Patents

Literature

377results about How to "Firm packaging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

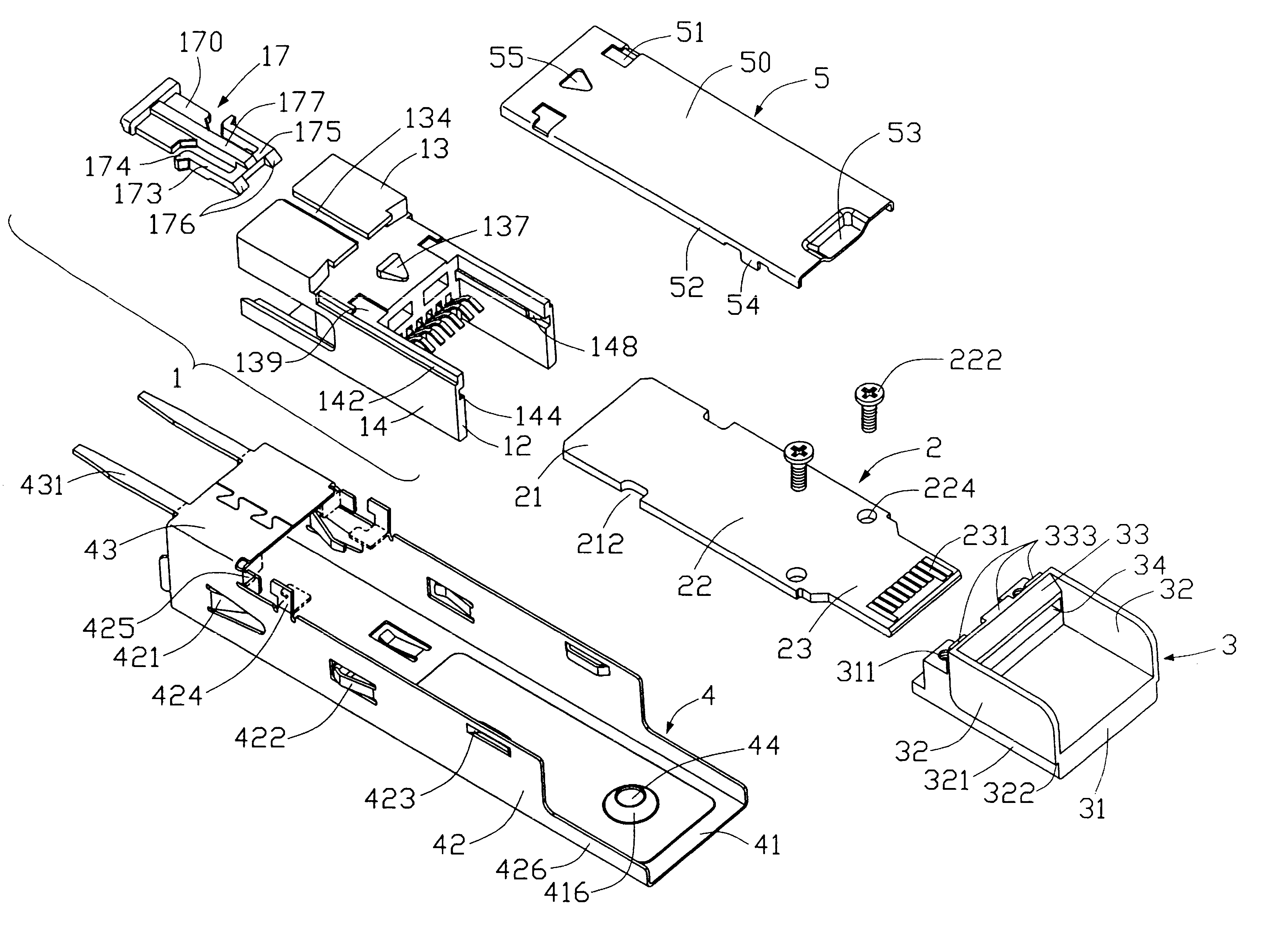

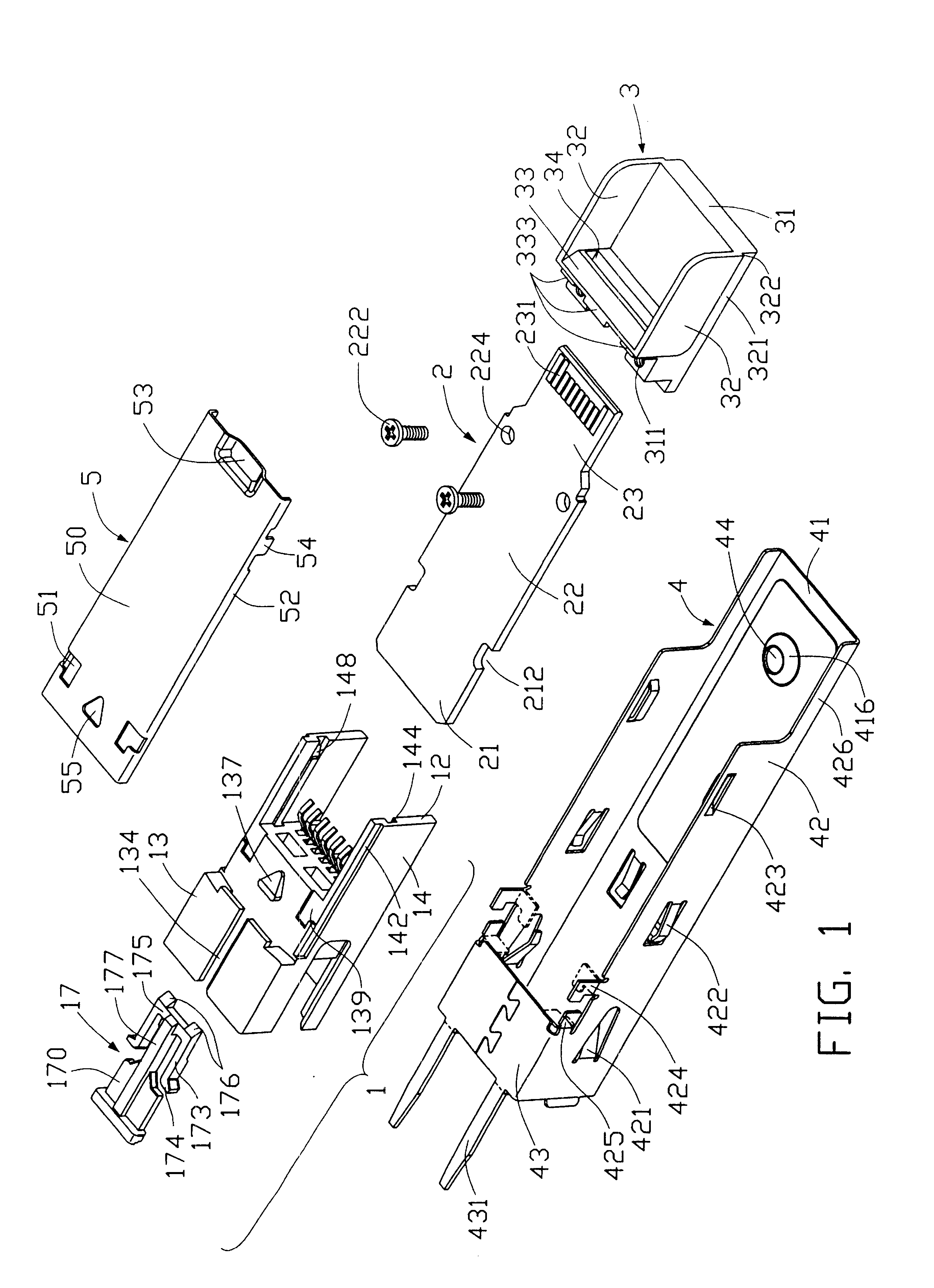

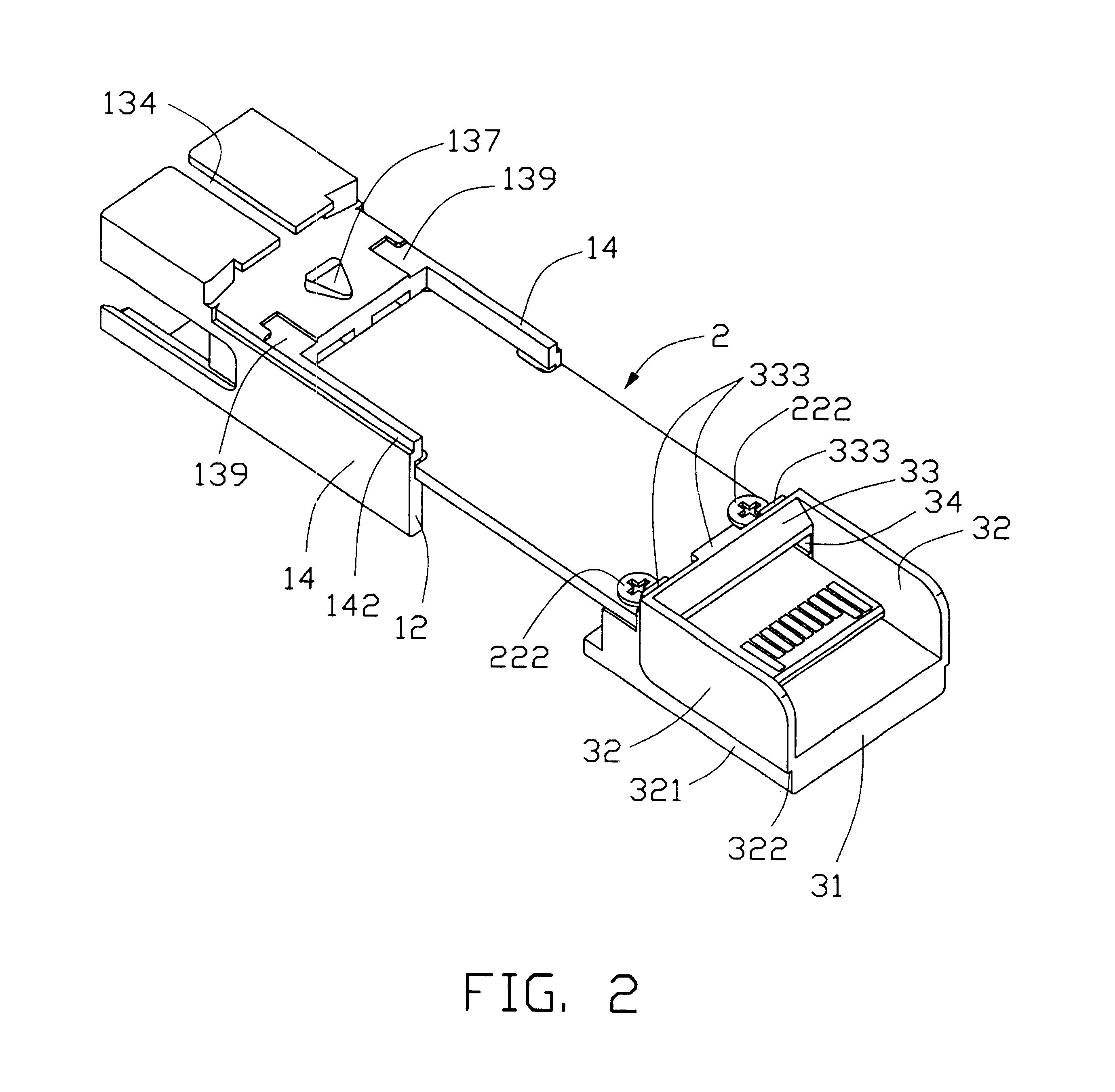

Packing means for small form-factor module

InactiveUS6530785B1Firm packagingTwo-part coupling devicesCoupling light guidesSmall form factorComputer module

Means to firmly pack an SFP module. The means comprises an upper cover (4) and a lower cover (5). The upper cover comprises an upper plate (41), two sidewalls (42) integrally depending from the upper plate, and a bottom plate (43) formed between front portions of the sidewalls. The lower cover has a main panel (50). A pair of flanges (52) extends from opposite longitudinal sides of the main panel respectively. Two elbow-shaped locking tabs (424) integrally depend from respective opposite bottom edges of the sidewalls of the upper cover. A pair of symmetric elbow-shaped cutouts (51) is respectively defined in opposite sides of a front portion of the lower cover, for extension of the elbow-shaped locking tabs of the upper cover therethrough.

Owner:HON HAI PRECISION IND CO LTD

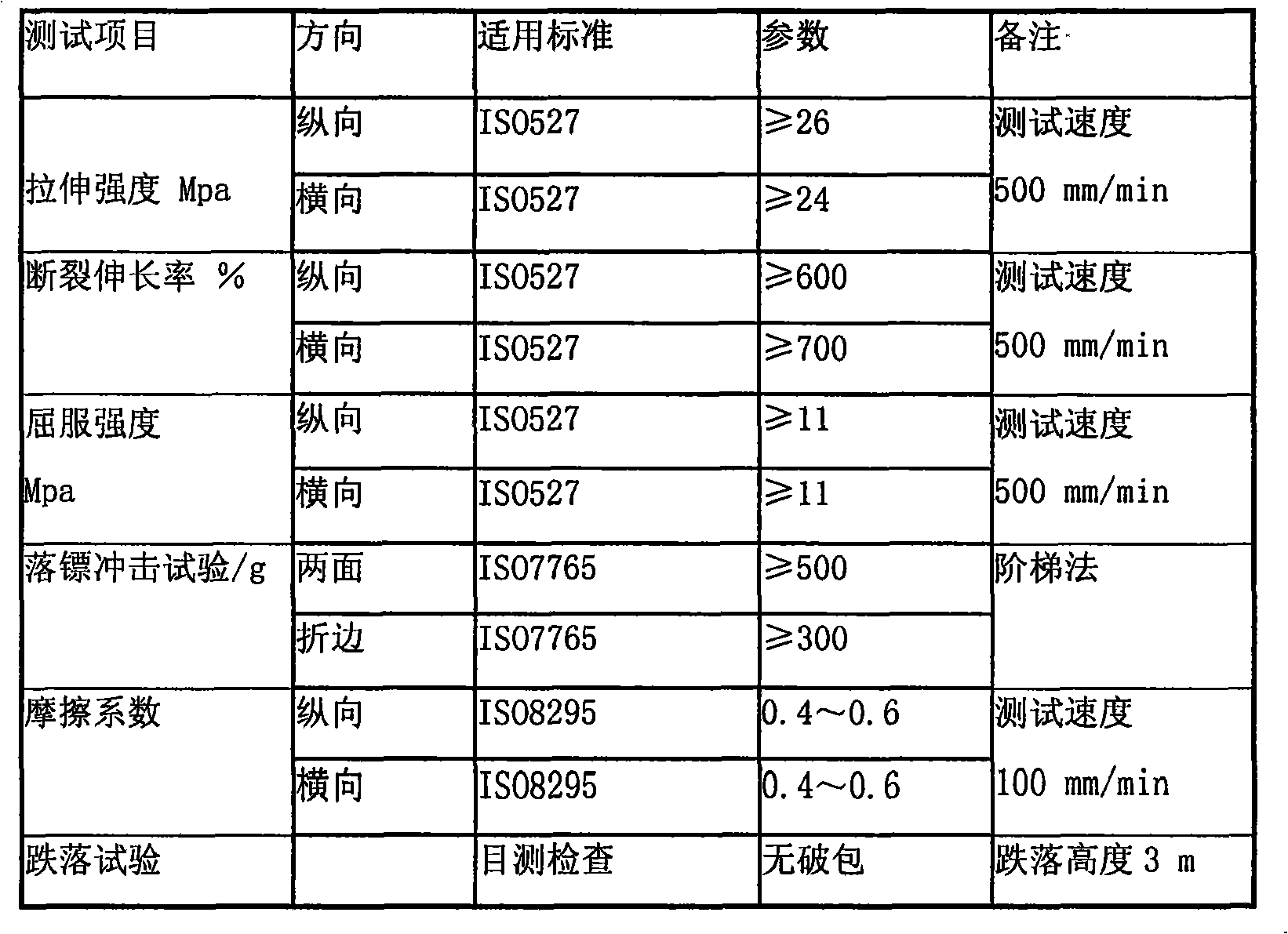

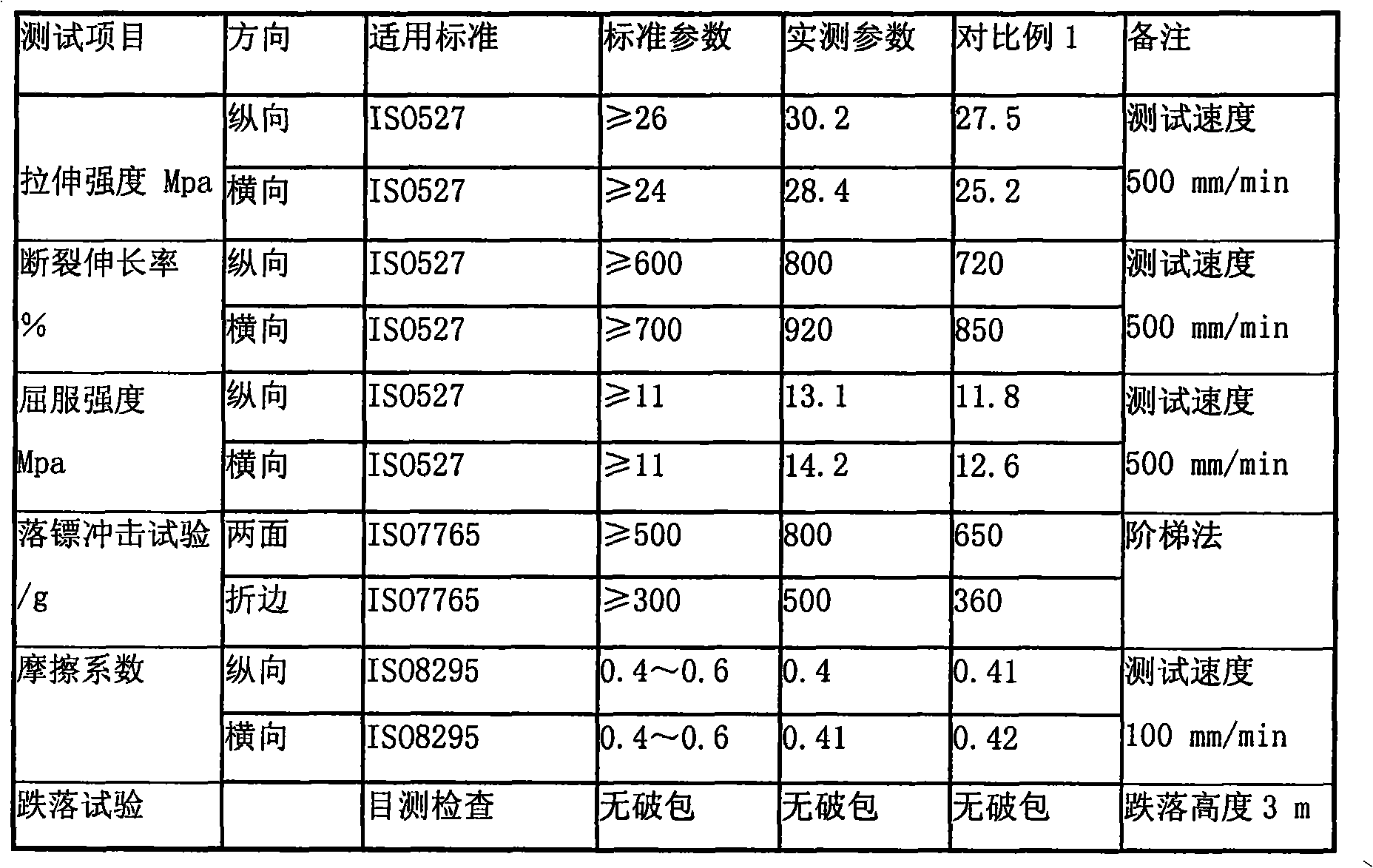

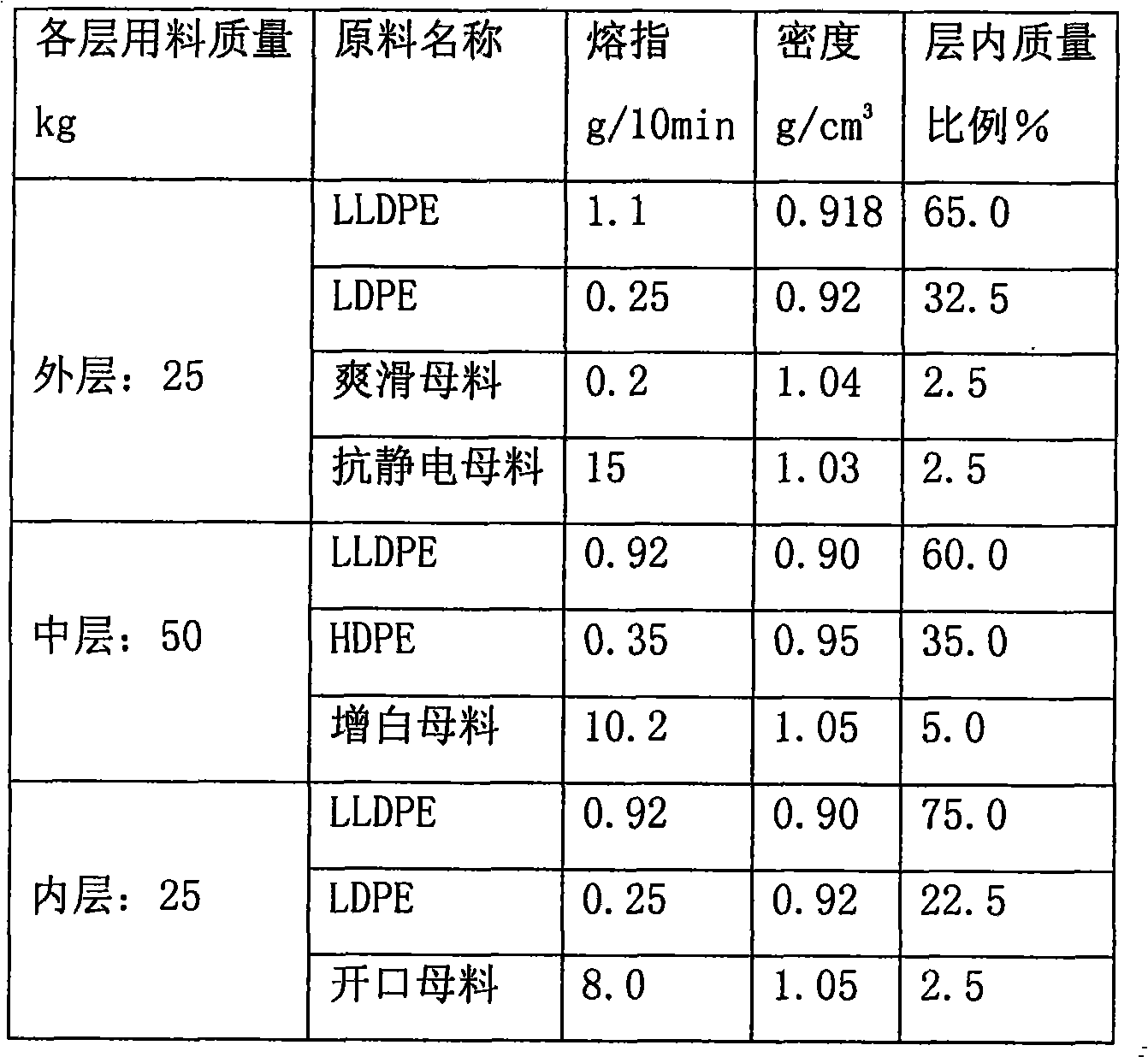

Polyethylene repackaging film material composition

ActiveCN101255249AHigh strengthImprove puncture resistanceLow-density polyethyleneLinear low-density polyethylene

A polyethylene heavy packaging film composite can be widely used for producing blisterpack, such as FFS package, large goods package, tray package and so on, which can effectively improve the all round performance of packaging film, and make the package of goods more beauty, firm, green and effective. The film composite comprises: linear low density polyethylene accounting for 60-80% of the sum of the material, low density polyethylene accounting for 5-25% of the sum of the material, metallocene linear low density polyethylene accounting for 10-30% of the sum of the material, additive accounting for 3-7% of the sum of the material. An automatic feed proportioning system feeds the material of three extruders to die head and the heavy packaging film combination is obtained after three-layer extruding and mixing. The additive is combination of one or several kinds of slippery agent, antistatic agent, antioxidant, opening agent, thermal stabilizer.

Owner:SINOPEC YANGZI PETROCHEM

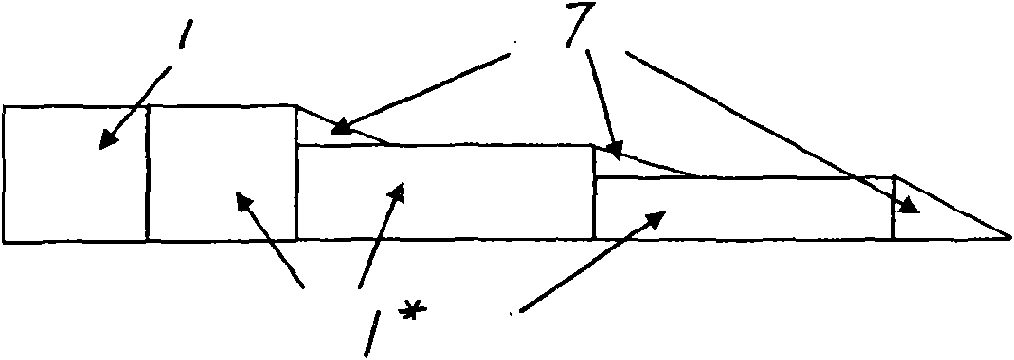

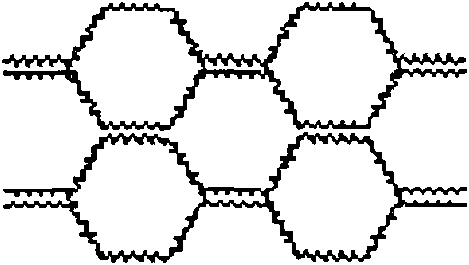

Wind turbine blade structure, processing and forming method and applications thereof

InactiveCN101666290AEasy to placeEvenly wrappedFinal product manufactureMachines/enginesFiberTurbine blade

The invention relates to a wind turbine blade structure, a processing and forming method and applications thereof. The blade consists of a root segment, a main beam and a covering that wraps the rootsegment and the external side of the main beam; the blade is fixed with a wind wheel by a connecting piece that is arranged at the root segment, thus forming a spatial cantilever beam structure; at the main beam area and the root segment, one or more solid or hollow wedge-shaped columns are arranged between a top paving layer and a bottom paving layer; the wedge-shaped column at the internal-mostside of the root end is solid and is internally provided with the connecting piece, wherein the fiber cloth is arranged at least among the adjacent wedge-shaped columns at the internal-most side of the root segment and continuously intersects and enwinds the wedge-shaped columns in a horizontal S-shaped, thus forming an interlayer; and the top paving layer, the bottom paving layer and the fiber cloth interlayer are dipped and solidified to form a framework with a honeycomb-shaped section. The structure and the method have the advantages of: leading the once pouring of resin and once solidifying and forming for the large blade and the realizing of the pre-embedding of the connecting piece of the root part to be possible, dispersing the synergistic effect and solidifying shrinkage quantity of solidified heating of the bottom paving layer and the top paving layer by the wedge-shaped columns, and leading the unsaturated resin used as a substrate material to be possible.

Owner:黄争鸣

Polycrystalline silicon

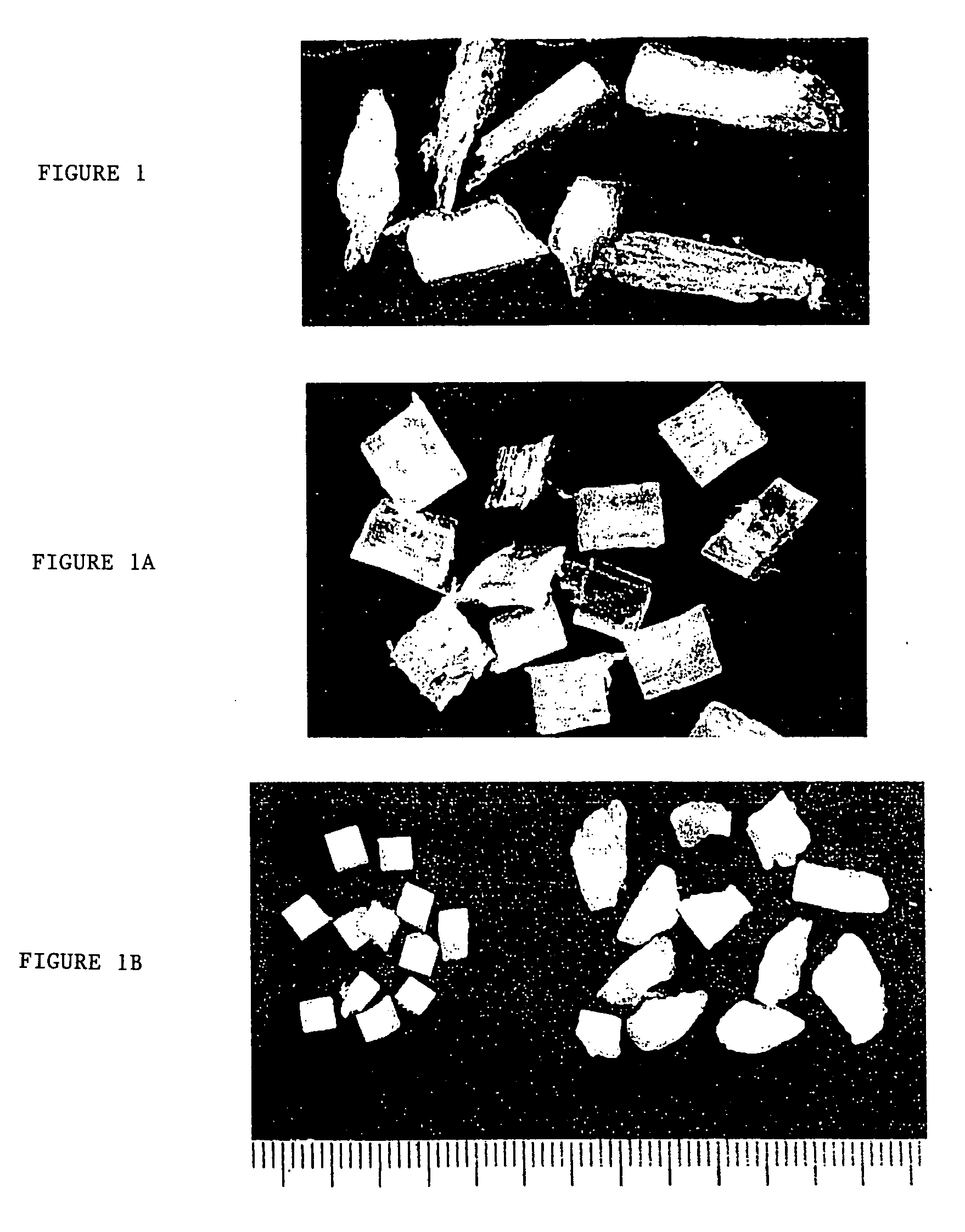

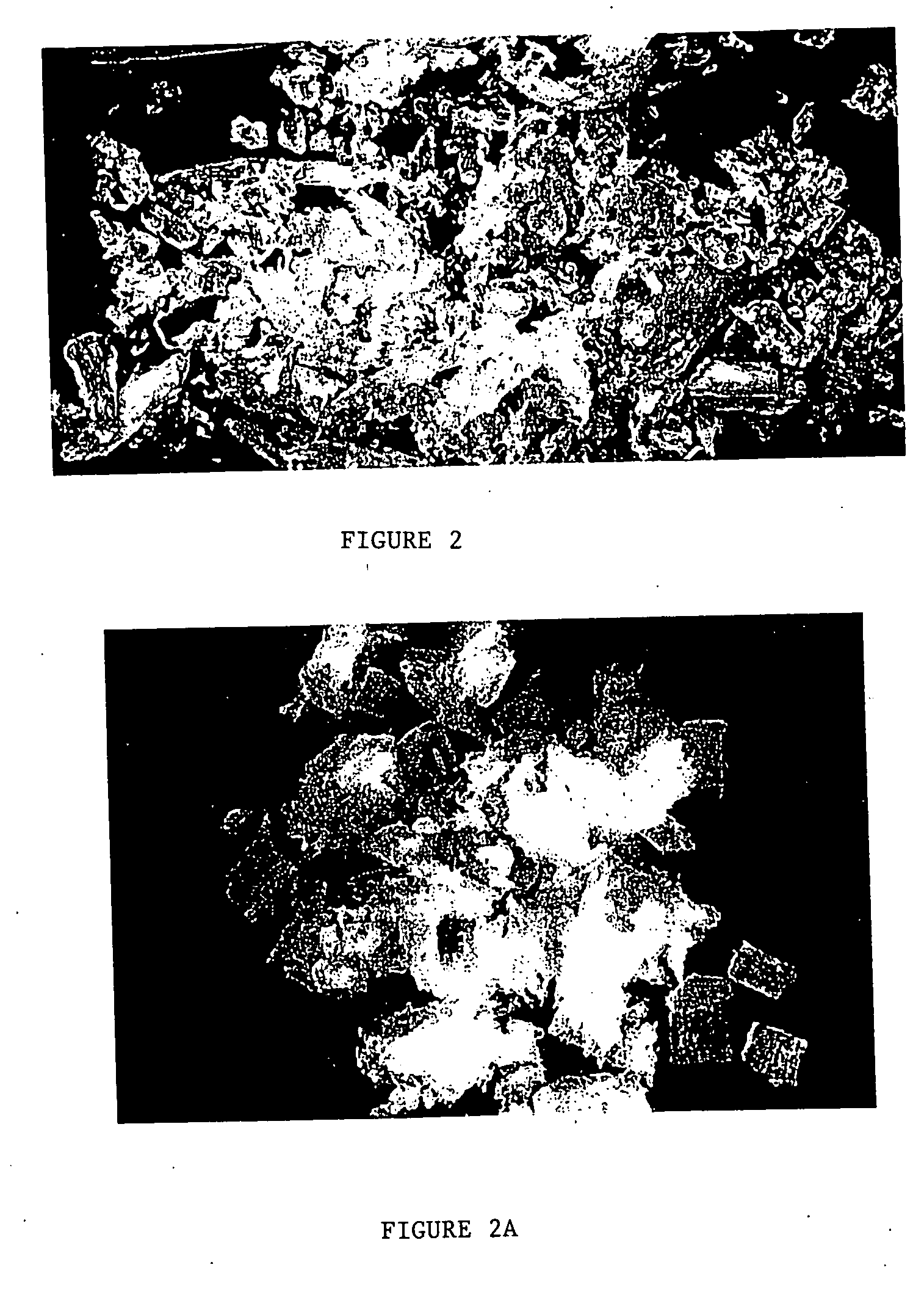

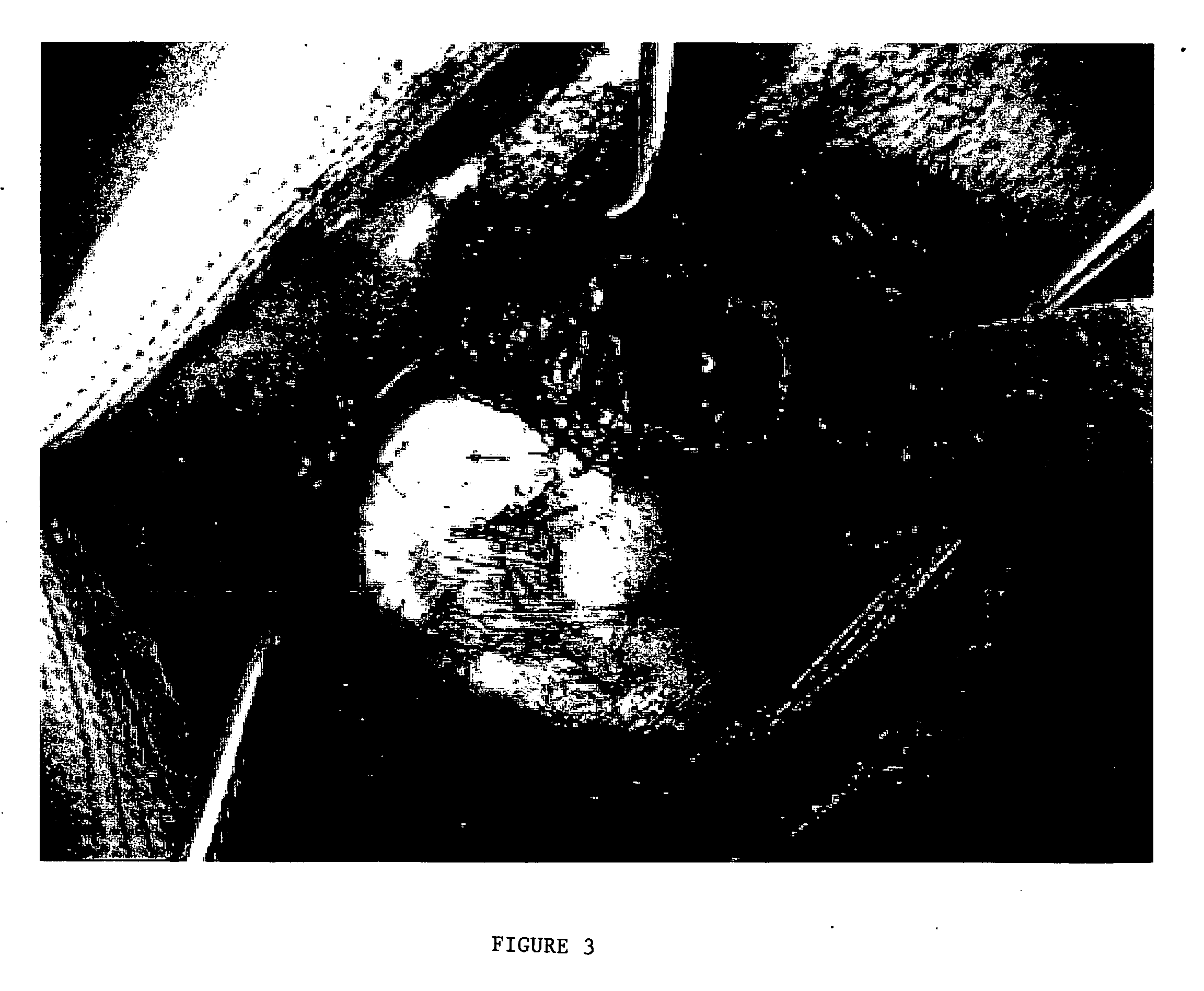

Polycrystalline silicon in the form of chunks packed in plastic bags containing a mass of at least 5 kg, including chunks of size from 20 to 200 mm, wherein any fines fraction in the plastic bag is less than 900 ppmw, preferably less than 300 ppmw, more preferably less than 10 ppmw. The polycrystalline silicon, after comminution of a silicon rod obtained by CVD (Siemens process), is sorted and classified, optionally dedusted and then metered and packed. Metering and packing units include elements for removing fines or small particles during metering and during packing. The packing unit includes an energy absorber or a reservoir vessel which enables sliding or slipping of the silicon chunks into the plastic bag. Gas flow generated within the plastic bag after the bag has been filled transports the dust or small particles out of the bag, and these are sucked out with a suction device.

Owner:WACKER CHEM GMBH

Volume maintaining osteoinductive/osteoconductive compositions

InactiveUS20060147545A1Superior volume maintain propertyRapid remodelSurgerySkeletal disorderBiomedical engineeringSurface-area-to-volume ratio

An osteoinductive / osteoconductive composition prepared from a quantity, of demineralized fibrous bone elements possessing an average surface area to volume ratio of about 100:1 to about 20:1, a quantity of mostly shaped regular non-fibrous bone elements possessing an average surface area to volume ratio of about 10:1 or less and a sufficient quantity of biocompatible fluid carrier sufficient to provide the composition as a deformable mass is provided herein. Also provided is a method of using the composition to repair a bone defect site.

Owner:SCARBOROUGH NELSON L +3

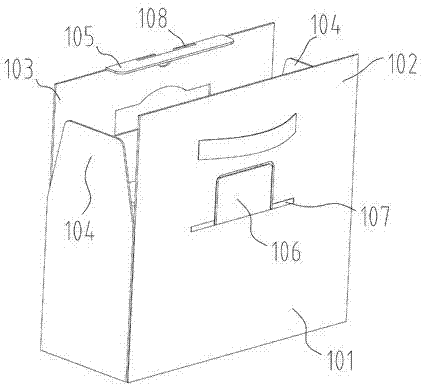

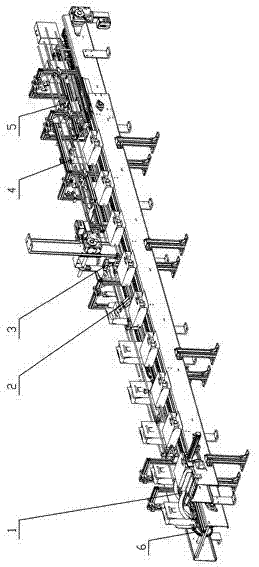

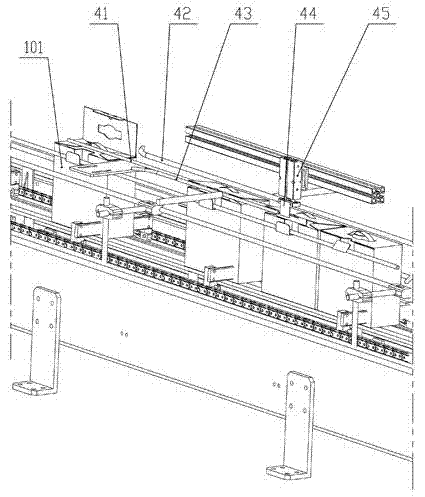

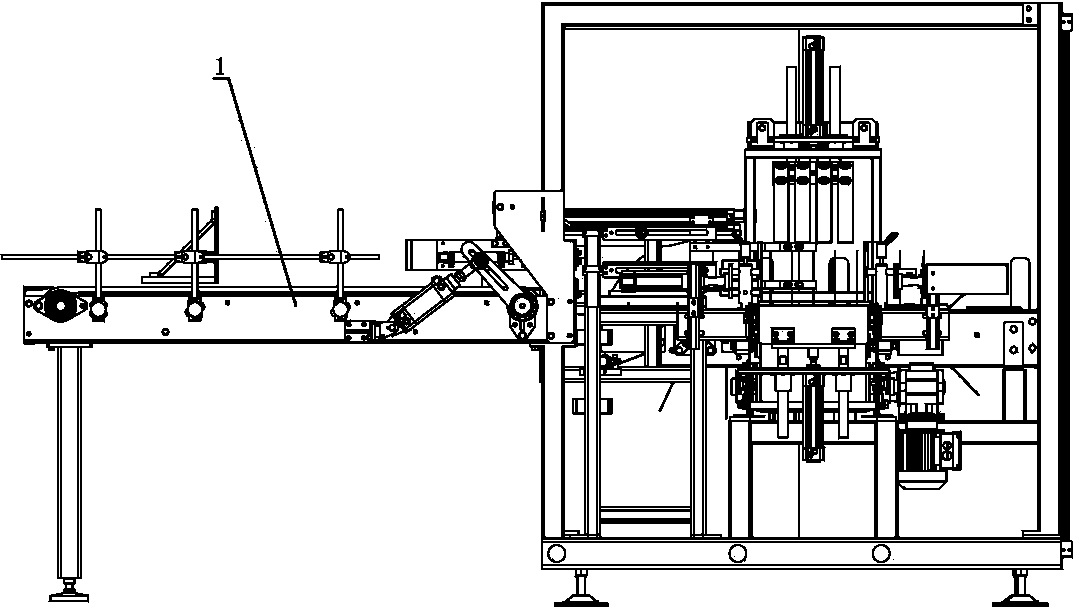

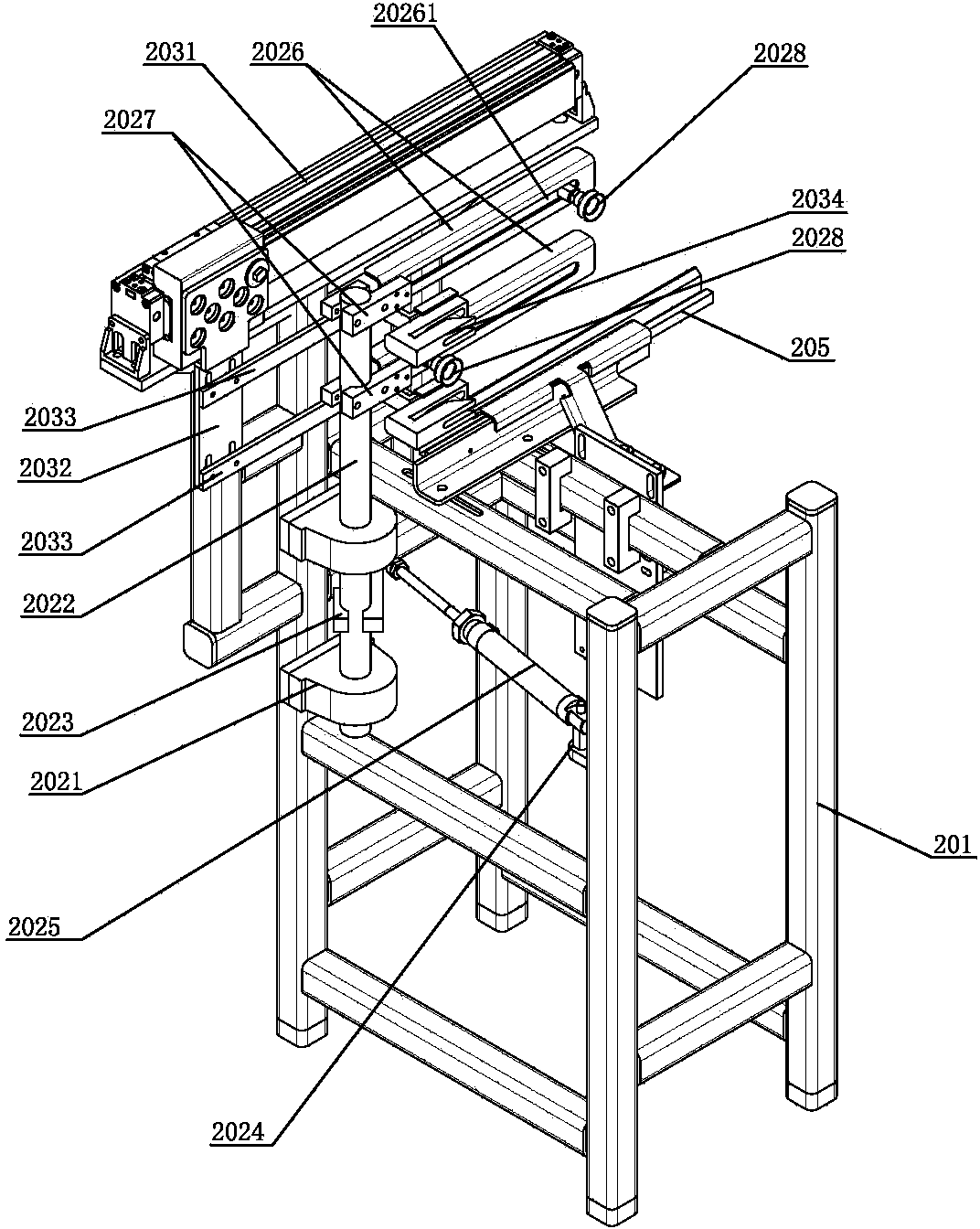

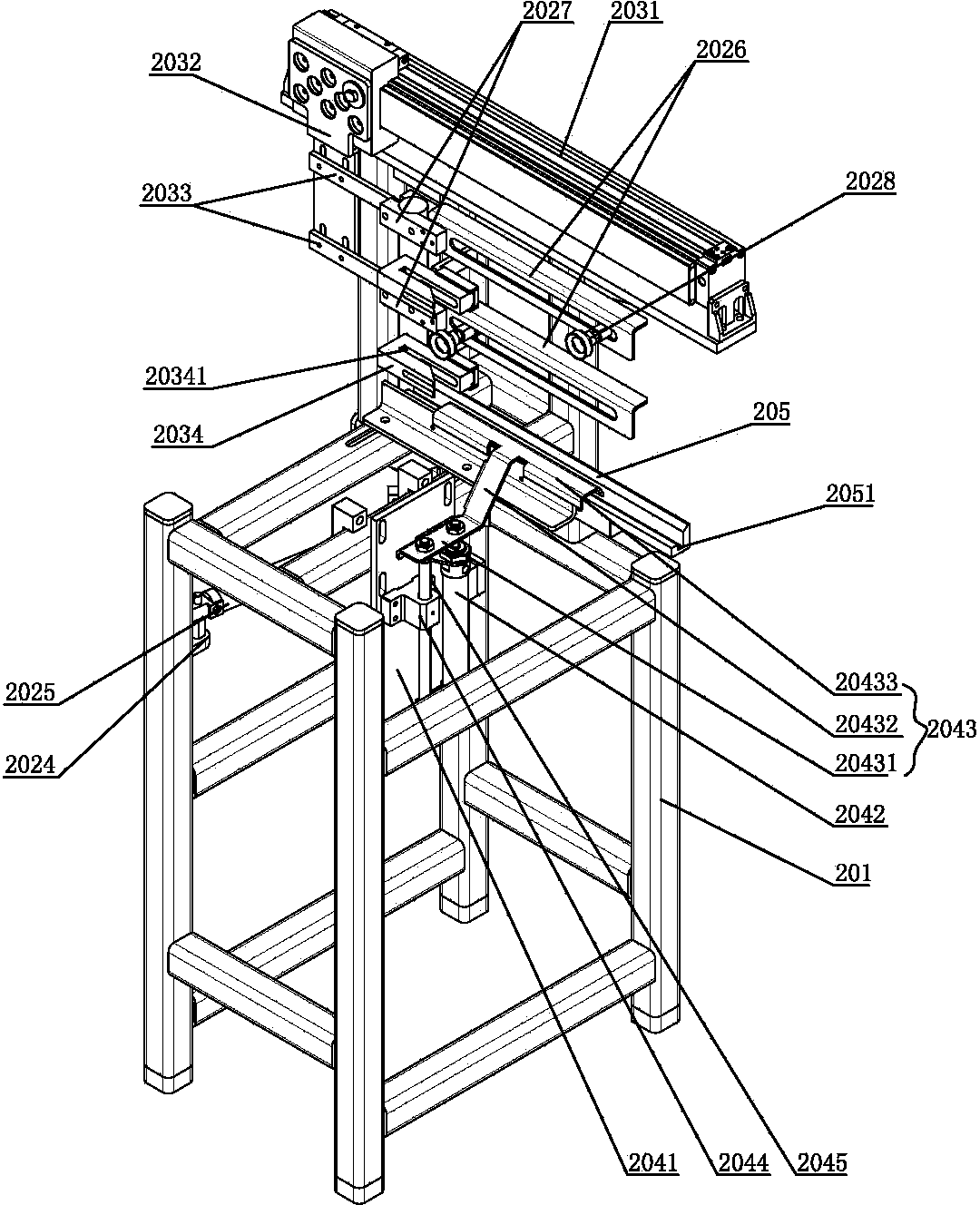

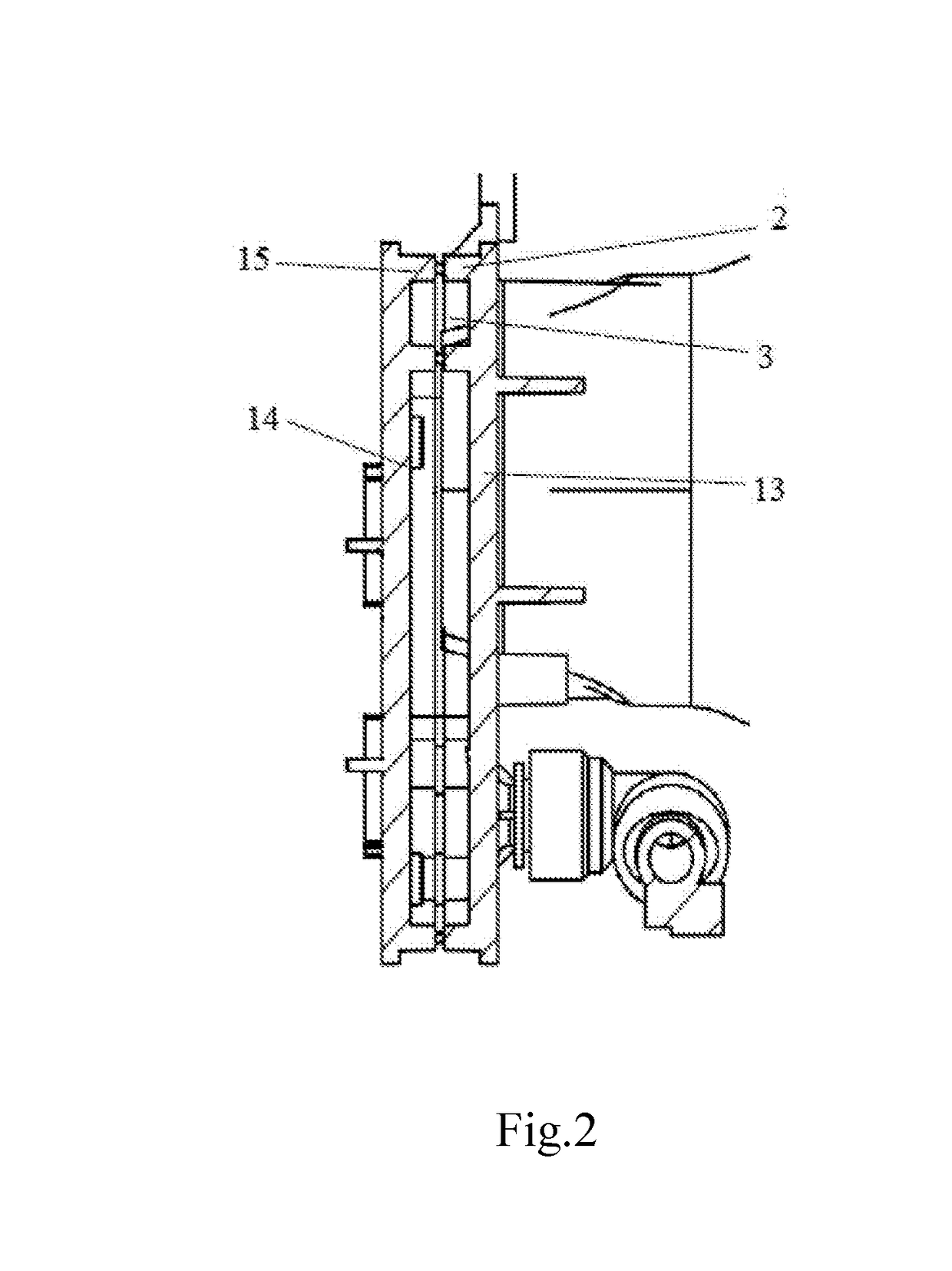

Automatic paper gift-box packing forming device and forming processes

The invention discloses an automatic paper gift-box packing forming device and forming processes. The automatic paper gift-box packing forming device comprises a box standing mechanism, a small tongue sucking mechanism, a front large page and small page folding mechanism, a large page tongue inserting mechanism and a small tongue inserting mechanism. Sealing work of gift boxes are completed by the automatic equipment to replace traditional manual sealing operation, labor investment and site using cost are reduced, so that package process is more stable, accurate and controllable, and working efficiency is improved.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

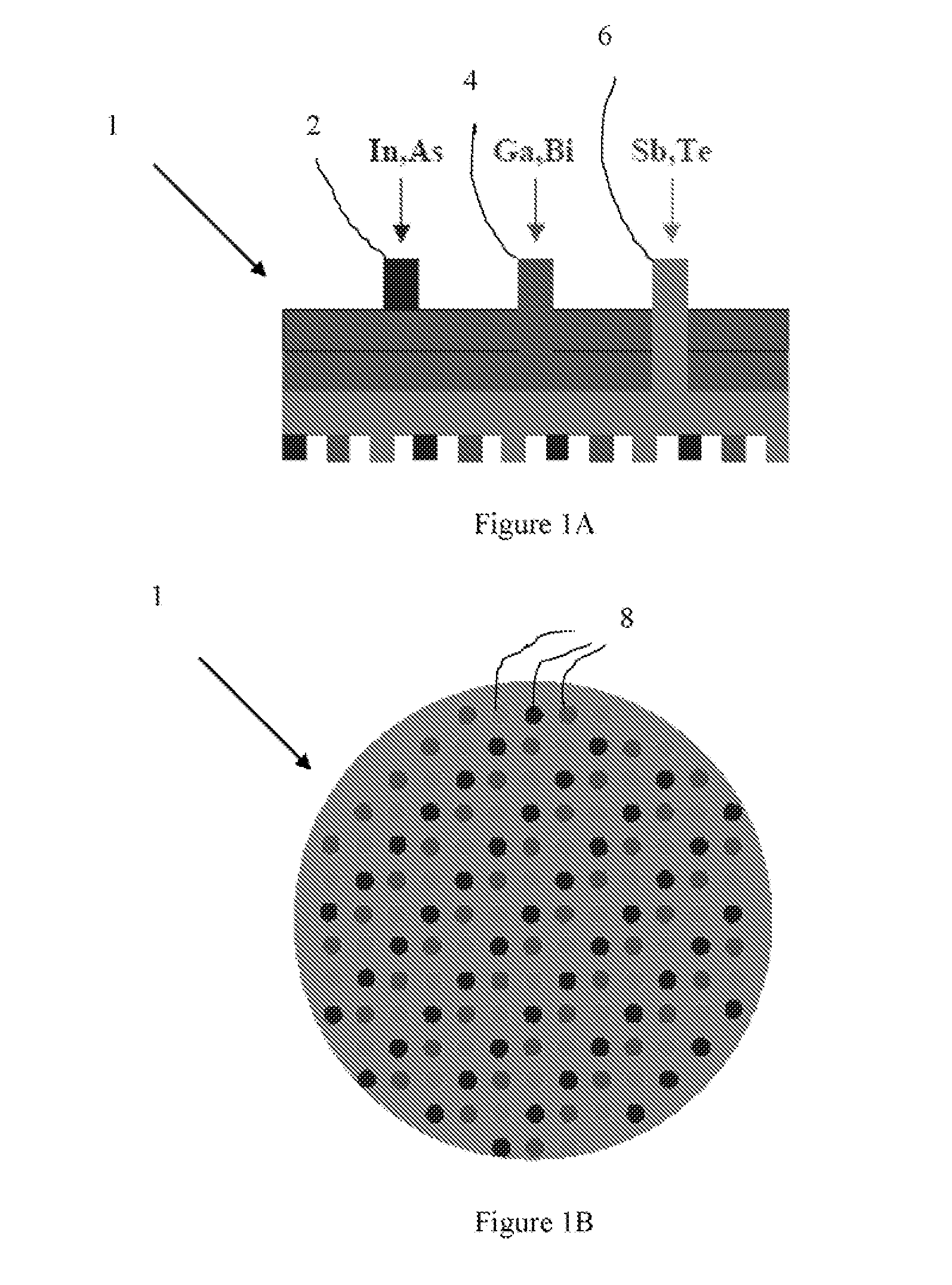

Thermoelectric nanowire composites

InactiveUS20080178921A1Improve reliabilityImproved thermal managementThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentContact padNanowire array

An MOCVD process provides aligned p- and n- type nanowire arrays which are then filled with p- and n-type thermoelectric films to form the respective p-leg and n-leg of a thermoelectric device. The thermoelectric nanowire synthesis process is integrated with a photolithographic microfabrication process. The locations of the p- and n-type nanowire micro arrays are defined by photolithography. Metal contact pads at the bottom and top of these nanowire arrays which link the p- and n-type nanowires in series are defined and aligned by photolithography.

Owner:ELORET CORP

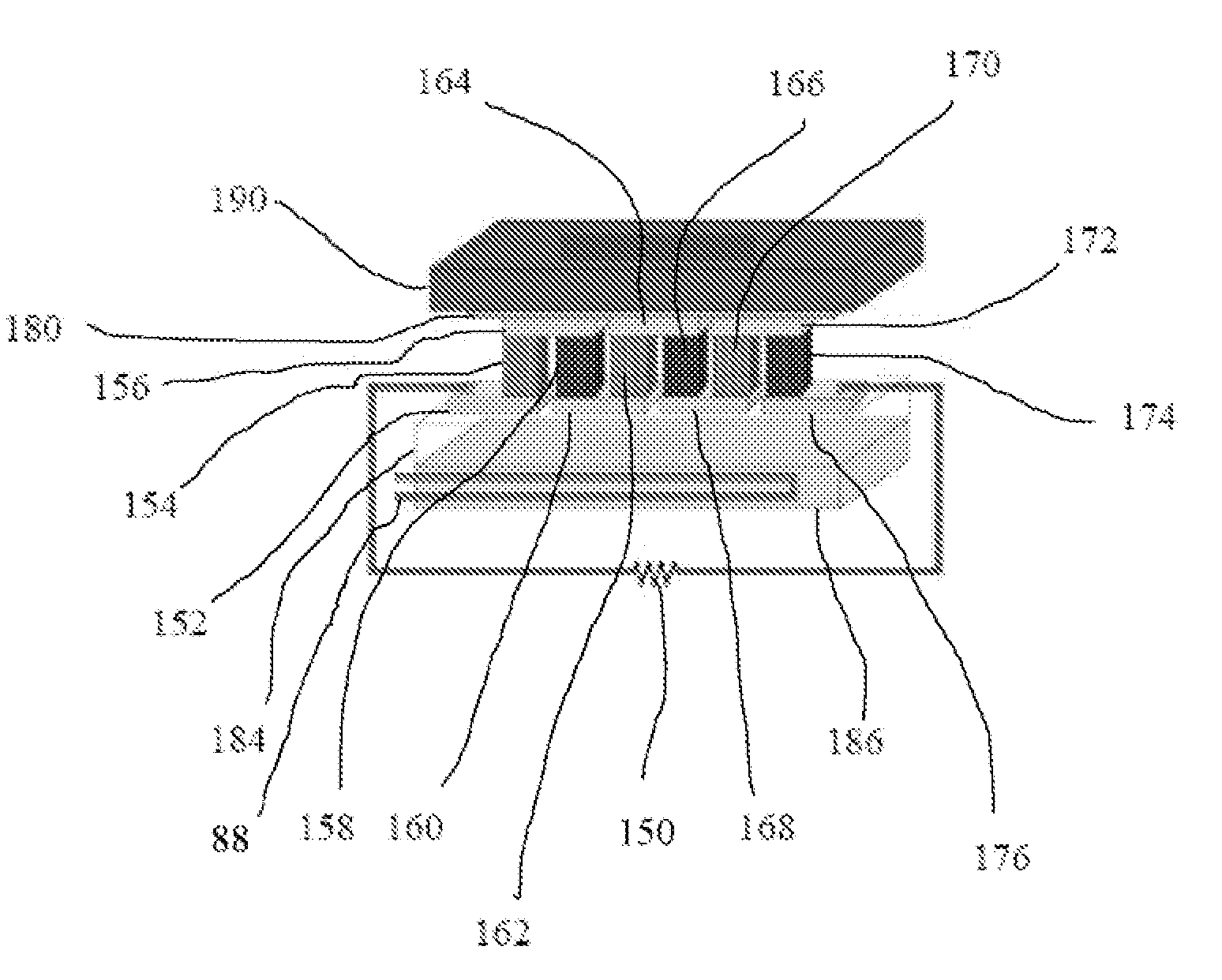

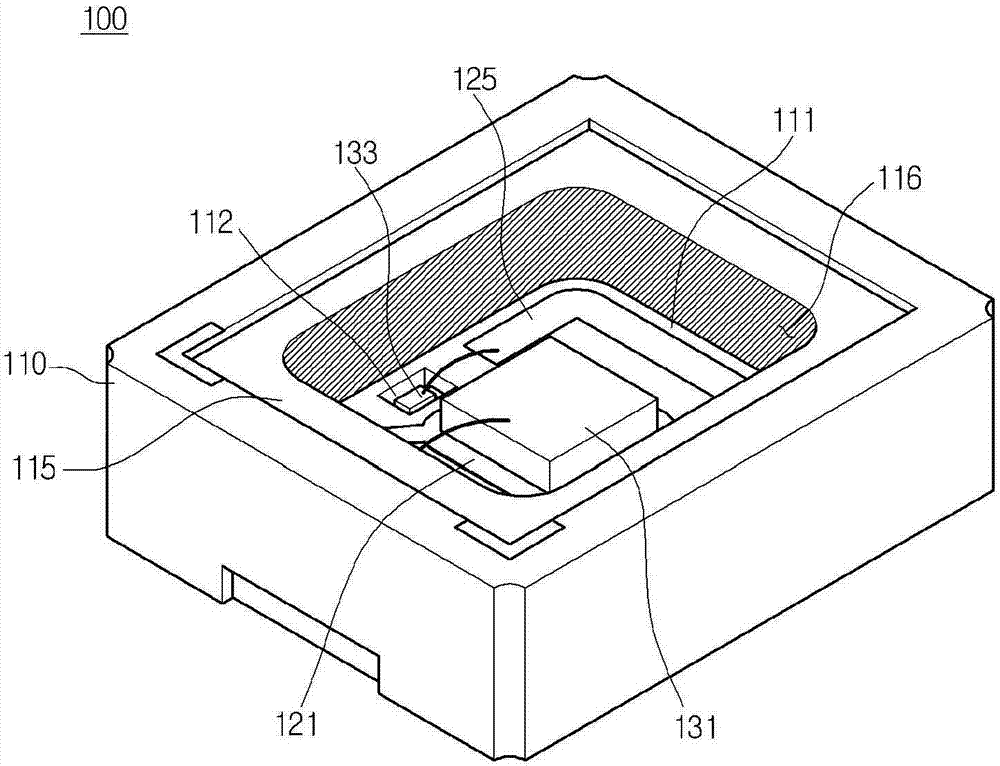

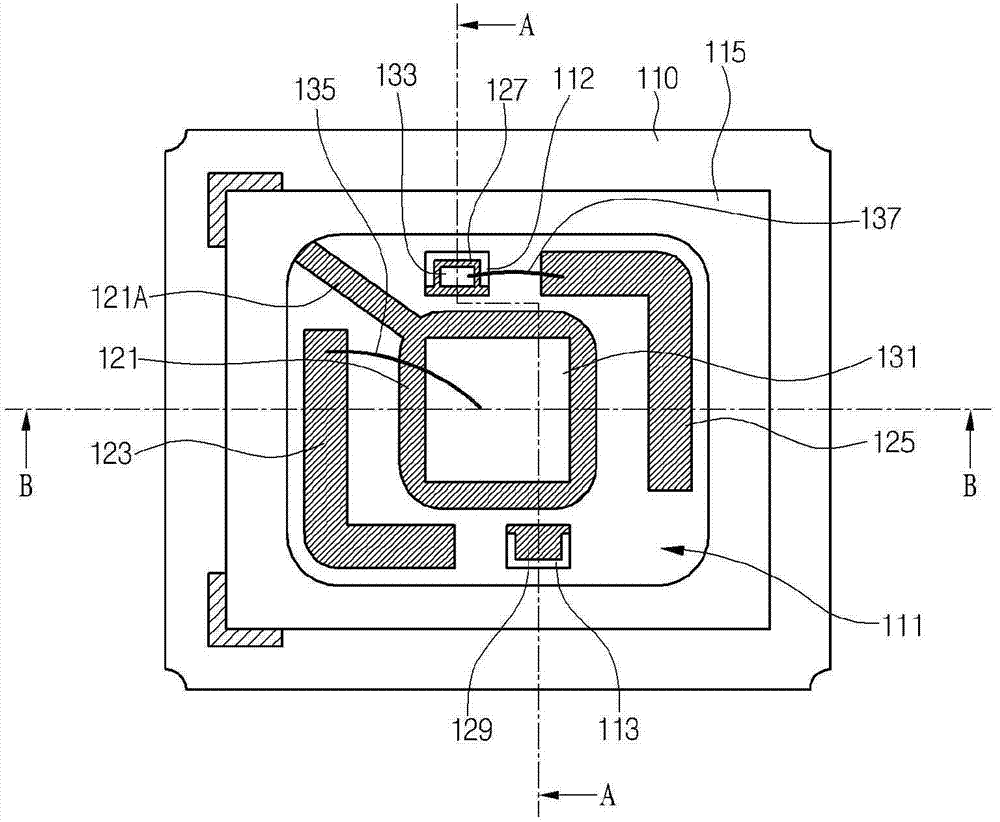

Light emitting device package and ultraviolet lamp having the same

ActiveCN102779932ANo drop in extraction efficiencyPrevent penetrationPoint-like light sourceElectric circuit arrangementsUltravioletLight emitting device

Provided is a light emitting device package. The light emitting device package comprises a body, a heat diffusing member, a light emitting diode (LED), and a buffer layer. A cavity with an opened topside is formed in the body. The heat dissipation member is disposed between a bottom surface of the cavity and a lower surface of the body. The LED is disposed on one of an electrode disposed on the bottom surface of the cavity. The buffer layer is disposed between the heat dissipation member and a pad and has a thickness thinner than the thickness of the heat dissipation member.The light emitting device package provided in the invention can increase the heat dissipation efficiency.

Owner:SUZHOU LEKIN SEMICON CO LTD

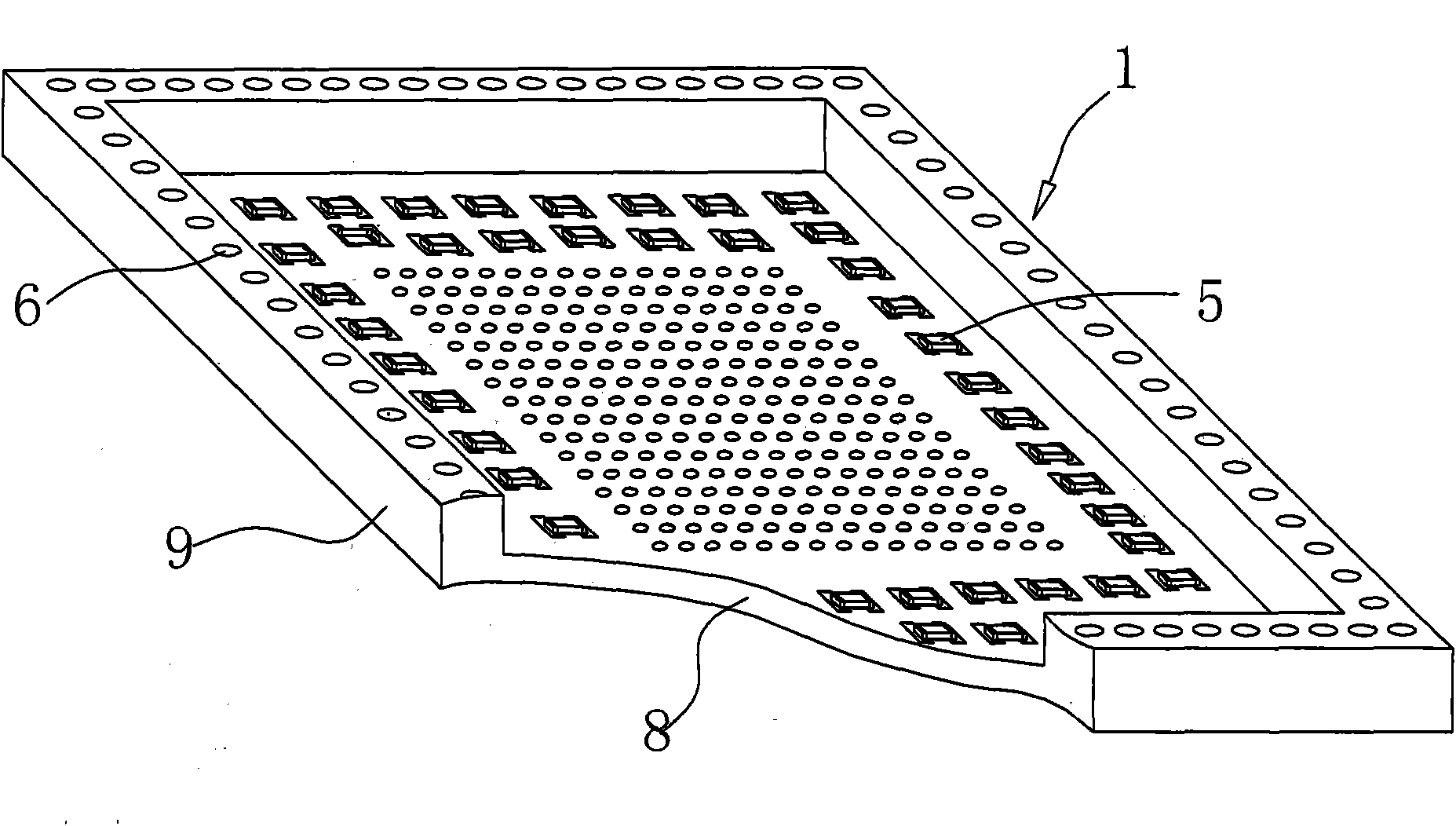

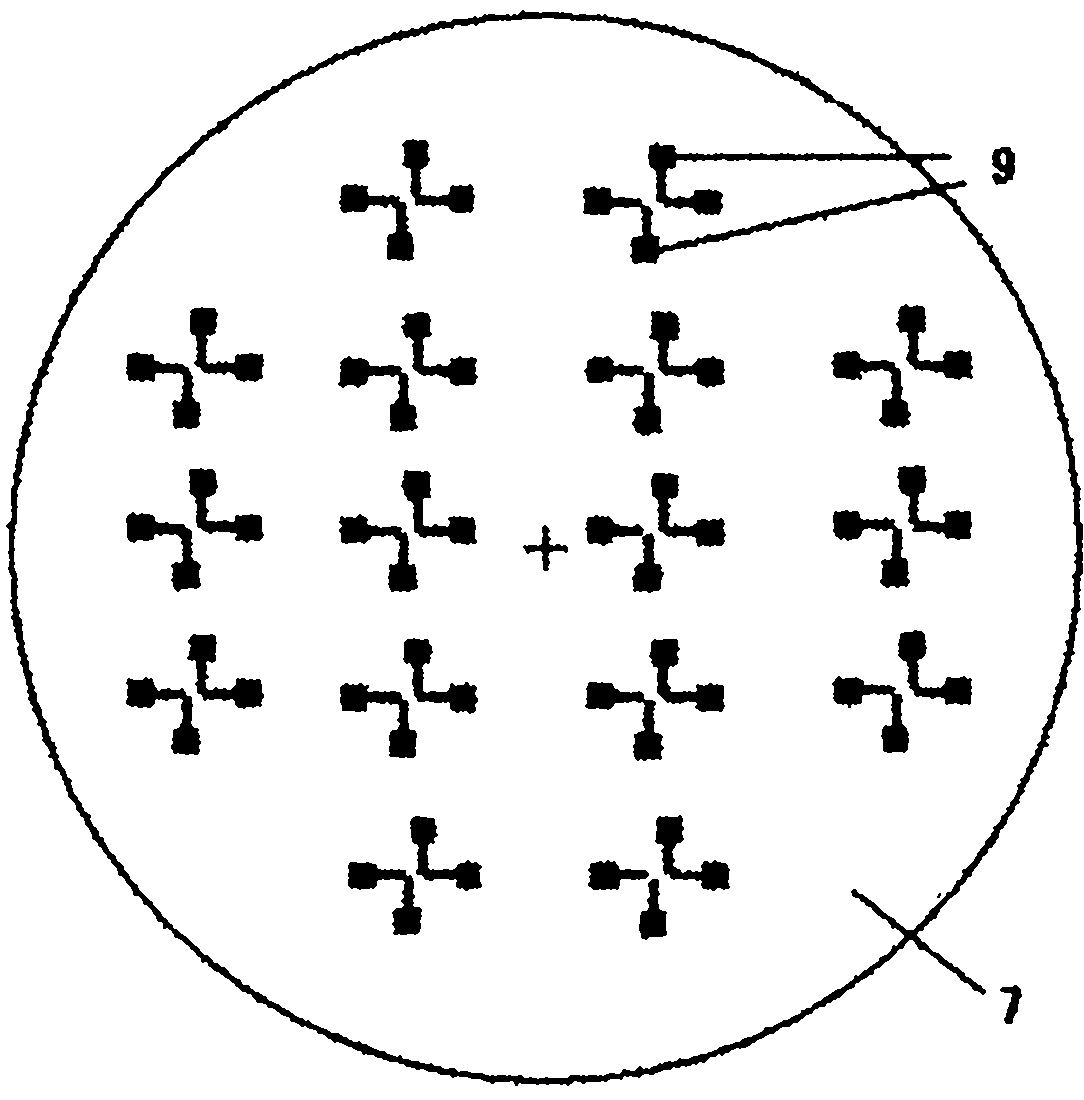

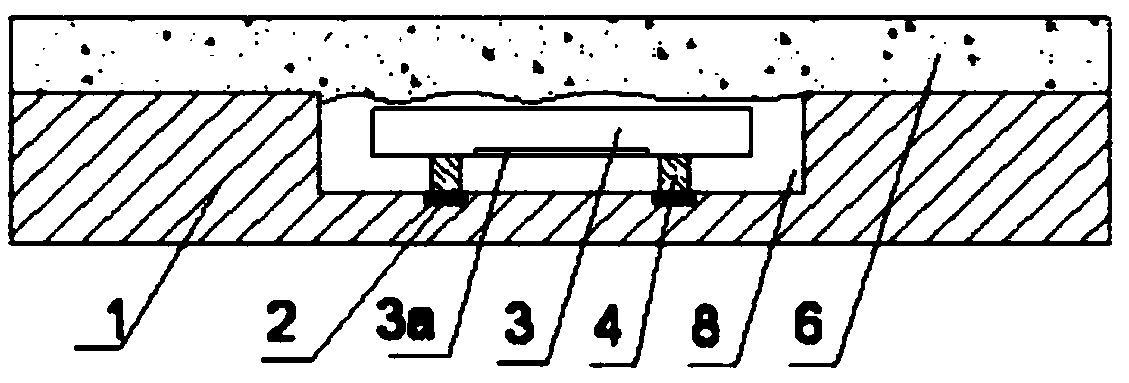

Inexpensive wafer level MMIC chip packaging

ActiveUS6888253B1Firm packagingCheap packagingSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

An inexpensive package for a semiconductor chip (1) that incorporates a stress relief buffer (13) between a side of the chip and the metal carrier layer (2) to absorb thermally induced stress produced by significantly different rates of thermal expansion of the wafer and the metal carrier. The buffer (13) is formed by a polymer that is flexible and can be etched, contains a coefficient of thermal expansion that does not significantly differ from that of the chip and / or a combination of CET and elasticity that retains a physical connection with the side of the chip and the metal carrier over the temperature range of operation anticipated for the chip. Polyimide or paraylene are preferred examples. Vias (15) extend through the buffer to place the metal carrier electrically in common with the metal layer (5) found on the back surface of the wafer so that an electrical ground applied to the metal carrier layer (2) may extend through to that surface.

Owner:NORTHROP GRUMMAN SYST CORP

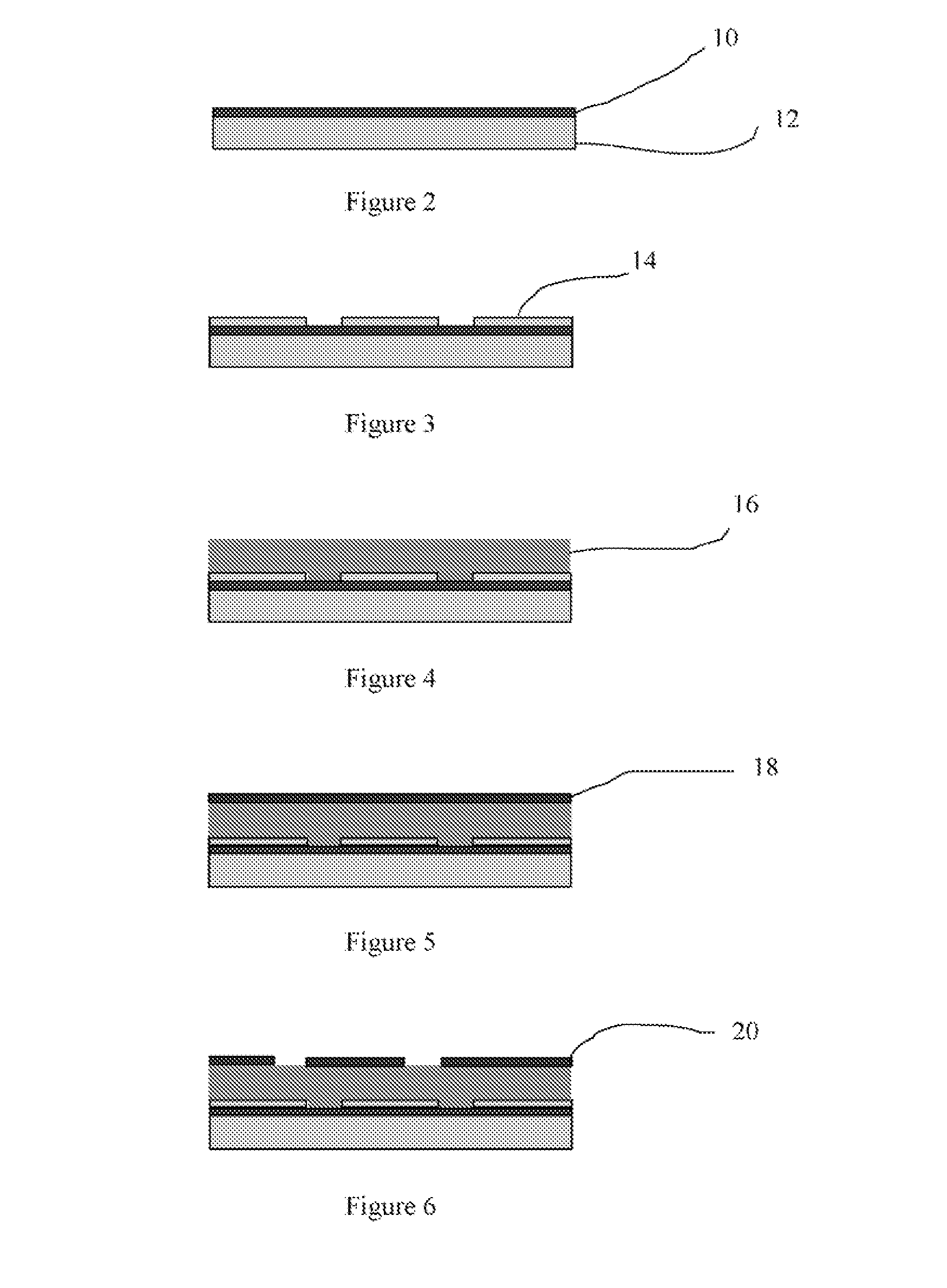

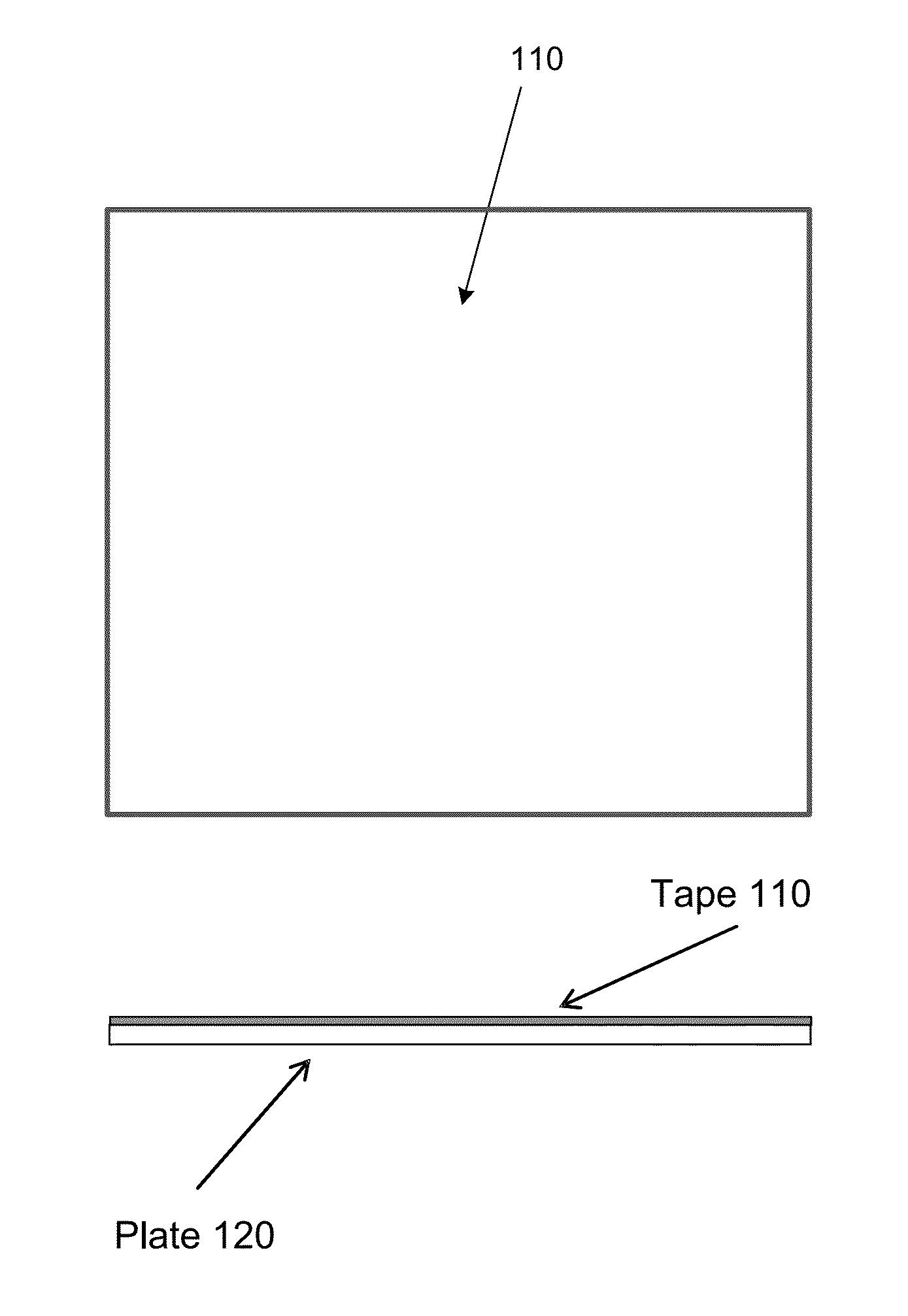

Printing phosphor on LED wafer using dry film lithography

ActiveUS20130210179A1Control thicknessReduce the temperatureSemiconductor/solid-state device manufacturingSemiconductor devicesScreen printingResist

A method for depositing a layer of phosphor-containing material on a plurality of LED (light-emitting diode) dies on a wafer includes disposing a layer of dry photoresist film over a plurality of LED dies on a wafer, disposing a mask layer over the dry photoresist film, and patterning the dry photoresist film to form a plurality of openings in the dry photoresist film to expose a top surface of each of the LED dies. The method also includes depositing a phosphor-containing material on the exposed top surface of each the LED dies using a screen printing process, and removing the patterned dry photoresist film.

Owner:LEDENGIN

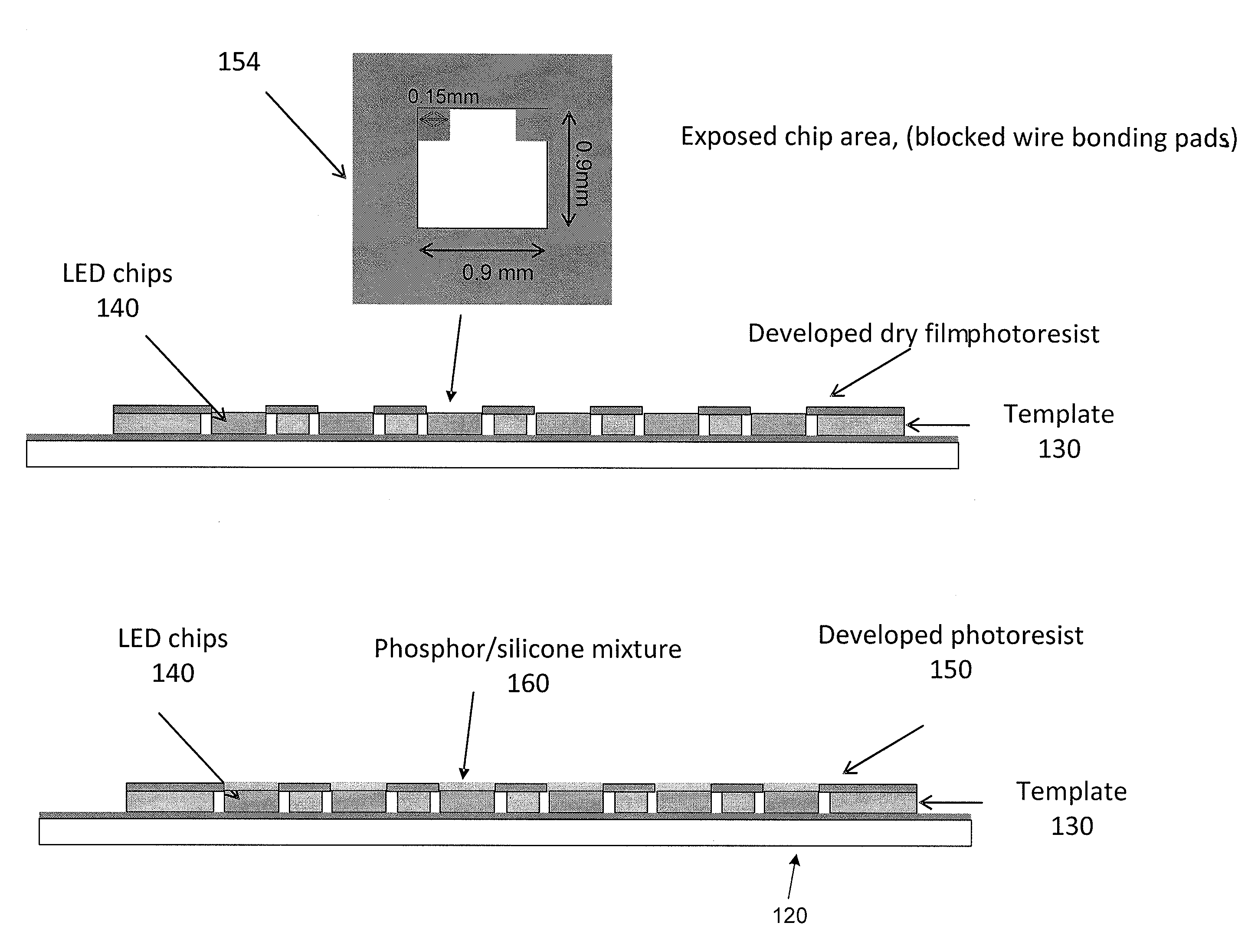

Deposition of phosphor on die top using dry film photoresist

ActiveUS8399268B1Suitable viscosityControl thicknessSolid-state devicesSemiconductor/solid-state device manufacturingPhotoresistEngineering

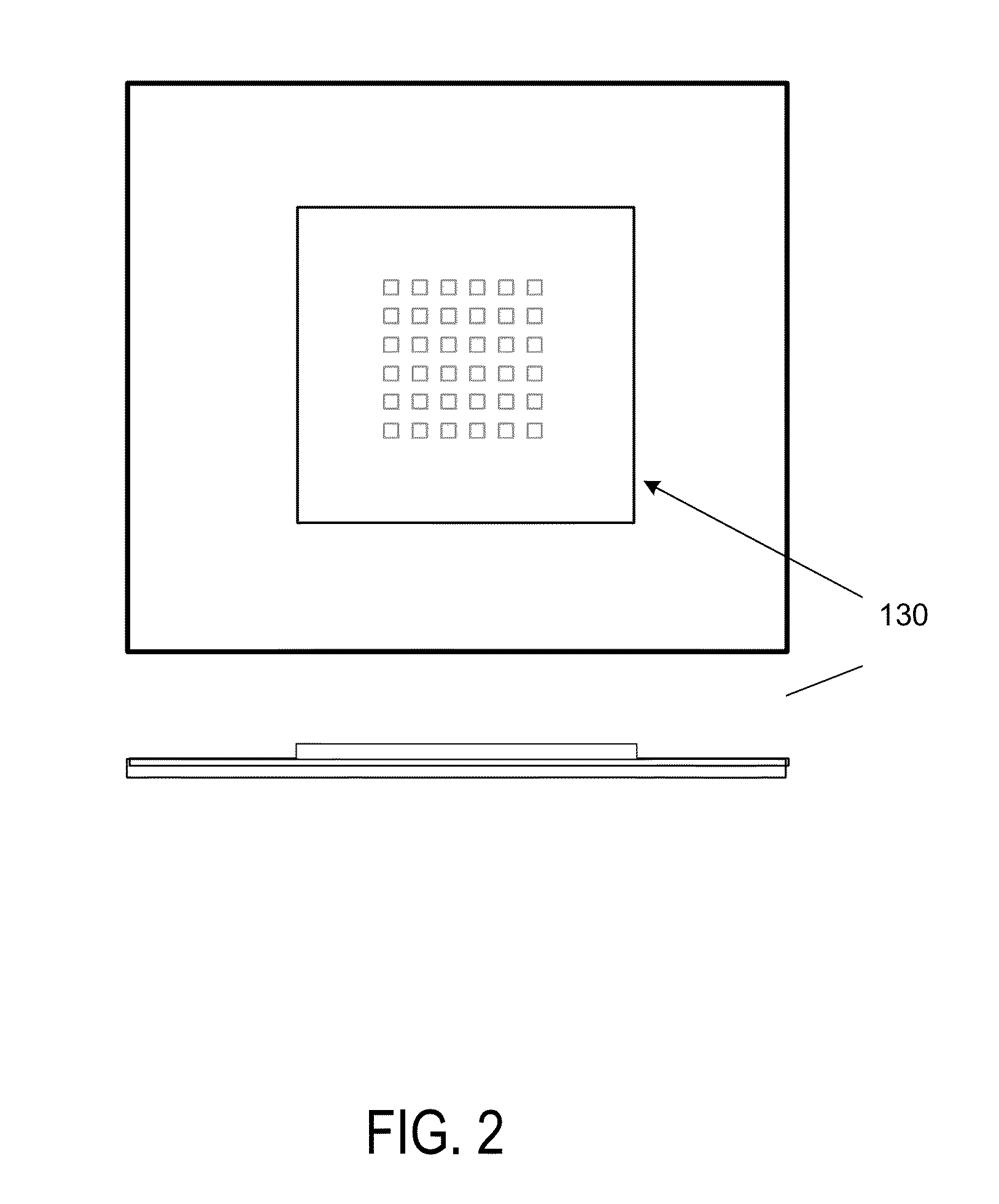

A method for depositing a layer of phosphor-containing material on a plurality of LED dies includes disposing a template with a plurality of openings on an adhesive tape and disposing each of a plurality of LED dies in one of the plurality of openings of the template. The method also includes forming a patterned dry film photoresist layer over the template and the plurality of LED dies. The photoresist layer has a plurality of openings configured to expose a top surface of each of the LED dies. Next, a phosphor-containing material is disposed on the exposed top surface of each the LED dies. The method further includes removing the photoresist layer and the template.

Owner:LEDENGIN

Standing bag box filler

Owner:广州市万世德智能装备科技有限公司

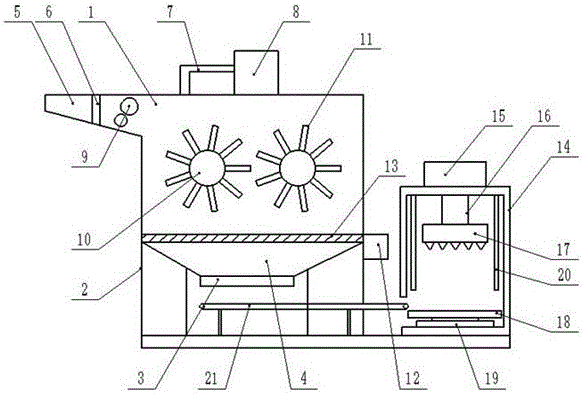

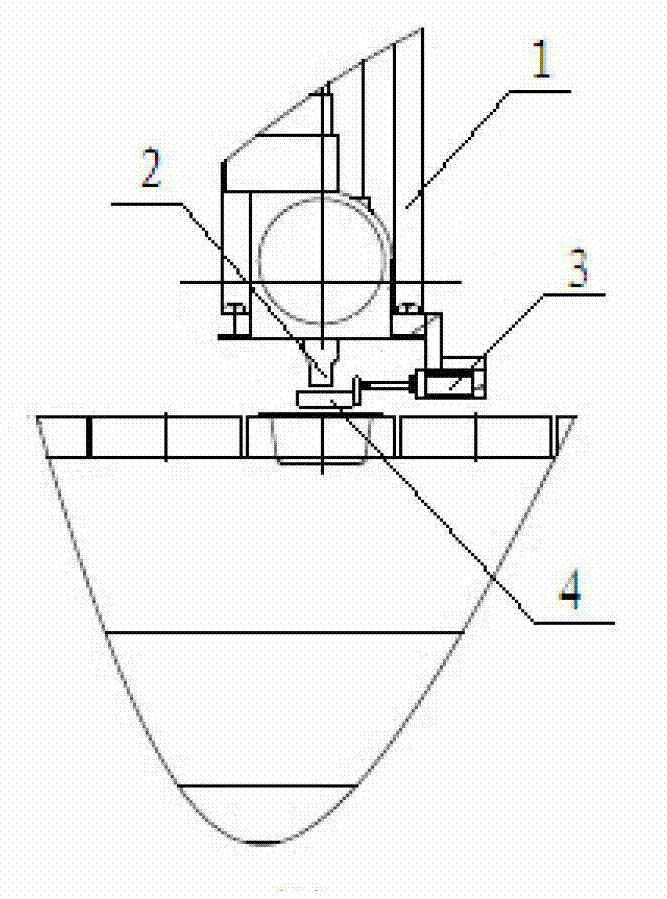

Environment-friendly processing equipment for straw

The invention discloses environment-friendly processing equipment for straw. The equipment comprises a crushing bin, crushing knives, a discharging hopper, a conveying belt, a packaging box and a base; the crushing bin is fixed above the base through a rack; a feeding hopper is arranged on the right side of the top of the crushing bin; a magnetic ring is arranged on the feeding hopper; a group of feeding rollers are further arranged inside the feeding hopper; the top of the crushing bin communicates with a dust suction pipe; the dust suction pipe is connected with a dust collector; two rotating shafts are arranged inside the crushing bin and are connected with motors; knife rests are arranged on the rotating shafts; the crushing knives are arranged on the knife rests; a screen is arranged at the bottom of the crushing bin and is in driving connection with a vibration motor; the discharging hopper is arranged below the screen; a valve is arranged below the discharging hopper; the conveying belt is arranged below the discharging hopper and is fixed above the base through a supporting frame; the right end of the conveying belt directly faces the left end of a downward pressing plate of the packaging box; and the lower side of the downward pressing plate is connected with a gas cylinder. The equipment is simple in structure, good in stability, convenient to maintain, good in packaging effect and high in working efficiency.

Owner:GUANGXI UNIV

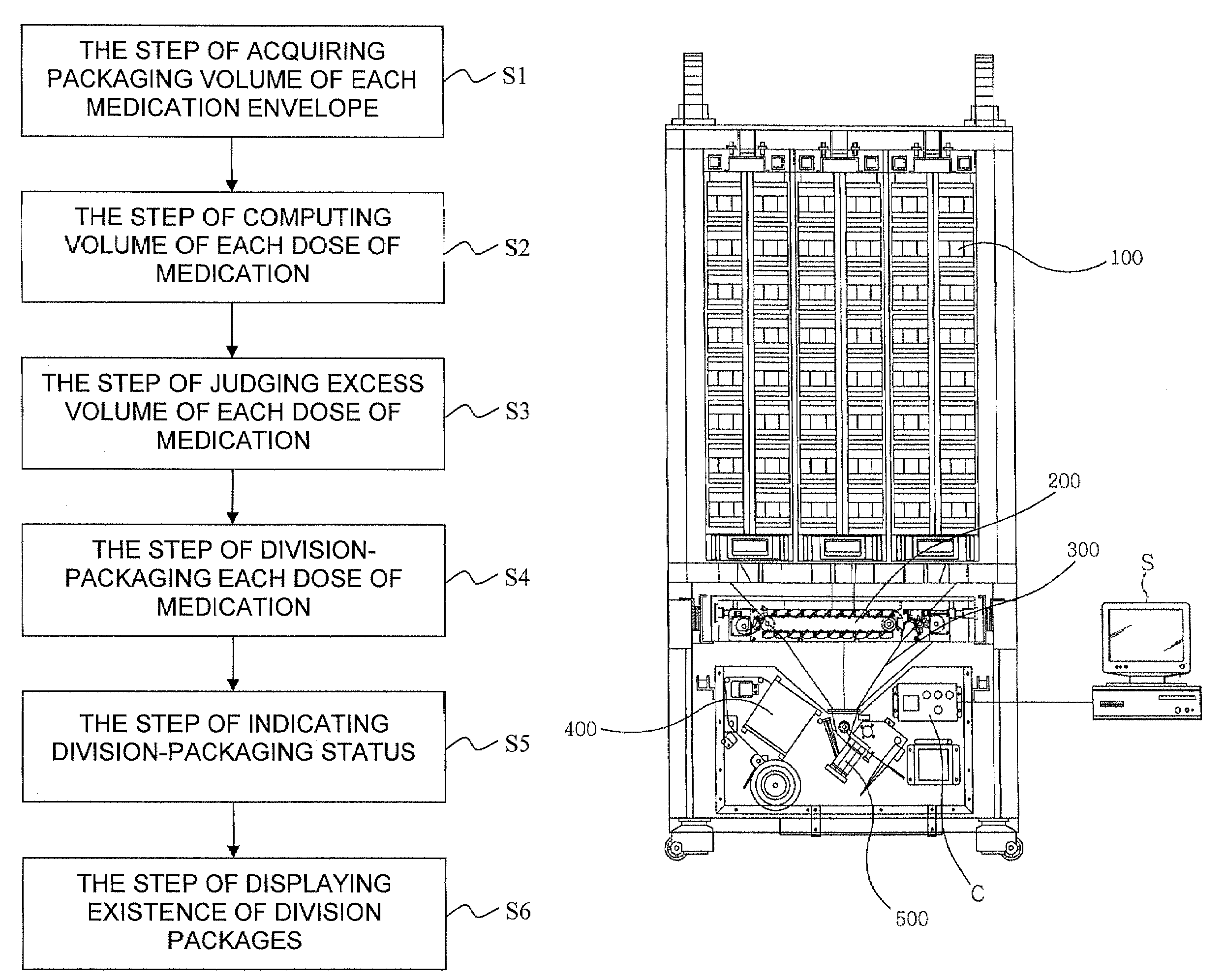

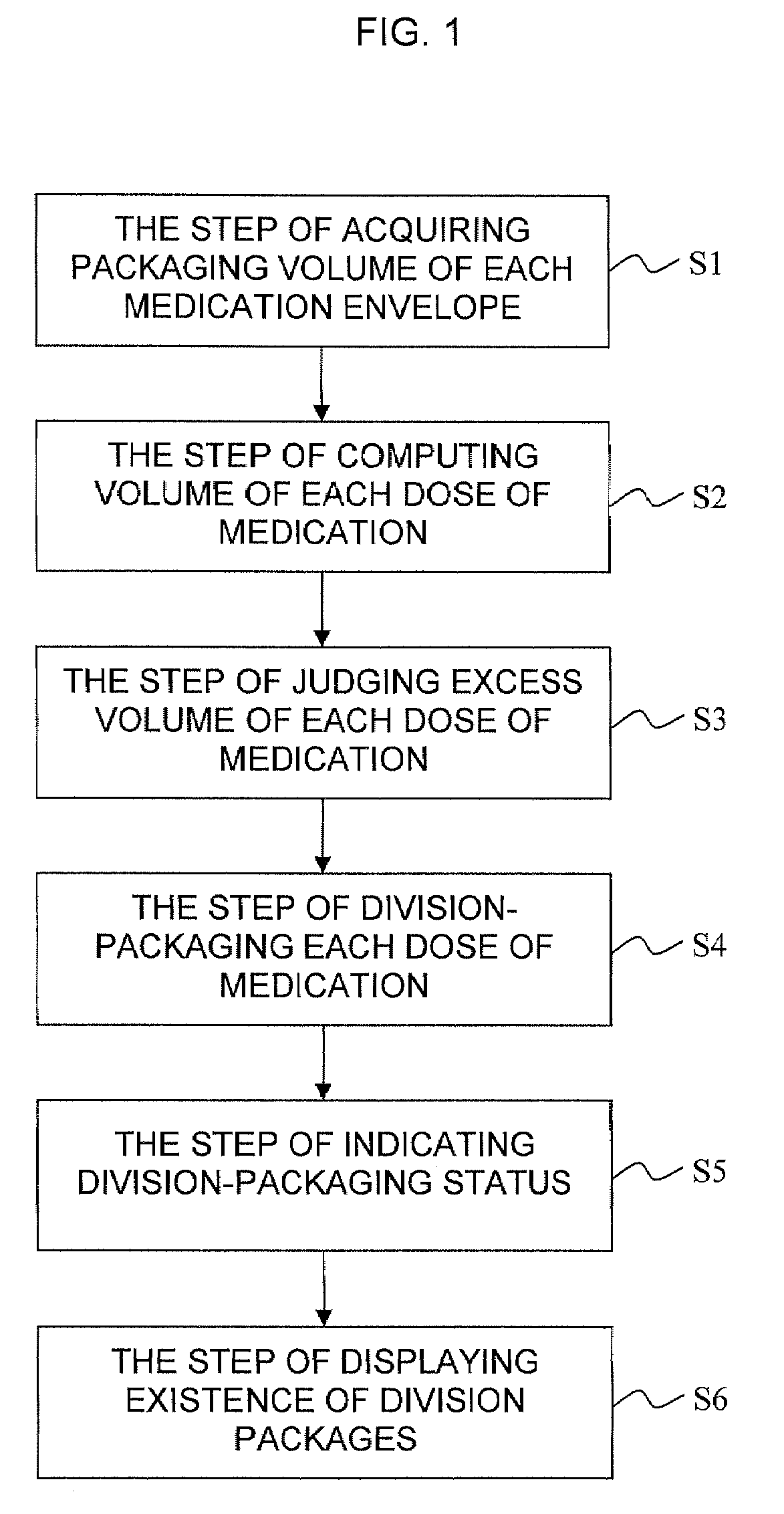

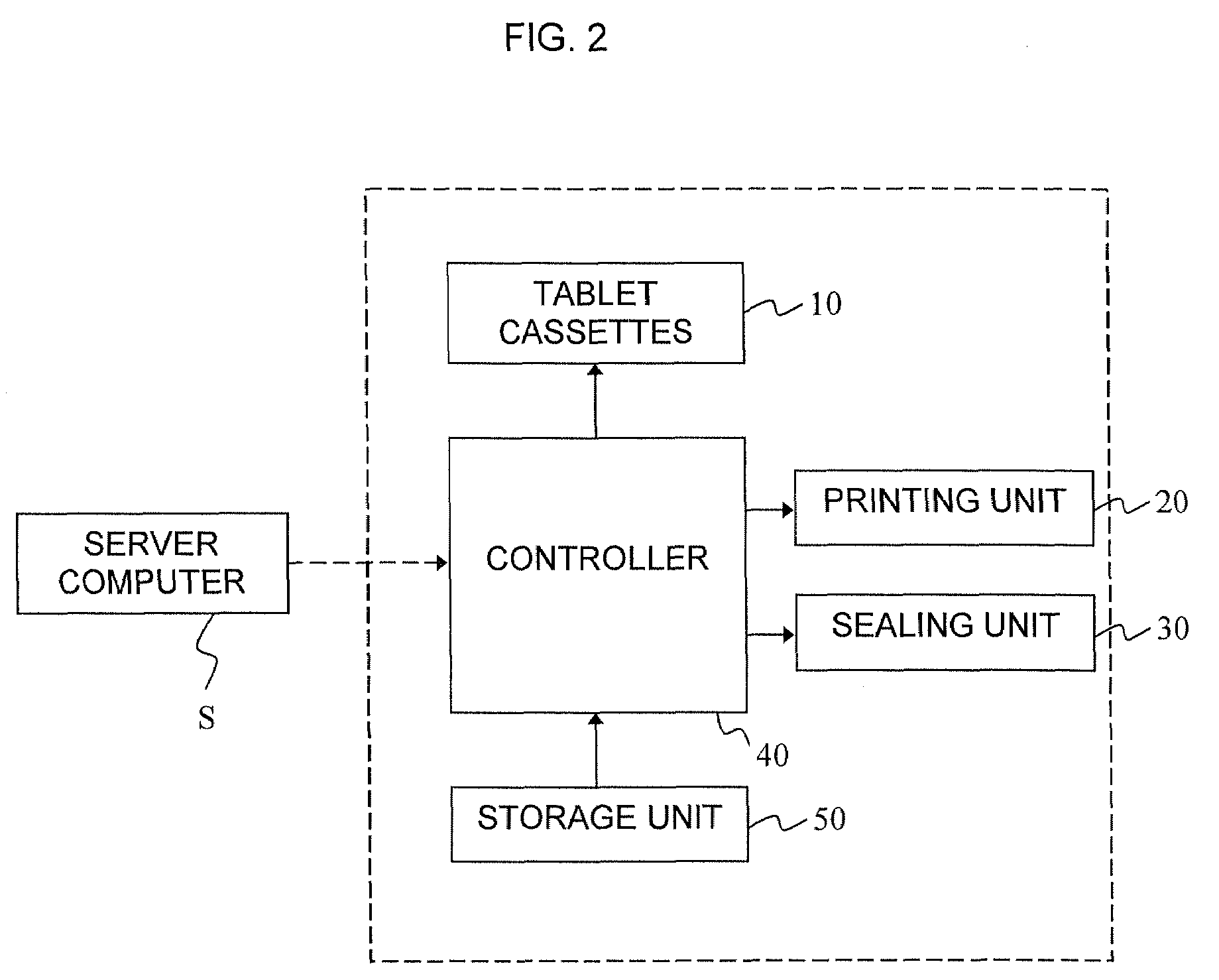

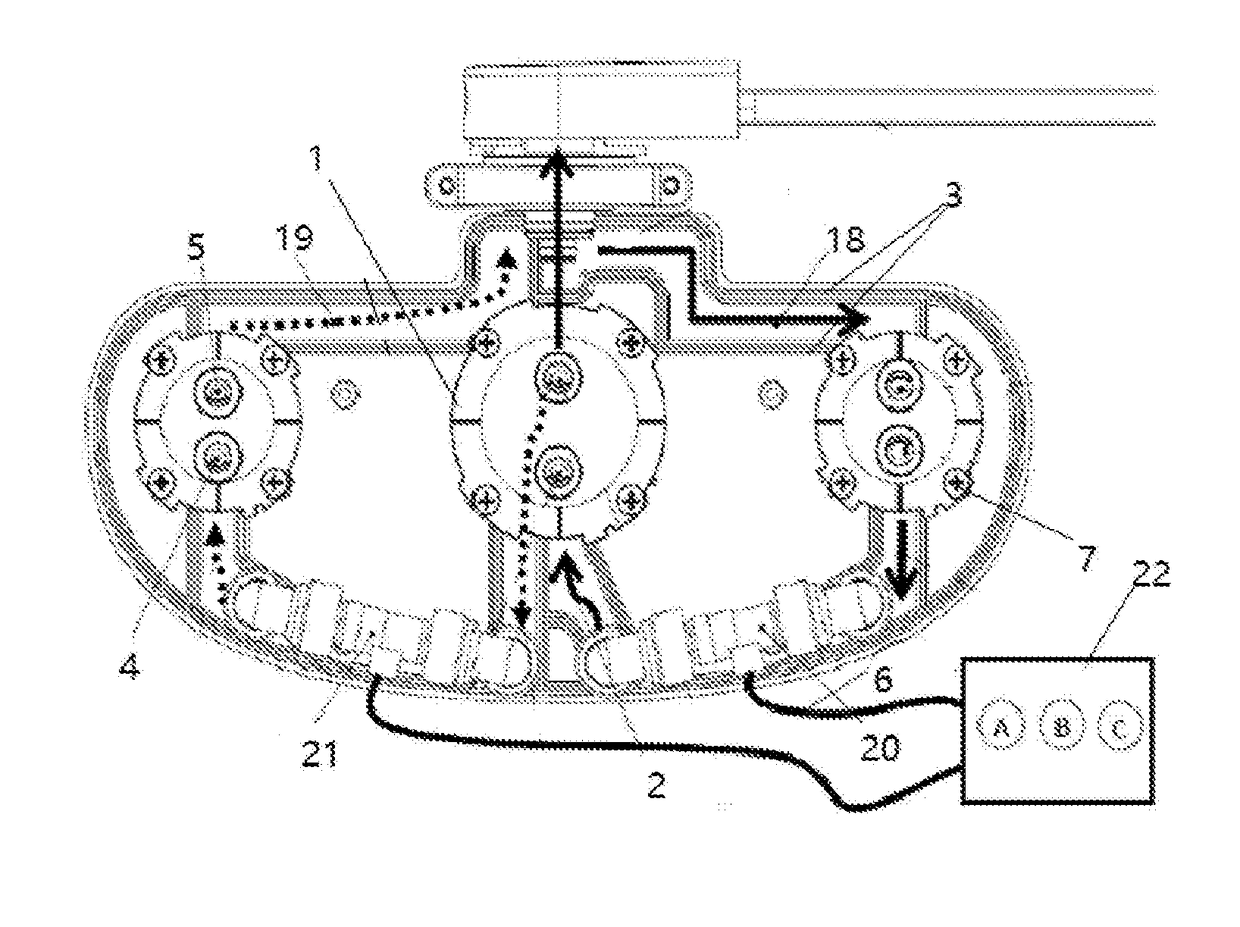

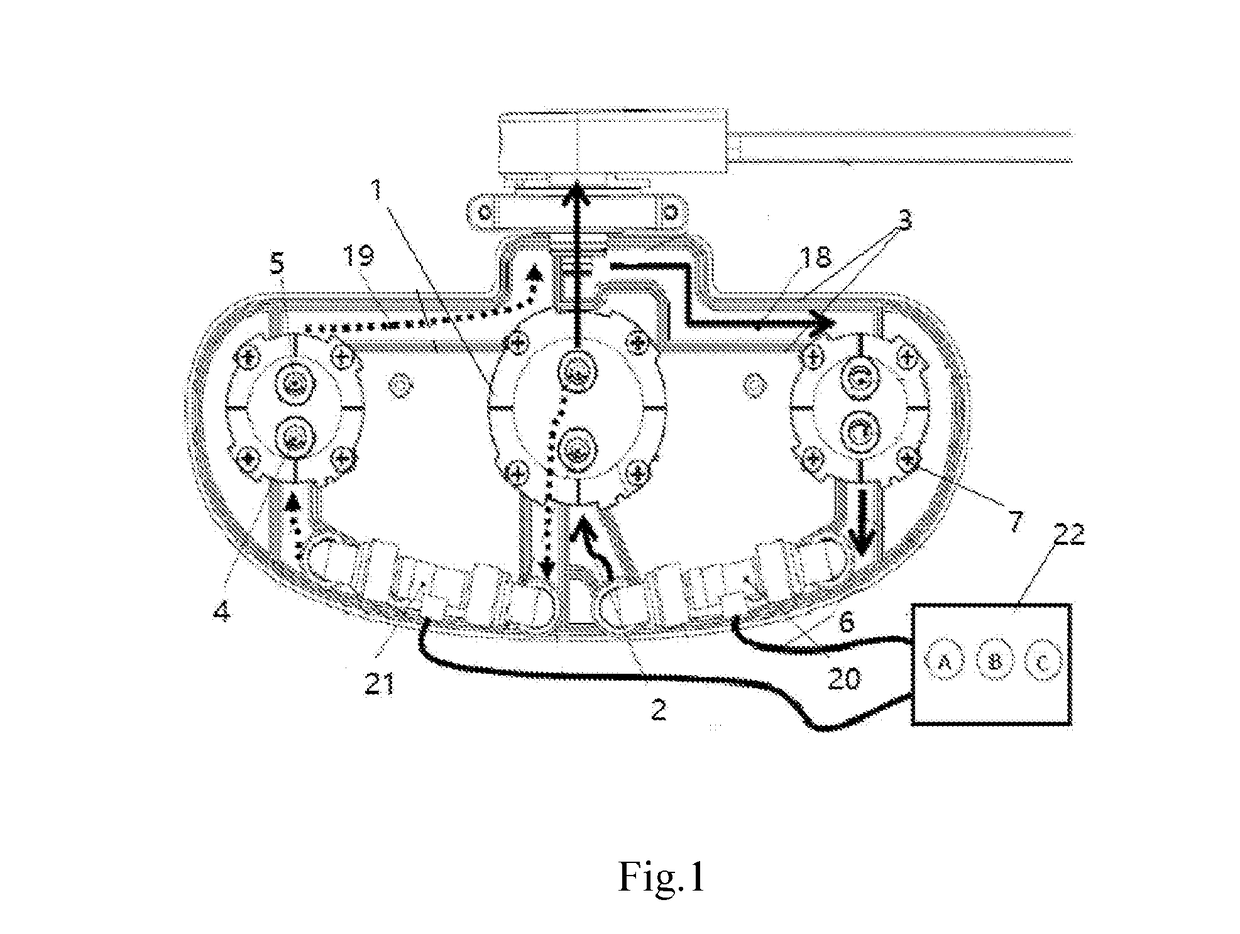

Division-packaging method and apparatus for automatic medicine packaging machine

ActiveUS7549268B2Prevent incapabilityFirm packagingSmall article dispensingOther accessoriesDrug overdoseDrug product

A division-packaging method for an automatic medicine packaging machine that allows stable packaging even when total volume of each dose of medication for making a package is bigger than packaging volume of any medication envelope established in the automatic medicine packaging machine and that prevents incapability of packaging due to excess volume of each dose of medication. The method includes step of acquiring packaging volume of each medication envelope; step of computing total volume of each dose of medication; step of judging excess volume of each dose of medication; and step of division-packaging each dose of medication when the total volume of each dose of medication for making a package is bigger than the packaging volume of any medication envelope established in the automatic medicine packaging machine.

Owner:JVM CO LTD

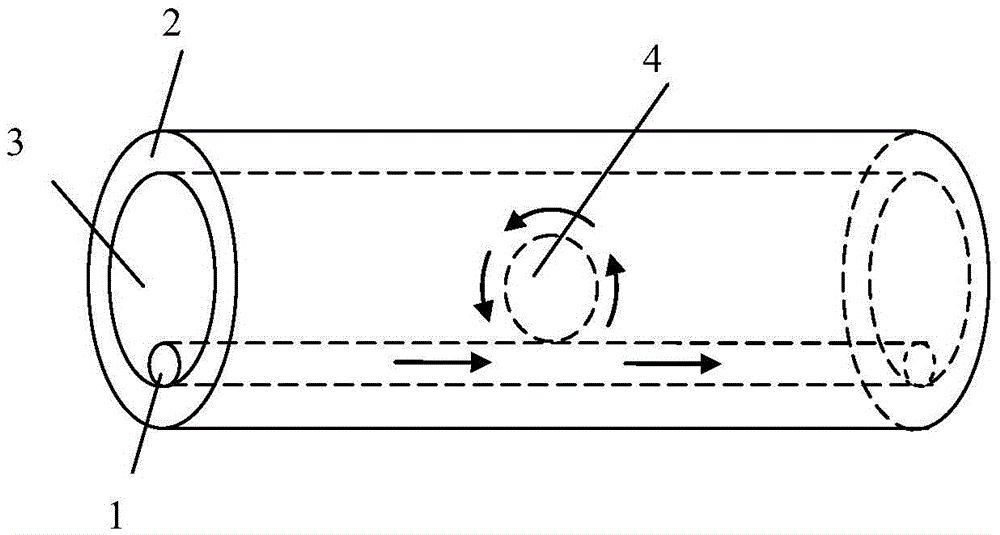

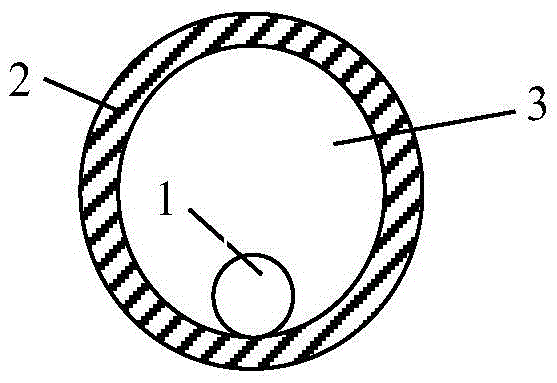

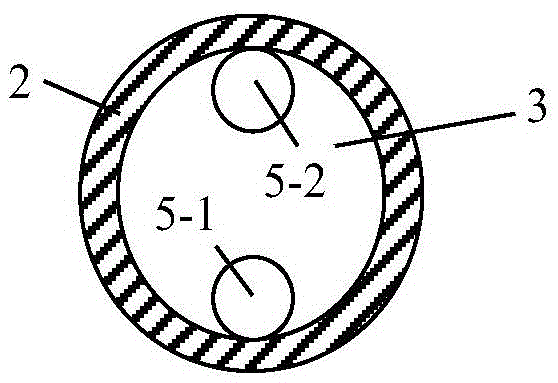

Microballoon resonance filter integrated into suspension core fiber

ActiveCN105549156AFirm packagingPacked tightlyCladded optical fibreOptical waveguide light guideResonanceMicrometer

The invention discloses a microballoon resonance filter integrated into a suspension core fiber. The microballoon resonance filter comprises the suspension core fiber and a microballoon, wherein the suspension core fiber comprises a cladding and a fiber core, the cladding is of an annular structure, the cladding is internally provided with an air hole, the internal diameter of the cladding is 50 to 250 micrometers, the difference between the internal diameter of the cladding and the external diameter of the cladding is 20 to 40 micrometers, the fiber core is suspended on the inner wall of the cladding, the diameter of the fiber core is 9 to 13 micrometers, and the refractive index of the fiber core is greater than the perpendicular incidence rate of the cladding; and the diameter of the microballoon is 50 to 200 micrometers, the refractive index of the microballoon is greater than and equal to that of the fire core, the microballoon is disposed inside the cladding, the microballoon is adhered to the fiber core through local heating, and the two ends of the suspension core fiber and a single-mode fiber are aligned and directly coupled by use of the fiber core. The filter provided by the invention has the advantages of firm and compact packaging, high integration and high anti-interference capability, thereby being suitable for long-term stable work.

Owner:HARBIN ENG UNIV

Method for producing circuit board thin plates

The invention discloses a method for producing circuit board thin plates. The technical scheme is characterized in that the method comprises the following steps that: conducting plating though holes; conducting outer layer circuit pattern transfer; conducting graph electric plating and etching; penetrating a string through locating holes of the circuit board thin plates, utilizing string beads to separate the circuit board thin plates, and plating the circuit board thin plates though the holes, after plating the circuit board thin plates through the holes, washing liquid medicine on the surfaces of the circuit board thin plates away by horizontally drawing the circuit board thin plates through a thick plate; conducting electric test; conducting routing; utilizing a plastic package tray to package a finished-product unit plate subjected to routing. From the procedure of layer circuit pattern transferring to the procedure of routing, the circuit board thin plates are compressed through pressing grooves by the adoption of a pig cage frame device to be transferred between the procedures. The method for producing the circuit board thin plate solves the problems that the circuit board thin plates are prone to plate adhesion, plate curving, plate clamping and plate fracture due to the fact that the circuit board thin plates are small in size. The method for producing circuit board thin plates is simple in process and stable in product quality.

Owner:广东依顿电子科技股份有限公司

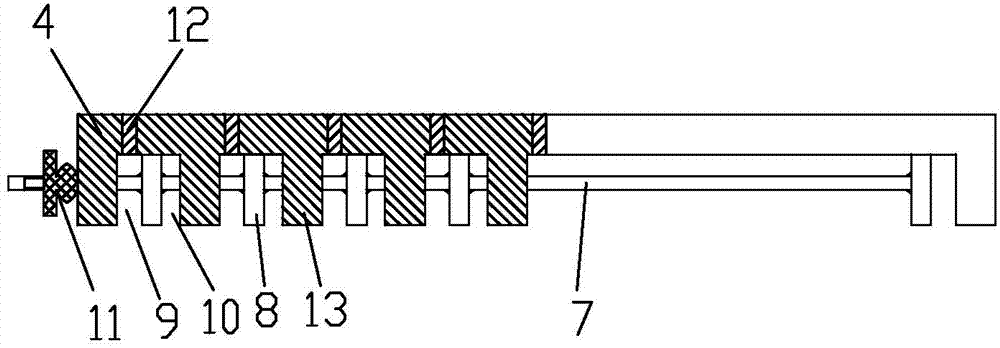

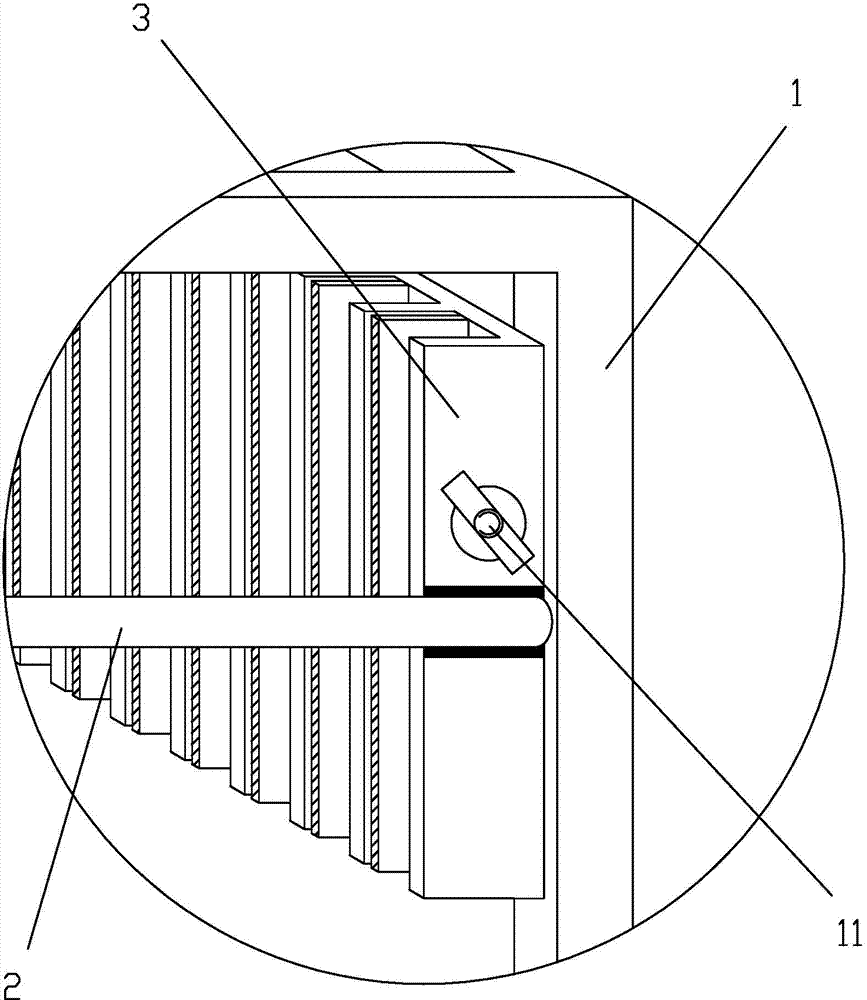

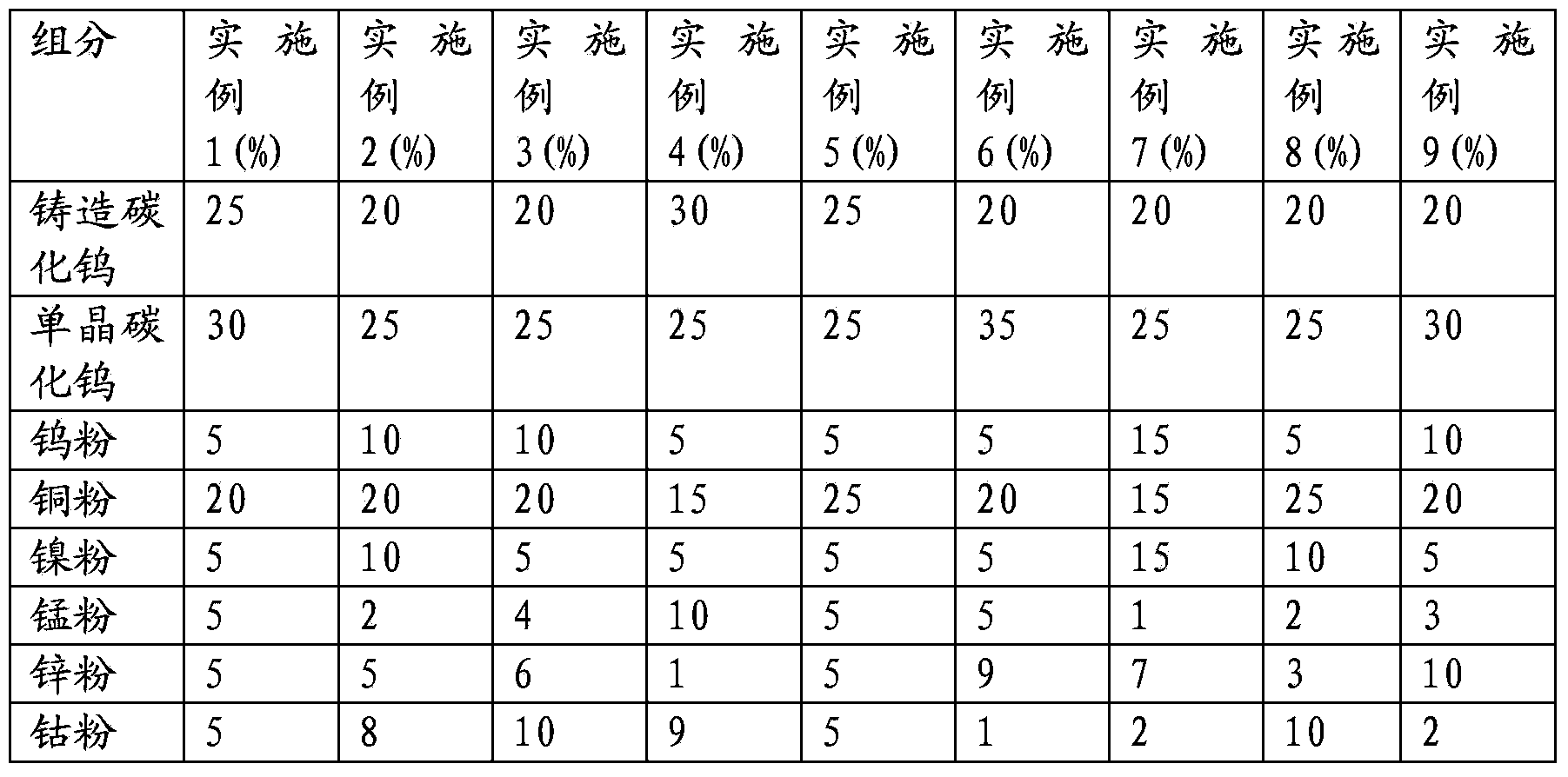

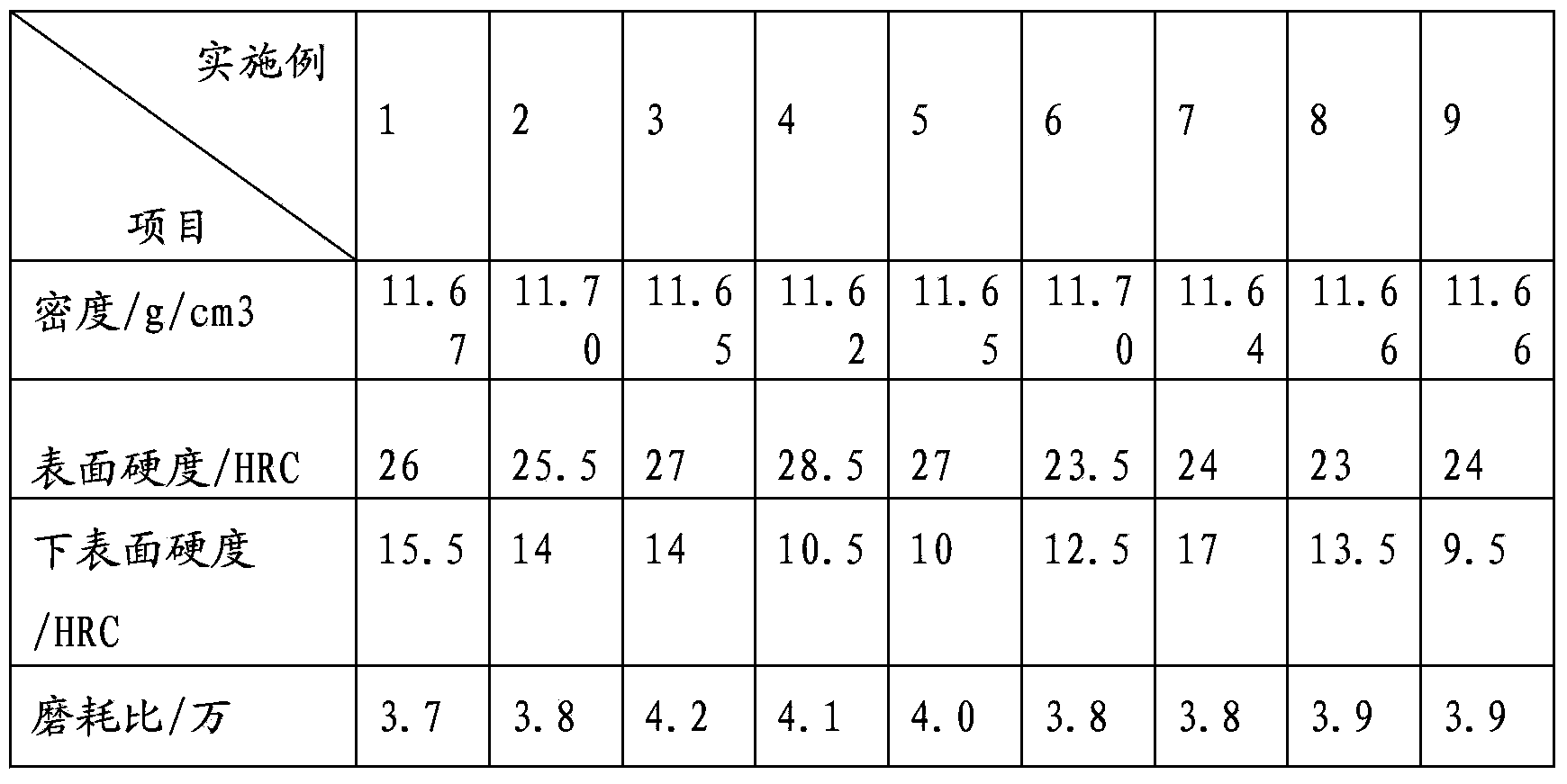

Impregnated column matrix powder for diamond-impregnated bit as well as method for manufacturing matrix

The invention discloses impregnated column matrix powder for a diamond-impregnated bit. The impregnated column matrix powder comprises components in percentage by mass as follows: 1), packaging powder: 20%-30% of cast tungsten carbide, 25%-35% of monocrystal tungsten carbide; 5%-15% of tungsten powder, 15%-25% of copper powder, 5%-15% of nickel powder, 1%-10% of manganese powder, 1%-10% of zinc powder and 1%-10% of cobalt powder; and 2), diamonds whose volume accounts for 17.5%-30% of the packaging powder. The invention further discloses a method for manufacturing an impregnated column matrix for the diamond-impregnated bit. The method comprises the steps as follows: 1), mixing; 2), pelleting; 3), charging; 4), sintering, 5), performing heat preservation; and 6), cooling and obtaining the impregnated column matrix. The impregnated column matrix powder has good abrasion resistance, hardness and holding force. According to the manufacturing method, the diamonds are uniformly distributed in matrix powder, and packaging is reliable.

Owner:SHENZHEN XINGWO IND

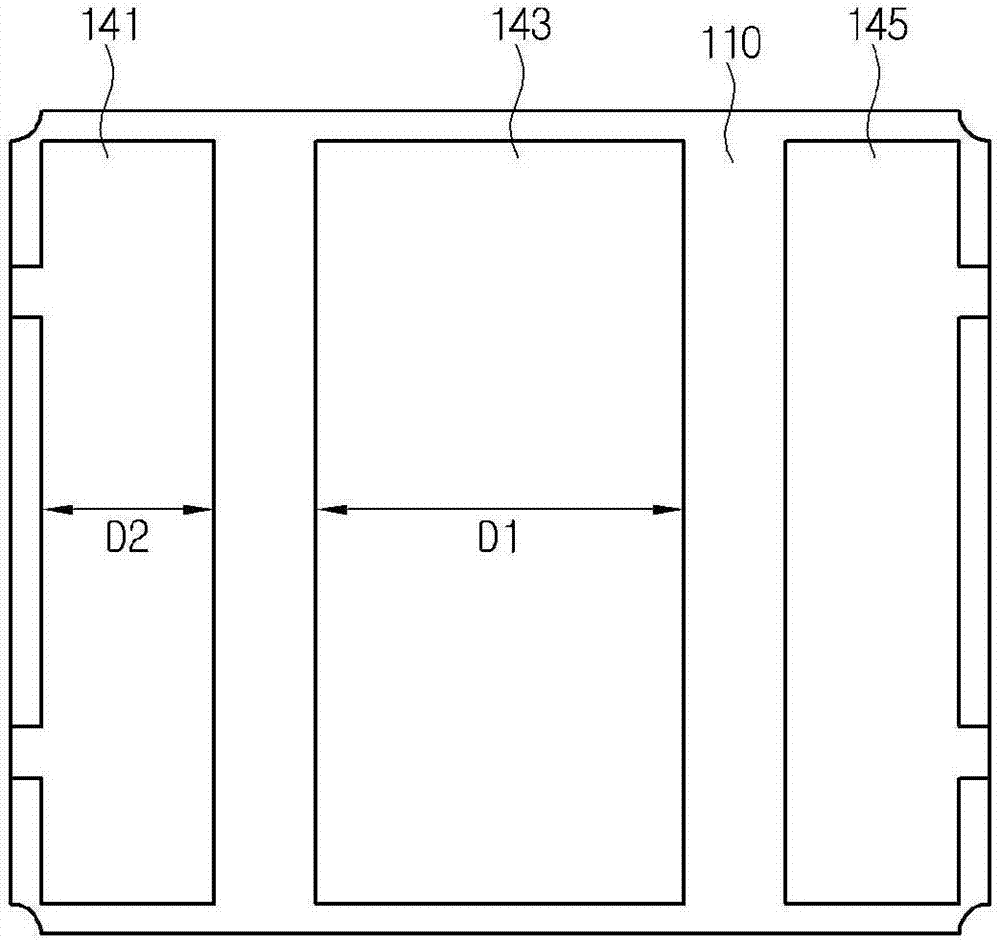

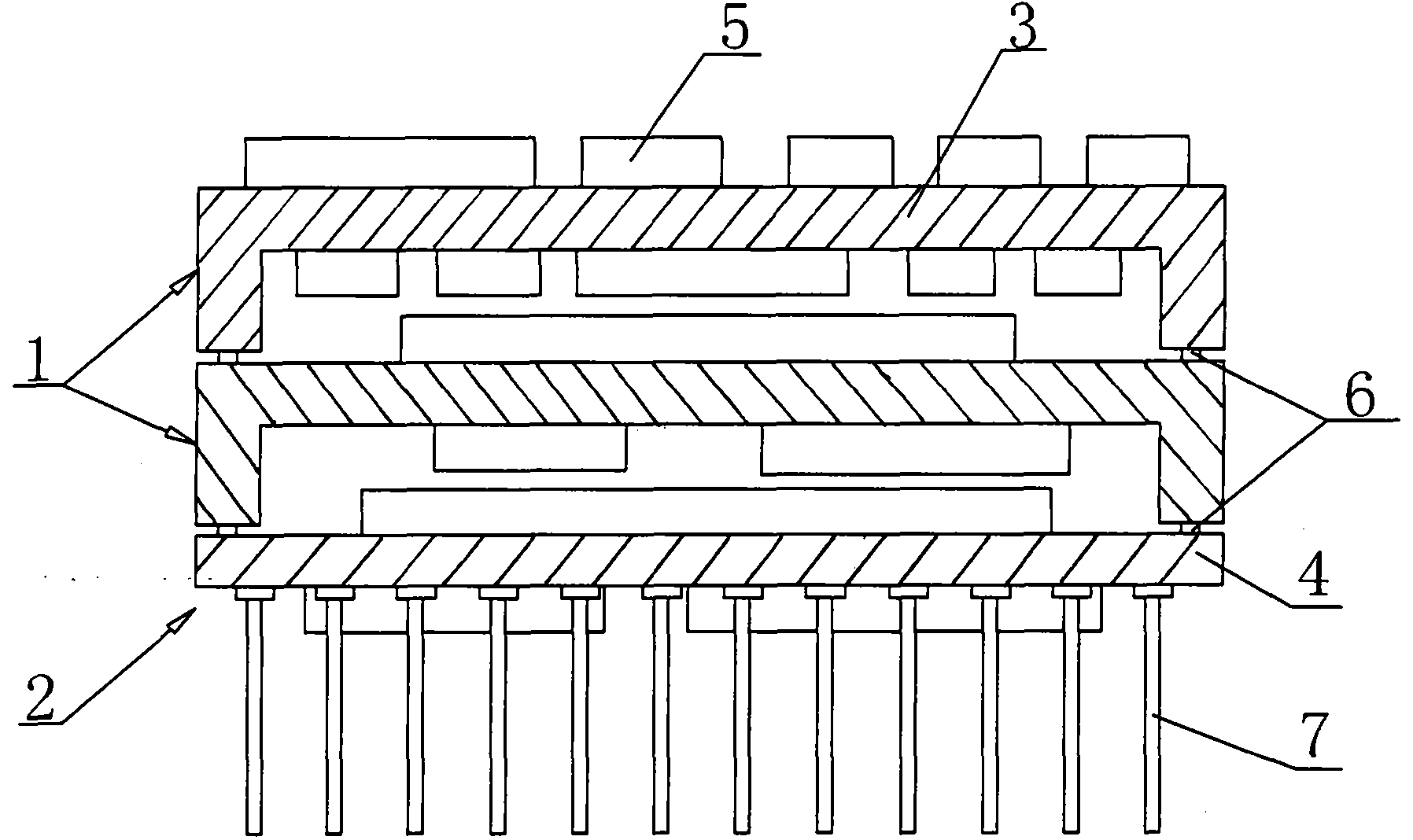

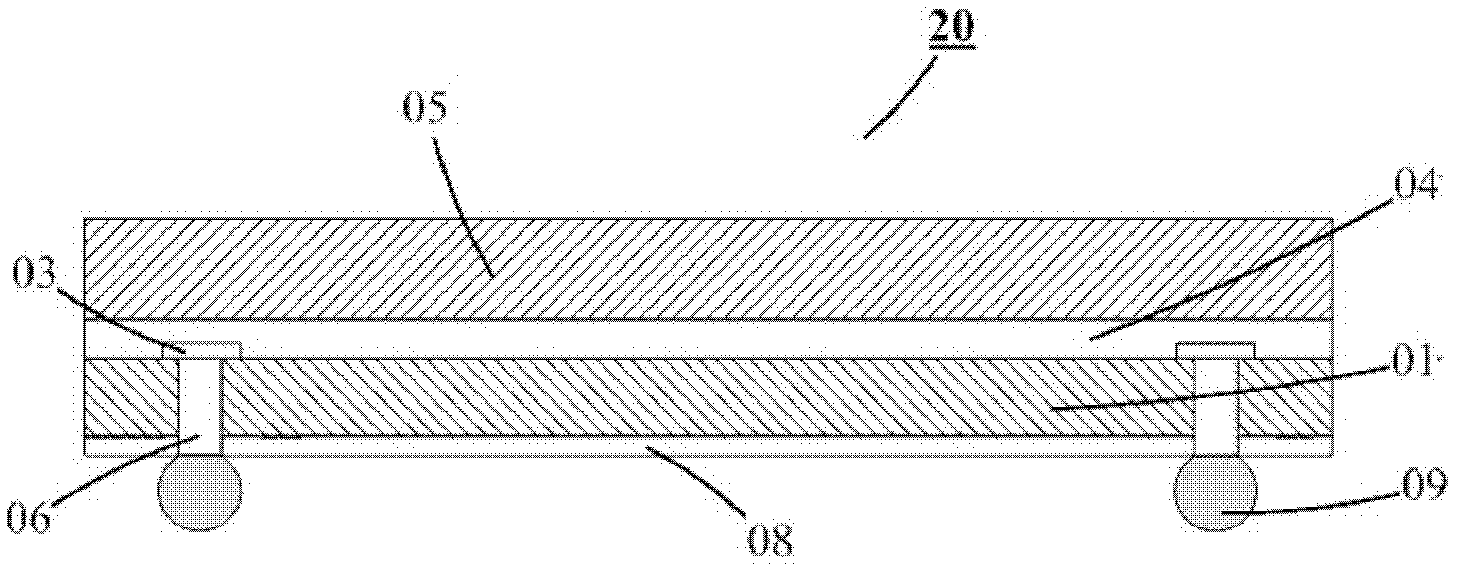

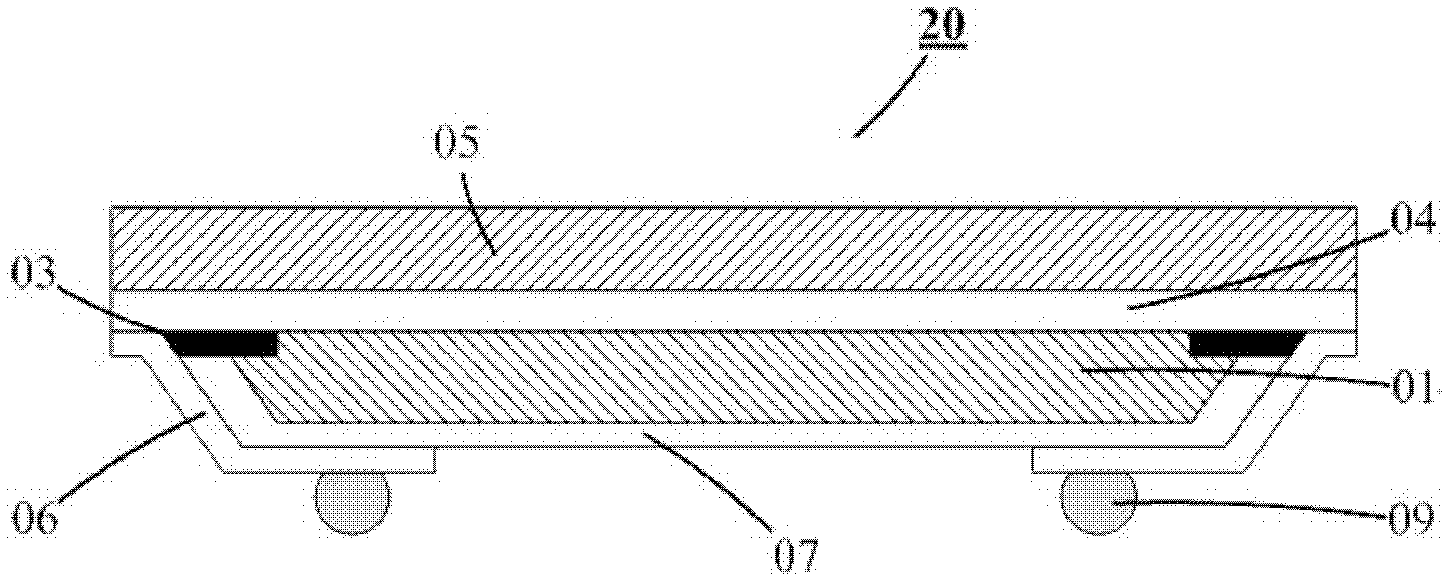

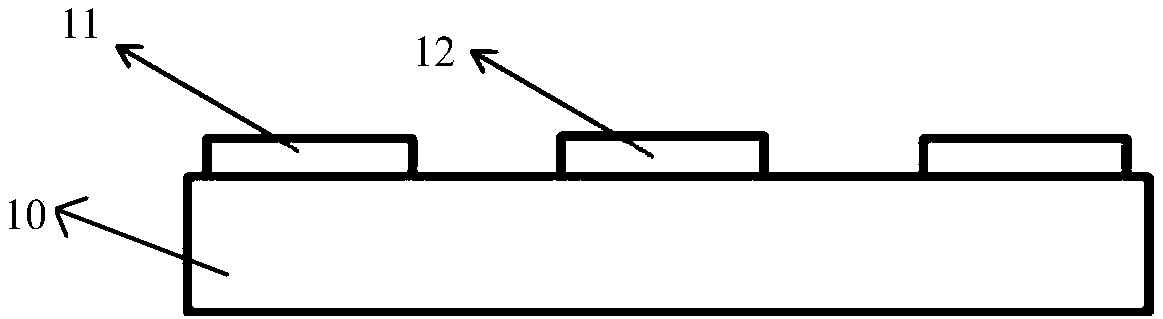

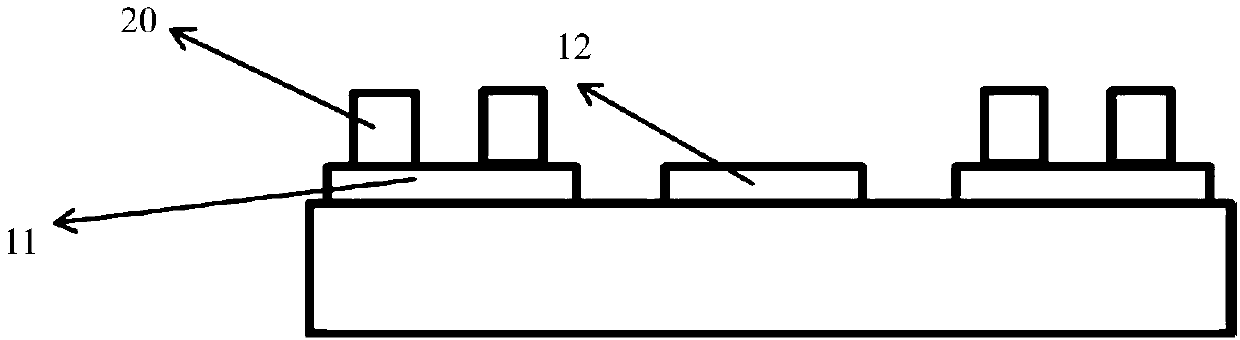

Multi-module packaged component

InactiveCN102064159AFirm packagingImprove packaging efficiencySolid-state devicesSemiconductor devicesEngineeringBall grid array

The invention relates to a multi-module packaged component, which comprises at least one first sub-module, a second sub-module and a second substrate, wherein the first sub-module comprises a first substrate, the at least side surface of the first substrate is adhered with a chip, and one side surface of the first substrate has a ball grid array welding area; the second sub-module comprises a second substrate, and at least one side surface of the second substrate is adhered with a chip; one side surface of the second substrate is provided with an external output pin; the first sub-module is stacked on the other side surface of the second sub-module longitudinally, and the other side surface of the second substrate also has a ball grid array welding area; and the first sub-module and the second sub-module are in physical and signal connection through a ball grid array welding process. In the invention, a plurality of sub-modules are combined by the ball grid array welding process, so the reliable packaged of multiple modules is realized; therefore, packaging times are reduced, packaging efficiency of the packaged component is improved, and the integration level of the packaged component is improved.

Owner:SUZHOU R&D CENT OF NO 214 RES INST OF CHINA NORTH IND GRP

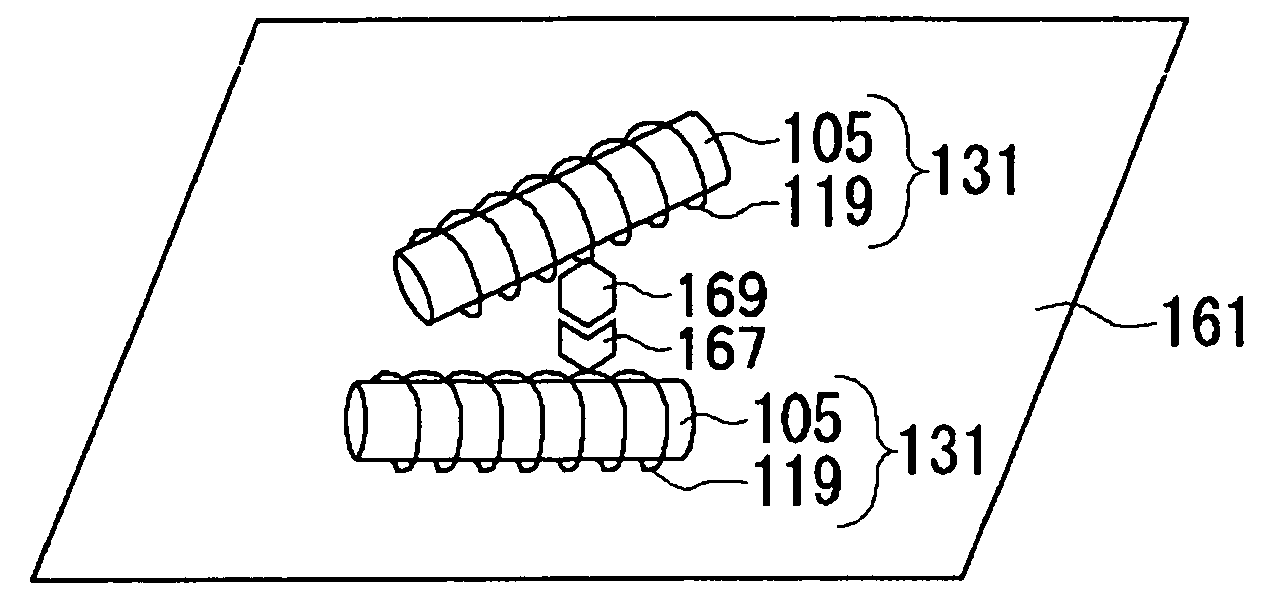

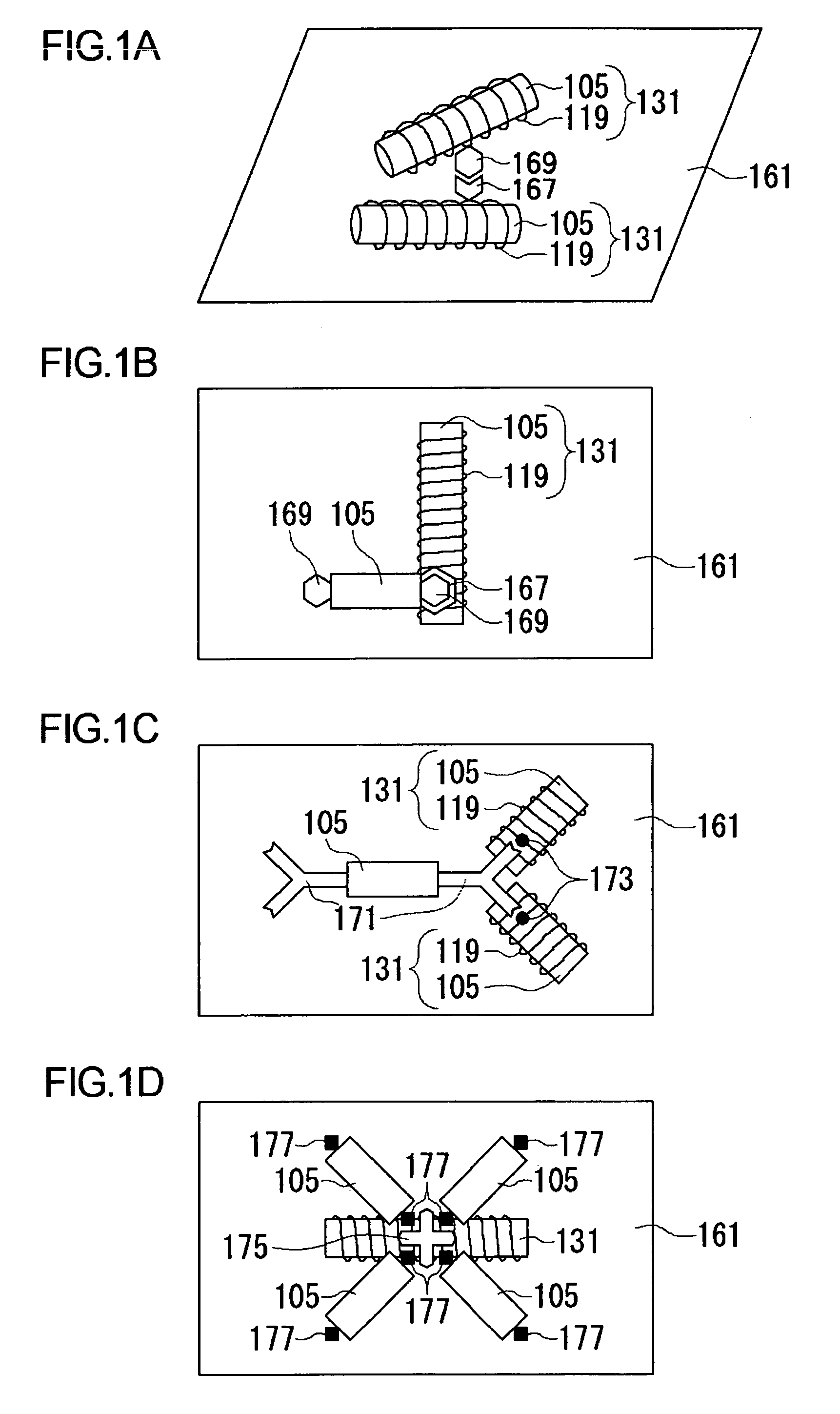

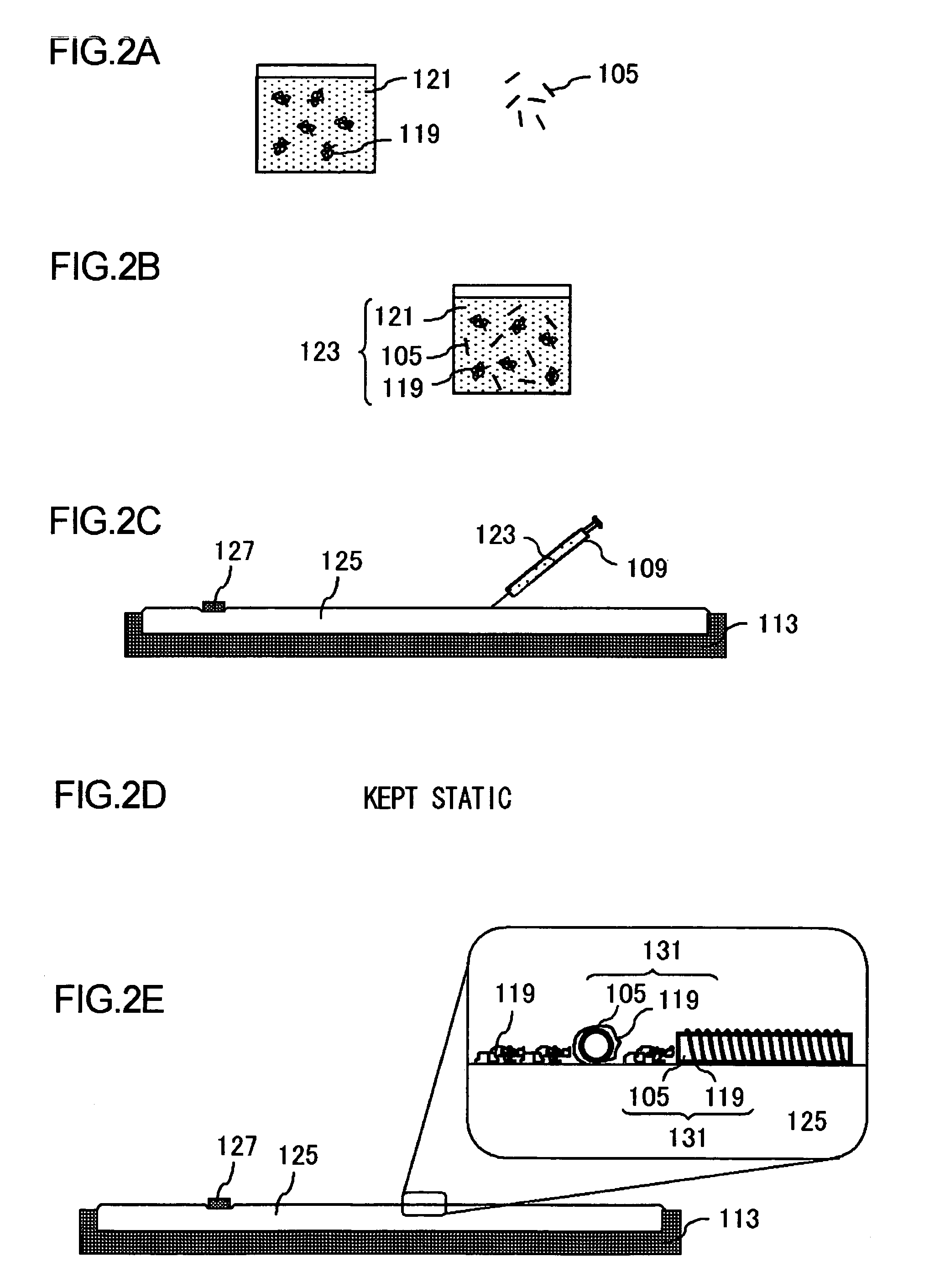

Bonded structure including a carbon nanotube

InactiveUS7244499B2Improve performanceImprove production efficiencyMaterial nanotechnologyNanoinformaticsNano-deviceLangmuir trough

A technique of stably bonding a structure including a carbon nanotube with another structure is to be provided. Also, a nano-device that offers excellent performance and high production efficiency is to be provided.A polymer and a carbon nanotube are dispersed in a dispersion medium and on a filled liquid in a Langmuir trough, to obtain a carbon nanotube-based structure constituted of a carbon nanotube and the polymer wound around its rounded surface. The carbon nanotube-based structure is adhered to a substrate, and a ligand is immobilized on a side chain of the polymer. A receptor is immobilized on another carbon nanotube-based structure, and the both carbon nanotube-based structures are joined because of a specific interaction between the ligand and the receptor.

Owner:SANYO ELECTRIC CO LTD

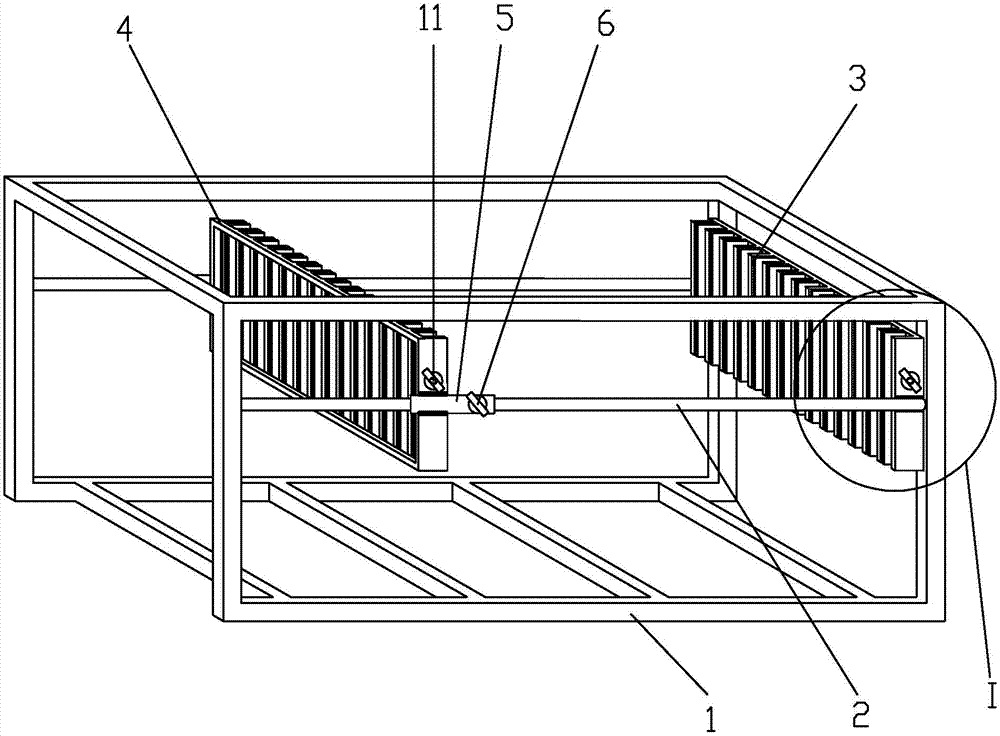

Water purifier

InactiveUS20180185774A1Increase the fermentation areaImprove fermentation effectWater treatment parameter controlWater contaminantsEngineeringLife time

The present application discloses a water purifier, which comprises a composite water path structure; a filter cartridge; a universal direction water outlet structure; a housing; a sliding module; and a locking module; a plurality of flow meters; and a controller. The water purifier provided by the present invention has its water path structure, filter cartridge, water outlet structure, housing, way for replacing the filter cartridge as well as way for detecting service life of the filter cartridge improved, to obtain significantly improved working and using effects.

Owner:INFINITUS (CHINA) CO LTD

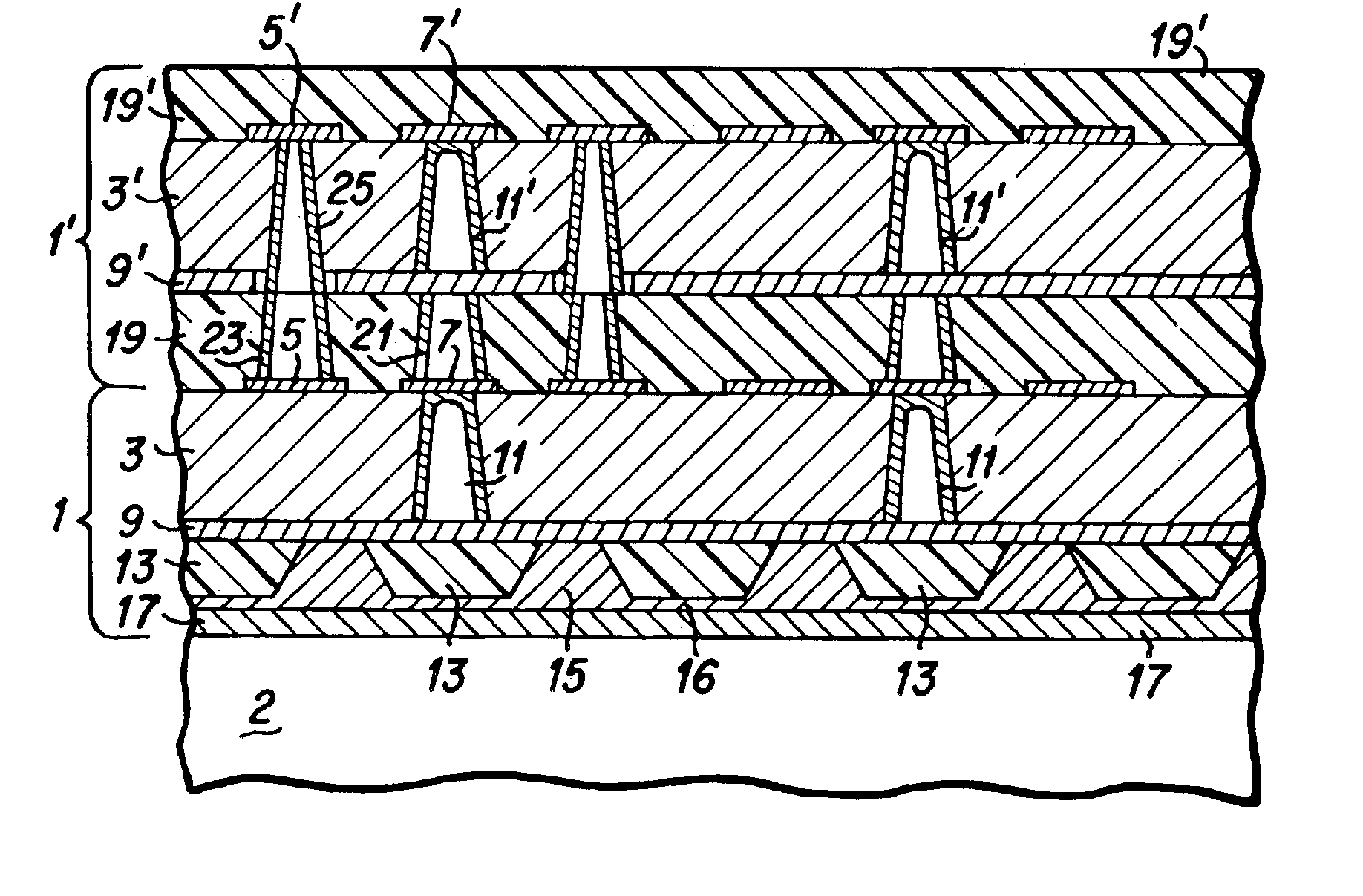

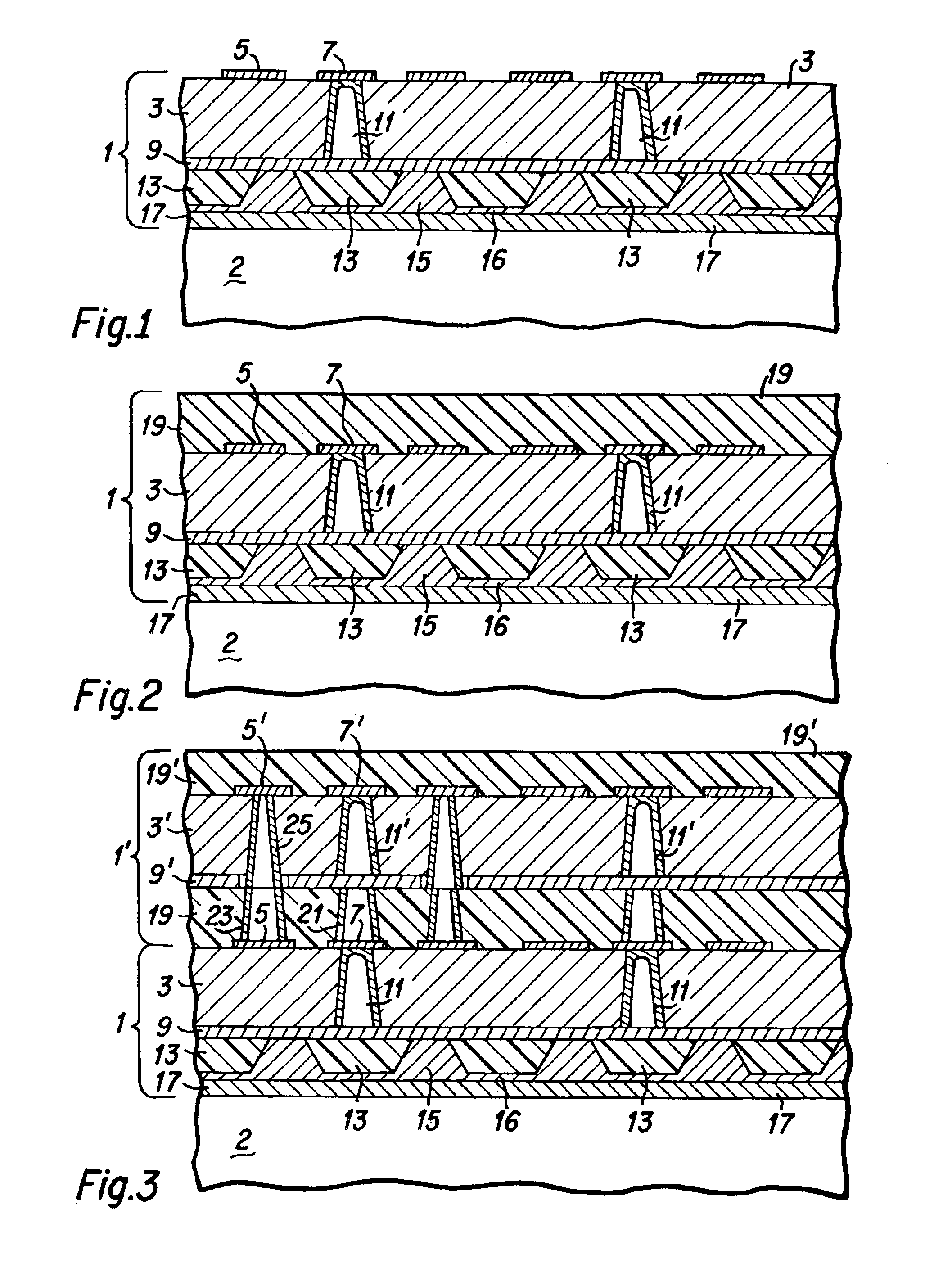

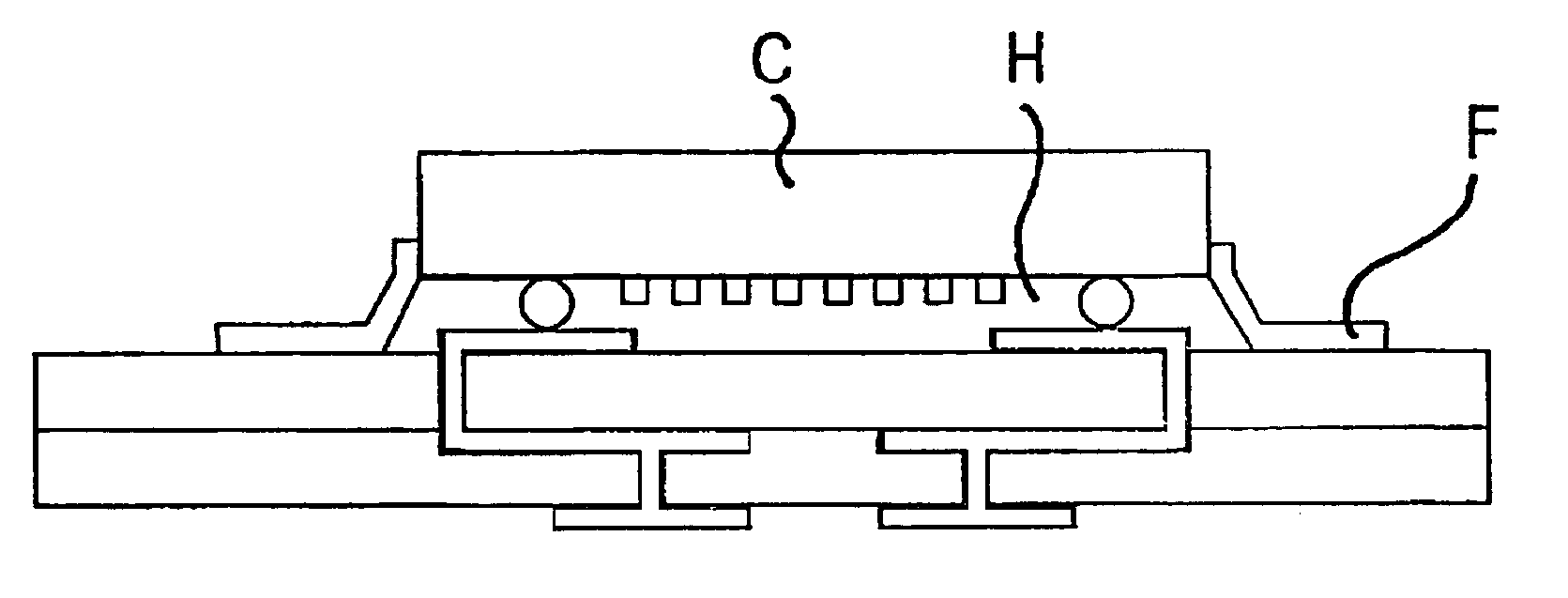

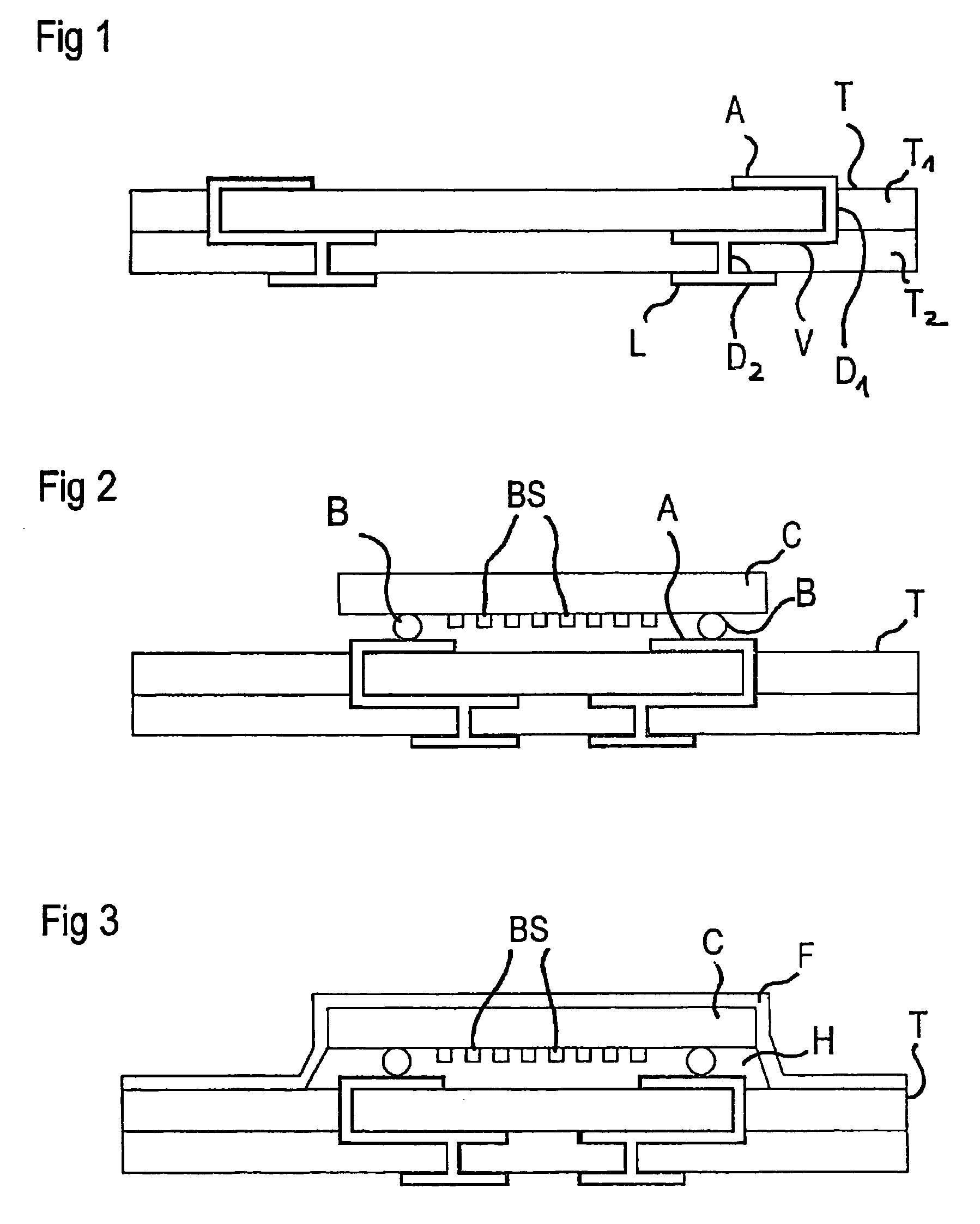

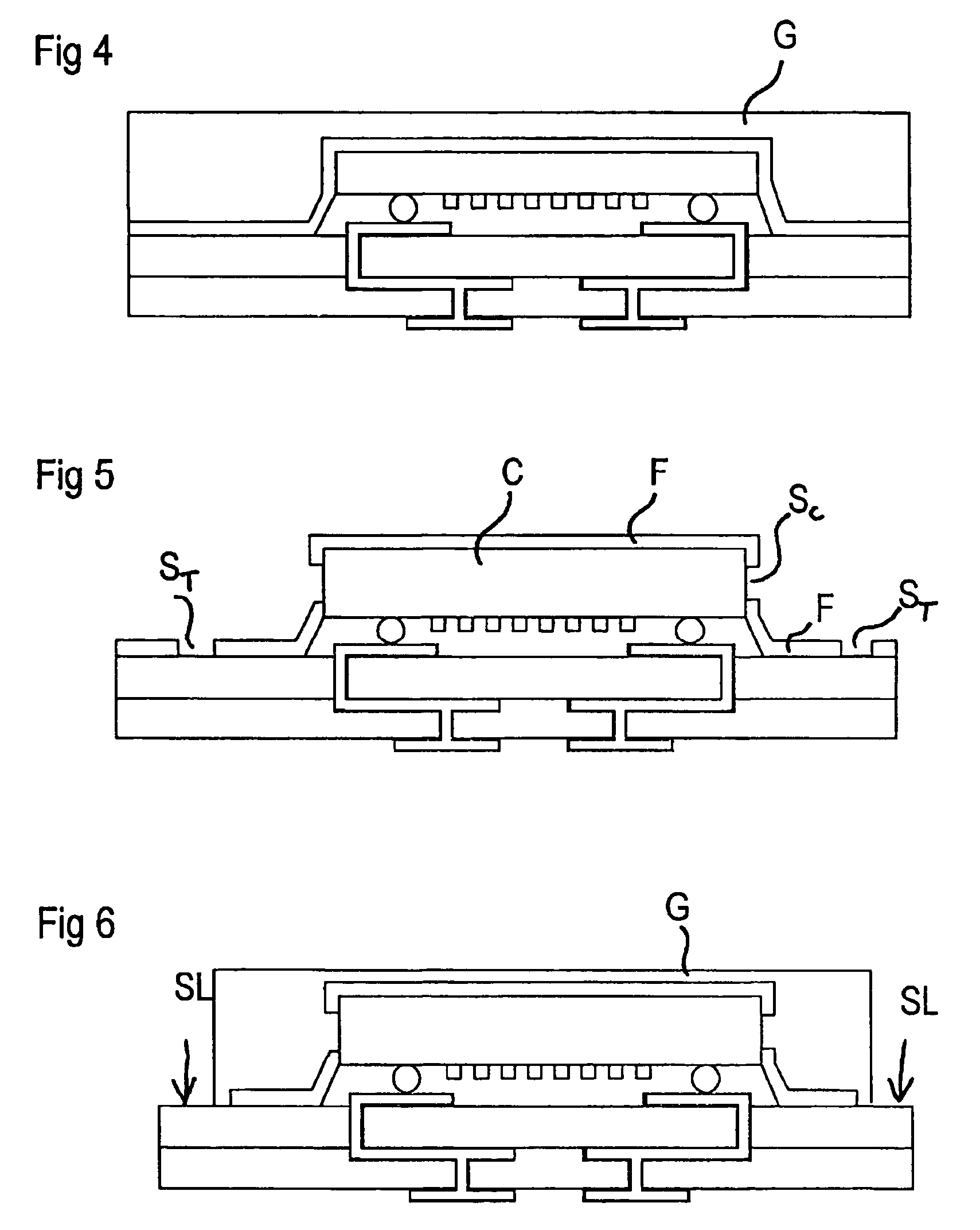

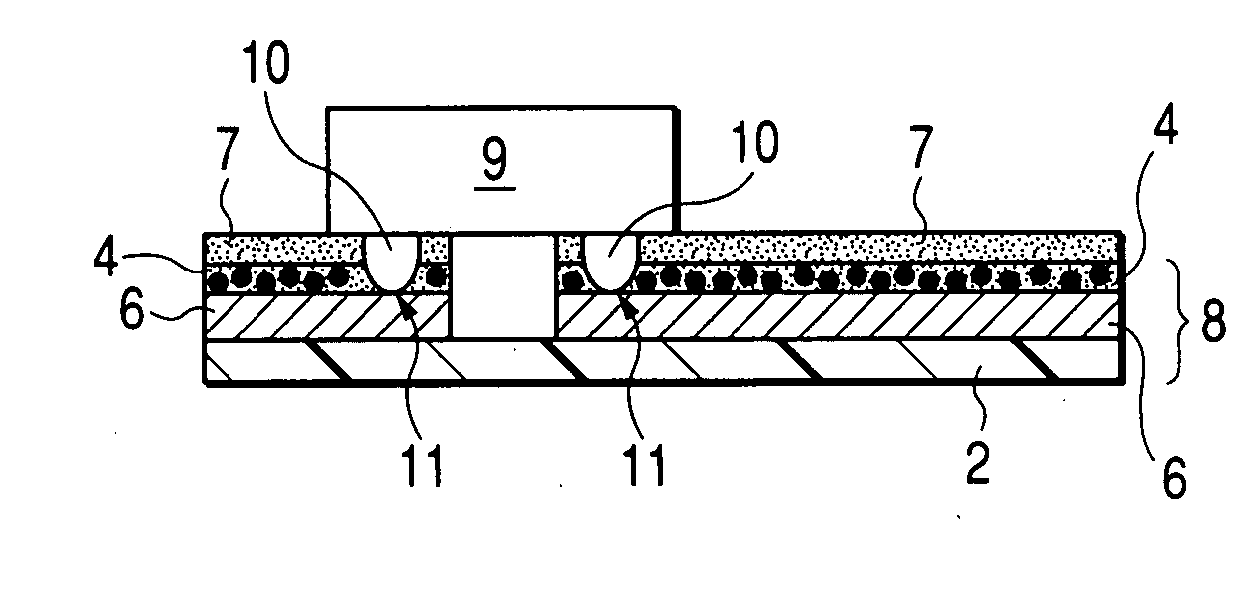

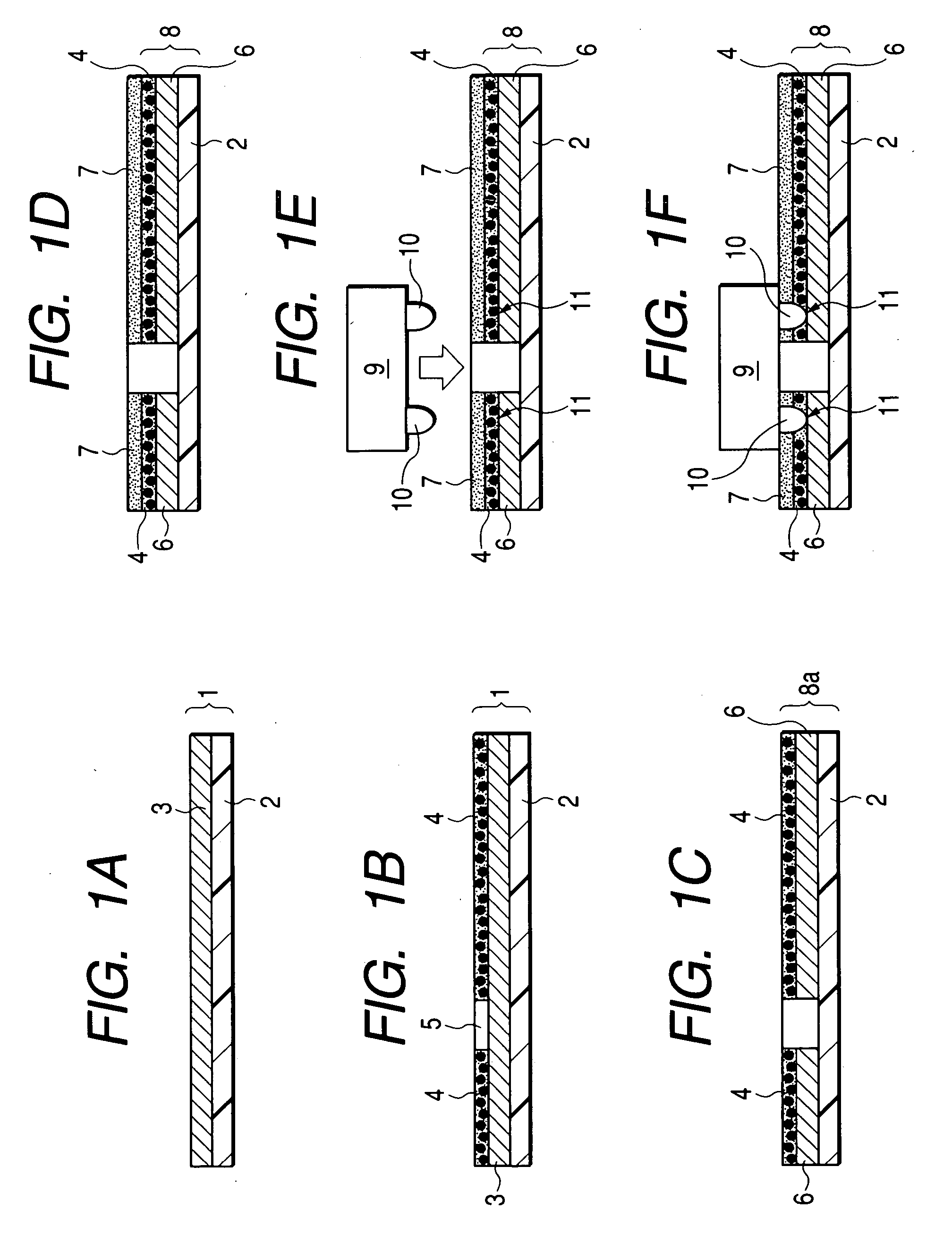

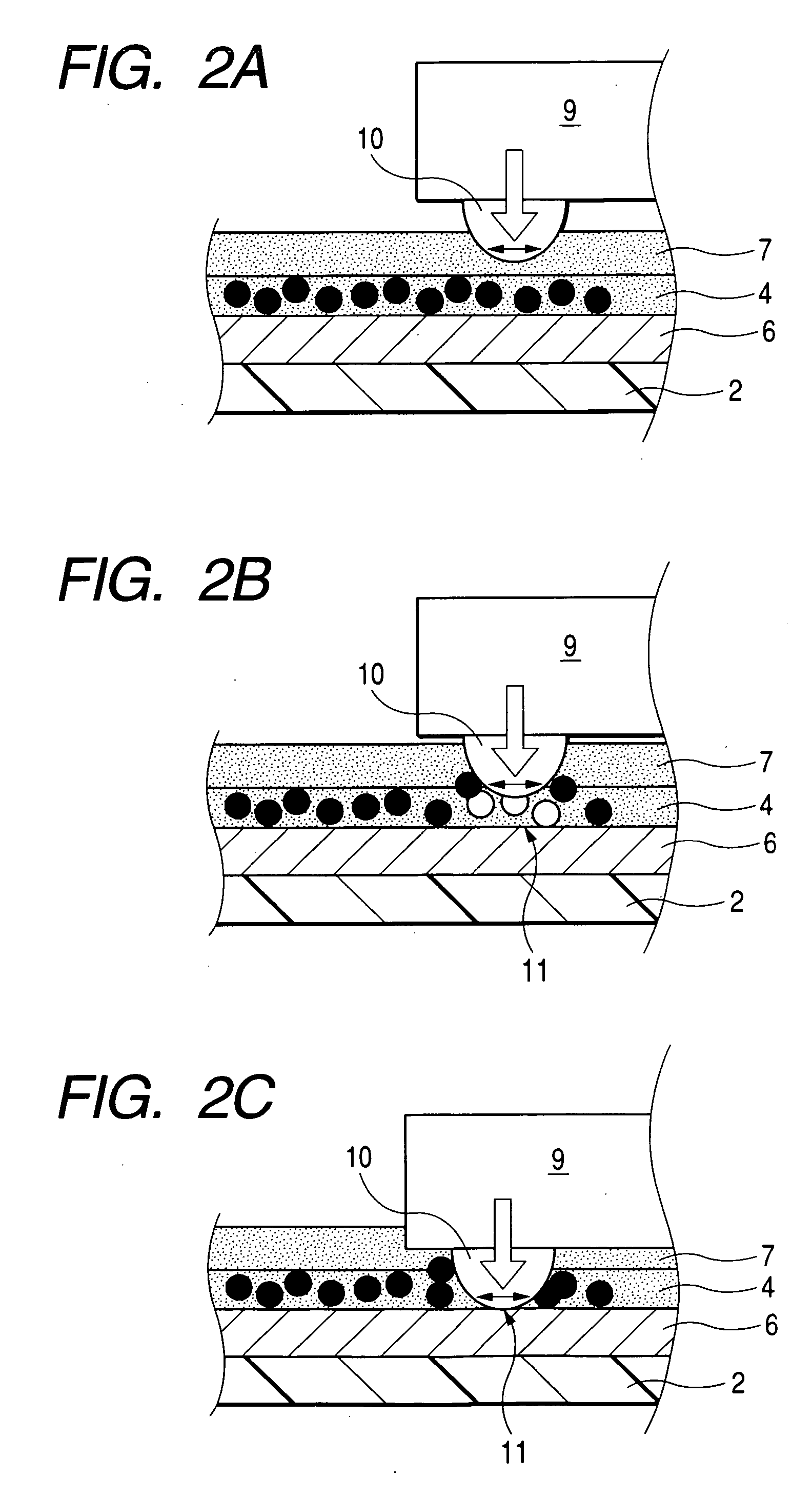

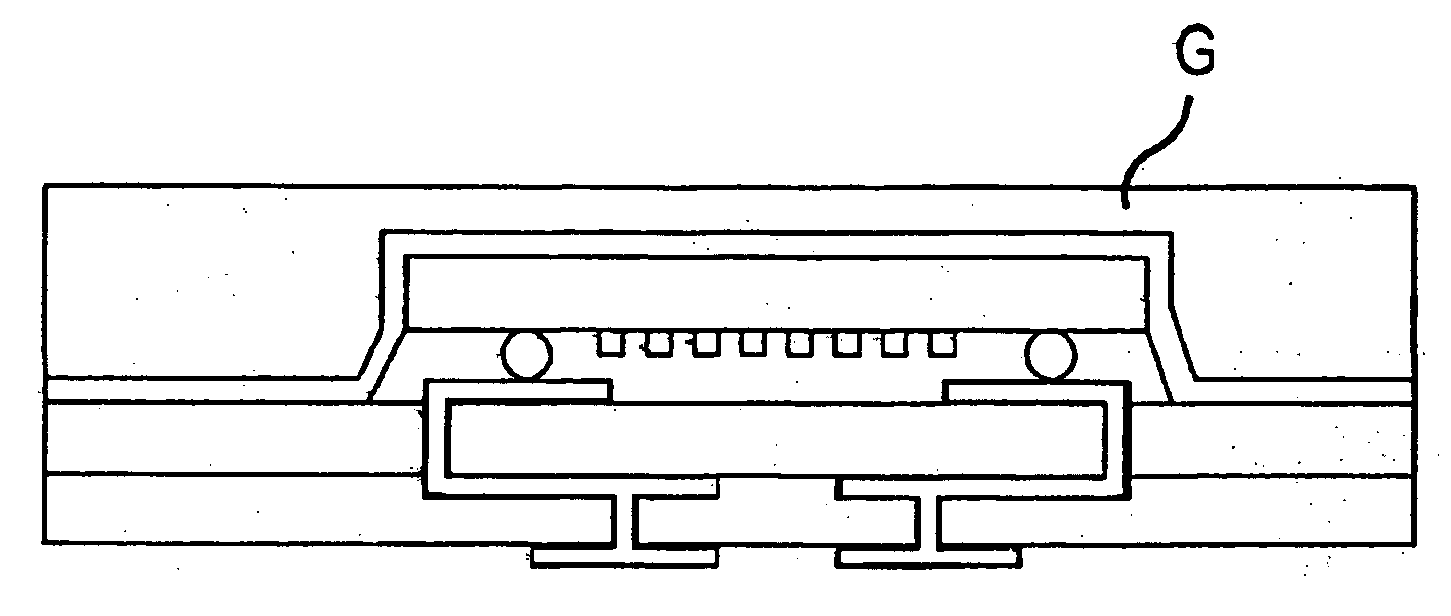

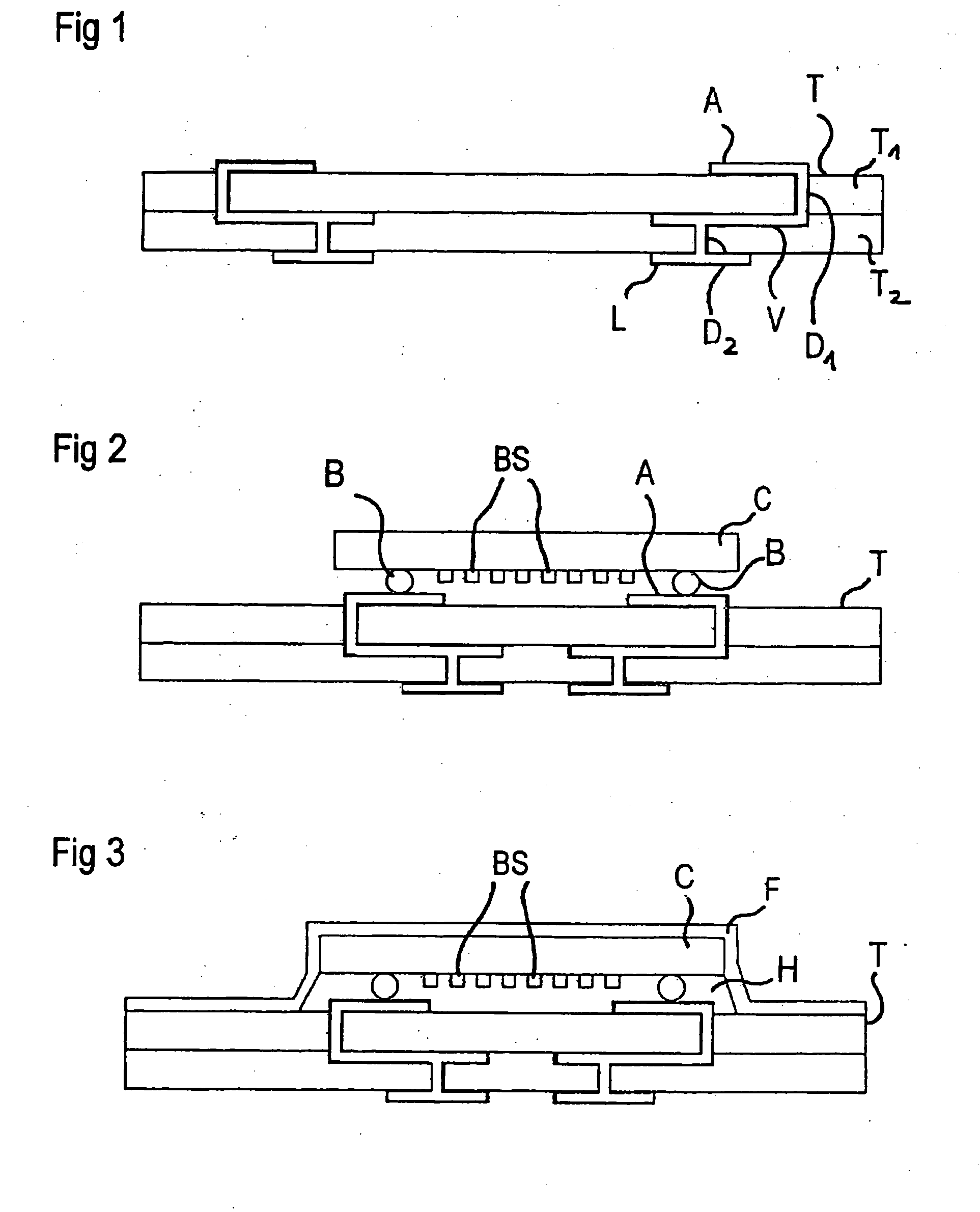

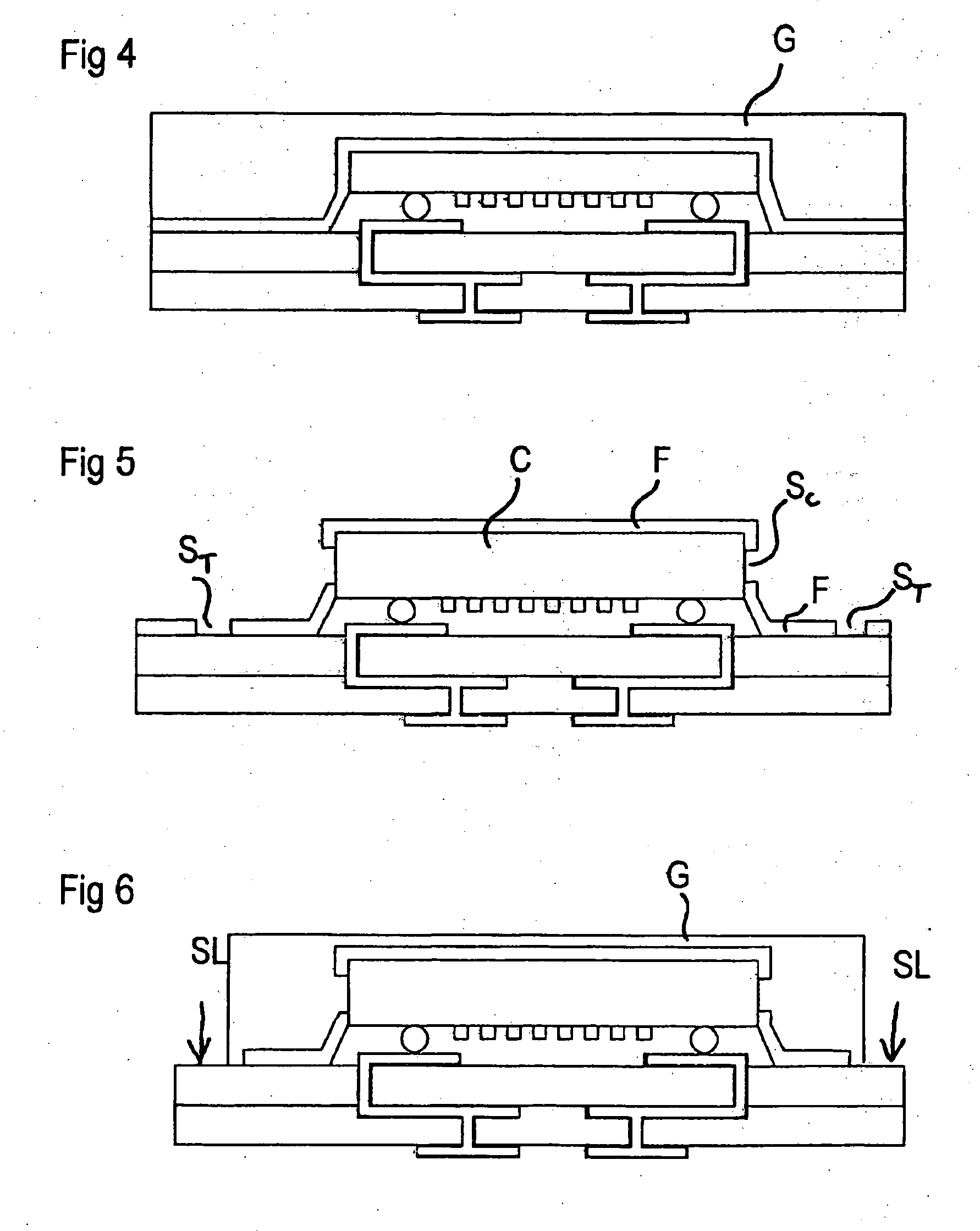

Method for encapsulating an electrical component

InactiveUS7094626B2Simple to executeFirm packagingImpedence networksSolid-state devicesPlastic filmEngineering

An encapsulation method for sensitive composition is provided in which a film, in particular a plastic film, is laminated over the entire surface of an arrangement having a component mounted on a carrier in a flip chip construction. For additional sealing and mechanical stabilization, a plastic compound in liquid form is subsequently applied and hardened so as to surround the chip. Optionally, before the application of the plastic compound, the film can be removed in the area of structuring lines in such a way that the plastic compound can come into contact both with the carrier and with the chip surface.

Owner:SNAPTRACK

Manufacturing method for electronic component module and electromagnetically readable data carrier

InactiveUS20040112636A1Low costPrevent a short-circuit from occurringPrinted circuit assemblingSemiconductor/solid-state device detailsThermoplasticComputer module

A semiconductor bear chip having a bump subjected to high temperatures is pressed, from the upper side, onto a wiring board including a wiring pattern, a thermosetting resin film covering an electrode area on the wiring pattern and having insulating particles dispersed and included and a thermoplastic resin film covering the thermosetting resin film, while applying a ultrasonic wave, thereby inserting the bumps of the semiconductor bear chip through the thermoplastic resin film and the thermosetting resin film to bond the top end portion of the bump with the electrode area.

Owner:ORMON CORP

Intelligent bolt for optical fiber grating sensor

InactiveCN103277387ARealize Distributed MeasurementsImprove measurement efficiencyScrewsUsing optical meansGratingStructure health monitoring

The invention relates to an intelligent bolt for an optical fiber grating sensor and relates to the optical fiber sensing and structure health monitoring field. According to the intelligent bolt, the optical fiber grating sensor is packaged in a bolt body and is used for monitoring, in an on-line mode, extension of the bolt body in a working state. The intelligent bolt comprises a transmission optical fiber, a protection sleeve, a rubber layer and the bolt body. The optical fiber grating sensor is arranged in the middle of the transmission optical fiber. A nut is arranged at the top end of the bolt body. The bolt body is provided with a countersink defined to be a sensor heeling-in hole. The bottom end of the bolt body is not through, and the top end of the bolt body is provided with a through hole. The intelligent bolt is simple in working principle, simple and convenient to manufacture, exquisite in structure, low in cost, and capable of achieving distribution type measurement easily, and effectively prevents large-scale structural pieces from causing accidents due to coming-off or breakage of bolts or other reasons.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

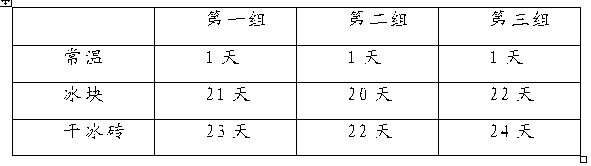

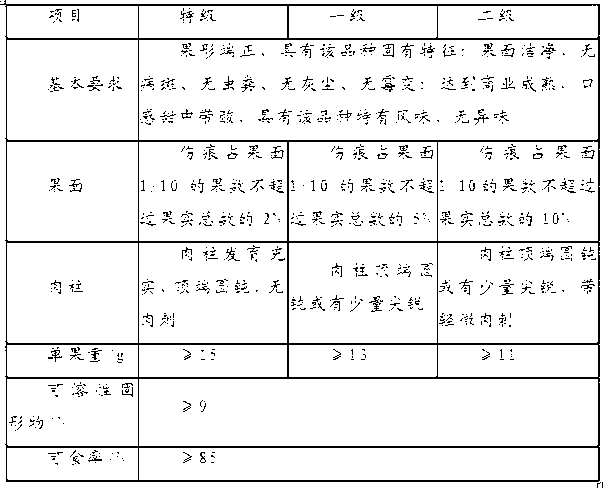

Red bayberry preservation method

InactiveCN102894071AFirm packagingImprove cooling effectFruits/vegetable preservation by freezing/coolingBrickDry ice

The invention discloses a red bayberry preservation method comprising the following steps of: firstly, picking up red bayberries; secondly, selecting fruits; thirdly, sterilizing a storehouse and a container; and fourthly, precooling, grading, refrigerating and packaging, wherein the packaging operation is carried out by using a method for preserving red bayberries through filling nitrogen gas in vacuum, which comprises the following steps of: (1) basketing, extracting air and filling air; placing precooled red bayberries into a plastic basket, covering the plastic basket, then, sleeving a preservation pouch, extracting air in the pouch by using air extraction equipment, then, filling pure nitrogen gas, next, sealing the pouch, and then placing the pouch into a foam box; (2) placing a purchased dry ice-cream brick in the middle of the foam box; and (3) boxing: covering a lid of the foam box, sealing a seam by using viscose paper, fixing the lid, and placing the sealed foam plastic box into an external paper packaging box. By using the red bayberry preservation method provided by the scheme, the red bayberries can be kept non-toxic and harmless, long in preservation period and firm in packaging on the premise that the tastes of the red bayberries are not changed, and damaging a package and a product can be avoided in the transportation process.

Owner:SUZHOU DONGSHAN WUNONG BILUOCHUN TEA SPECIALIZED COOP

Fluid drip-proof device

The invention discloses a fluid drip-proof device which comprises a support, a material injection nozzle, a cylinder and a fluid receiving box, wherein the material injection nozzle and the cylinder are fixed on the support, and the cylinder is located at the lower side part of the material injection nozzle; and the fluid receiving box is connected with a push rod of the cylinder and can move to be below the material injection nozzle along with the push rod. The fluid drip-proof device can prevent residual fluid on the material injection nozzle from dripping onto a working table surface or the edge of the fluid box so as to ensure that the working table is clean and the fluid box is firmly packaged.

Owner:JIANGSU XINGMALI TECH

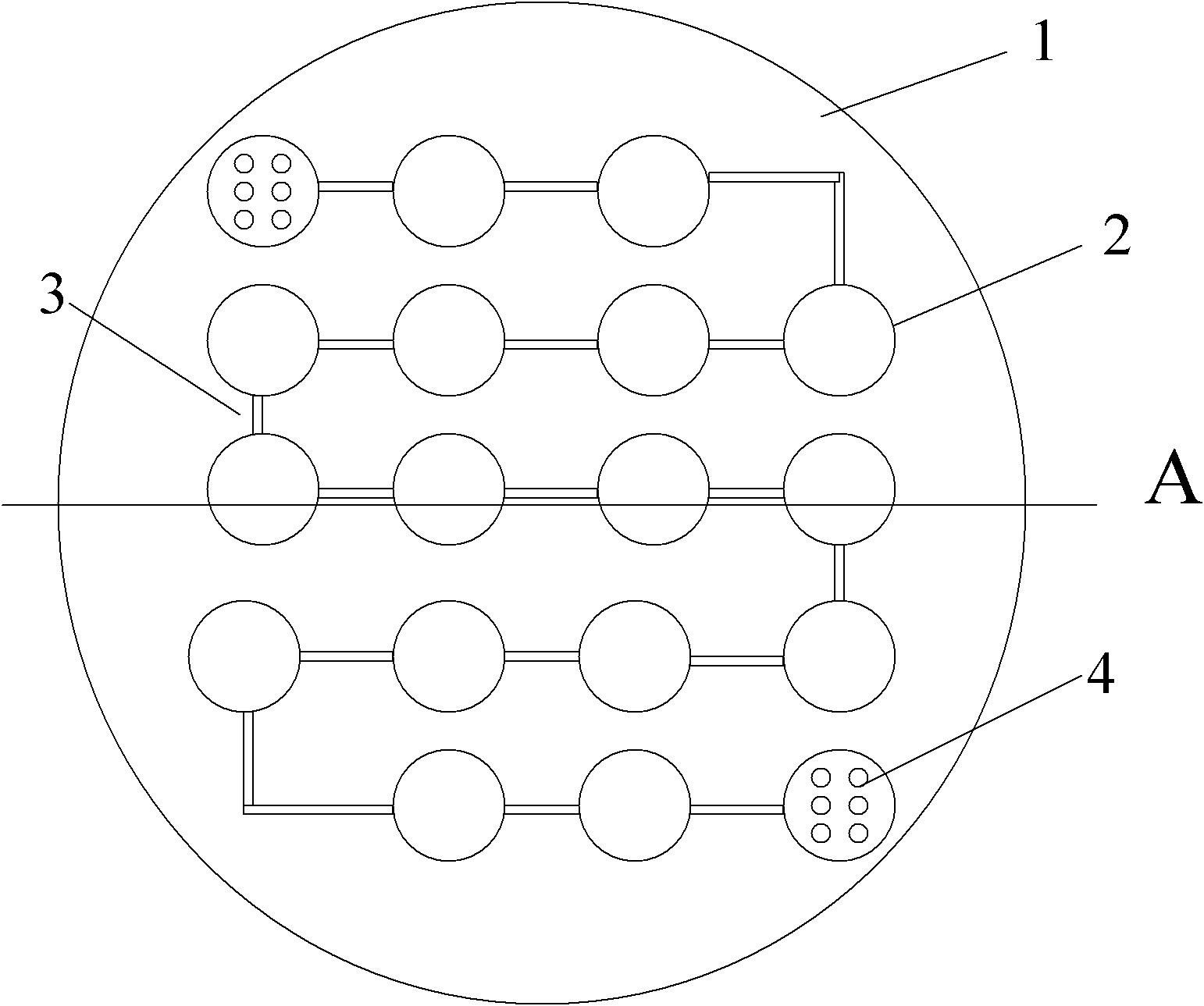

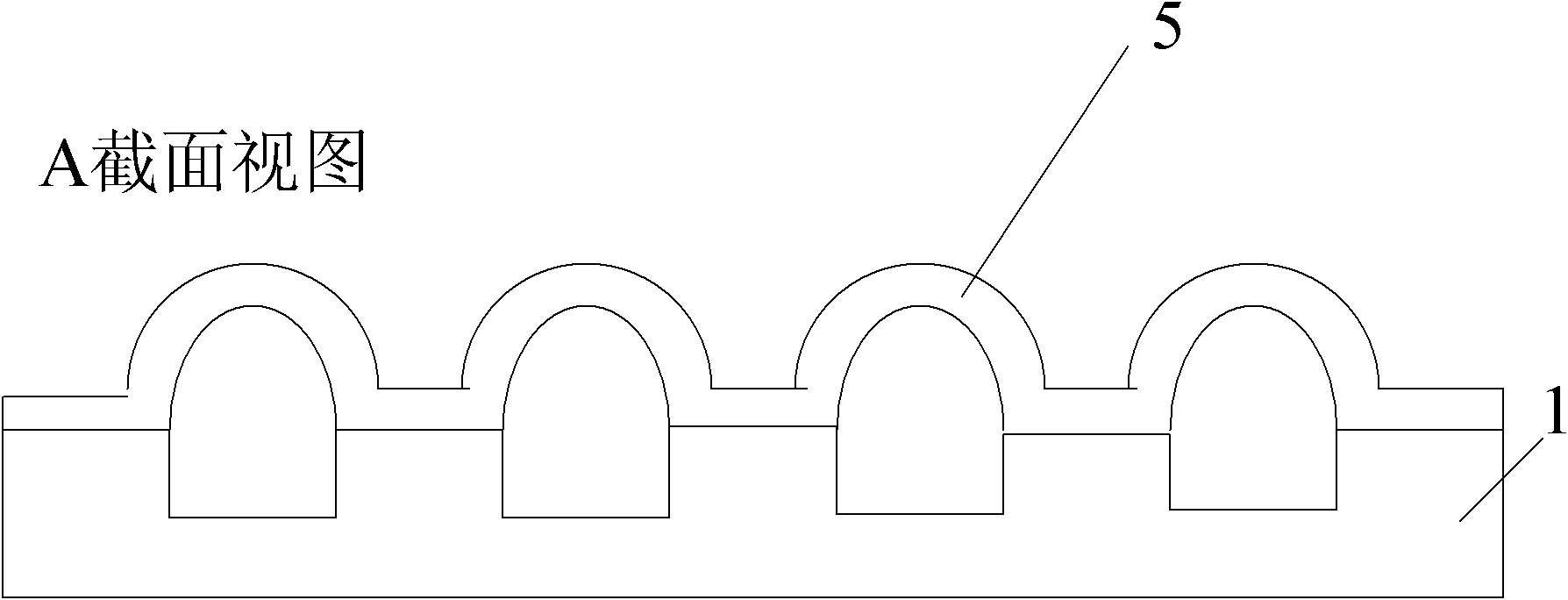

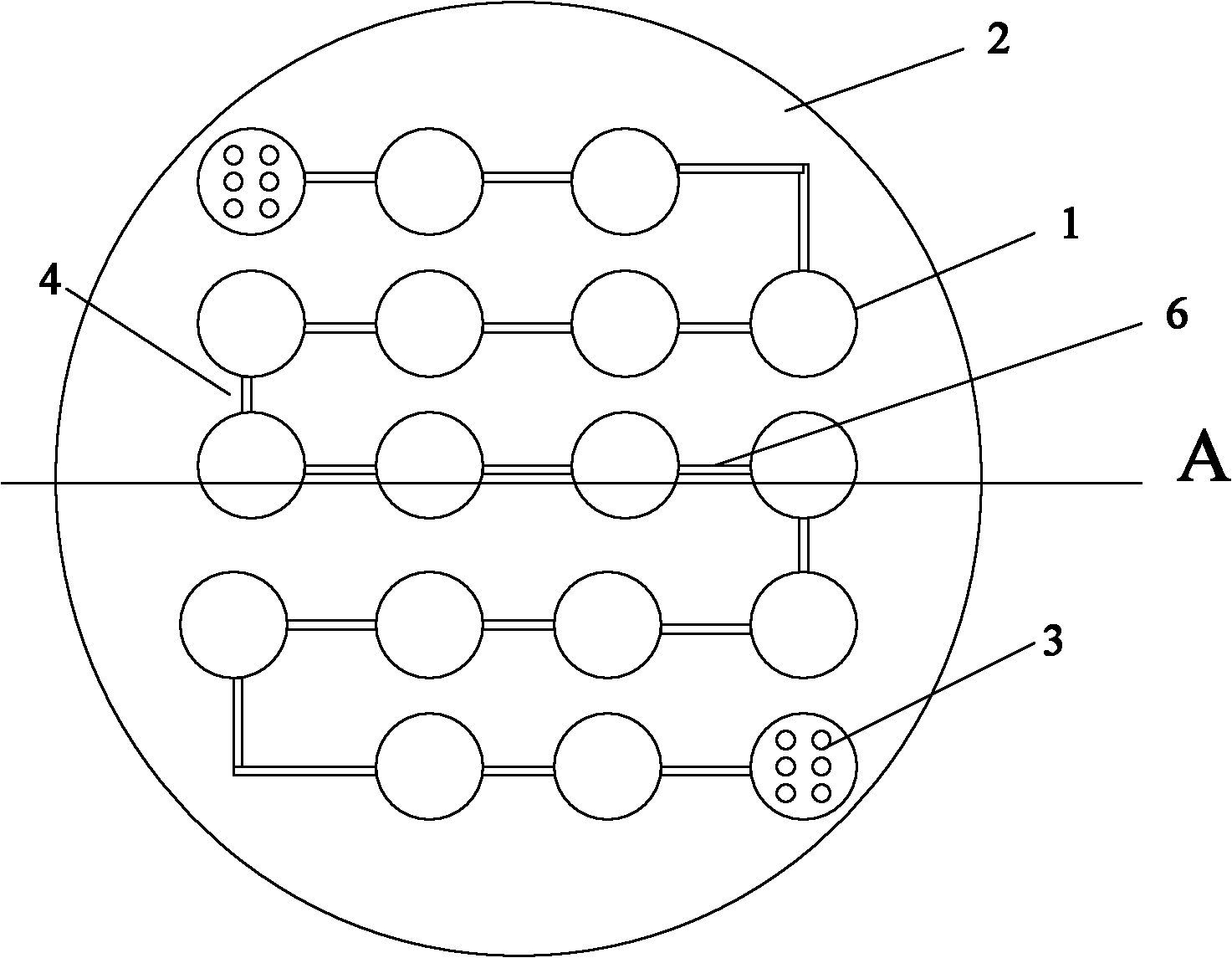

Method for packaging glass-silicon wafer-grade chiponboard (COB) of light emitting diode (LED)

ActiveCN102097545AReduce luminous attenuationImprove performanceSolid-state devicesSemiconductor devicesHeat resistanceSilica gel

The invention discloses a method for packaging a glass-silicon wafer-grade chiponboard (COB) of a light emitting diode (LED). The method comprises the following steps: 1, etching a silicon micro slot array with the micro slots communicated with each other through micro channels, and placing a proper amount of heat outgas agent in the micro slots; 2, performing anodic bonding on the Si wafer with patterns and the heat outgas agent and borosilicate glass wafer in air or in vacuum to form a sealed cavity; 3, heating and preserving heat to form a spherical glass micro cavity, cooling the cavity to normal temperature, annealing and removing silicon to obtain a wafer-grade glass micro cavity; 4, preparing a lead substrate; 5, mounting a chip and leading a wire; 6, carrying out wafer-grade bonding; and 7, filling silica gel to realize the wafer-grade packaging of the LED. By achieving the integration with the wafer-grade LED reflecting cup, the method reduces heat resistance and cost.

Owner:SOUTHEAST UNIV

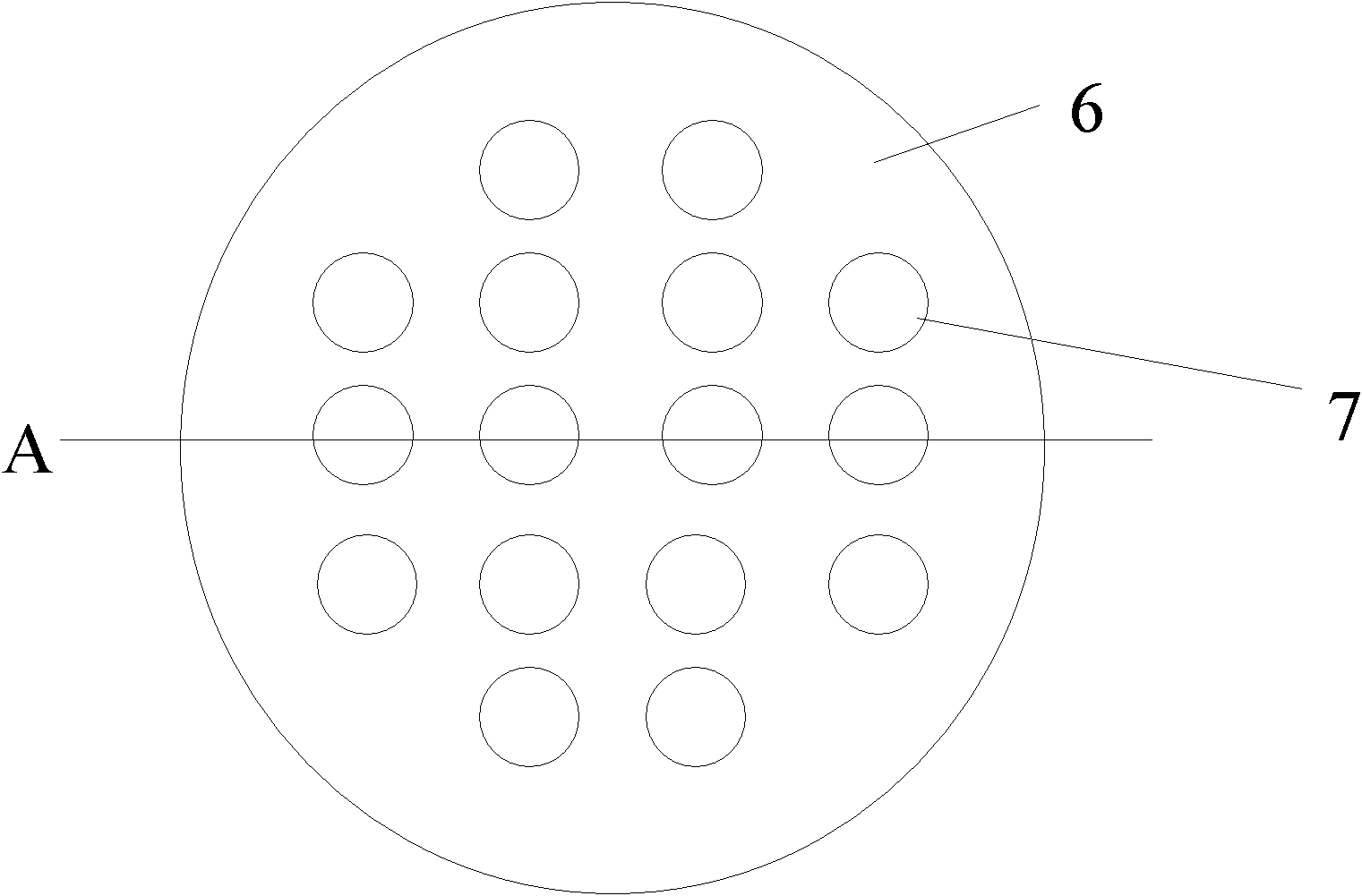

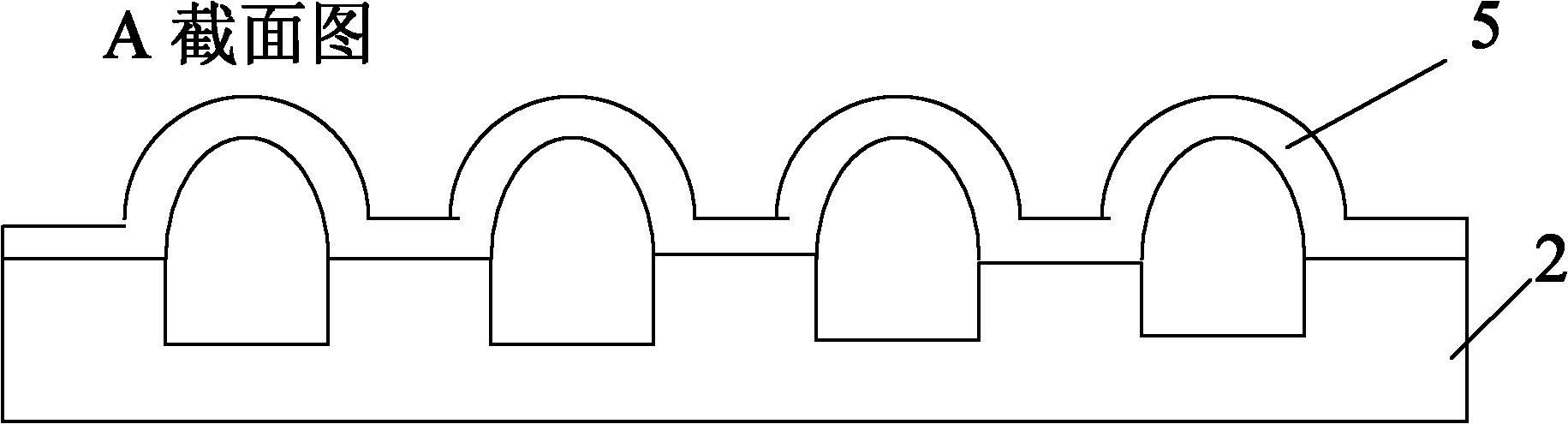

Method for packaging wafer level glass micro-cavity of light-emitting diode (LED)

ActiveCN102110750AReduce optical interfaceGood optical performanceSolid-state devicesSemiconductor devicesLed arrayLight beam

The invention discloses a method for packaging a wafer level glass micro-cavity of a light-emitting diode (LED), and the method comprises the following steps: (1) etching a micro-slot array corresponding to the pattern of a packaged LED array on a silicon wafer, wherein the micro-slots are communicated through a micro-channel, and a proper amount of heat gas releasing agent is arranged inside the micro-slots; (2) forming a closed cavity; (3) heating the bonded wafer in the air to form a spherical glass micro-cavity and a cylindrical glass micro-channel connected with the spherical glass micro-cavity, cooling to room temperature, annealing, and removing silicon to obtain a wafer level glass micro-cavity; (4) sputtering a metal layer on the silicon wafer, and preparing a metal lead through photolithography, so as to obtain a lead substrate, wherein the position of the metal lead corresponds to the position of the micro-channel of the glass micro-cavity; (5) mounting an LED chip on the lead substrate, and leading; (6) bonding the wafer level glass micro-cavity with the substrate to form a bonded wafer; and (7) filling the gap between the LED chip and the wafer level glass micro-cavity with silicone through the glass micro-channel. According to the invention, the light emitting efficiency is high, and a packaged glass lens realizes beam collimation.

Owner:SOUTHEAST UNIV

Wafer-level chip size encapsulation technology for GaAs (gallium arsenide) CCD (Charge Coupled Device) image sensor

ActiveCN102509718AImprove interconnect densityFirm packagingDecorative surface effectsSemiconductor/solid-state device manufacturingInterconnection densityCharge couple device

The invention relates to a wafer-level chip size encapsulation technology for a GaAs (gallium arsenide) CCD (Charge Coupled Device) image sensor. The technology is characterized by comprising the following steps of: (1) firstly bonding a glass wafer and a GaAs wafer through a resin adhesive so as to protect the active surface of a chip and improve the strength of a chip wafer; (2) manufacturing a trapezoidal-slot structure by a wet corrosion or physical method so as to reduce the lining thickness of a chip interconnection area; (3) manufacturing vertical interconnected through holes by a dry etching technology so as to expose a pad on the active surface of the chip; (4) sputtering seed-layer metal and electroplating, and manufacturing a hole metalizing and RDL layer to realize circuit interconnection from the active surface to the back surface of the chip; (5) manufacturing a passivation layer, a UBM layer and raised points; and (6) finally scribing to form an independent encapsulation chip. As the trapezoidal-slot structure on the back realizes thickness reduction only in the area with the pad, the cost is effectively lowered; and through the interconnection of the vertical through holes, the encapsulation interconnection density can be improved, and the signal transmission path is shortened.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Method for encapsulating an electrical component, and surface acoustic wave device encapsulated using said method

InactiveUS20060249802A1Simple to executeFirm packagingPiezoelectric/electrostriction/magnetostriction machinesImpedence networksMechanical stabilityCompound (substance)

An arrangement having a component mounted on a carrier in a flip chip construction which is encapsulated by a film, in particular a plastic film, laminated over the entire surface of the component. For additional sealing and mechanical stabilization, a plastic compound in liquid form is subsequently applied and hardened so as to surround the chip.

Owner:EPCOS AG

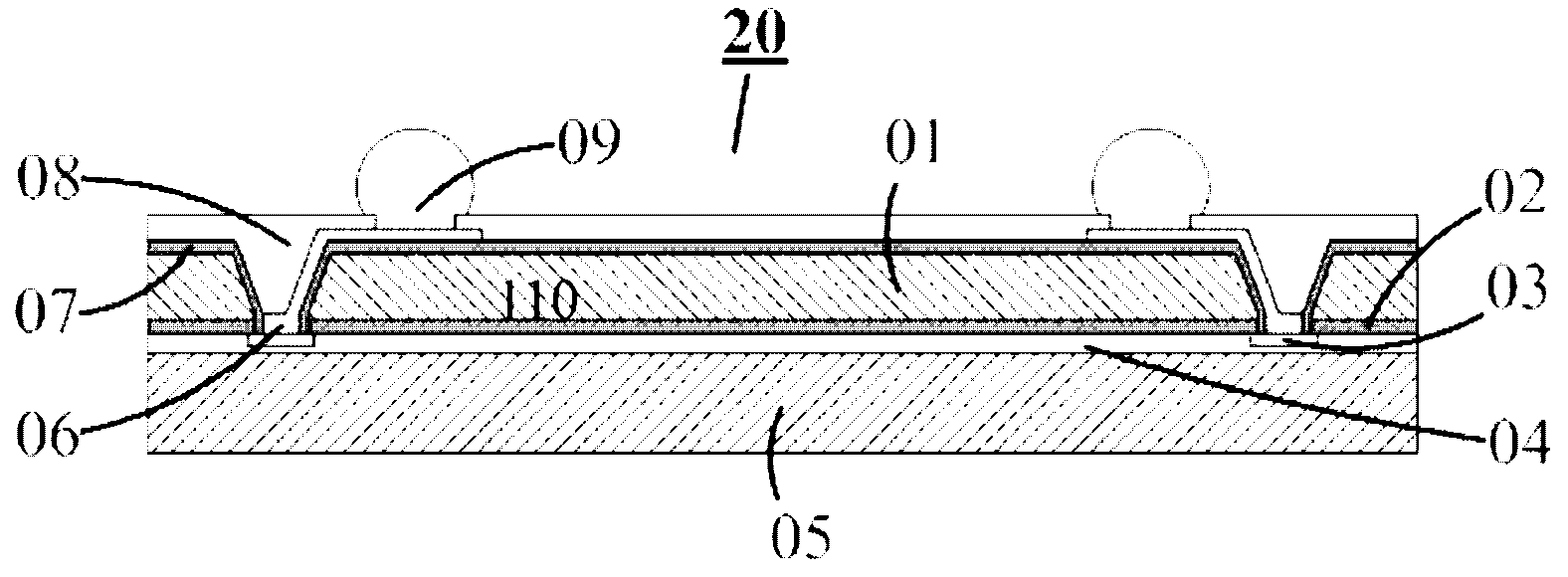

A wafer level packaging structure of a filter and a process thereof

The invention discloses a wafer-level packaging structure of a filter and a process thereof, and the structure comprises a chip substrate, and the working surface of the chip substrate is provided with a bonding pad and an IDT. The structure further comprises a first film layer, a second film layer and a metal connecting piece. Wherein the first thin film layer is located on the working surface ofthe chip substrate and exposes a part of the bonding pad and the IDT; The second thin film layer is positioned on the surface of the first thin film layer and exposes part of the bonding pad; A protection cavity is formed among the second thin film layer, the first thin film layer and the working surface of the chip substrate, and the IDT is located in the protection cavity; And the metal connecting piece is electrically connected with the bonding pad and is provided with a welding part. The surface of the filter is covered with the two films, the cavity is formed, the packaging reliability can be improved, the technological process is greatly optimized, and the whole packaging cost is low. Due to the fact that the thin film is adopted to serve as the cavity cover plate, smaller warpage is achieved after wafer level packaging, and the process yield of products is improved.

Owner:XIAMEN SKY SEMICON TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com