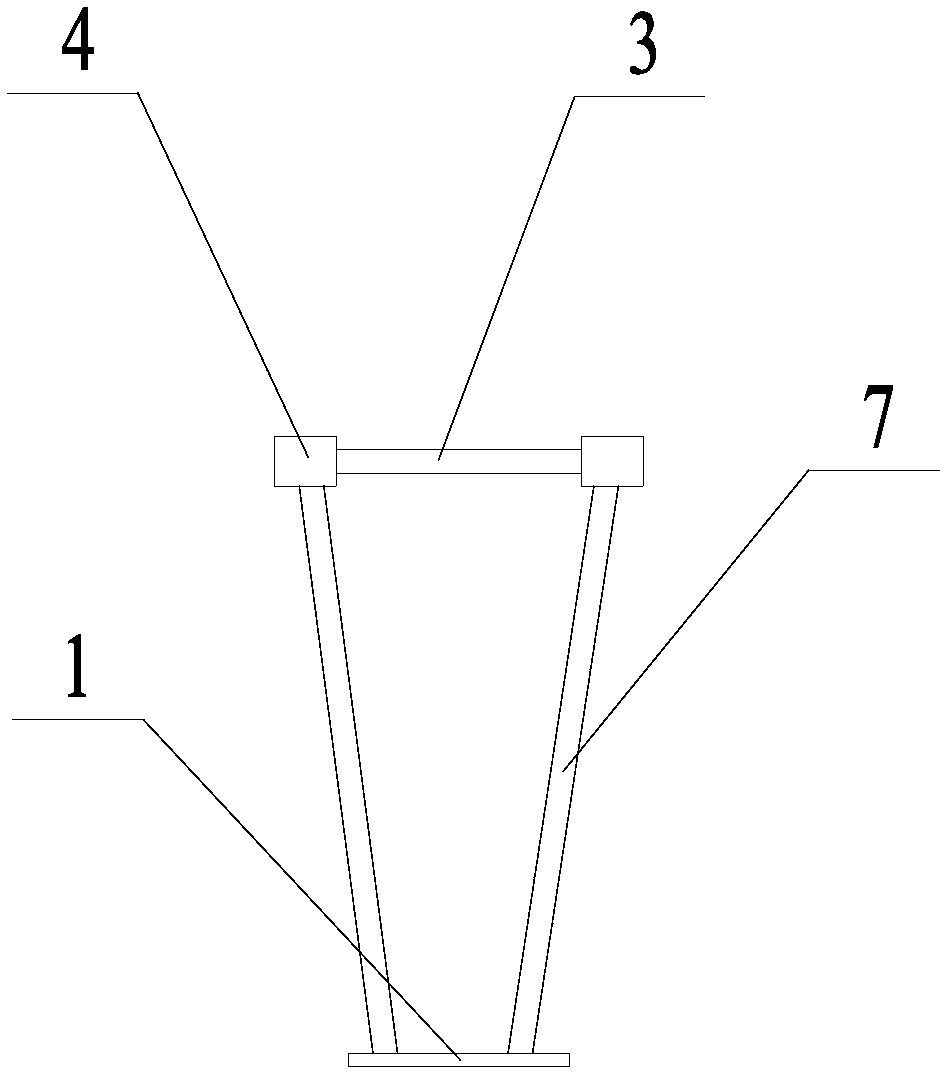

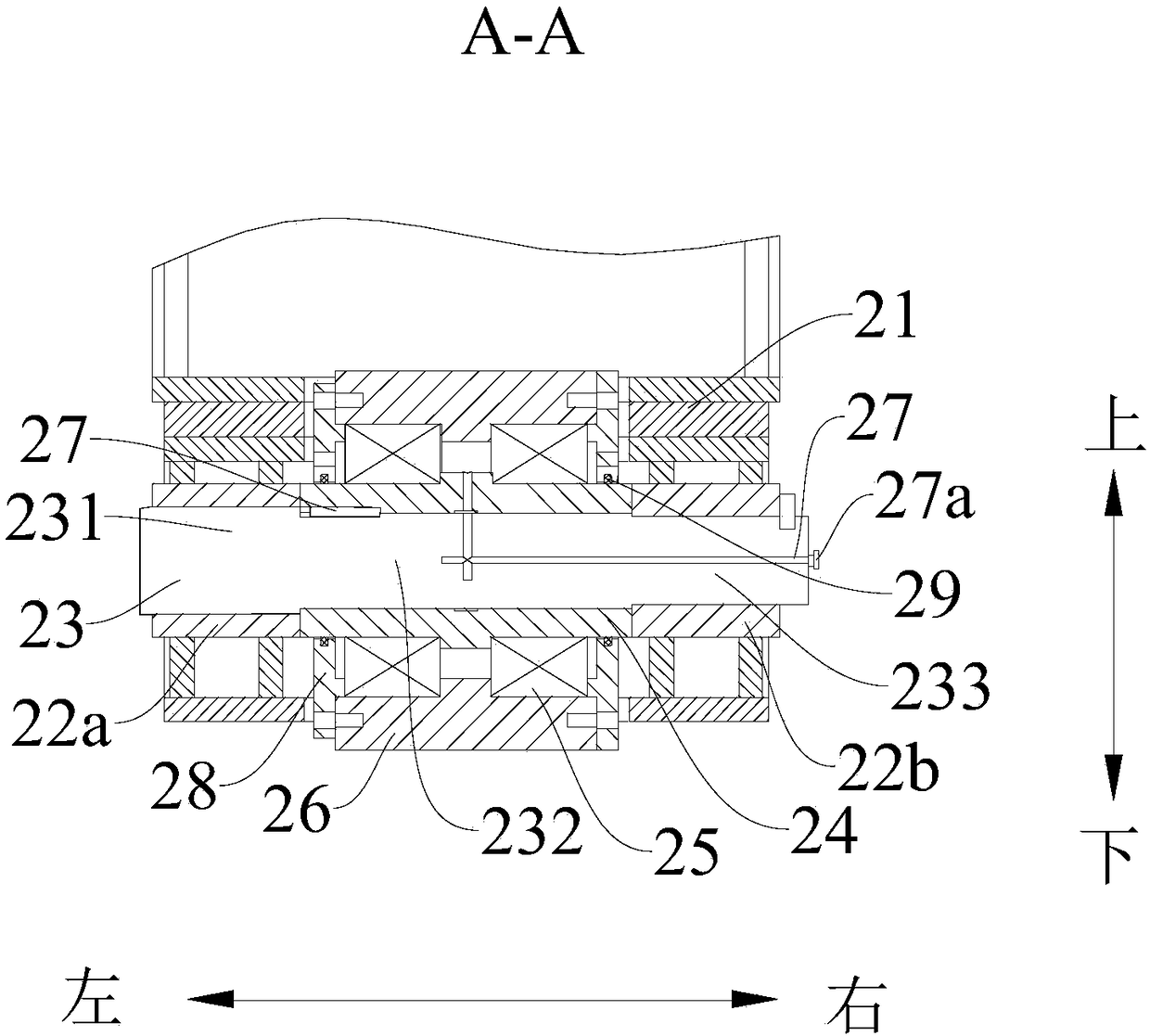

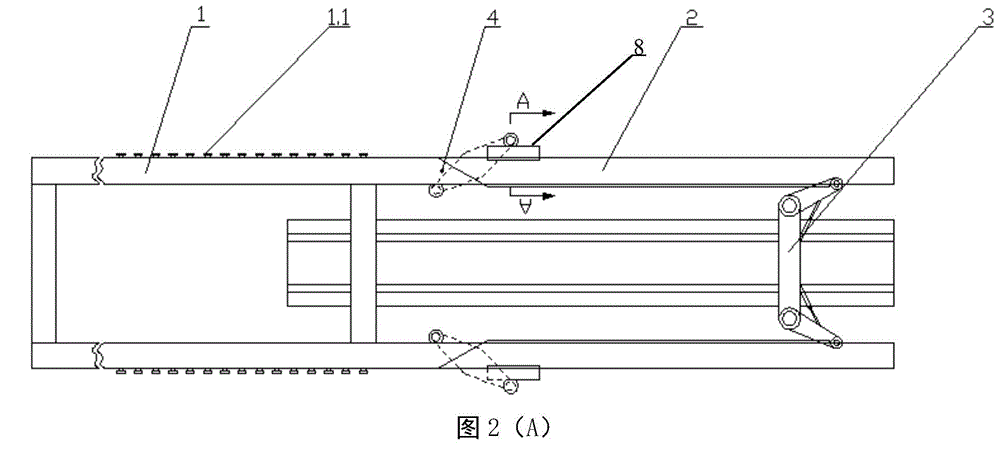

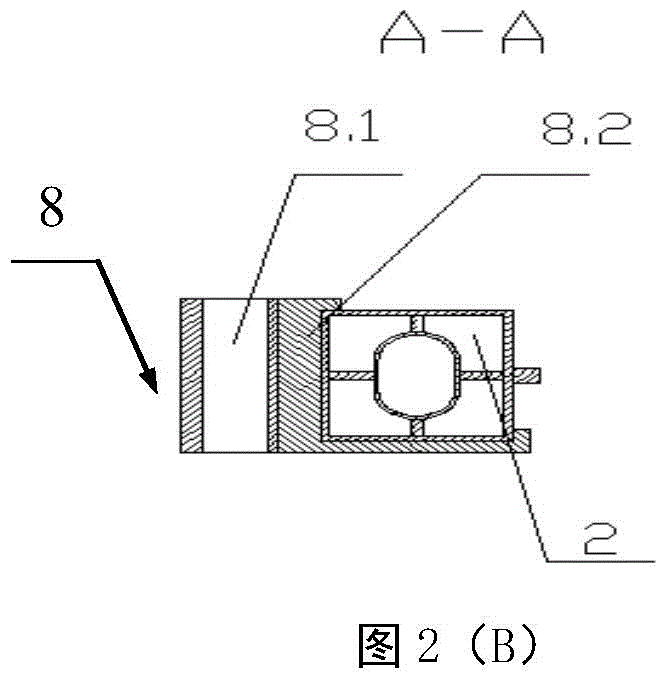

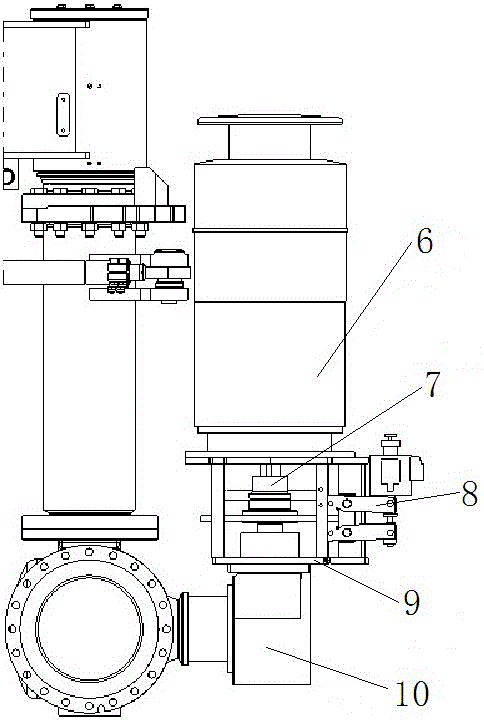

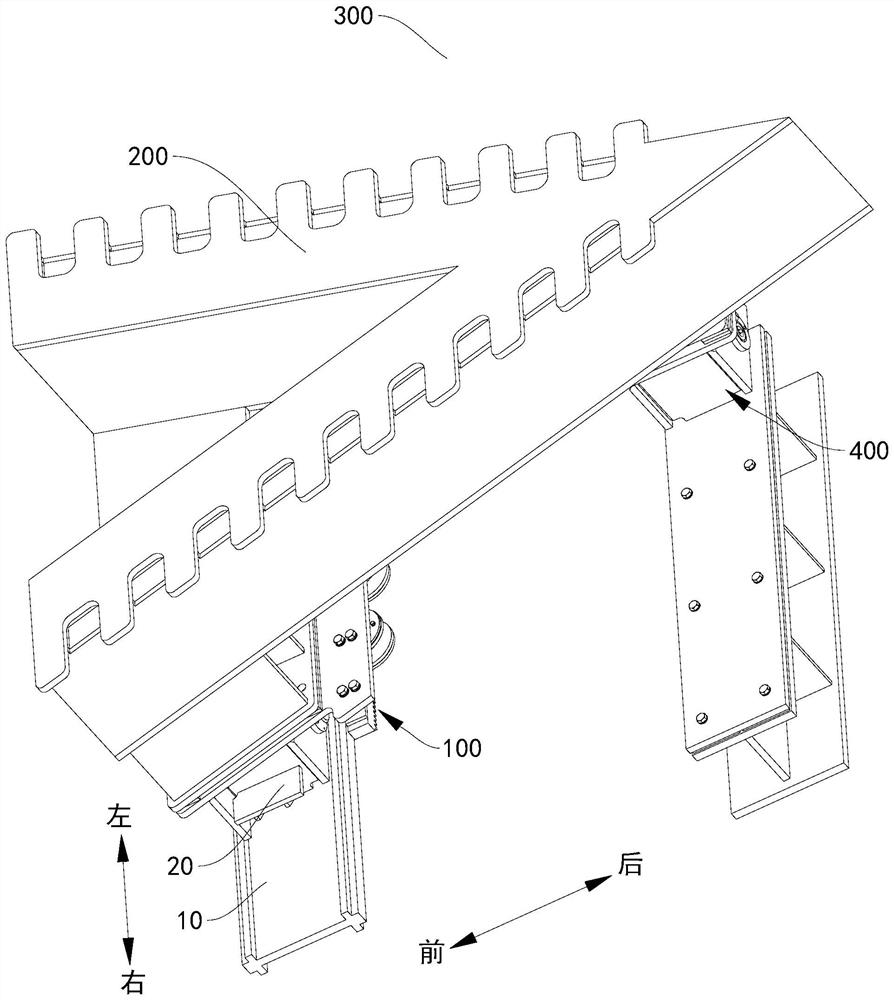

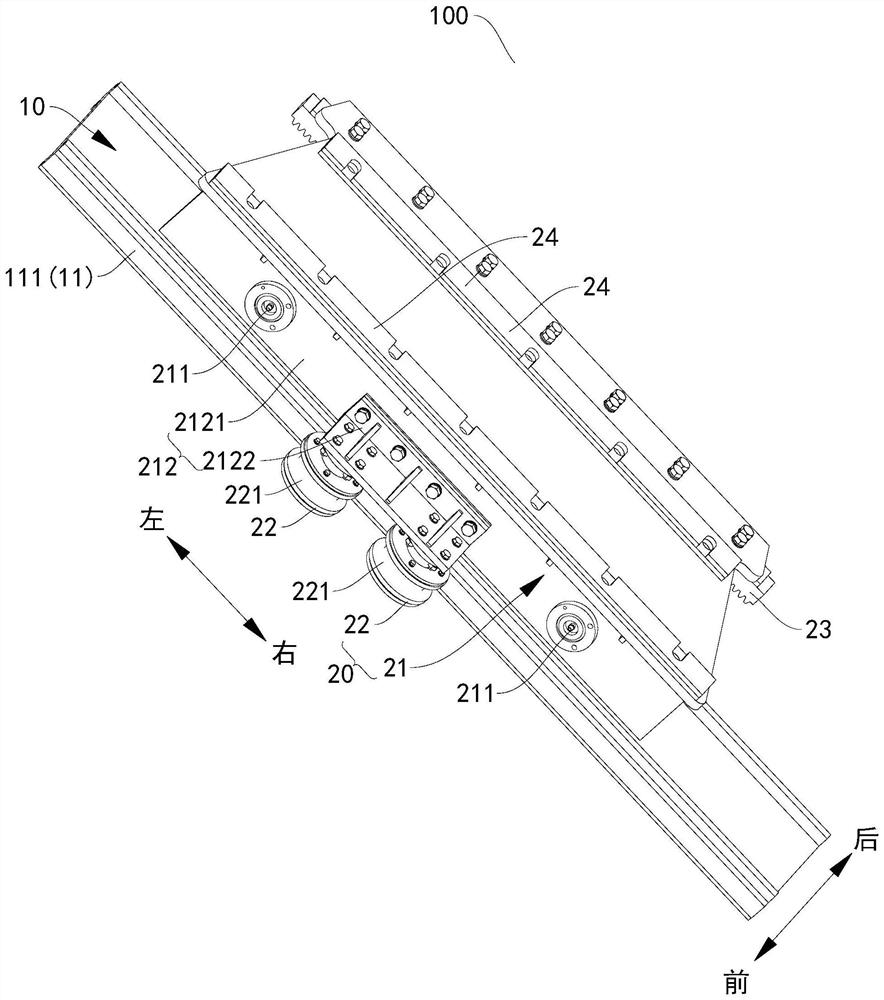

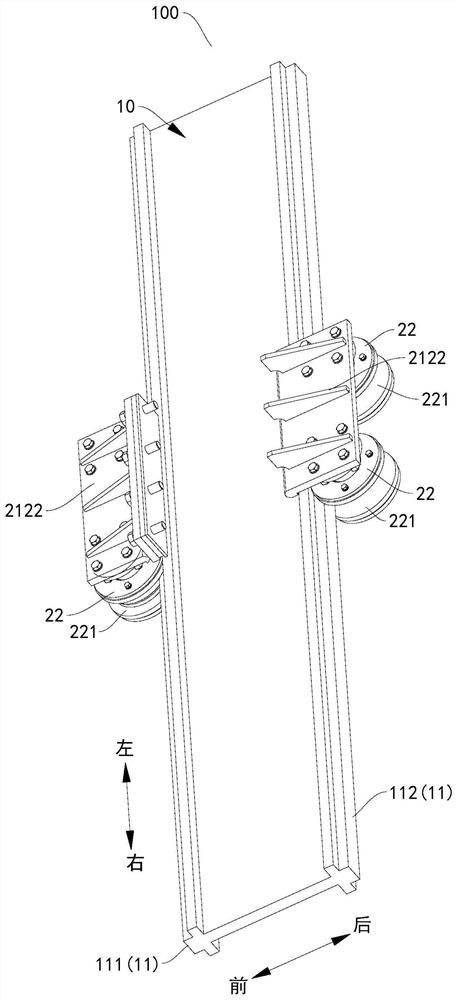

Straddle type monorail turnout beam walking supporting trolley

InactiveCN108263403AGuaranteed structural strengthHigh degree of modularityMonorailsCarriagesBeam walkingModularity

The invention discloses a straddle type monorail turnout beam walking supporting trolley. The straddle type monorail turnout beam walking supporting trolley comprises a trolley body and a wheel group.The wheel group comprises two groups of wheels, the wheels in each group of wheels are separately arranged on both sides of the trolley body, an included angle exists between the axes of the two groups of wheels, and the wheels are welded to the trolley body in a fitting mode or are connected with the trolley body by bolts. According to the straddle type monorail turnout beam walking supporting trolley, the wheel group and the trolley body are arranged as a split type structure, and the wheel group is connected with the trolley body by bolts or welded to the trolley body in the fitting mode,so that the overall structural strength of the straddle type monorail turnout beam walking supporting trolley is ensured; and at the same time, the degree of modularity and interchangeability of all parts of the supporting trolley are increased, the manufacturing difficulty is reduced, and the production efficiency is improved.

Owner:BYD CO LTD

Scraping plate material taking machine

The invention discloses a scraping plate material taking machine which comprises a machine body and a track system. The machine body comprises a main beam, wherein the side face of the main beam is provided with a rake bracket, a mobile trolley is arranged above the main beam, and the left side and the right side of the main beam are provided with a head wheel end beam walking mechanism and a tail wheel end beam walking mechanism which are matched with the track system. The lower portion of the main beam is provided with a scraping plate chain, a plurality of scraping plates are arranged on the scraping plate chain and include main plates and lining plates, the lining plates are arranged in front of the main plates, and the main plates and the lining plates are curved plates. The scraping plate chain adopts the circular-arc-shaped scraping plates, scraped materials can be effectively prevented from being leaked from two sides of each scraping plate during scraping, and the material taking efficiency is improved. In addition, a deviation rectifying device can effectively prevent the main beam, the head wheel end beam walking mechanism, the tail wheel end beam walking mechanism and other key parts from distorting and deforming, and the service life is greatly prolonged.

Owner:嘉兴市一建机械制造有限公司

Formwork system of bridge cantilever sidewalk slab and construction method

ActiveCN106245534AEnsure construction safetyImprove straightnessBridge erection/assemblyShaped beamBeam walking

The invention discloses a formwork system of a bridge cantilever sidewalk slab. The formwork system comprises an arched combination internal mold and a cantilever combination mold, wherein a cantilever combination mold tensioning device is arranged externally in the longitudinal direction of the cantilever combination mold, a cantilever combination mold suspending device is arranged on the upper side of the cantilever combination mold, a walking combination is arranged between one end of a cross beam and one transverse end of a T-shaped beam combination, suspension rods are arranged in the transverse direction of the T-shaped beam combination, every three suspension rods is set as one row, and multiple rows of suspension rods are arranged in a matrix manner in the longitudinal direction of the T-shaped beam combination. A construction method comprises steps as follows: A, mold installation; B, mold dismounting; C, cross beam walking. The device is compact in structure, the method is simple and easy, two ends of the cross beam are balanced on the basis of the lever principle, safety in construction of concrete pouring of the bridge cantilever sidewalk slab is guaranteed, and the reliability of connection between the bridge cantilever sidewalk slab and the T-shaped beam combination is improved. Formwork joints cannot be staggered, so that the straight degree of the bridge cantilever sidewalk slab in the length direction is increased, and the construction cost is reduced.

Owner:CHINA COMM 2ND NAVIGATIONAL BUREAU 3RD ENG

Dismounting and mounting tool for hoist crane lifting motor

InactiveCN106429930APrecise disassembly positionSave human effortWinding mechanismsMetal-working hand toolsBeam walkingMechanical engineering

The invention discloses a dismounting and mounting tool for a hoist crane lifting motor. The tool comprises two outer side plates which are symmetrically arranged and at least two guide shafts connected between the two outer side plates, guide wheels are arranged in the middle portions of the guide shafts, two moving wheels are arranged above the inner side of each outer side plate, the axes of the four moving wheels are located on the same horizontal plane, the axes of the two guide shafts are located on the same horizontal plane, and positioning rods are located below the inner sides of the two outer side plates; according to the dismounting and mounting tool, a dismounting and mounting workpiece can be wholly suspended on an upper flat beam walking rail through the four moving wheels to transversely move, a hoist crane is fixed to the positioning rods through hooks, a chain on the hoist crane penetrates two moving wheels to be suspended, the suspension end is connected to the position above a crane motor, and therefore through the dismounting and mounting tool, the motor can be driven to transversely and vertically move, and the precise dismounting and mounting position is achieved; through the tool, dismounting and mounting of the crane motor can be completed through extremely small manpower, and the tool can be used for the field of ship construction assisted tools.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD

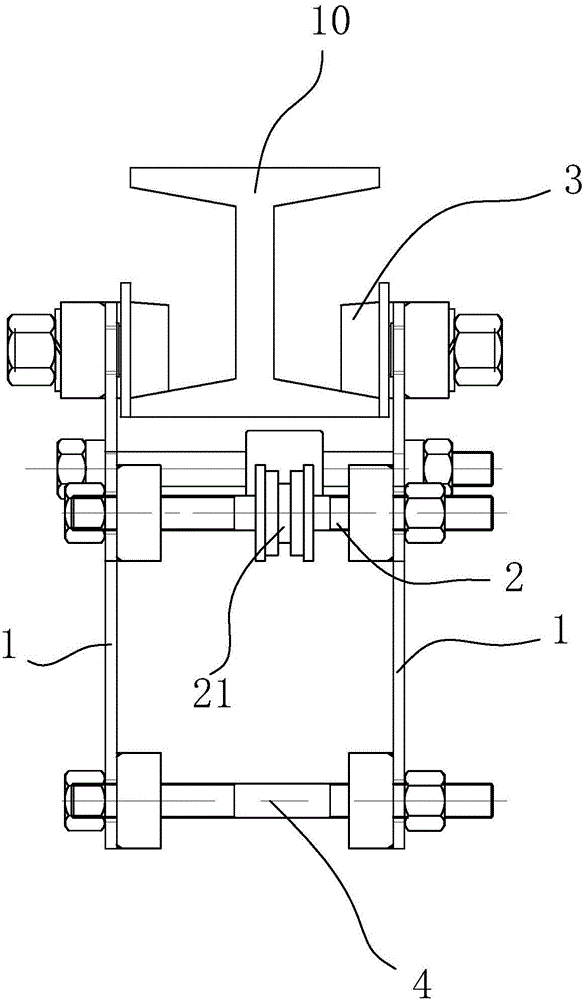

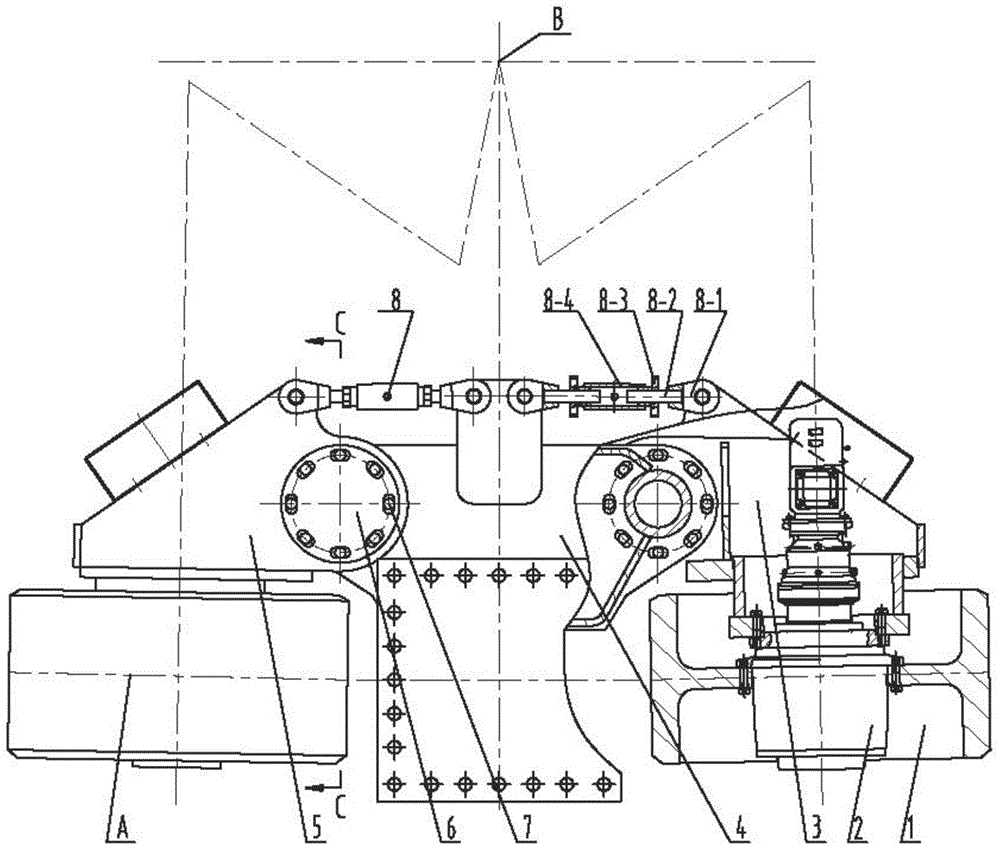

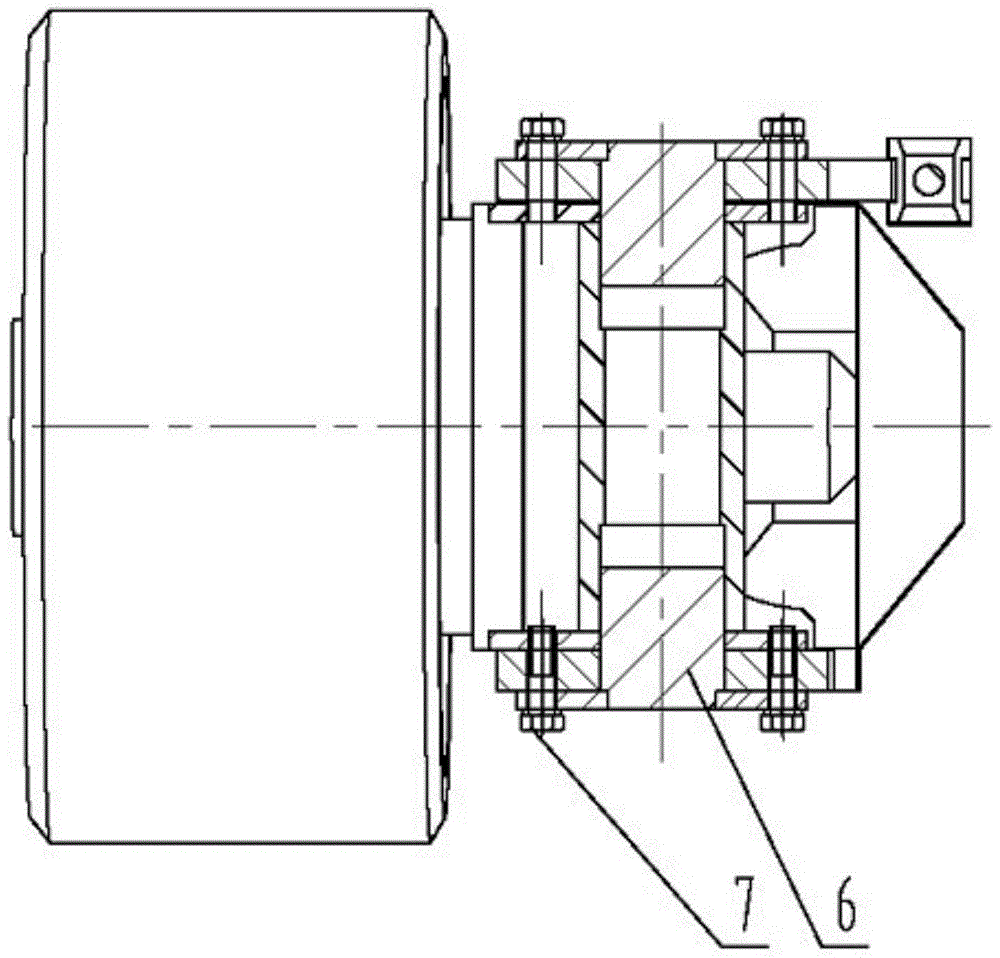

A Device for Adjusting the Axial Angle of an End Beam Traveling Wheel

The invention discloses an axial angle adjusting device of an end beam walking wheel, which is applied to circular storage homogenization stockyards in such fields as papermaking, water conservancy, metallurgy, electric power, port docks, coals, building materials and chemical engineering. The device comprises wheels, driving units, a left wheel frame, a bogie frame, a right wheel frame, pin shafts, connecting bolts and an adjusting device combination, wherein the bogie frame is connected with the left wheel frame and the right wheel frame by hinge shafts; the bogie frame is connected with the left wheel frame and the right wheel frame through the pin shafts in the hinged points by the connecting bolts; the wheels are mounted on the driving units, and are connected with the left wheel frame and the right wheel frame; the two sets of wheels and the two sets of driving units are respectively connected with the left wheel frame and the right wheel frame; and one side of the adjusting device combination is connected with the left wheel frame and the right wheel frame. The device is convenient to operate, so that the scene installation and debugging period is largely shortened; an end beam body is wholly welded in a factory, so that the strength is enhanced, and the scene welding workload is reduced; and the structural part quality is controlled.

Owner:NORTHERN HEAVY IND GRP CO LTD

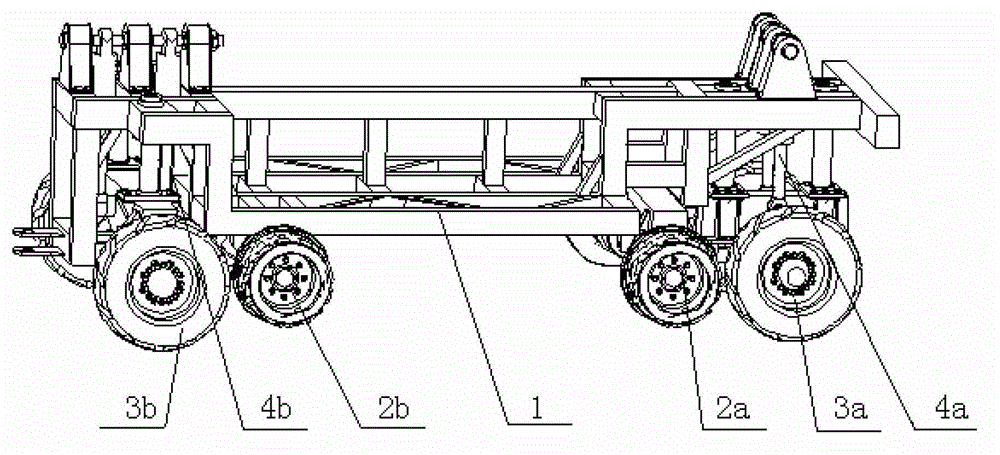

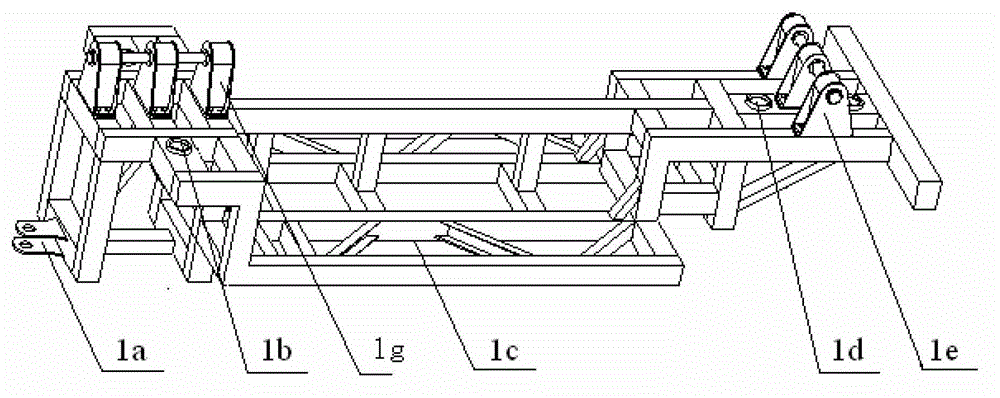

Guide beam walking type bridge inspection and rescue vehicle

InactiveCN103541304BMove at a steady speedDoes not affect operationBridge structural detailsBeam walkingEmergency rescue

The invention discloses a guide beam walking type bridge detection and rescue work vehicle which is composed of a guide beam, a motor vehicle, a detection vehicle and a rescue vehicle. The guide beam walking type bridge detection and rescue work vehicle works under bridges. The detection vehicle and the rescue vehicle are respectively of a multi-level truss structure, and can be contracted and rotationally folded under the action of a hydrocylinder, and a lifting device is arranged inside the truss of the rescue vehicle. The detection vehicle and the rescue vehicle on the guide beam are completely contracted and folded when passing through a bridge pier, and the maximum cross sectional dimension of the detection vehicle and the rescue vehicle is within 1.1m*1.1m. On the working condition of bridge detection, the rescue vehicle is completely contracted and folded, the detection vehicle is partly unfolded, and a work platform used for bridge detection is provided. On the working condition of rescue, the detection vehicle and the rescue vehicle are completely unfolded, a door frame structure is connected to the two sides of the bridge pier in an overlapped mode, and at the moment, a winch on the rescue vehicle is located in the middle of the door frame and can conduct lifting rescue operation. The guide beam walking type bridge detection and rescue work vehicle has the functions of loading, bridge detection and lifting rescue, automatically provides power, has the capability of passing through the bridge pier, is wide in detection range, can be applied to daily maintenance work of the bridge conveniently and effectively, and can also be used as a device for railway accident emergency rescue.

Owner:长沙铁信交通科技有限公司 +1

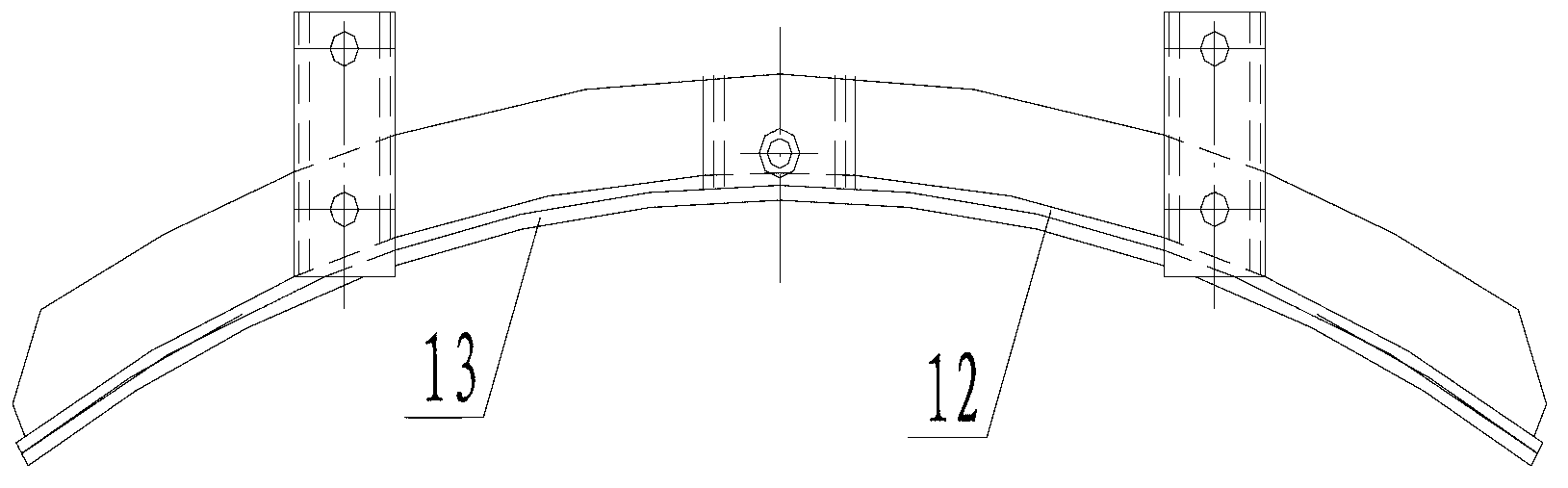

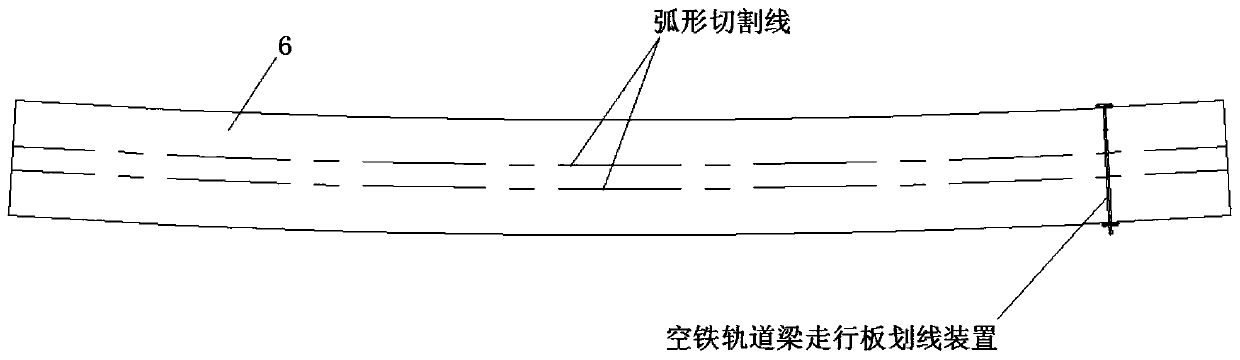

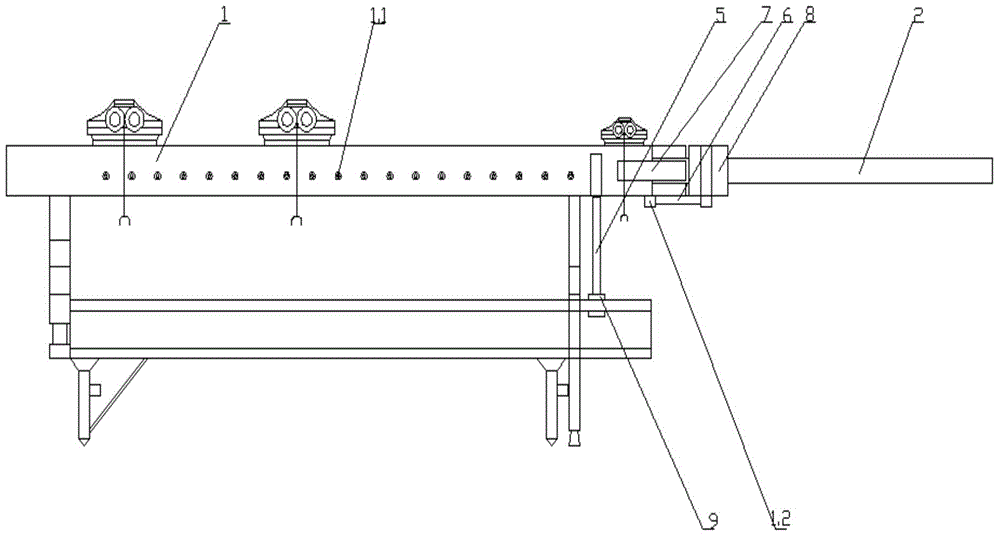

Sky train track beam walking plate lineation device and lineation method thereof

InactiveCN110370244ASimple structureScientific and reasonable designOther workshop equipmentBeam walkingEngineering

The invention discloses a sky train track beam walking plate lineation device and a lineation method thereof. The problem that in the prior art, a curve-replaced-fold fitted curve lineation manner, the requirement of an arc cutting line for precision cannot be met is solved. The sky train track beam walking plate lineation device comprises a support, a fixing guiding wheel mechanism, walking wheels, a lineation mechanism and an adjusting guiding wheel mechanism. According to the lineation method, mainly, the sky train track beam walking plate lineation device is arranged on a to-be-lineated walking plate through the fixing guiding wheel mechanism and the adjusting guiding wheel mechanism, the lineation mechanism accurately moves to the set lineation position on the to-be-lineated walking plate, and after moving adjustment, the lineation mechanism and the support are fixed through a lineation positioning fixing bolt; and finally, the sky train track beam walking plate lineation device is pushed at constant speed to run in the length direction of the to-be-lineated walking plate, and accurate lineation can be achieved. The sky train track beam walking plate lineation device is simplein structure and scientific and reasonable in design, and by means of the sky train track beam walking plate lineation device, the arc cutting line parallel to the inner arc plate edge or the outer arc plate edge of the walking plate can be accurately drawn on the walking plate according to the design requirements.

Owner:CHINA MCC5 GROUP CORP

Full circle once lining segregation type nose girder module bench and its construction method

The invention relates to a linear separated guide beam template table, wherein its annular linear beam is connected to the inner side of template; the annular linear beam and the table support top template support screw disc, side template support lead screw and bottom template support lead screw between them; the table via walking device is supported on the table walking steel track above the bottom template; one table and two bottom templates are alternatively matched; the bottom template is fixed with guide beam walking steel track which supports the detachable support guide beam; the bottom of detachable support guide beam has walking wheel, while its top is detachably connected via adjustable base and table; the end of detachable support guide beam via the end base of guide beam is supported on the support concrete structure, while its one end is connected to the drawing system; another bottom template is at the concrete pouring position. And it can be used on the template table machine whose section diameter is 6-3m, with large operation space and lower cost.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

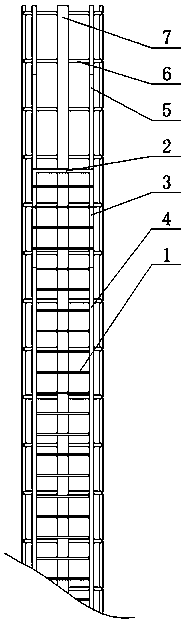

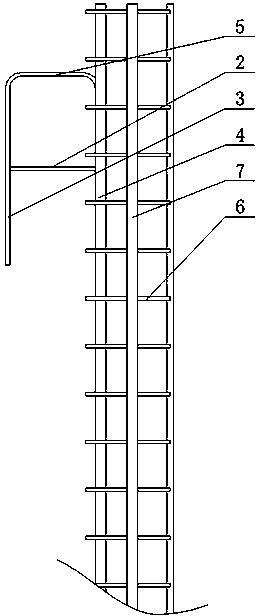

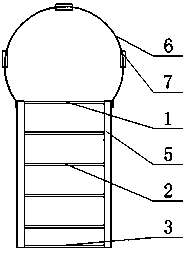

Steel beam walking protection device

ActiveCN104032971AImprove climbing safetySummit safelyBuilding material handlingShaping building partsBeam walkingArchitectural engineering

The invention discloses a steel beam walking protection device. The device comprises a climbing ladder mechanism and a protecting cage mechanism, wherein the climbing ladder mechanism comprises a climbing ladder main body, a top platform and a hook part, the climbing ladder main body is parallel to the hook part, the upper ends of the climbing ladder main body and the hook part are respectively connected with both ends of the top platform, and the length of the top platform is the same as the width of a steel beam; the protecting cage mechanism comprises a protecting cage main body and two vertical mounting beams, wherein the two vertical mounting beams are respectively and fixedly arranged at both sides of the climbing ladder main body, the climbing ladder main body is in a C-shaped cross section structure, and the two sides of the protecting cage main body are respectively and fixedly arranged on the two vertical mounting beams. When the steel beam walking protection device is used, the climbing ladder main body, the top platform and the hook part are only required to be formed into an integrated hook-shaped part to be hooked on the steel beam, the device is convenient and fast to mount, and the climbing safety of operating personnel is high.

Owner:TONGLING FERROUS CONSTR & INSTALLATION STEEL STRUCTURE

Bridge cantilevered sidewalk slab formwork system and construction method

ActiveCN106245534BEnsure construction safetyImprove straightnessBridge erection/assemblyShaped beamBeam walking

The invention discloses a formwork system of a bridge cantilever sidewalk slab. The formwork system comprises an arched combination internal mold and a cantilever combination mold, wherein a cantilever combination mold tensioning device is arranged externally in the longitudinal direction of the cantilever combination mold, a cantilever combination mold suspending device is arranged on the upper side of the cantilever combination mold, a walking combination is arranged between one end of a cross beam and one transverse end of a T-shaped beam combination, suspension rods are arranged in the transverse direction of the T-shaped beam combination, every three suspension rods is set as one row, and multiple rows of suspension rods are arranged in a matrix manner in the longitudinal direction of the T-shaped beam combination. A construction method comprises steps as follows: A, mold installation; B, mold dismounting; C, cross beam walking. The device is compact in structure, the method is simple and easy, two ends of the cross beam are balanced on the basis of the lever principle, safety in construction of concrete pouring of the bridge cantilever sidewalk slab is guaranteed, and the reliability of connection between the bridge cantilever sidewalk slab and the T-shaped beam combination is improved. Formwork joints cannot be staggered, so that the straight degree of the bridge cantilever sidewalk slab in the length direction is increased, and the construction cost is reduced.

Owner:CHINA COMM 2ND NAVIGATIONAL BUREAU 3RD ENG

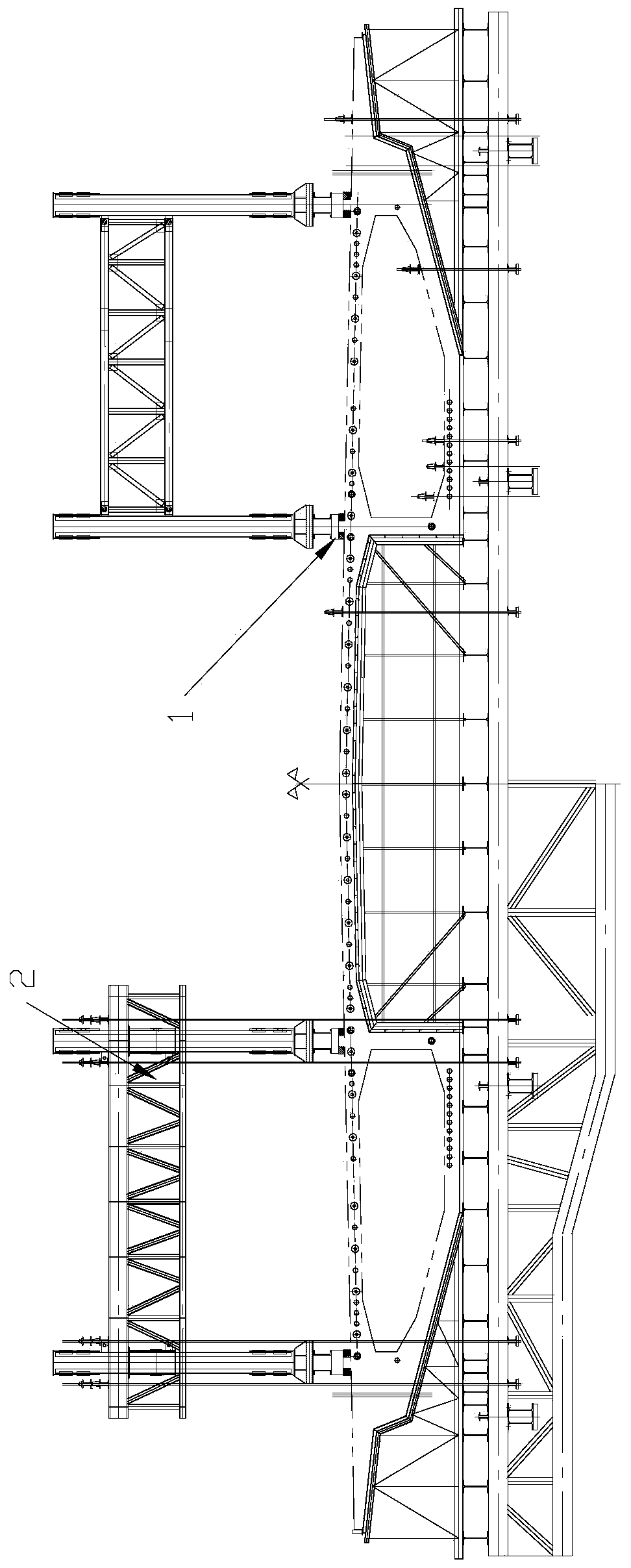

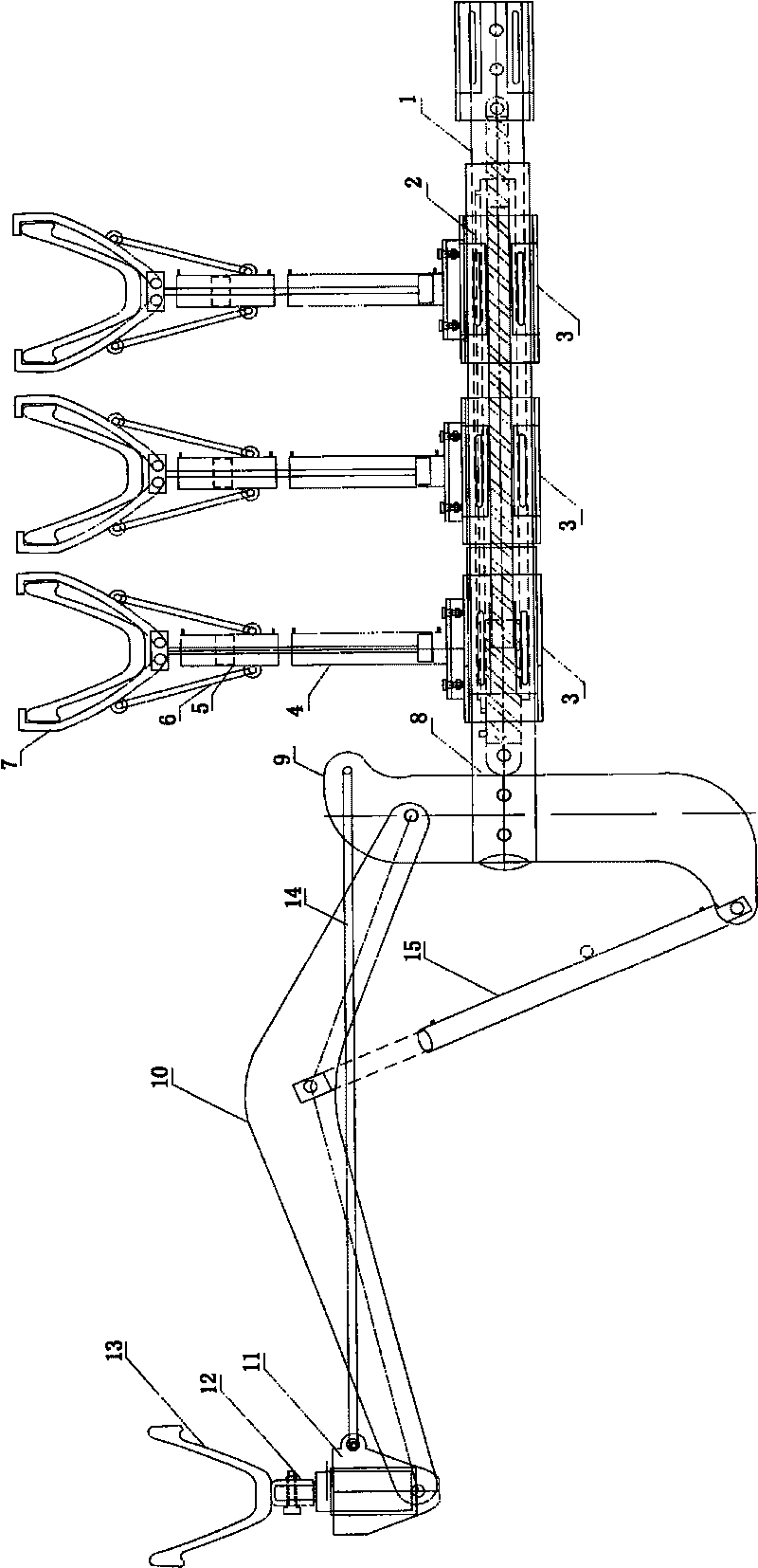

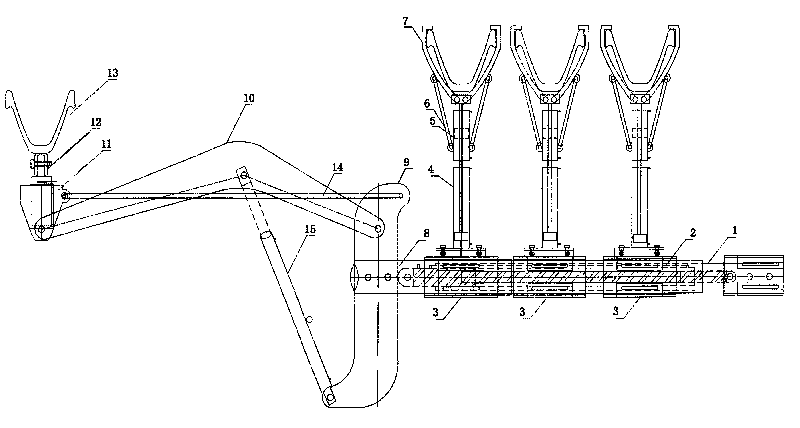

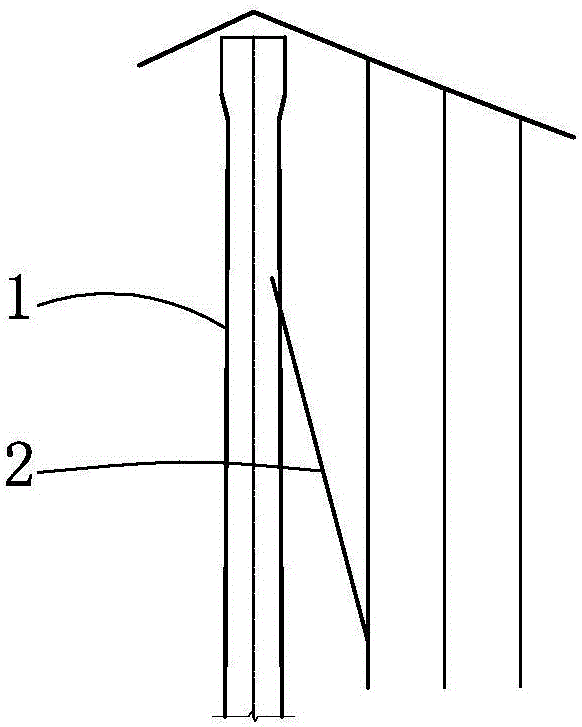

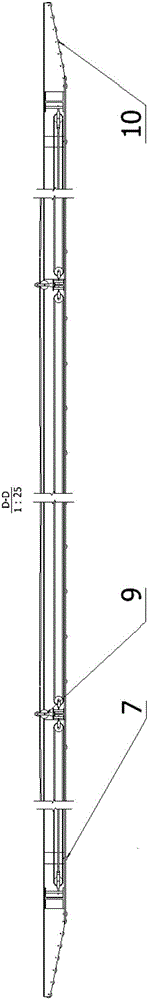

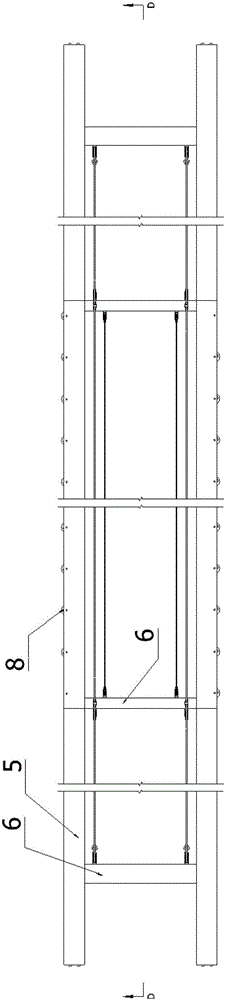

Folding telescopic cantilever beam system of walking bridge erecting machine with lower guide beam

ActiveCN103541309BEasy to operateImprove construction efficiencyBridge erection/assemblyCantilevered beamBeam walking

The invention discloses a bending retractable cantilever system of a lower guide girder crawler-type bridge erecting machine. The bending retractable cantilever system comprises a main girder, cantilevers, a cantilever beam, positioning pins, bridge erecting machine supports, a connecting rod, a connecting board and a walking driver. The main girder and the cantilevers are connected together through the connecting rod and the connecting board or a connecting sleeve; the positioning pins are arranged on the lower portion of the main girder, the cantilever beam is disposed on the cantilevers; the bridge erecting machine supports are arranged under the main girder and drivingly connected with the walking motor. According to the lower guide girder crawler-type bridge erecting machine with the bending retractable cantilever system, the retraction process of the cantilever beam does not require long-distance upward or outward bending of the cantilever beam and just needs to integrally retract backwards; during the retraction process of the cantilever beam, the auxiliary supports can support the cantilever beam to move towards the main girder, so that backward retraction of the cantilever beam during a large-cantilever process can be avoided and the security coefficient is relatively high.

Owner:HEBEI UNIV OF TECH

Walking support of flexible turnout beam section of straddling monorail transit track

ActiveCN102787535BEasy accessGuaranteed comfortRailway tracksManufacturing cost reductionBeam walking

The invention discloses a travelling support for a flexible turnout beam section of a straddle-type monorail traffic track, which comprises a travelling side and a flexible side support board, wherein the flexible side support board comprises two guide boards which are positioned at the upper part and two stabilization boards which are positioned at the lower part. The travelling support which can be forcefully deformed flexibly is adopted to form the flexible turnout beam section and a flexible turnout beam structure, when a track is needed to be transferred and joined, flexible deformation is generated due to the drive of the external force, both the guide side and the stabilization side of the flexible turnout beam section are in smooth transition, fold lines are eliminated, the travelling of light rails is benefited; and moreover, compared with the existing turnout structure, the travelling support is more greatly simplified, the manufacturing cost is lowered, the manufacturing period is shortened, the service life is longer, the use and maintenance costs are saved, the comfortability and safety of the light rail can be ensured, the vehicle travelling noise is lowered, and travelling support has better environmental protection property.

Owner:重庆川东船舶重工有限责任公司

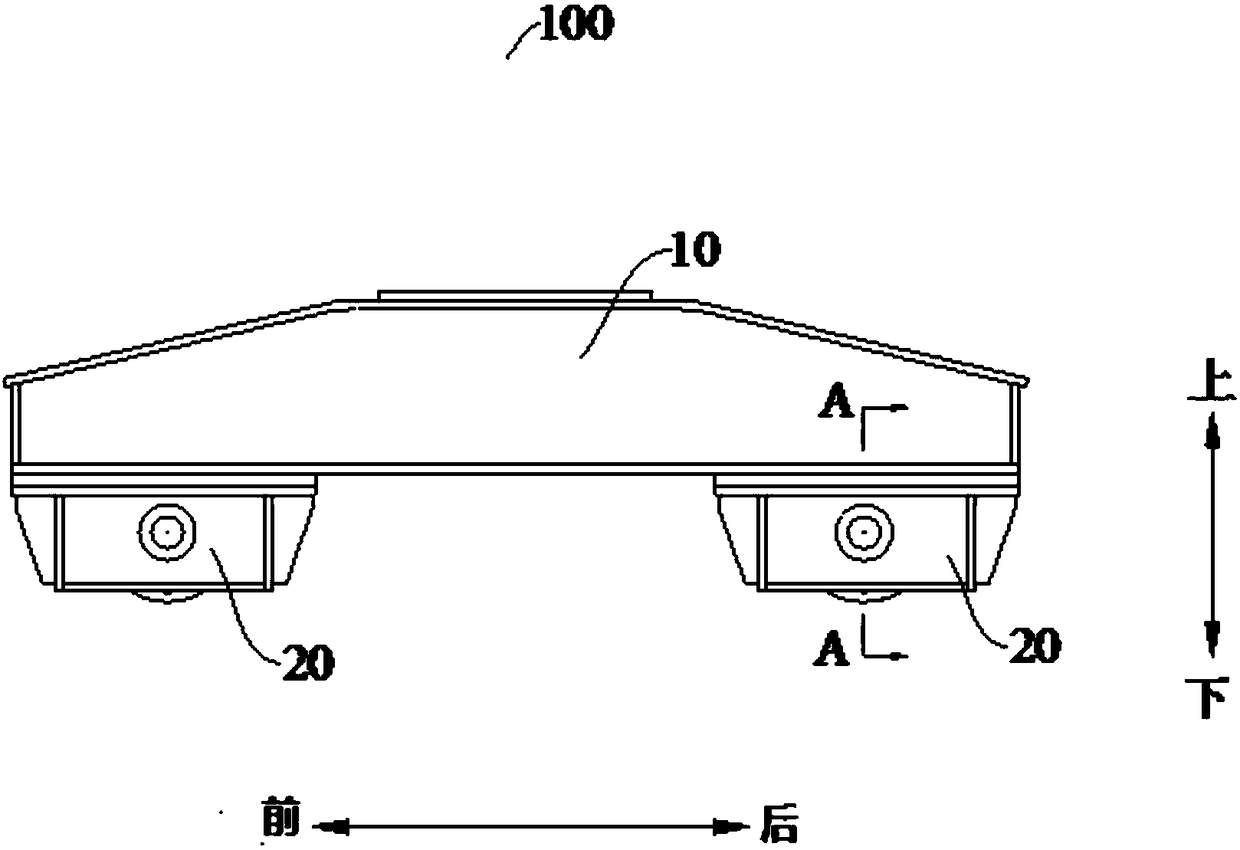

Suspension type single-shaft bogie and suspension type single-rail working vehicle

ActiveCN113200058AImprove stabilityGuaranteed stabilityElevated railway with suspended vehicleBogiesBogieBeam walking

The invention belongs to the technical field of suspension type rail transit, particularly relates to a suspension type single-shaft bogie and a suspension type single-rail working vehicle, and aims to solve the problem that a double-shaft bogie in the prior art cannot adapt to a small-radius curve. The bogie a body structural part, a walking wheel device, a guide wheel assembly, a stabilizing wheel assembly and an anti-tilting system, the stabilizing wheel assembly comprises two stabilizing wheel sets which are symmetrically distributed in the walking direction, each stabilizing wheel set comprises two stabilizing wheels which are symmetrically arranged in the axial direction of the walking wheel, and the distance between the two stabilizing wheels in each stabilizing wheel set is larger than the diameter of the walking wheel; the stabilizing wheels are arranged under the track beam walking plate, the axes of the stabilizing wheels are parallel to the axes of the walking wheels, according to the suspension type single-axle bogie, the longitudinal distance of the bogie is reduced, and the steering and guiding capacity of the bogie in a small-radius curve can be effectively improved.

Owner:ZHONGJIAN AIR TRAIN BEIJING TECH CO LTD

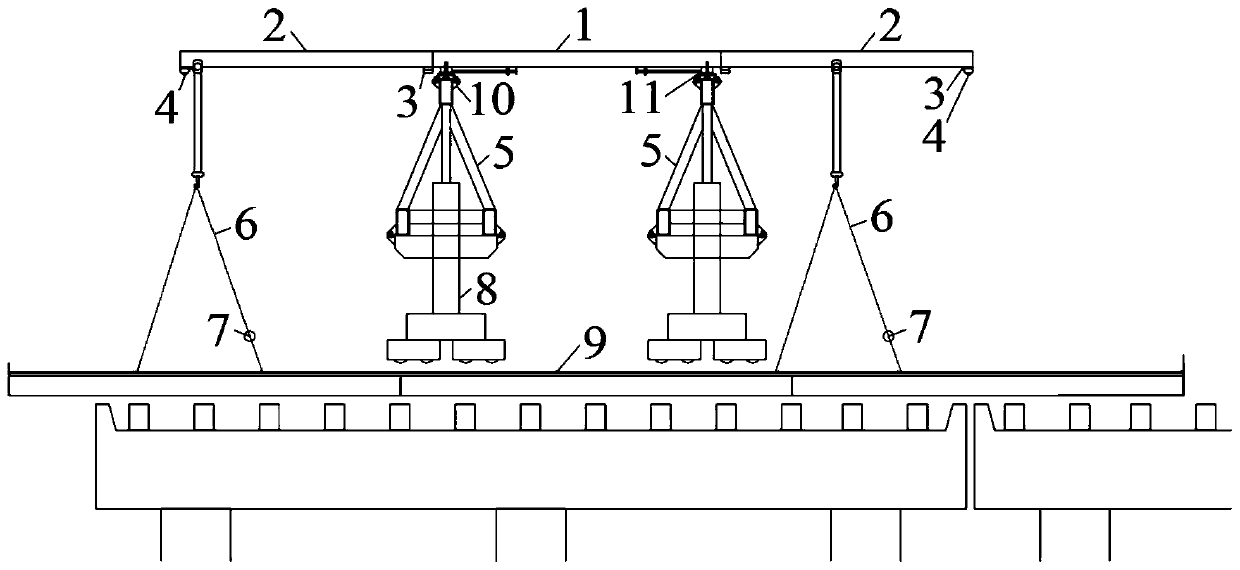

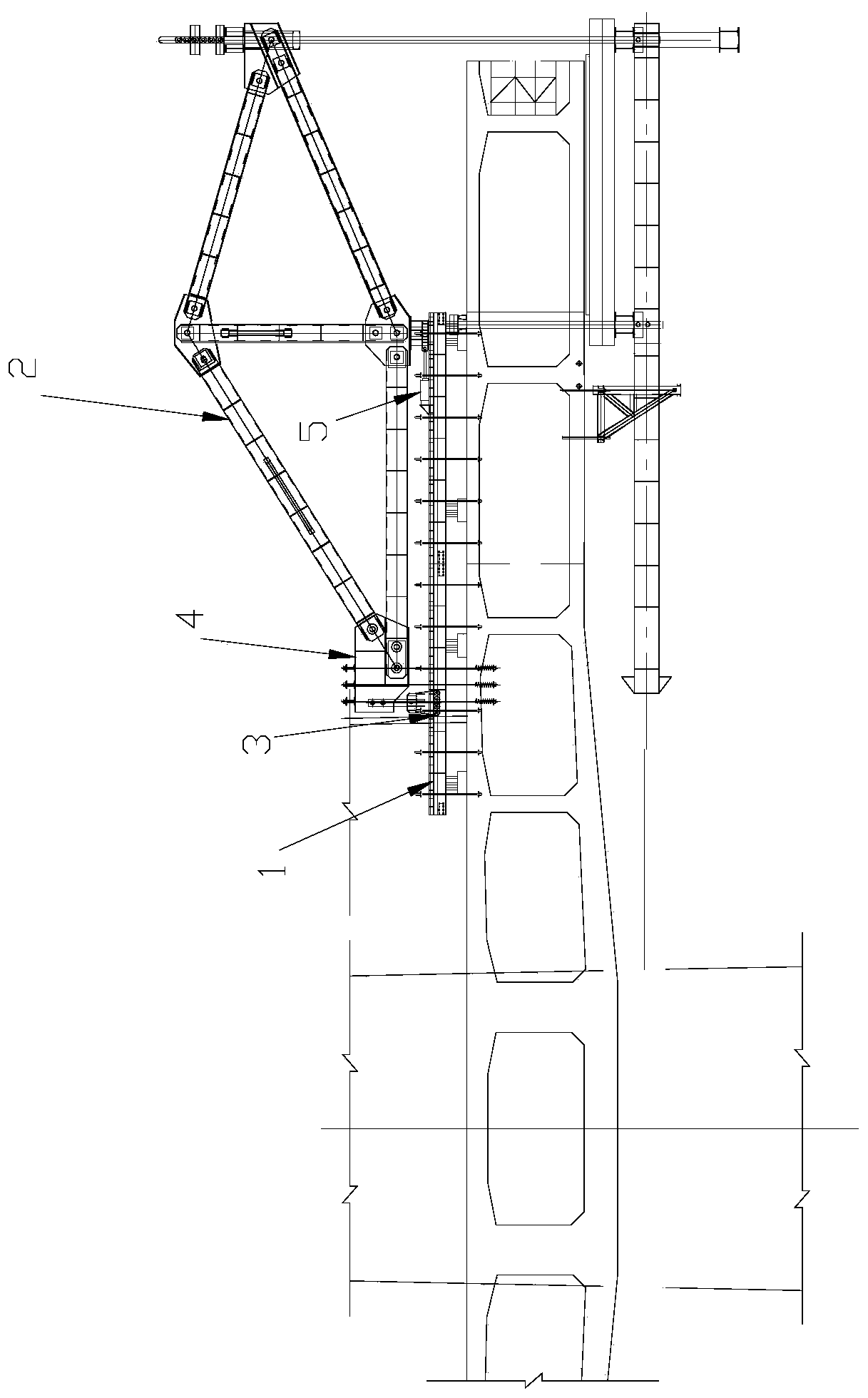

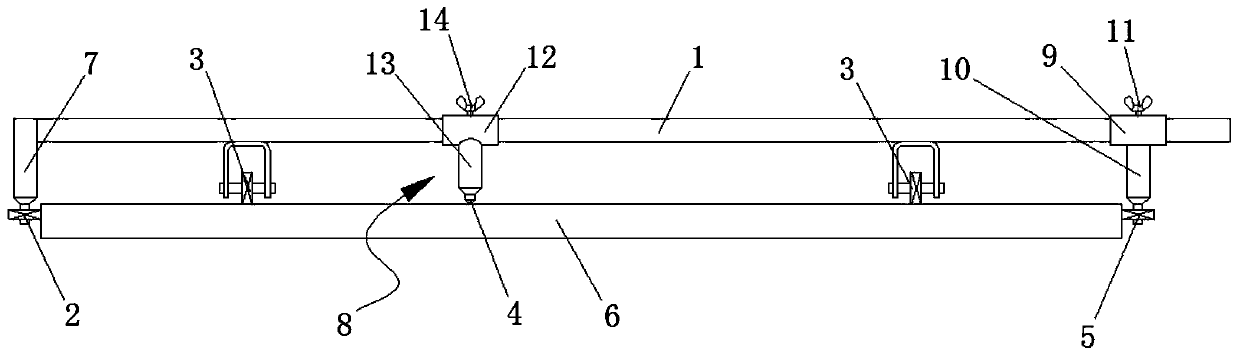

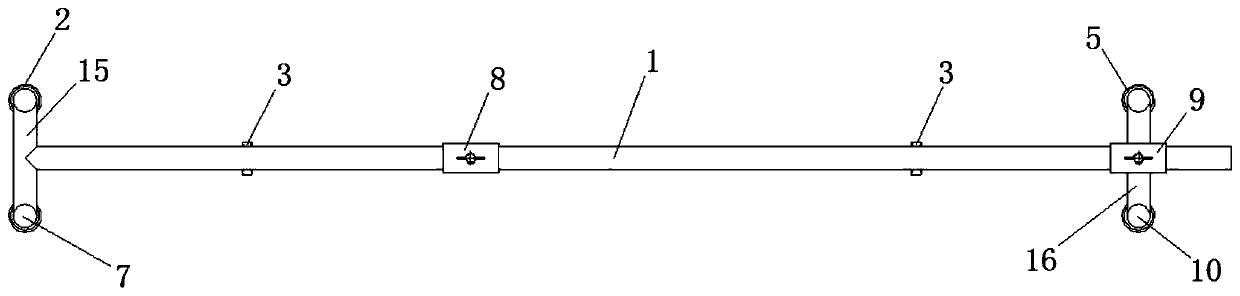

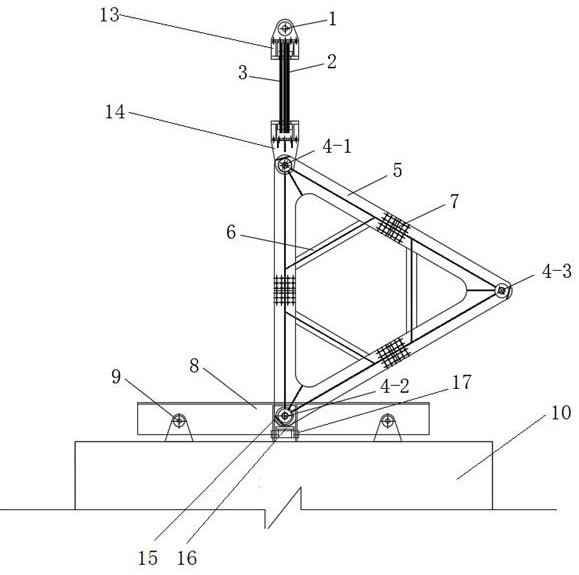

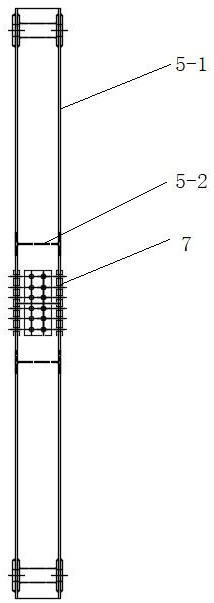

Under-beam beam transport lifting appliance system and lifting method

PendingCN113086827AAvoid congestionAvoid spaceLoad-engaging girdersTrolleysBeam walkingStructural engineering

The invention provides an under-beam beam transport lifting appliance system and a lifting method. The under-beam beam transport lifting appliance system comprises a lifting frame, an upper connecting assembly, a lower connecting assembly and a carrying pole beam. The lifting frame is of an equilateral triangle structure, a reinforcing rod is arranged between every two adjacent force transfer rod assemblies, a positioning pin I, a positioning pin II and a positioning pin III are arranged at the three vertexes of the lifting frame, and one vertex is connected with the carrying pole beam. The vertex of the mounting positioning pin I of the lifting frame is connected with one end of the upper connecting assembly, and the other end of the upper connecting assembly can be connected with an under-beam walking mechanism. The vertex of the mounting positioning pin II of the lifting frame is connected with the lower connecting assembly. Compared with a traditional method of transporting beams on a trestle, the method has the advantages that the aim of under-beam beam transport is achieved by using the track of an under-beam maintenance car, the occupied space of the trestle is reduced, the passing efficiency of the trestle is improved, and the production efficiency is improved.

Owner:山东省公路桥梁建设集团有限公司

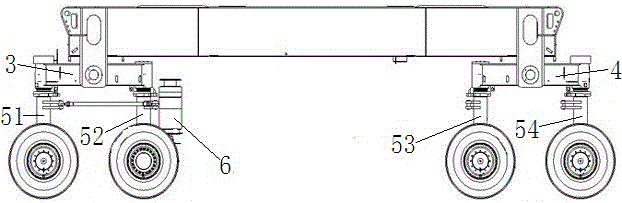

A double drive cart

ActiveCN104228951BReduce manufacturing costReduce post-maintenance costsElectric propulsion mountingUnderstructuresBeam walkingEngineering

The invention relates to a double-drive cart, which comprises an RTG front beam, an RTG rear beam, a balance beam providing driving force when walking, a balance beam providing supporting force when walking, and a walking driving mechanism. The balance beam that provides driving force when walking and the balance beam that provides support force when walking are located at both ends of the front beam of the RTG, and the balance beam that provides driving force when walking and the balance beam that provides support force when walking are located on the RTG At both ends of the rear beam, two balance beams that provide driving force during walking are installed along one diagonal direction, and two balance beams that provide supporting force during walking are installed along the other diagonal, and the two diagonal lines cross each other. Two walking drive mechanisms are respectively located on the RTG front beam and the RTG rear beam. The advantages of the present invention are as follows: under the premise of satisfying the normal use function, four sets of driving mechanisms are reduced to two sets, which saves manufacturing cost, reduces installation difficulty and later maintenance cost.

Owner:RAINBOW CARGOTEC IND

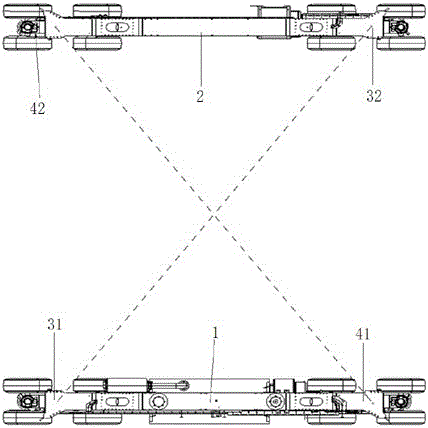

Sliding block beam walking system, turnout, rail transit system, guide wheel trolley and guide rail

ActiveCN112298255AImprove the problem of overturningImprove securityRail derailment preventionBeam walkingStructural engineering

The invention discloses a sliding block beam walking system, a turnout, a rail transit system, a guide wheel trolley and a guide rail. The sliding block beam walking system is used for driving a sliding block beam to move, and the sliding block beam walking system comprises: a guide rail provided with a limiting part; a guide wheel trolley which can move along the guide rail. The guide wheel trolley supports the sliding block beam and comprises a trolley body and a guide wheel body, the guide wheel body is provided with a limiting matching part, and the limiting part is matched with the limiting matching part to limit the guide wheel trolley. According to the sliding block beam walking system, the limiting matching part of the guide wheel body is matched with the limiting part of the guiderail, so that the problem that a sliding block beam is liable to overturn can be effectively solved, and the safety performance of vehicle driving is remarkably improved.

Owner:BYD CO LTD

A mobile formwork for the construction of a single-rectangular-top-closed water conservancy aqueduct

ActiveCN106149639BReduce investmentShorten the construction periodArtificial water canalsPunchingBeam walking

The invention relates to a movable formwork for single rectangular top closed type water conservancy aqueduct construction. The movable formwork comprises an outer beam system, an inner beam system and a hoisting system, wherein the outer beam system comprises an outer beam, an outer rib, an outer formwork, a No.1 landing leg, a No.2 landing leg, a No.3A landing leg, a No.3B landing leg and No.4 landing leg; the No.2 landing leg, the No.3A landing leg and the No.3B landing leg are matched with each other so as to move the outer formwork under the driving of a girder; the inner beam system comprises an inner beam, an inner beam holding support leg, an inner beam walking support leg and an inner formwork; the inner beam has a single girder truss structure; the inner formwork is driven to move by the inner beam walking support leg; the hoisting system comprises a hauling mechanism and a hoisting mechanism; the hoisting system can drive the landing leg to move to an effective construction position. According to the invention, in the manner of striding the outer beam for a half of length, positioning the No.3B landing leg on a groove surface while pouring, driving the outer beam to walk by the hydraulic system and punching twice, the punching manner is more stable and safe and the structure form and construction mode are different from those of the previous water conservancy aqueduct machine.

Owner:ZHENGZHOU NEW DAFANG HEAVY IND & TECH

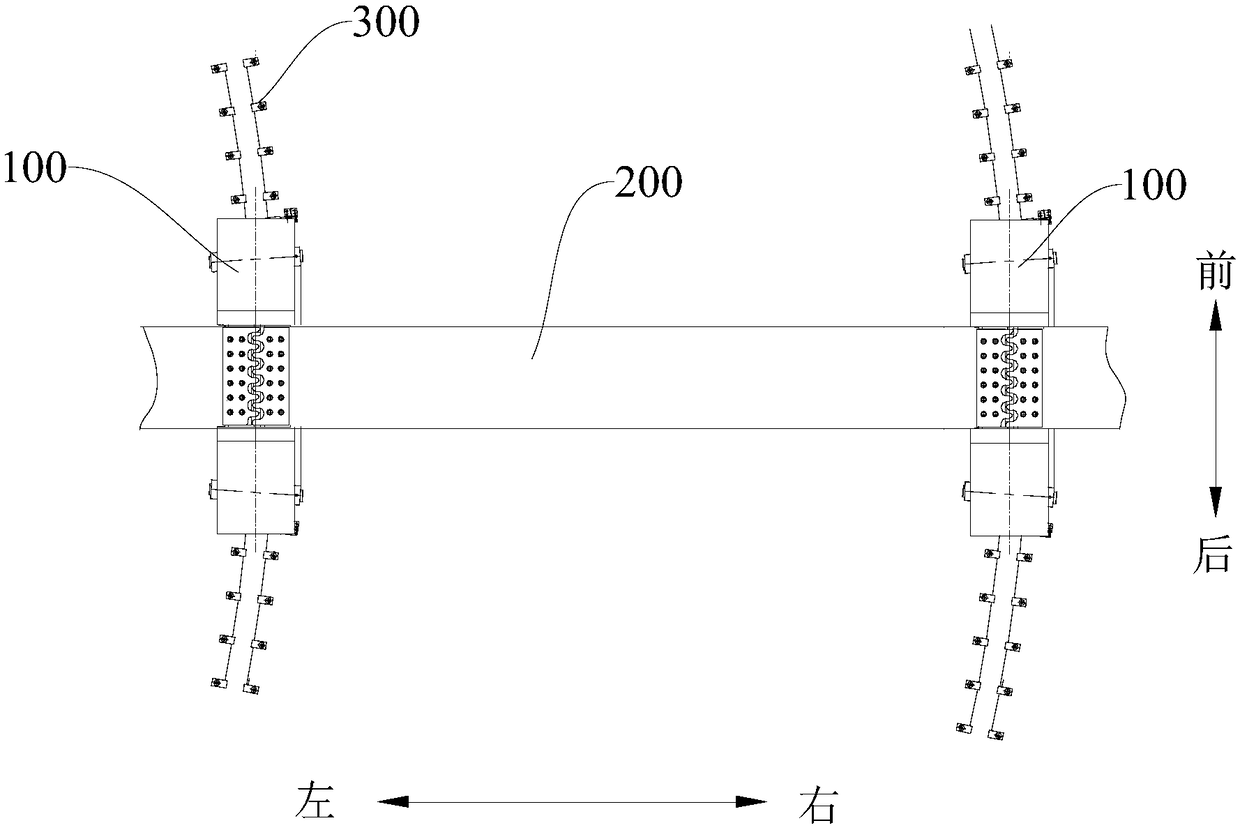

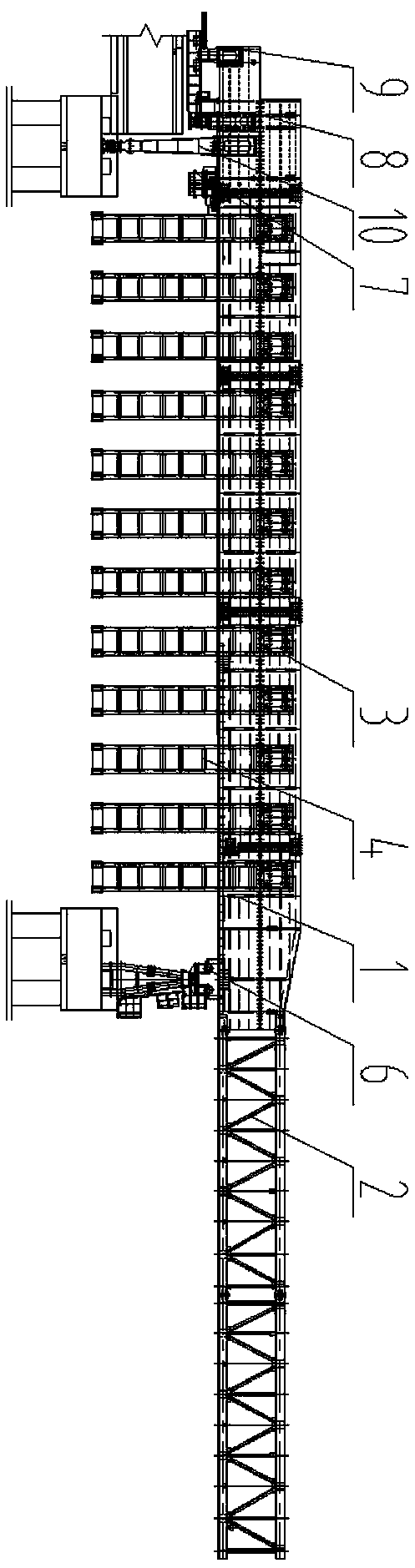

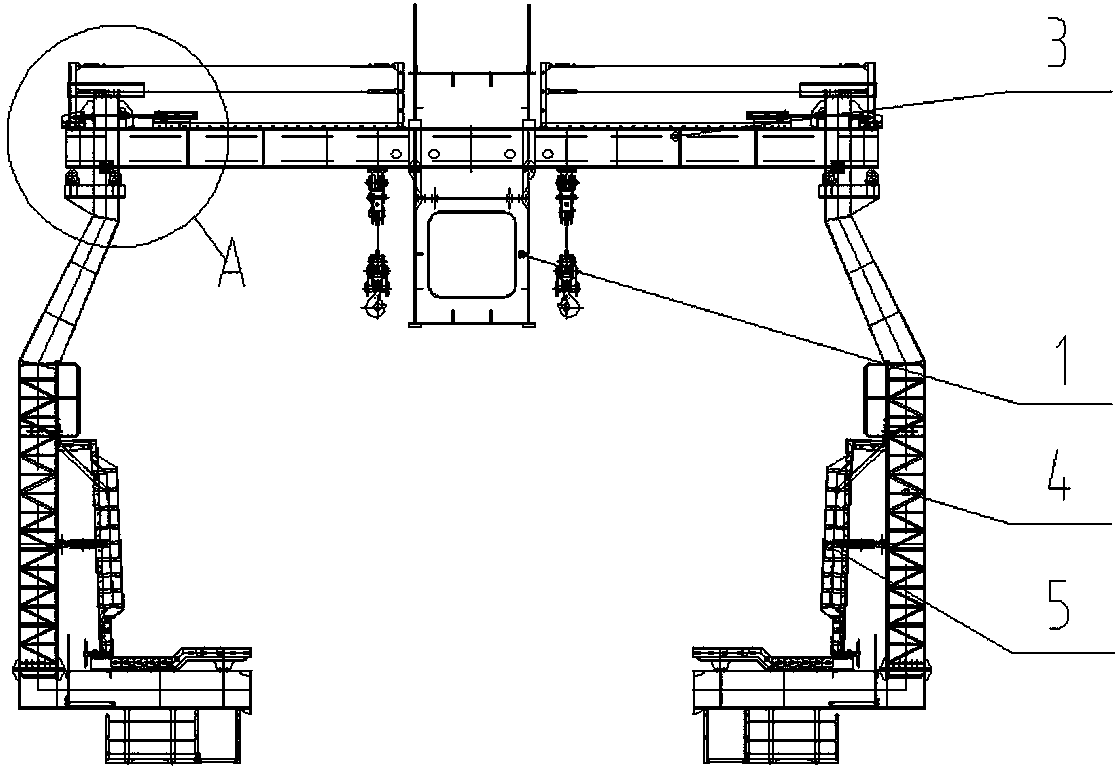

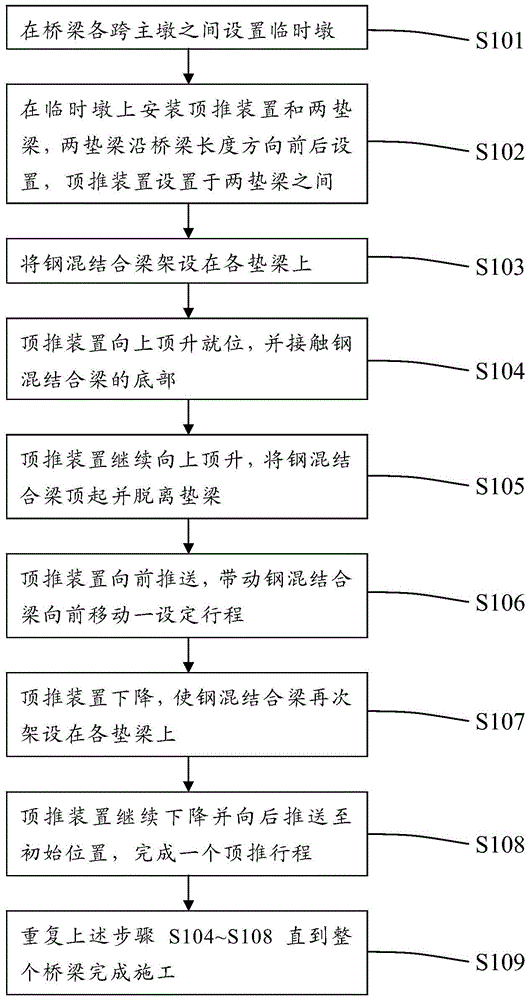

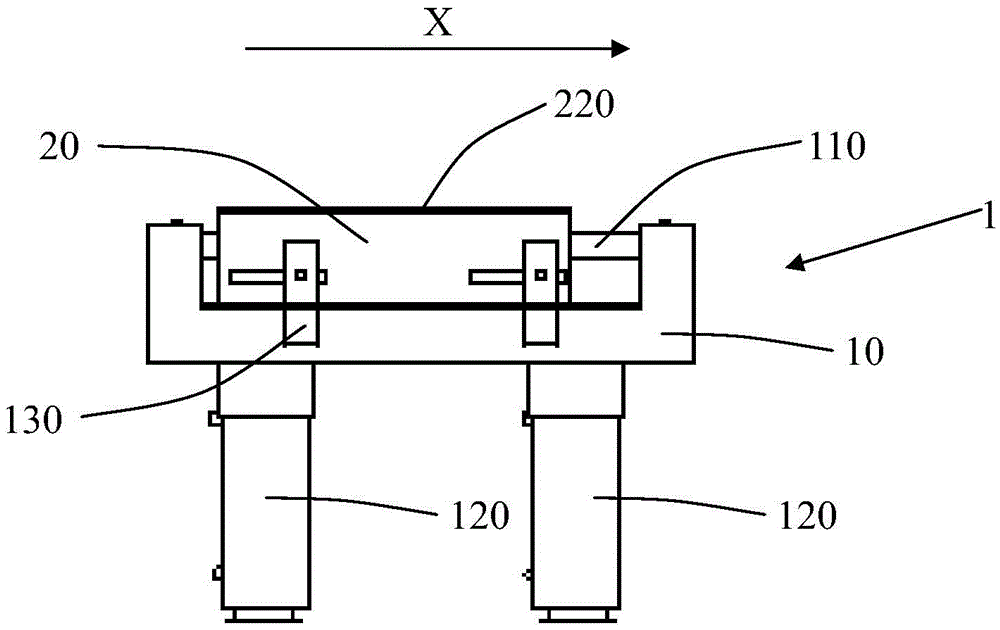

Construction method and device for walking jacking of large-span steel-concrete combined beams

ActiveCN103993560BEasy to operateGuaranteed durationBridge erection/assemblyReinforced concreteBeam walking

The invention provides a walking type jacking construction method and device for large-span reinforced concrete combined beams. The walking type jacking construction method comprises the following steps that temporary piers are arranged between all main piers of a bridge girder; a jacking device and two bearing beams are installed on each temporary pier, wherein each jacking device is arranged between the corresponding two bearing beams; the reinforced concrete combined beams are arranged on the bearing beams of the temporary piers; the jacking devices carry out upward jacking in place and make contact with the bottoms of the reinforced concrete combined beams; the jacking devices continue to carry out upward jacking, jack the reinforced concrete combined beams and break away from the bearing beams; the jacking devices are pushed forward and drive the reinforced concrete combined beams to move forward by a set stroke; the jacking devices descend so that the reinforced concrete combined beams can be arranged on the bearing beams of the temporary piers in a supporting mode again; the jacking devices continue to descend to the initial positions and are pushed backwards to the initial positions, so that a jacking stroke is finished; the above steps are conducted repeatedly until construction of the whole bridge girder is completed. According to the walking type jacking construction method and device for the large-span reinforced concrete combined beams, manpower, material resources and financial resources are saved on the premise of guaranteeing the construction period; meanwhile, the walking type jacking construction method and device for the large-span reinforced concrete combined beams have the advantages that construction and operation are convenient, safety and reliability are realized, efficiency is high, the construction period is short, and the comprehensive cost is low.

Owner:SHANGHAI TUNNEL ENG CO LTD +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com