Intelligent bolt for optical fiber grating sensor

A fiber grating and smart bolt technology, which is applied in the direction of optical devices, instruments, screws, etc., can solve the problems of multiplexing of white light interference sensors, the influence of ceramic core and optical fiber loss, and the inability to achieve single-point strain measurement. , to achieve the effect of easy distributed measurement, smart structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

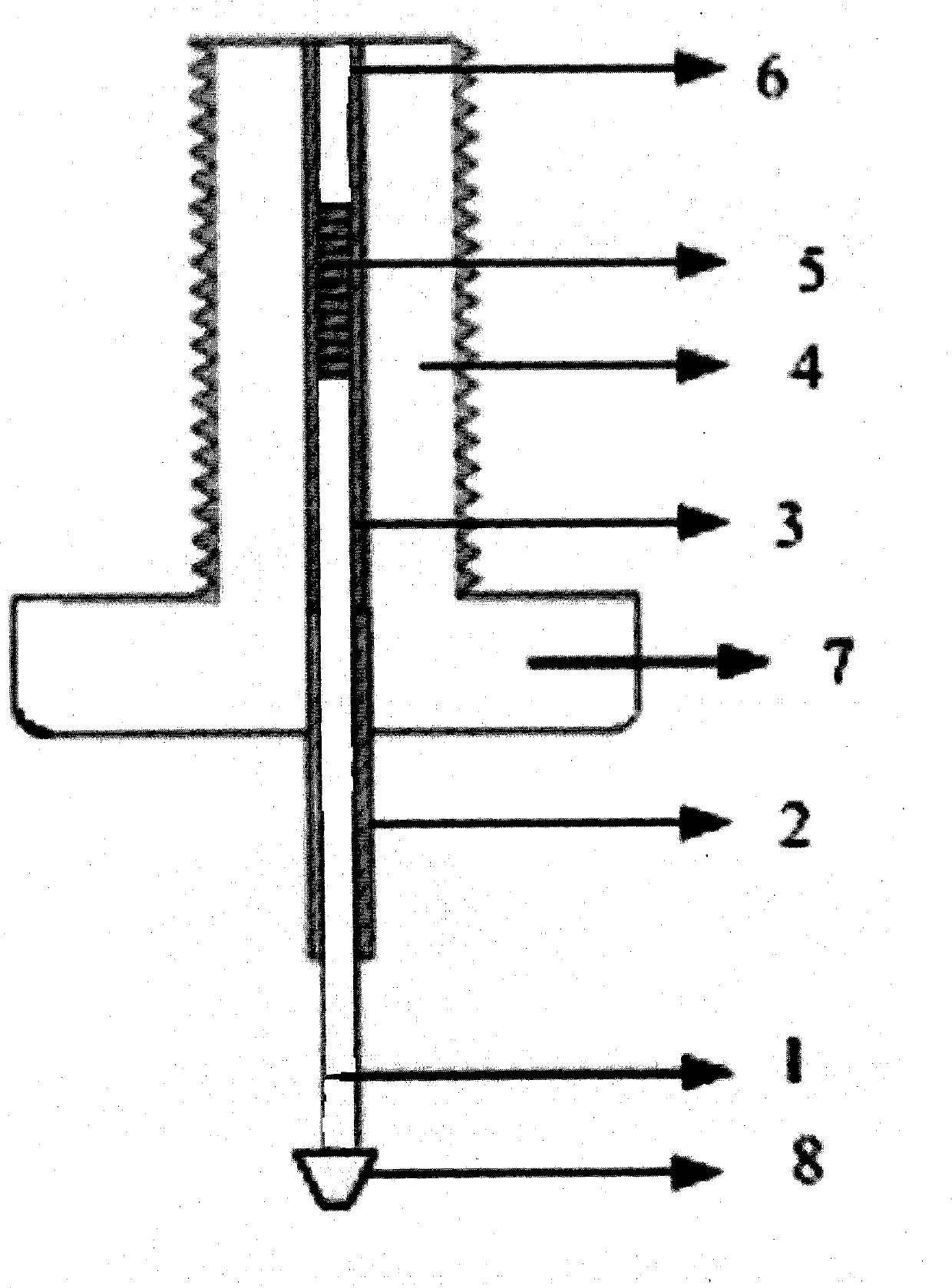

[0023] A smart bolt for a fiber grating sensor, the smart bolt includes a transmission fiber 1, a protective sleeve 2, an adhesive layer 3 and a bolt body 4, and the middle part of the transmission fiber 1 has a fiber grating sensor 5;

[0024] The material of the bolt body 4 is titanium alloy;

[0025] The material of the protective sleeve 2 is glass fiber;

[0026] The glue used in the adhesive layer 3 is epoxy glue;

[0027] The coating layer of the transmission optical fiber 1 is polyimide;

[0028] The top of the bolt body 4 has a bolt cap 7;

[0029] The bolt body 4 has a counterbore defined as the sensor embedding hole 6, the bottom of the bolt body 4 is blocked, and the top is a through hole;

[0030] The transmission optical fiber 1 is embedded in the bolt body 4 through the sensor embedding hole 6, and the fiber grating sensor 5 is also embedded in the bolt body 4;

[0031] The gap between the transmission optical fiber 1 and the sensor embedding hole 6 is filled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com