The construction method of hoisting the stiffening beam of suspension bridge with cross-cable crane walking with beam

A construction method and crane technology, which is applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of increasing equipment investment, site occupation and labor costs, low efficiency of swinging construction, and limited scope of use, etc., to achieve economical Significant benefits and social benefits, reduced construction procedures and procedures, saving space and labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

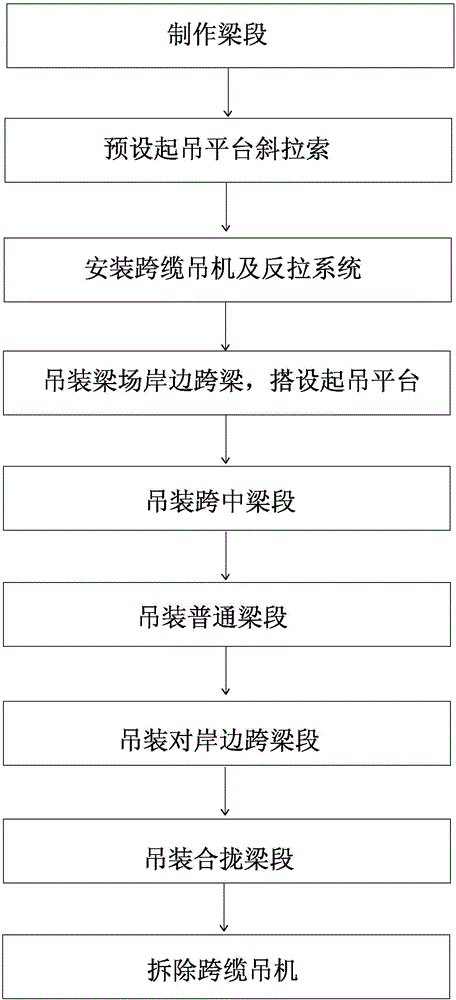

[0044] figure 1 It is a method flowchart of the present invention, mainly comprising the following steps:

[0045] (1) Beam section prefabrication: Set up a beam field on one side of the bridge, prefabricate the suspension bridge section, and make the width of each beam section in the transverse bridge direction greater than its length along the bridge direction when prefabricating;

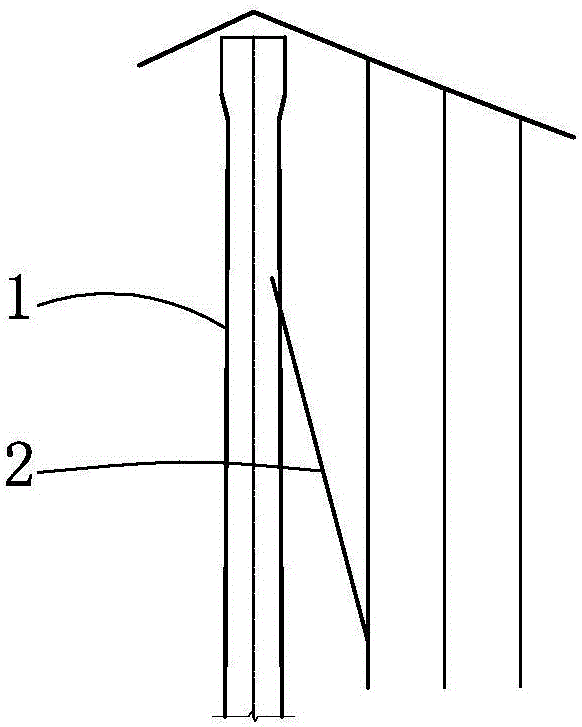

[0046] (2) Preset cable-stayed beams: During the construction of the tower column, the pre-stressed pipes are pre-buried in the tower body in advance, and the prestressed cable-stayed beams are set; the cable-stayed beams are used for fixed lifting;

[0047] (3) Set up the cross-cable crane and anti-tension system: install the cross-cable crane on the side cables of the mid-span of the tower column on the bank of the beam yard, and set up the anti-tension system on the side-span side approach bridges of the tower columns on both banks;

[0048] (4) Installation of the beam span section on the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com