Patents

Literature

58results about How to "Guaranteed swing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

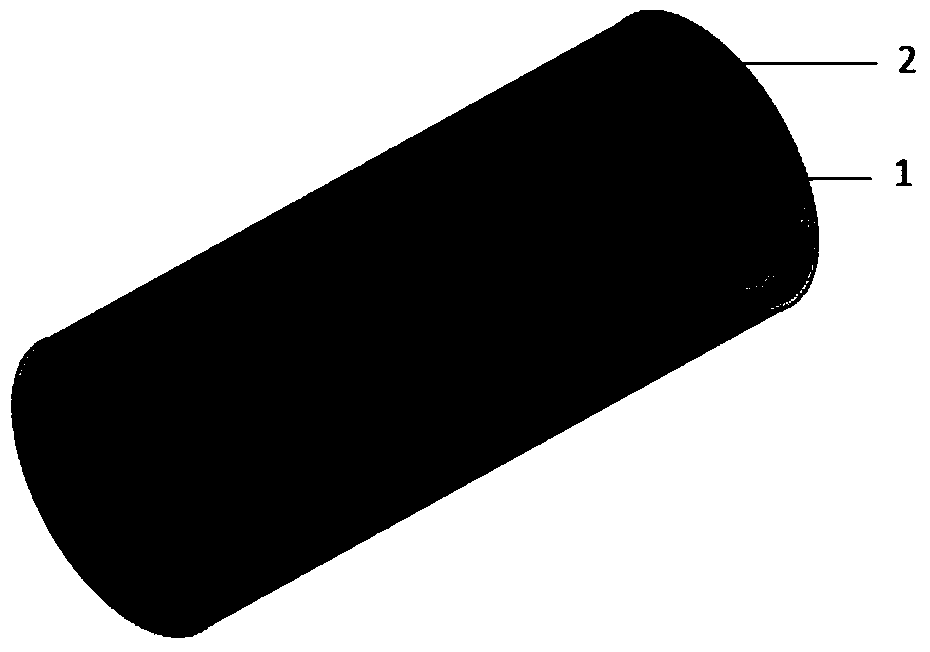

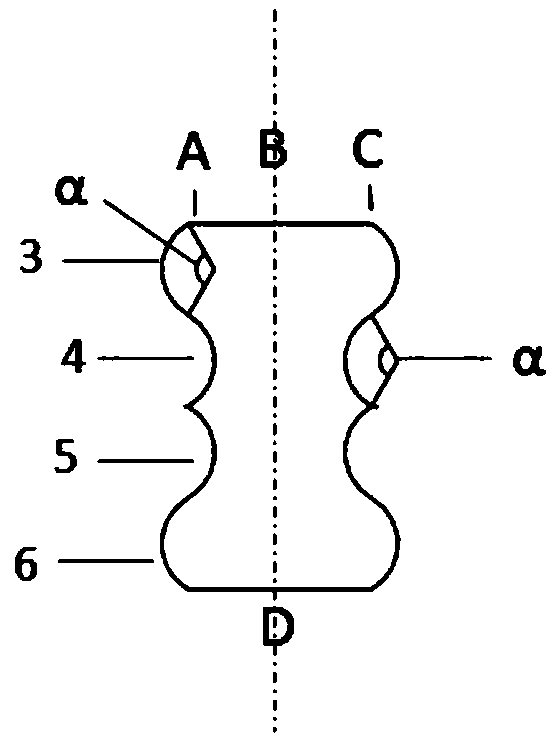

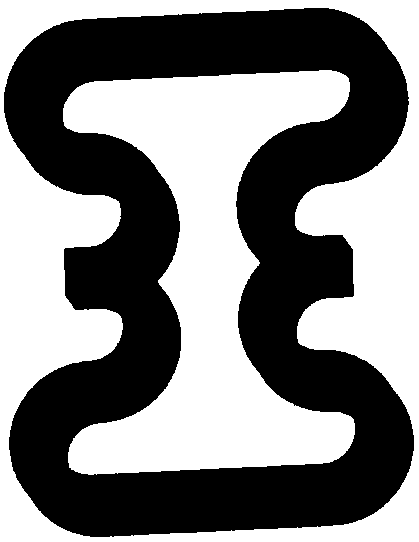

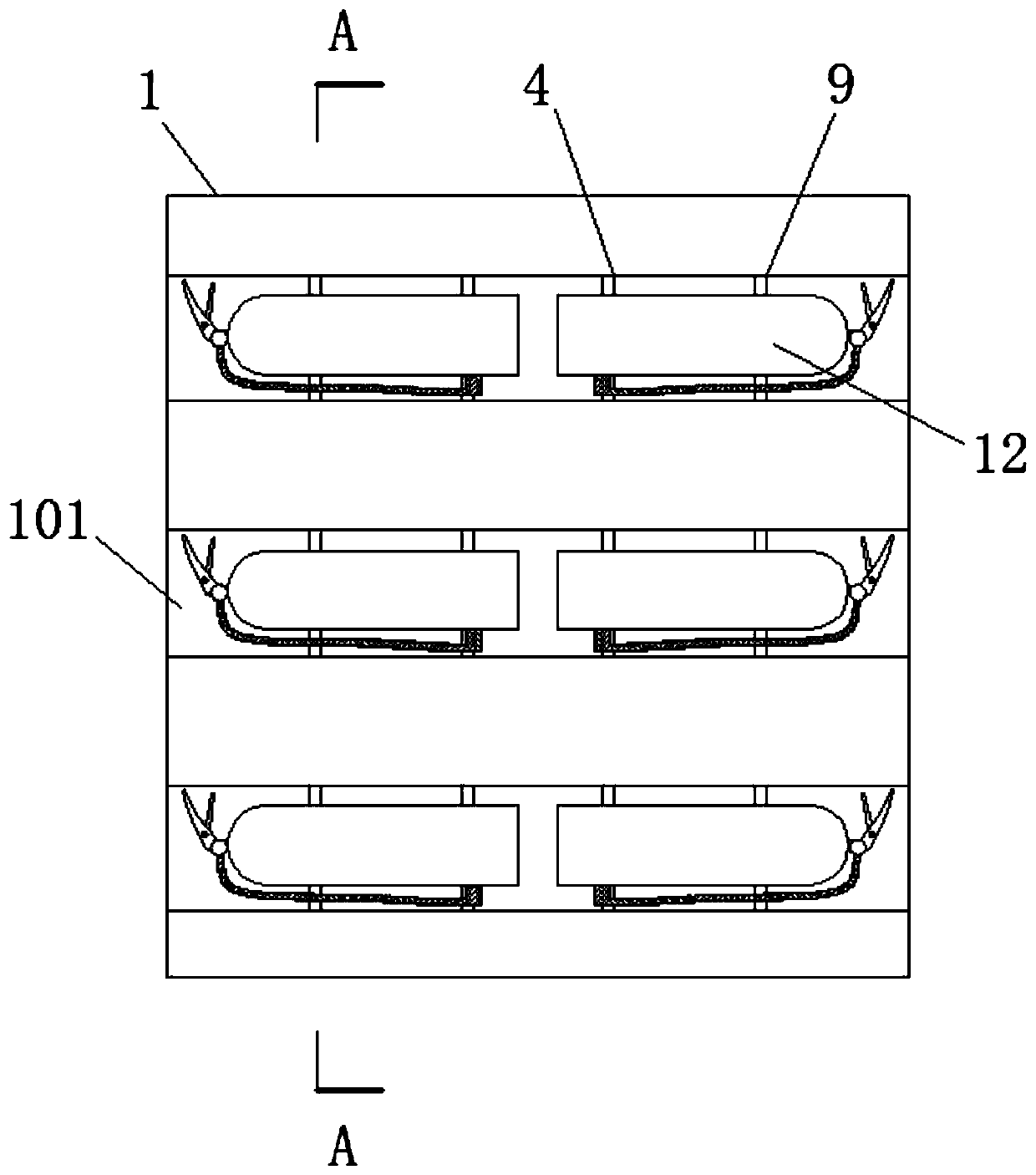

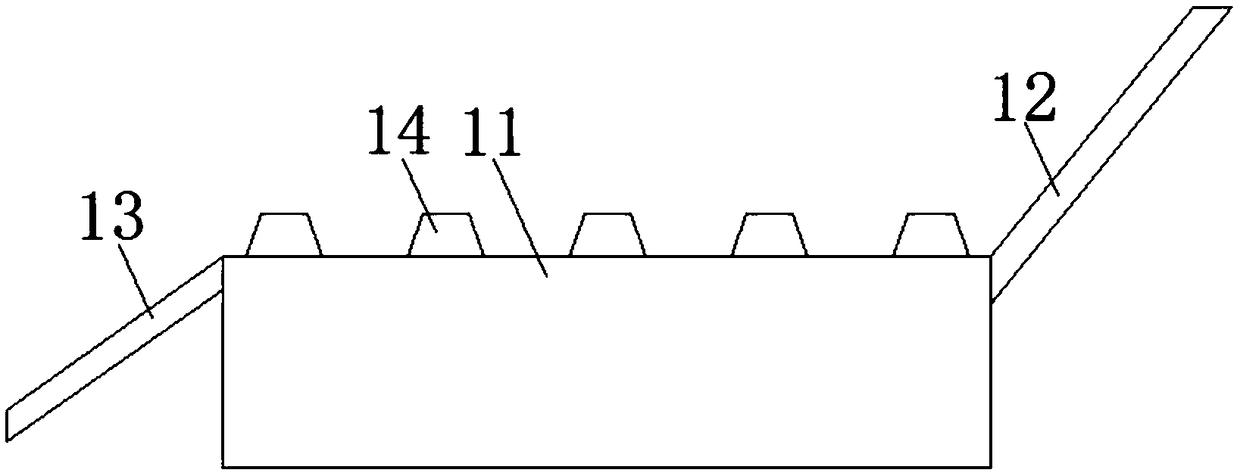

4D-printing shape-memory-polymer-composite-material tracheal stent and preparing method thereof

The invention discloses a 4D-printing shape-memory-polymer-composite-material tracheal stent and a preparing method thereof, and belongs to the technical field of 4D printing. As for the problem thata traditional tracheal stent is difficult to implant, and the secondary stricture problem caused by the overlarge hole diameter of the tracheal stent, and the problem that as the hole diameter of thetracheal stent is over small, swinging of airway cilia is blocked, a compound of a shape memory polymer and nanometer iron oxide serves as a material, a curve-edge rectangle serves as a basic unit, and a tracheal-stent three dimensional structure model is designed; the tracheal-stent three dimensional structure is printed and formed with the fused deposition or direct writing printing method, is subjected to electrostatic spinning medicine carrying covering, and then is subjected to in-vitro remote excitation so that the shape of the stent is recovered, and a formed tracheal stent is obtained.The 4D-printing shape-memory-polymer-composite-material tracheal stent and the preparing method thereof are suitable for production of the tracheal stent.

Owner:HARBIN INST OF TECH

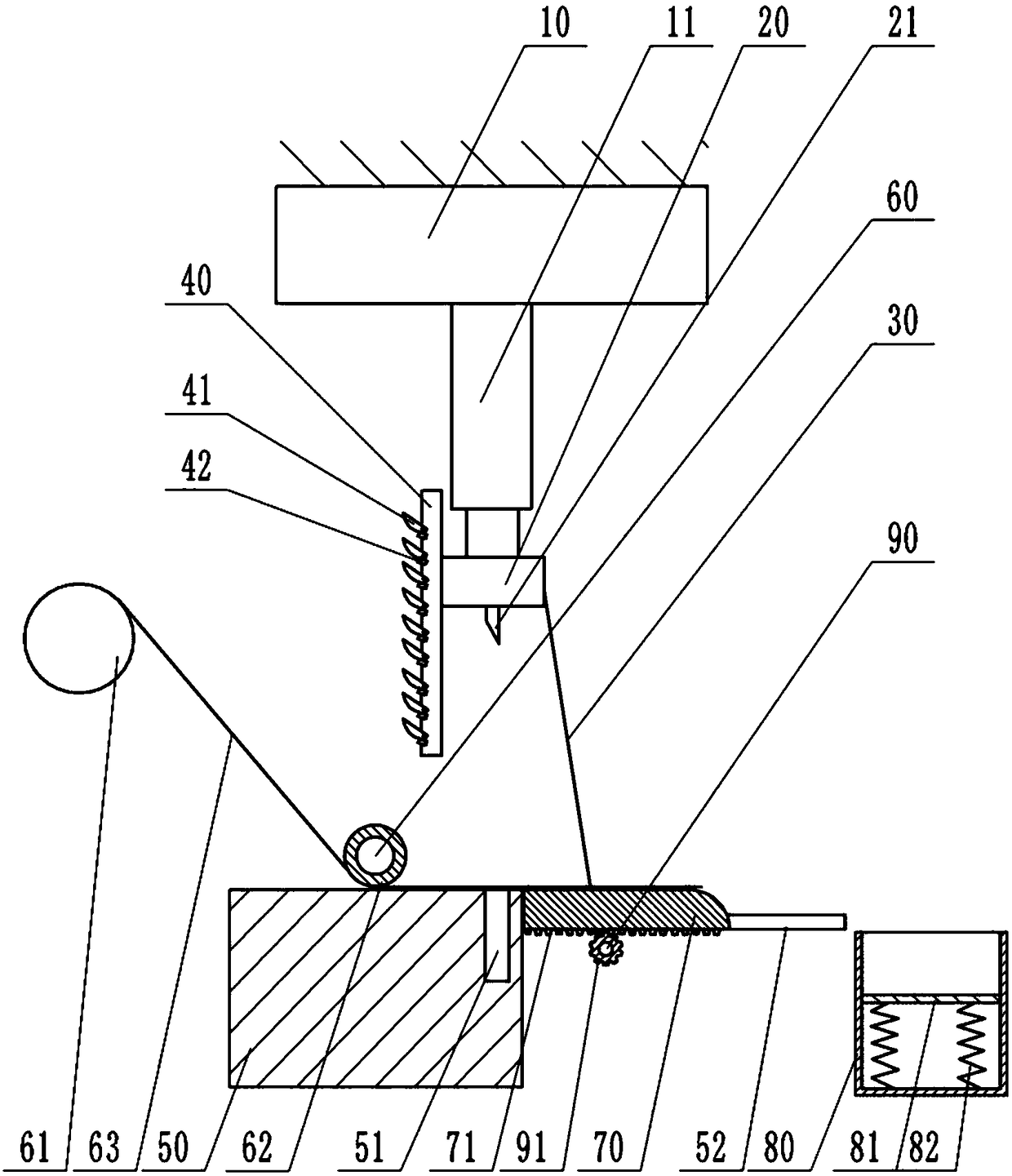

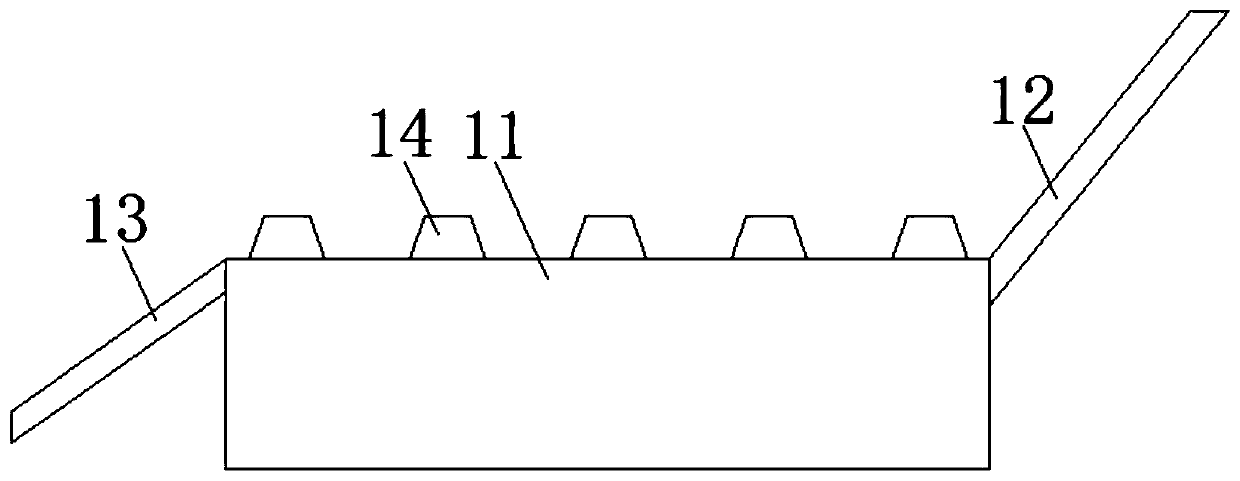

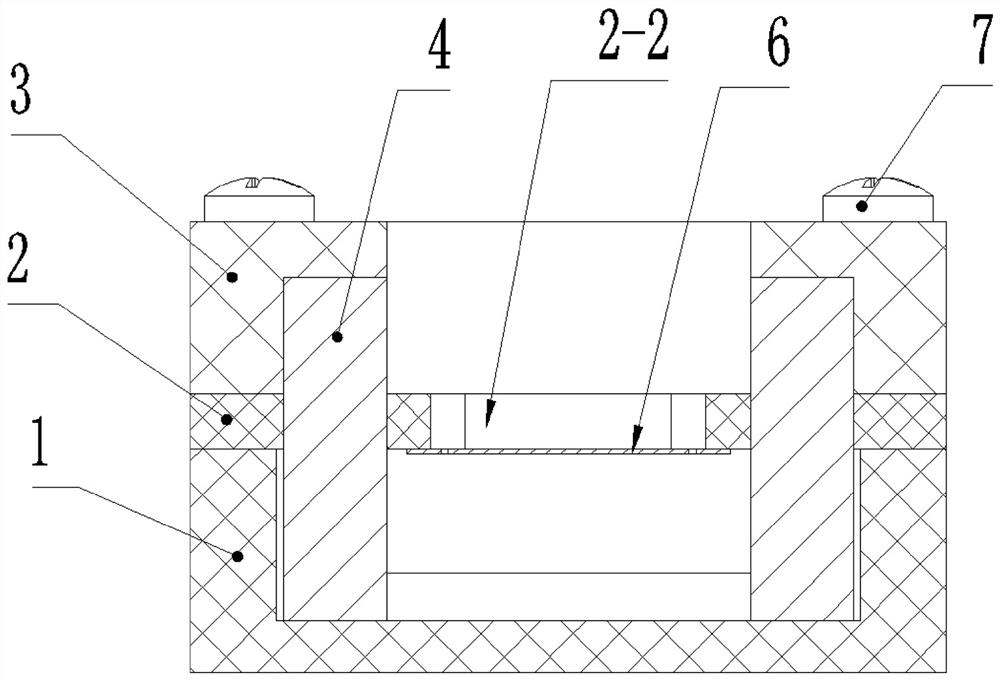

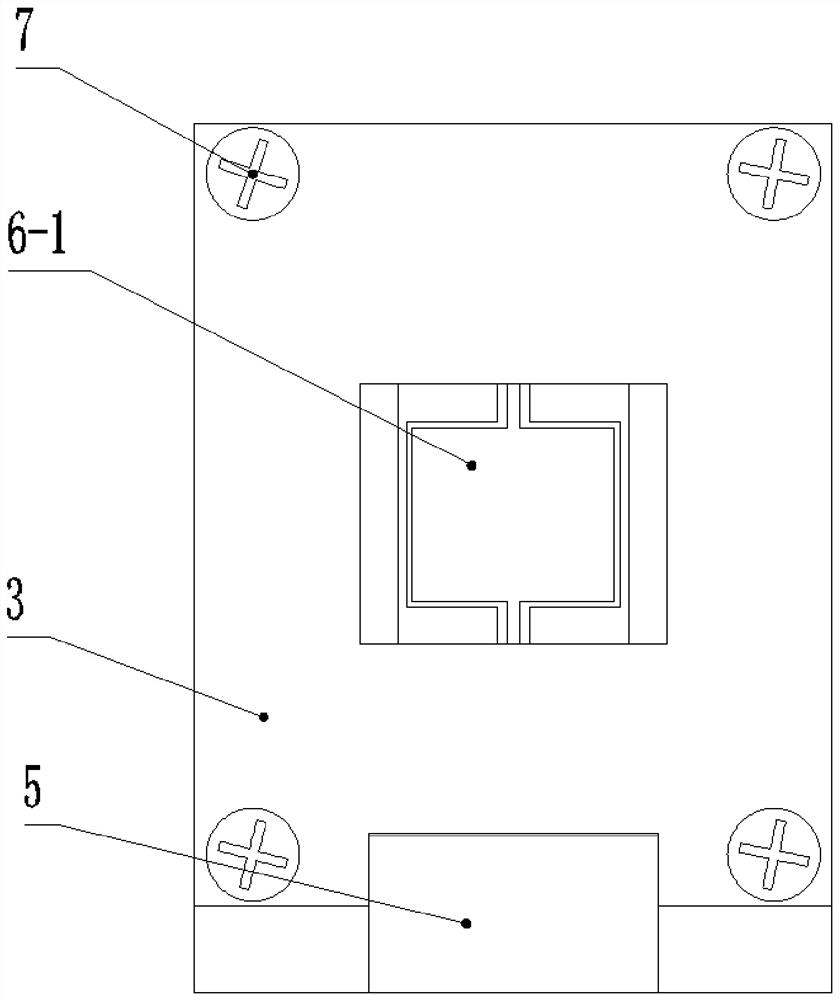

Paper cutting machine

ActiveCN108145760AAvoid compromising cut qualityEasy to collectMetal working apparatusDrive shaftPulp and paper industry

The invention belongs to the field of paper processing devices, and particularly discloses a paper cutting machine. The paper cutting machine comprises a paper feeding mechanism, a cutting mechanism and a collection mechanism, wherein the cutting mechanism comprises a workbench, a rack, a mounting base, a cutter and a power device; a cutting groove is formed in the upper surface of the workbench;the paper feeding unit comprises an uncoiling roller, a rotary shaft and a paper feeding roller; the paper feeding roller is fixed to the rotary shaft; the rotary shaft is provided with a ratchet wheel; the mounting base is provided with a mounting strip; a plurality of clamping jaws are hinged to the mounting strip and can be clamped to the ratchet wheel; the collection mechanism comprises a slide rail, a torsional spring, a transmission shaft, a conveying board and a collection tank; the conveying board is in sliding connection with the slide rail; a gear is fixed to the transmission shaft;a rack is arranged on the lower surface of the conveying board; one end of the torsional spring is fixed to the workbench; the other end of the torsional spring is fixed to the transmission shaft; thetransmission shaft is wound with a pull rope; and the pull rope is connected to the mounting base. When the paper cutting machine is used, the cutting quality can be ensured, burrs at notches are avoided, cut paper can be effectively collected, and pieces of paper are stacked orderly.

Owner:滁州三界外工业设计有限公司

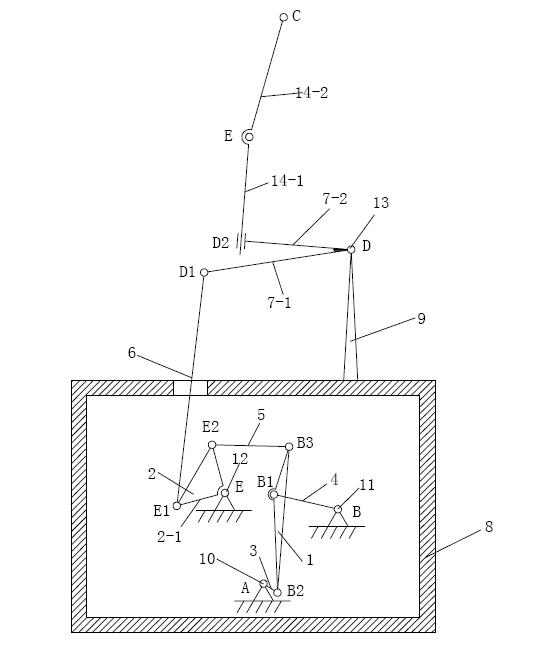

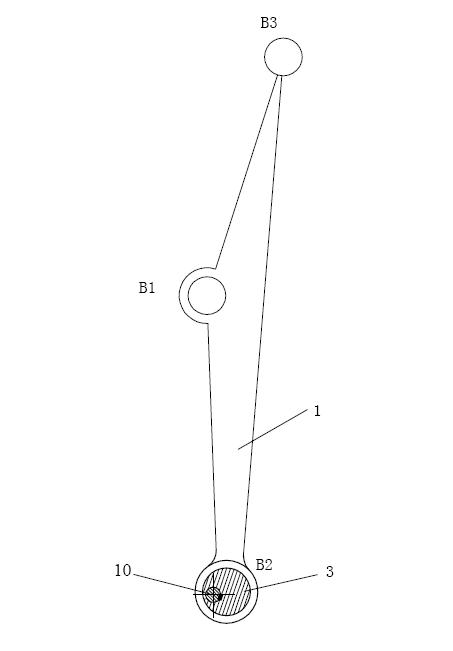

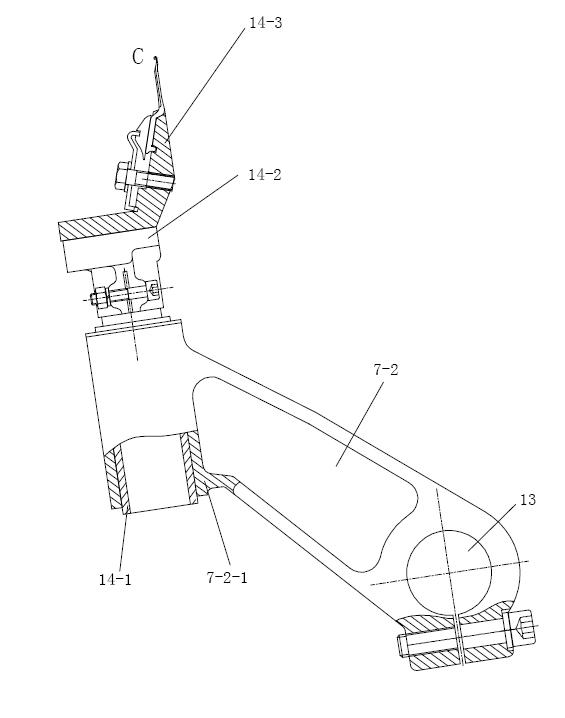

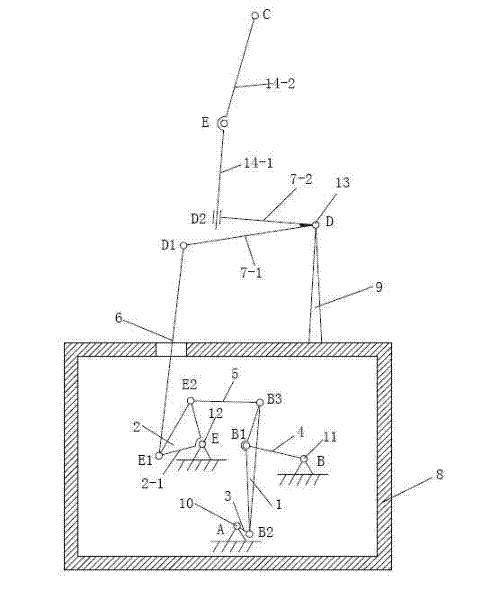

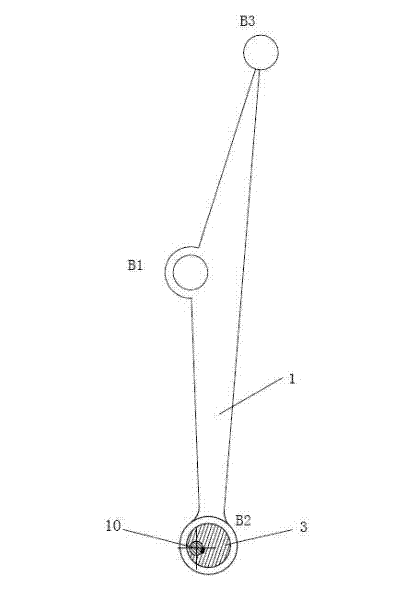

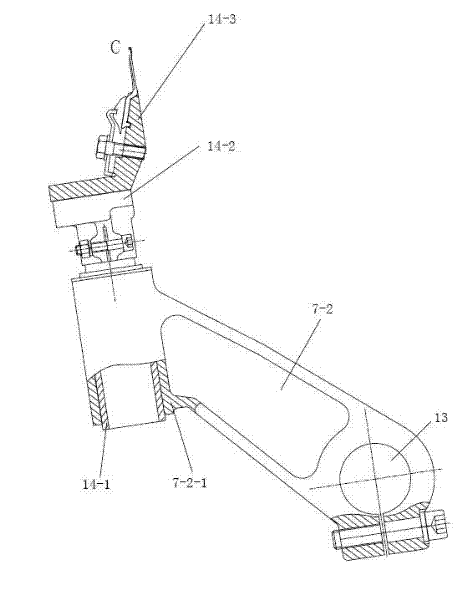

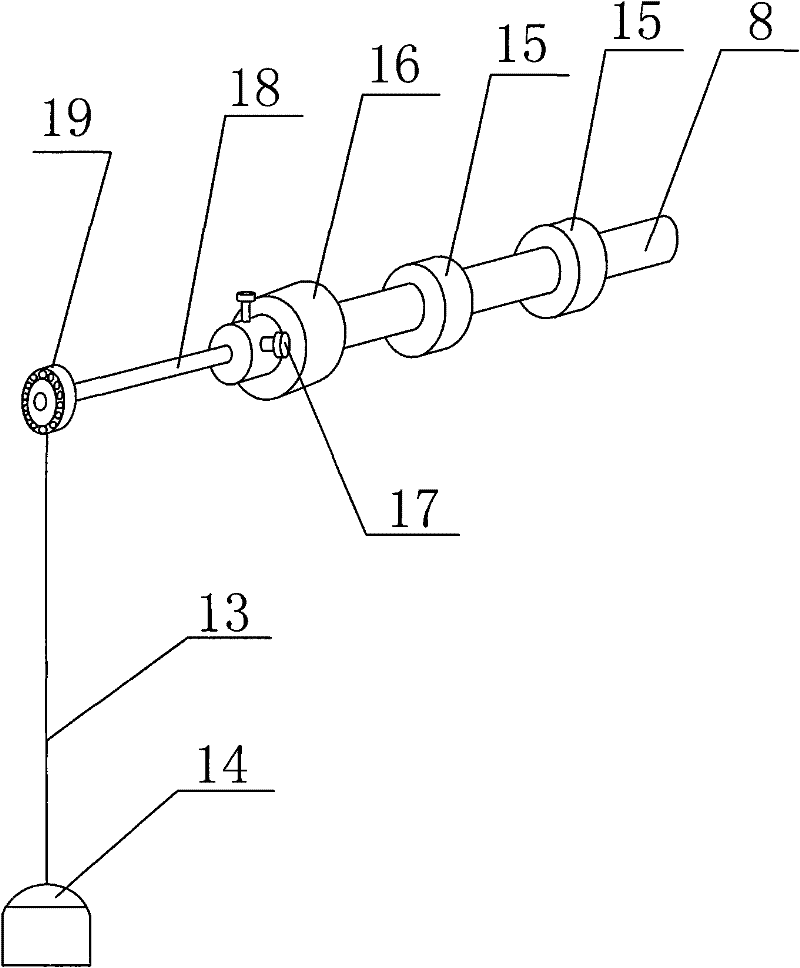

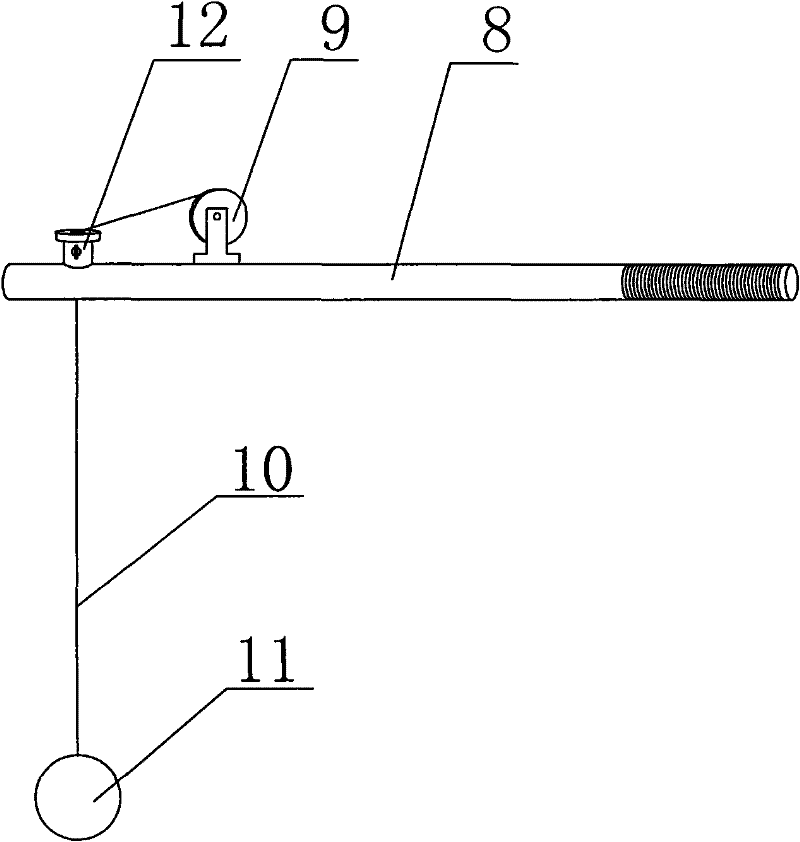

Knitting needle bed swinging mechanism of warp knitting machine

The invention relates to a knitting needle bed swinging mechanism of a warp knitting machine, which is provided with a main shaft, a swinging shaft, a knitting needle bed and a knitting needle seat, wherein the knitting needle seat supports the knitting needle bed and is connected with a needle bed driven swinging arm in a moving pair way. In addition, the knitting needle bed swinging mechanism of a warp knitting machine is also provided with a pin shaft I, a pin shaft II, a triangular member I, a triangular member II, a connecting rod I, a connecting rod II and a connecting rod III, wherein an eccentric wheel is fixed to the main shaft; one end of the triangular member I is connected to the eccentric wheel in a rotating pair way, and other two ends of the triangular member I are respectively connected with the connecting rod I and the connecting rod II in the rotating pair way; the connecting rod I is connected with the pin shaft I in the rotating pair way; one end of the triangular member II is connected to the pin shaft II in the rotating pair way, and other two ends of the triangular member II are respectively connected with the connecting rod II and the connecting rod III in the rotating pair way; and the connecting rod III is connected with a needle bed drive swinging arm of a knitting needle bed assembly in the rotating pair way after penetrating through an oil tank. The invention is beneficial to improving the rotating speed of the whole machine, reduces the manufacture cost, and has wide realized travel speed variation coefficient range.

Owner:临沂高新区金蓝领劳务有限公司

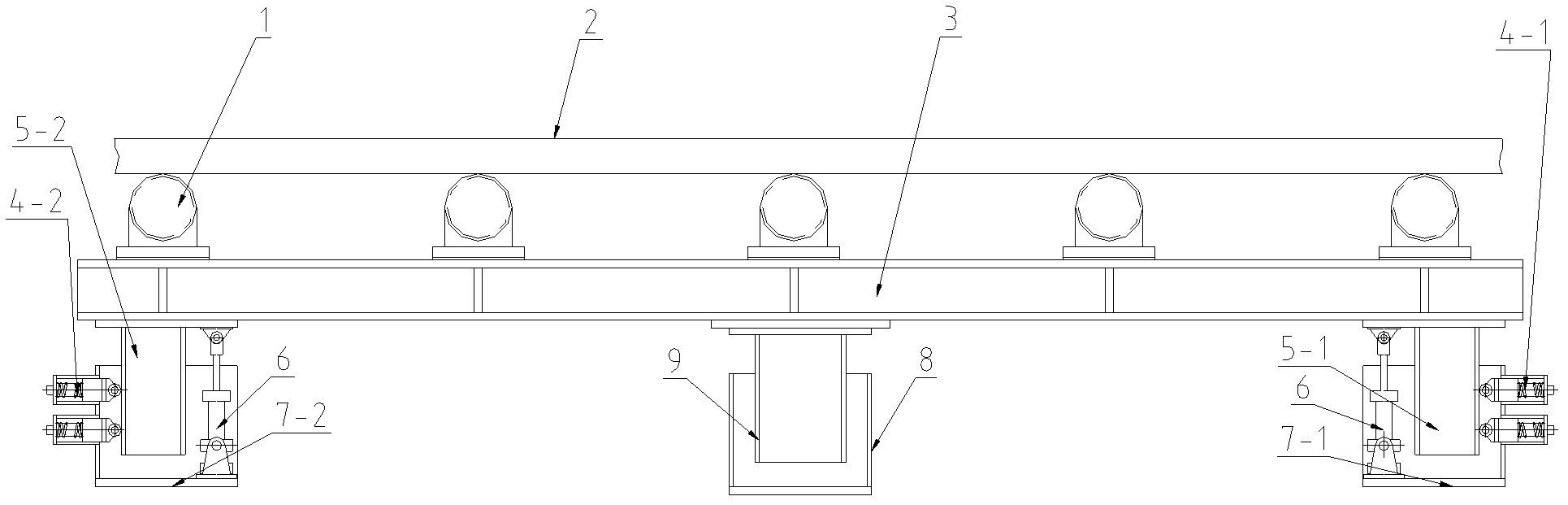

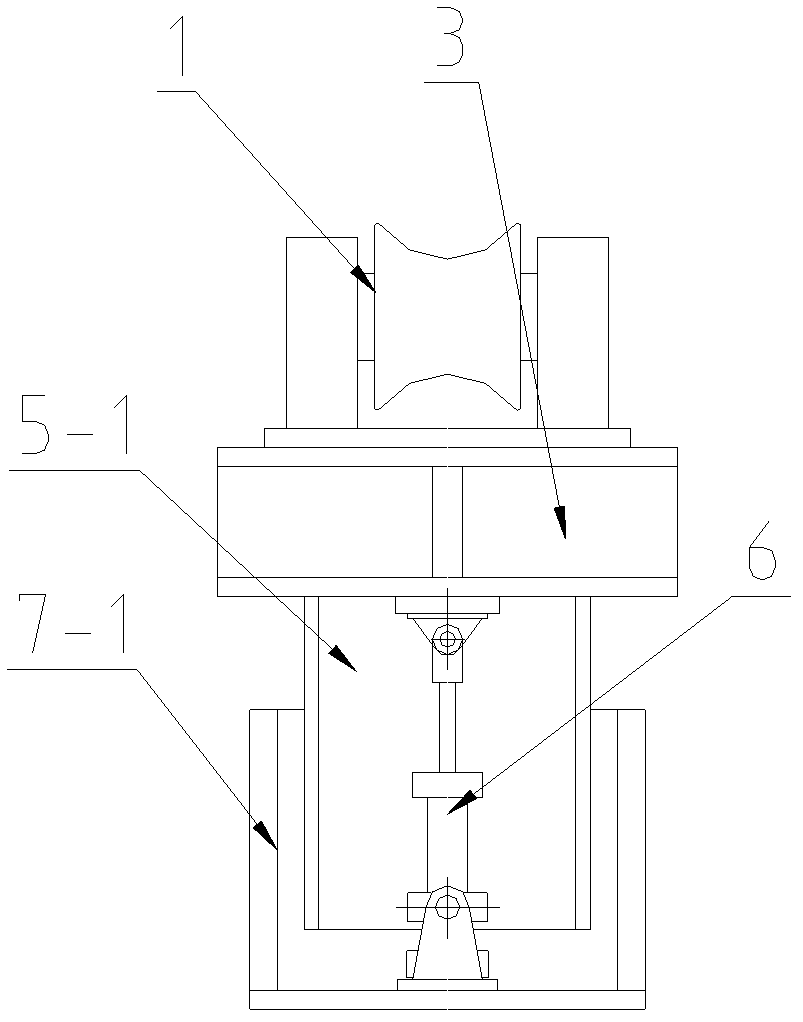

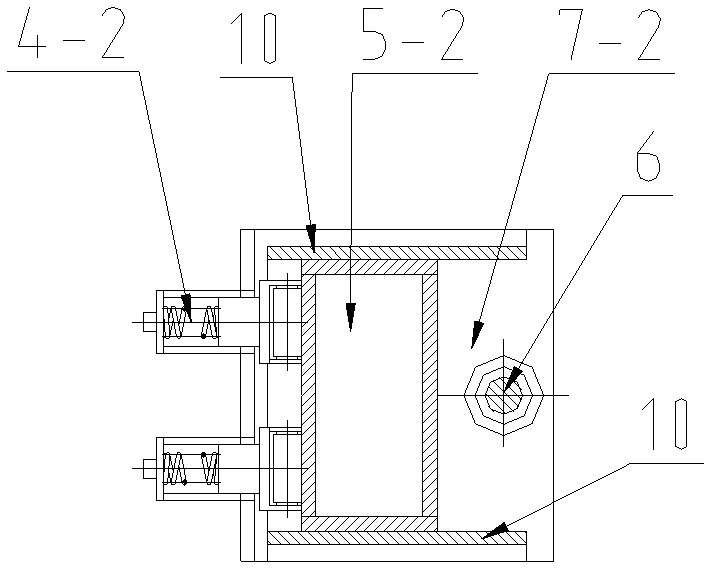

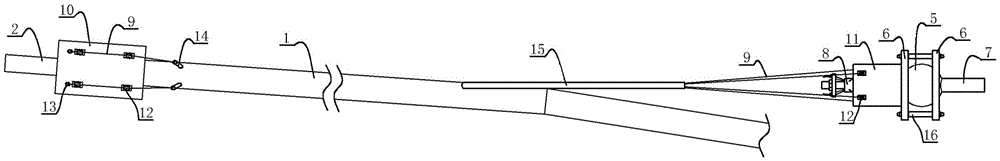

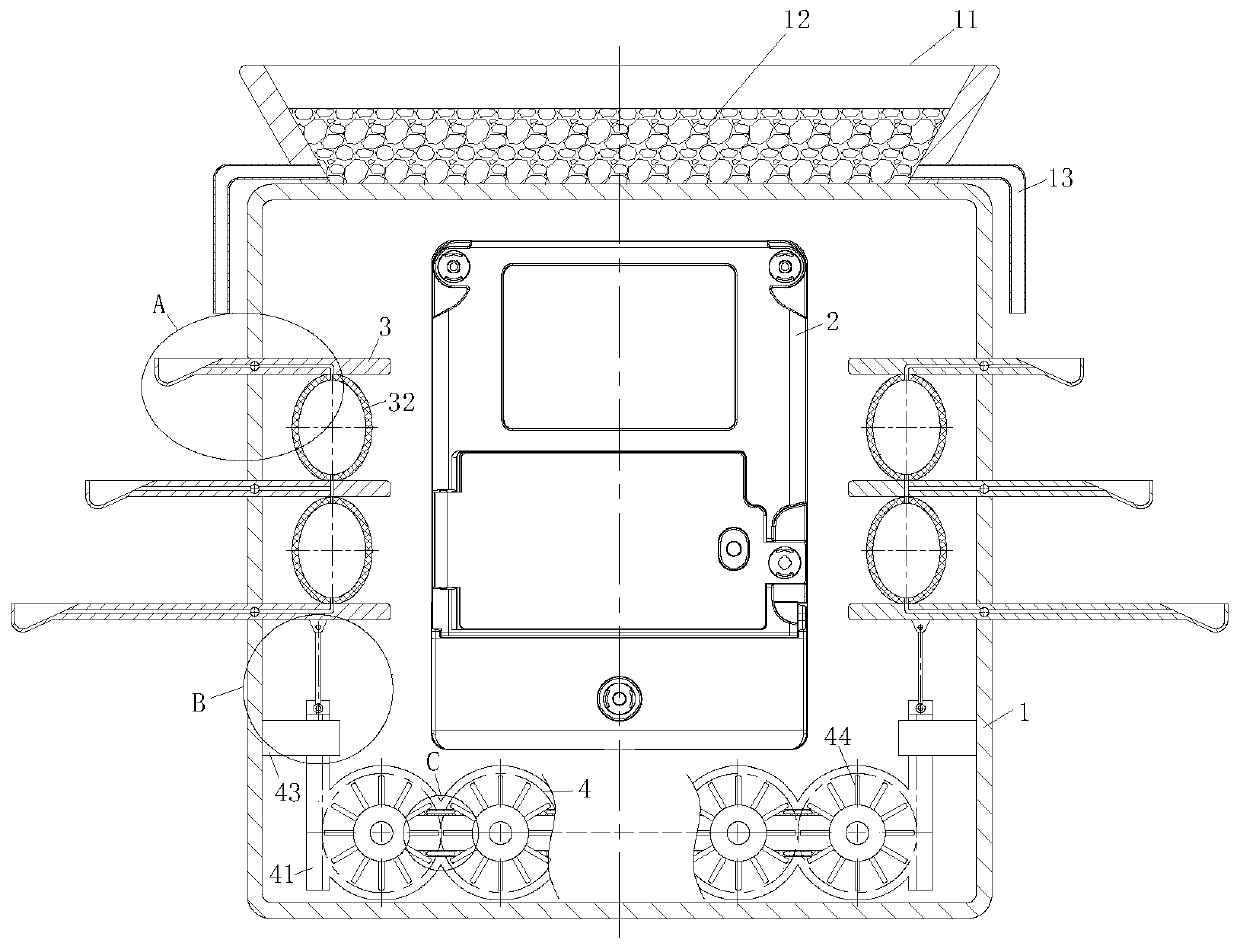

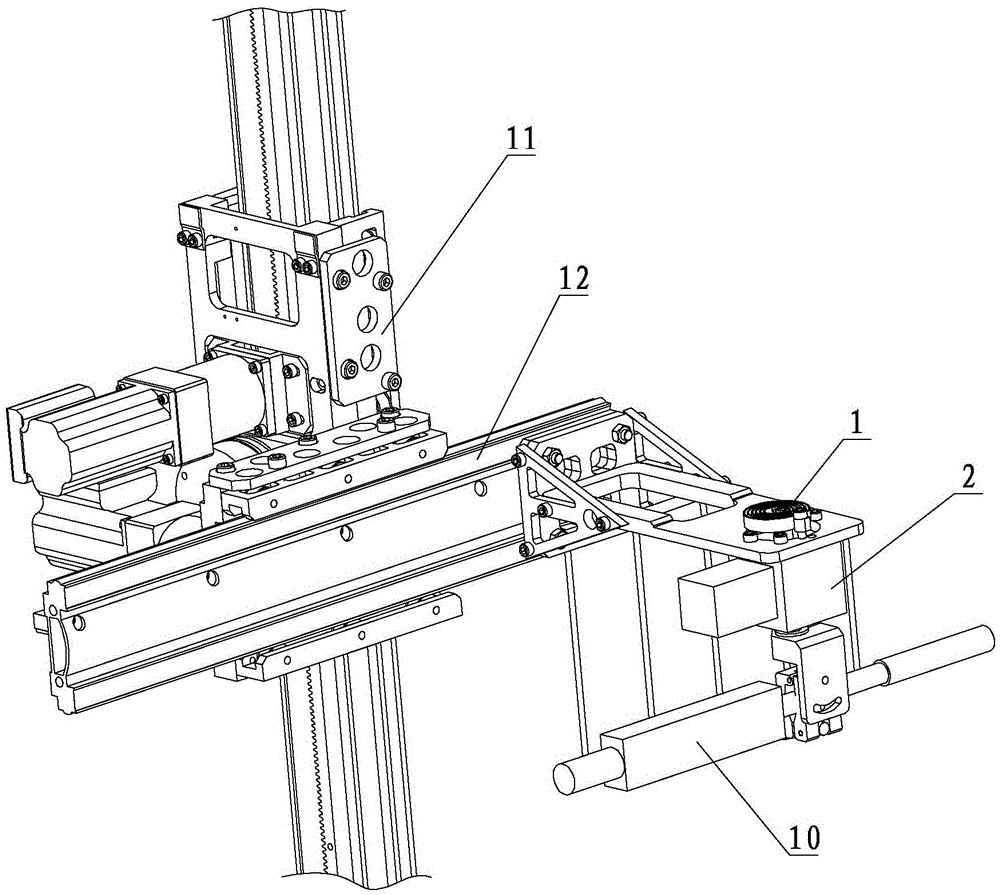

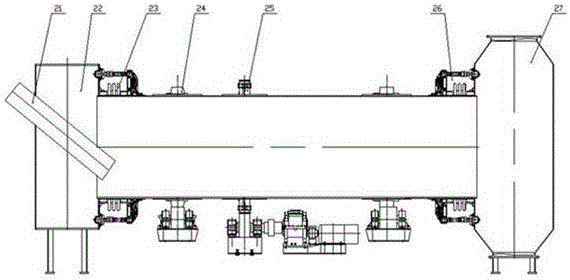

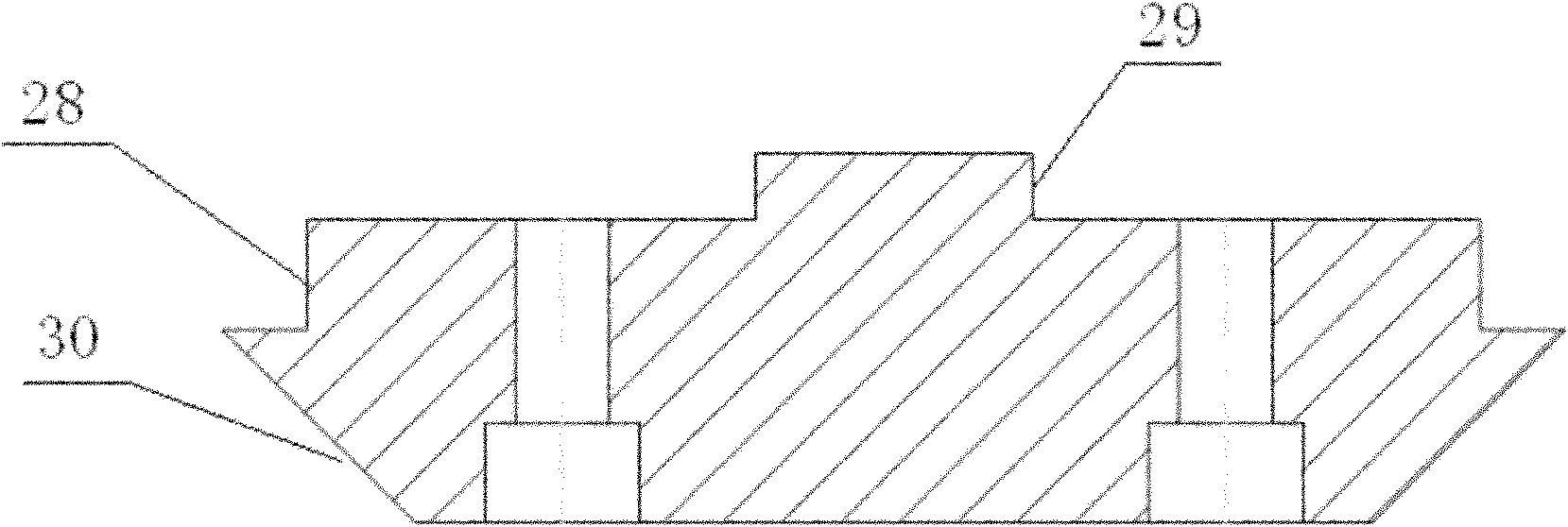

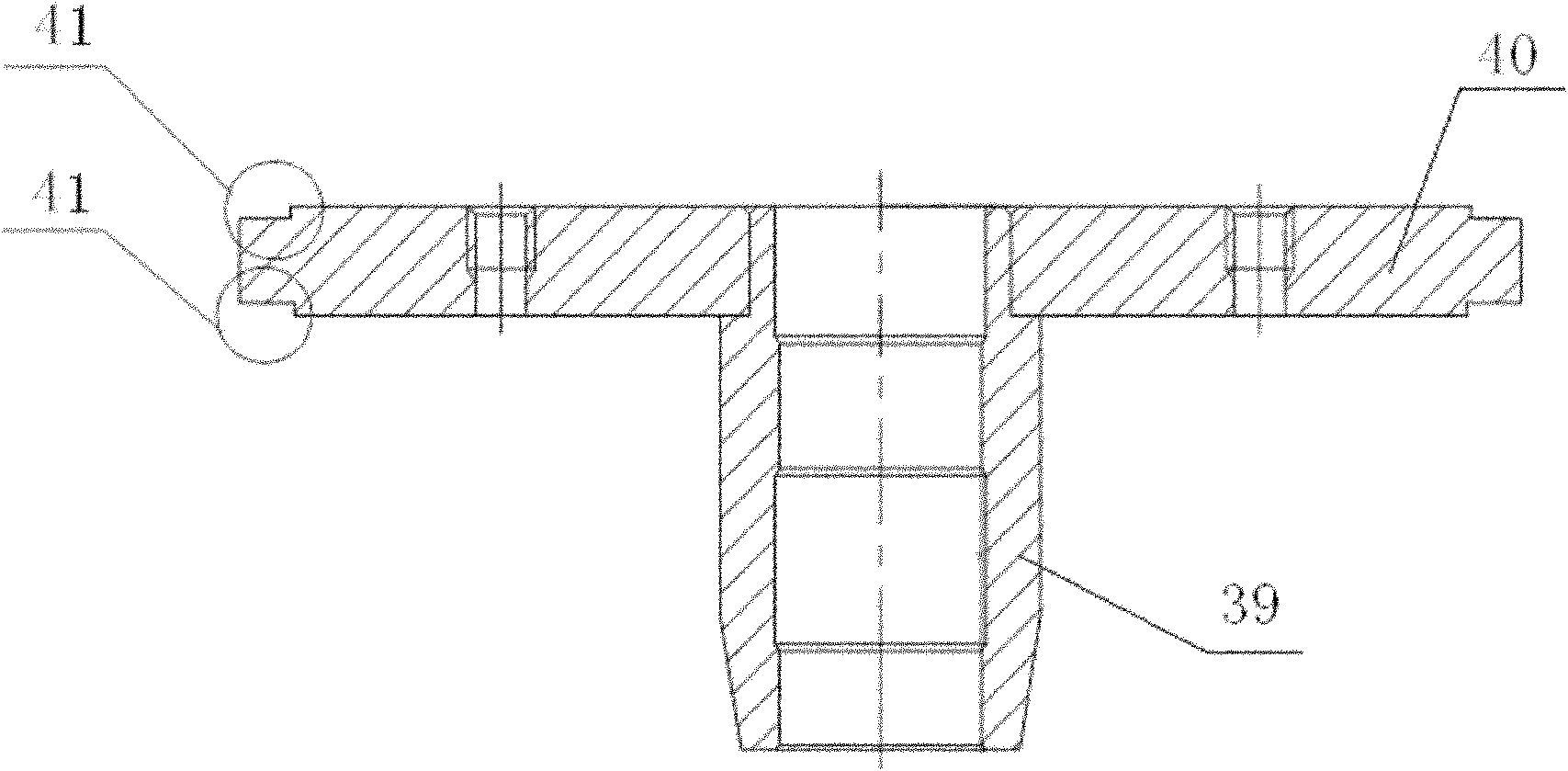

Vertical lifting flexible feeding system of bar straightening machine

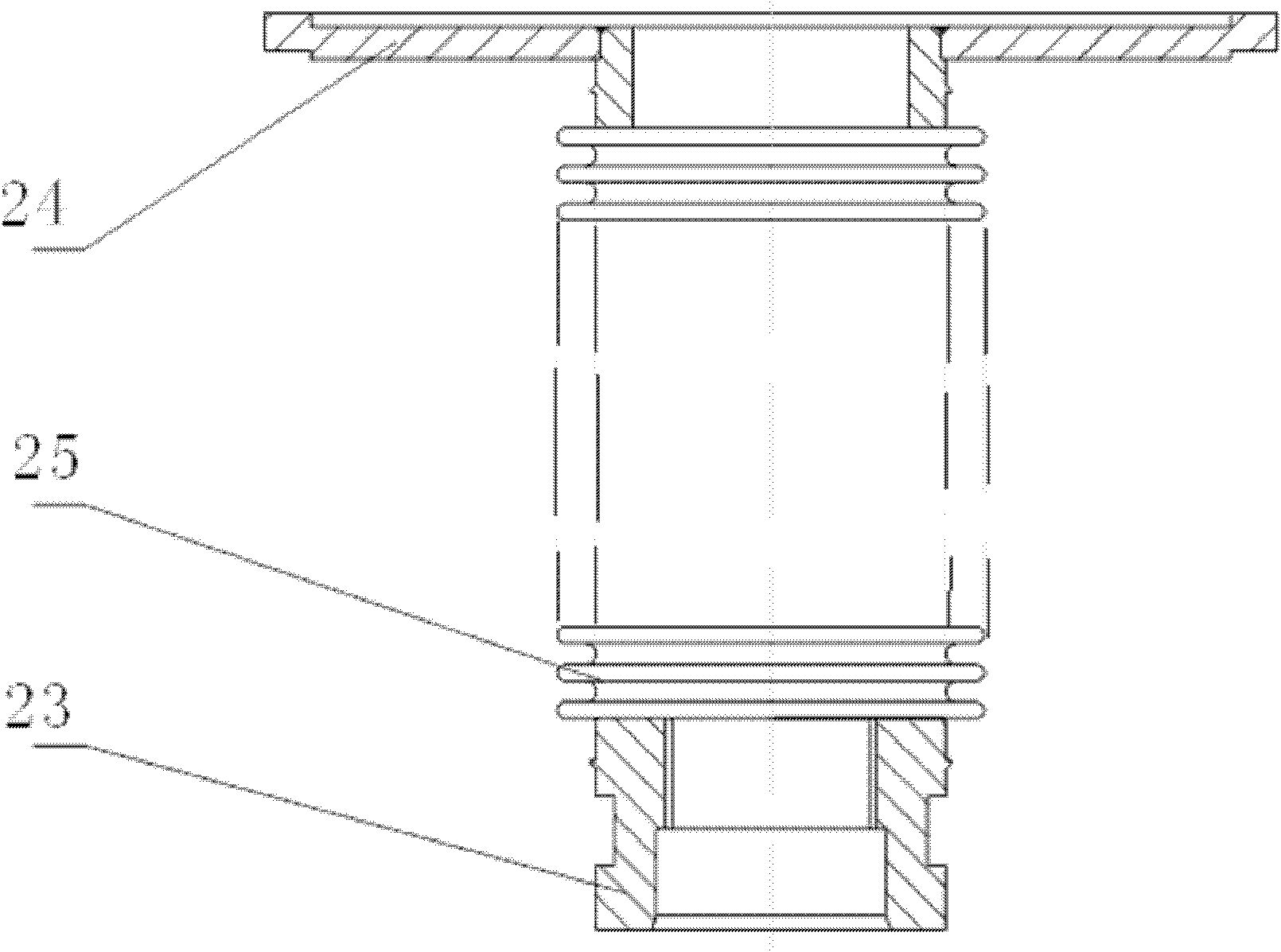

ActiveCN102489621AGuaranteed swingAvoid excessive impactMetal-working feeding devicesPositioning devicesTrunnionPetroleum engineering

A vertical lifting flexible feeding system of a bar straightening machine comprises a beam. A feeding roller way is installed on the beam, and the portion below the beam is connected with guide posts which are placed on bases. The beam is in hinged connection with oil cylinder rods of two lifting oil cylinders which are installed on the bases in a middle trunnion connection mode. A hinge shaft through which the lifting oil cylinders are connected with the beam and the middle trunnions through which the lifting oil cylinders are connected with a left base and a right base are installed in perpendicular crossing mode. One side of a left guide post is respectively provided with two pairs of first spring top rollers, one side of a right guide post is respectively provided with two pairs of second spring top rollers, and the middle trunnions of the lifting oil cylinders and the hinge shaft of the oil cylinder rods are installed in the perpendicular crossing mode, thereby enabling the feeding roller way and the beam to be free in the four directions of forwards, backwards, left and right, ensuring that the feeding roller way and the beam can swing after struck by bars, avoiding excessive impact, prolonging service life and meanwhile reducing work amount of device maintenance.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

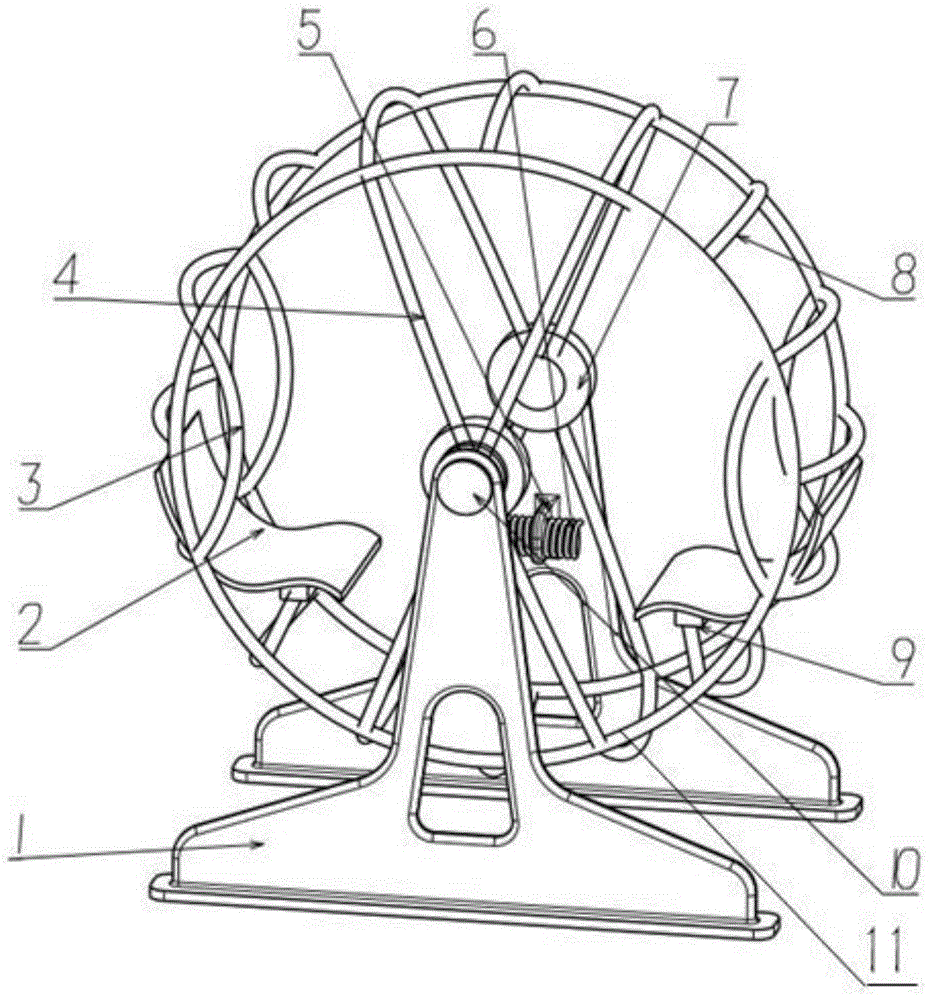

Leisure runner

InactiveCN103550934AFacilitate communicationGuarantee your own spaceRussian swingsGreat wheelsHandrailEngineering

The invention discloses a leisure runner which comprises brackets, seats, handrails, a clamping spoke, a spring supporting block, a spring, turntables, bent pipes, seat supporting pieces, rotating shafts and outer rings and is characterized in that the rotating shafts are fixedly connected to the upper ends of two same brackets which stand oppositely and are connected with the turntables through rotating pairs; the two outer rings which stand oppositely are fixedly connected to the turntables through the clamping spoke; a plurality of bent pipes are fixed between the two outer rings; the seats are fixed between the two outer rings; the bottoms of the seats are fixed on the lower bent pipes through the seat supporting pieces; the handrails are arranged above two sides of the seats; the spring is connected to the brackets through the spring supporting block. The invention aims to provide novel creative leisure equipment in a park or other leisure places to provide a new creative option in the leisure place. The invention provides a novel leisure way to general leisure people.

Owner:NANCHANG HANGKONG UNIVERSITY

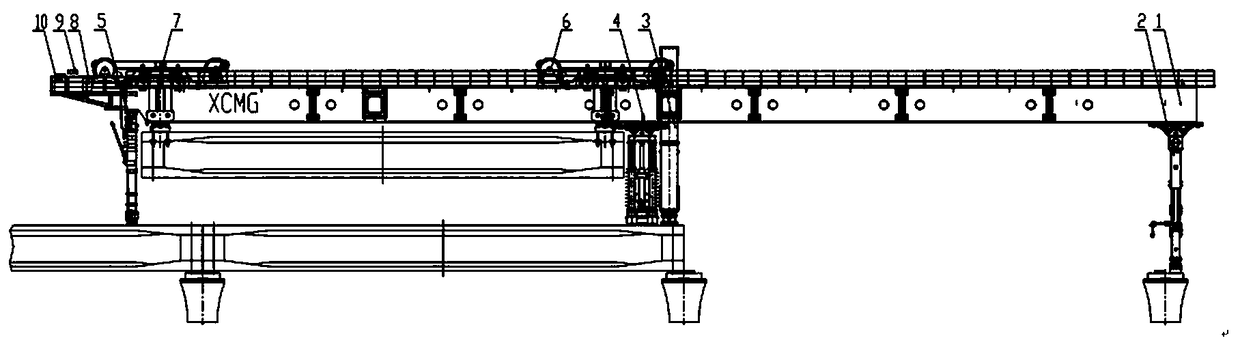

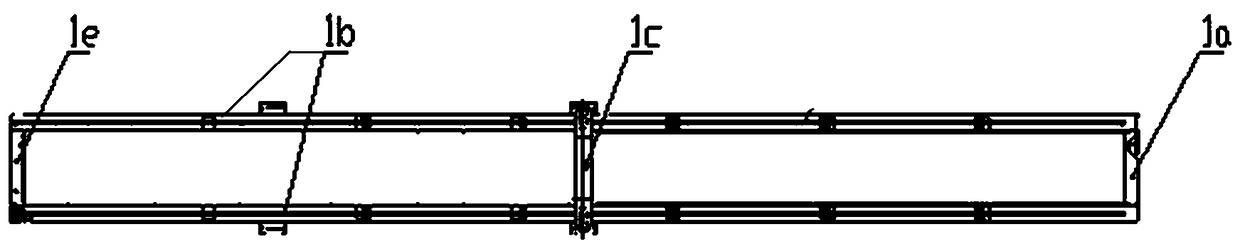

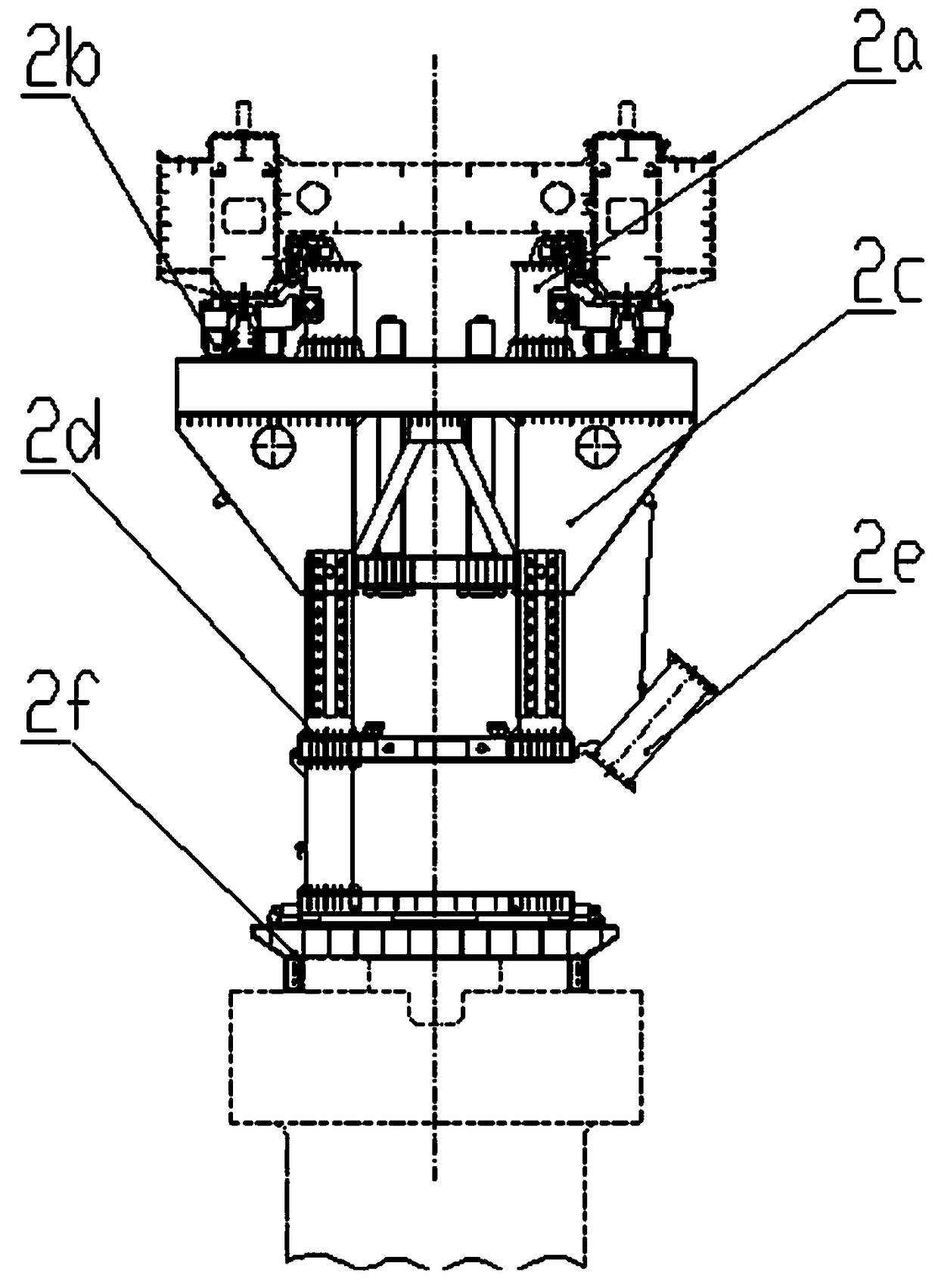

Double-beam walking-type bridge girder erection machine used for box girder erection and compatible with G-series high-speed train single-line and double-line girder erection

PendingCN108824218AGuaranteed swingAvoid constructionBridge erection/assemblyEngineeringBeam walking

The invention relates to a double-beam walking-type bridge girder erection machine used for box girder erection and compatible with G-series high-speed train single-line and double-line girder erection and belongs to the technical field of bridge girder erection machines. The bridge girder erection machine comprises main beams, supporting legs, overhead travelling cranes, an electric control system, a hydraulic system and a power system and is characterized in that the supporting legs include a front supporting leg, a middle supporting leg, a via hole supporting leg and a rear supporting leg,the overhead travelling cranes include a front overhead travelling crane and a back overhead travelling crane, the front supporting leg, the middle supporting leg and the rear supporting leg are sequentially connected and arranged at a main beam supporting leg installing position, a middle supporting leg installing position and a rear supporting leg installing position. The double-beam walking-type bridge girder erection machine has the advantages that a walking-type structure form is adopted, the construction problem under complicated working conditions is solved, and the adaptability and working efficiency of the machine are improved; the bottom of the front supporting leg and the bottom of the via hole supporting leg are both provided with transverse moving mechanisms, and constructionof a curve R smaller than 2000 m is really solved; the machine is compatible with G-series high-speed train single-line and double-line box girders, and the utilization rate of the machine is improved.

Owner:徐州徐工铁路装备有限公司

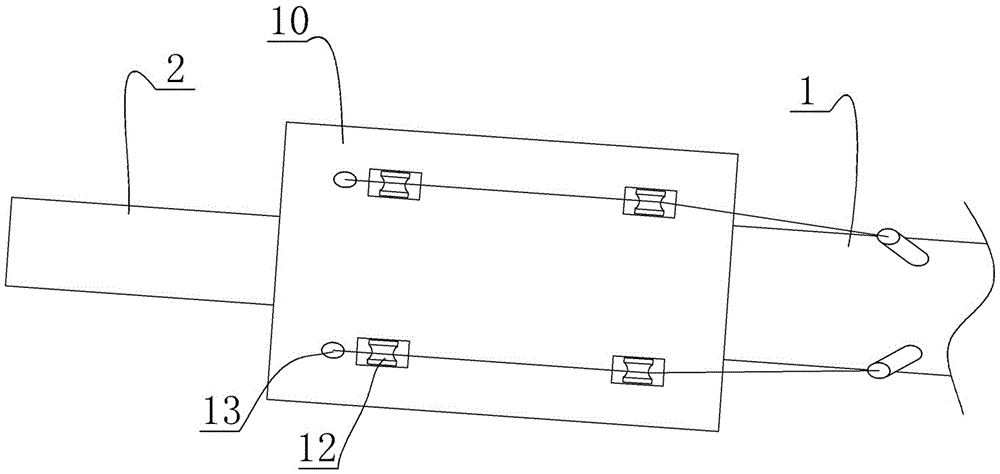

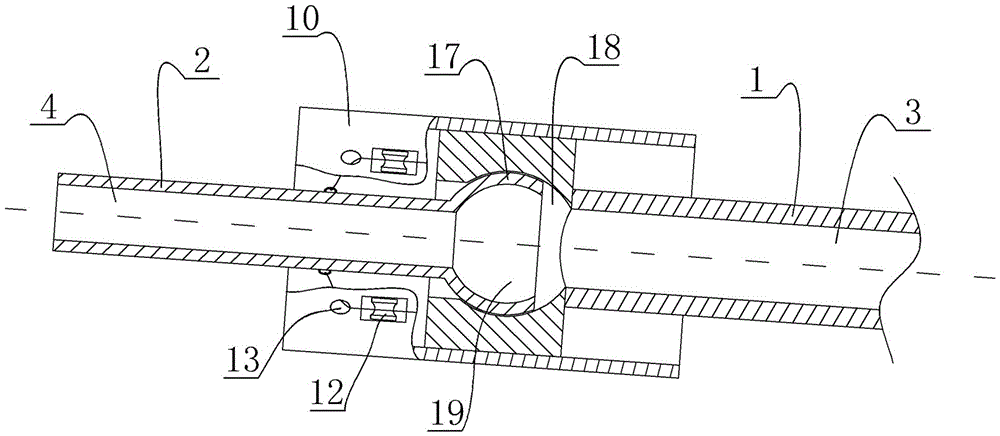

Fluid jet direction adjusting device

The invention provides a fluid jet direction adjusting device which comprises a fluid pipeline, an injector head, a driving ball and multiple stay wires. The fluid jet direction adjusting device is characterized in that the driving ball is located at the rear end of the fluid pipeline, a handle is fixed to the rear end of the driving ball, a supporting rod is fixed to the front end, a front outer cylinder is arranged on the periphery of the injector head, a rear outer cylinder is arranged on the periphery of the supporting rod, the front ends of the stay wires are fixed to the periphery of the injector head, and the rear ends of the stay wires are fixed to the periphery of the supporting rod. The stay wires are in a tension state so that the direction of the injector head can change along with changing of the direction of the supporting rod, the injector head can rotate along with the supporting rod, and the jet direction of the injector head can be adjusted so as to carry out effective extinguishment operation. The fluid jet direction adjusting device has the advantages of being simple and reasonable in structure, low in manufacturing cost, flexible to control, remarkable in benefit effect and suitable for application and popularization.

Owner:张正泉

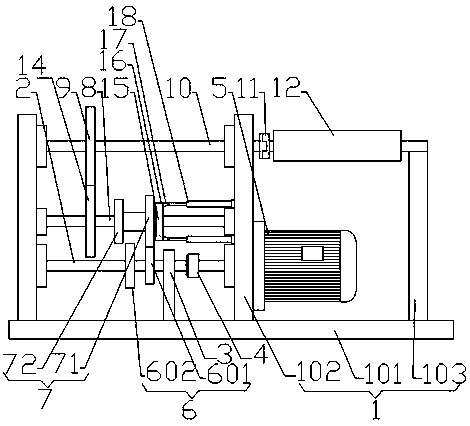

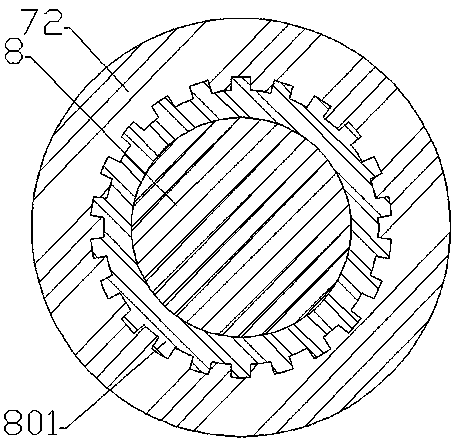

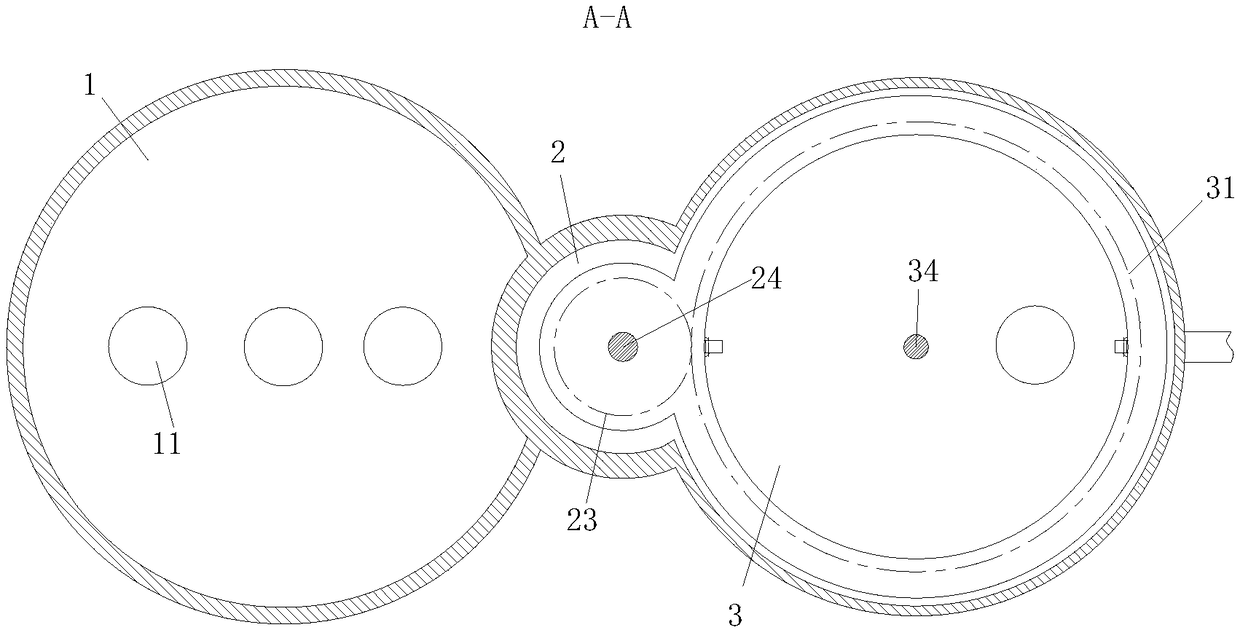

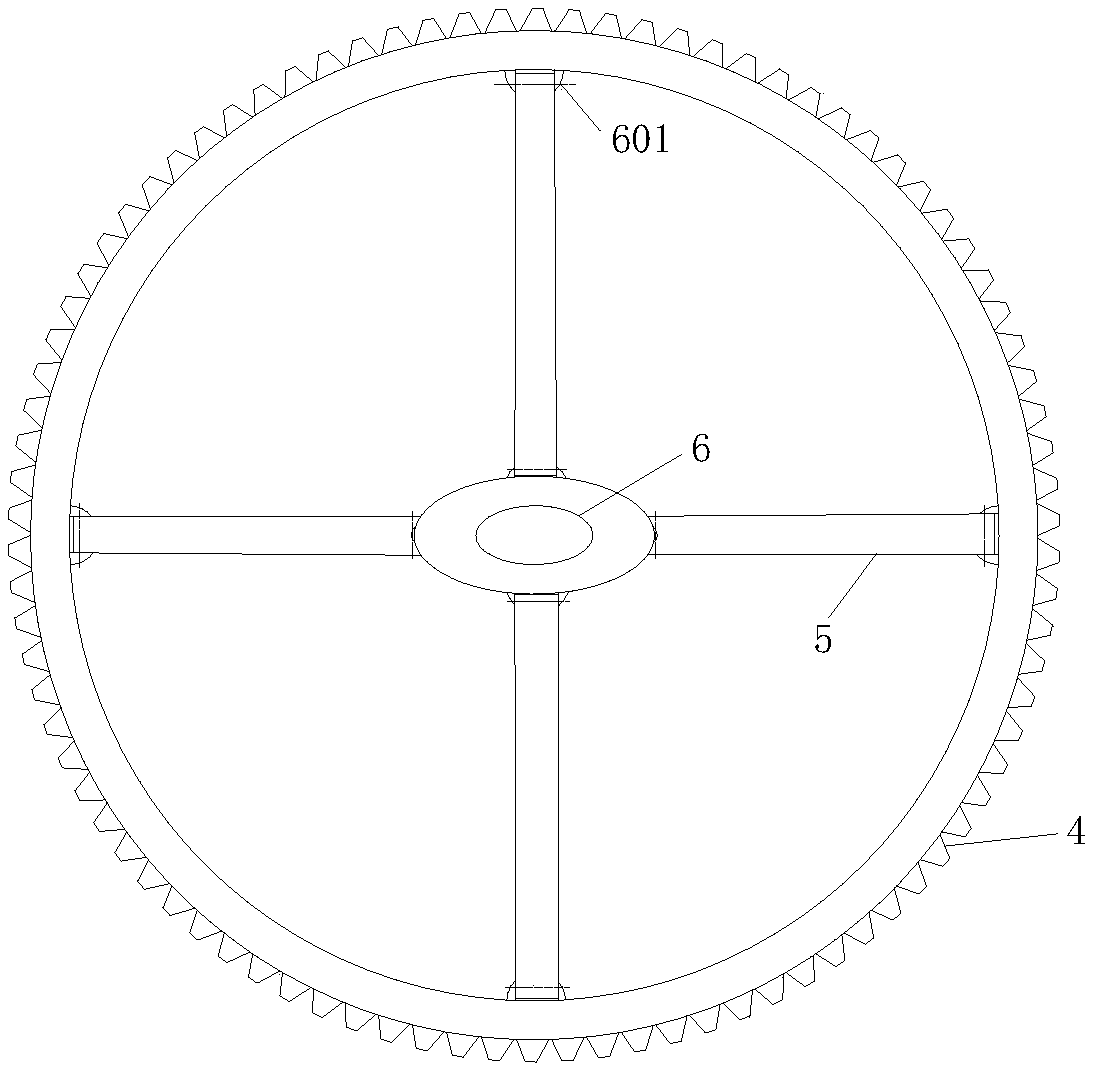

Net belt variable-speed winding device for fabricating safety nets

The invention discloses a net belt variable-speed winding device for fabricating safety nets. The net belt variable-speed winding device comprises a rack, a bottom plate of the rack is provided with vertical plates, a middle shaft and an upper shaft are connected between the vertical plates, one end of a lower shaft is further connected between the vertical plates, the other end of the lower shaftis connected with a motor through a clutch, the motor is installed on the outer side of the right vertical plate, the other end of the lower shaft is connected with a supporting plate, the supportingplate is vertically installed between the vertical plates, the lower shaft is connected with a driving gear train in a sleeved manner and the driving gear train is connected with a driven gear trainon the middle shaft in an engaged manner, a transition wheel on the middle shaft is connected with a power wheel on the upper shaft in an engaged manner, and one end of the upper shaft is connected with one end of a net roller through a coupler after running through the right vertical plate. The net belt variable-speed winding device for fabricating the safety nets is compact in structure and reasonable in design, rotating of a shaft and the net roller is controlled by the clutch, and the shaft is provided with an adjustable-speed wheel to control the rotating speed of the net roller, in addition, the supporting plate is strengthened to prevent the lower shaft from jumping, the stability of gear transmission is guaranteed, the net belt variable-speed winding device for fabricating the safety nets is more reliable in operation and more convenient to use than a traditional net winding device, especially, the net roller rotating-speed mechanical adjustment is suitable for winding of net belts of different specifications.

Owner:太和县海诚绳网业有限公司

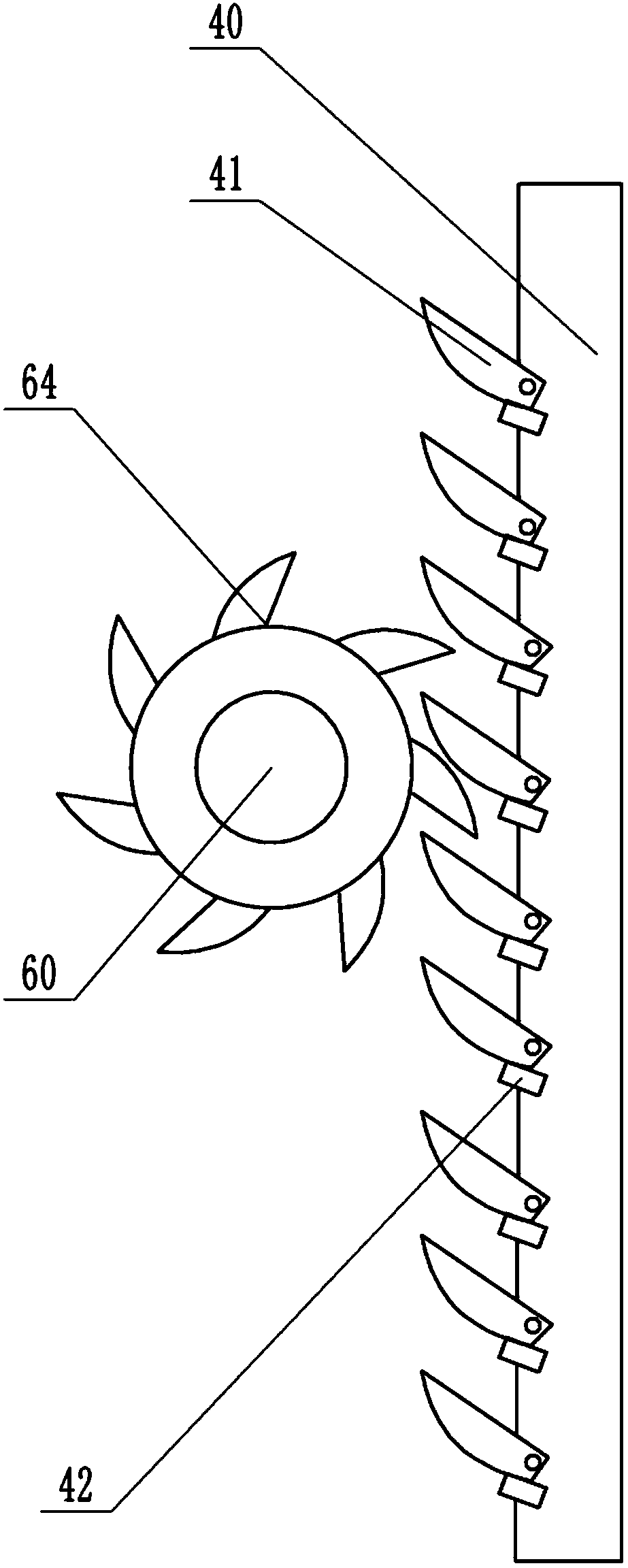

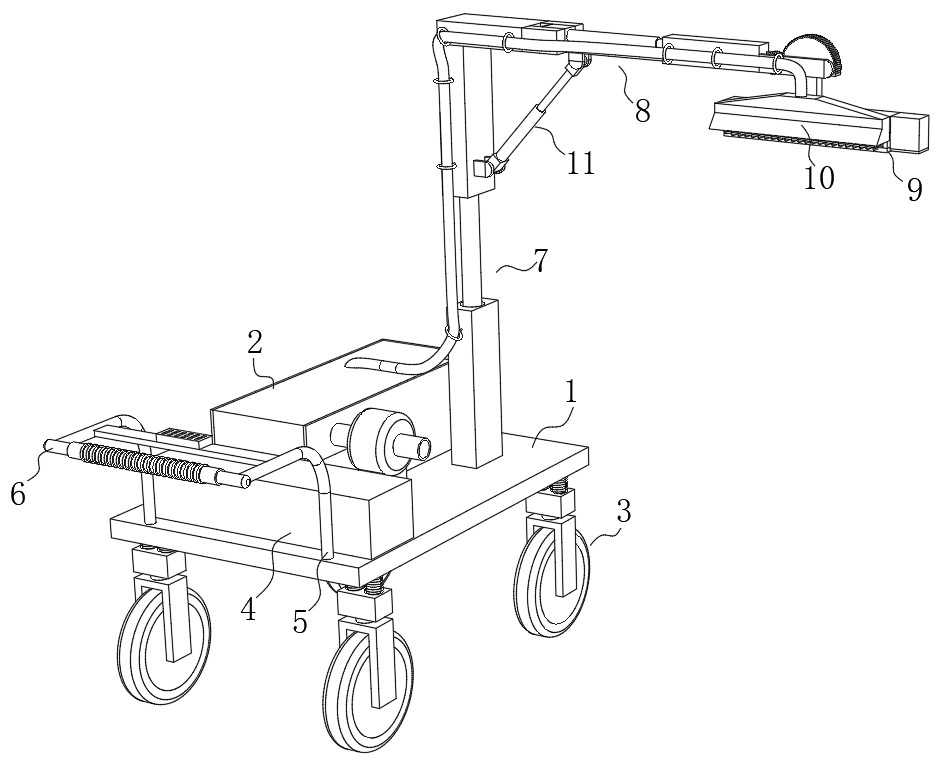

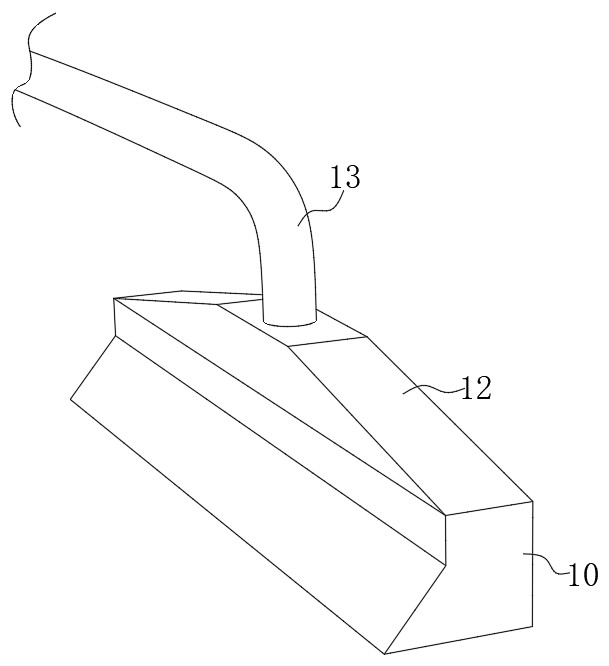

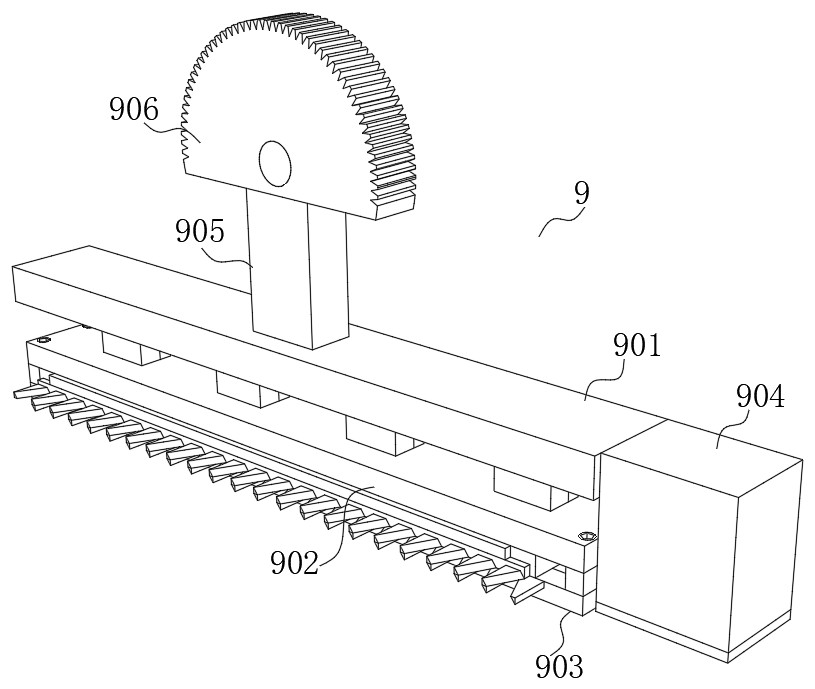

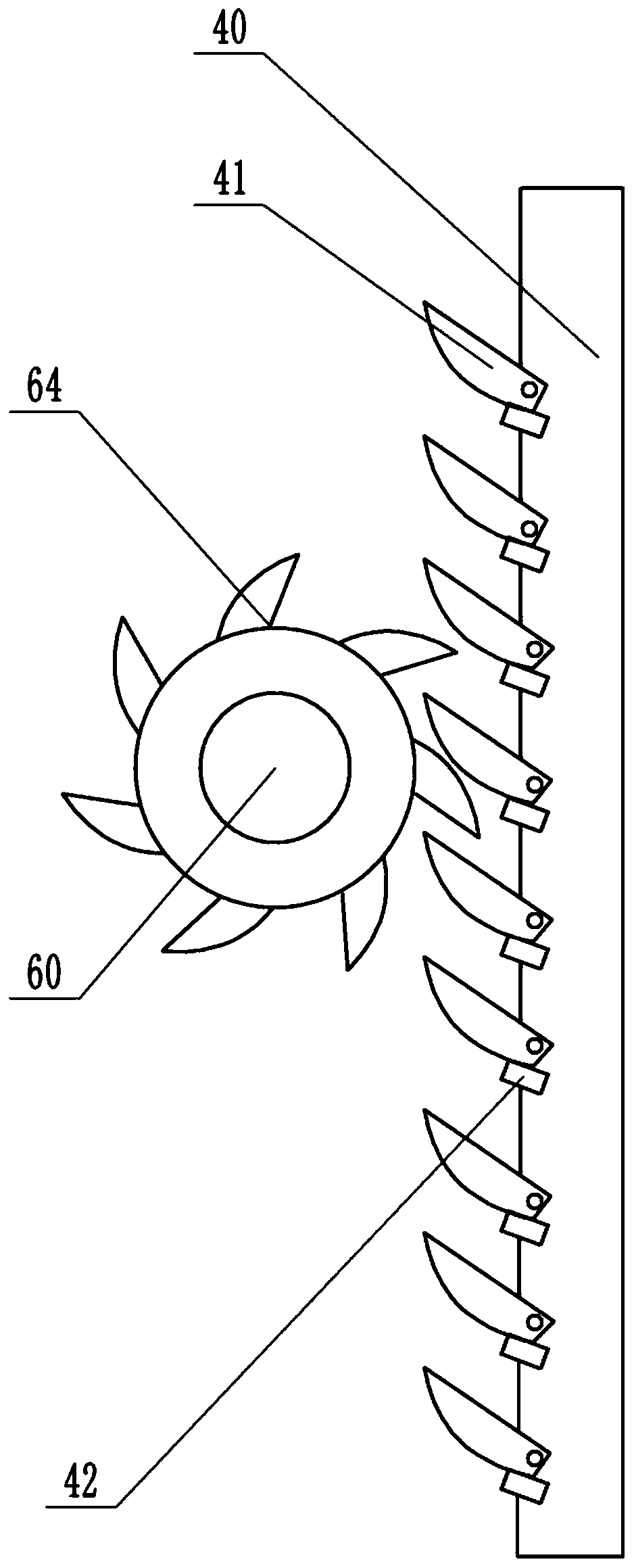

Automatic plant pruning device for gardens

InactiveCN112470744ASmooth reciprocating motionEasy to disassembleGas current separationCuttersHydraulic cylinderAgricultural engineering

The invention discloses an automatic plant pruning device for gardens, and belongs to the technical field of landscaping equipment. The automatic plant pruning device comprises a bottom plate and a control panel, wherein a collecting box and a lifting assembly are fixed to the upper surface of the bottom plate, a moving assembly is fixed to the bottom surface of the bottom plate, a telescopic assembly is fixed to the top of the lifting assembly, a cutting assembly is rotatably connected to one end of the telescopic assembly, a hydraulic cylinder is fixed between the lifting assembly and the telescopic assembly, the cutting assembly comprises a suspension plate, an arc-shaped gear is fixed to the top of the suspension plate, the telescopic assembly comprises a fixing block and a cantilever,two end plates are fixed to the other end of the cantilever, a main gear is rotationally connected between the two end plates, and the arc-shaped gear is rotationally connected between the two end plates and engaged with the main gear. By means of the design of the telescopic assembly, the cutting assembly, the lifting assembly, the hydraulic cylinder, the collecting box and an anti-blocking assembly, automatic plant pruning device can conduct multi-angle pruning on plants with different depths and different heights and collect pruned branches and leaves.

Owner:南京荧河谷科技有限公司

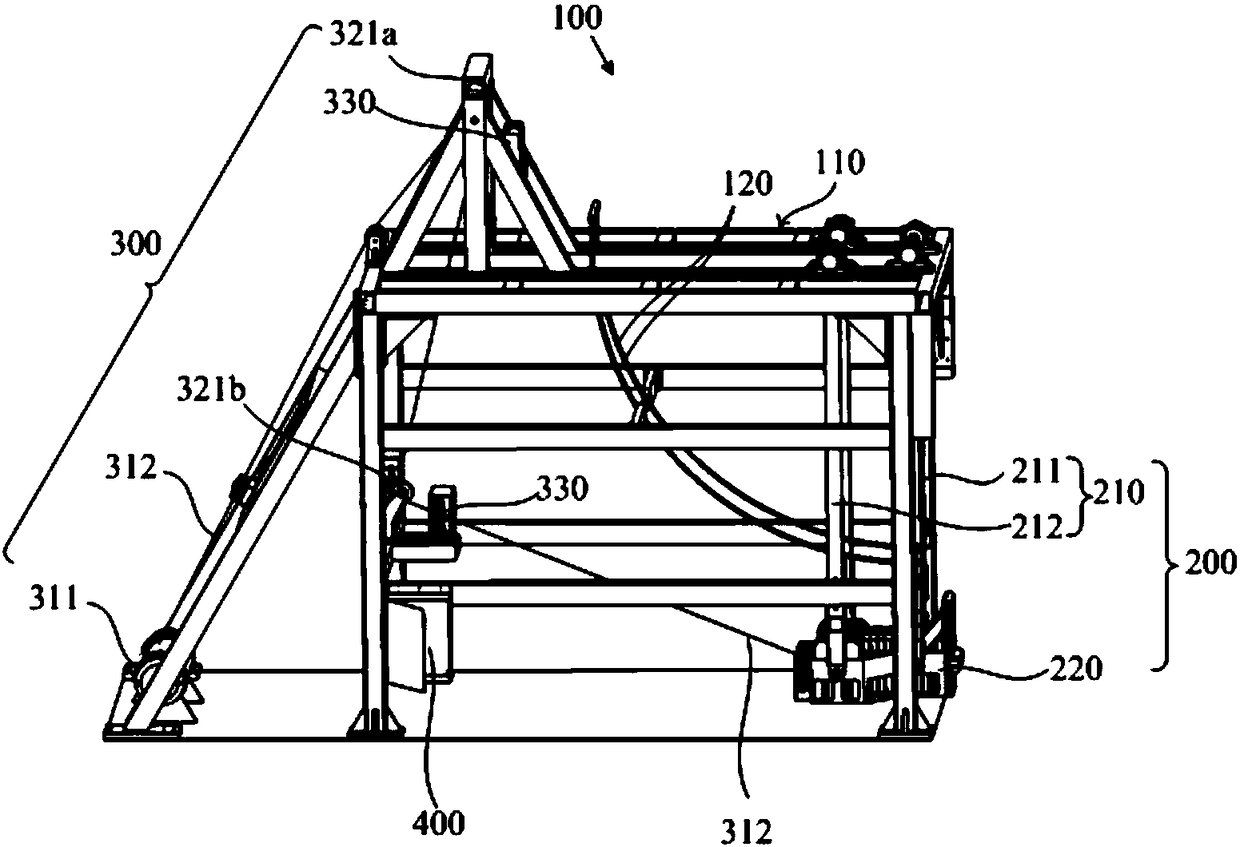

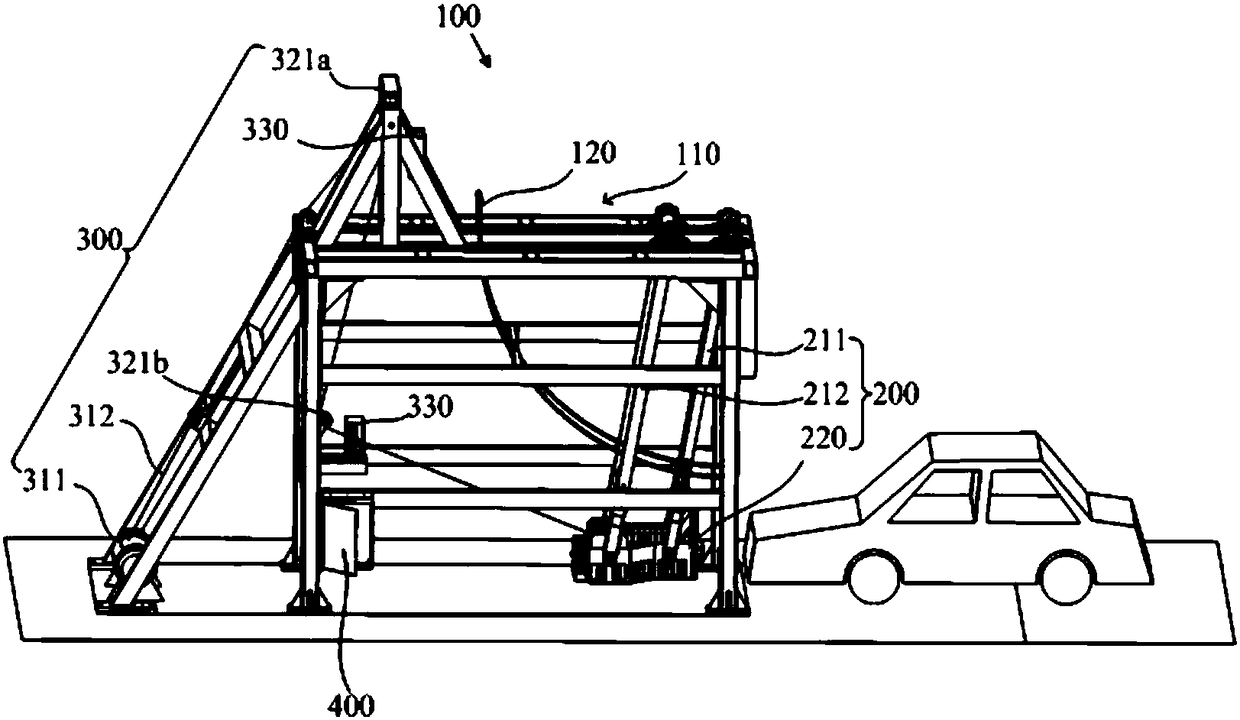

Test bench

ActiveCN105841912AMeet the needs of different test environmentsWon't swing freelyShock testingSupporting systemEngineering

The invention discloses a test bench. The test bench includes a supporting system and a swing hammer system hinged to the supporting system; the swing hammer system comprises a swing rod portion and a swing hammer portion; the swing rod portion includes a first swing rod and a second swing rod; at least one first swing rod and at least one second swing rod are adopted; the swing plane of the first swing rod and the swing plane of the second swing rod are parallel to each other and are not overlapped with each other; the swing hammer portion includes a large swing hammer and a small swing hammer; the large swing hammer is connected with the bottom of the first swing rod and the bottom of the second swing rod; and the small swing hammer is connected with the bottom of the first swing rod or the bottom of the second swing rod. According to the test bench, the large swing hammer and the small swing hammer can be installed selectively according to test types; when simultaneously acting, the first swing rod and the second swing rod can be connected with the large swing hammer, so that an impact test of a front bumper and a back bumper of an automobile can be carried out; when acting alone, the first swing rod or the second swing rod can be connected with the small swing hammer, so that a free impact test can be carried out, and thus, the needs of different test environments can be satisfied.

Owner:江苏彪发化妆品有限公司

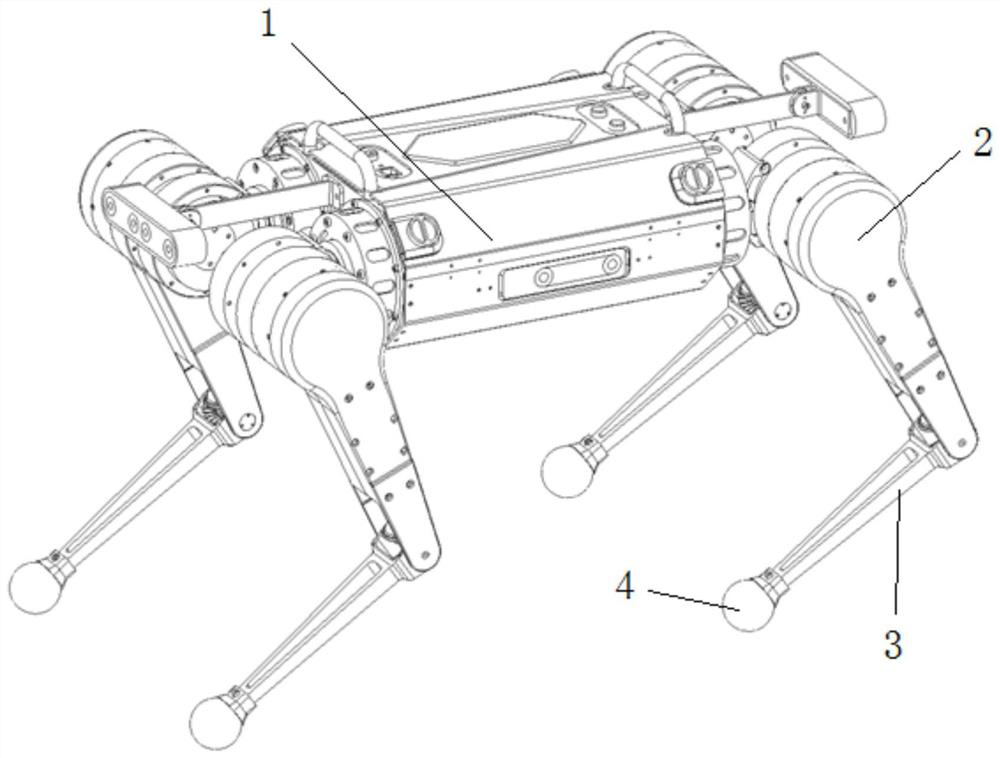

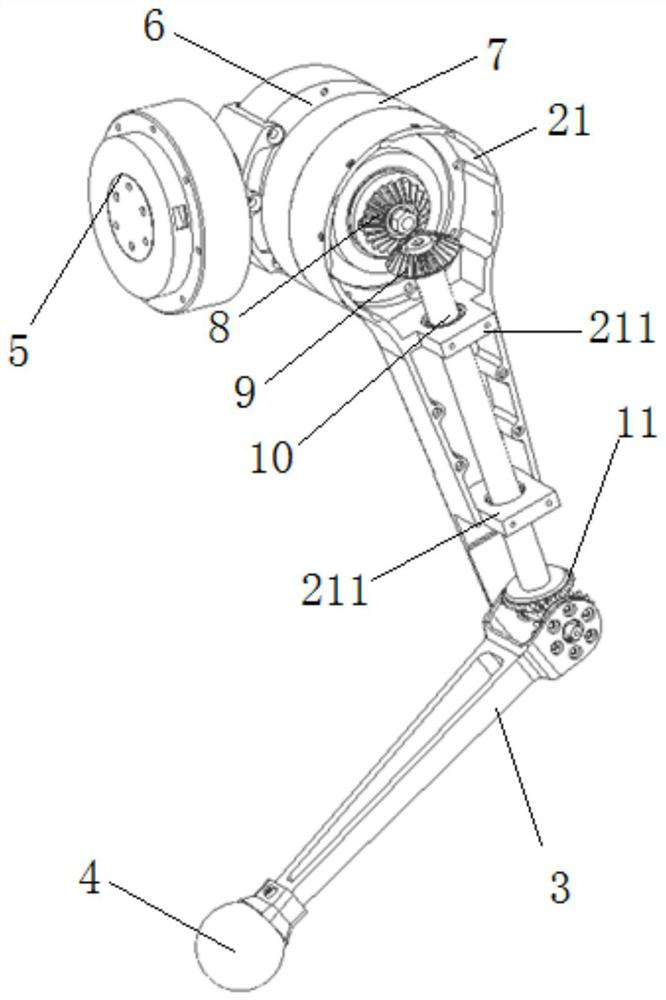

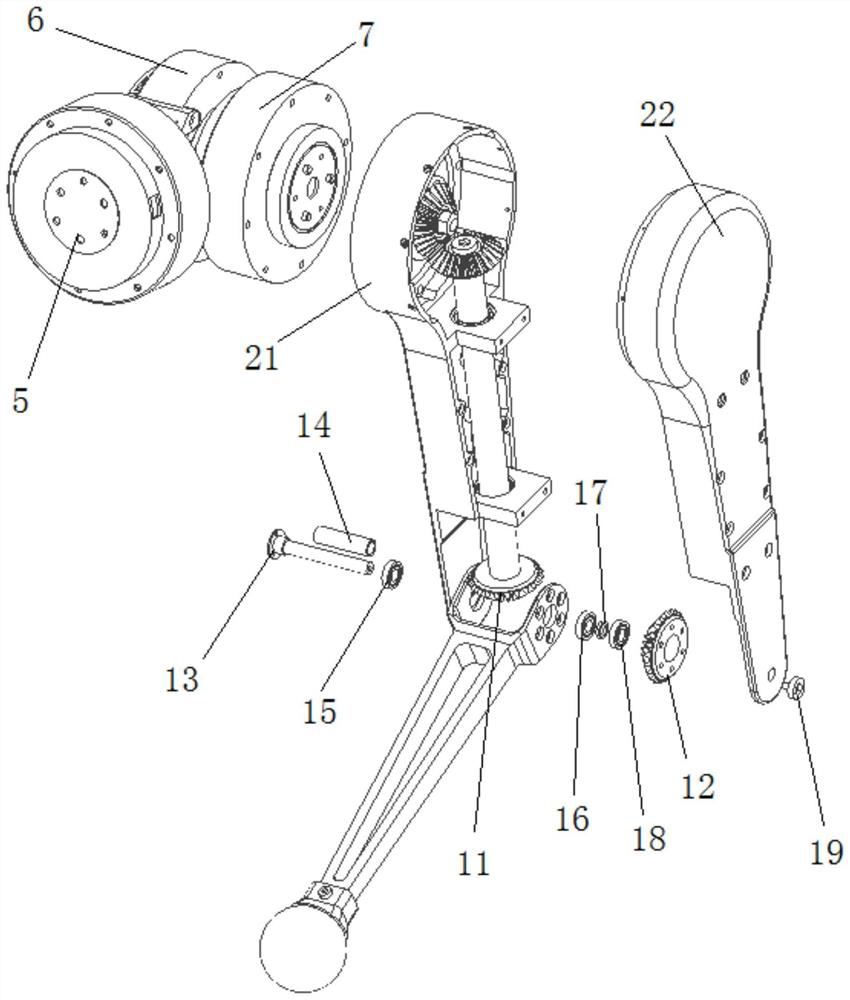

Leg mechanism of robot and quadruped robot

PendingCN112623064AReduce organizational redundancySmall moment of inertiaVehiclesElectric machineryDrive motor

The invention provides a leg mechanism of a robot and a quadruped robot, the leg mechanism of the robot comprises a thigh, a thigh driving motor, a shank, a shank driving motor, a foot, a hinge shaft and a transmission assembly, and the transmission assembly comprises a driving gear, a first transmission gear, a second transmission gear, a driven gear and a transmission shaft; the transmission assembly is used for transmitting torque generated by the shank driving motor to the shank. The mechanism redundancy of the legs can be effectively reduced, the movement inertia of the legs during movement is reduced, the movement of the robot is more stable, and the control precision of the robot is improved. And meanwhile, the output torque of the thigh driving motor can be reduced, so that the thigh driving motor can adopt a smaller size, or the thigh driving motor with the same size is more beneficial to leg movement of the robot.

Owner:THE 21TH RES INST OF CHINA ELECTRONIC TECH GRP CORP

Fire extinguisher carrying device capable of avoiding collision for fire fighting

InactiveCN111559419AAvoid bumpingAvoid settingSupporting partsHand carts with multiple axesCircular discEngineering

The invention relates to the technical field of fire-fighting tools and discloses a fire extinguisher carrying device capable of avoiding collision for fire fighting. The fire extinguisher carrying device comprises a carrying vehicle including a placement groove, a rotating column, a fan-shaped groove and a storage groove, magnetic blocks are connected to the outer side ends of L-shaped rods, first supporting arc plates are connected to the inner side ends of the L-shaped rods, fixing rods are connected to the rear ends of the L-shaped rods, second supporting arc plates are connected to the inner side ends of connecting rods, discs are connected to the two sides of the front side of the fixing rod, and springs are arranged between the discs. Under the action of gravity of the fire extinguishers, the first supporting arc plate drives the L-shaped rods to rotate on the rotating column; the L-shaped rods drive the magnetic blocks to swing upwards; the magnetic blocks push the magnetic blocks on the upper sides to move upwards, the magnetic blocks on the upper sides drive the corresponding L-shaped rods to rotate on the rotating column on the upper sides, and the L-shaped rods on the upper sides drive the corresponding first supporting arc plates to move out. On the basis of the structure, problems that in the carrying process of an existing fire extinguisher, taking is inconvenient, and the fire extinguisher is prone to collision and friction are solved.

Owner:张伟

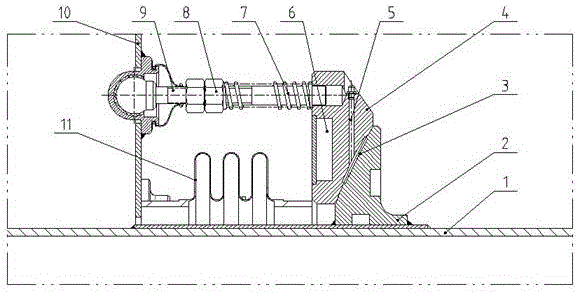

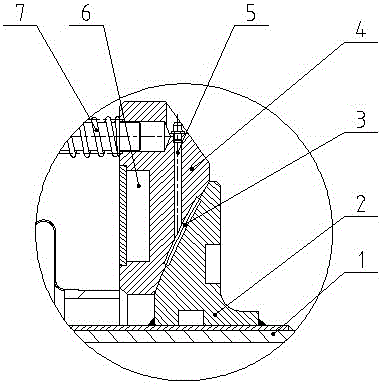

Safety valve for polypropylene loop reactor

ActiveCN102313051AEasy to disassembleEasy to replaceEqualizing valvesSafety valvesEngineeringSolid particle

The invention relates to the technical field of polypropylene reaction equipment, in particular to a safety valve for a polypropylene loop reactor. In the safety valve, the entrance of a valve seat is in an arc shape; a seal surface and a horizontal surface of the valve seat form an angle of 45 degrees; the entrance of a cavity is provided with a press ring; a valve clack is fixedly connected to the press ring; a press rod is arranged above the valve clack; by a structure, a medium in the loop reactor can smoothly pass through the valve seat of the safety valve and is prevented from being collected and crystallized at the entrance of the safety valve to block a pipeline; the safety valve is relieved and rapidly meets the requirement so as to ensure that the safety valve has enough relieving capability; the safety valve can still stably run in an environment of relatively high back pressure; a seal structure of the safety valve for the loop reactor is a soft seal structure, so the tightness of the safety valve is ensured under the conditions of the existence of solid particles in the medium and high pressure; and the seal structure is easy and convenient to disassemble and assemble, a failure seal ring can be simply and conveniently disassembled and replaced, and repair and maintenance are facilitated.

Owner:BEIJING AEROSPACE PROPULSION INST +1

Intelligent electric meter box

ActiveCN110412323AReduce the temperatureAccurate measurementTime integral measurementWater storage tankSmart meter

The invention relates to an intelligent electric meter box, and belongs to the technical field of electric meter boxes. The intelligent electric meter box comprises a casing; an electric energy meteris mounted in the casing, a water storage tank storing rainwater is arranged in the top of the casing, and water absorbing sponge is arranged in the water storage tank; and a group of swing rods is hinged to the side surface of the casing, the end, positioned in the casing, of each swing rod is plate-shaped, and the end, outside the casing, of the swing rod is provided with a water storing groove,and water outlet pipes communicated with the swing rods are correspondingly arranged in the bottom of the water storage tank. According to the intelligent electric meter box, the structure is simple,rainwater drops on each swing rod outside the casing under a horizontal wind force, and is then slowly gathered in the water storing grooves, the water storing grooves fall to drive the ends in the casing of the swing rods to swing, air flow near the electric energy meter in the casing is accelerated, and further the temperature of the electric energy meter is reduced, and accurate normal metering of the electric energy meter is ensured.

Owner:江苏弘硕智能电气有限公司

Bus frame with temperature monitoring function

ActiveCN112260188AQuick disassembly for cleaningGuaranteed swingSwitchgear arrangementsCooling bus-bar installationsPhysicsElectric machinery

The invention relates to the technical field of bus frames, in particular to a bus frame with a temperature monitoring function, which comprises a bus frame main body and a storage battery, wherein the inner side of the left end of the bus frame main body is fixedly connected with a temperature monitoring control device; the temperature monitoring control device comprises an air blowing cover, anelectromagnetic valve, a first air outlet pipe, a temperature sensor, a draught fan, a push rod, a rotary disc and a first motor, and the inner side of the rear end of the bus frame body is fixedly connected with the first motor. The bus frame is provided with the air blowing cover, the electromagnetic valve, the air outlet pipe, the temperature sensor, the draught fan, the push rod, the rotary disc and the first motor; the temperature of the inner side of the bus frame body can be monitored in real time through the temperature sensor, then the interior of the bus frame body is cooled throughthe effect of the draught fan, what is guaranteed is that the temperature of the inner side of the bus frame body is not too high, and meanwhile what can be guaranteed is that the air blowing cover can swing during air outlet through the effect of the rotary disc; and the air blown out from the air blowing cover is blown to each position of the bus frame body.

Owner:HXXN ELECTRICITY

Coal chemical industry sewage treatment device

InactiveCN108996719AImprove processing effectIncrease impeller speedWater aerationSustainable biological treatmentCoal chemical industryTreatment pond

The invention relates to the field of sewage treatment, and particularly relates to a coal chemical industry sewage treatment device. The invention comprises a first sewage treatment tank, a middle treatment tank, a second sewage treatment tank, fluted discs, stirring pieces, elastic stirrers, a stirring shaft and a motor; the first sewage treatment tank, the middle treatment tank and the second sewage treatment tank are integrally formed; the fluted discs are arranged in slide ways in the wall of the second sewage treatment tank; the elastic stirrers are arranged on the stirring shaft; the stirring shaft is connected with the motor; and two ends of each stirring piece are respectively connected with one fluted disc and one corresponding elastic stirrer through hinge seats. The device canbe used for carrying out secondary full treatment on sewage, cyclic utilization and multi-stage utilization of energy are realized in the design of the mechanical structure, and the application rangeis wide.

Owner:冷应杰

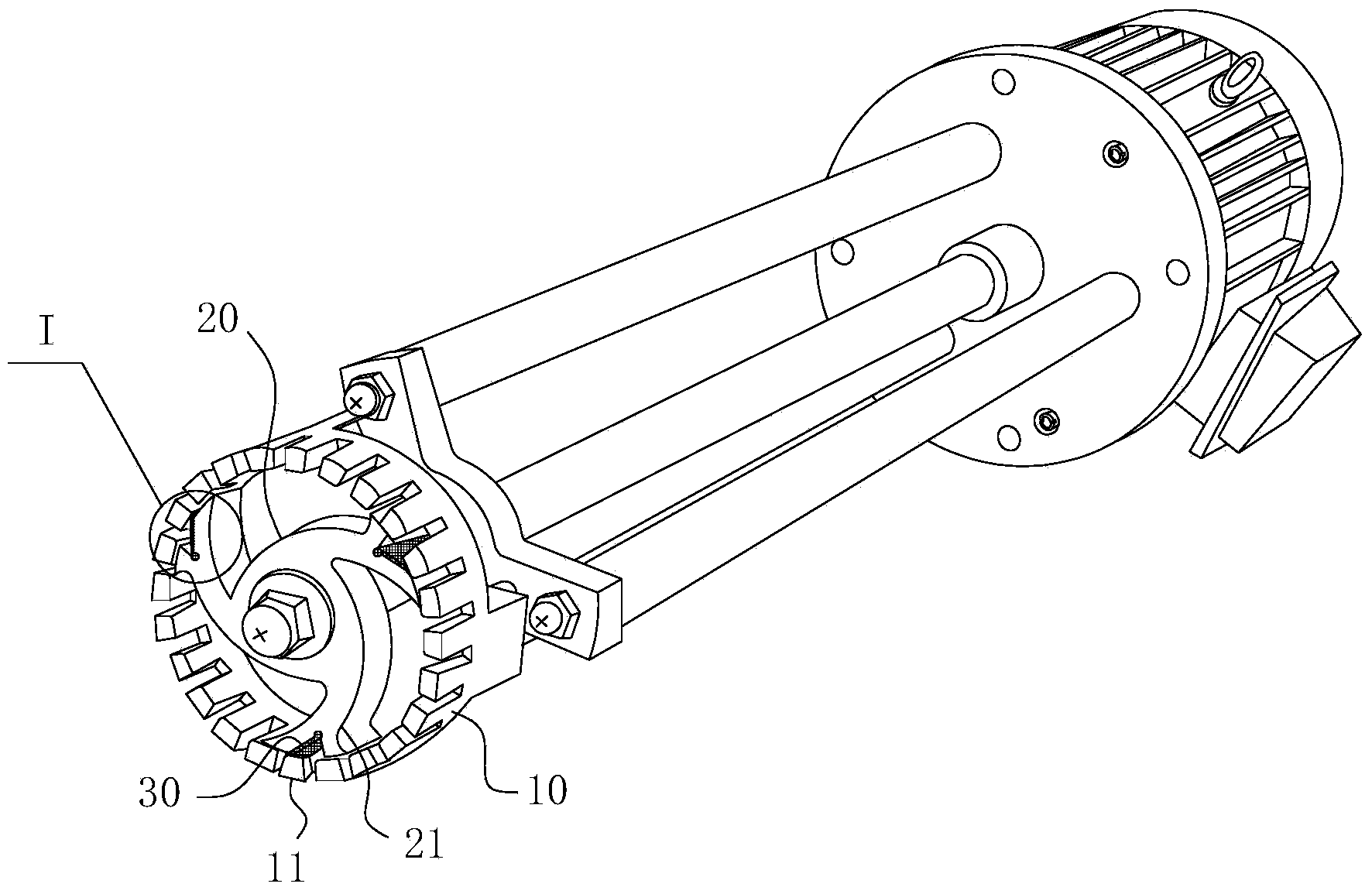

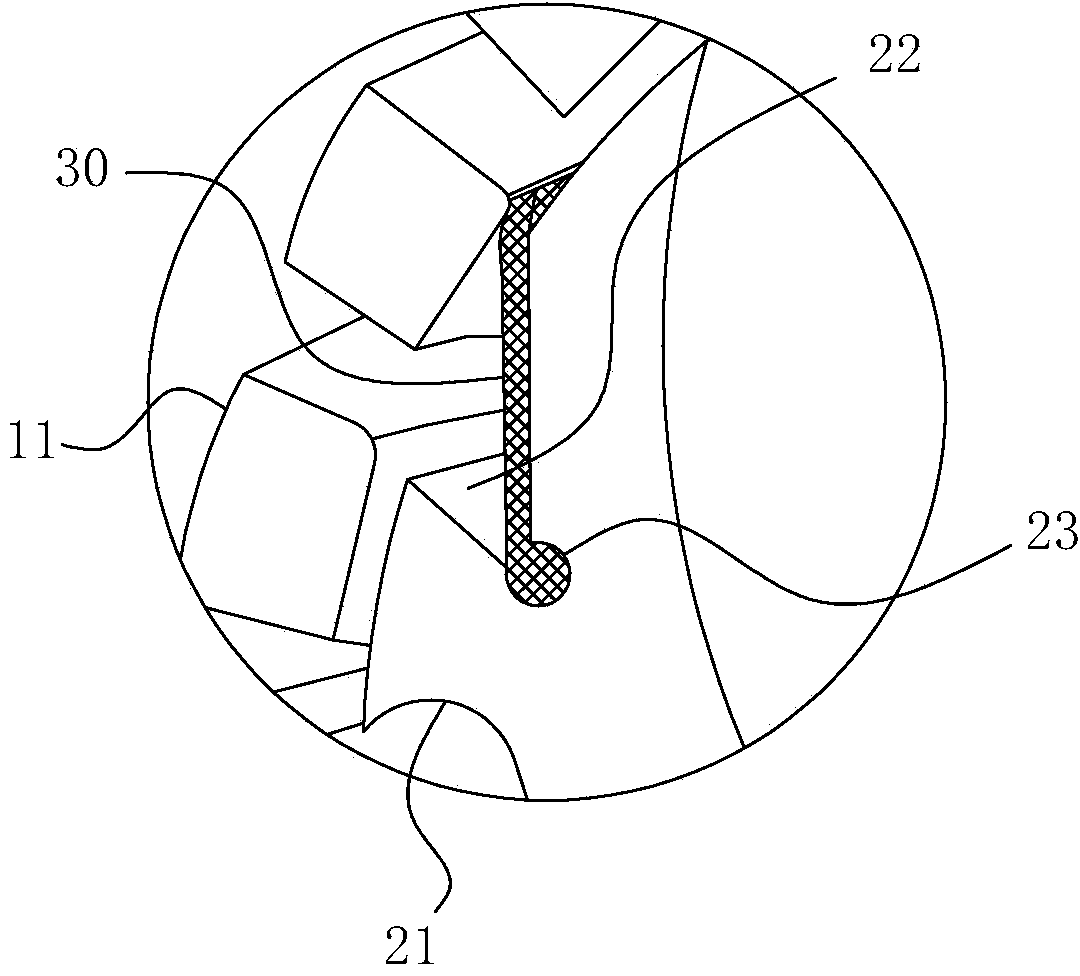

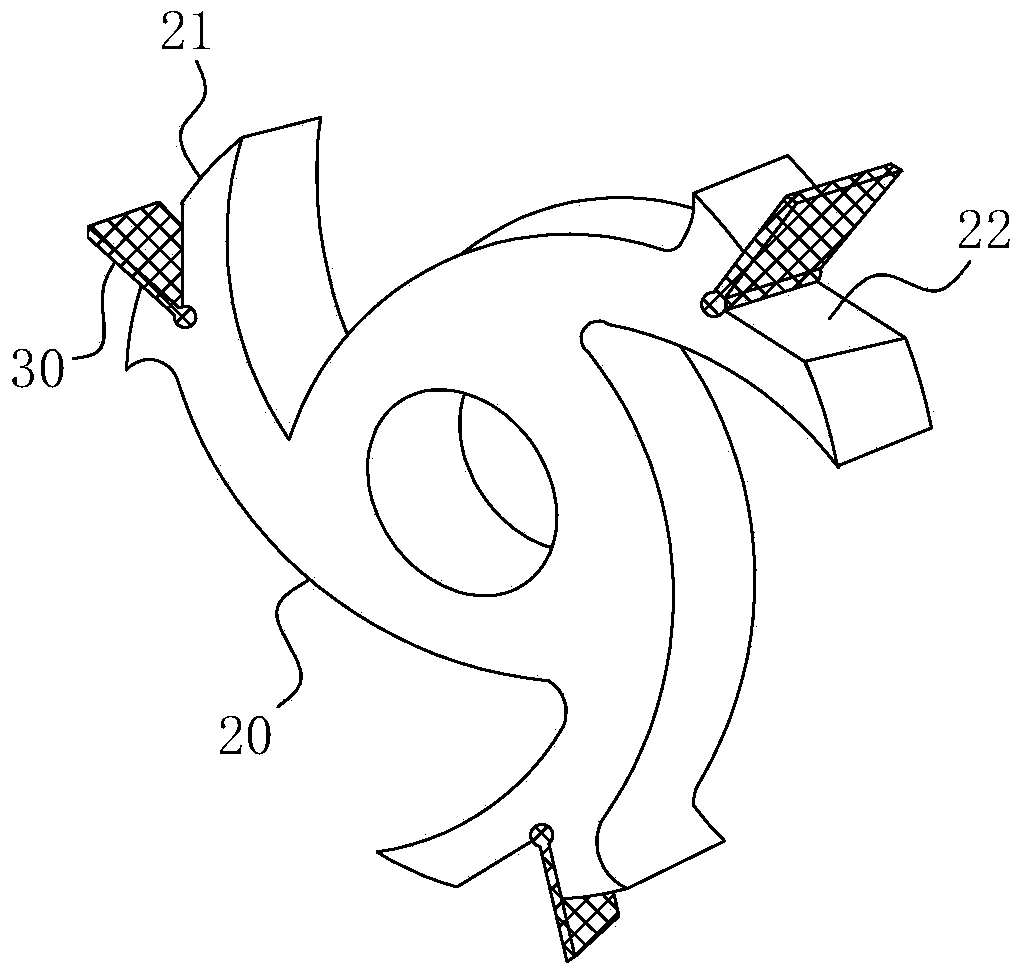

Emulsifying and mixing equipment with grinding, twisting and rolling functions

InactiveCN104174323AImprove stirring efficiencyReliable placement effectMixing methodsMixer accessoriesEngineeringRestoring force

The invention belongs to the field of emulsifying and mixing equipment and in particular relates to emulsifying and mixing equipment with grinding, twisting and rolling functions. The emulsifying and mixing equipment disclosed by the invention at least comprises a stator and a rotor, which are in running fit with each other, and a gap between the running fit surfaces of the stator and the rotor forms a material emulsifying and mixing gap; the emulsifying and mixing equipment also comprises elastic grinding discs; one end of each elastic grinding disc is arranged at the rotor and / or the stator to form a hinged end, and the other end of each elastic grinding disc extends to the running fit surface of the stator and / or the rotor and is pressed against the running fit surface to form a suspension end; in the radial direction of the stator, the length of each elastic grinding disc is larger than the minimum spacing between the hinged end of the grinding disc and the running fit surface which the suspension end is pressed against; a return unit is arranged on each elastic grinding disc; the restoring force provided by each return unit and the rotating of the rotor are in the same direction. The emulsifying and mixing equipment disclosed by the invention is reasonable in structure and high in stirring efficiency, and effects of high-efficiency dispersing, homogenizing and mixing of fine materials, even nanometer level materials, can be effectively improved.

Owner:中慈(青岛)新能源汽车制造有限公司

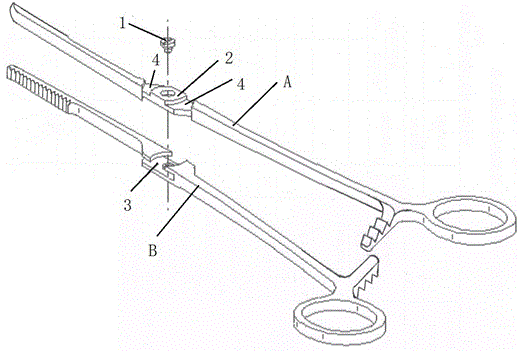

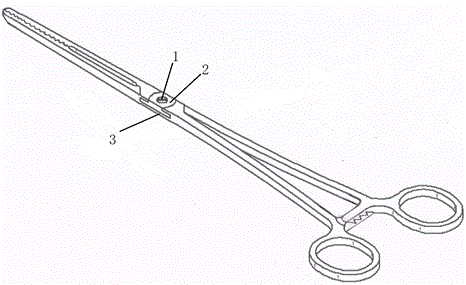

Embedded-assembled type medical forceps

The invention discloses embedded-assembled type medical forceps. A metal pressure injection molding method is used for forming a male piece and a female piece of the forceps respectively. A notch is formed in a gill portion on the upper side of the female piece, a gill portion of the male piece is embedded into a gap of the gill portion of the female piece, and a protruding locating cylinder at the bottom of the gill portion of the female piece is embedded into a counter bore in the bottom of the gill portion of the male piece for locating; the female piece is rotated clockwise until a forceps head of the female piece and a forceps head of the male piece are combined, and a fixing screw is used for screwing up the female piece and the male piece, so that the requirement for free opening and closing of a forceps opening of the forceps is met. According to the embedded-assembled type medical forceps, the assembling structure of the female piece and the male piece is changed, so that the precision in rotation and the vertical swing degree of the female piece and the male piece are guaranteed and controlled; then the fixing screw is used for fixing the female piece and the male piece, in this way, it can be ensured that the forceps smoothly rotate after being assembled, it can also be ensured that the swing quantity of the forceps in the using process is not large, and the clamping precision of the forceps is ensured.

Owner:HEHONG SURGICAL INSTR SHANGHAI CO LTD

A corn threshing device

ActiveCN108966850BGuarantee threshing qualityThreshing cleanThreshersGear wheelAgricultural engineering

The invention discloses a corn threshing device and relates to the technical field of corn threshing. The progressive corn threshing device based on the geometric relationship of the space coordinate axis includes a body, the left side of the top of the body is provided with a material inlet, and the right side of the inner wall of the body is fixedly installed with a guide slide plate, and the bottom of the guide slide plate is provided with a A support plate, and the front and rear sides of the support plate are respectively fixedly connected with the front and rear sides of the inner wall of the body, the middle part of the top of the support plate is provided with a first rotating motor, and the output shaft of the first rotating motor is sleeved with a driving gear. The corn threshing device based on the progressive geometric relationship of the spatial coordinate axis effectively solves the problem of It solves the problem that the traditional corn thresher cannot perform relatively complete threshing of the corn kernels at both ends of the corn.

Owner:徐州全盛电机有限公司

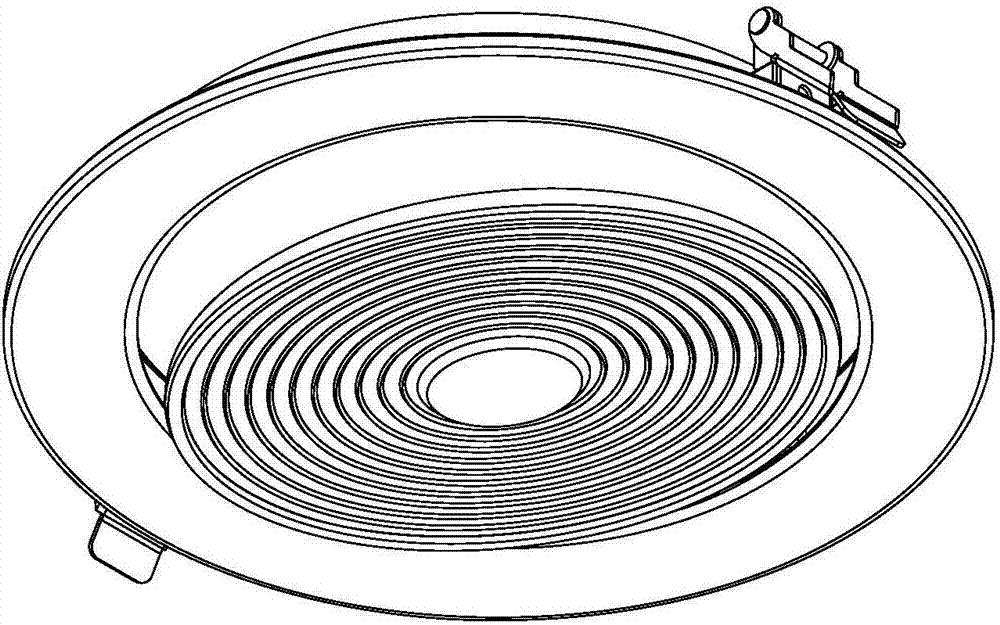

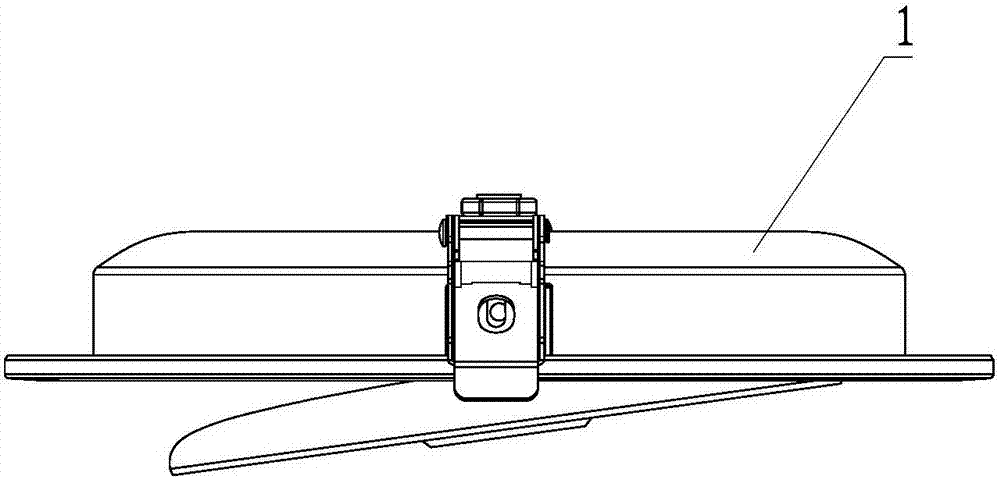

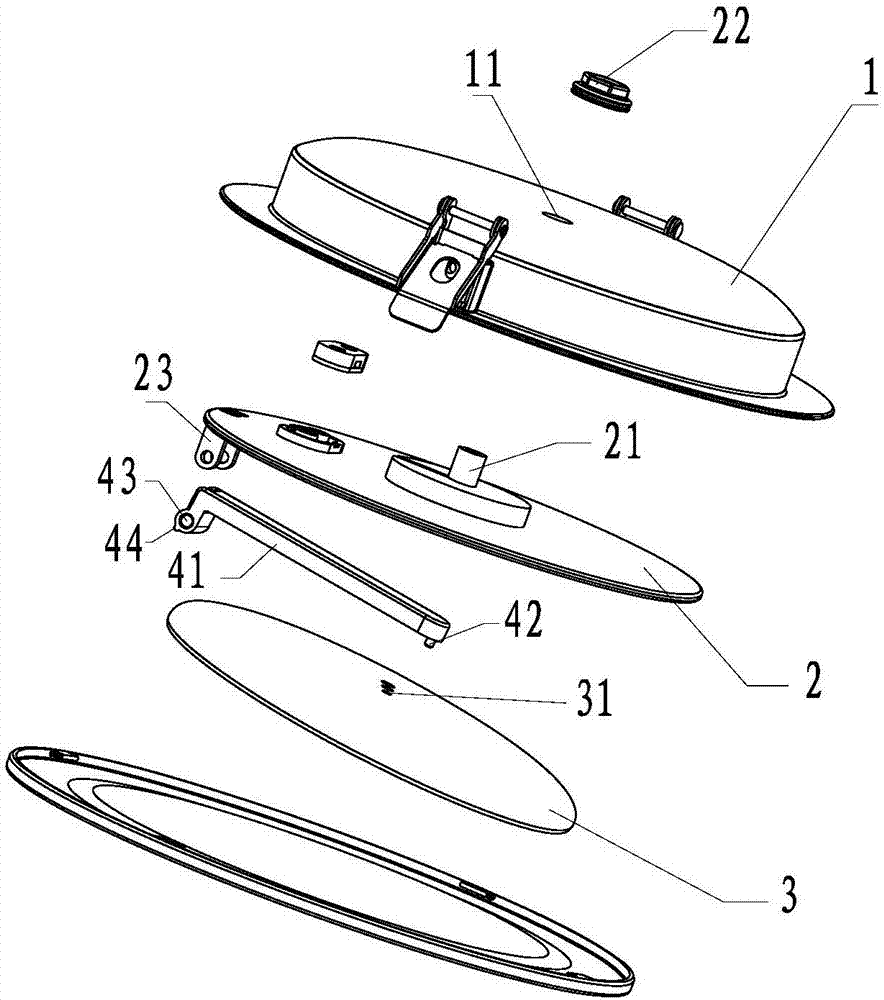

Down lamp structure capable of rotating and swinging

PendingCN107238028ALow costUniform light outputLighting support devicesSemiconductor devices for light sourcesEngineeringMechanical engineering

Owner:LEEDARSON LIGHTING FIXTURES CO LTD

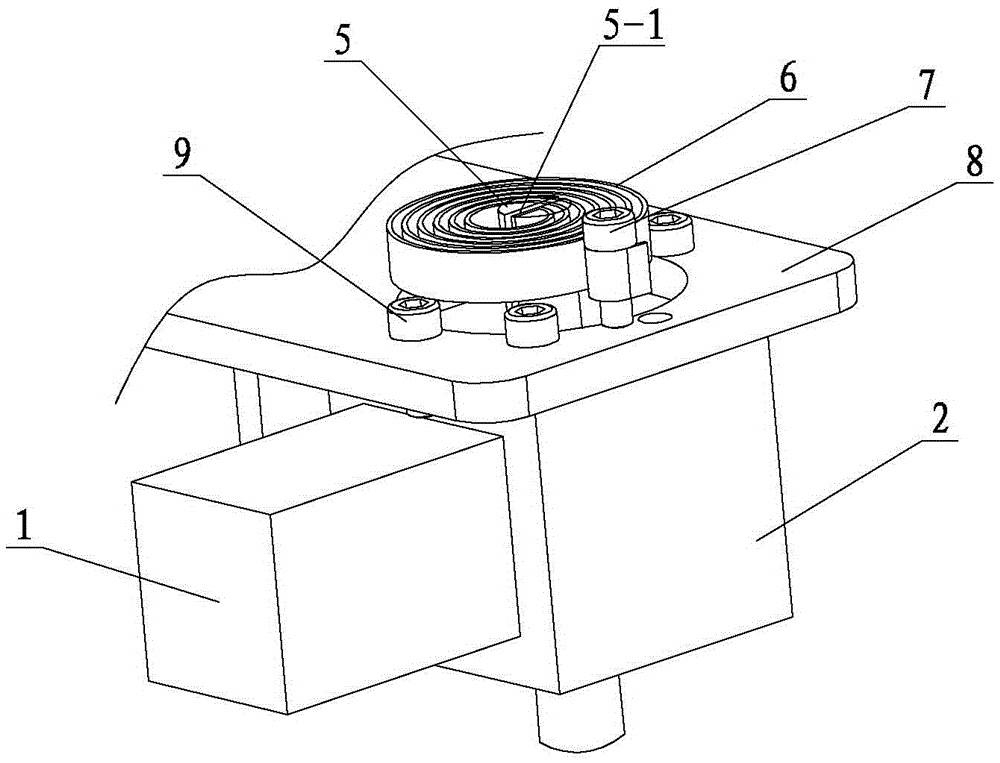

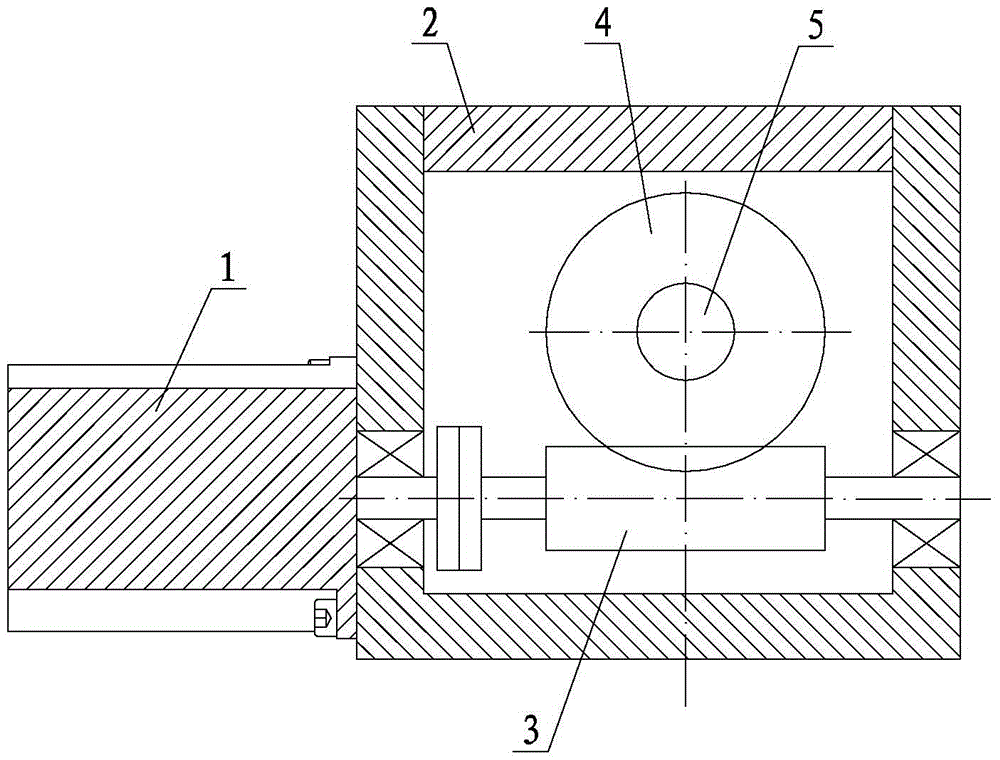

Volute spiral spring type swing device with gap removing function

InactiveCN105463449AAvoid shakingGuaranteed shakingMetallic material coating processesCouplingDrive shaft

The invention discloses a volute spiral spring type swing device with a gap removing function. The volute spiral spring type swing device aims to solve the problems that a worm gear reducer is adopted for a swing device on an existing full-automatic cladding robot, after the swing device works for a long time, gaps may be generated between engaged teeth in the transmission process of a worm gear and a worm, consequently, a swing head wobbles, swinging cannot reach the required angle, and the repairing effect of the full-automatic cladding robot on a water wall is influenced. A motor is fixedly arranged outside a shell; a worm is arranged in the shell and is connected with the output shaft of the motor through a coupler; a worm gear is engaged with the worm and is fixedly arranged on a driven shaft; a gap exists in the upper end of the driven shaft along the axis; a volute spiral spring is arranged outside the shell and is wound on the driven shaft; the inner end of the volute spiral spring is inserted in the gap; the outer end of the volute spiral spring is fixed to a screw; the screw is in threaded connection with a fixing plate; and the shell is fixedly arranged on the fixing plate. The volute spiral spring type swing device is used for the full-automatic cladding robot.

Owner:HARBIN KENENG CLADDING TECH

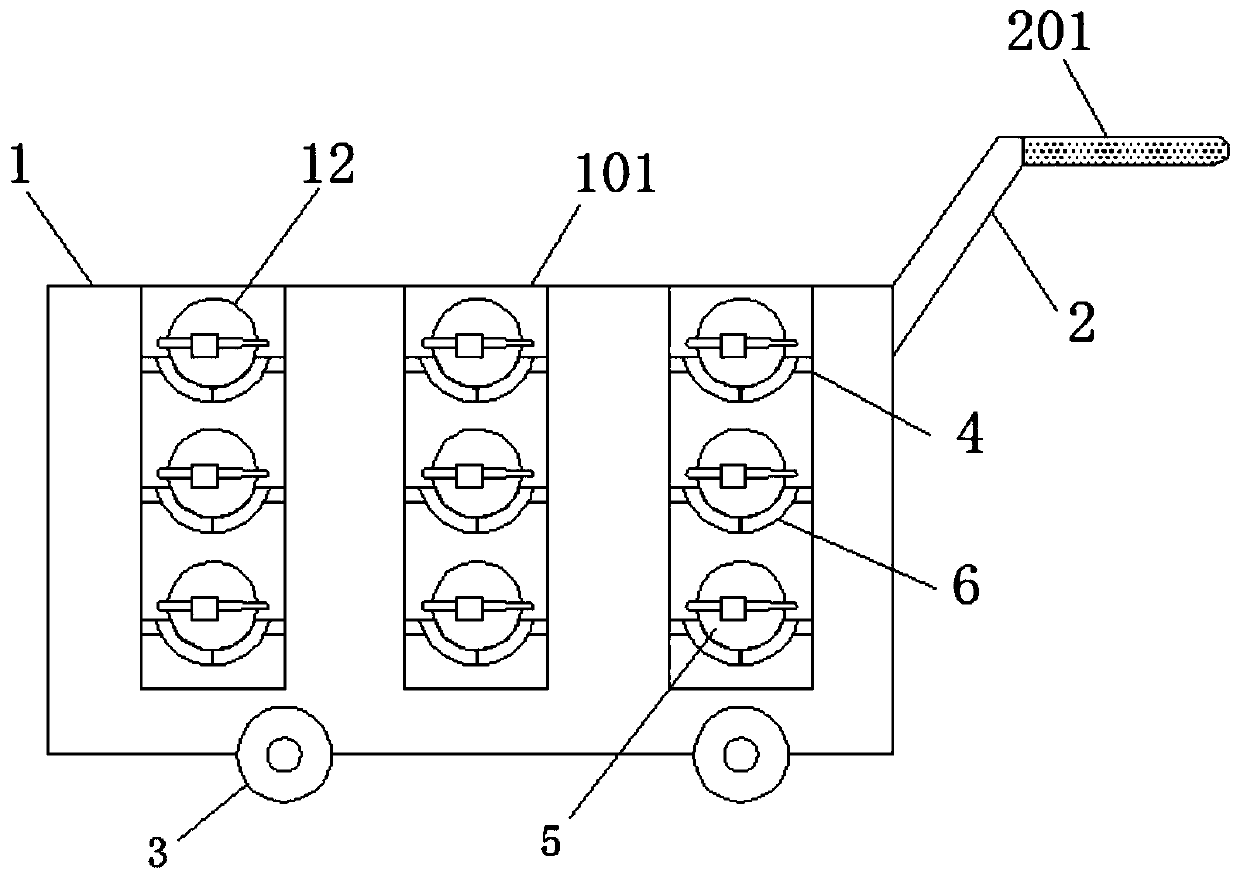

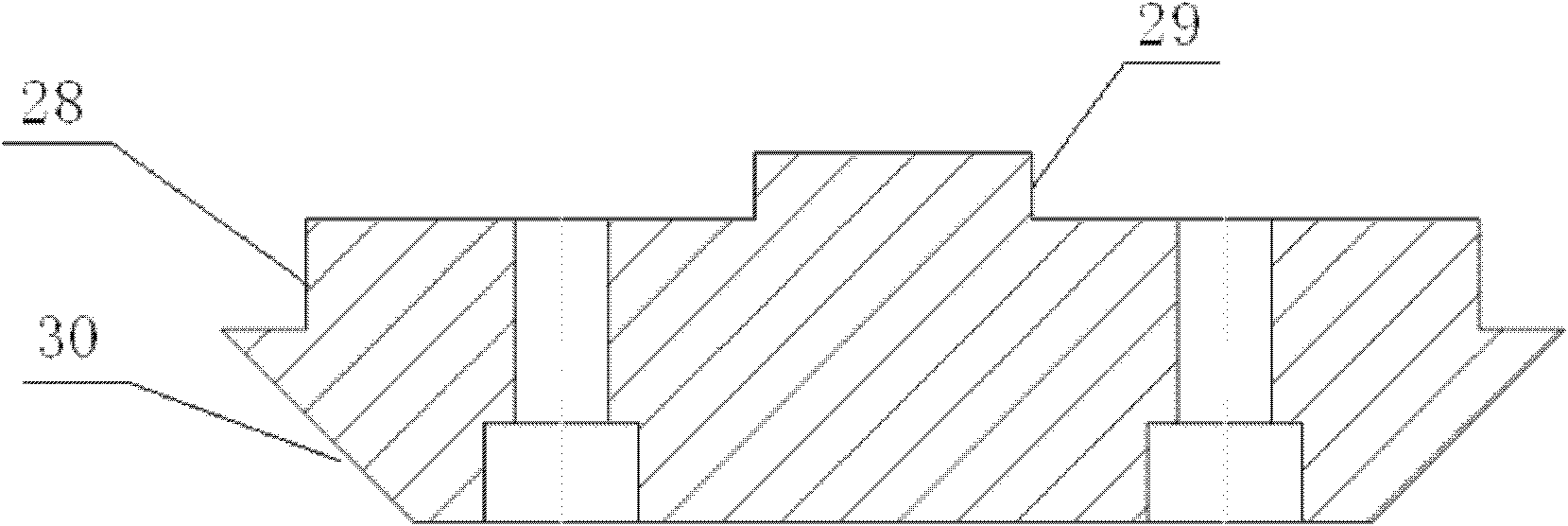

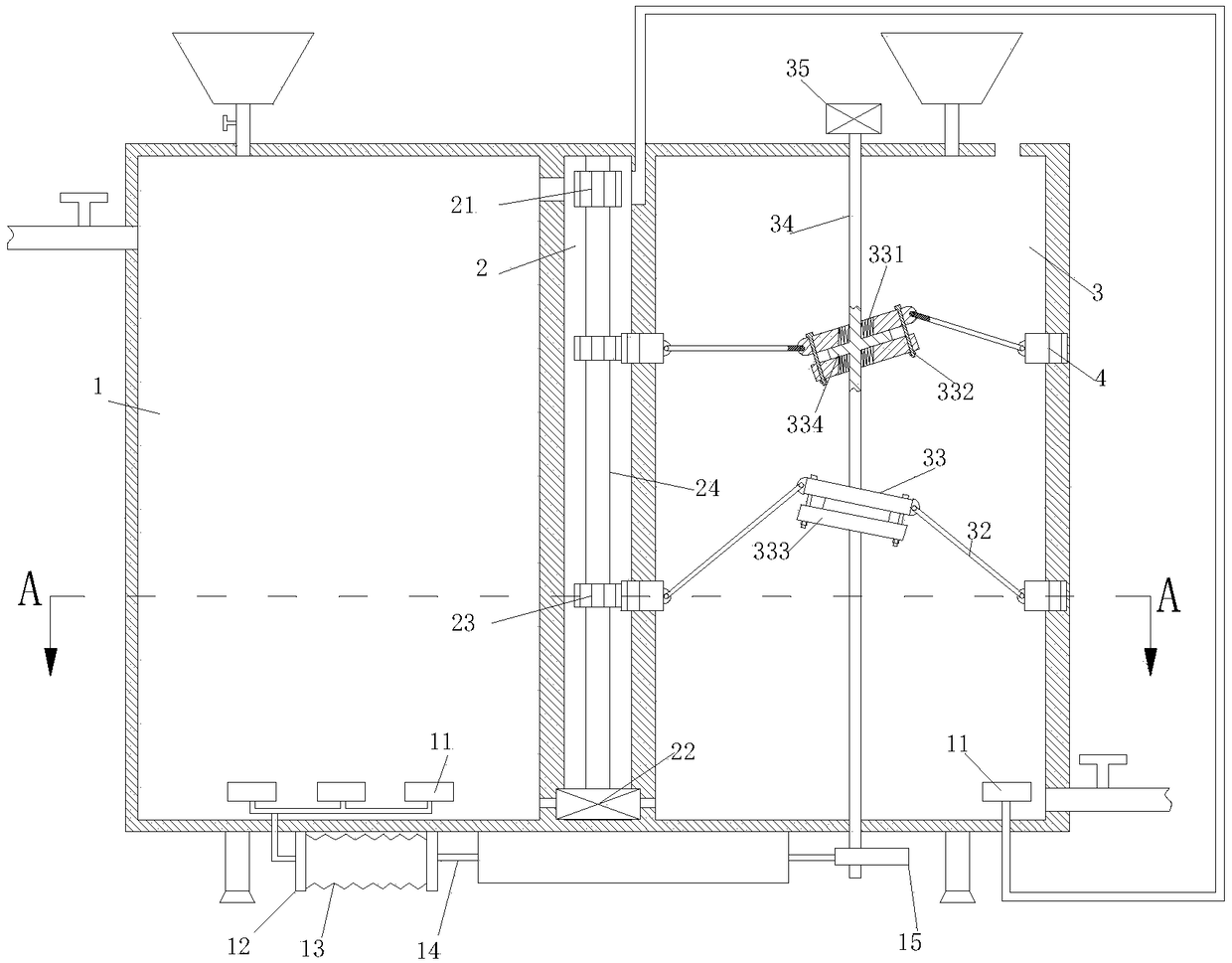

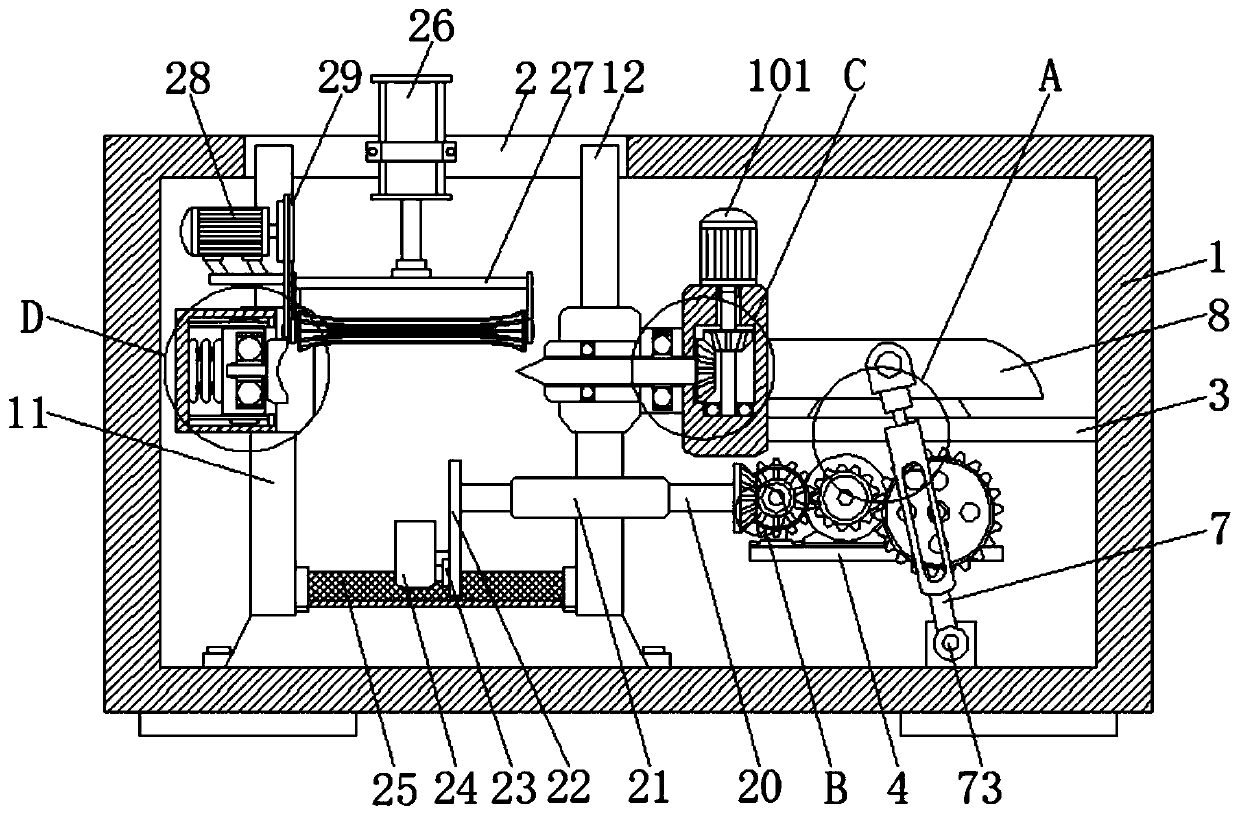

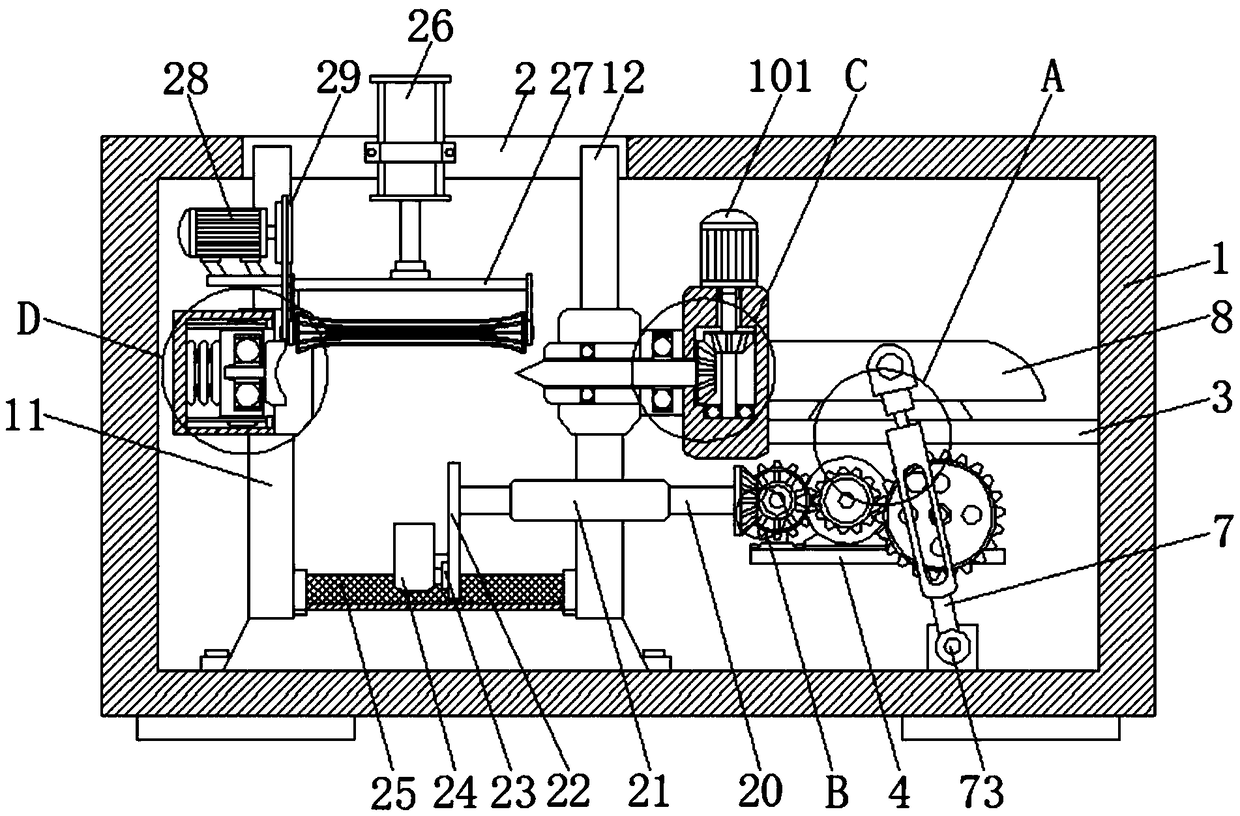

Progressive corn threshing device based on spatial coordinate axis geometric relationship

ActiveCN108966850AGuarantee threshing qualityThreshing cleanThreshersGeometric relationsTransmission belt

The invention discloses a progressive corn threshing device based on a spatial coordinate axis geometric relationship, and relates to the technical field of corn threshing. The progressive corn threshing device based on the spatial coordinate axis geometric relationship comprises a machine body, wherein the left side of the top of the machine body is provided with a feeding port, the right side ofthe inner wall of the machine body is fixedly provided with a guiding sliding plate, a supporting plate is arranged under the guiding sliding plate, the front and rear sides of the supporting plate are fixedly connected to the front and rear sides of the inner wall of the machine body respectively, the middle of the top of the supporting plate is provided with a first rotating motor, an output shaft of the first rotating motor is in sleeved connection with a driving gear. The progressive corn threshing device based on the spatial coordinate axis geometric relationship has the advantages thatthrough the cooperative arrangement of an air cylinder, a beam, a third rotating motor, a rotating wheel, a transmission belt, a connecting rod, a moving plate, a rotating shaft and a concave cutter wheel, the problem is effectively solved that a traditional corn thresher cannot more completely thresh corn kernels at the two ends of corn.

Owner:徐州全盛电机有限公司

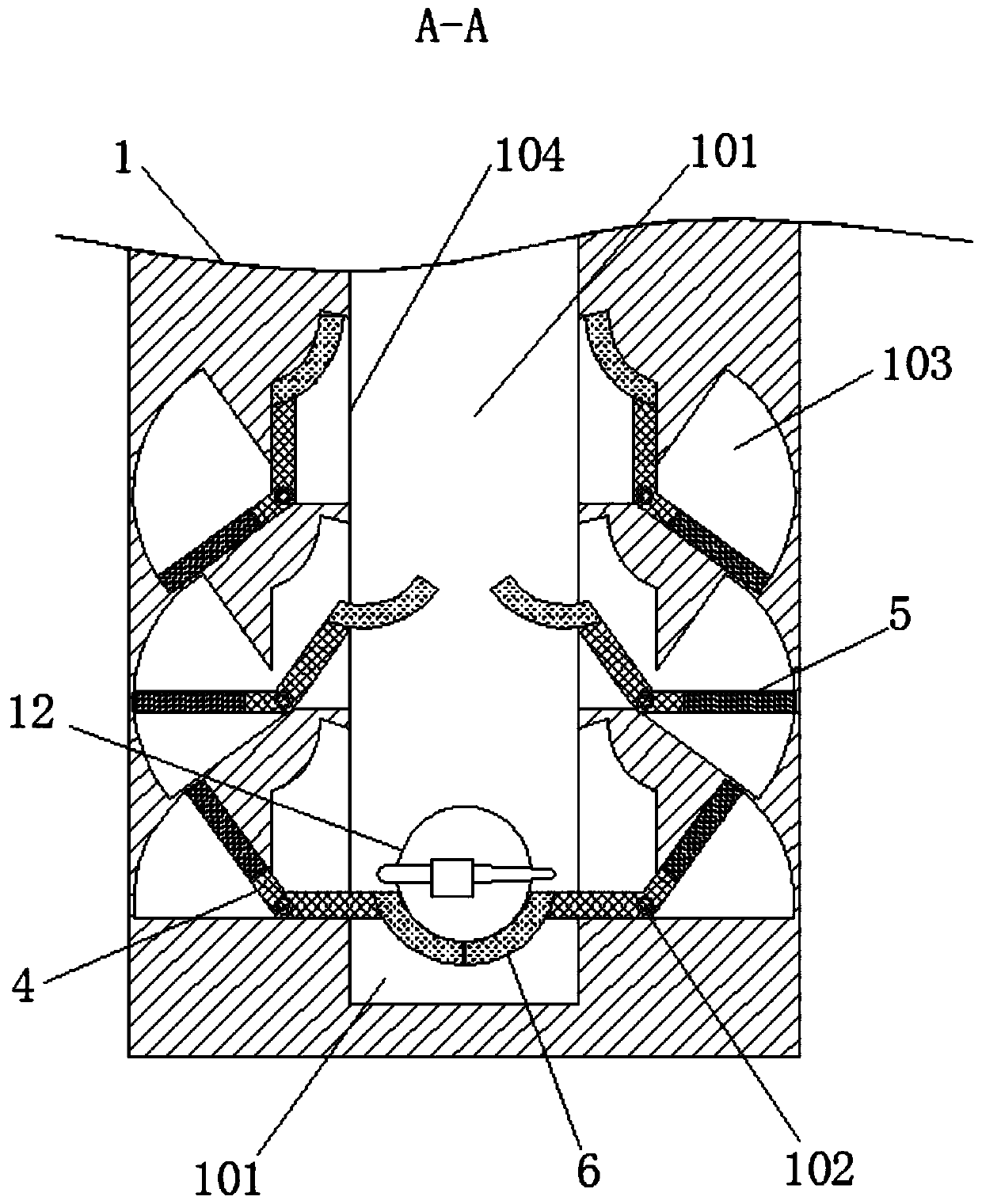

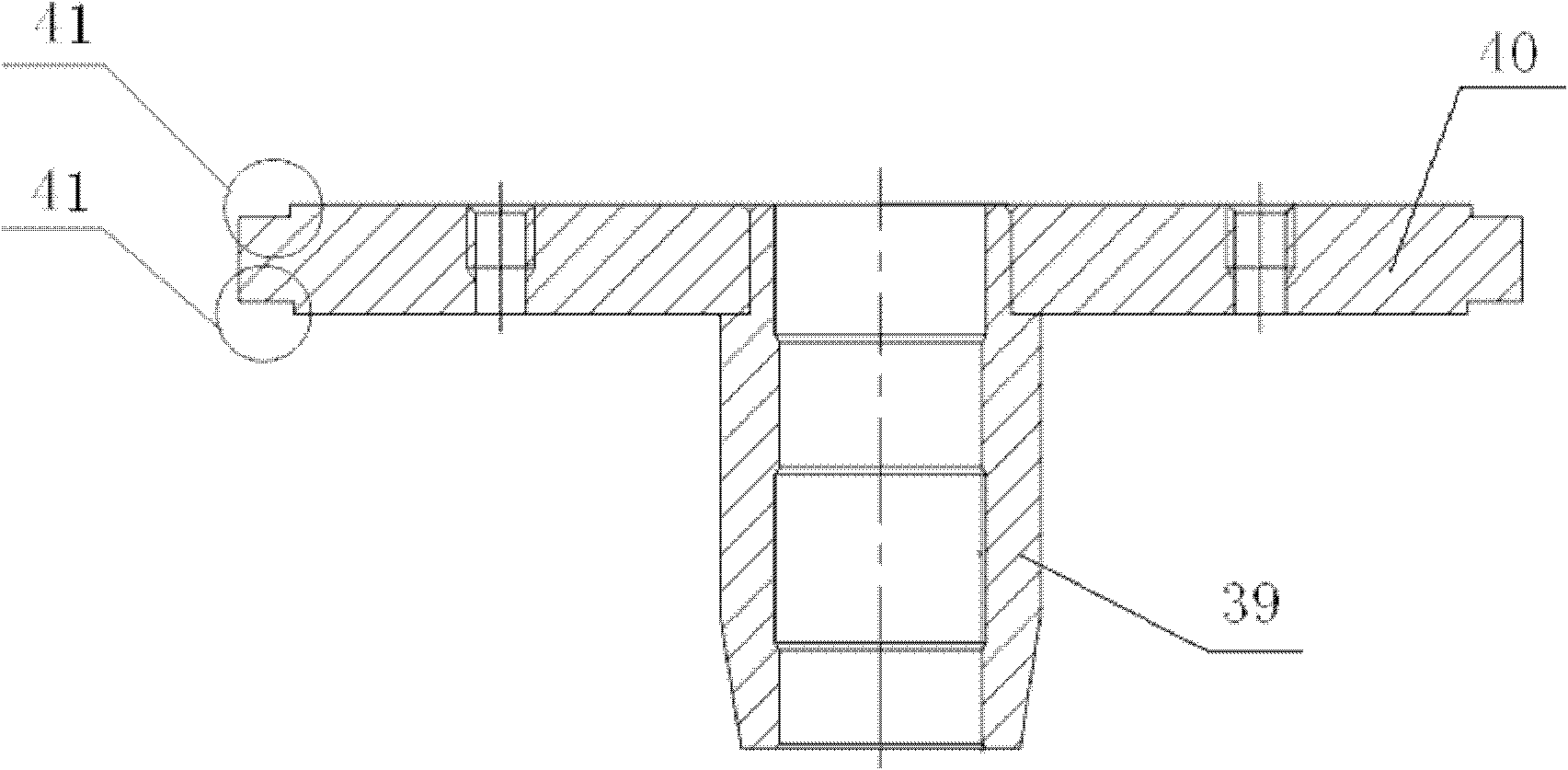

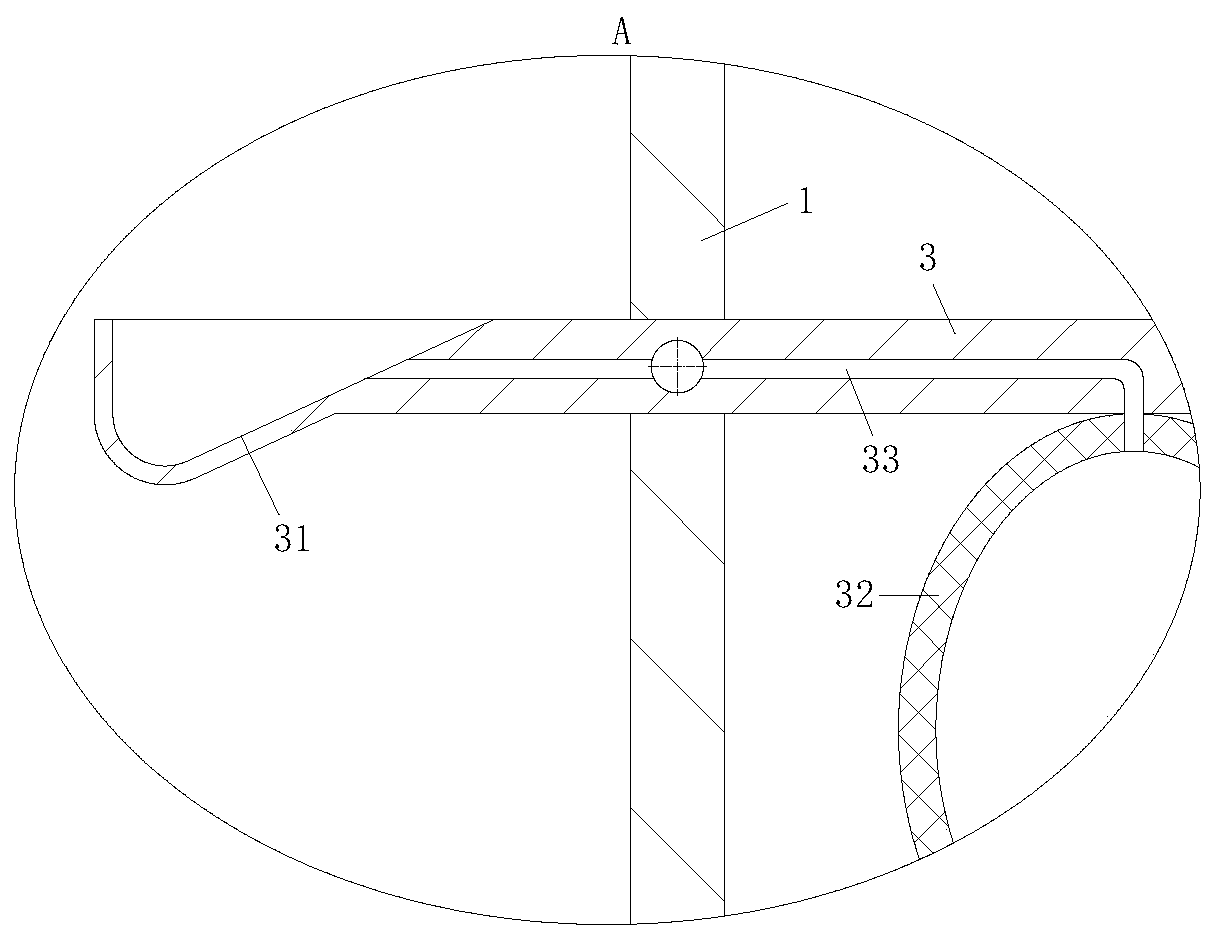

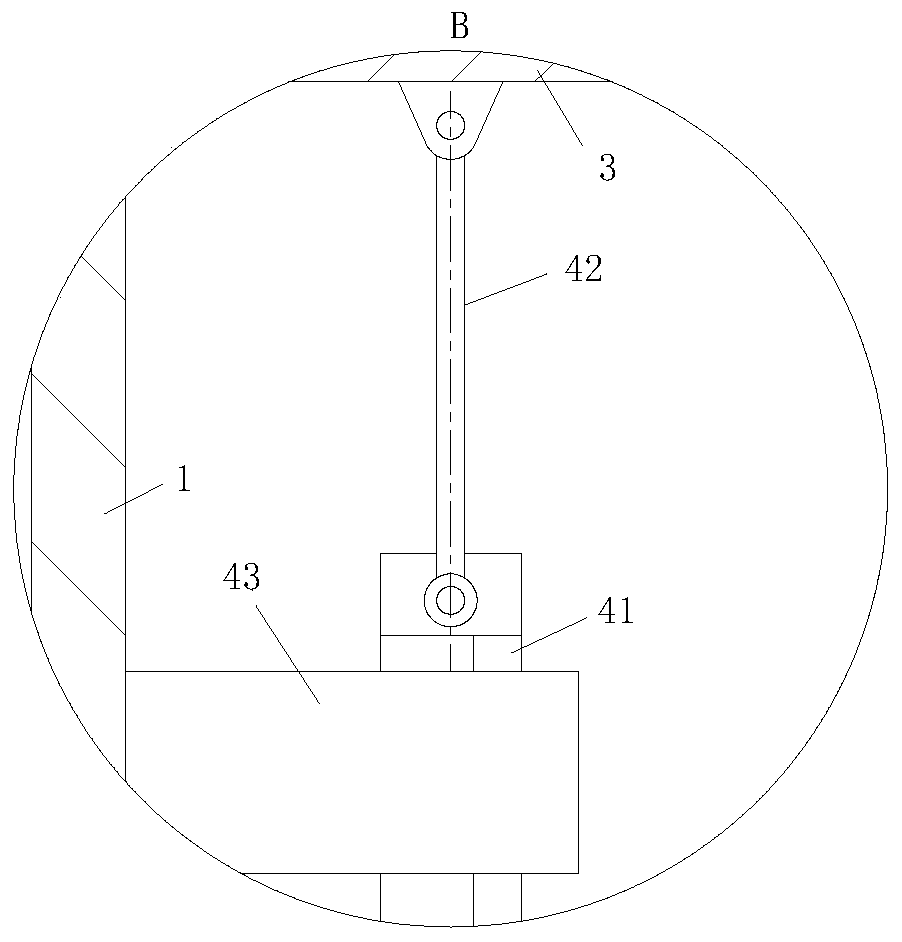

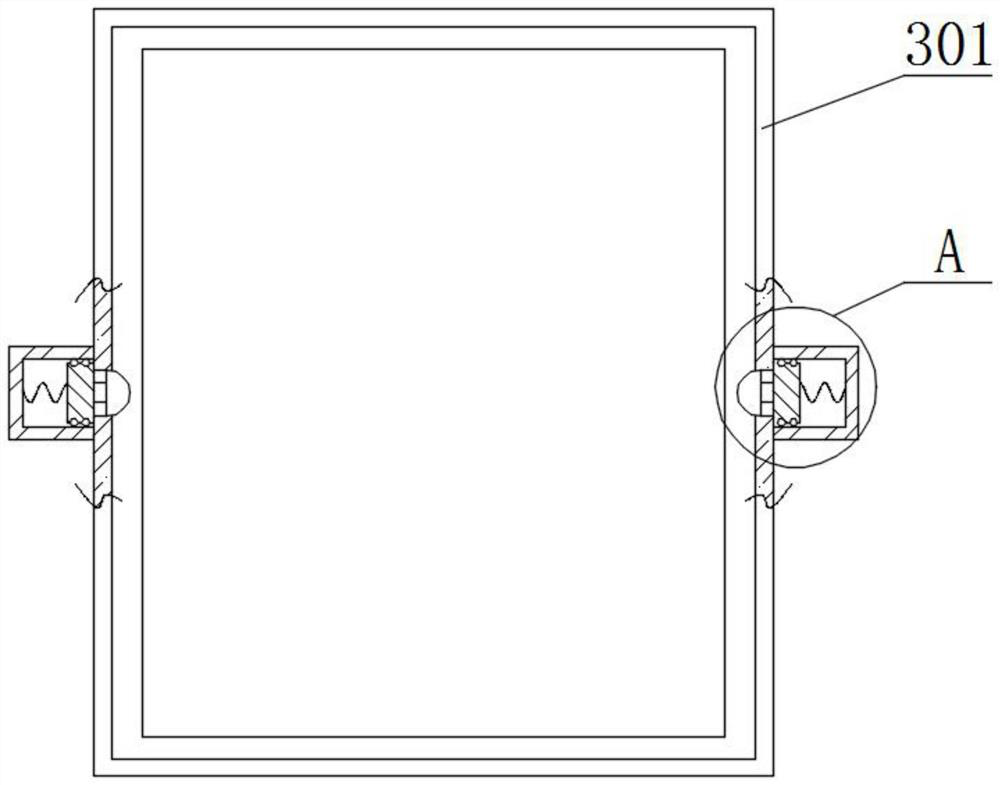

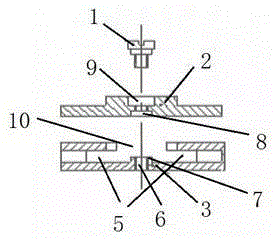

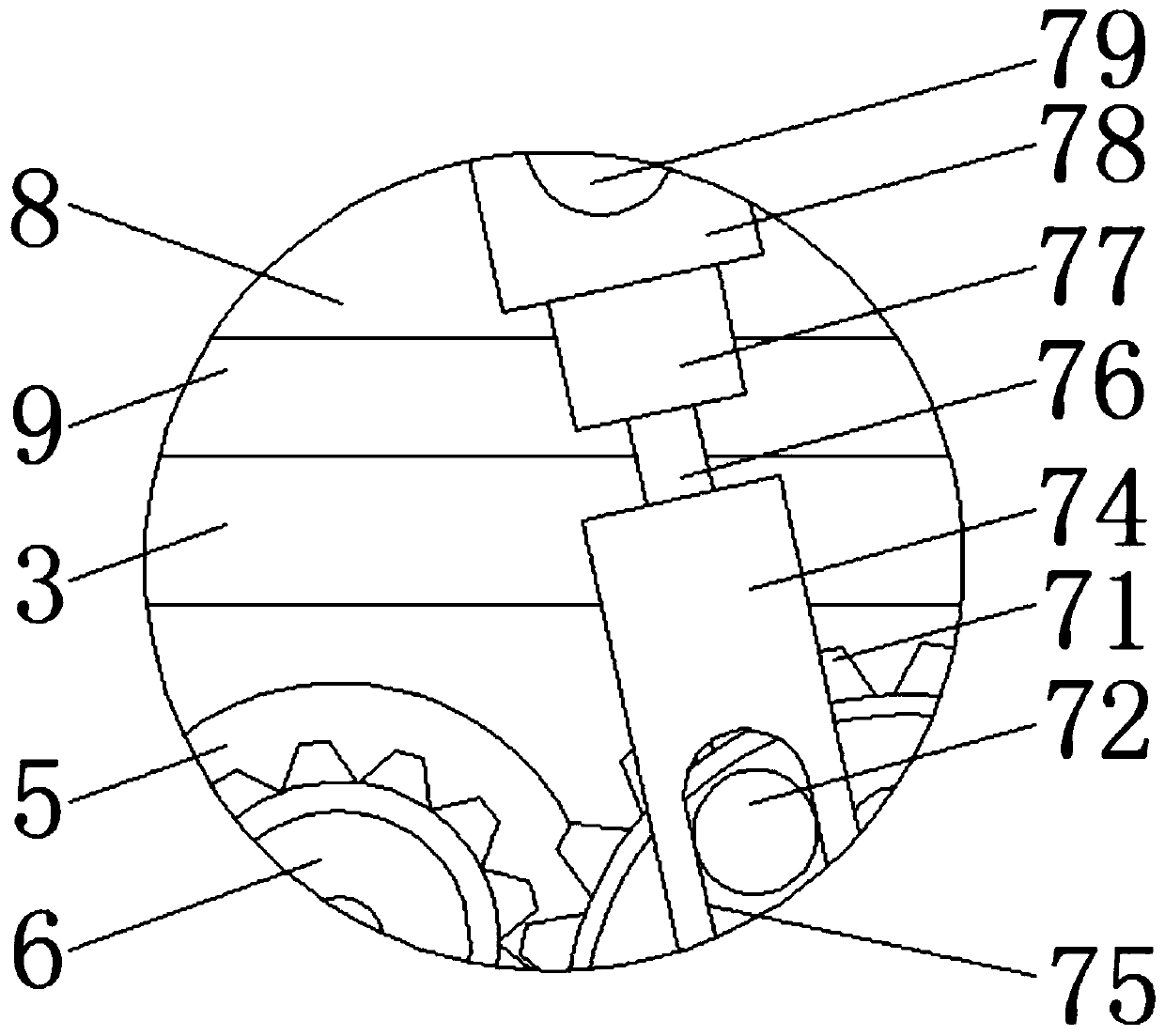

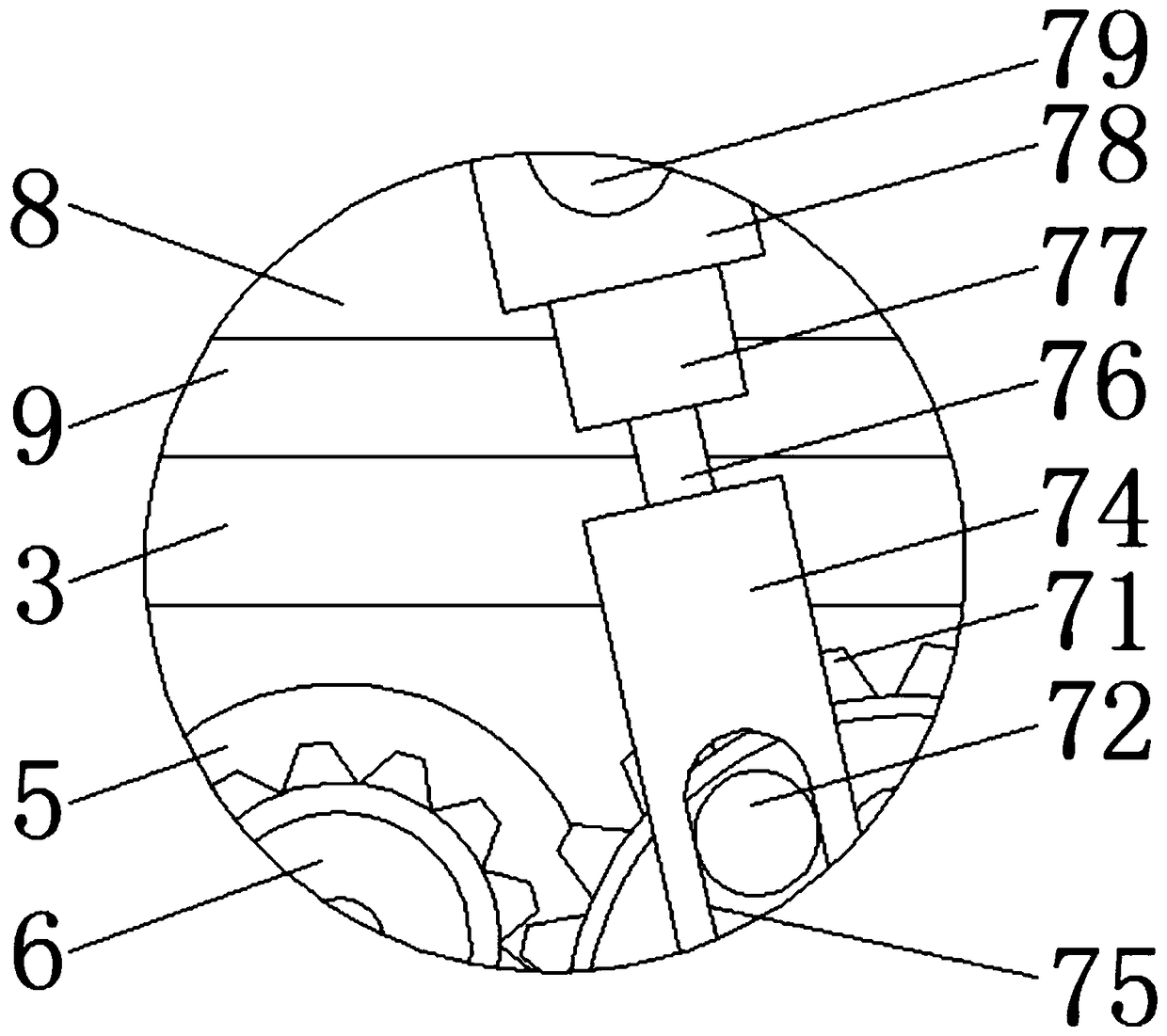

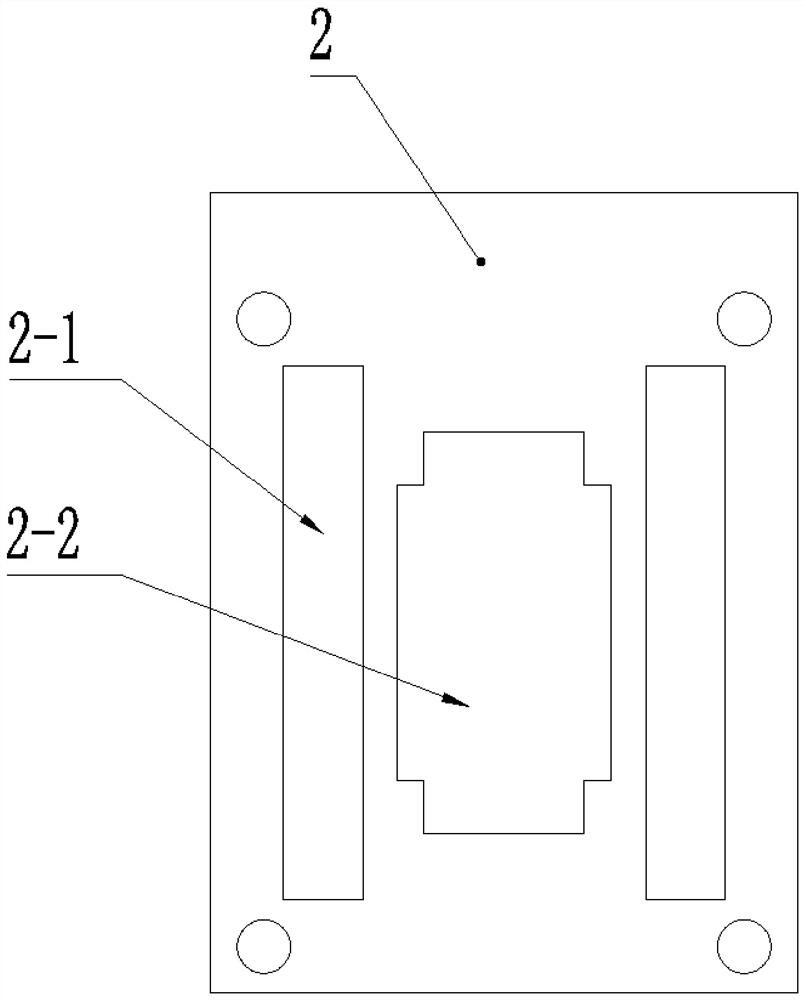

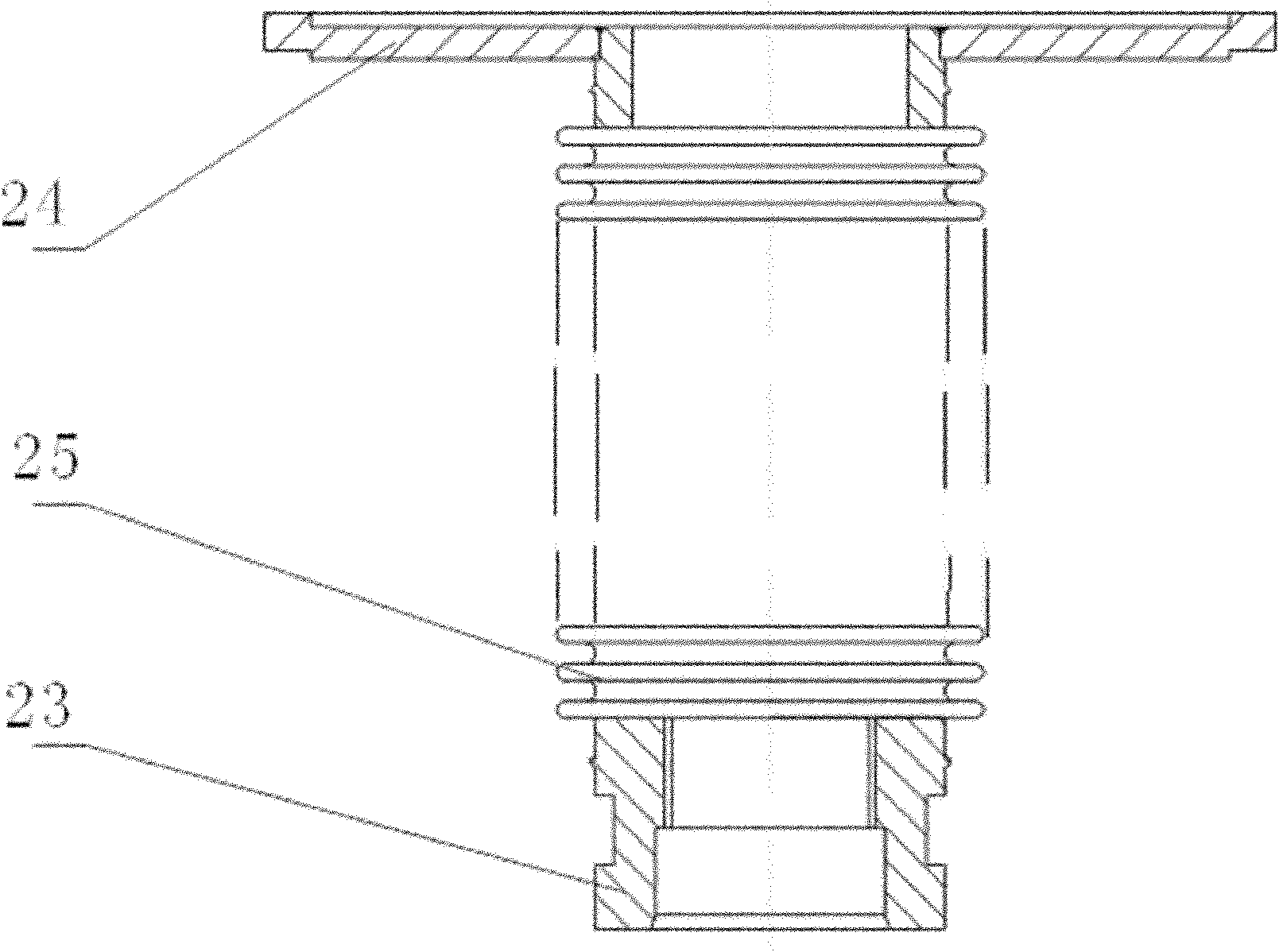

Packaging structure of scanning micromirror

ActiveCN111200909BGuaranteed swingFirm packagingSupport structure mountingPrinted circuit non-printed electric components associationEngineeringMechanical engineering

The invention relates to an encapsulation structure of a scanning micromirror, comprising a base, the upper end of the base is provided with a concave cavity, a printed circuit board is placed on the upper end of the base, and the middle of the printed circuit board is provided with a via hole for light to pass through, so the Two mounting holes are symmetrically arranged on the left and right sides of the via holes on the printed circuit board, magnets are respectively fixed in the mounting holes, the lower ends of the magnets are pressed against the bottom of the cavity of the base, and a scanning micromirror chip is fixed on the bottom of the cavity. The lower end face of the printed circuit board, the mirror surface of the scanning micromirror chip is located below the through hole of the printed circuit board, the upper end of the printed circuit board is provided with a cable terminal, and one end is covered on the printed circuit board. On the upper end, the printed circuit board and the magnet are pressed, and the end cover, the printed circuit board and the base are fixed together by bolts. The structure is simple and stable, the packaging is simple and fast, the packaging consistency is good, and the positioning of the two magnets is good.

Owner:CHONGQING CHUANYI AUTOMATION

A universal rotary dynamic sealing device and rotary equipment

ActiveCN103438217BTightly boundGuaranteed swingEngine sealsEngine lubricationEngineeringThermal expansion

The invention discloses a universal rotary dynamic sealing device and gyration equipment. The dynamic sealing device comprises a dynamic ring and a static ring, wherein the dynamic ring is fixed on a rotating part and makes gyration movement together with the rotating part; the static ring is connected with a static part through a universal rod, and the sealing surface of the static ring is attached to the sealing surface of the dynamic ring; the universal rod is composed of a bulb component and a threaded rod, the bulb end is connected with the static part, the threaded rod is connected with the static ring, springs and clamp nuts are installed on the universal rod, and the springs are tightly pressed on the static ring by the clamp nuts. The dynamic sealing device disclosed by the invention can effectively solve the problem of seal failure caused by radial runout of the rotating part and axial movement caused by thermal expansion, and has the characteristics of good sealing effect and, high-temperature resistance and the like.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

Knitting needle bed swinging mechanism of warp knitting machine

ActiveCN101798725BLarge stroke ratio coefficientMeet the swing angle requirementsWarp knittingManufacturing cost reductionEngineering

The invention relates to a knitting needle bed swinging mechanism of a warp knitting machine, which is provided with a main shaft, a swinging shaft, a knitting needle bed and a knitting needle seat, wherein the knitting needle seat supports the knitting needle bed and is connected with a needle bed driven swinging arm in a moving pair way. In addition, the knitting needle bed swinging mechanism of a warp knitting machine is also provided with a pin shaft I, a pin shaft II, a triangular member I, a triangular member II, a connecting rod I, a connecting rod II and a connecting rod III, wherein an eccentric wheel is fixed to the main shaft; one end of the triangular member I is connected to the eccentric wheel in a rotating pair way, and other two ends of the triangular member I are respectively connected with the connecting rod I and the connecting rod II in the rotating pair way; the connecting rod I is connected with the pin shaft I in the rotating pair way; one end of the triangular member II is connected to the pin shaft II in the rotating pair way, and other two ends of the triangular member II are respectively connected with the connecting rod II and the connecting rod III in the rotating pair way; and the connecting rod III is connected with a needle bed drive swinging arm of a knitting needle bed assembly in the rotating pair way after penetrating through an oil tank. The invention is beneficial to improving the rotating speed of the whole machine, reduces the manufacture cost, and has wide realized travel speed variation coefficient range.

Owner:临沂高新区金蓝领劳务有限公司

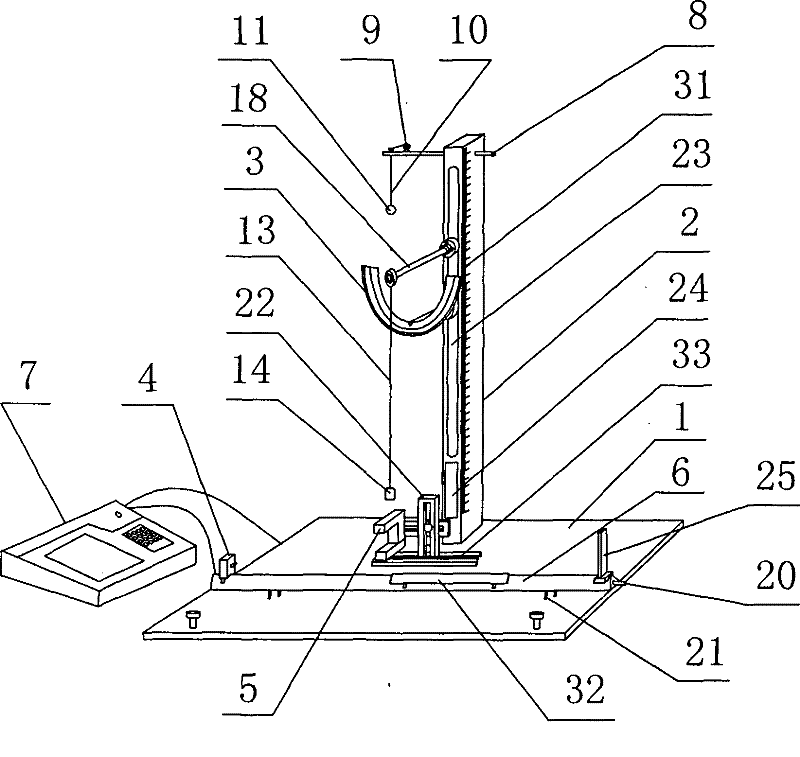

Magnetic pendulum and simple pendulum combined experimental instrument

InactiveCN101908293BReasonable structureEasy to operateEducational modelsMeasurement deviceEngineering

The invention relates to a magnetic pendulum and simple pendulum combined experimental instrument, which belongs to the field of basic physic teaching and research instruments. The magnetic pendulum and simple pendulum combined experimental instrument comprises a base, a stand column, an angle indicating device, a simple pendulum device, a magnetic pendulum device, a laser alignment device, a photoelectric detector and the like, wherein an intelligent measuring device is arranged on one side of the base; the stand column and an air track are arranged on the base; the two ends of the air trackare provided with the laser alignment device and a correction plate; the single pendulum device is arranged at the top of the stand column; and the magnetic pendulum device and the angle indicating device are arranged in a chute of the stand column. In the experimental instrument, the single pendulum is combined together with a magnetic pendulum experimental instrument, so that two kinds of experiment can be completed by one set of instrument; and a cycloid and a pendulum rod are guaranteed to swing in one plane by adopting laser alignment positioning and pivot angle acoustic image indication, so that the measurement results are more accurate and scientific. The magnetic pendulum and simple pendulum combined experimental instrument solves the problem that the instruments occupy a lot of space because the conventional single pendulum experiment and magnetic pendulum experiment are completed by different experimental instruments, and the problem that the measuring precision of the experiment is low and cannot meet the requirements of physic teaching and researches.

Owner:李克 +4

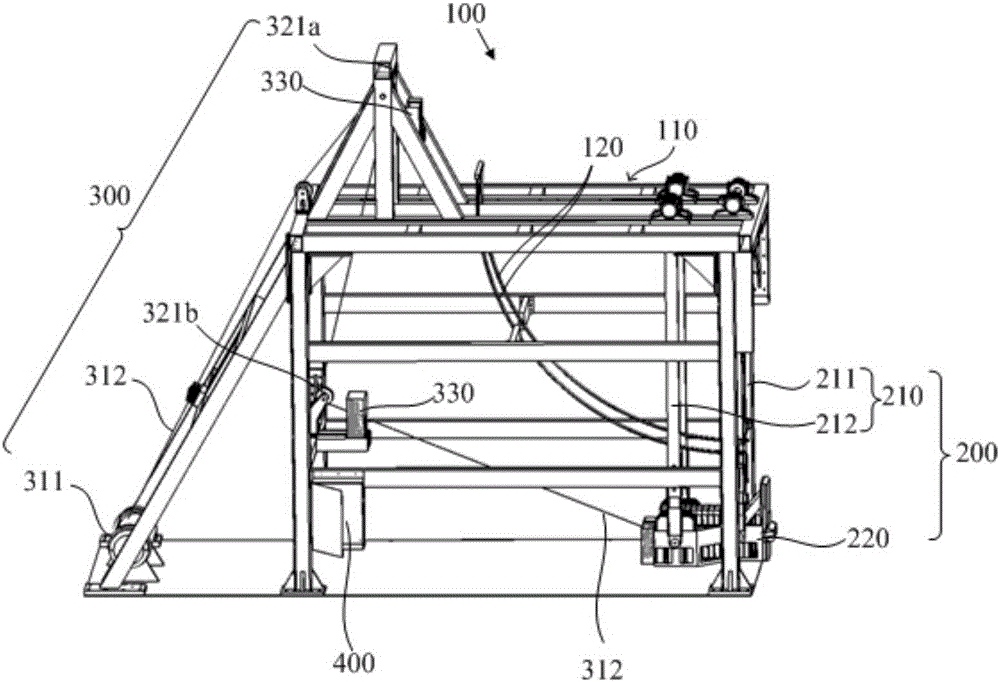

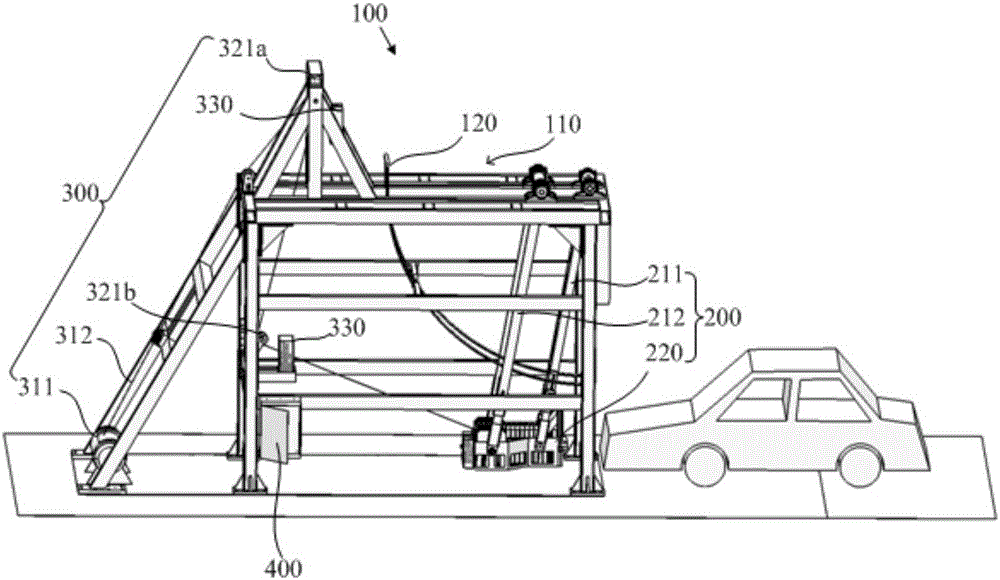

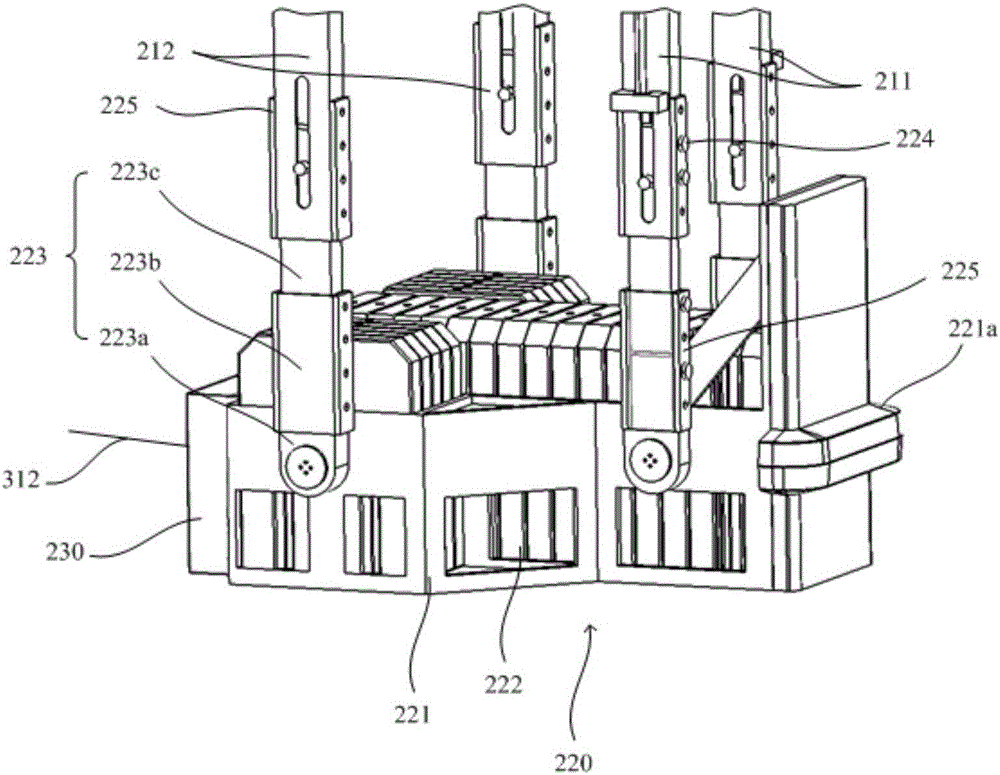

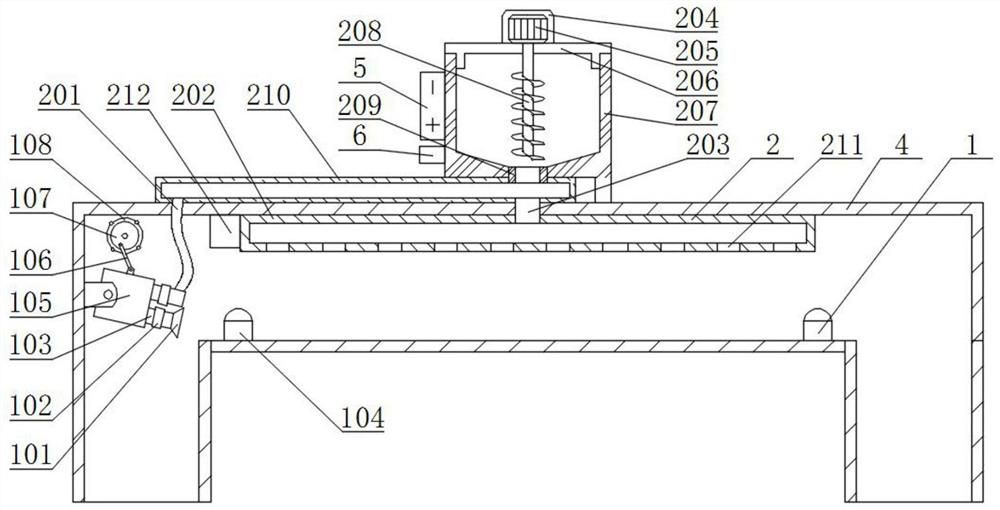

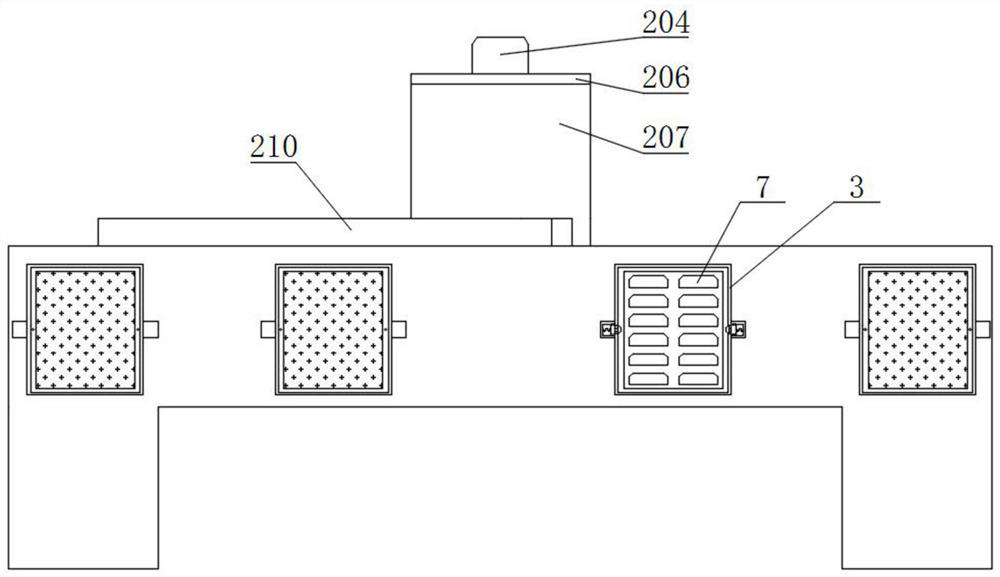

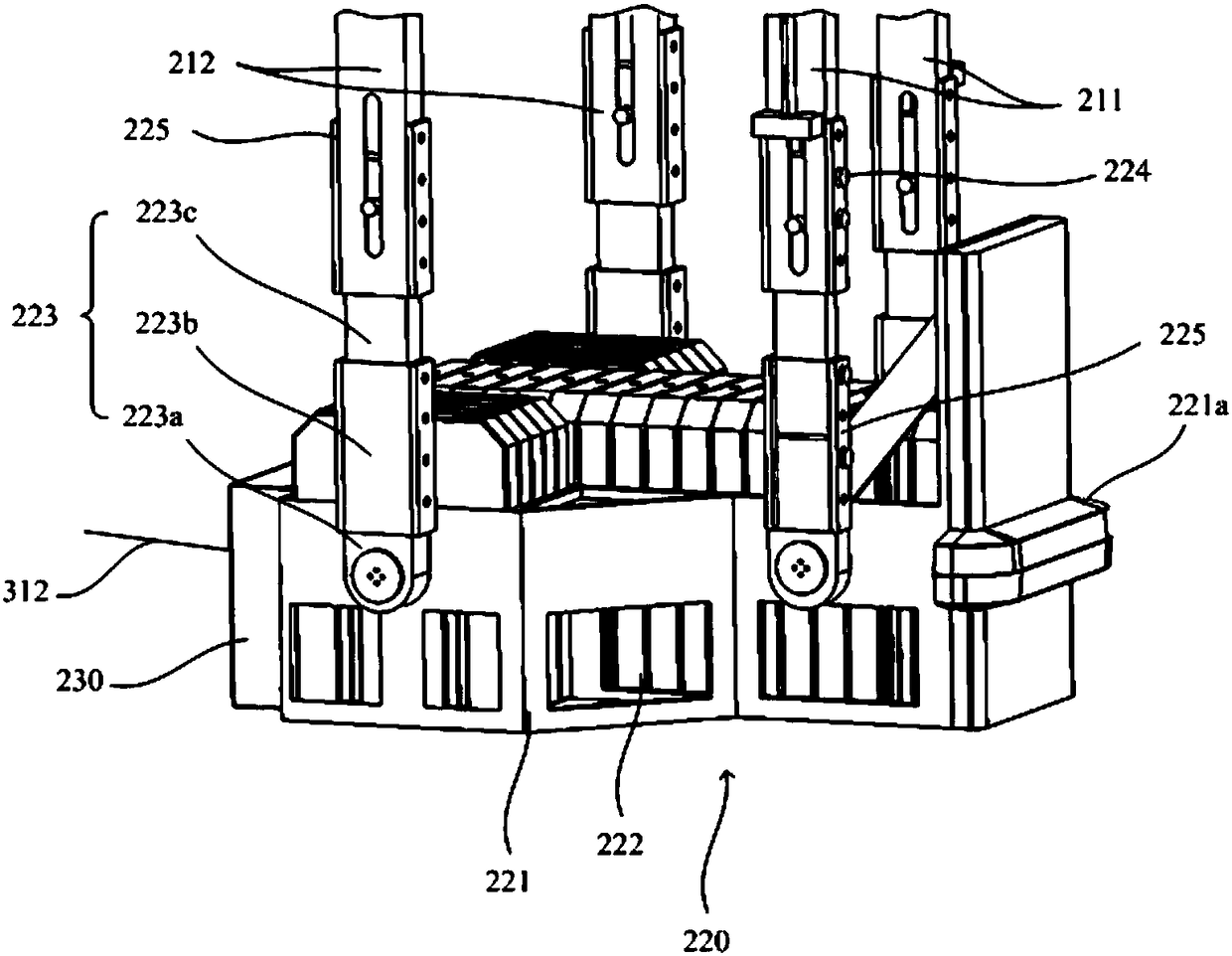

a test bench

ActiveCN105841912BMeet the needs of different test environmentsWon't swing freelyShock testingSupporting systemEngineering

A test bench, comprising: a support system (100) and a pendulum system (200) hinged to the support system (100), the pendulum system (200) comprising a pendulum rod portion (210) and a pendulum portion (220), the pendulum rod portion (210) comprising at least one first pendulum rod (211) and at least one second pendulum rod (212), a swing plane of the first pendulum rod (211) being parallel to but not coinciding with a swing plane of the second pendulum rod (212), the pendulum portion (220) comprising a large pendulum and a small pendulum, the large pendulum being connected to the bottom of the first pendulum rod (211) and the second pendulum rod (212), the small pendulum being connected to the bottom of the first pendulum rod (211) or the second pendulum rod (212). The large pendulum or the small pendulum are selected for mounting according to a test type, the large pendulum may be connected for an automobile front and rear end bumper impact test when the first pendulum rod (211) and the second pendulum rod (212) act simultaneously, and the small pendulum may be connected for a free impact test when the first pendulum rod (211) or the second pendulum rod (212) acts individually, thereby satisfying different test environment requirements.

Owner:江苏彪发化妆品有限公司

Safety valve for polypropylene loop reactor

ActiveCN102313051BEasy to disassembleEasy to replaceEqualizing valvesSafety valvesEngineeringSolid particle

Owner:BEIJING AEROSPACE PROPULSION INST +1

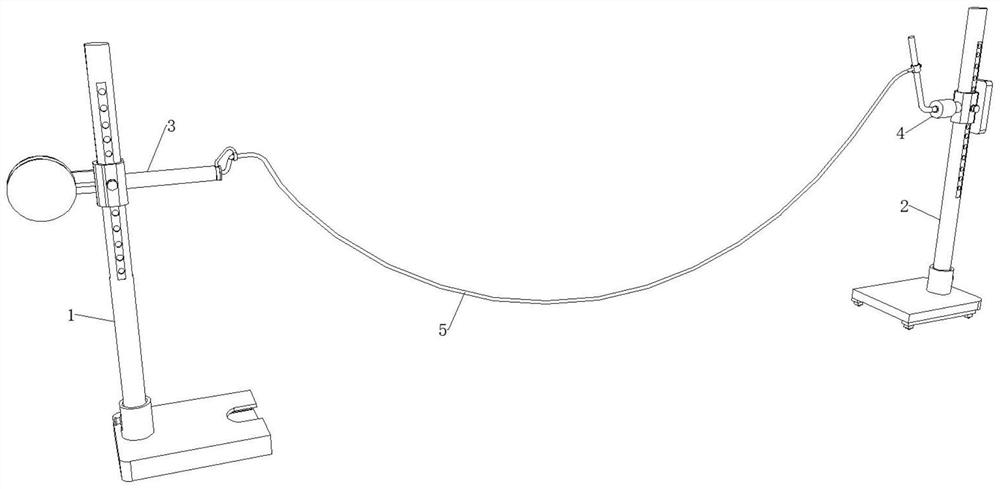

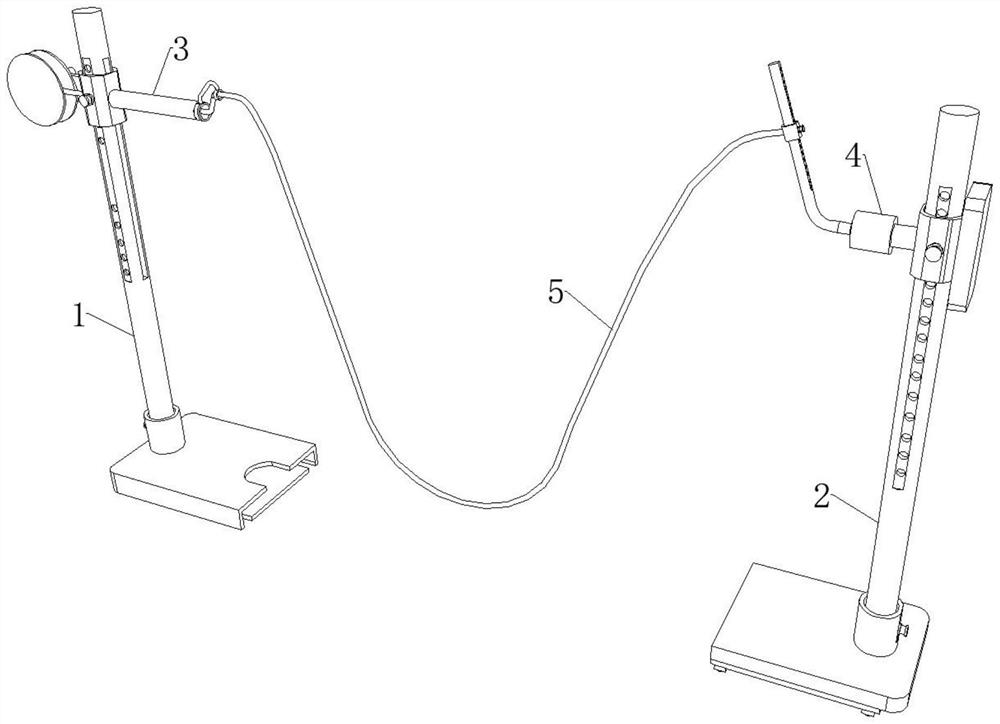

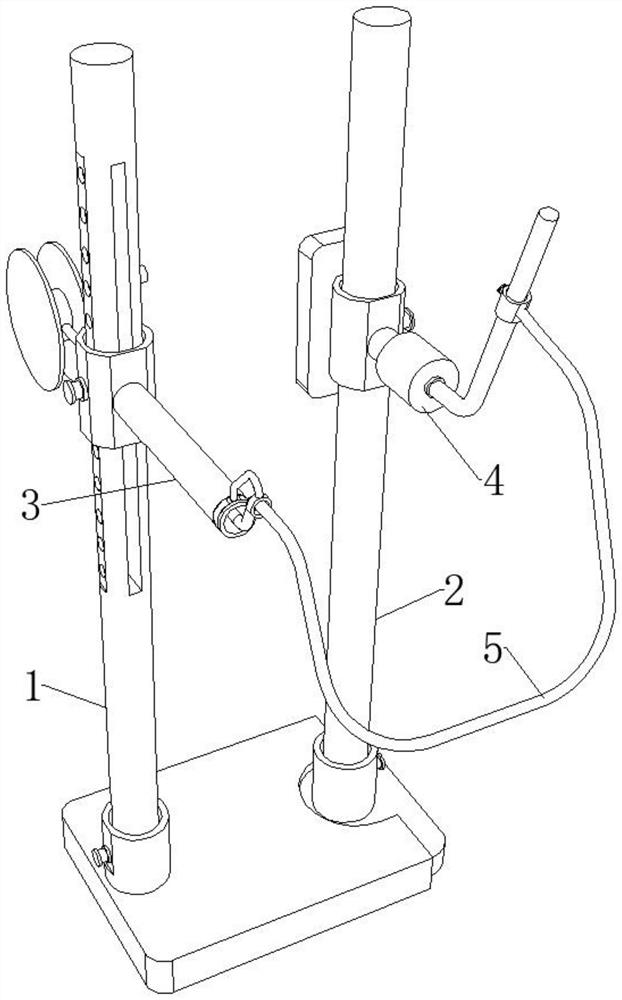

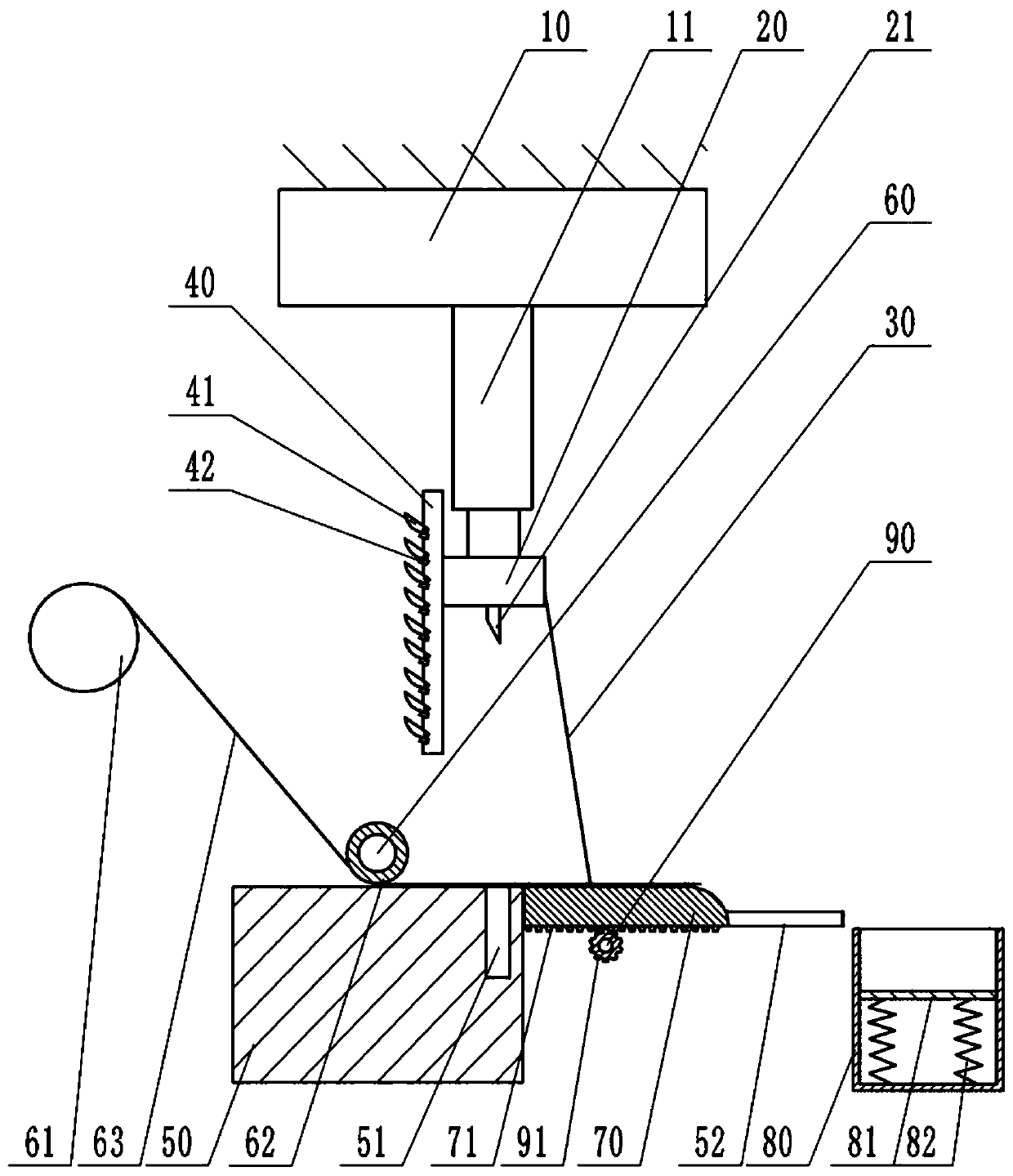

Auxiliary rope swinging comprehensive machine for rope skipping teaching and training

ActiveCN114558274AIncrease the lengthGuaranteed swingSpace saving gamesSkipping-ropesJumping ropeSports equipment

The invention discloses an auxiliary rope swinging comprehensive machine for rope skipping teaching training, and relates to the technical field of sports equipment, the auxiliary rope swinging comprehensive machine comprises a left supporting device and a right supporting device, a skipping rope is arranged between the left supporting device and the right supporting device, and the left supporting device and the right supporting device are respectively provided with a connecting device and a power device. The left supporting device and the right supporting device are arranged to support the connecting device and the power device respectively, the two ends of the skipping rope can be supported, when a large skipping rope space is needed, the skipping rope only needs to be pulled on the connecting device, and at the moment, the skipping rope can slide in a positioning sleeve, a hollow cylinder, a round hole and a vertical strip groove and can be pulled out of a winding disc; the length of the skipping rope is increased, the left supporting device and the right supporting device are far away from each other by a certain distance, then the rope skipping space can be increased, then the skipping rope can be driven to swing when the inclined rods are driven by the driving motor to rotate, and then the rope skipping requirements of different people are met.

Owner:QUFU NORMAL UNIV

paper cutter

ActiveCN108145760BAvoid compromising cut qualityEasy to collectMetal working apparatusDrive shaftPulp and paper industry

The invention belongs to the field of paper processing devices, and particularly discloses a paper cutting machine. The paper cutting machine comprises a paper feeding mechanism, a cutting mechanism and a collection mechanism, wherein the cutting mechanism comprises a workbench, a rack, a mounting base, a cutter and a power device; a cutting groove is formed in the upper surface of the workbench;the paper feeding unit comprises an uncoiling roller, a rotary shaft and a paper feeding roller; the paper feeding roller is fixed to the rotary shaft; the rotary shaft is provided with a ratchet wheel; the mounting base is provided with a mounting strip; a plurality of clamping jaws are hinged to the mounting strip and can be clamped to the ratchet wheel; the collection mechanism comprises a slide rail, a torsional spring, a transmission shaft, a conveying board and a collection tank; the conveying board is in sliding connection with the slide rail; a gear is fixed to the transmission shaft;a rack is arranged on the lower surface of the conveying board; one end of the torsional spring is fixed to the workbench; the other end of the torsional spring is fixed to the transmission shaft; thetransmission shaft is wound with a pull rope; and the pull rope is connected to the mounting base. When the paper cutting machine is used, the cutting quality can be ensured, burrs at notches are avoided, cut paper can be effectively collected, and pieces of paper are stacked orderly.

Owner:浙江拉菲草纸制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com