Double-beam walking-type bridge girder erection machine used for box girder erection and compatible with G-series high-speed train single-line and double-line girder erection

A double-girder walking type and bridge erecting machine technology, which is applied in the direction of erecting/assembling bridges, bridge construction, bridges, etc., to achieve the effect of improving utilization rate, improving adaptability and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

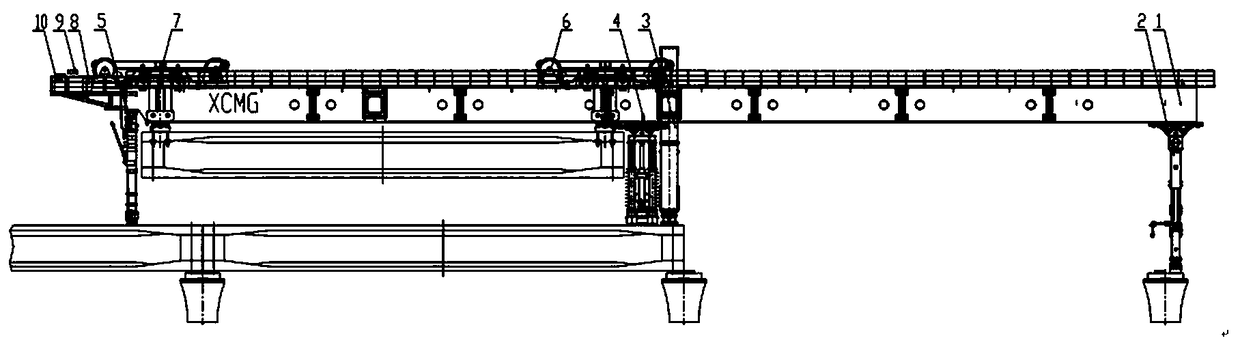

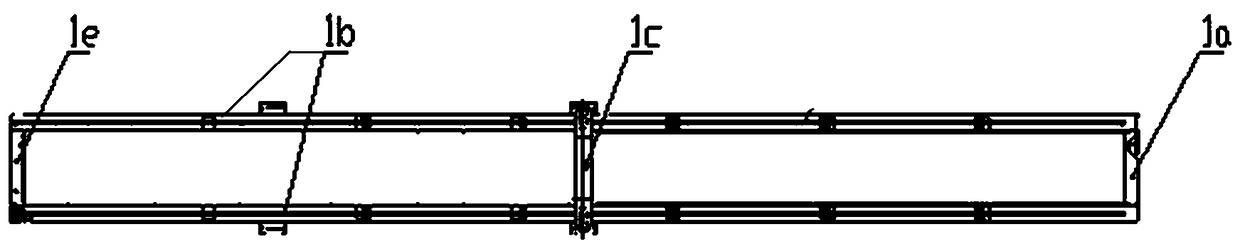

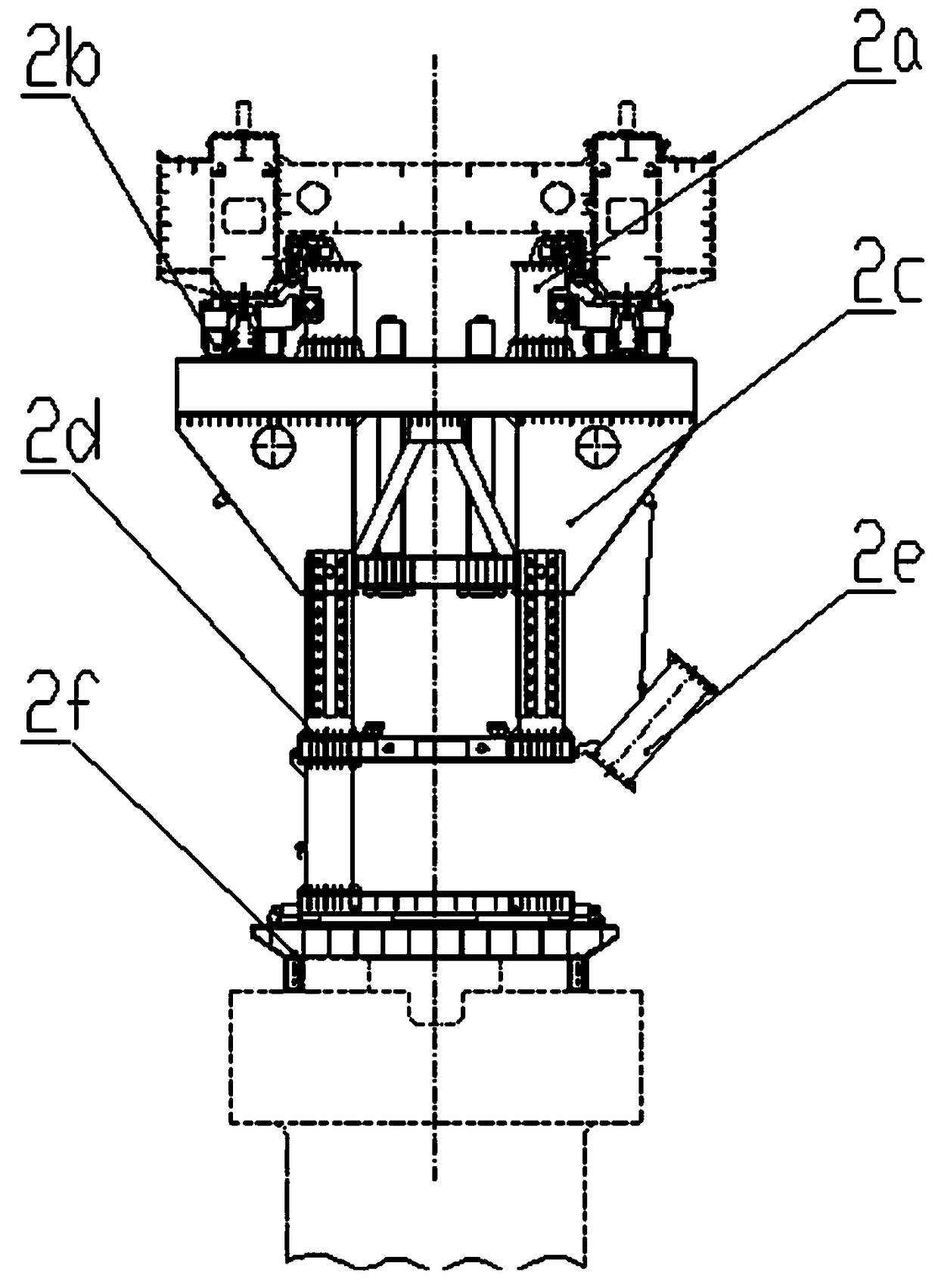

[0045] Such as Figure 1 to Figure 16 A double girder walking bridge erecting machine shown for box girder erection compatible with high-speed rail single and double wire girders includes a main girder 1, outriggers, a crane, an electric control system 8, a hydraulic system 9 and a power system 10, and its It is characterized in that: the outriggers include front outriggers 2, middle outriggers 3, through-hole outriggers 4 and rear outriggers 5, the crown block includes front crown block 6 and rear crown block 7; the main beam 1 It is composed of two parallel box girders 1b connected with the front tie beam 1a, middle tie beam 1c and rear tie beam 1e; the outer sides of the front tie beam 1a, middle tie beam 1c and rear tie beam 1e of the main beam 1 are respectively There are front outrigger installation positions, middle outrigger installation positions and rear outrigger installation positions; the front outriggers 2, middle outriggers 3 and rear outriggers 5 are sequential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com