Vertical lifting flexible feeding system of bar straightening machine

A flexible lifting and feeding system technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of roller table strike, broken cylinder rod, difficult maintenance, etc., to extend service life, avoid excessive impact, and reduce work. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings of the embodiments.

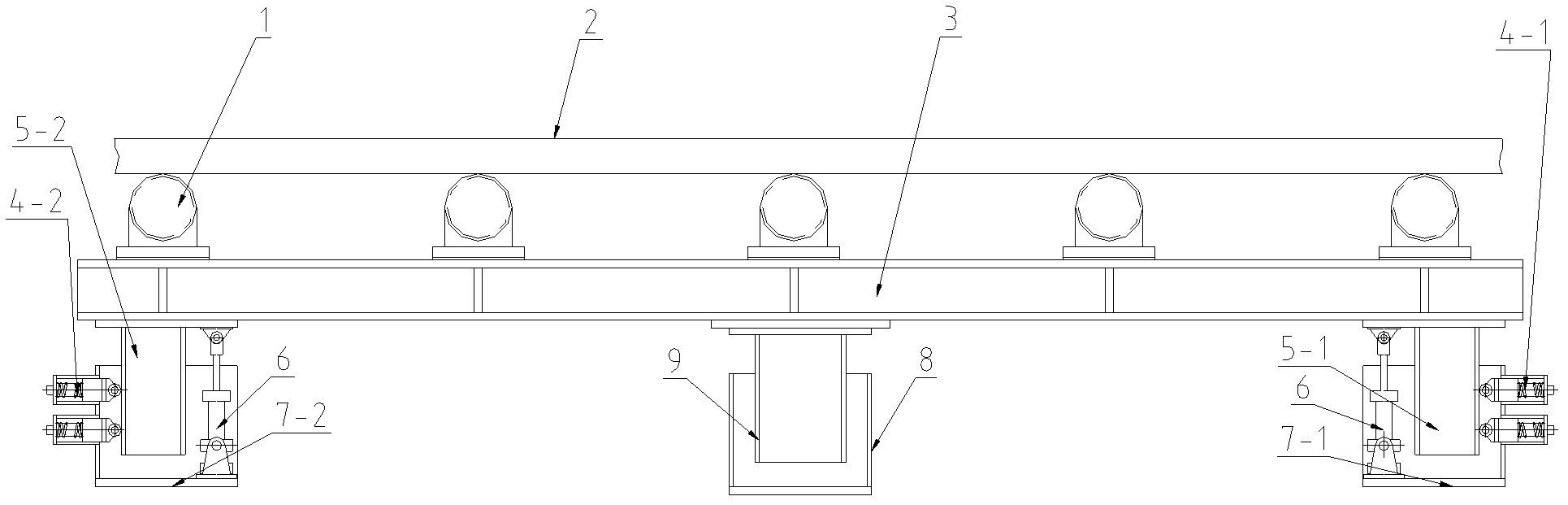

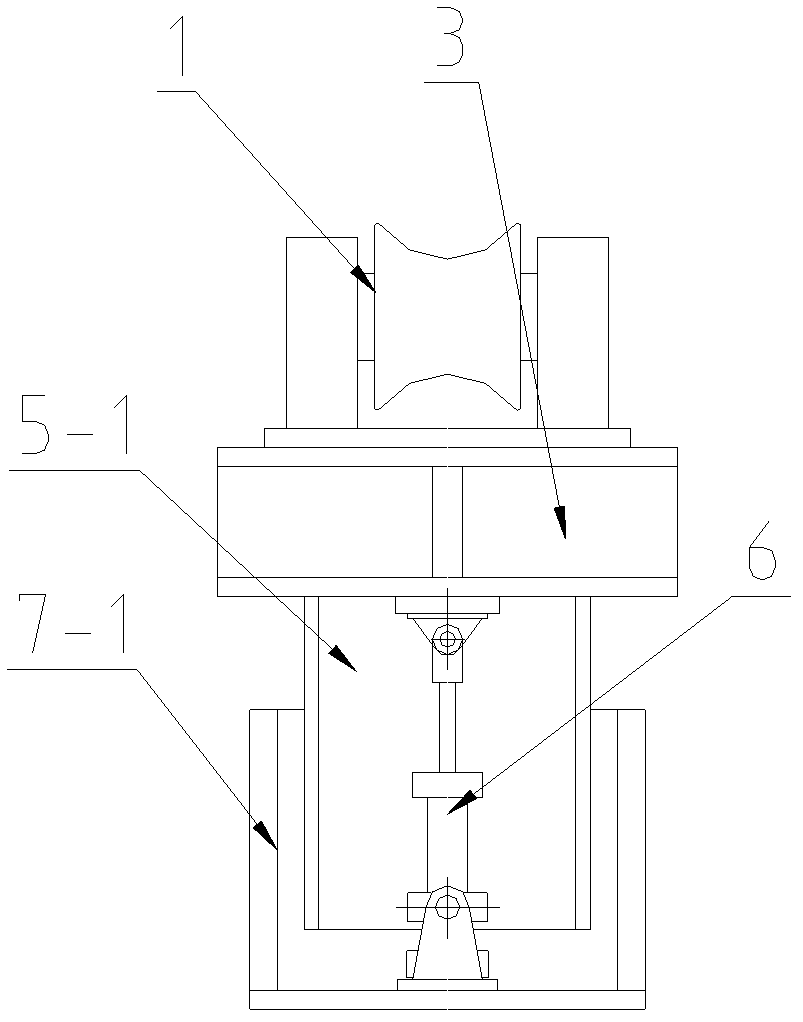

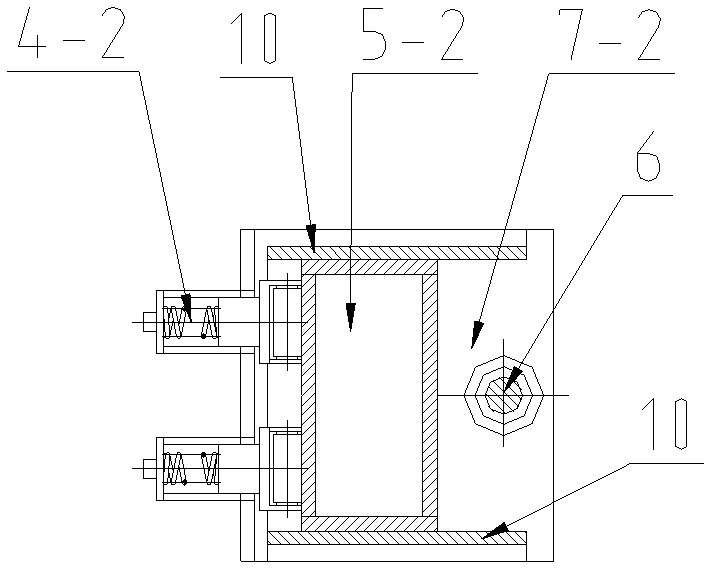

[0011] refer to figure 1 , figure 2 And Fig. 3, a kind of bar straightening machine vertical lifting flexible feeding system, comprises beam 3, and feeding roller table 1 is installed on beam 3, and the bottom of beam 3 and left guide column 5-2, right guide column 5-1 and The middle guide post 9 is connected, the left guide post 5-2 is placed on the left base 7-2, the right guide post 5-1 is placed on the right base 7-1, the middle guide post 9 is placed on the middle base 8, and the beam 3 is the same as The cylinder rods of the two lifting cylinders 6 are hinged, and the lifting cylinder 6 is installed on the left base 7-2 and the right base 7-1 by means of a middle trunnion connection. The middle trunnion that base 7 connects adopts vertical cross installation, and two pairs of first spring top rollers 4-2 are respectively installed on one sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com