Patents

Literature

175results about How to "Smart structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

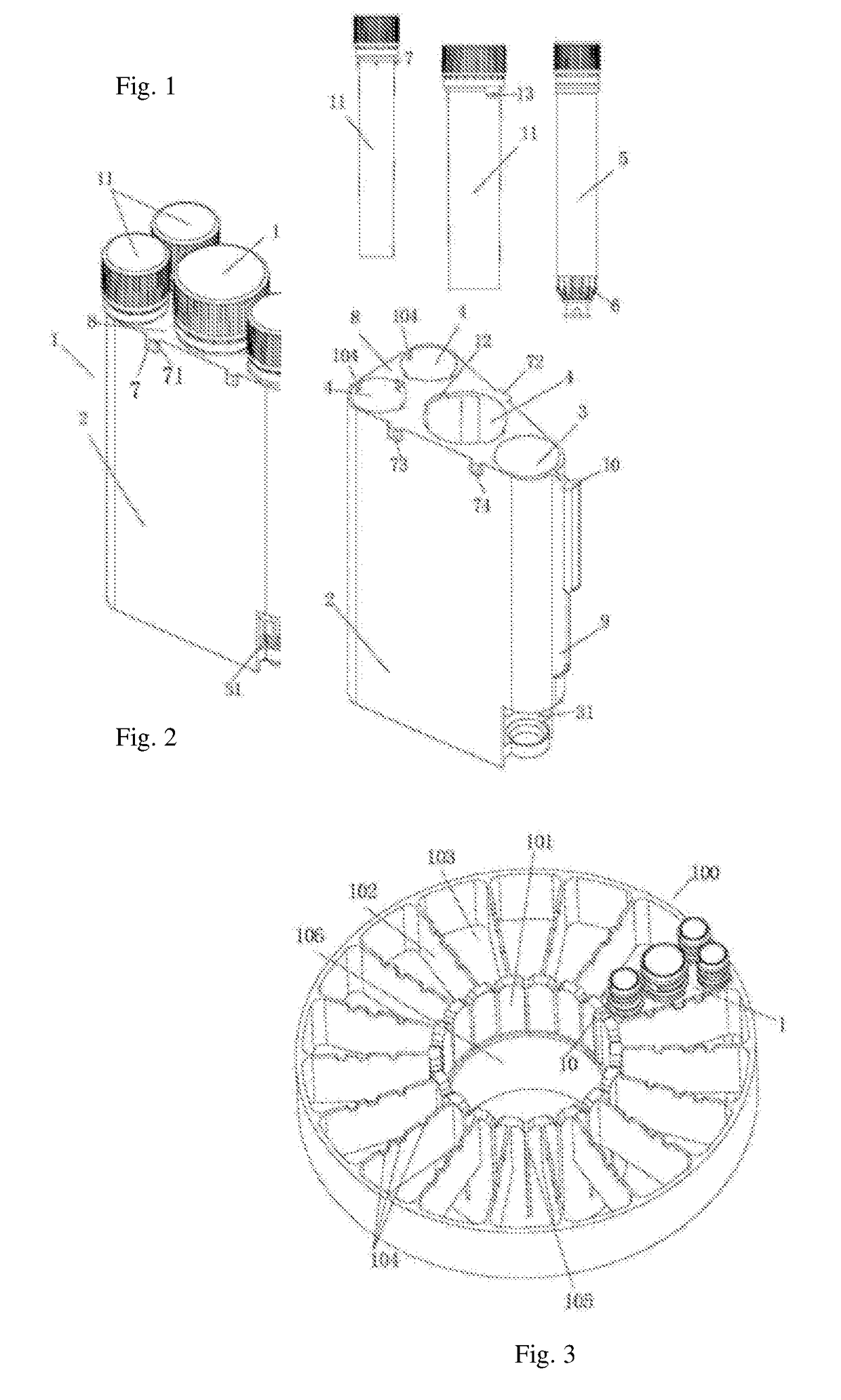

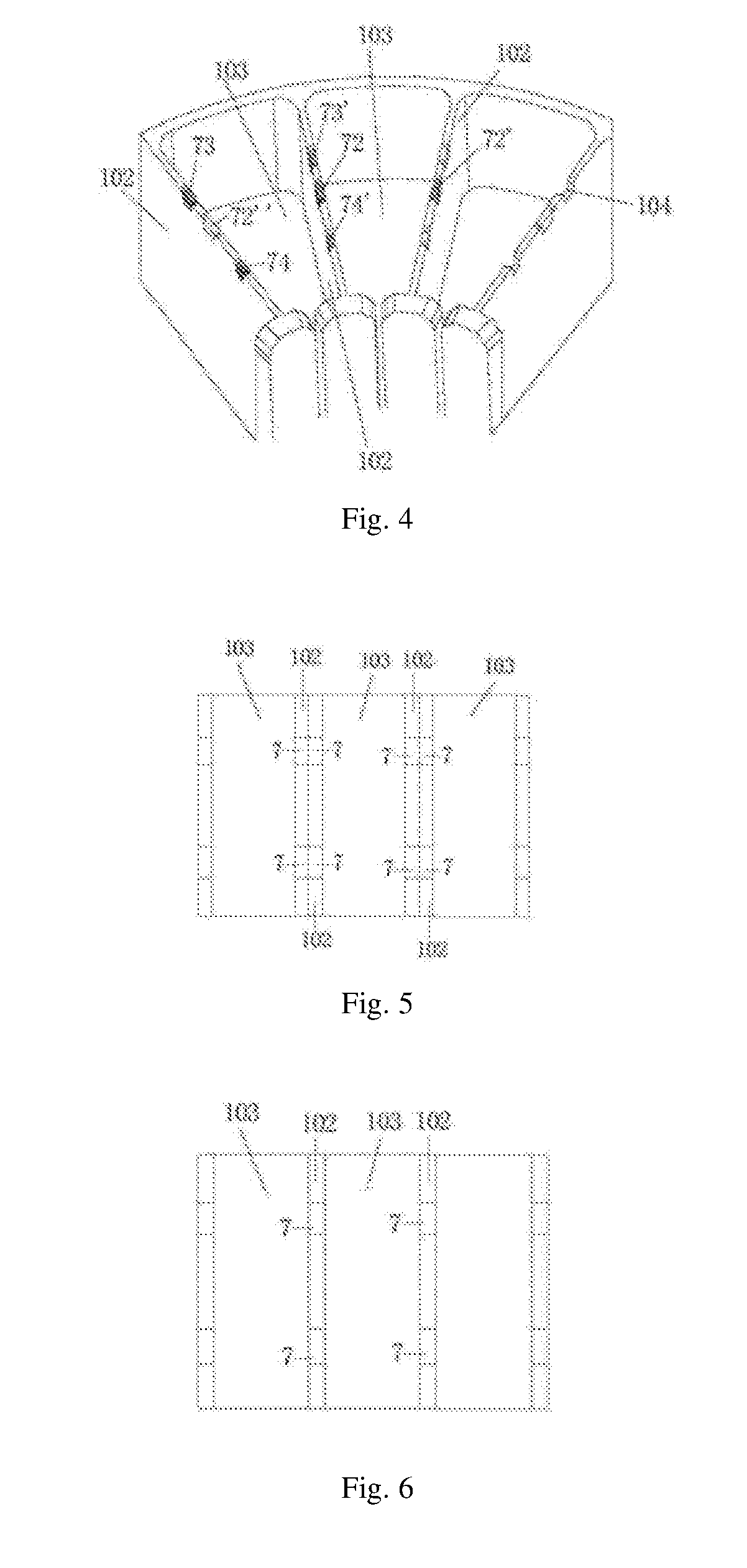

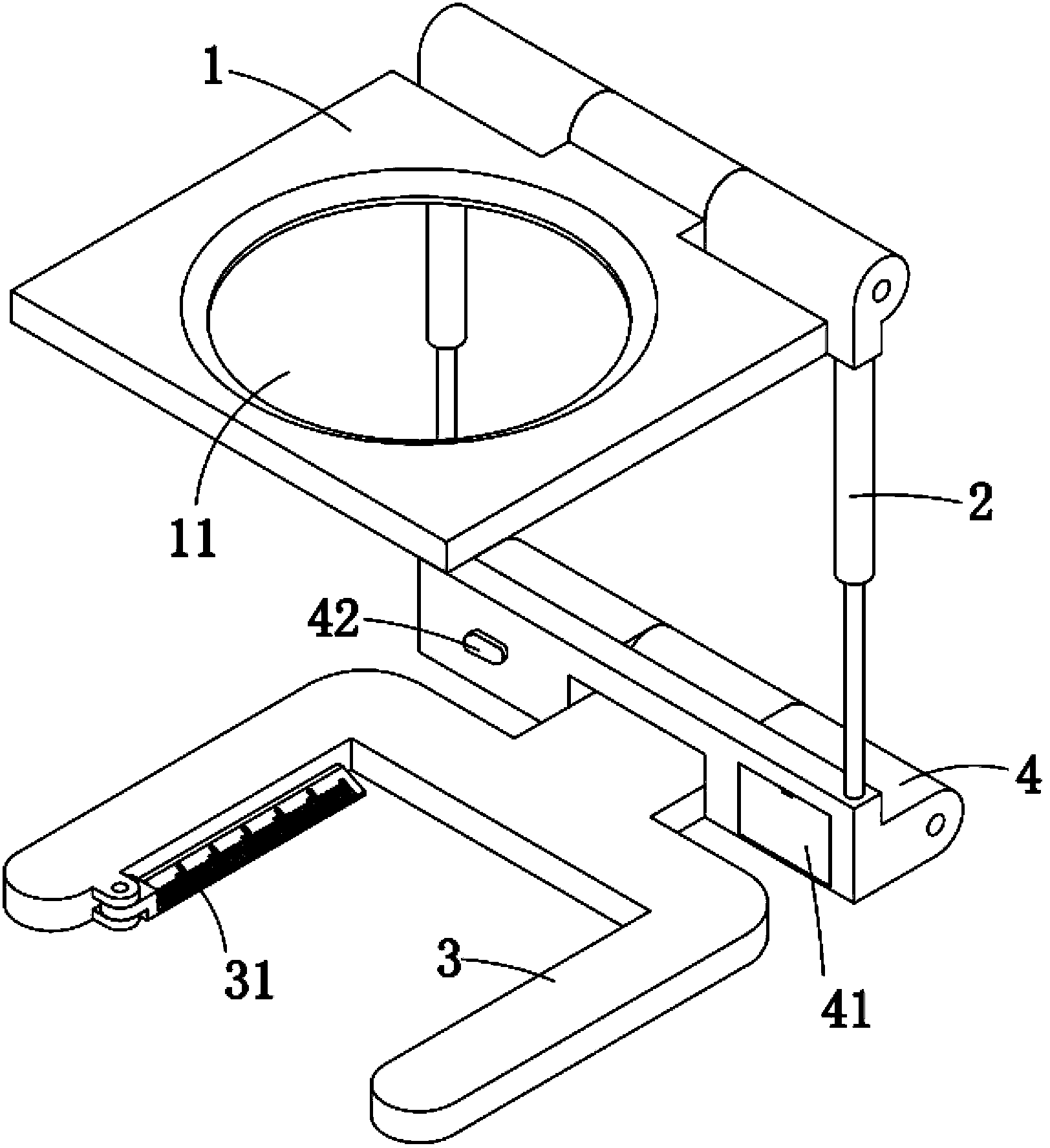

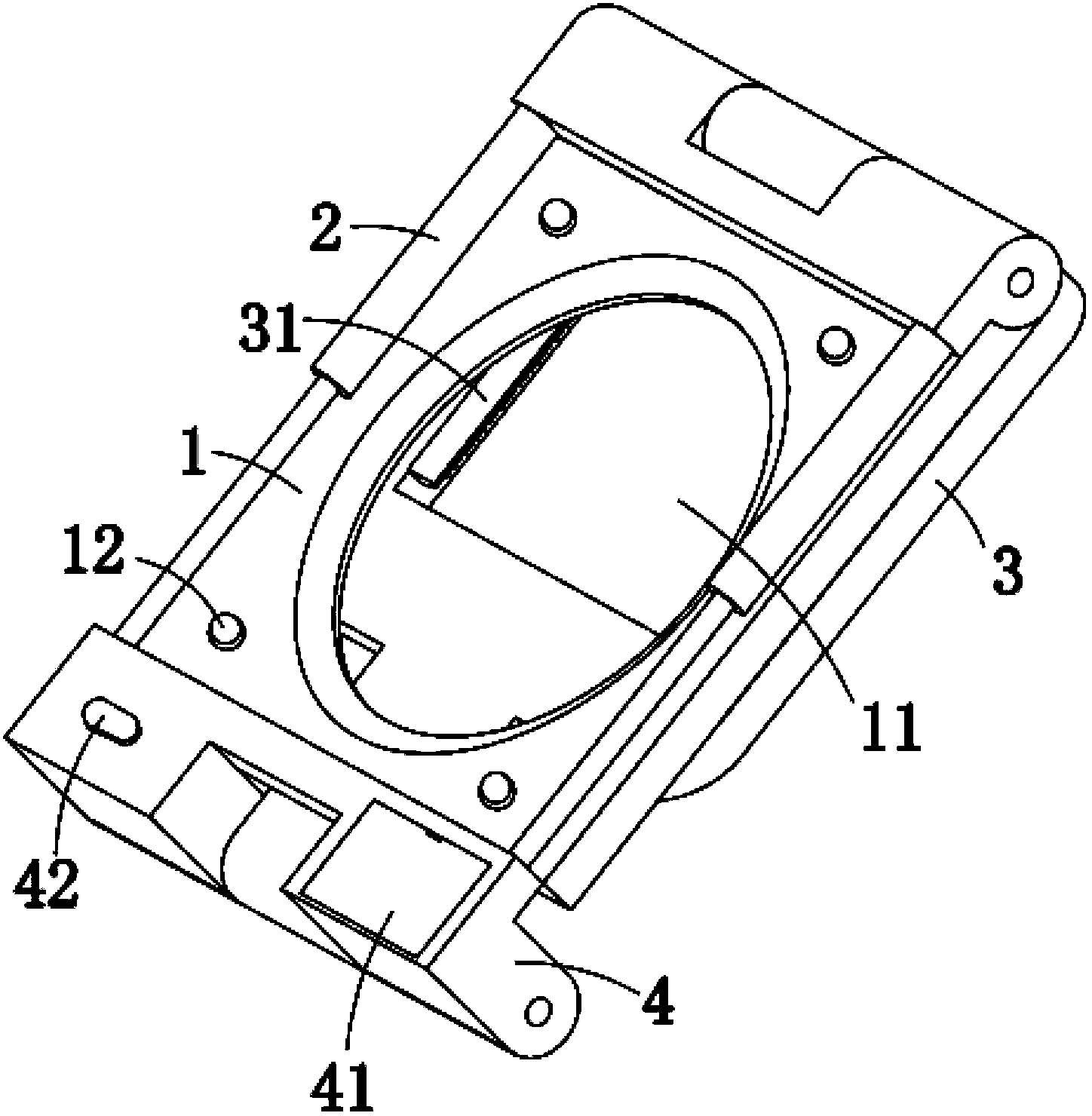

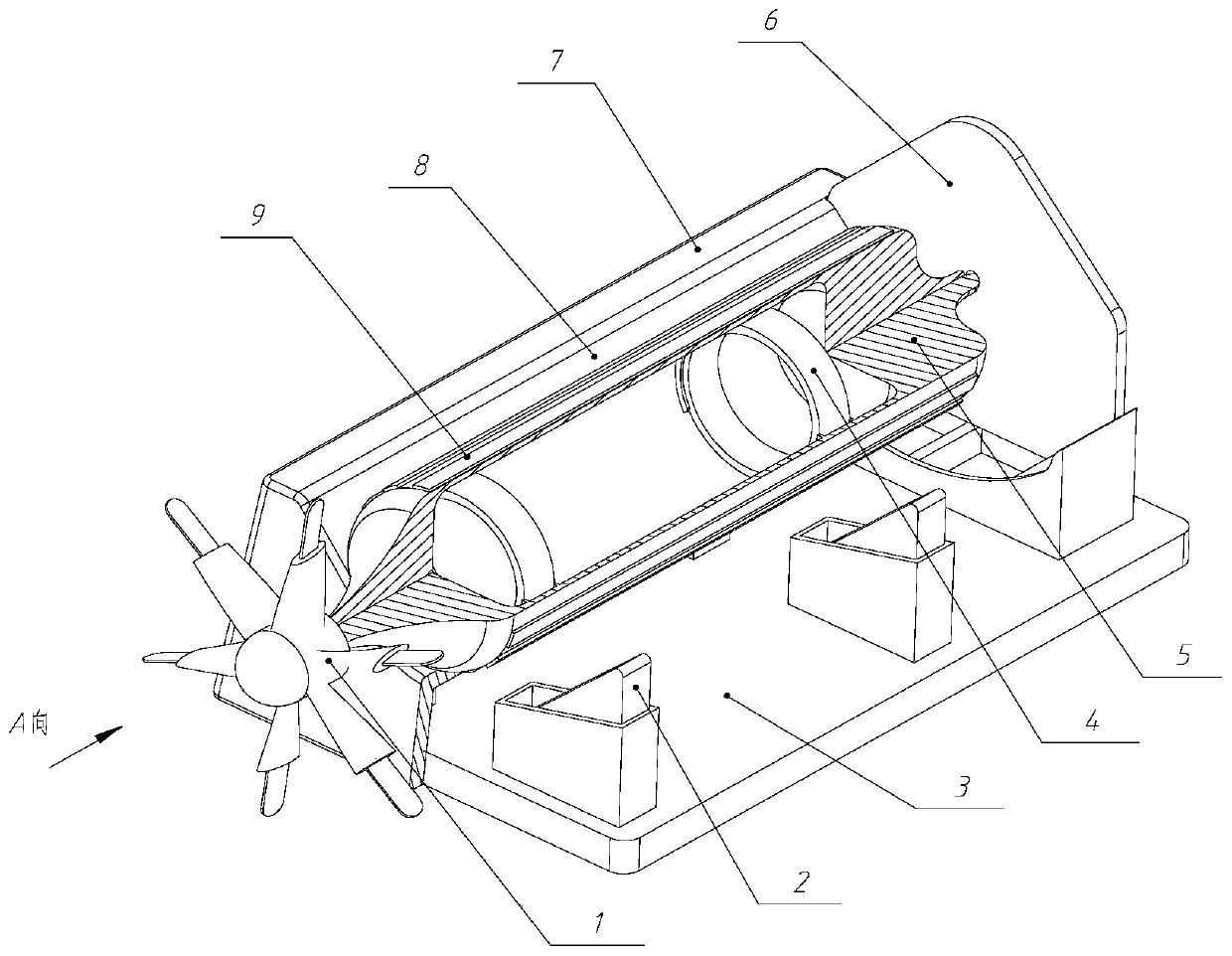

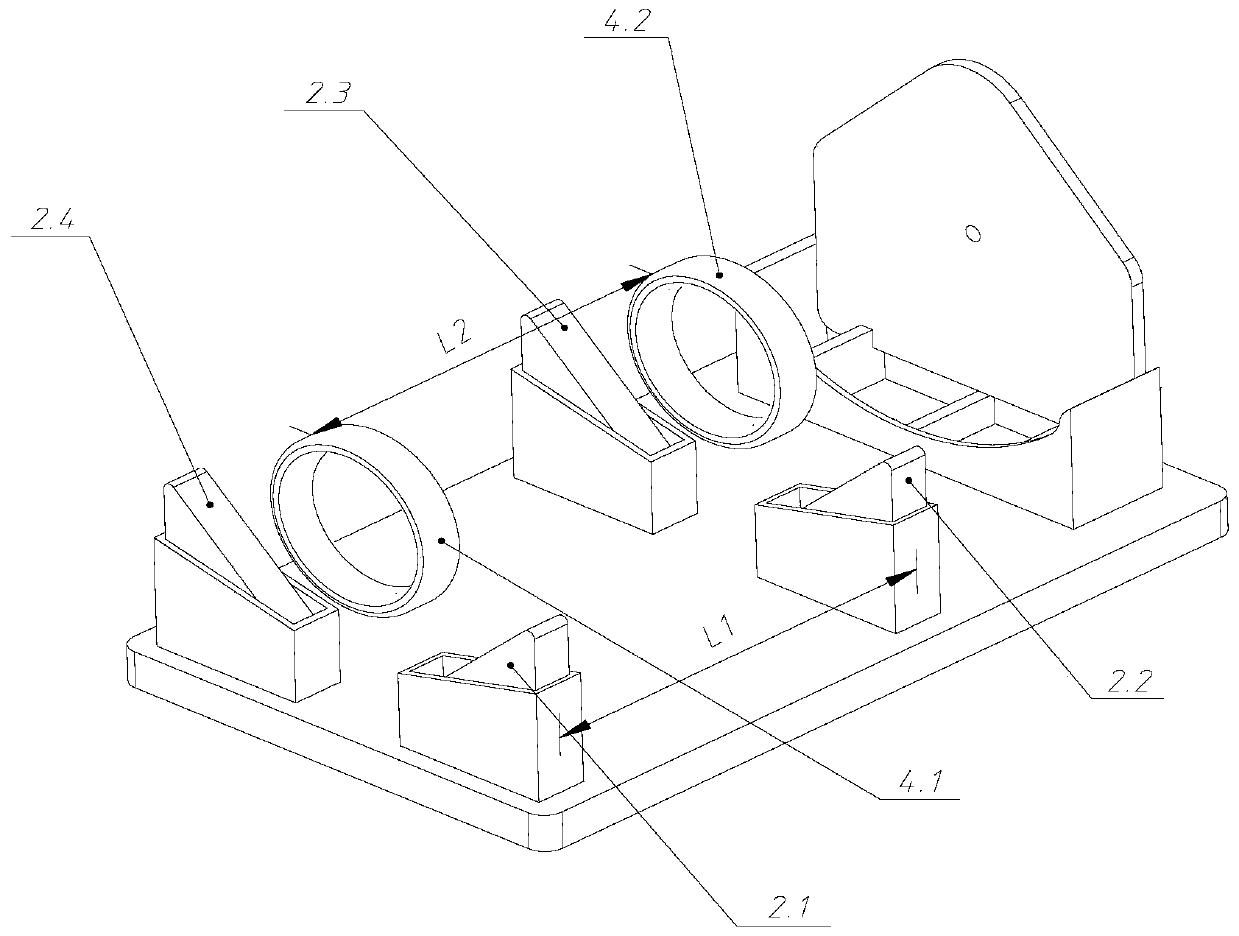

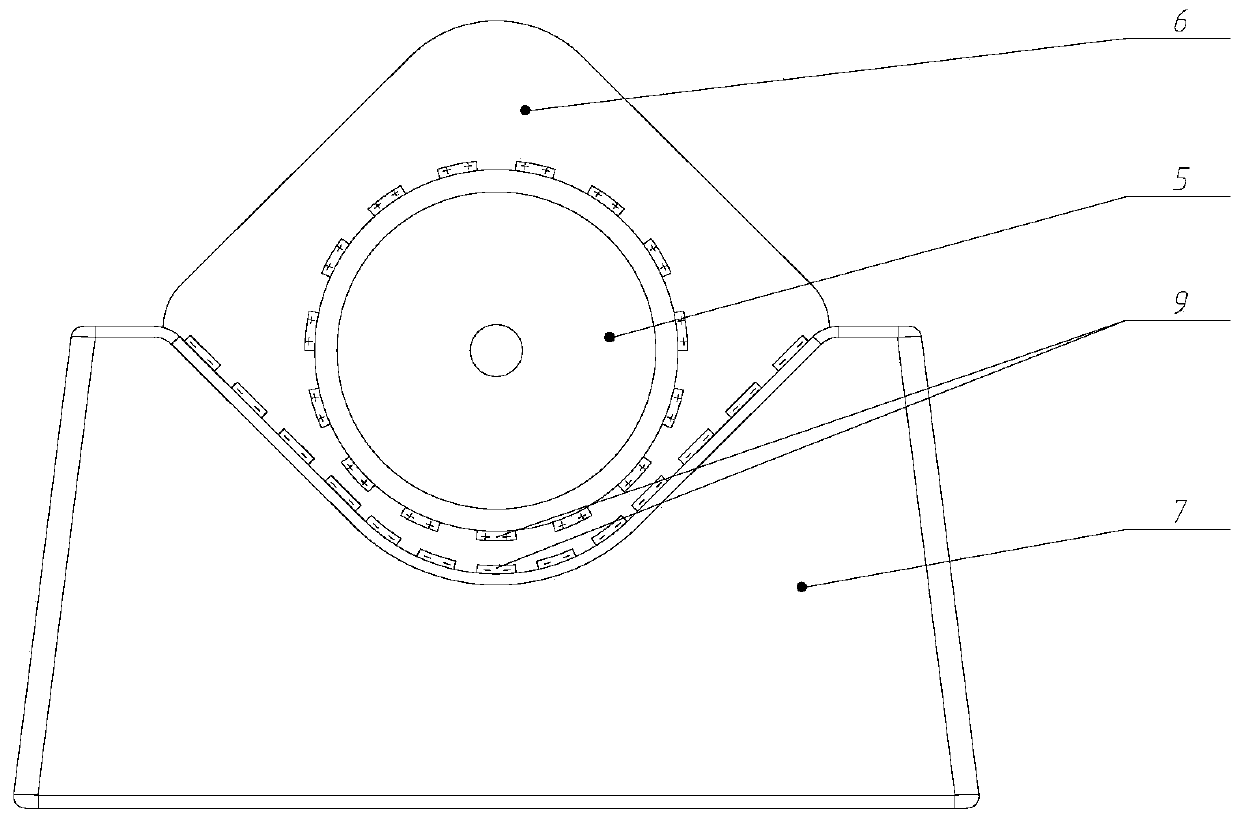

Reagent mixing and conveying device and reagent mixing method

ActiveUS20180252707A1Small sizeSmart structureRotating receptacle mixersTransportation and packagingMechanical engineeringChemiluminescence immunoassay

The present invention provides a reagent mixing device, which comprises a driving device, a transport device and a rotating part, wherein the transport device comprises a conveying mechanism for conveying a reagent kit and a mixing mechanism for mixing a reagent; the conveying mechanism is driven by the driving device to move relative to the mixing mechanism; the rotating part and mixing mechanism are in transmission matching; the conveying mechanism and the mixing mechanism are sleeved with each other to form a bearing structure. The present invention further provides a reagent mixing method. The reagent mixing device is small in size, smart in structure, easy to assemble and low in manufacturing cost. The reagent mixing method provided by the present invention is simple and reliable, high in overall operation reliability, and has very high application values in such analysis and test fields as full-automatic chemiluminescence immunoassay analyzers and biochemical analyzers.

Owner:LEADWAY HK

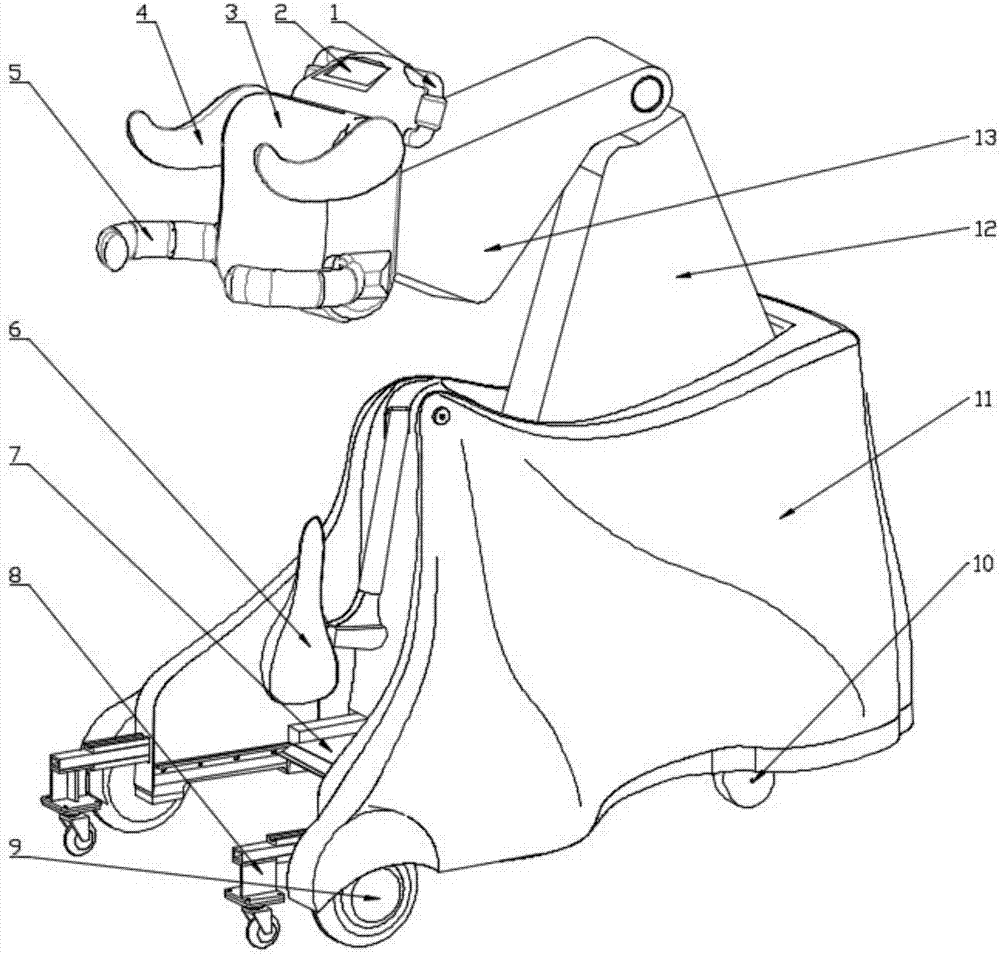

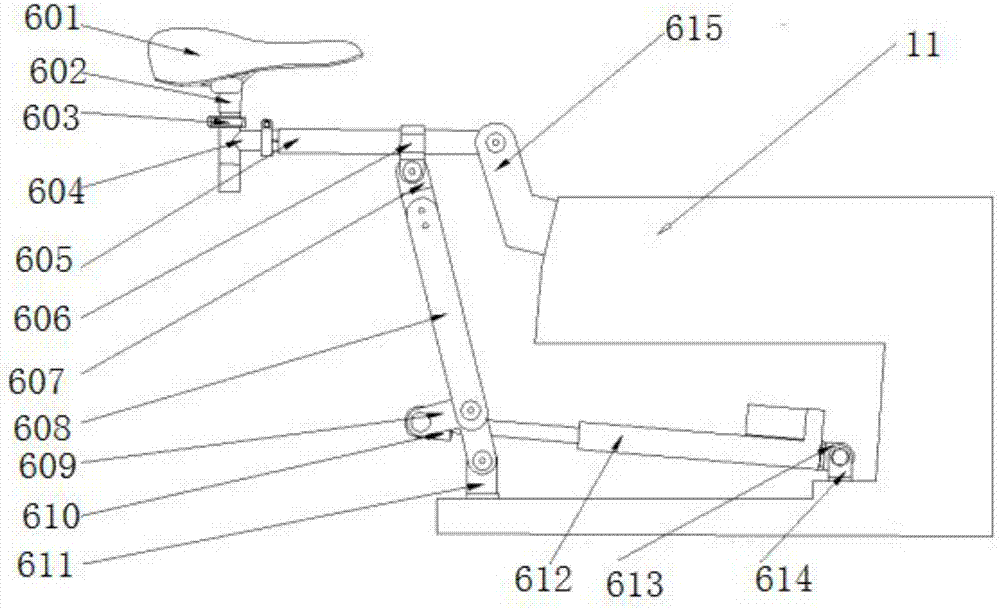

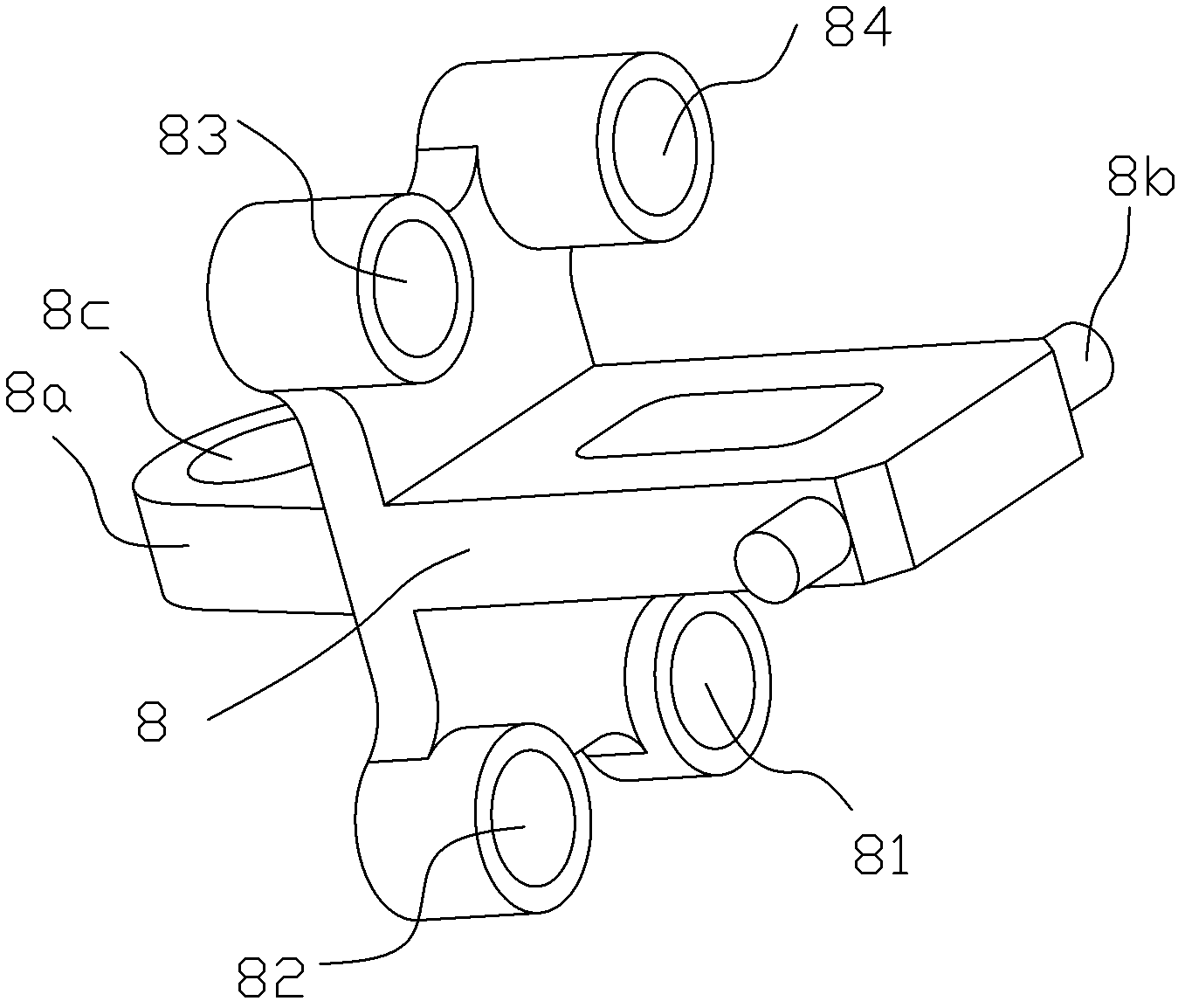

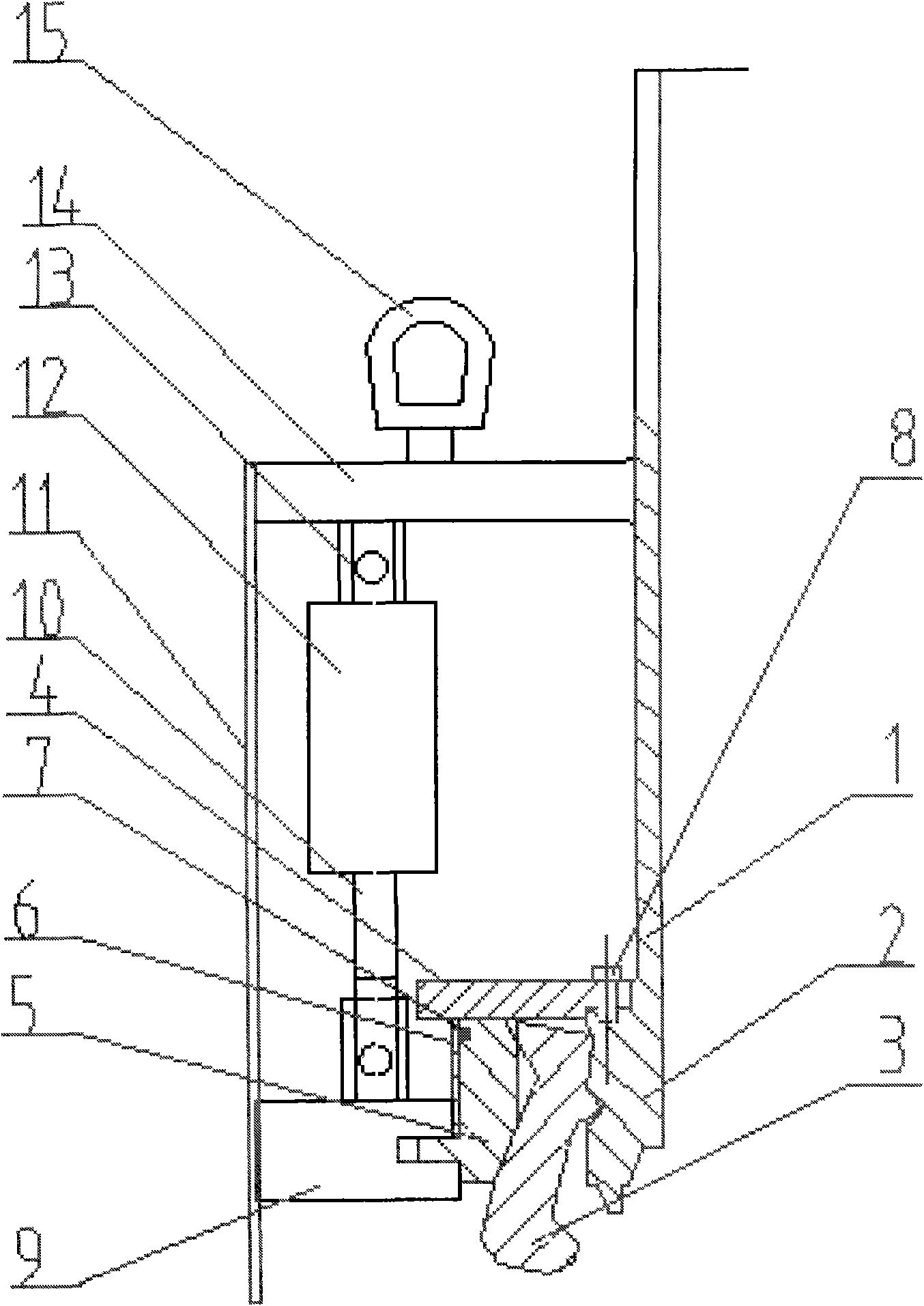

Transfer carrying and nursing robot

ActiveCN106983619AEasy to operateSmooth operation and labor-savingNursing bedsManipulatorEngineeringAbutment

The invention relates to a transfer carrying and nursing robot. The robot is characterized by comprising a handrail, a lifting seat mechanism, a foot treadle mechanism, a turnover prevention mechanism, a robot body, guide trundles, a body support connecting rod, a body rotary connecting rod, a chest relying part, rigid support parts and encircling parts; the rear part of the robot body is internally provided with the body support connecting rod, the upper portion of the body support connecting rod is hinged to one end of the body rotary connecting rod, the body rotary connecting rod extends out of the exterior of the robot body, the other end of the body rotary connecting rod is hinged to the back face of the chest relying part, and the chest relying part, the body support connecting rod and the body rotary connecting rod jointly constitute a three-connecting-rod structure; the upper ends of the left and right sides of the chest relying part are provided with the rigid support parts symmetrically; the upper portion of the back face of the chest relying part is provided with the handrail; the middle lower parts of the left and right sides of the chest relying part are provided with the encircling parts symmetrically, and the encircling parts are in symmetric working states, and have closing and opening states in the working process.

Owner:HEBEI UNIV OF TECH

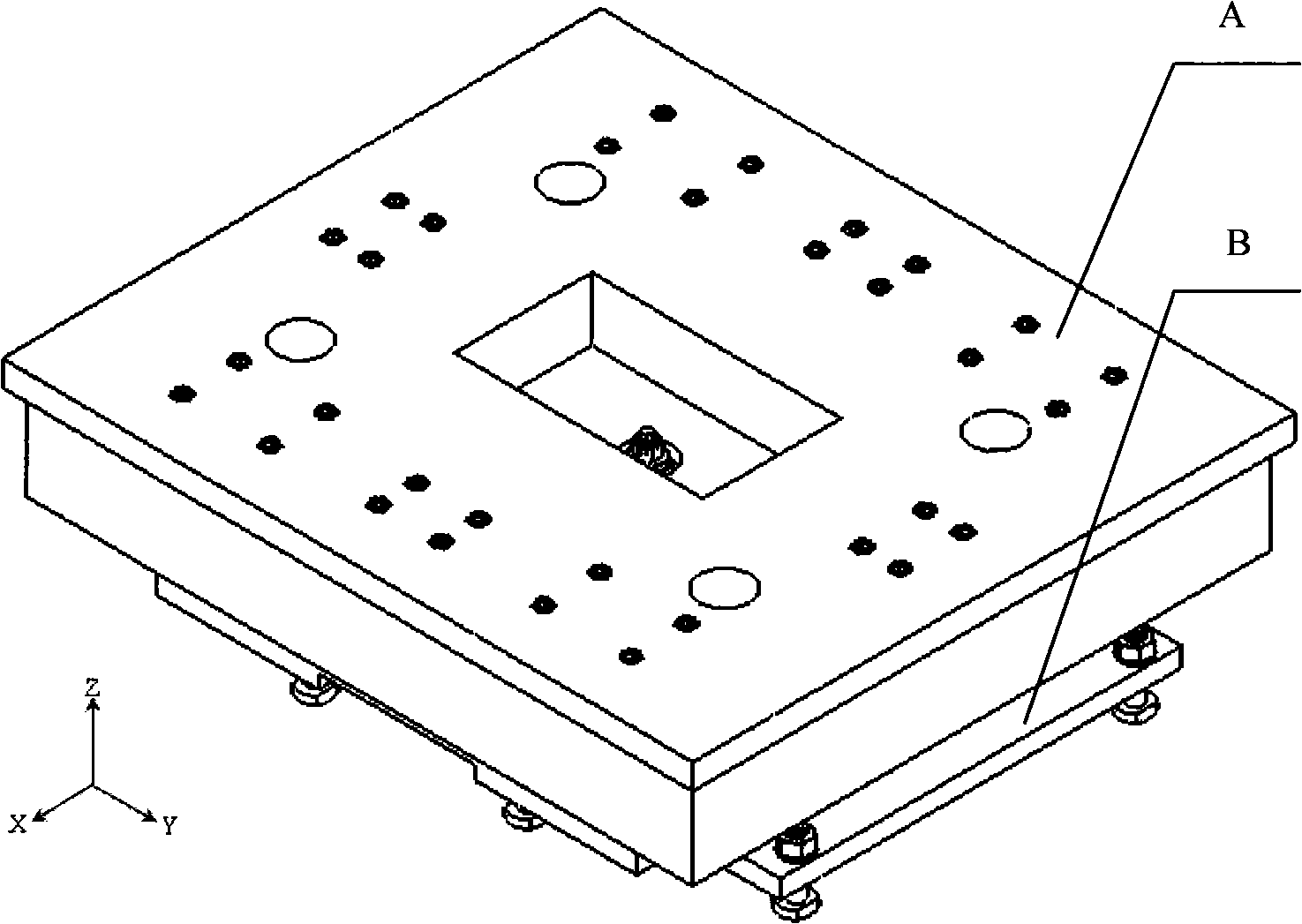

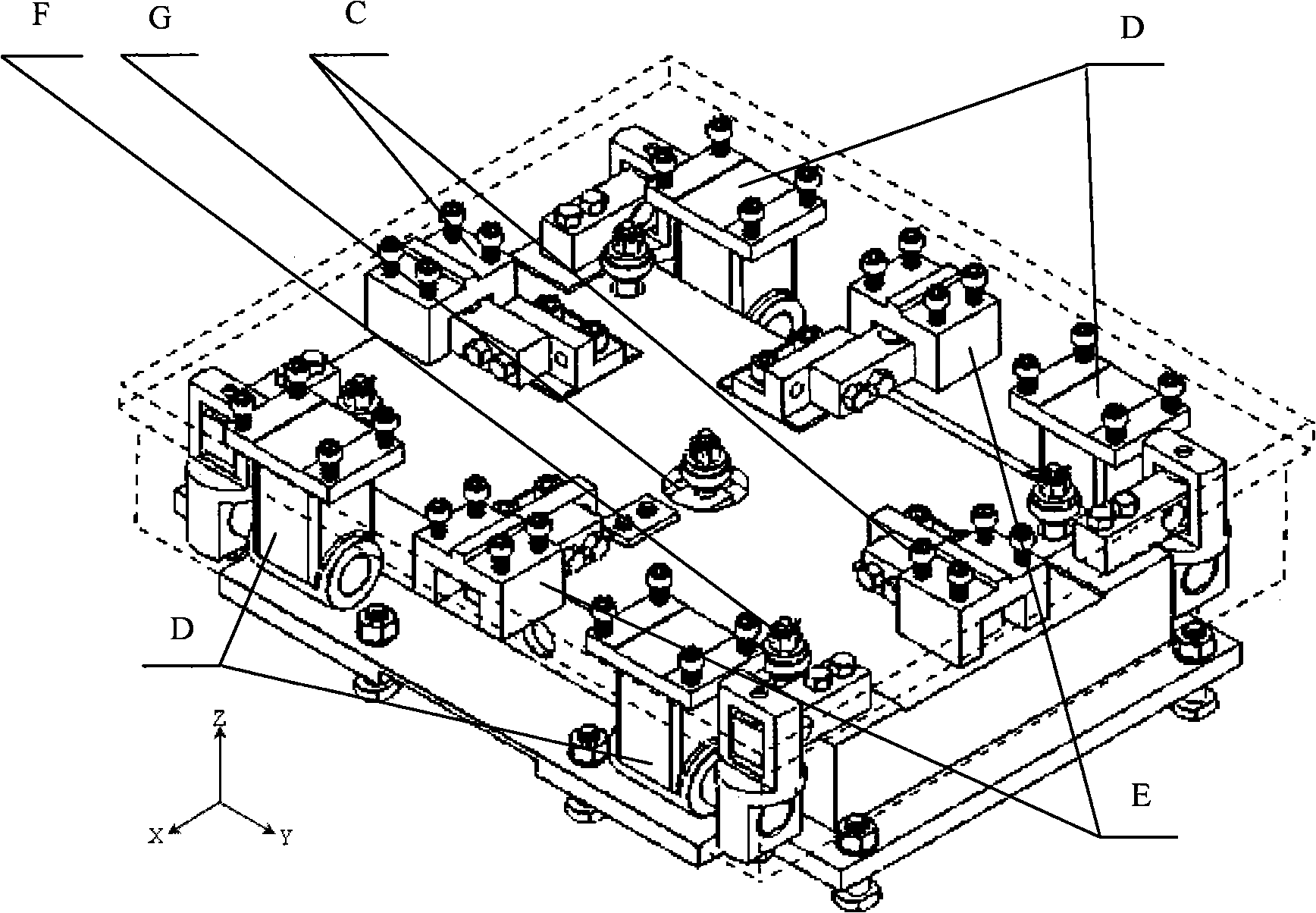

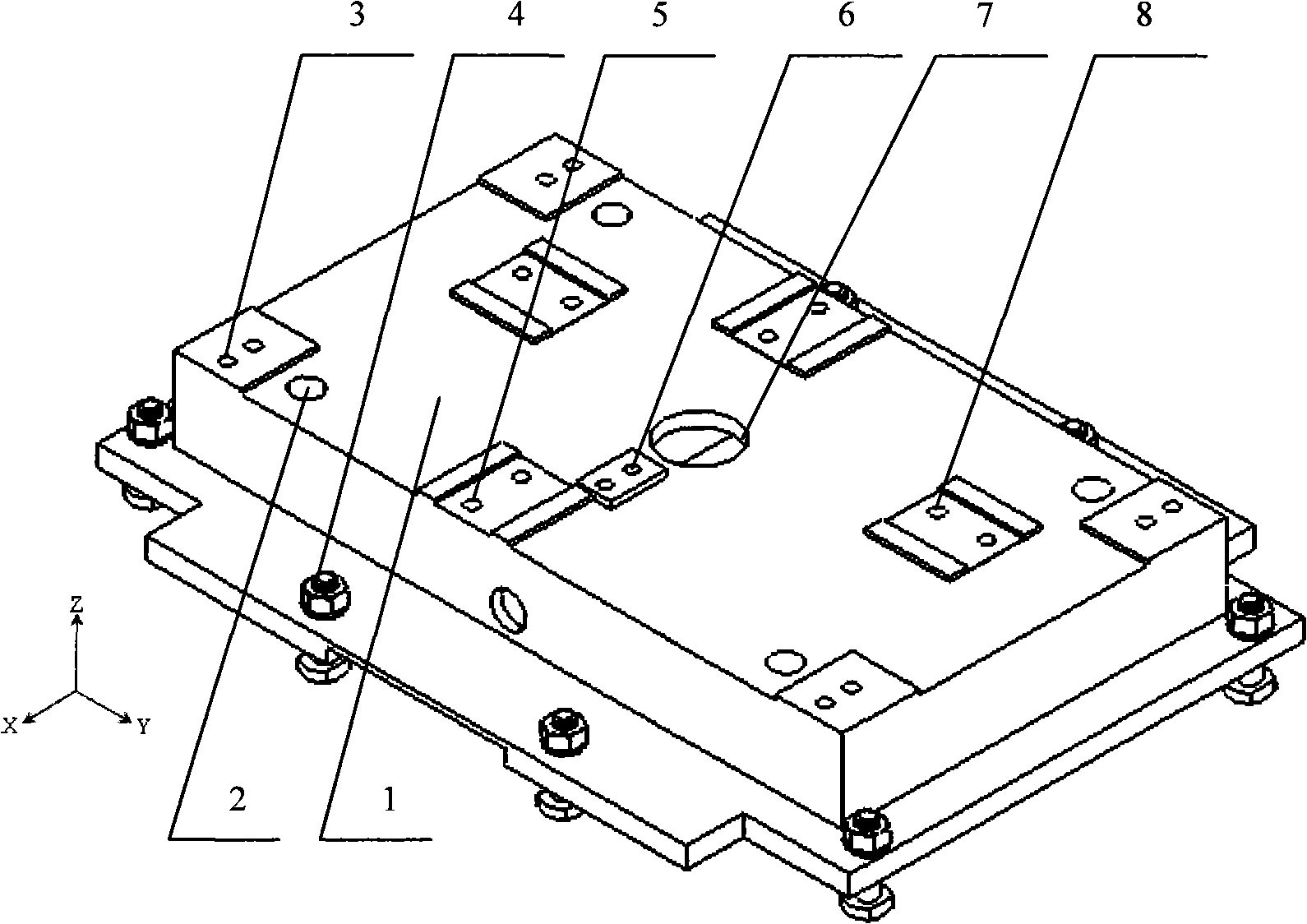

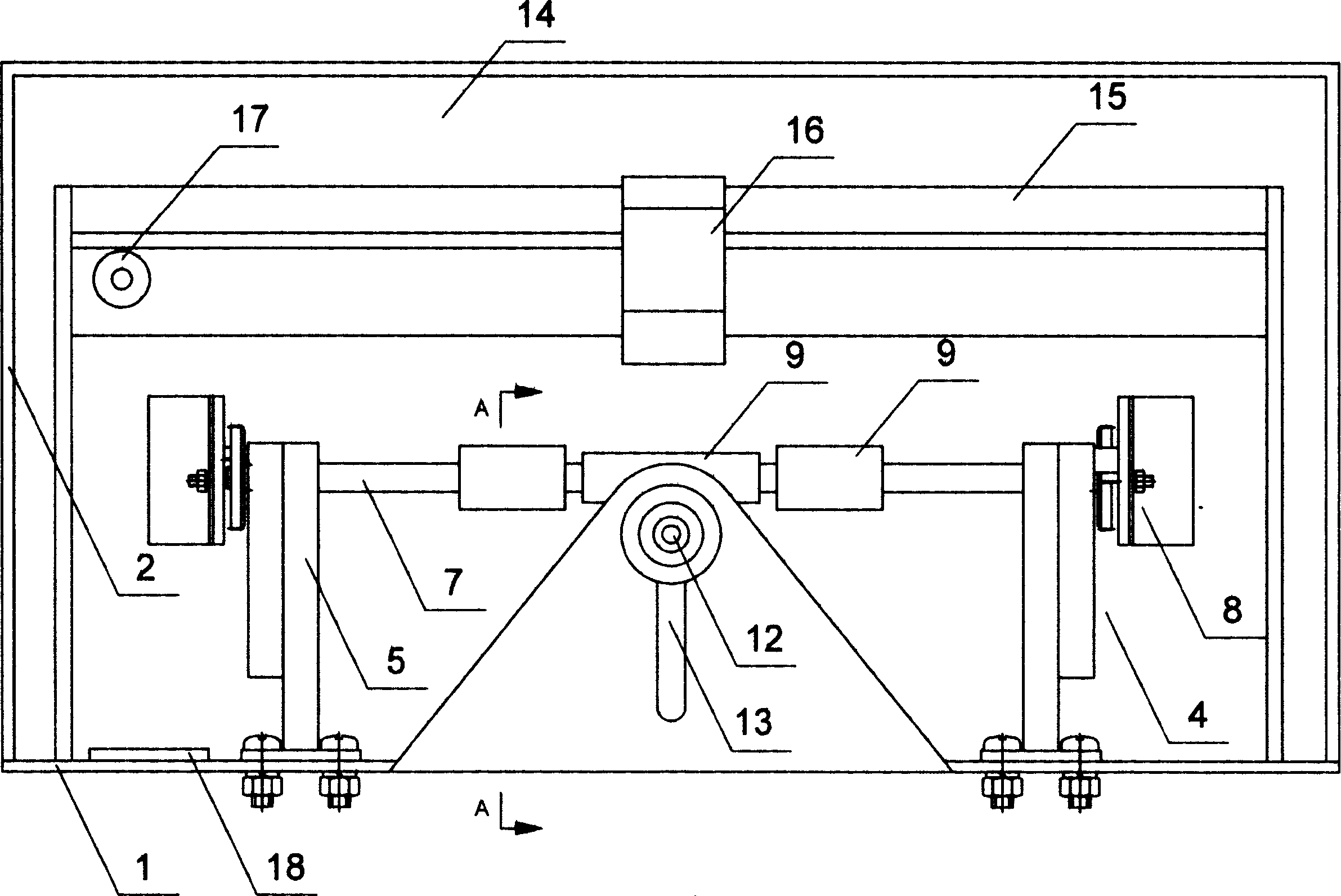

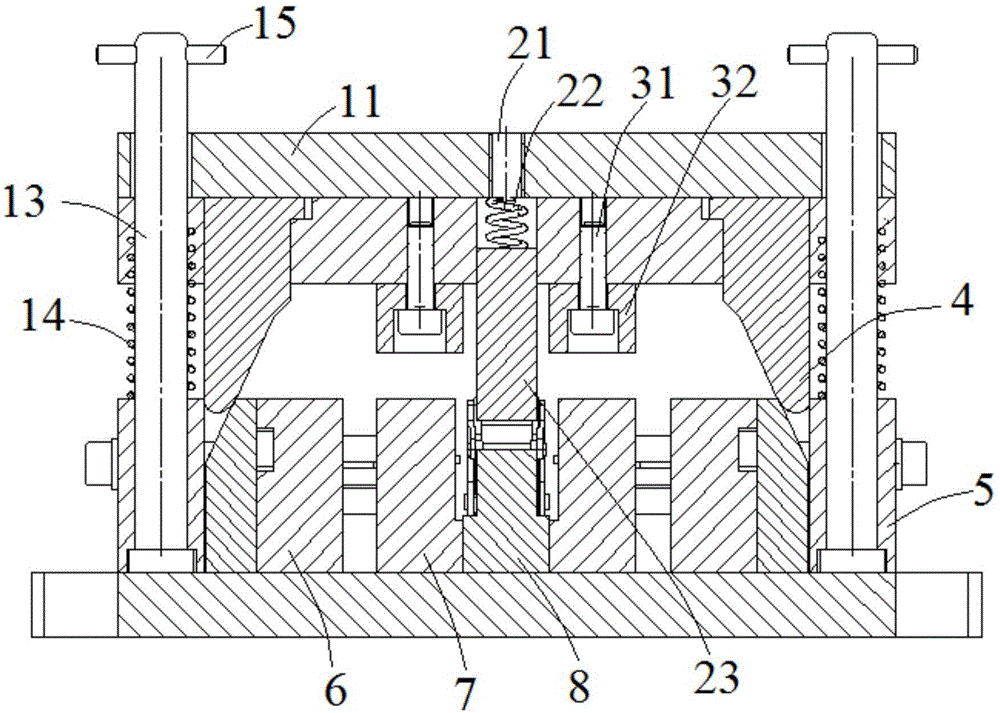

Combined three-dimensional force and moment test board integrated device

InactiveCN101526406AGuaranteed accuracySmart structureForce measurementWork measurementHorizontal forceBogie

The invention relates to railway vehicle bogie parameter detection equipment; aiming at the technical status that dynamic performance can not be fully and accurately evaluated in the existing railway vehicle bogie parameter detection, the invention provides a combined three-dimensional force and moment test board integrated device; the device comprises a horizontal force-testing sensor (C) and a longitudinal force-testing sensor (E) which are respectively composed of two shear beam sensors (16) and a supporting part, and each two shear beam sensors (16) are respectively arranged on a bearing board symmetrically along the X and Y directions by a supporting part I; four shear beam sensors (16) which are vertical to a force-testing sensor mechanism (D) are respectively arranged at the four comers of the bearing board along the Z direction by a supporting part II, and an overturning moment testing mechanism (G) and an anti-overturning bolt mechanism (F) are arranged on the bearing board; the bearing board comprises a bearing cover board (A) and a bearing bottom plate (B) which are connected into one body by the anti-overturning bolt mechanism (F).

Owner:JILIN UNIV

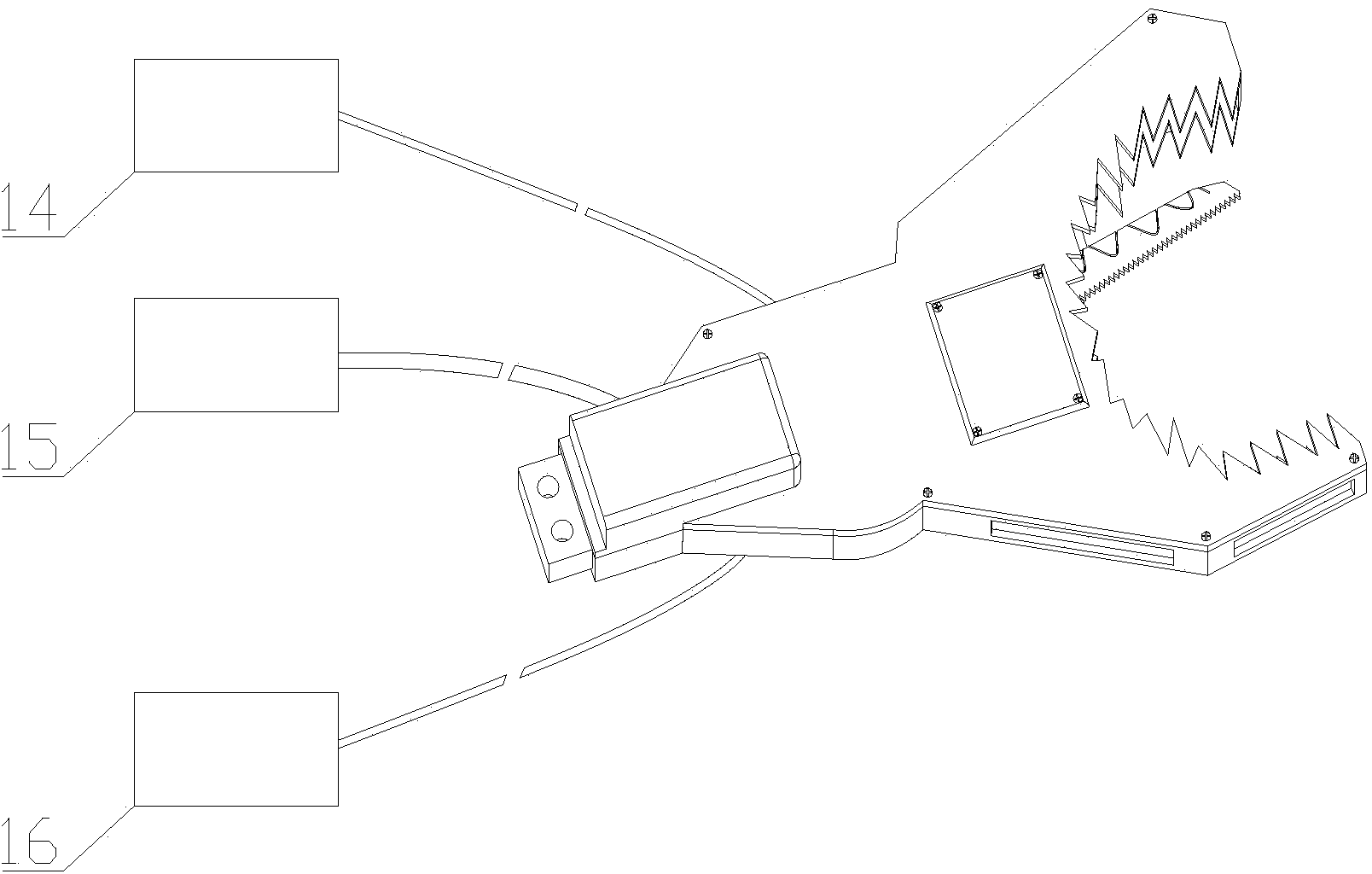

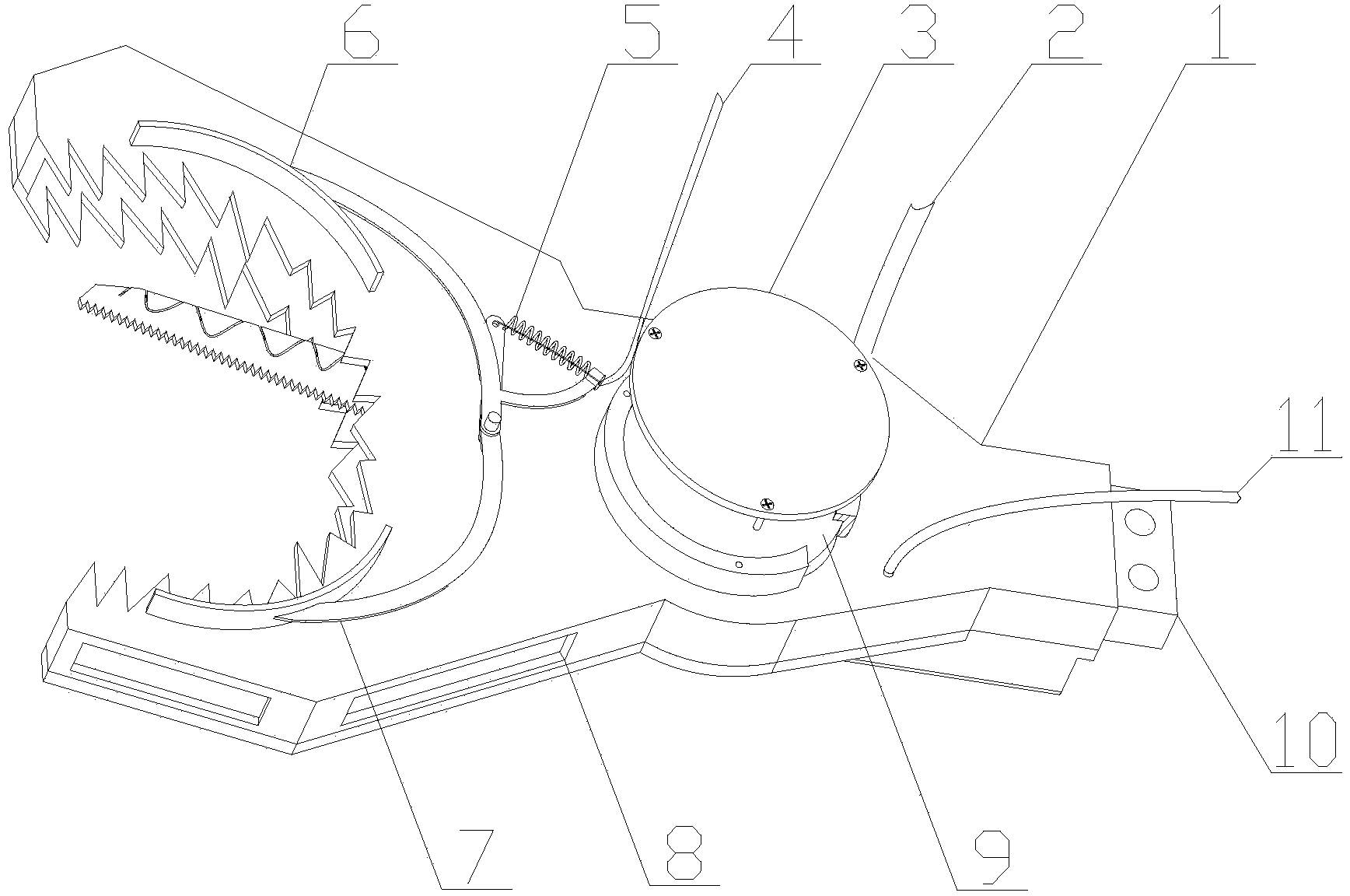

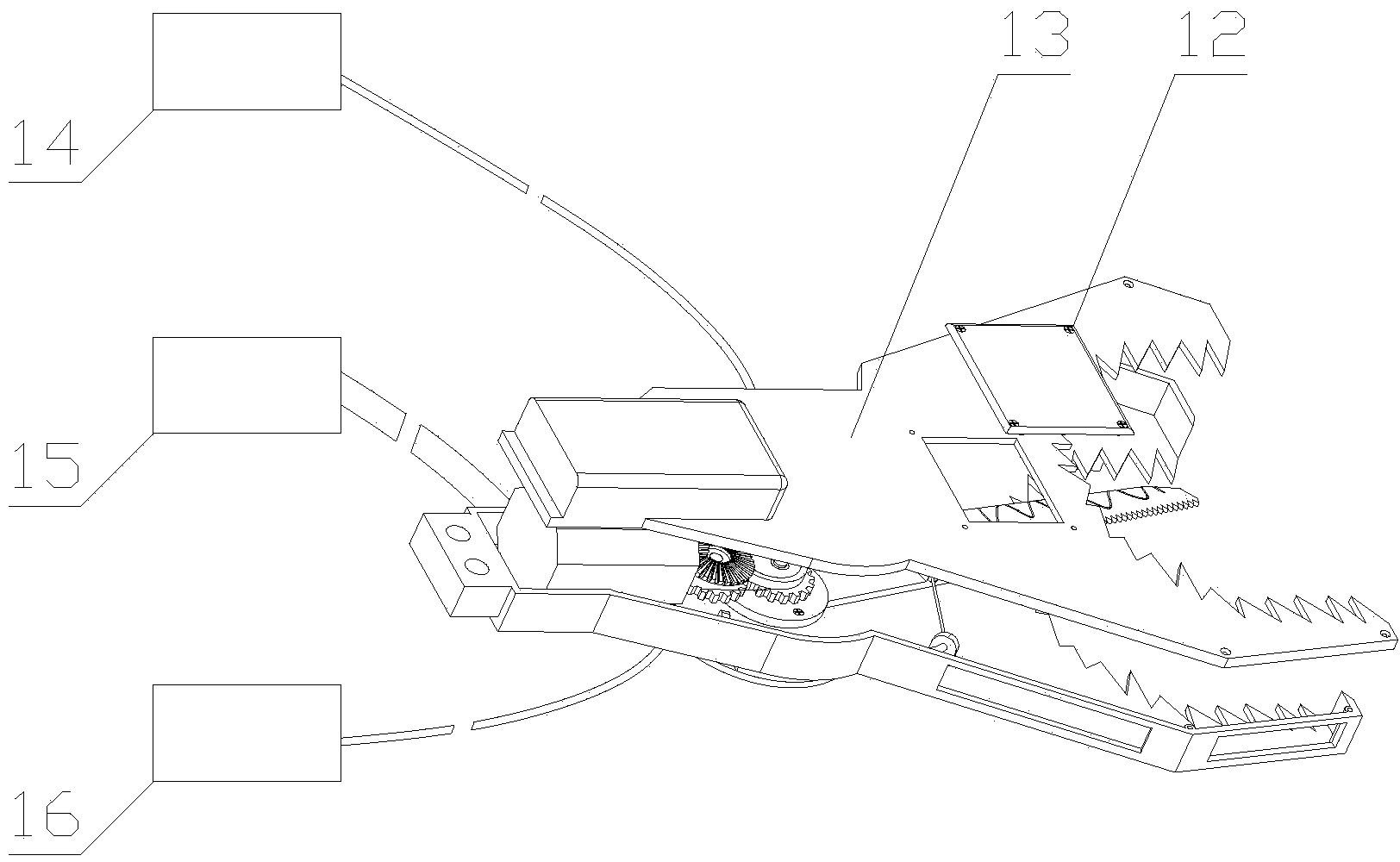

Guide clamping lock type high branch pruning and stubble protecting saw

InactiveCN103798063AAvoid infectionPromote stable and high yieldCuttersCutting implementsSprayerPruning

The invention relates to a guide clamping lock type high branch pruning and stubble protecting saw which comprises a shell mechanism, a clamping mechanism, a pruning mechanism and a stubble maintaining mechanism, wherein the shell mechanism comprises a main shell, a bearing overhaul cover, an auxiliary shell and a saw blade overhaul cover; the clamping mechanism comprises a first clamping jaw, a second clamping jaw, a clamping spring, a clamping brake cable and a clamping push rod; the pruning mechanism comprises a motor, a bevel gear, a coaxial gear, a guide plate, a bearing, an eccentric wheel, a cylindrical gear, a connecting rod, a sliding block, a pesticide storage saw blade, a pruning brake cable, a pruning push rod and a guide plate spring; the stubble maintaining mechanism comprises a sector-shaped sprayer, a pesticide conveying pipe and a pesticide liquid box. The guide clamping lock type high branch pruning and stubble protecting saw can carry out stubble maintaining while pruning according to agricultural requirements of branch pruning and stubble maintaining, prevent the stubbles from being infected by viruses, guarantee stable and high yield of high-yield plantations, and promote sustainable development of forestry.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

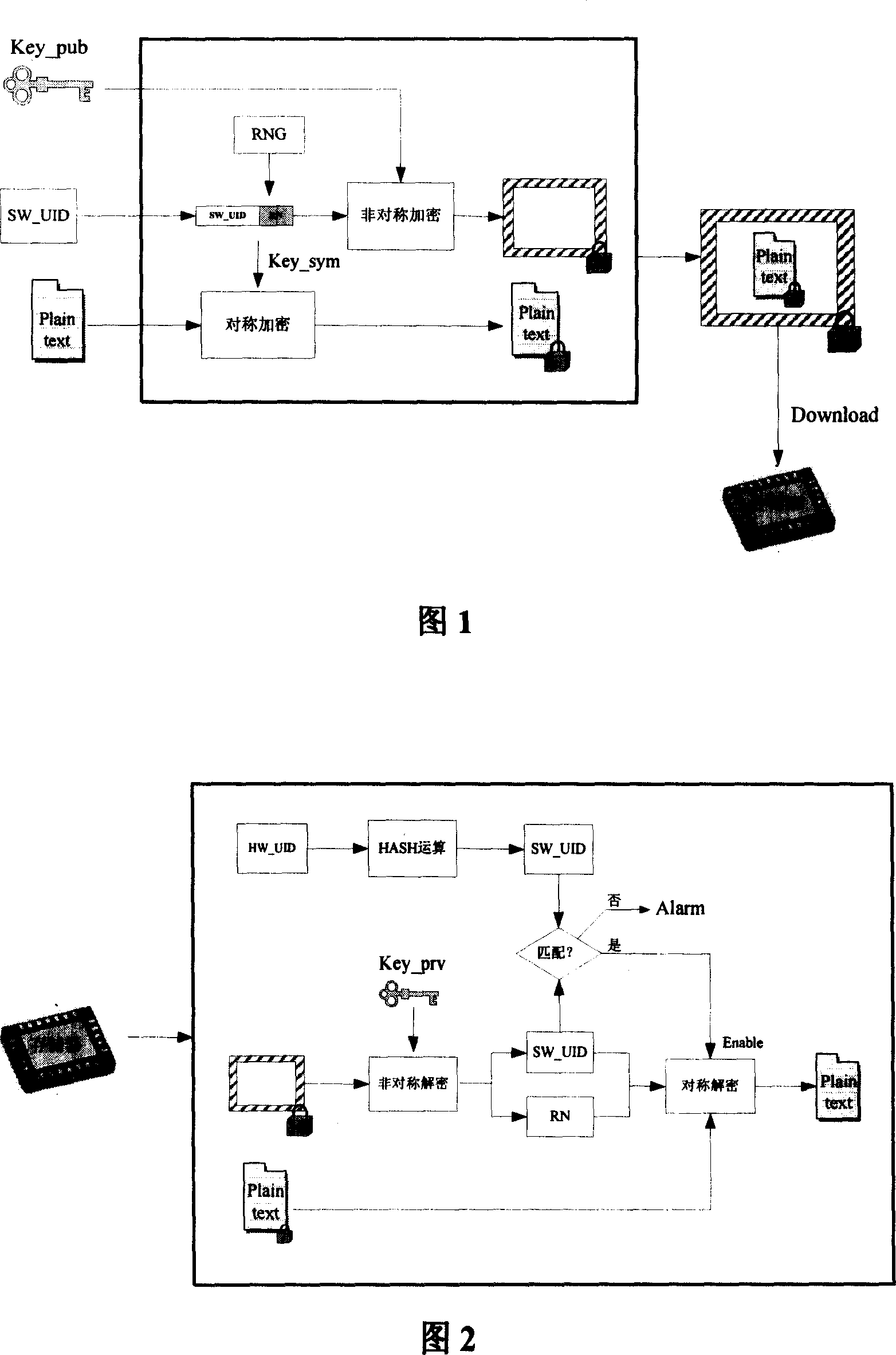

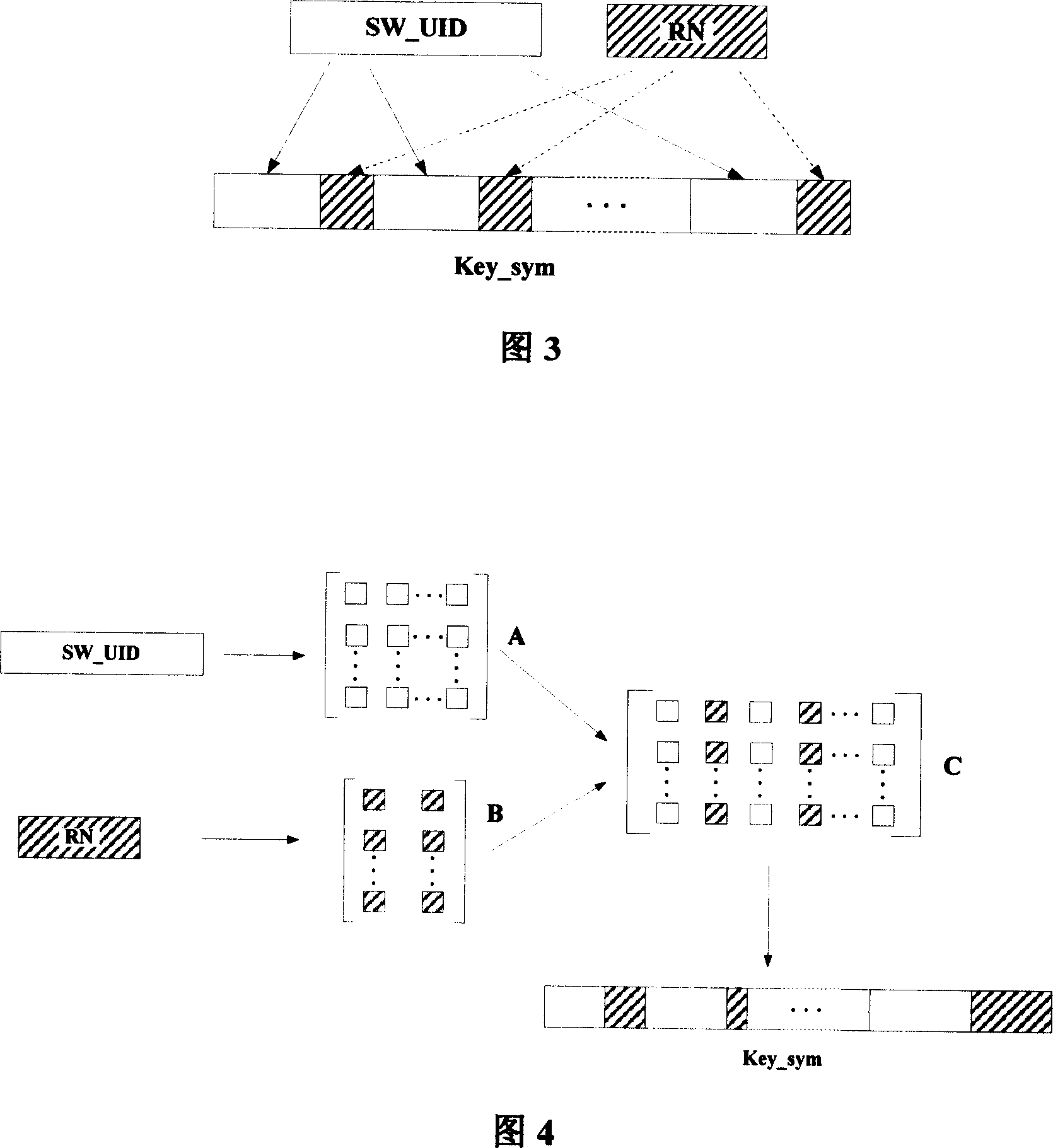

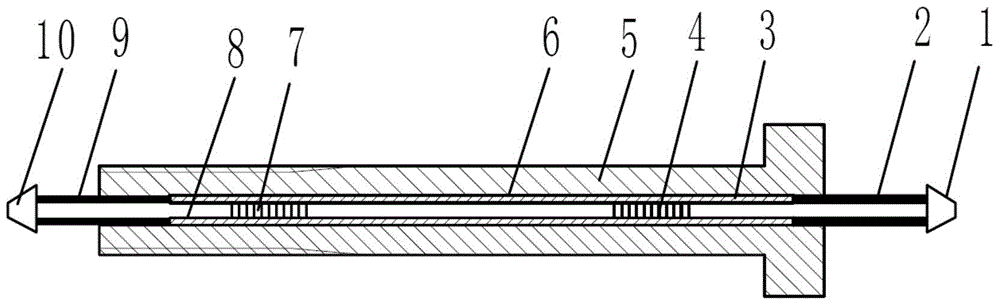

Special processor software encryption and decryption method

ActiveCN101149768AAvoid breakingFunction increaseProgram/content distribution protectionHash functionNumber generator

This invention relates to encryption and decryption method of software of dedicated processors, especially encryption and decryption process for the phone, PDA, and other intelligent terminal software. The encryption process is: random generate number RN by random number generator RNG; RN and the only one software serial number SW_UID constitute symmetric key system, encrypt software Plaintext through symmetric encryption algorithm; thereinto, the SW_UID was transformed through hash function from the only serial number HW_UID which represent the identity of slug and saved in the special processor; the public Key_pub encrypt Key_sym through asymmetry encryption algorithm; encrypted Plaintext and Key_sym were put together and downloaded to memory. In addition, it also provides a decryption method to the above encryption method. The method by this invention use certain transformation of hardware serial numbers of dedicated processor to achieve the encryption to special software, enhanced security of processor software and its own hardware equipment.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

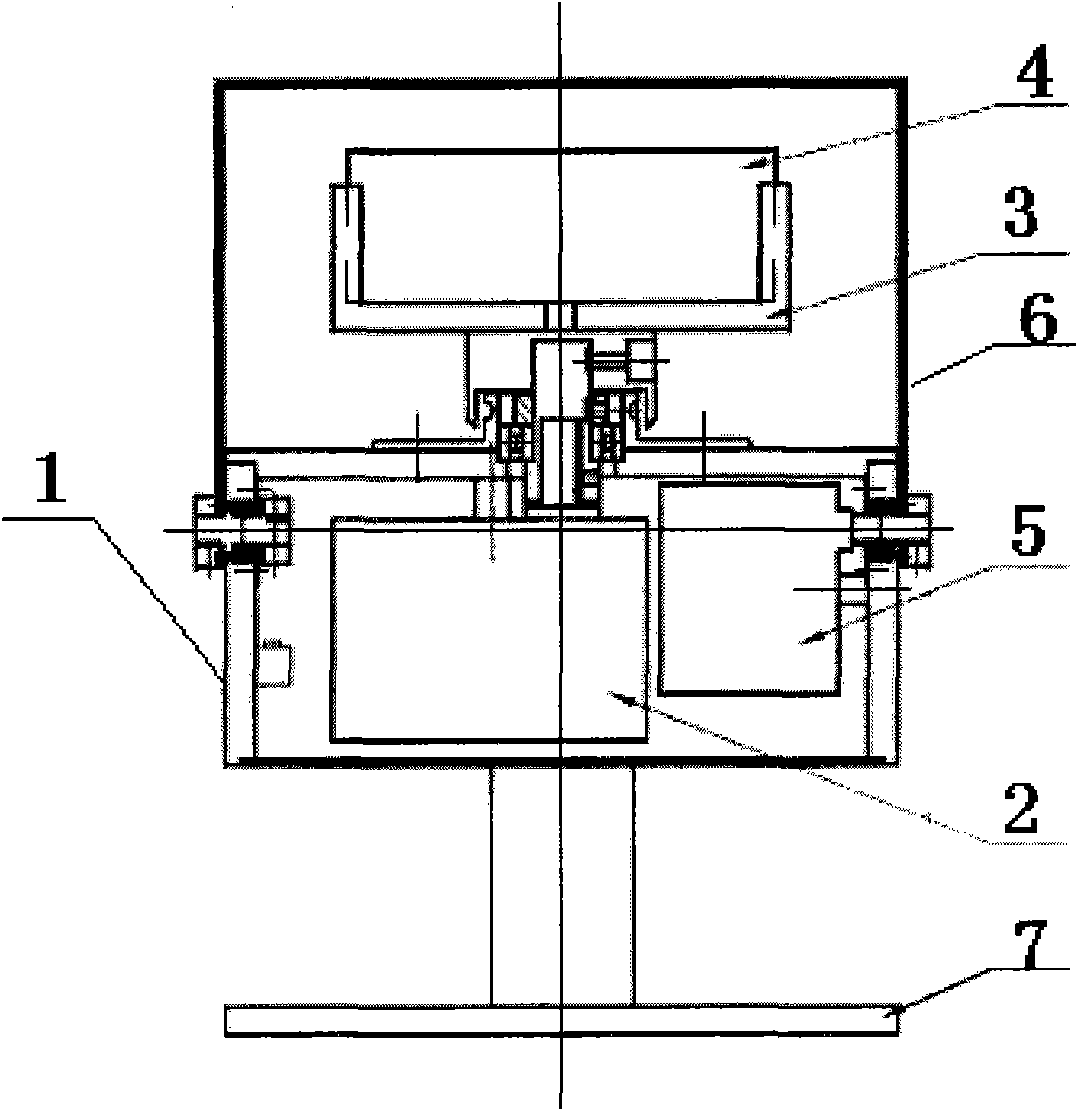

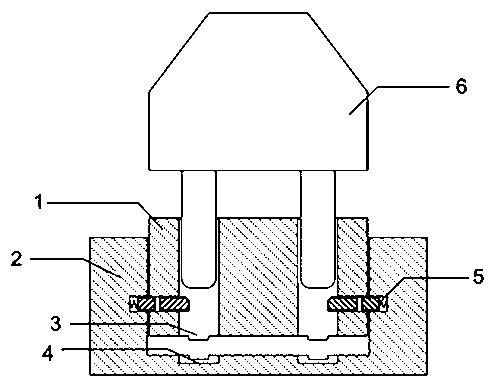

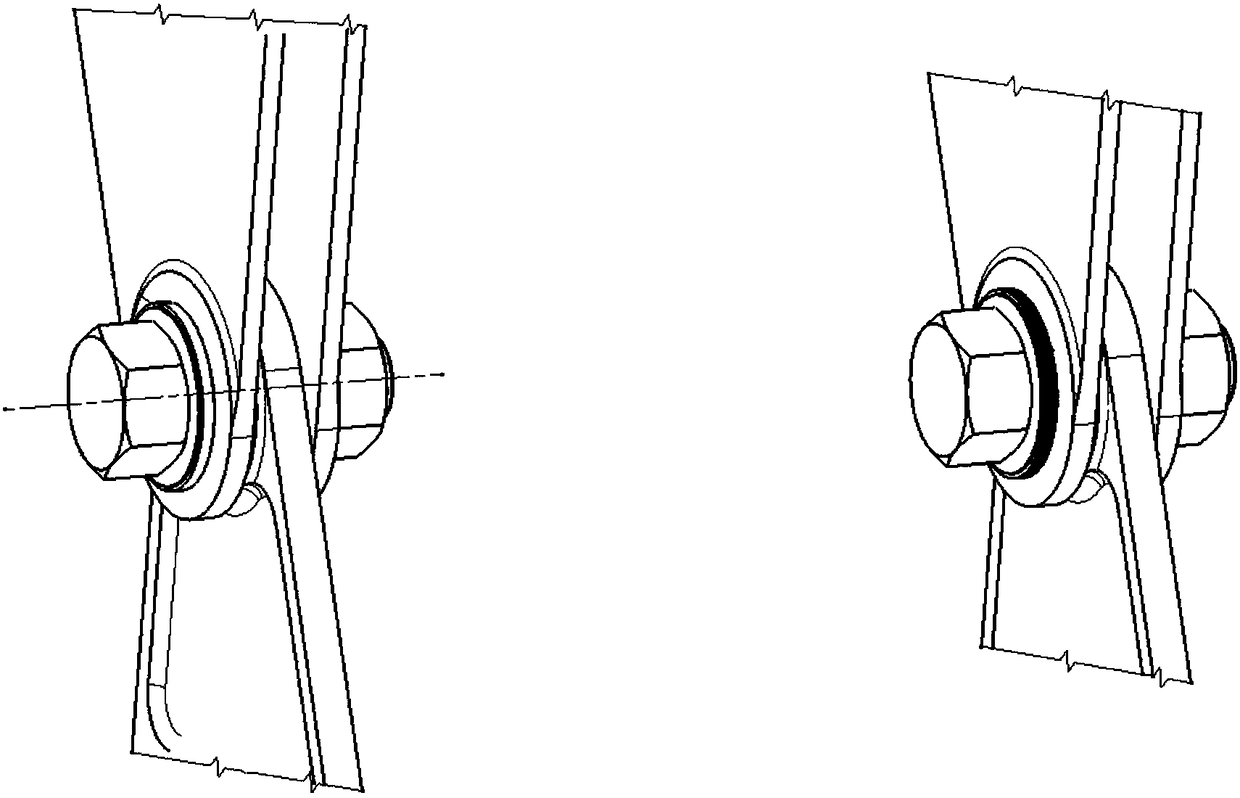

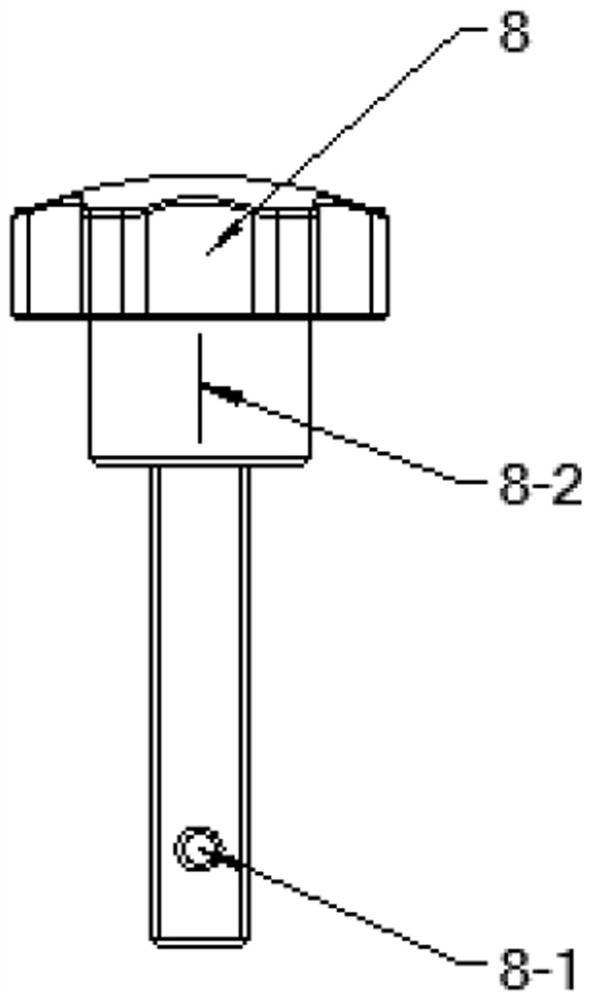

Optical fiber Bragg grating sensing principle-based temperature-self-compensating intelligent bolt

InactiveCN104567998AEnables strain monitoringInhibit sheddingConverting sensor output opticallyGratingAdhesive

The invention relates to an optical fiber Bragg grating sensing principle-based temperature-self-compensating intelligent bolt, and belongs to the field of optical fiber sensing and structure health monitoring. The optical fiber Bragg grating sensing principle-based temperature-self-compensating intelligent bolt comprises a bolt body 5, an optical fiber 8, a first optical fiber Bragg grating sensor 4 and a second optical Bragg grating sensor 7, wherein the first optical fiber Bragg grating sensor 4 and the second optical Bragg grating sensor 7 are formed in the same optical fiber 8 by carving; the first optical fiber Bragg grating sensor 4 senses temperature and strain; the second optical Bragg grating sensor 7 senses the temperature; an axial sensor implanting hole 6 which penetrates through the bolt body 5 is formed in the bolt body; the optical fiber 8 penetrates through the sensor implanting hole 6; the first optical fiber Bragg grating sensor 4 and the second optical Bragg grating sensor 7 are positioned in the sensor implanting hole 6; a packaging adhesive is injected into the sensor implanting hole 6 to package the first optical fiber Bragg grating sensor 4 in the sensor implanting hole 6; heat-conducting silicone grease is injected into the sensor implanting hole 6 to package the second optical Bragg grating sensor 7. According to the temperature-compensating intelligent bolt, the strain of the bolt in a working state can be monitored online in real time.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

Pollen collector

InactiveCN101806676AEfficient collectionEasy to carryWithdrawing sample devicesPollenAgricultural engineering

The invention discloses a pollen collector, which comprises a machine box, a bearing speed reducing motor and a sampling bracket, wherein the bearing speed reducing motor is arranged in the machine box and provided with a bearing driving output shaft; the sampling bracket is arranged on the machine box. The bearing driving output shaft is vertical to the horizontal plane. The top end of the bearing driving output shaft penetrates through the upper end wall of the machine box and is connected with the sampling bracket. A vertical sampling sheet is fixedly connected to the sampling bracket. The invention can carry out both continuous long-term observation and sampling and intermittent sampling in a fixed time, and can carry out sampling in overcast and rainy days or shower days. The specially designed rotary protective closure can protect the sampling sheet, and also can ensure the accuracy of the collecting concentration and flux calculation. The invention has the advantages of simple structure, small volume and convenient carrying.

Owner:GRADUATE SCHOOL OF THE CHINESE ACAD OF SCI GSCAS +1

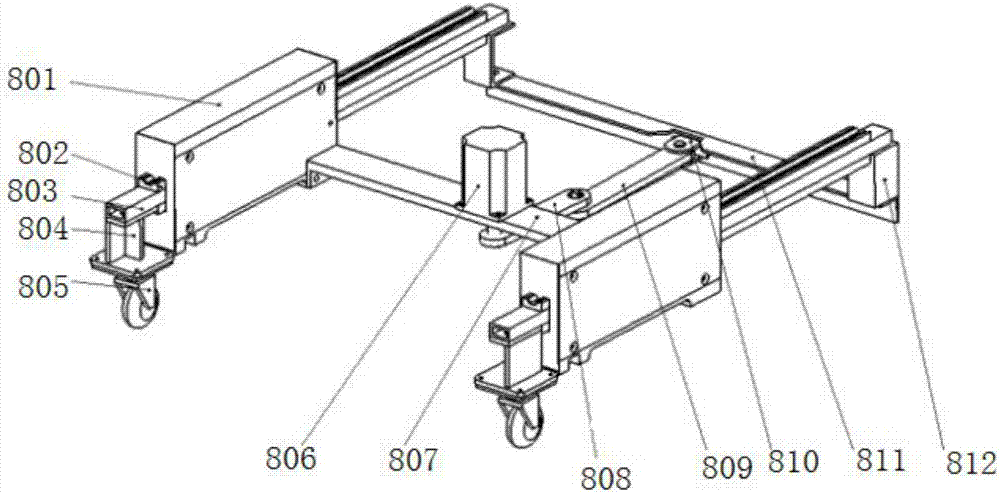

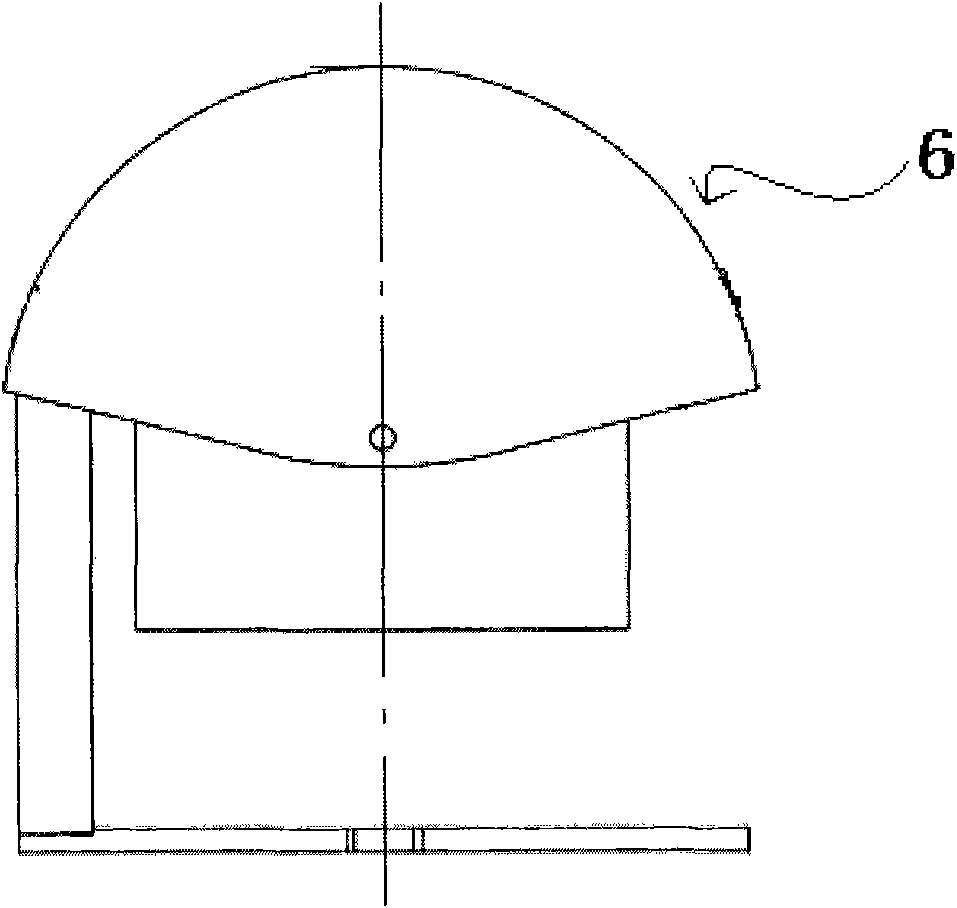

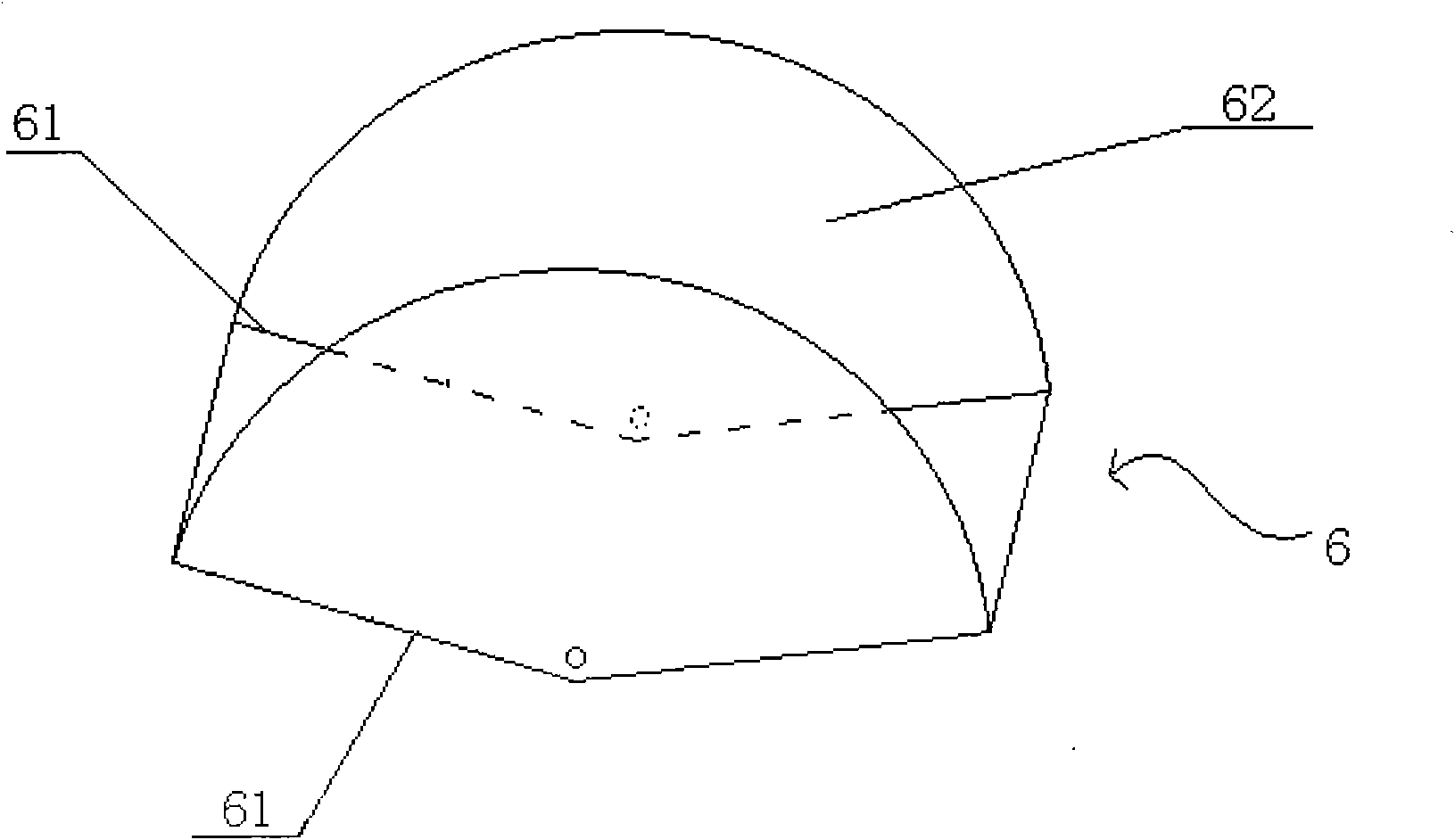

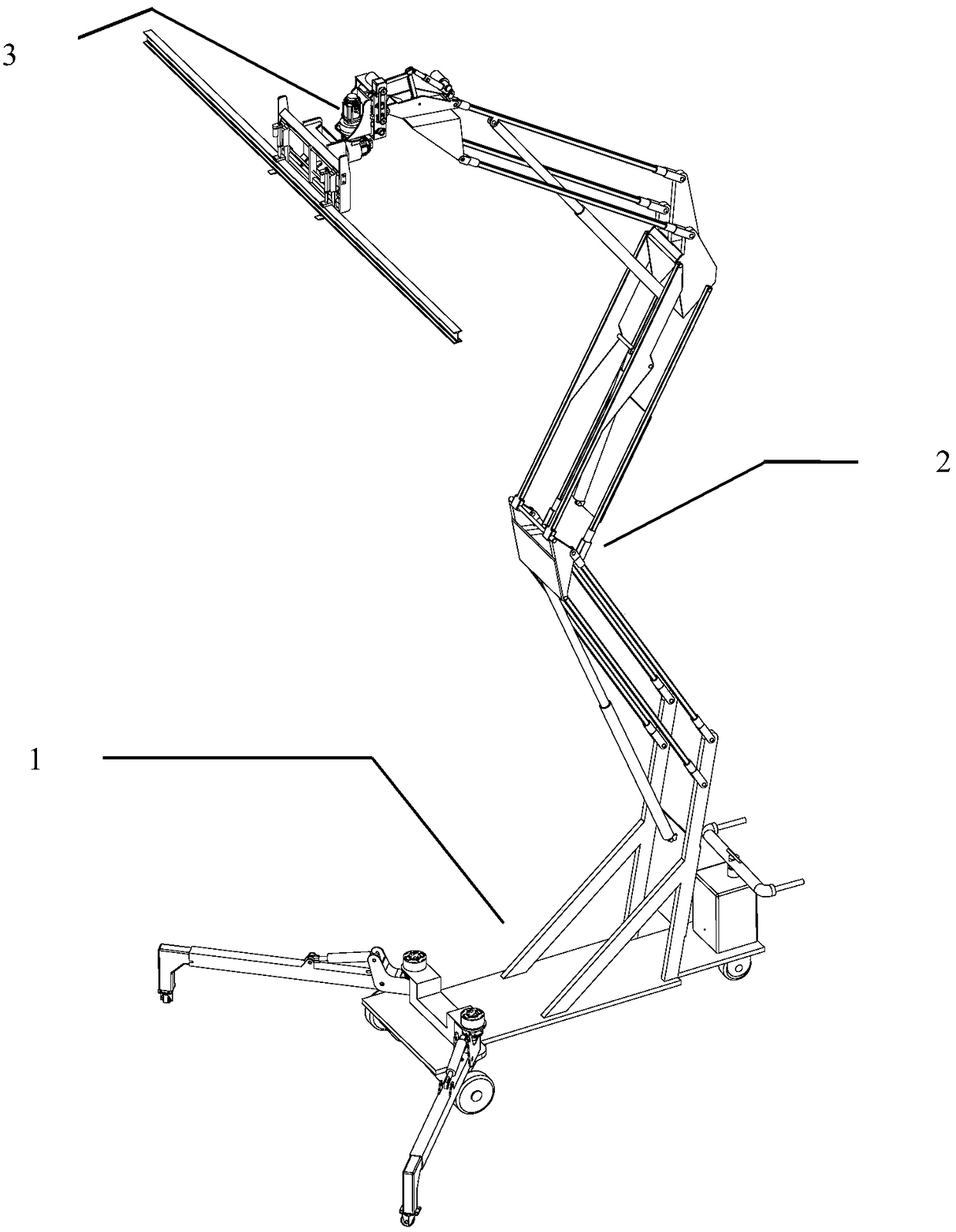

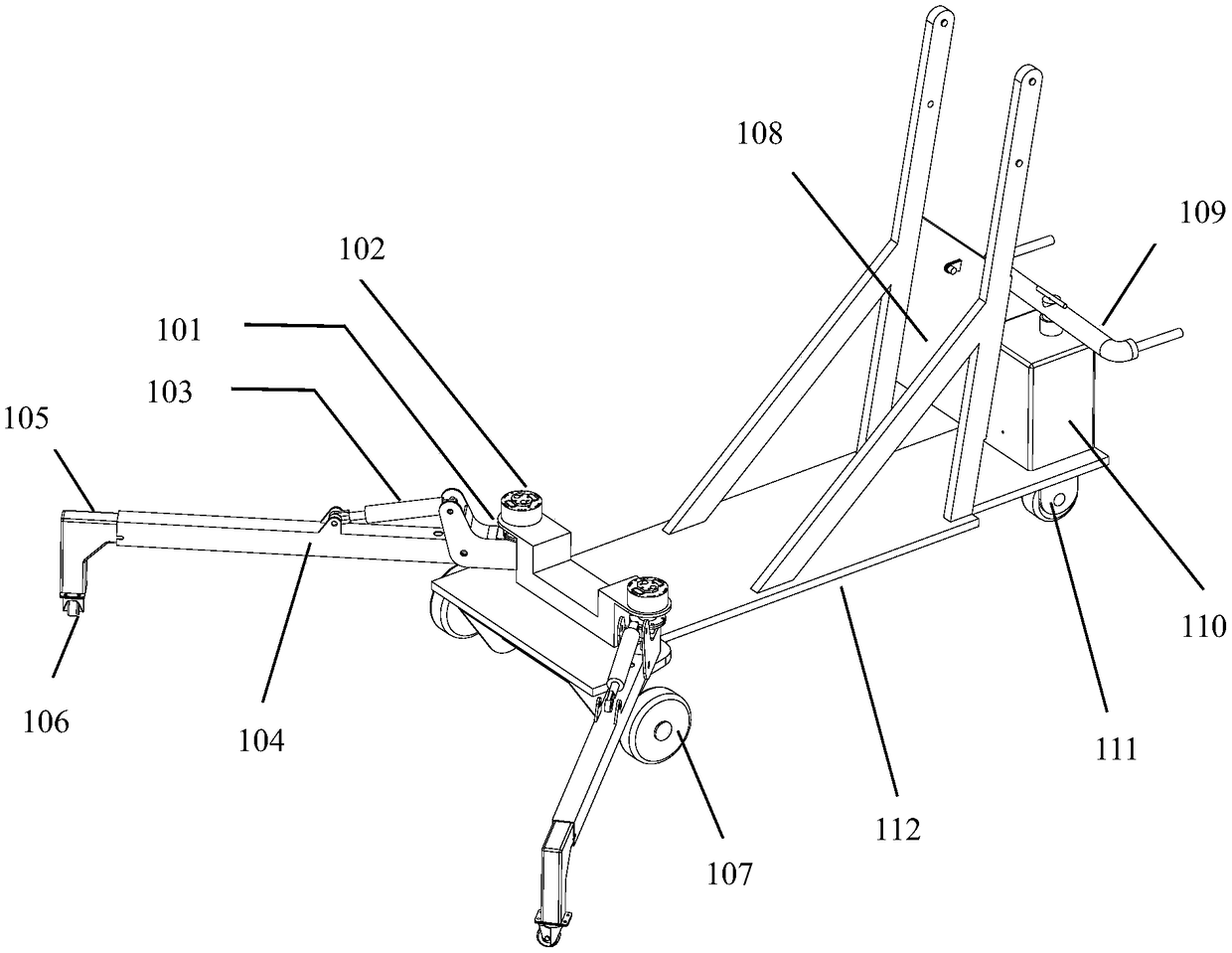

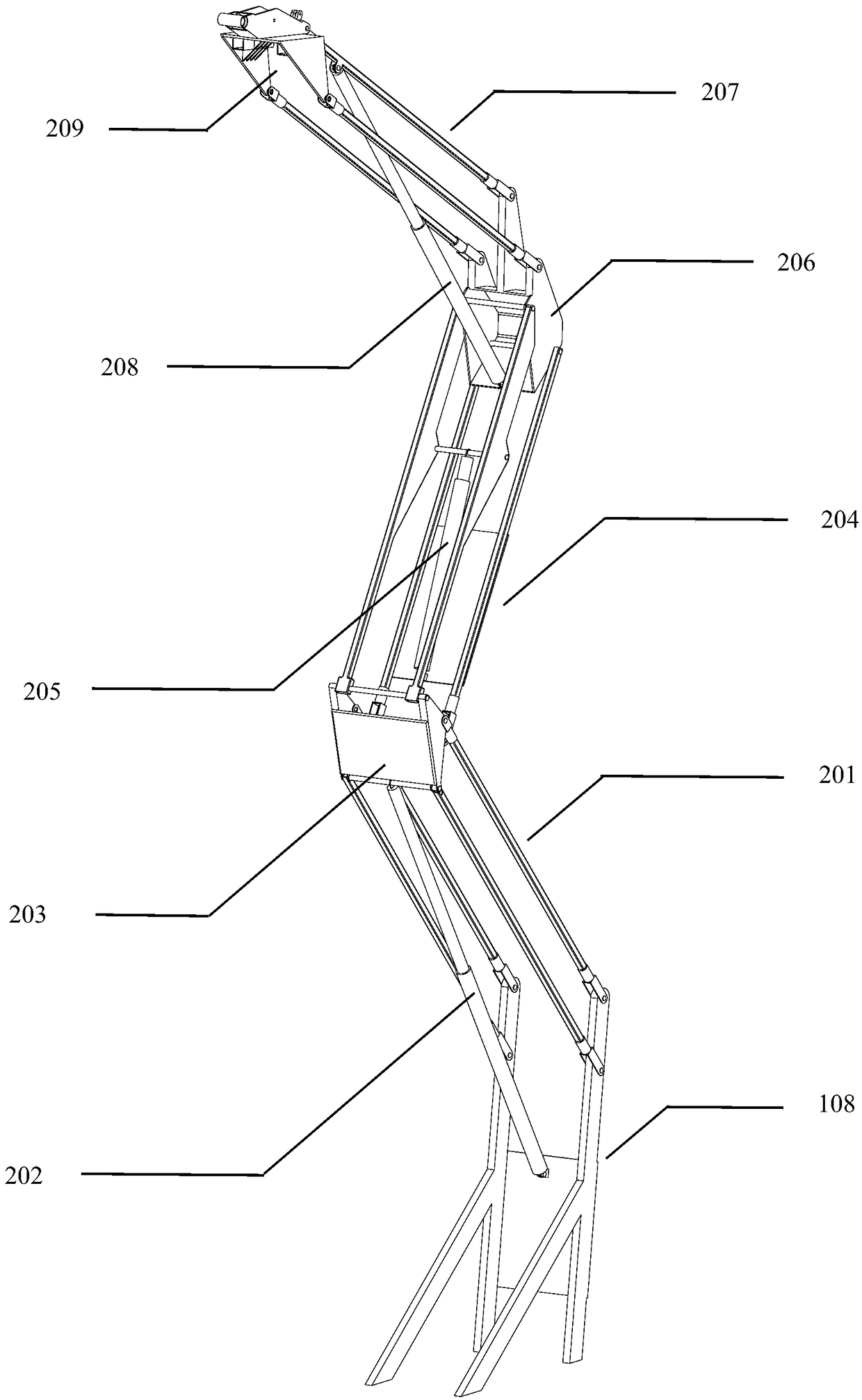

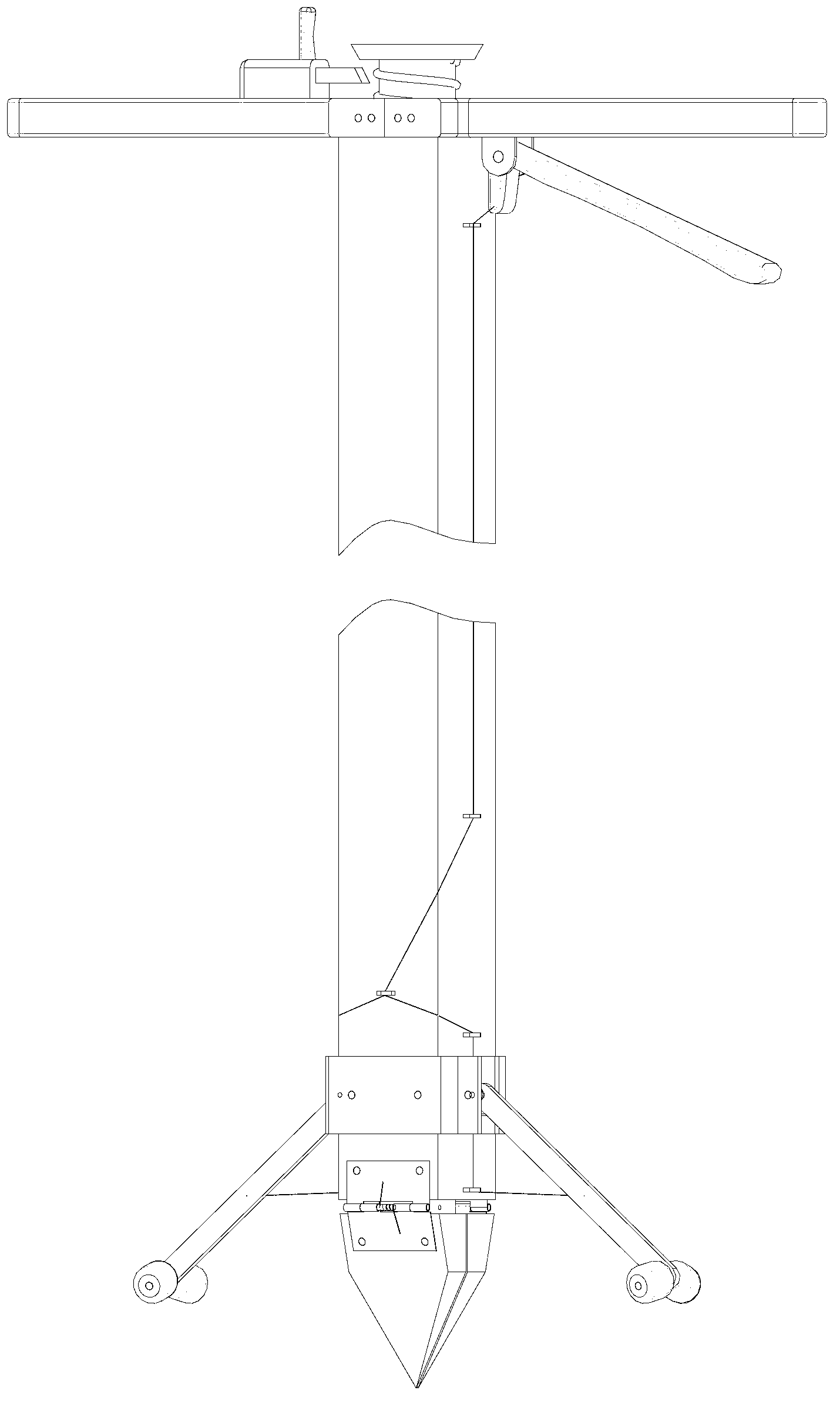

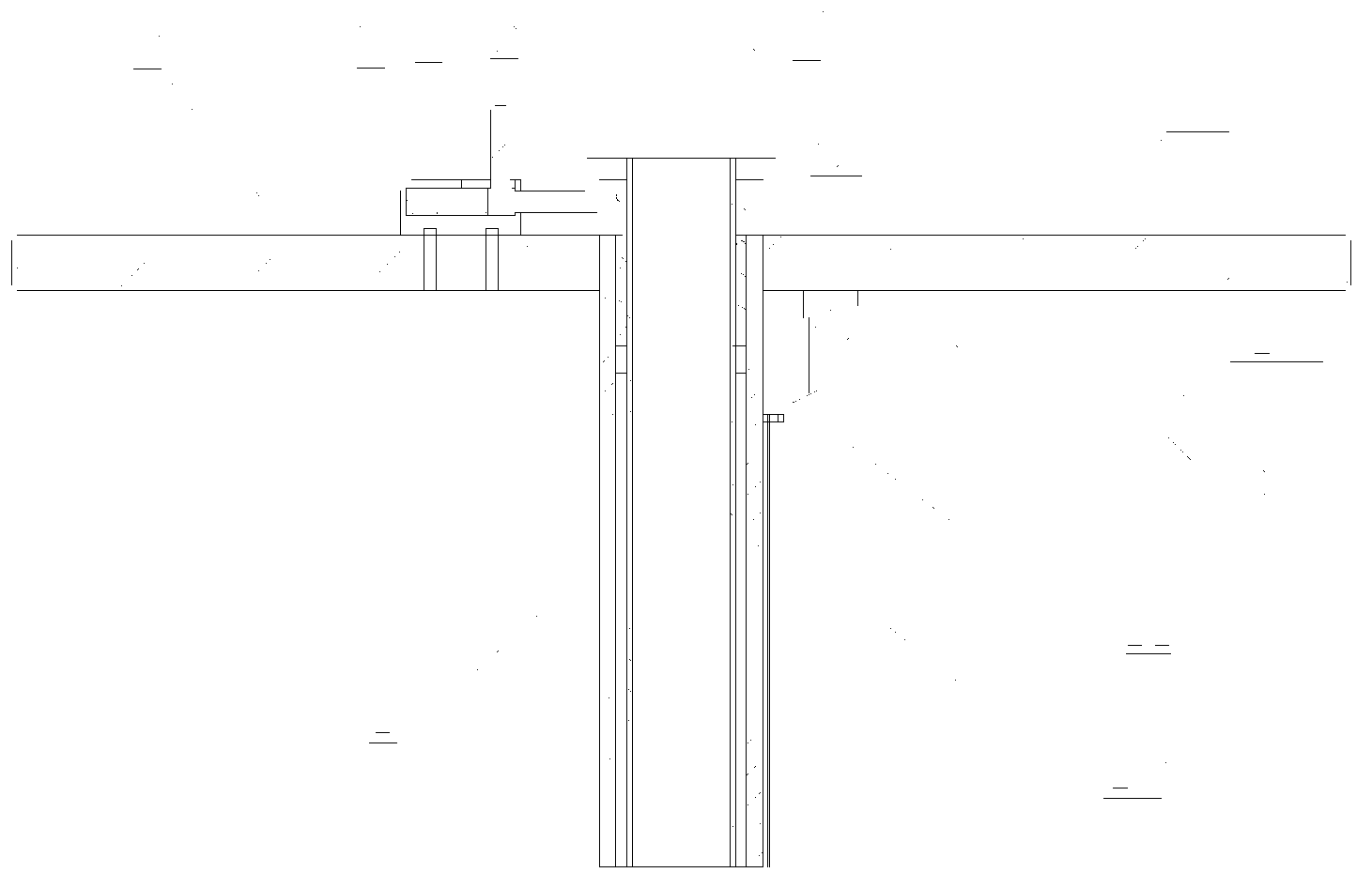

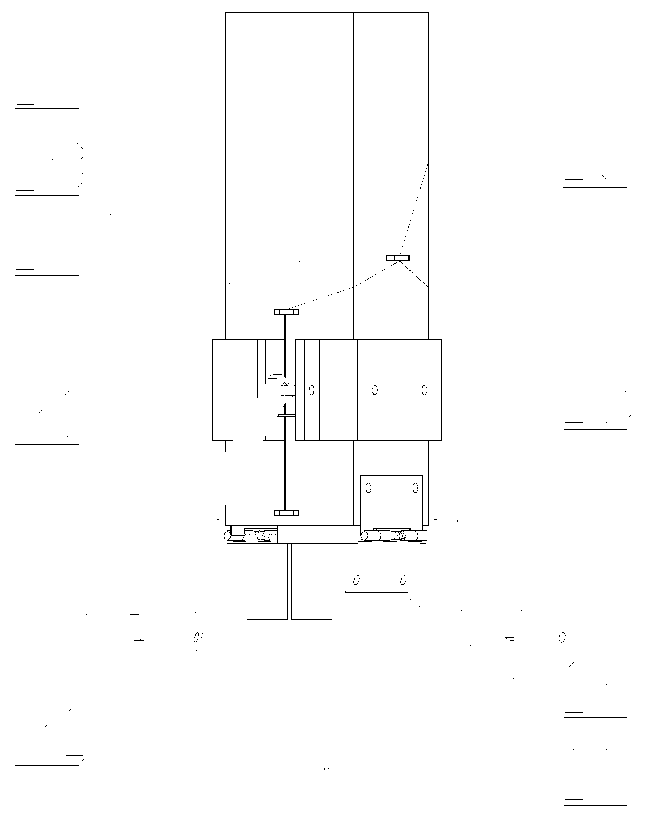

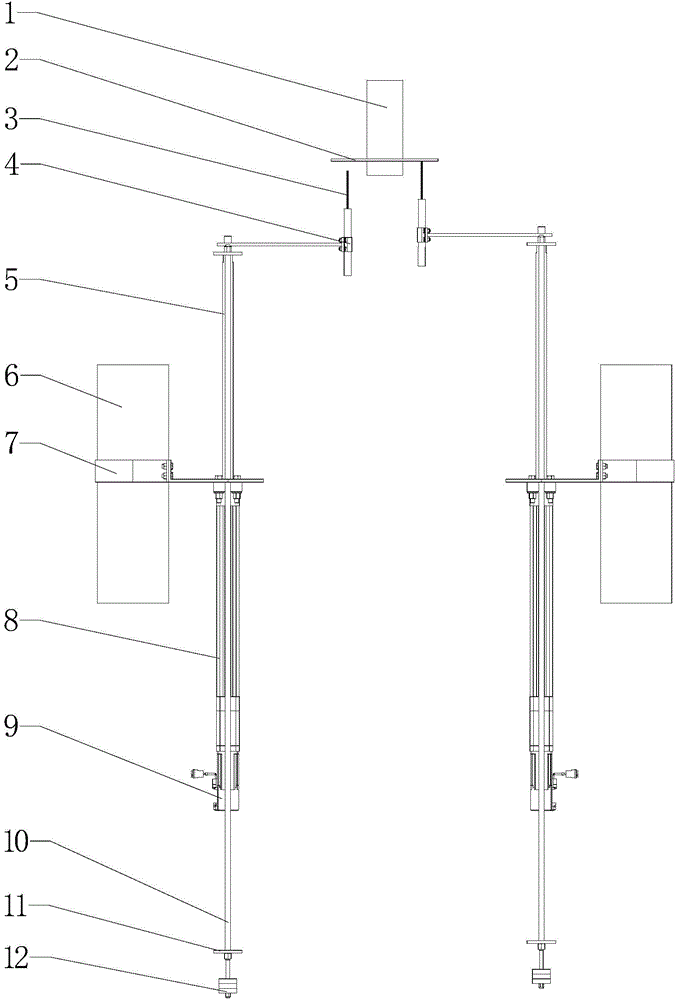

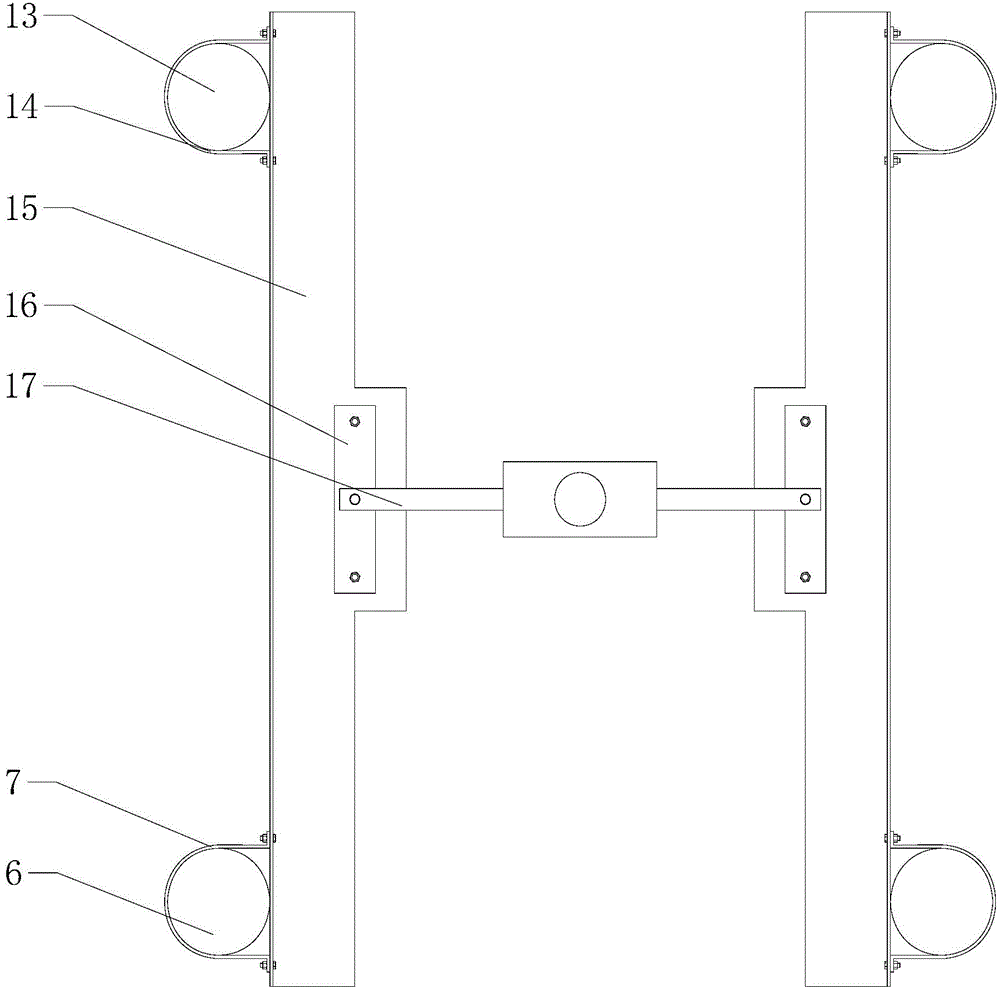

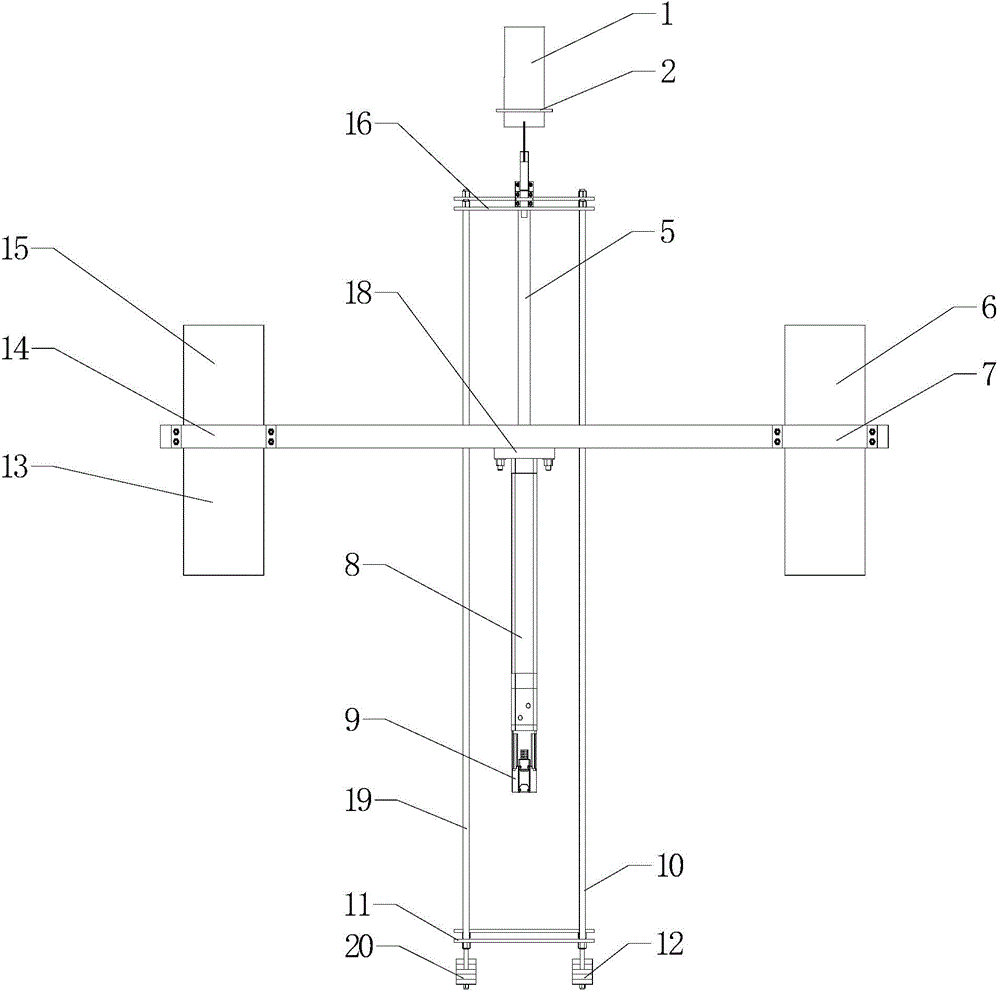

Mechanical structure of indoor building profile installation robot

ActiveCN109505400ASolve the installationReduce the number of people requiredBuilding material handlingControl systemEngineering

The invention discloses a mechanical structure of an indoor building profile installation robot. The mechanical structure comprises a base, a mechanical arm and a mounting end. The mechanical arm is composed of three sets of connecting rods in series. Each set of connecting rods is connected with the last set by a connecting rod in a hinged mode, a rotating driving force is provided by a hydraulicoil cylinder in a both-end hinged mode, the set of connecting rods at the top is composed of three connecting rods and hinged to the mounting end through a tail end hinged part, and it can be ensuredthat the mounting end performs translational motion in the up-and-down and front-rear direction when the mechanical arm moves. The mechanical structure of the robot cooperates with a control system and a driving device, the problem of large-size high-weight building profile installation under the conditions of height and working space limitation can be solved, the mechanical structure can be usedfor transport installation of building profiles in indoor and outdoor low-altitude environments such as a workshop and a workshop, the operation is simple, the running is smooth and saves labor, andthe mechanical structure is efficient and safe.

Owner:HEBEI UNIV OF TECH

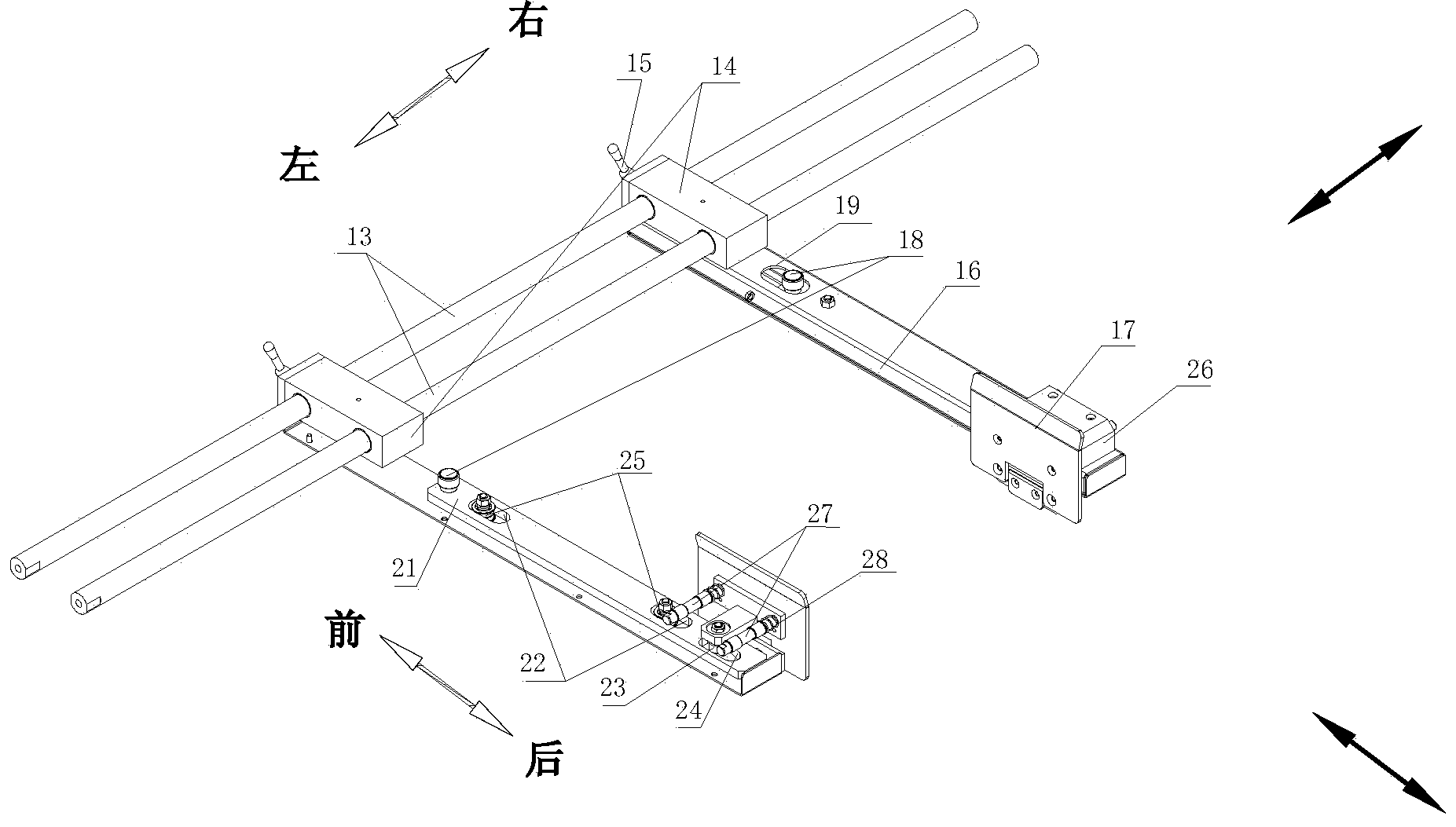

Handheld onion transplanting device

The invention relates to a handheld onion transplanting device. The device comprises a hole punching mechanism, a seedling guide mechanism and an earthing mechanism. The hole punching mechanism is used for penetrating through a mulching film to punch a taper hole and is a stander of the whole device; a seedling guide pipe in the seedling guide mechanism downwards moves to unfold a taper hole punching machine arranged at the lower end, normative field planting holes are punched in the earth, and seedlings enter the field planting holes under the action of the seedling guide pipe; the earthing mechanism is used for earthing after the seedlings are guided, so that the vertical state after the seedlings are transported can be guaranteed, and the transportation can be completed. The handheld onion transplanting device is simple in structure and convenient to operate, the work efficiency can be improved, and the labor intensity can be reduced. The uniformity of the transplanting depth can be realized, the device is good for growth of the seedlings at the later period, and the production and the income of onions can be preferably increased.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

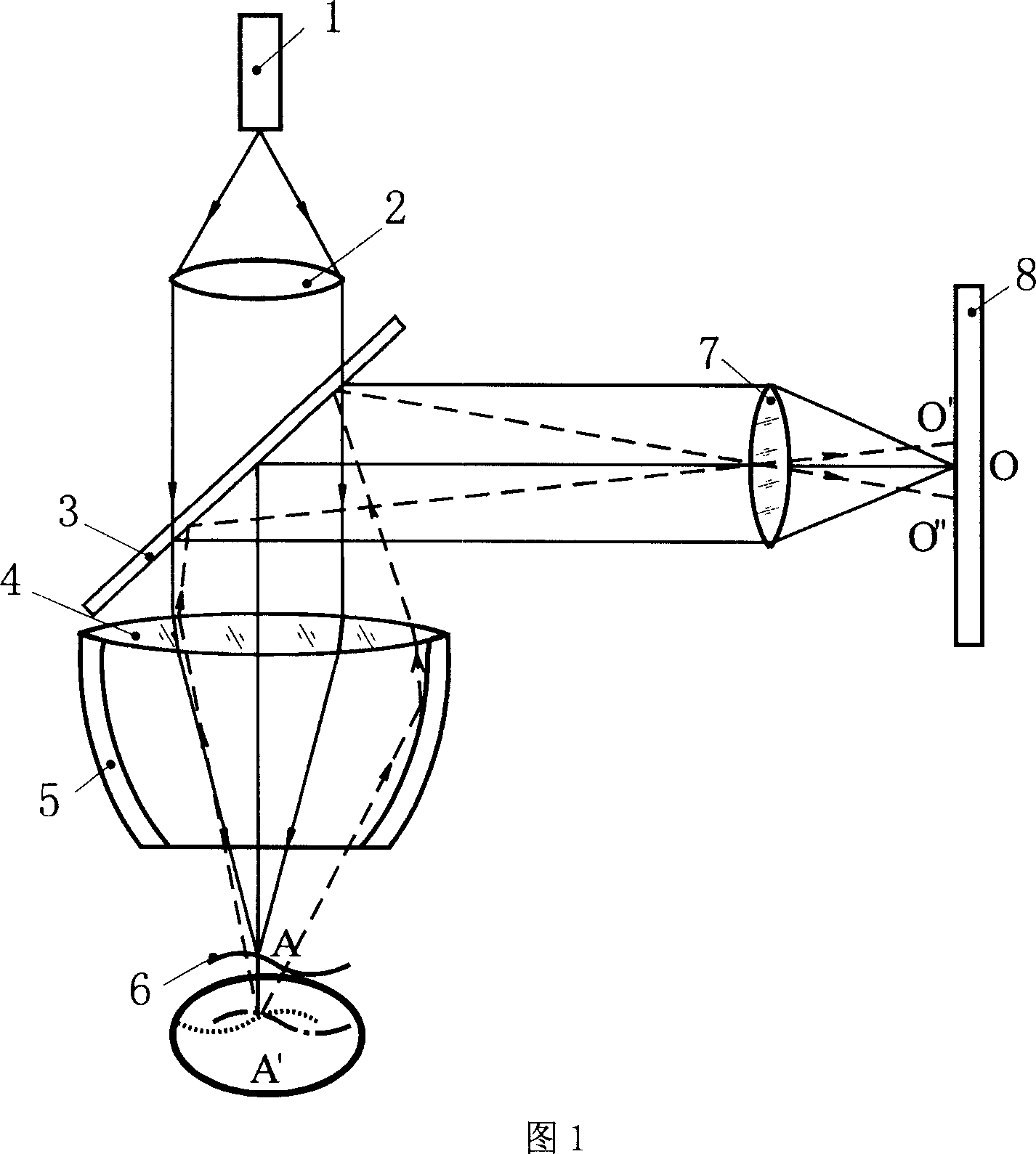

Single-photodetector confocal laser triangulation device

InactiveCN1995908AEasy to achieve focus overlapReduce assembly requirementsUsing optical meansPhotodetectorPlane mirror

The invention relates to single photo detector cofocal laser triangulation. It provides authentic three dimensional data, solves the issues resulted from the oblique angle of the inspected surfaces. It comprises laser, collimation lens, half reflective half transparent lens, aspheric lens, ring type inner reflector, inspected surface, image forming lens, and side photo detector, with the collimation right in front of the laser beam, the included angle of the half reflective and half transparent lens optical axis and the collimation lens optical axis in 45 degree clockwise. The aspheric lens and the collimation lens share the same optical axis. The center of sphere of the ring reflector shares the same optical axis with the single beam released by the symmetrical axis and the laser, collimation lens and the aspheric lens. The optical axis of the image forming lens is perpendicular with the light beam of the laser. The photo detector is set at the focal position of the imaging lens.

Owner:XIAMEN UNIV

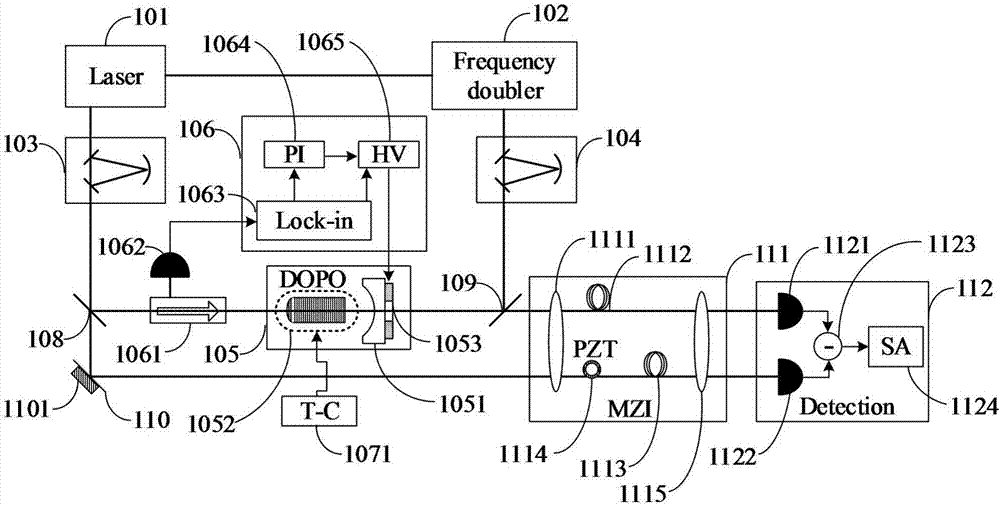

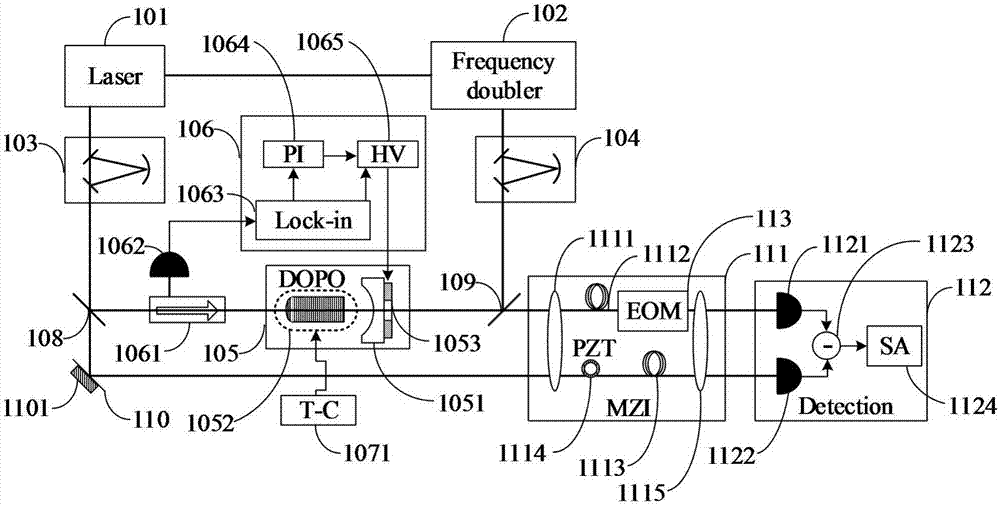

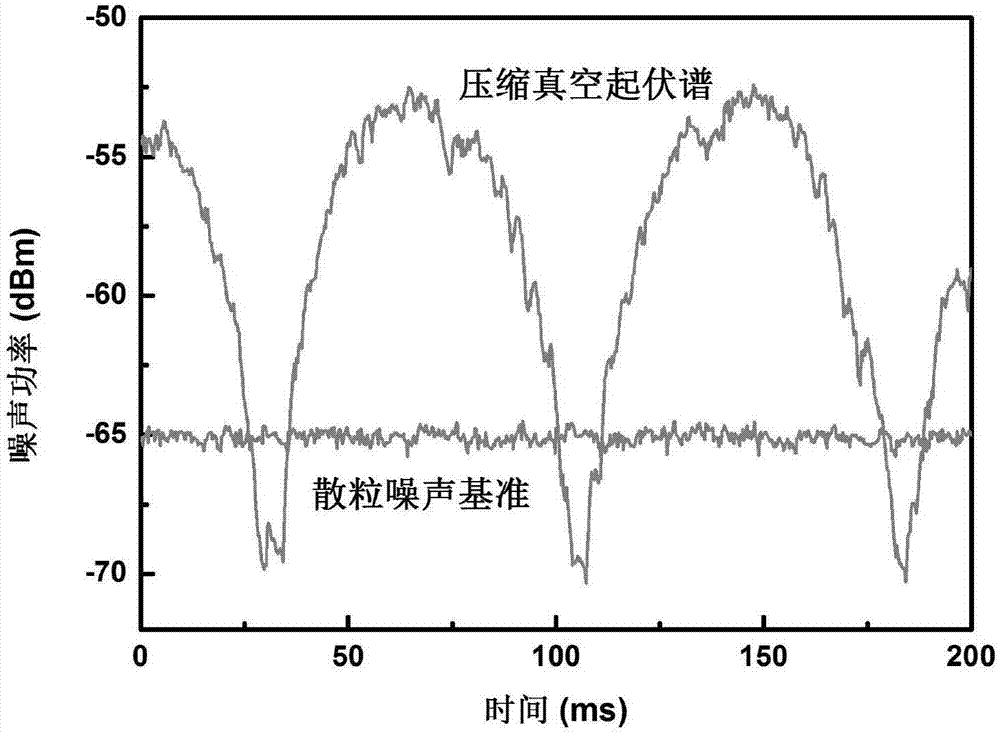

Frequency spectrum generation device and physical quantity change amount measurement device and method

ActiveCN107300355AReduce decoherence effectsHigh sensitivityUsing optical meansFrequency spectrumOptical communication

The invention discloses a frequency spectrum generation device and a physical quantity change amount measurement device and method. The device and method adopt an optical parametric oscillator in a compact structure to convert continuous single-frequency laser in an optical communication wave band into a squeezed light field in the optical communication wave band, thereby effectively reducing the de-coherence effect due to loss when the continuous variable squeezed light field transmits in an optical fiber, and maintaining compression degree to be maximum degree to allow the squeezed light field not to be damaged when transmitting in the fiber; and the squeezed light field in the optical communication wave band is injected to a vacuum channel of a fiber Mach-Zehnder interferometer, so that quantum precision measurement lower than shot noise limit is realized, and sensitivity of the fiber Mach-Zehnder interferometer is improved. The device is ingenious in structure, high in anti-interference capability and high in sensitivity, and is more suitable for measurement of tiny physical quantity change amount.

Owner:SHANXI UNIV

Device for printing picture-word on candle surface

InactiveCN1775540AHeight adjustableSimple structureTypewritersPower drive mechanismsReciprocating motionGold colour

The present invention relates to an equipment capable of printing gold colour, silver colour, white and chromatic pattern and characters on the surface of candle. Said equipment includes ink-jet printing unit, said ink-jet printing unit includes printing supporting frame, on the printing supporting frame a printing head is set, said printing head can make linear reciprocating movement relatively to said supporting frame, under the ink-jet printing unit two mutual parallel rotating shafts are set, at least one rotating shaft is coupled with drive device, and the drive device is coupled with ink-jet printing unit and circuit board.

Owner:王红

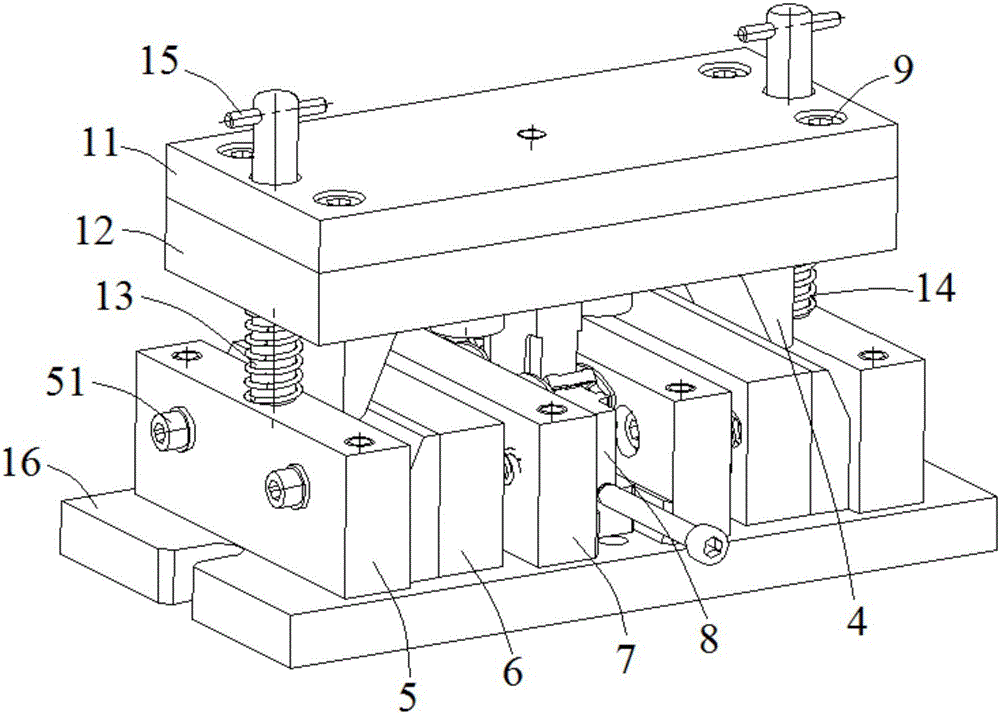

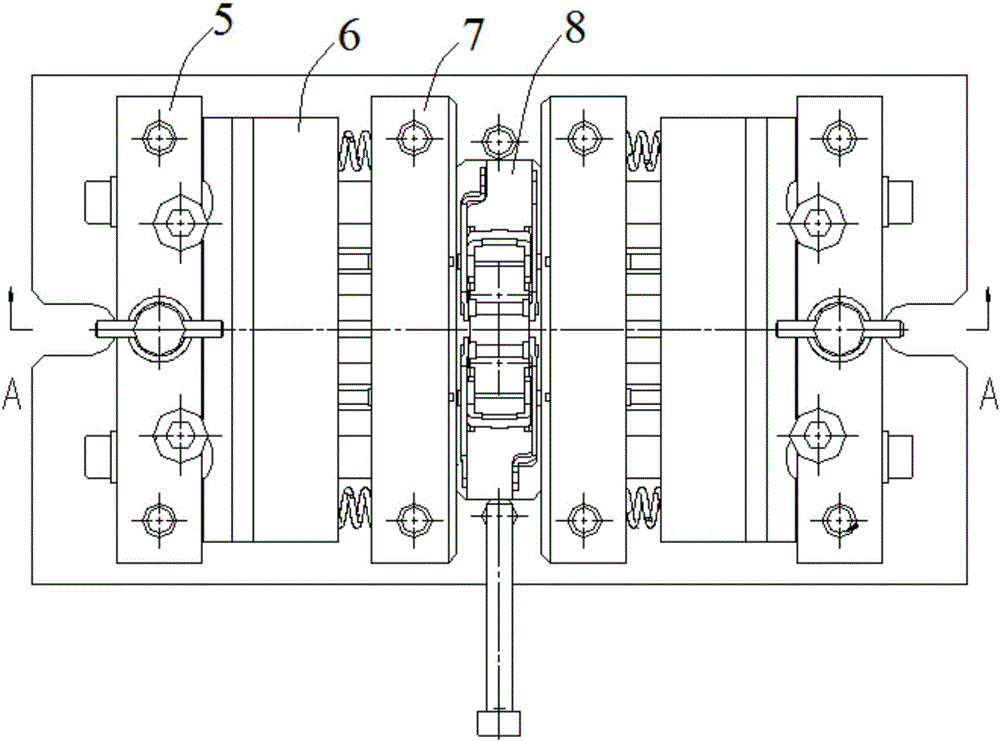

Jump catch clamp, integrated tool for jump catch riveting and flanging and machining method thereof

ActiveCN106653495AEasy to placeNot easy to scatterEmergency protective device manufactureEngineeringMechanical engineering

The invention discloses a jump catch clamp, an integrated tool for jump catch riveting and flanging and a machining method thereof, and the jump catch clamp is a special clamp. The tool disclosed by the invention comprises an upper die, a guide post, a guide post spring, a base plate, sliding block assemblies, a first lower die upright post plate and the jump catch clamp, wherein the guide post is serially connected to the upper die, the first lower die upright post plate and the base plate; the guide post spring is arranged on the guide post in a penetrating manner; the jump catch clamp can be inserted in a drawer groove in the middle part of the base plate; the sliding block assemblies capable of moving horizontally are arranged on the left side and the right side of the jump catch clamp; a riveting punch is arranged on the side, close to the jump catch clamp, of each sliding clock assembly, and an inclined wedge surface is arranged on the other side of each sliding block assembly; an inclined pressing block is arranged above each inclined wedge surface; the inclined pressing blocks are connected with the upper die; and the inclined pressing blocks are provided with inclined wedge surfaces matched with the inclined wedge surfaces of the sliding block assemblies. The jump catch can be assembled at a time, the riveting and flanging quality is reliable, and the production efficiency is improved.

Owner:JIANGSU DAQO KFINE ELECTRIC

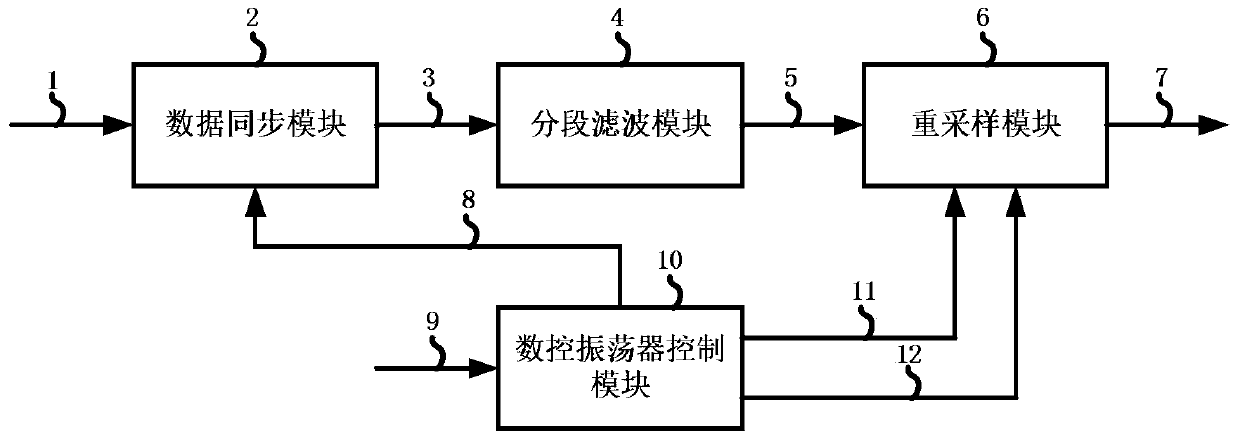

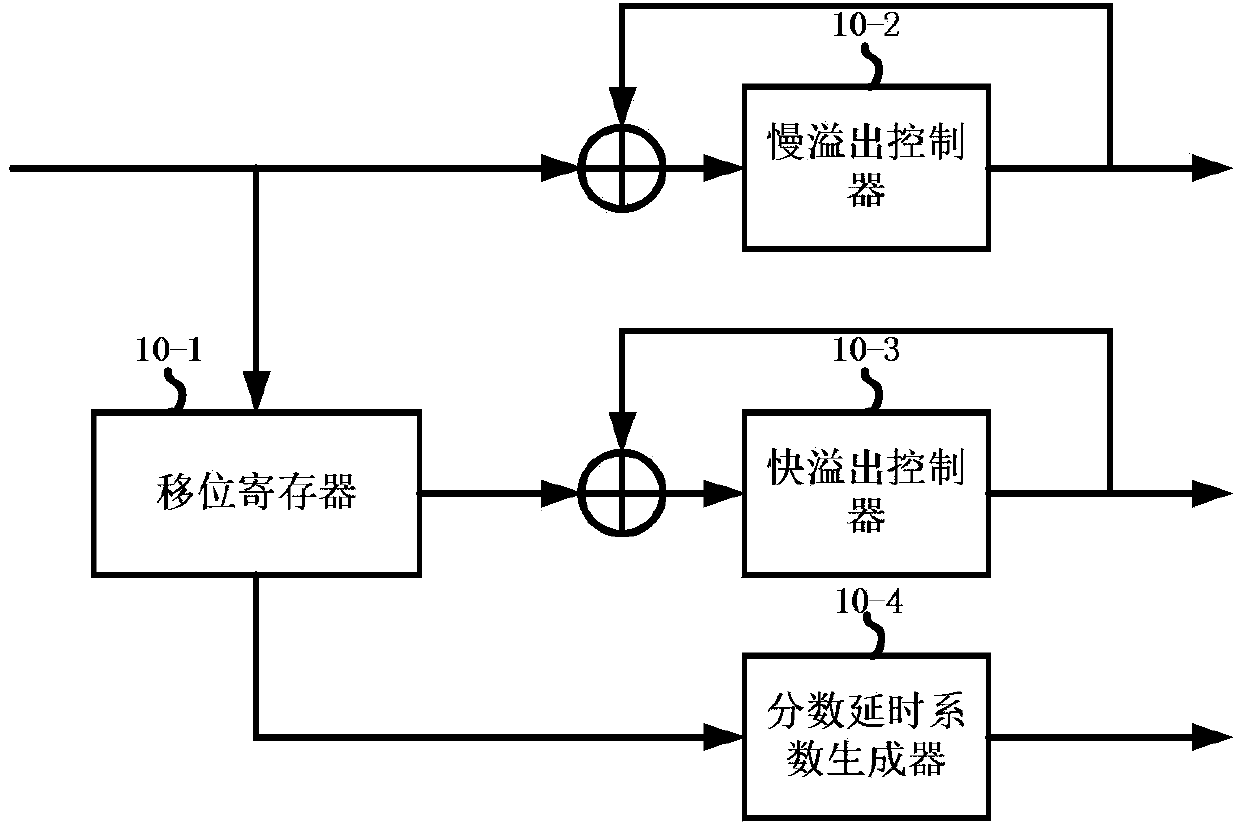

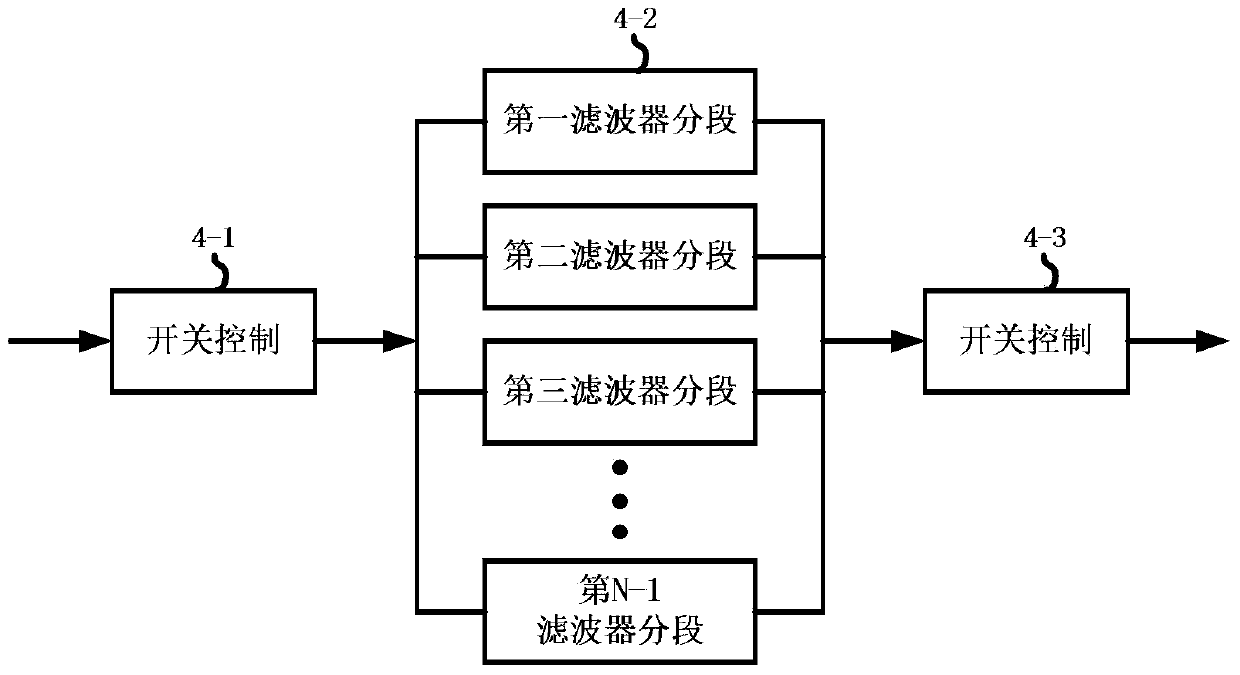

Fractional-multiple interpolation shaping filter and implementation method thereof

ActiveCN104218919ASmart structureSimple interfaceDigital technique networkData synchronizationTime delays

The invention provides a fractional-multiple interpolation shaping filter and an implementation method thereof. The fractional-multiple interpolation shaping filter comprises a data synchronization module, a segmented filtering module, a resampling module and a numerically controlled oscillator control module. The numerically controlled oscillator control module generates a slow overflow flag according to baseband modulation rate input and sends the slow overflow flag to the data synchronization module to generate slow synchronous data output; the slow synchronous data output is processed by the segmented filtering module to generate a filter group output; the filter group output and a fast overflow flag as well as the time delay of a fractional time delay filter are processed by the resampling module to generate shaped filtered data. The fractional-multiple interpolation shaping filter is used for realizing fractional-multiple conversion between a user input rate and the rate after interpolation shaping filtering, and is adaptive to the ksps grade real-time adjustment of the user rate and capable of breaking through the traditional limitation on the user input rate; besides, the fractional-multiple interpolation shaping filter is light and ingenious in structure, simple in interface, and high in flexibility and applicability; the fractional-multiple interpolation shaping filter can be migrated to a programmable logic device or designed into a special integrated circuit, and the variable rate range of the filter can be expanded according to requirements.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

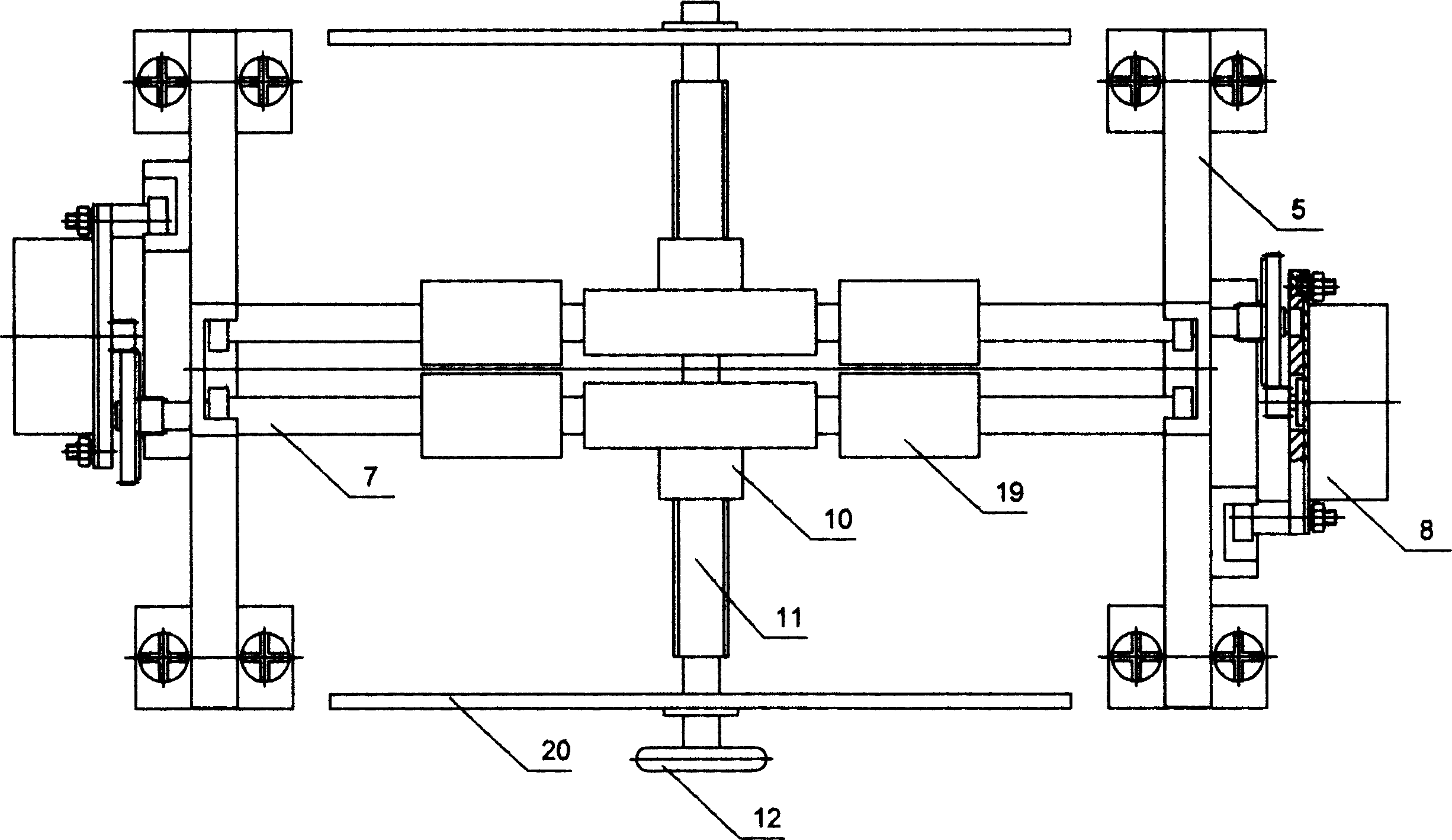

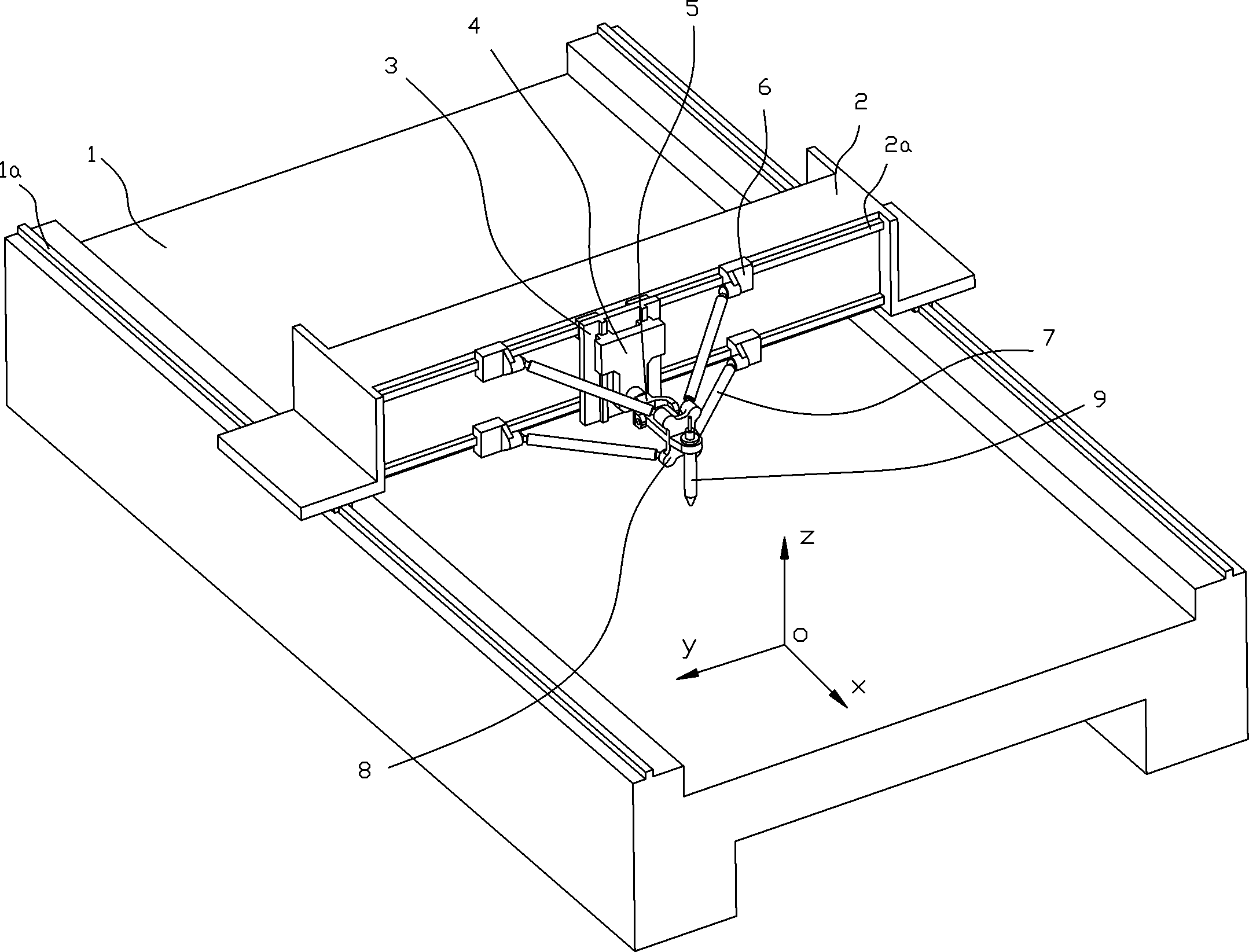

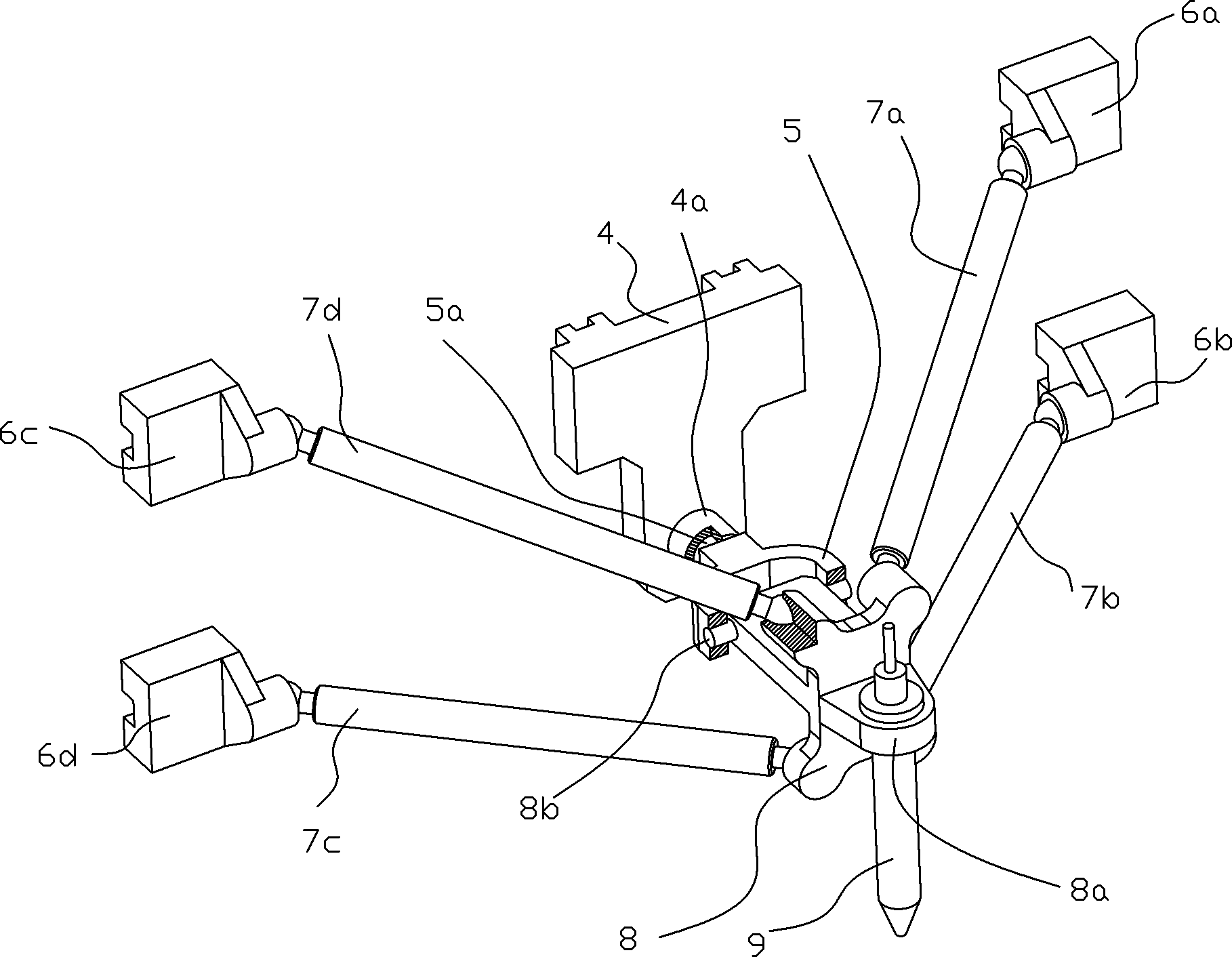

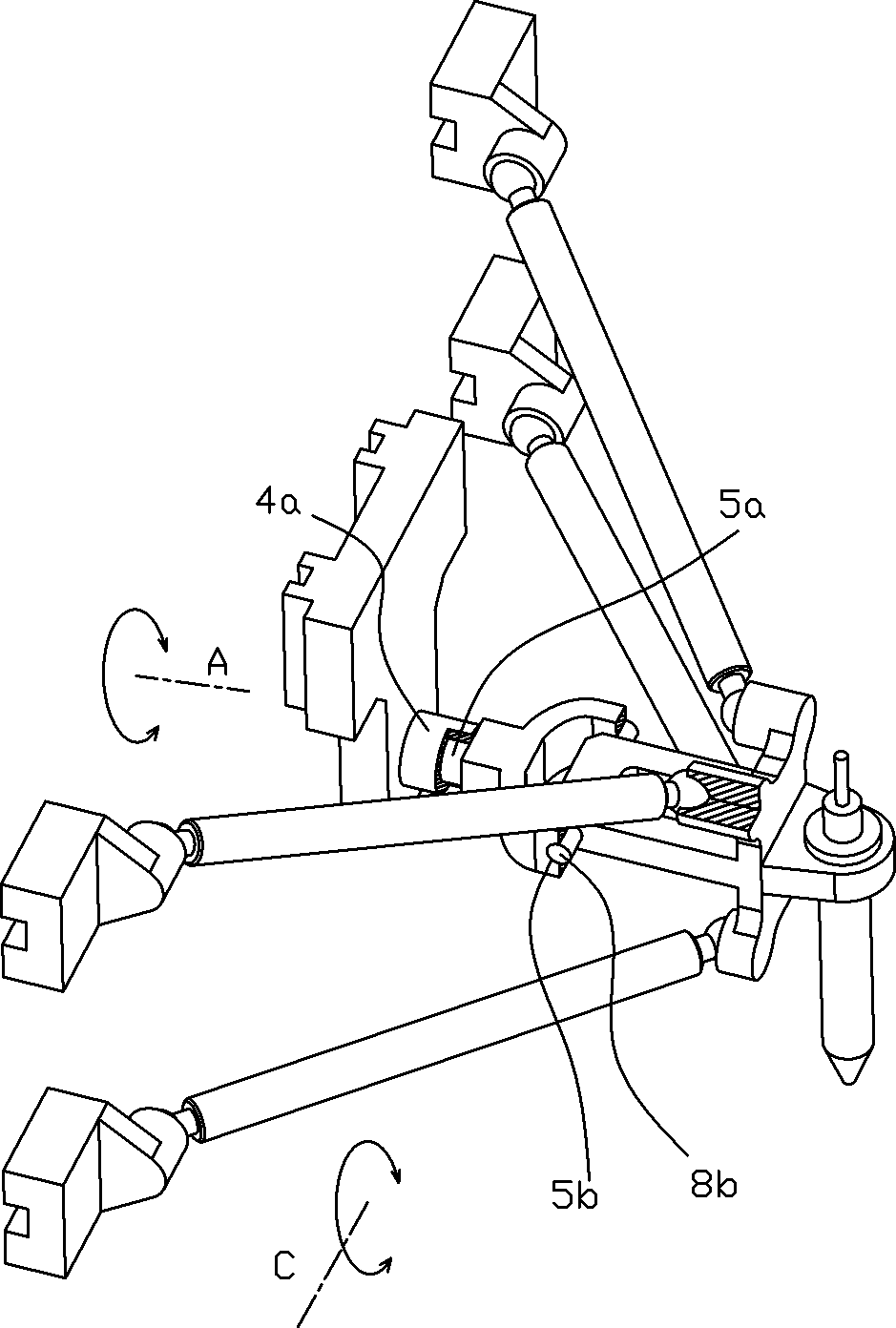

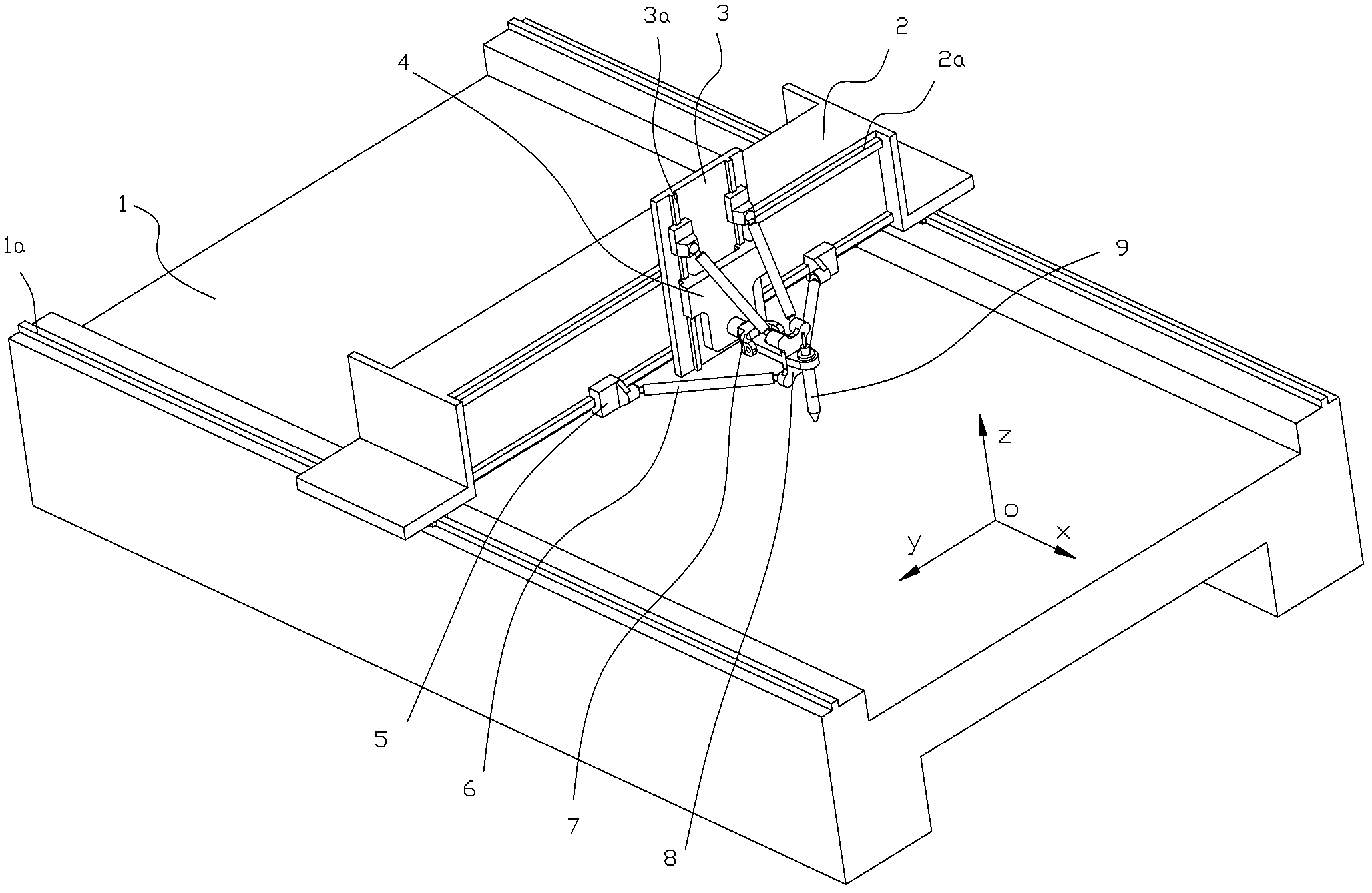

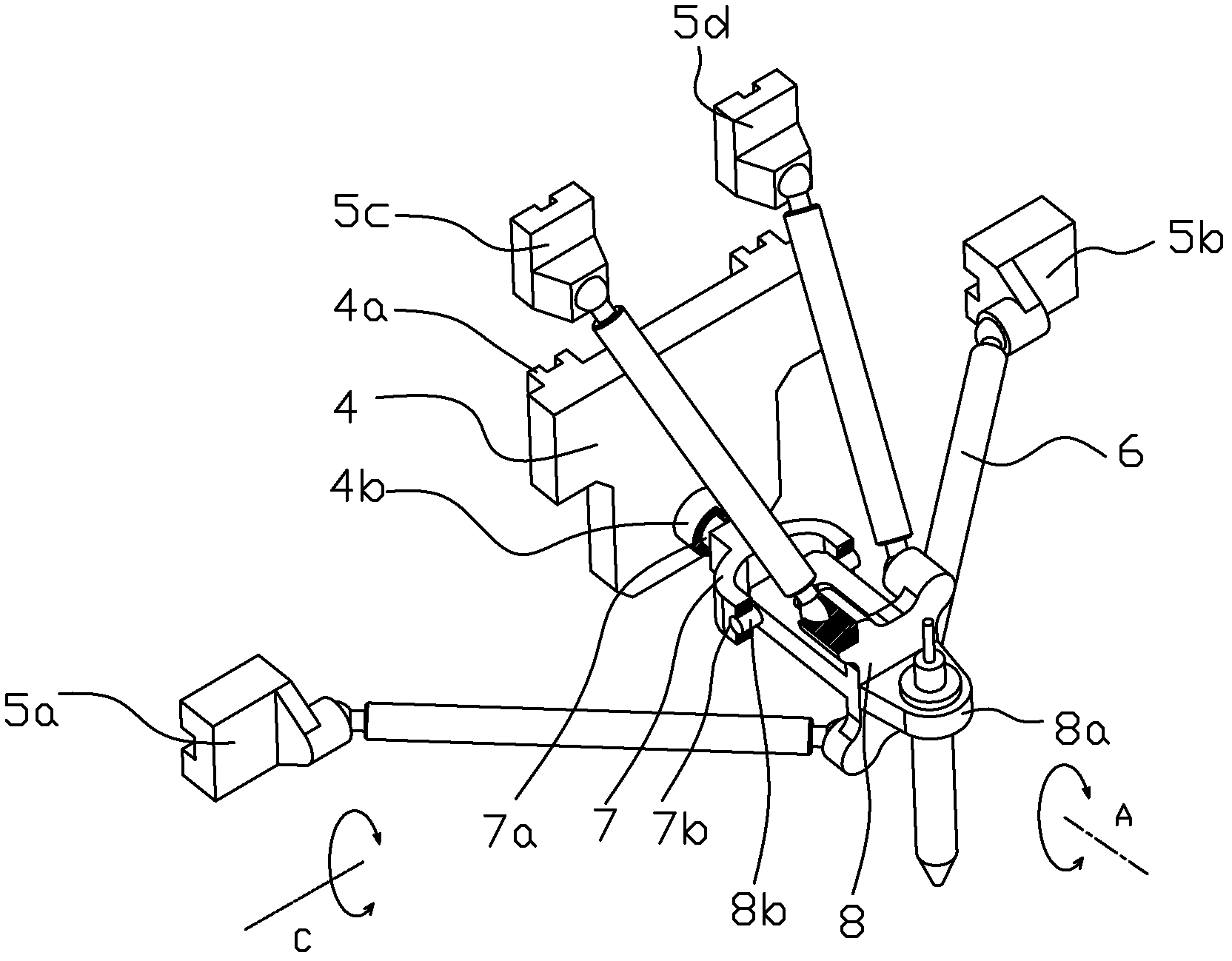

Imperfect degree-of-freedom parallel connection five-axis computerized numerical control laser cutting machine

ActiveCN102303186ARealize Joint MovementSmart structureLaser beam welding apparatusNumerical controlLaser cutting

The invention discloses an imperfect degree-of-freedom parallel connection five-axis computerized numerical control laser cutting machine, relating to a laser cutting machine with an imperfect degree-of-freedom parallel connection five- axis drive mechanism. The laser cutting machine comprises a machine body, an X-direction guide rail, a beam, a laser cutting heat and a controller, wherein the side surface of the beam is provided with a Y-direction guide rail, the laser cutting head is movably connected with the Y-direction guide rail through an imperfect degree-of-freedom parallel connectionmechanism; and the imperfect degree-of-freedom parallel connection mechanism comprises a Y-axis slide carriage device, a Z-axis slide carriage device, a cross, a laser head installing support, four equilong connecting rods and four linear driving devices. The invention realizes five-axis motion of the conventional laser cutting head through the imperfect degree-of-freedom parallel connection device, wherein the beam realizes basic X-direction motion relative to the motion of the machine body; four drive blocks respectively move and drive the laser heat installing support to make translation or rotation motion through respective connecting rods, mutual motion among the four drive blocks realizes combined motion of an Y axis, a Z axis, an A axis and a C axis; and the imperfect degree-of-freedom parallel connection five-axis computerized numerical control laser cutting machine has skilled structures of all parts, large rigidity and small inertia, so that the motion precision can be ensured.

Owner:江苏扬力数控机床有限公司

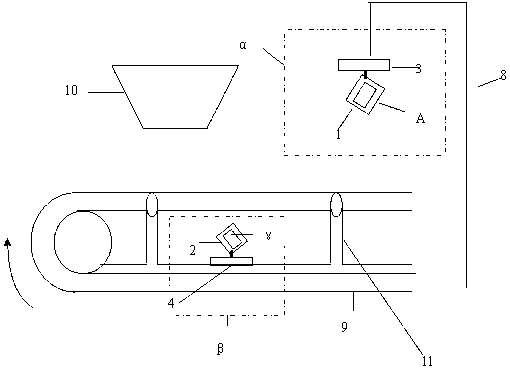

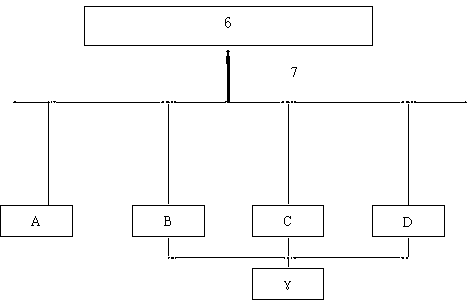

Visual inspection and pre-warning system for longitudinal tear of conveying belt and application method of conveying belt

InactiveCN103213823AAvoid damageEnsure transportation safetyControl devices for conveyorsVisual inspectionWorking environment

The invention discloses a visual inspection and pre-warning system for a longitudinal tear of a conveying belt and an application method of the conveying belt and belongs to the technical field of on-line testing of coal mining equipment. The visual inspection and pre-warning system for the longitudinal tear of the conveying belt is characterized in that inspection is performed in the manner that an infrared visual sensor system and advanced RISC machine (ARM) framework-based embedded system platform are combined to accurately judge an ongoing longitudinal tear fault and a hidden dangerous source of the conveying belt; and the conveying belt is inspected and pre-warned from two levels so as to guarantee the safe operation of the conveying belt. According to the system, image information is normally acquired under the dark condition, and therefore, the defect that auxiliary backlight needs to be adopted when a common industrial camera is used in traditional visual inspection is avoided, the defects that a traditional visual inspection instrument is complex to install, is serious in energy consumption, cannot be applied to complicated work environments and is not ideal in inspection effect are overcome, the damage degree of the conveying belt is reduced to the maximum limit, the possibility of accident occurrence and hazards brought after an accident occurs are fundamentally reduced, the safe transport of the conveying belt is comprehensively guaranteed, the work cost is reduced, and the work efficiency is effectively improved.

Owner:TAIYUAN UNIV OF TECH

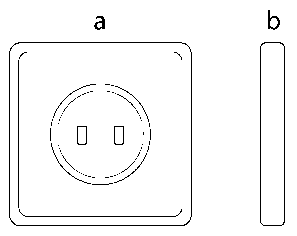

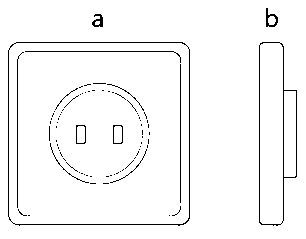

Secure socket and use method thereof

InactiveCN103280672AAvoid enteringSmart structureCoupling device engaging/disengagingCoupling device detailsForeign matterEngineering

The invention discloses a secure socket and a use method thereof. The secure socket comprises a socket movable main body and a socket fixed main body, wherein the socket movable main body is provided with a jack and is divided into a periphery area and a central area by the jack, the periphery of the socket movable main body is connected with the socket fixed main body through a safe lock, the socket fixed main body is concave, and the bottom of the socket fixed main body is provided with a socket internal circuit; the safe lock is divided into a part A and a part B which are separated, and the part A is connected with the socket fixed main body through a spring; when a plug is not plugged, the part A is embedded into the socket movable main body and the socket fixed main body simultaneously, one part of the part B is embedded into the socket movable main body, and the other part of the part B stretches into the jack; and when the plug is plugged and is connected with the socket internal circuit, the part A is embedded into the socket fixed main body, and the part B is embedded into the socket movable main body. The secure socket and the use method thereof have the beneficial effects of being smart in structure, convenient to use, low in cost and convenient for mass production and application and effectively preventing fingers of children or foreign matters from entering the socket.

Owner:ZHEJIANG UNIV

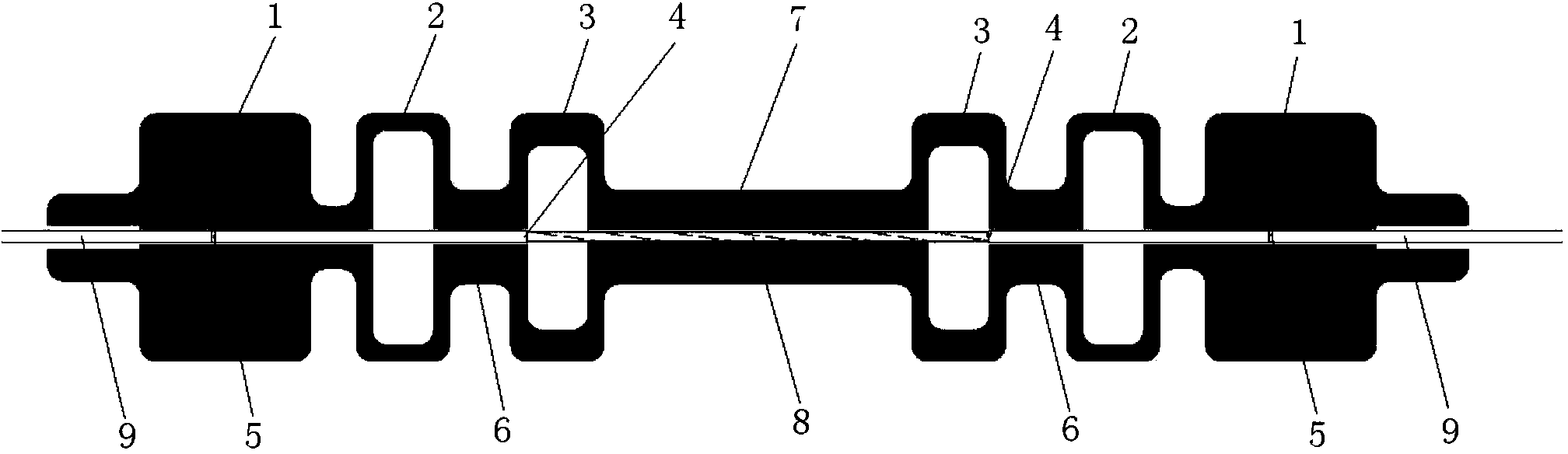

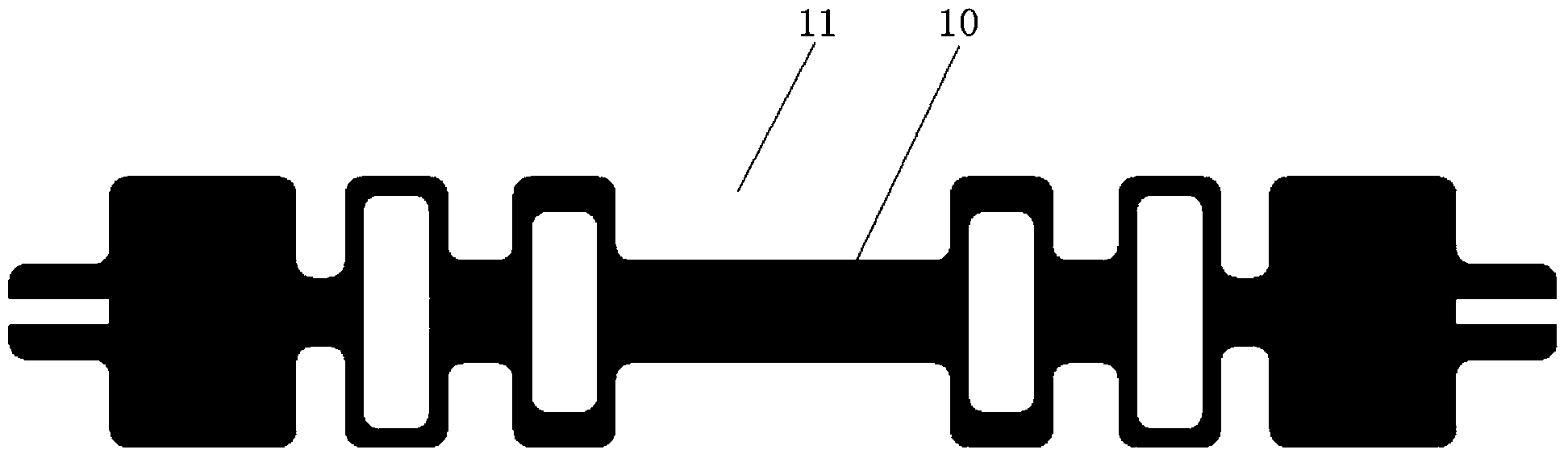

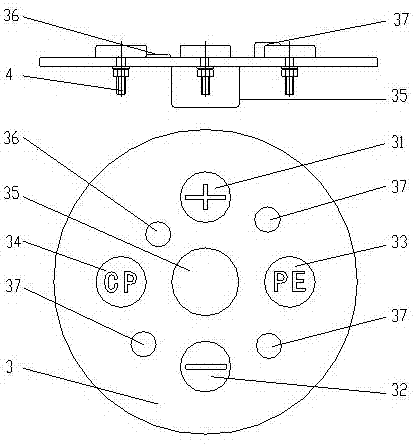

Ultrahigh strain sensor based on fiber bragg grating

ActiveCN104019759AIncrease stiffnessRealize real-time monitoringUsing optical meansGratingFiber Bragg grating

The invention relates to an ultrahigh strain sensor based on a fiber bragg grating. Double elastic structures are designed on a substrate (11), the rigidity of the inner side elastic structure is larger than that of the outer side elastic structure, the fiber bragg grating (8) with prestress is fixed between the inner side elastic structure and the outer side elastic structure, and it is ensured that under the strain action, the inner side elastic structure (3) and the outer side elastic structure (2) bear the same drawing force or compressing force. As the inner side elastic structure (3) and the outer side elastic structure (2) are different in rigidity, the stretching length of the inner side elastic structure (3) is smaller than that of the outer side elastic structure (2), namely the strain of the inner side elastic structure (3) is smaller than that of the outer side elastic structure (2), and consequently ultrahigh strain can be measured. Compared with the prior art, the ultrahigh strain sensor based on the fiber bragg grating has the advantages that the process is simple, the structure is stable, measurement is accurate, and the ultrahigh strain (+ / -3000 mu epsilon or above) can be measured.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

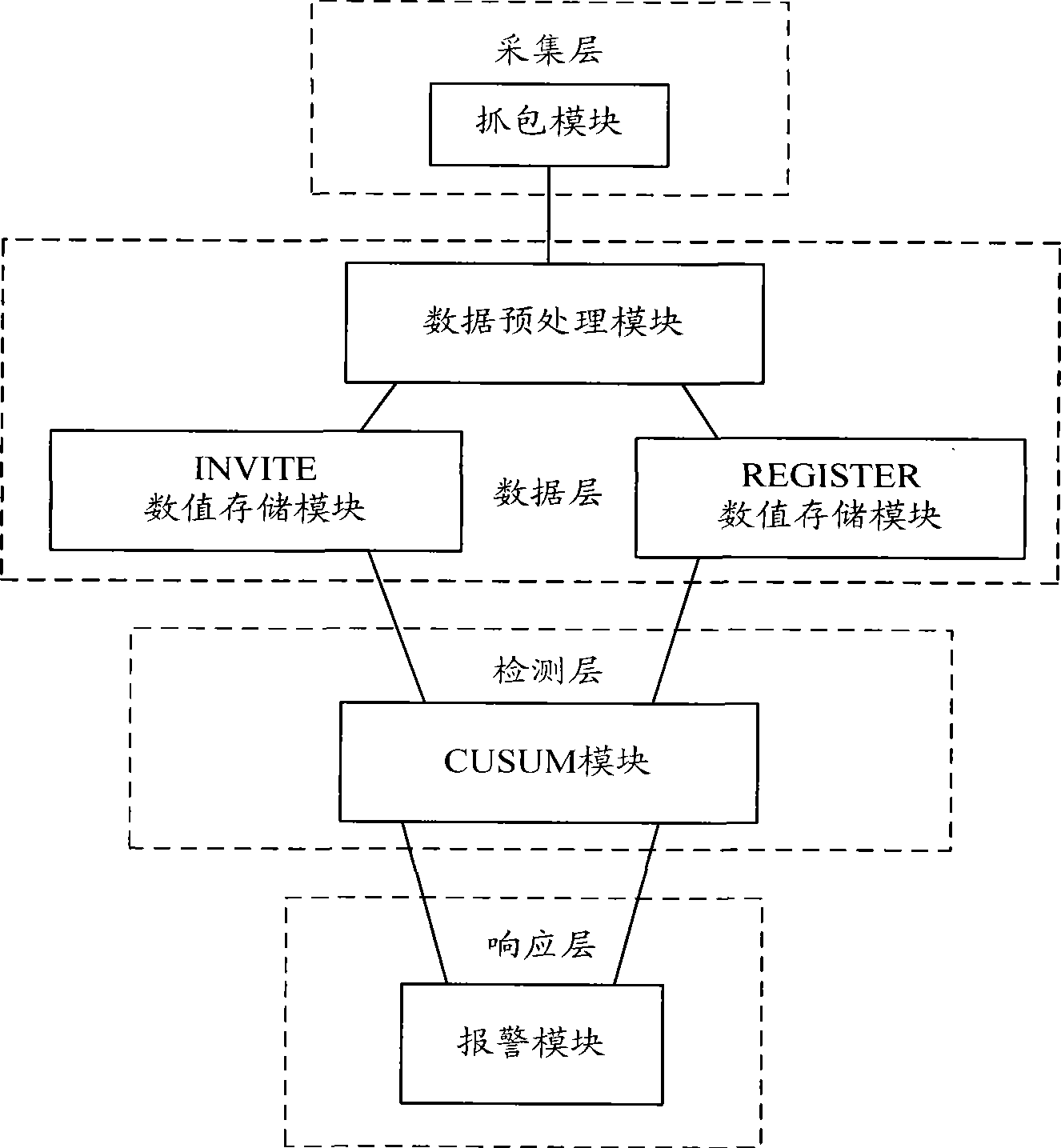

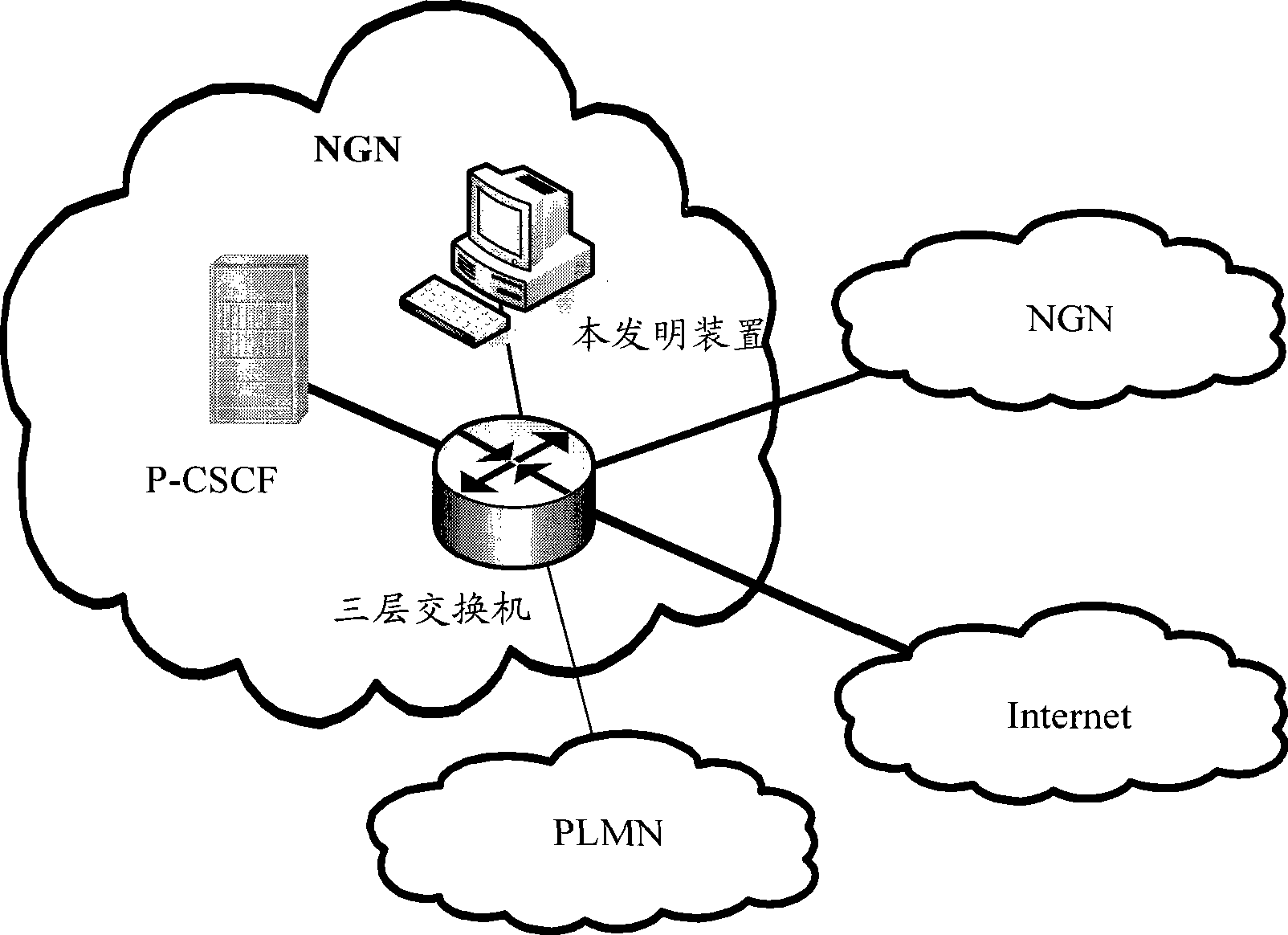

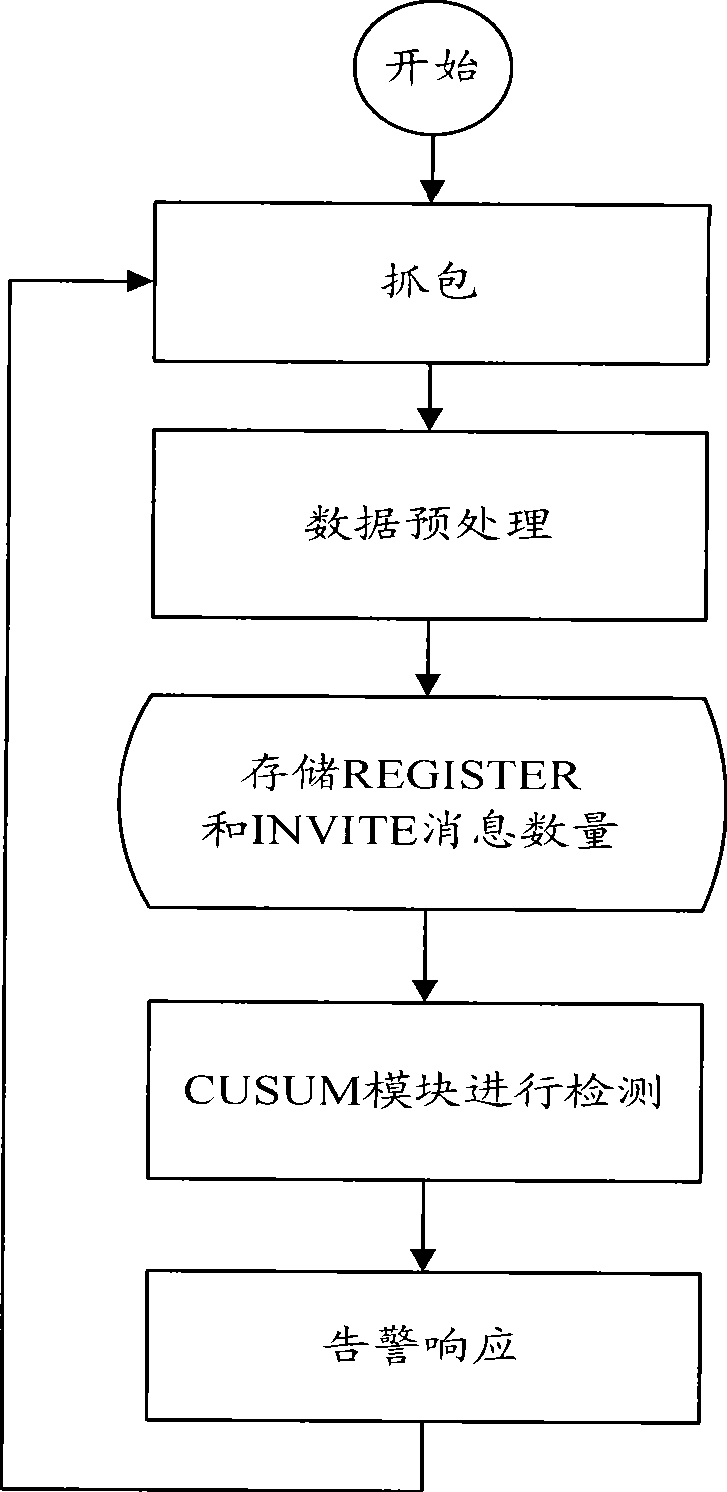

Apparatus and method for detecting SIP message flooding attack based on CUSUM algorithm

The invention relates to a device and a method for detecting SIP message flood attacking based on a CUSUM algorithm, wherein the device is formed by a multifunction module formed by a gathering layer, a data layer, a detecting layer and a response layer, wherein a bale grabber module of the gathering layer gathers an SIP data packet in network, a module of the data layer preprocesses the SIP data packet from the gathering layer, and respectively stores the grabbed total amount of INVITE messages and REGISTER messages, a CUSUM module of the detecting layer adopts a CUSUM algorithm to correct INVITE message value and REGISTER message value, which are stored to detect and output detection results. An alarm module of the response layer judges whether the detection result gives alarm or not to the detection result, if the detection result exceeds a preset threshold value, SIP information flood attacking is regarded to come across, and alarm signals are sent out, if not, network is represented to be normal. The device and the method are simple and practical, which are easily achieved, and can effectively detect out flood attacking aiming at SIP information in NGN network.

Owner:BEIJING UNIV OF POSTS & TELECOMM

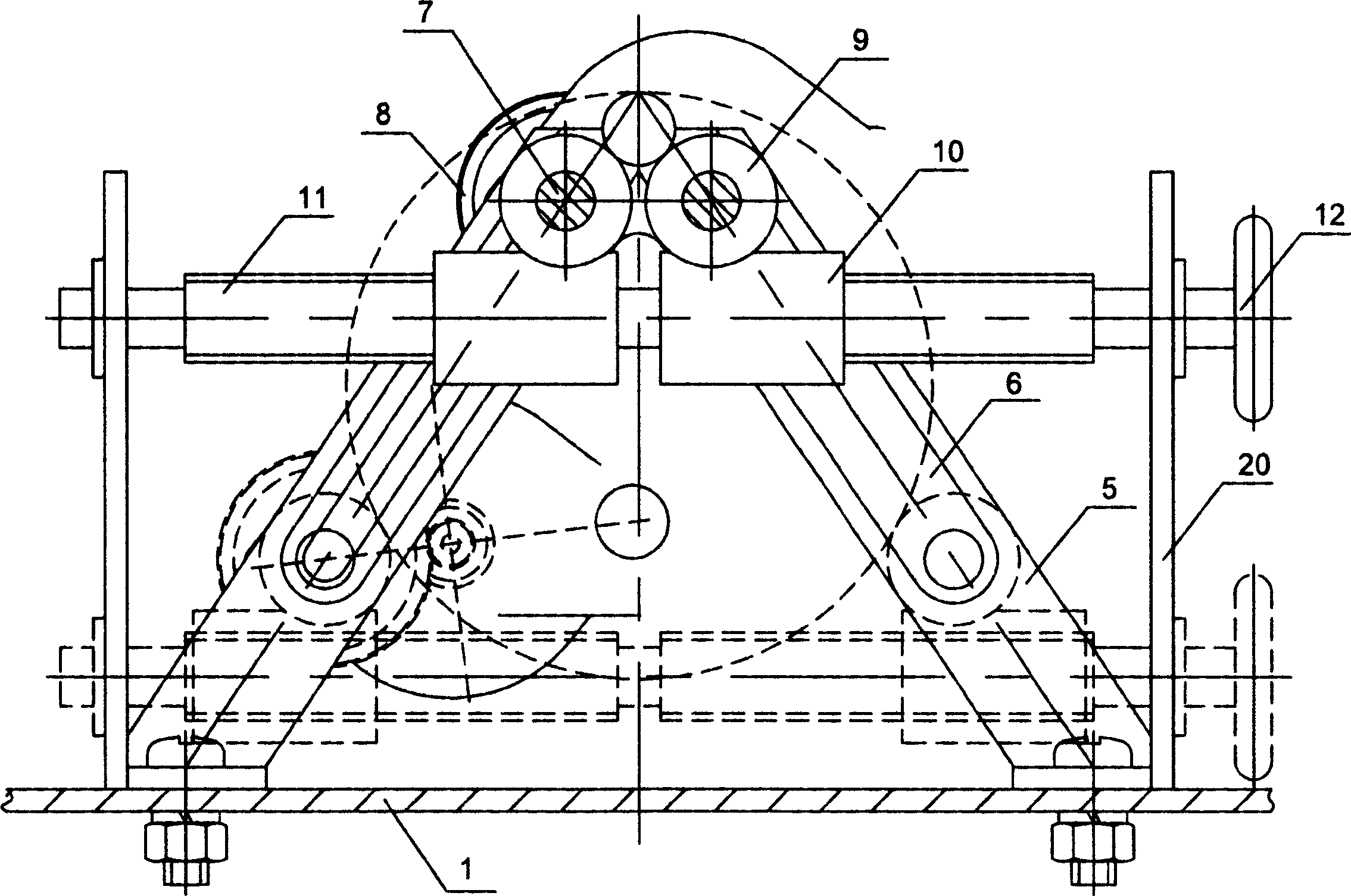

Three-dimensional five-axis computerized numerical control laser cutting machine

ActiveCN102303187AAvoid spatial symmetryImprove rigidityLaser beam welding apparatusNumerical controlLaser cutting

The invention discloses a three-dimensional five-axis computerized numerical control laser cutting machine, relating to a computerized numerical control laser cutting machine with a composite motion parallel connection five-axis drive mechanism, which comprises a machine body, an X-direction guide rail, a beam, a laser cutting head and a controller, wherein the side surface of the beam is provided with a Y-direction guide rail, and the laser cutting head is movably connected with the Y-direction guide rail on the side surface of the beam through a composite motion parallel connection mechanism. The invention realizes five-axis motion of the conventional laser cutting head through the composite motion parallel connection device, wherein the beam realizes basic X-direction motion relative to the motion of the machine body; and combined motion of an Y axis, a Z axis, an A axis and a C axis is realized through the composite motion parallel connection mechanism. The three-dimensional five-axis computerized numerical control laser cutting machine has an ingenious design, skilled structures of all parts, large rigidity and small inertia, so that the motion precision can be ensured. The three-dimensional five-axis computerized numerical control laser cutting machine integrates a lathe technology, a robot technology and a computerized numerical control technology, and has the advantages of simple structure and complex and accurate arithmetical operation in comparison with the traditional serial connection lathe. The three-dimensional five-axis computerized numerical control laser cutting machine has the remarkable advantages of large rigidity, rapid response speed, high precision, strong adaptability, high technical additional value and the like.

Owner:江苏扬力数控机床有限公司

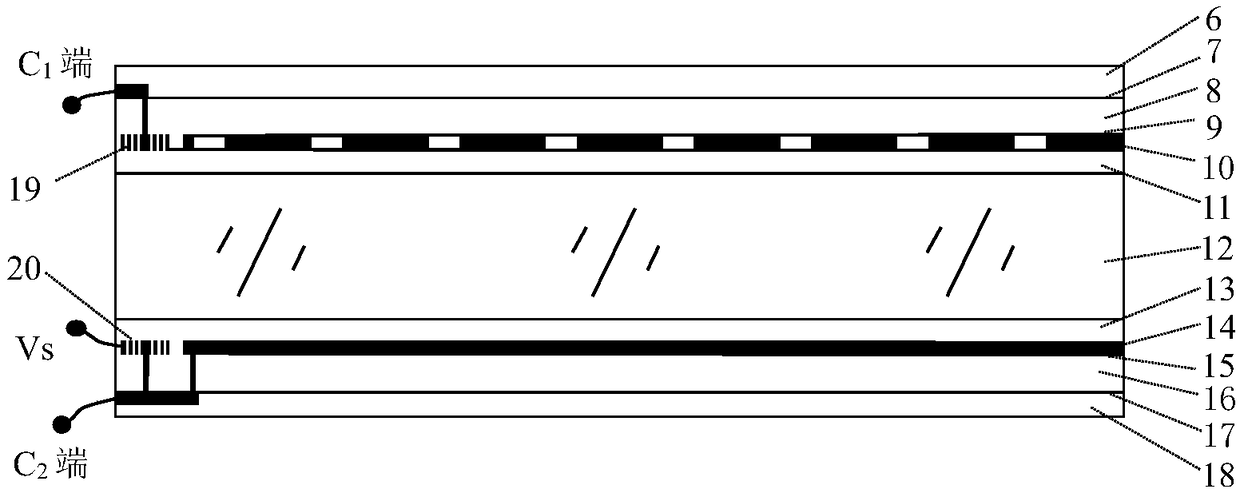

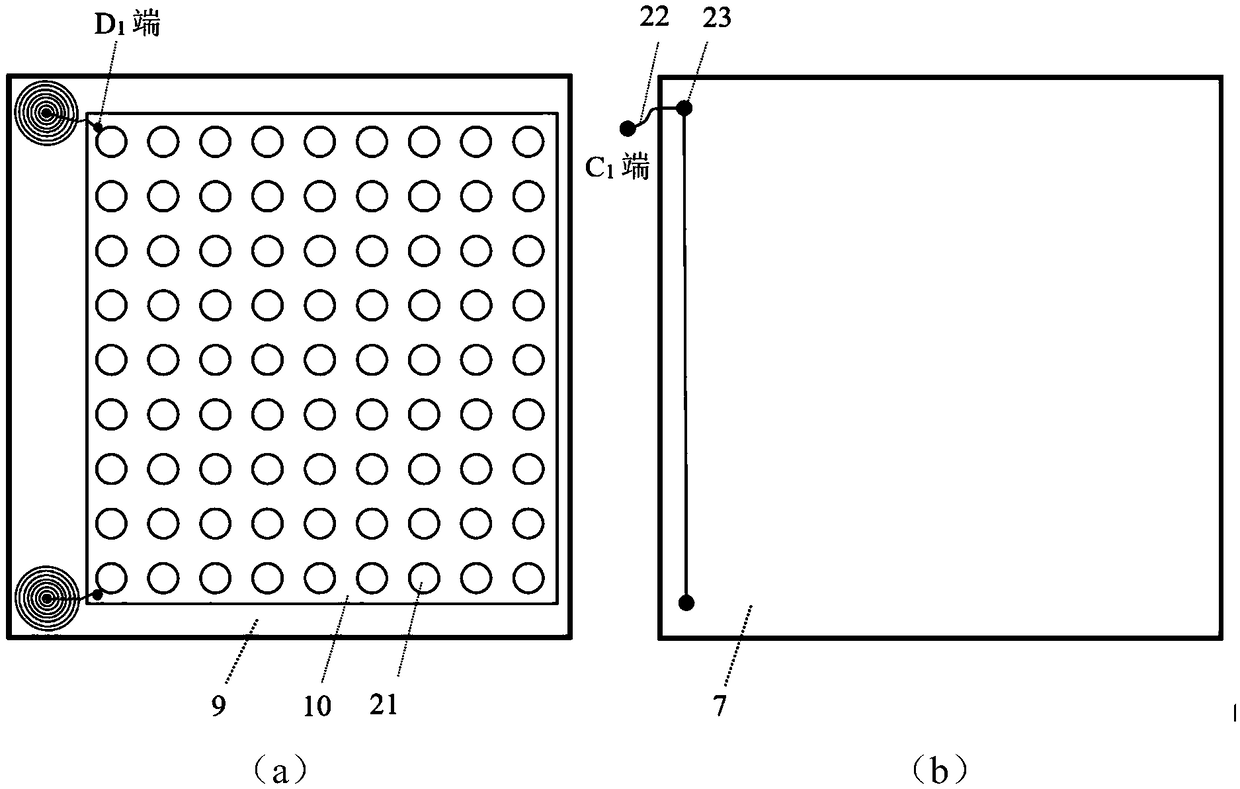

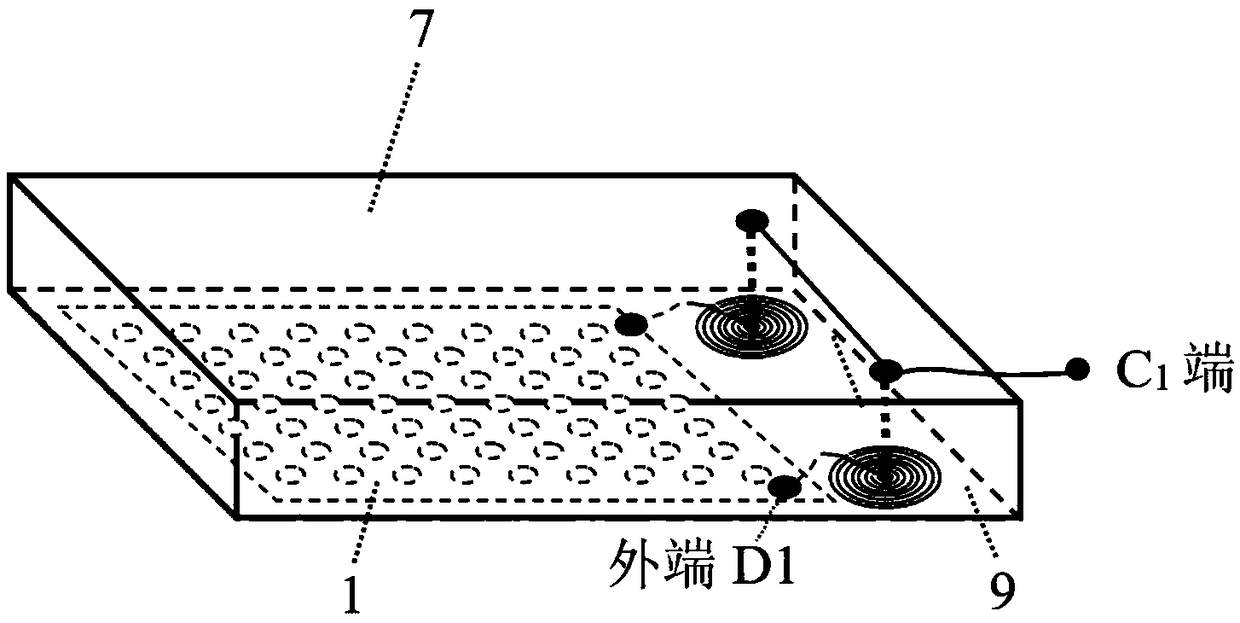

Liquid crystal condensation micromirror array driven and controlled on the basis of frequency signal, and preparation method thereof

InactiveCN109001924AGood light control adaptabilityHigh control precisionNon-linear opticsMicro coilMicromirror array

The invention discloses a liquid crystal condensation micromirror array driven and controlled on the basis of a frequency signal. A voltage signal is loaded on the liquid crystal condensation micromirror array, wherein the frequency of the voltage signal is adjustable, and the maximum mean square amplitude value of the voltage signal is only about few volts; and on the basis of a signal inductionand voltage amplification function between electric insulation micro-coils, specific intensity required by the micromirror array and a spatial distribution control electric field or magnetic field areconstructed to finish a condensation operation for driving and controlling the liquid crystal condensation micromirror array on the basis of the frequency signal. The liquid crystal condensation micromirror array has the advantages that the condensation efficiency of the liquid crystal condensation micromirror array is elaborately regulated, power consumption is low, and a frequency voltage regulation device and the liquid crystal condensation micromirror are integrated so as to be easily coupled with other functionally optical, photoelectric, light-emitting and electronics structures.

Owner:NANJING OPY ELECTRONICS TECH CO LTD

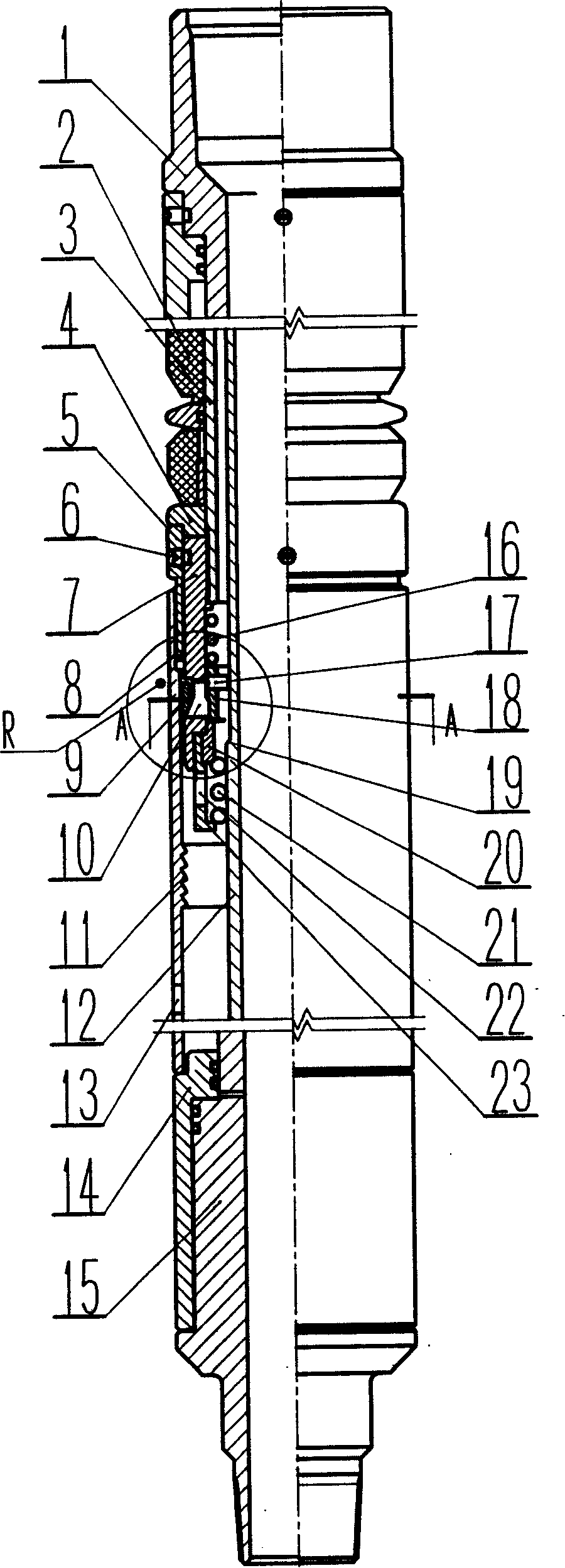

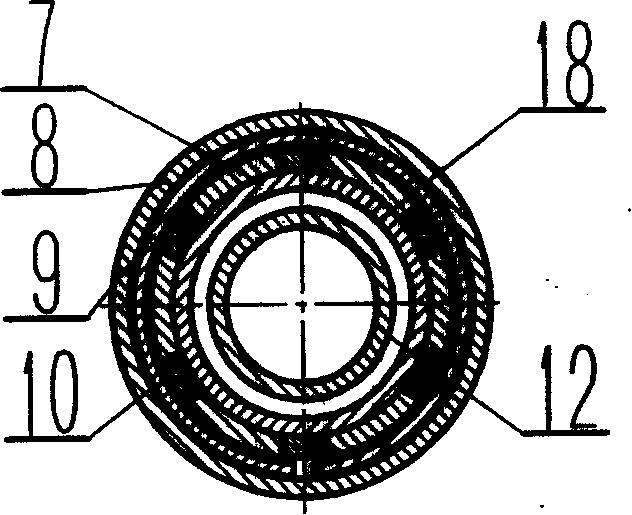

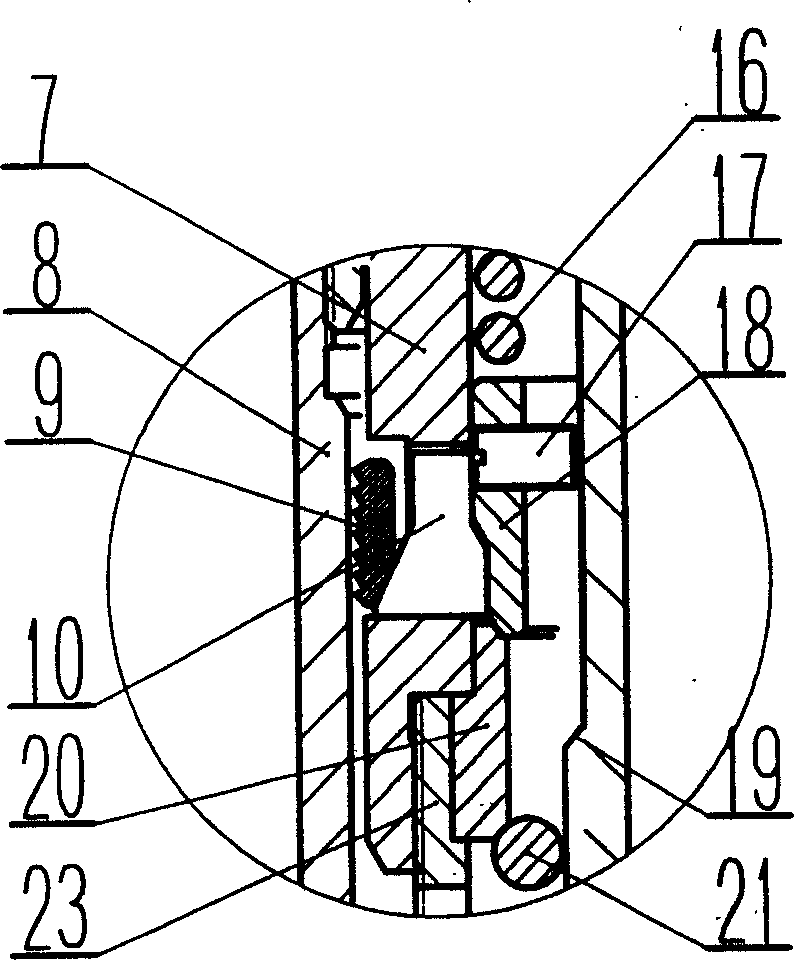

Compression type packer

The compressed packer has one seat sealing mechanism comprising one locking sleeve, one locking ring, one locking ring seat and one central pipe. Inside the locking ring seat, there are wedged locking blocks with outer surface matching the inner conic surface of the locking ring, locking block support sleeve to hold the locking blocks inside the holes of the locking ring seat, return springs, and limit stops. The central pipe has steps for pushing the limit stops to shift upwards. The compressed packer has rigid wedged locking block to replace elastic support pawls, and possesses stable and reliable seat sealing, flexible smooth and reliable locking block desterilizing, and flushing path between the central pipe and the locking block support sleeve for flushing job.

Owner:刘宜贵

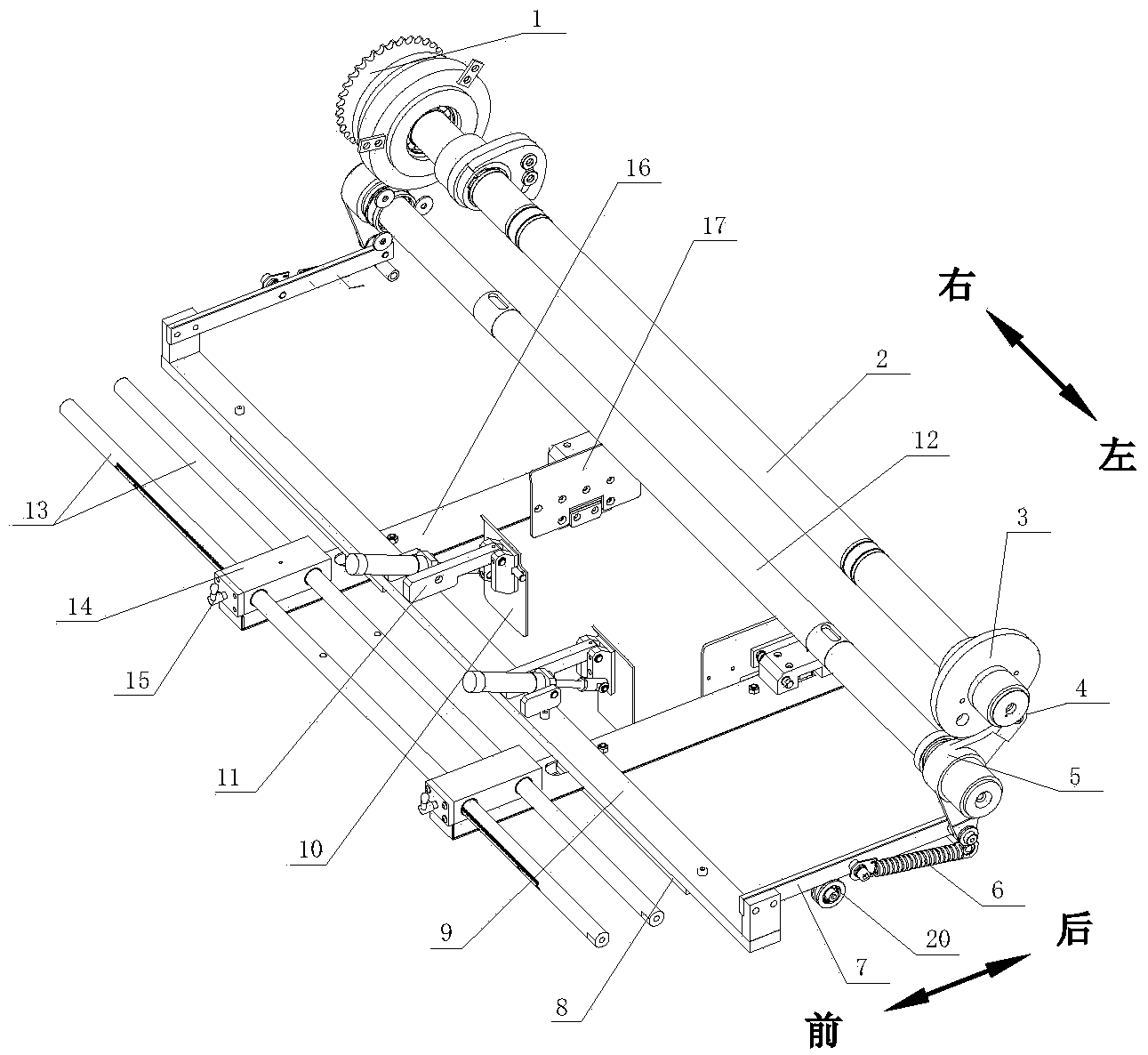

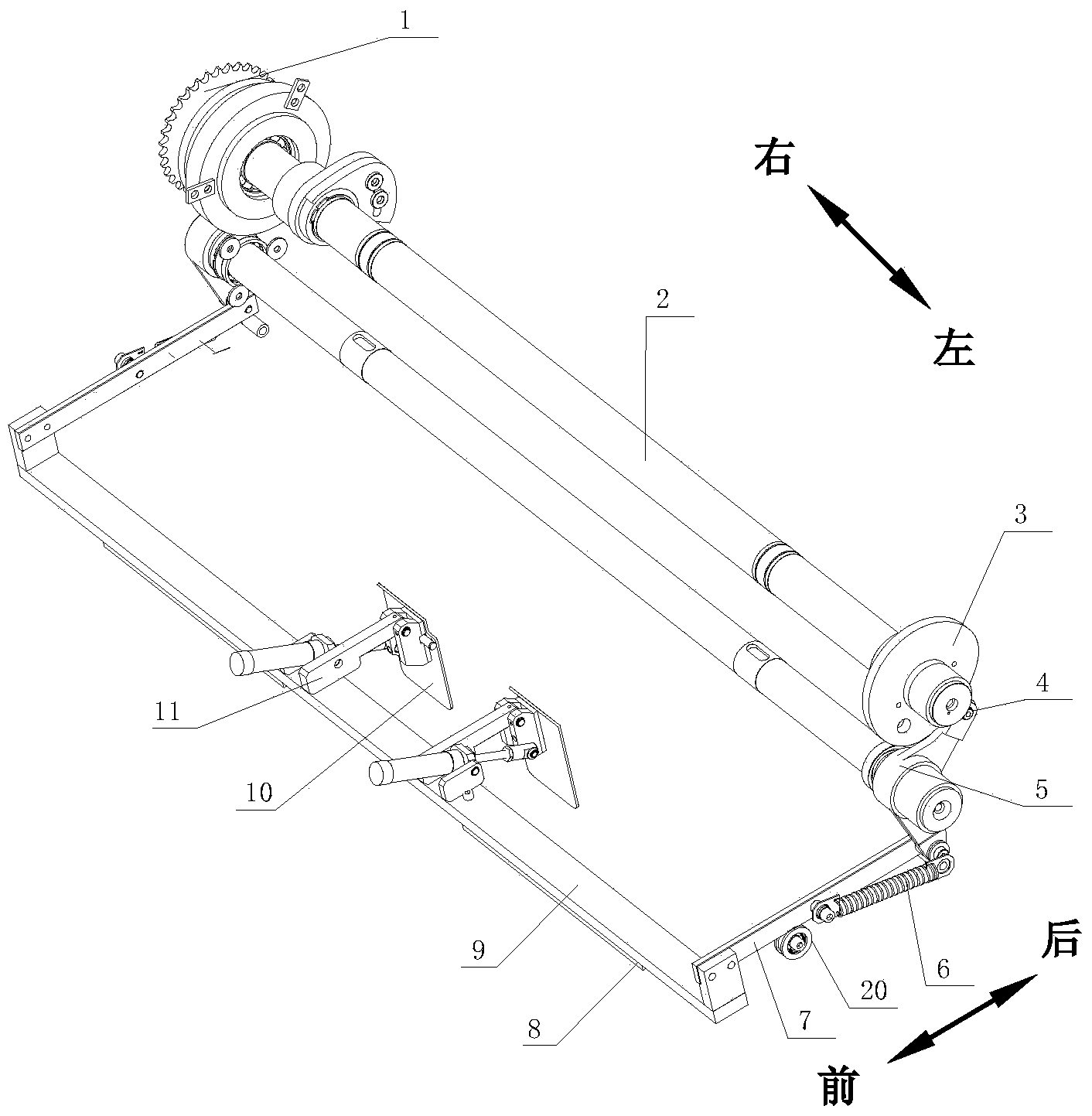

Paper aligning device and working method thereof

The invention discloses a paper aligning device, which is characterized by comprising a power source, a cam connecting rod mechanism, a direction changing mechanism, a front paper aligning device, side paper aligning devices and a breadth adjusting device, wherein the power source is connected with the power input end of the cam connecting rod mechanism; the power output end of the cam connecting rod mechanism is connected with the direction changing mechanism and the front paper aligning device; the side paper aligning devices are connected with the direction changing mechanism; front paper aligning and side paper aligning actions of the front paper aligning device and the side paper aligning devices are realized through the direction changing mechanism by using the same power source; the breadth adjusting device is connected with the side paper aligning devices. In a working method of the paper aligning device, the distance between the two side paper aligning devices is adjusted through the breadth adjusting device; the power source is used for driving the cam connecting rod mechanism to act, and the direction changing mechanism connected with the cam connecting rod mechanism moves together, so that the front paper aligning device and the side paper aligning devices act simultaneously. The paper aligning device has the advantages that paper aligning actions in front / back direction and left / right direction can be finished by using one power source, and the structure is flexible.

Owner:MASTERWORK GROUP CO LTD

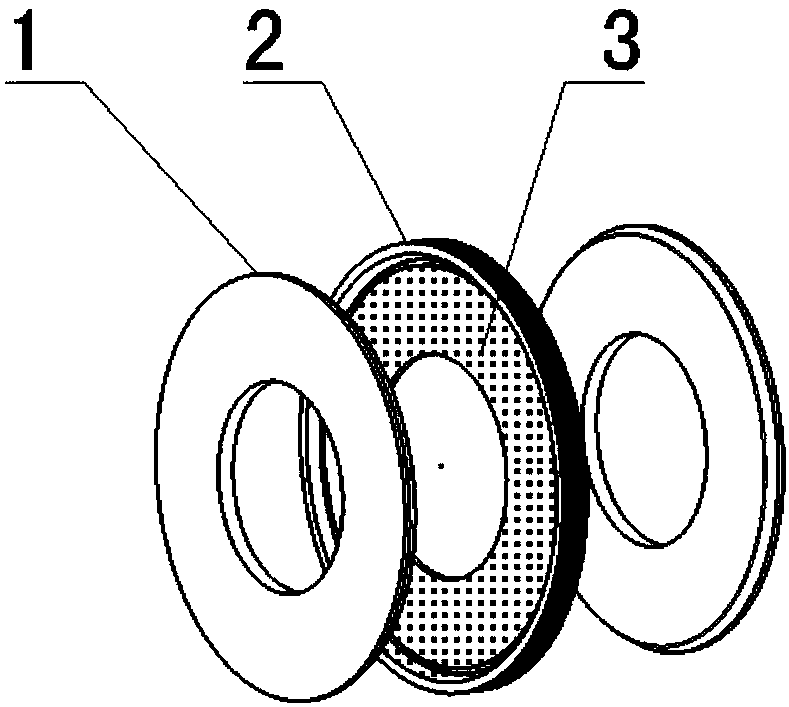

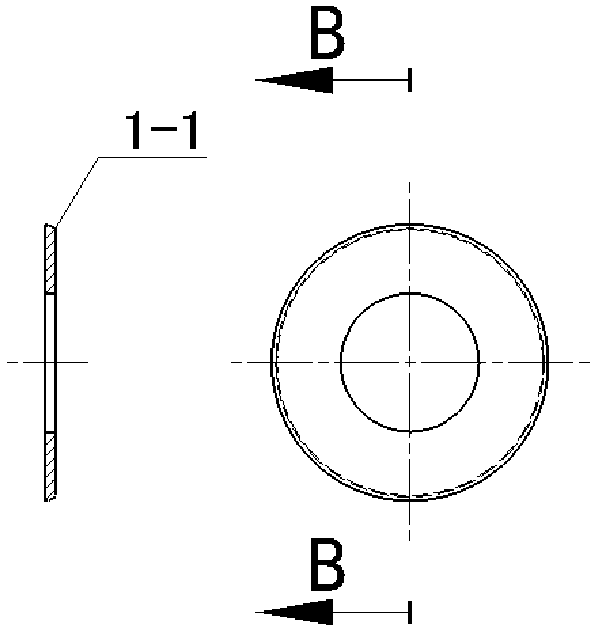

Gasket based on force-induced color change coating

The invention relates to an intelligent lock gasket based on a force-induced color change coating. Safety and reliability of bolt connection are guaranteed. The intelligent lock gasket is composed ofthe force-induced color change coating and a lock gasket body. The force-induced color change coating is arranged at the top end of the gasket body. According to the intelligent lock gasket, safety and reliability of gasket connecting can be achieved, the structural weight is low, and demounting and mounting are convenient; and maintainability is good, and the accident caused by gasket loosening and breakage to key structure connection can be effectively avoided.

Owner:CHENGDU AIRCRAFT DESIGN INST OF AVIATION IND CORP OF CHINA

Walking type high-precision and wide-range displacement detection apparatus

ActiveCN104406839AEliminate clearance errorsHigh precisionStrength propertiesEngineeringMeasurement precision

A walking type high-precision and wide-range displacement detection apparatus belongs to the technical field of mechanical engineering test. The apparatus comprises a measured movement shaft, an axial movement measuring baffle plate, small-range and high-precision displacement sensors, an electric cylinder body, a servo motor and counterweights. The measured movement shaft drives the axial movement measuring baffle plate in the loading process in order to realize downward movement. The contacts of the small-range and high-precision displacement sensors are vertically arranged to detect the displacement change of the axial movement measuring baffle plate. The two small-range and high-precision displacement sensors are positioned in a staggered manner at intervals to guarantee the measuring continuity. The two small-range and high-precision displacement sensors repeatedly alternatively walk and are accurately located and controlled to realize continuous high-precision measurement of wide-range displacement. The apparatus has the advantages of smart structure, reasonable layout, high measuring precision, solving of the high precision measurement problem in a full wide range, and good popularization value.

Owner:DALIAN UNIV OF TECH

Portable cloth inspection mirror

InactiveCN103409981AIncrease brightnessImprove the accuracy of cloth inspectionInspecting textilesMagnifying glassEngineering

The invention relates to a portable cloth inspection mirror which comprises a top plate, a connection rod and a base, wherein a support base is fixed at the bottom end of the connection rod, the top plate is hinged to the top end of the connection rod, and the base is hinged to a support base. A magnifying glass is installed on the top plate, a light-emitting diode (LED) lamp is arranged on the back surface, and a power source and a switch are installed on the inner side of the support base. A movable scaleplate is hinged to one side of the base and can rotate for 180 degrees in the horizontal direction. The light source is arranged on the top plate and directly irradiates on an observation area on the base, brightness of the observation area can be increased, cloth inspection accuracy is improved, meanwhile the height of the connection rod can be adjusted according to requirements, and the portable cloth inspection mirror is convenient to use, foldable in all parts, flexible in structure and convenient to carry.

Owner:WUJIANG QINGYI TEXTILE

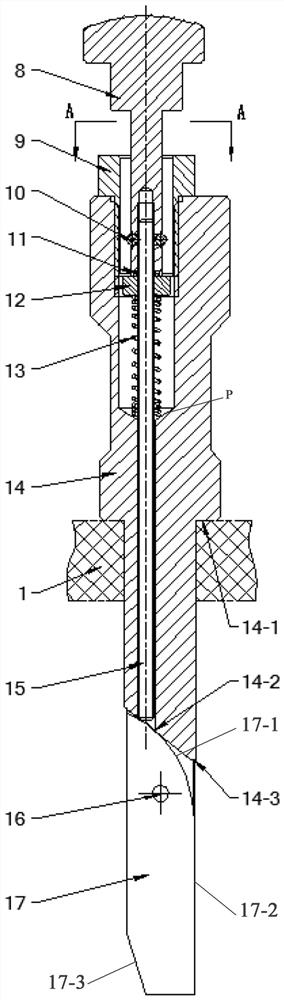

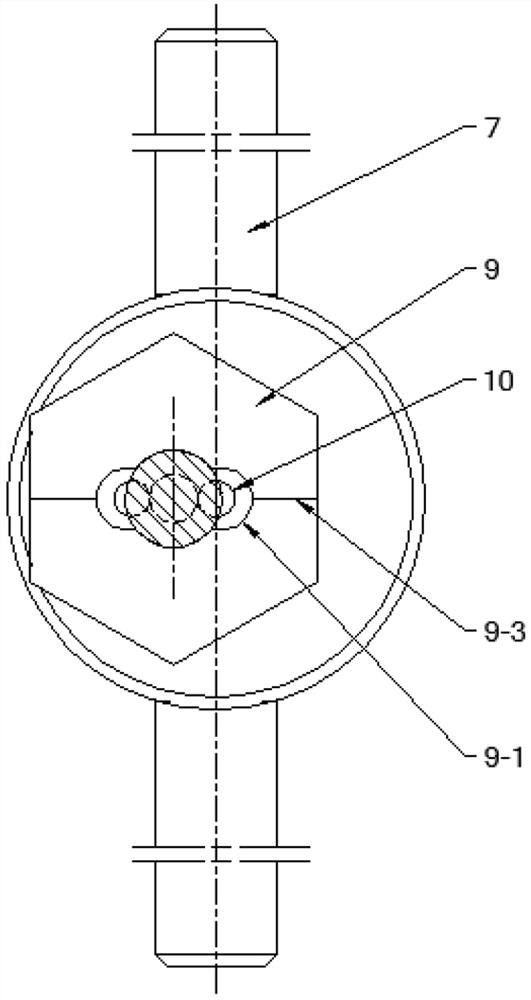

Emergency unlocking device for electronic well lid

ActiveCN111706175ASmart structureImprove securityArtificial islandsNon-mechanical controlsElectric machineryStructural engineering

The invention relates to an emergency unlocking device for an electronic well lid. A limiting screw of the emergency unlocking device is fixed in a sleeve, a handle shaft is arranged in the limiting screw, the limiting screw is in clearance fit with the handle shaft, the shaft end of the lower portion of the handle shaft is fixedly connected with one end of an ejector rod, the other end of the ejector rod penetrates through a spring arranged in an inner hole of the sleeve to be in contact connection with a shifting piece, one end of the spring is connected with the end face of a positioning nut screwed on the ejector rod, the other end of the spring is connected with the conical surface P of the inner hole of the sleeve, the shifting piece is rotationally connected with the bottom end of the sleeve, and the inner hole of the sleeve is of an eccentric structure. The emergency unlocking device is ingenious in structure, a mechanical emergency opening device is adopted, and once an intelligent control module or a motor of the electronic well lid accidentally fails, the emergency unlocking device can be inserted into an emergency opening hole of the well lid outside a well, a well lidlock is opened, the well lid lock cannot be opened by inserting other existing tools, the safety is high, and the purposes of safety and theft prevention are achieved.

Owner:沈阳达能电安全高新产业技术研究院有限公司

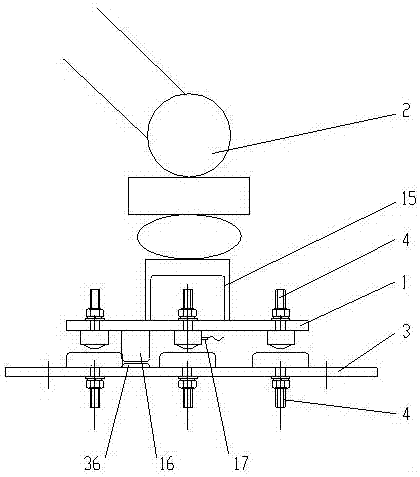

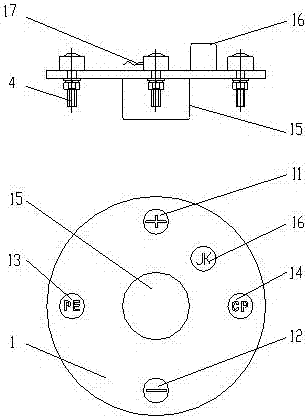

Intelligent contact disk device and control method

InactiveCN107994370AGreat suctionReduce volumeEngagement/disengagement of coupling partsVehicle connectorsPower batteryProximity sensor

The invention relates to a power battery charging device and a power battery charging method. An intelligent contact disk device comprises a current collecting disk (1) and an incoming panel (3); theincoming panel is located at a vehicle-mounted side, the current collecting disk is located at the charging device side and installed at the top part of a mechanical arm (2) of a robot device; the incoming panel and the current collecting disk comprise four contacts which are high voltage position terminals (11, 31), high voltage negative terminals (12, 32), grounding terminals (13, 33) and control terminals (14, 34). A suction coil (15), an approach sensor (16) and a temperature sensor (17) are mounted on the current collecting disk, the center part of the current collecting disk is the suction coil, and four contacts are distributed at four sides; the temperature sensor is arranged on the high voltage positive terminals and the high voltage negative terminals; the approach sensor is installed at the gap of for contacts; the center part of the corresponding incoming panel is a suction armature (35), and four sides therefore are distributed with four contacts; a sensing plate of the approach sensor (36) is located in the gap of four contacts, and the incoming panel is further equipped with a positioning mark (37).

Owner:齐洪元 +1

Multifunctional electret generator based on permanent magnetic suspension gyroscope

ActiveCN110474558AIncrease the rate of change of intrinsic capacitanceAvoid stress concentrationInfluence generatorsFriction generatorsAC powerDynamo

A multifunctional electret generator based on a permanent magnetic suspension gyroscope includes a vibration pickup rotor component and an external fixed component. A structure formed by assembling atriangular permanent magnet, an insulating substrate, a positioning baffle, and a fixing magnet cover in accordance with an assembly order is called the external fixed component. A structure formed byassembling a blade rotor, a vibration pickup rotor, and two annular permanent magnets in accordance with an assembly order is called the vibration pickup rotor component. By adjusting the positions of the triangular permanent magnet and the annular magnets, the vibration pickup rotor component can be suspended over the external fixed component under the point contact limitation of the positioningbaffle. By using the power generation principle of the electret film electrostatic induction, charges are injected into an electret film so as to generate a bias voltage on a substrate electrode covered by the vibration pickup rotor, thereby outputting AC power to an external circuit. Mechanical vibration energy, wind energy and hydraulic energy are converted into electric energy. The multifunctional electret generator has good output characteristics, a simple structure, low damping, a wide frequency band, and excellent durability and dexterity.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Jaw-type pipe coupler with simple structure

InactiveCN101576188ASolve the problem of accurate positioningResolving fast auto joinsCouplingsHydraulic cylinderOcean bottom

The invention provides a jaw-type pipe coupler with a simple structure, which comprises a flange body which is welded at the end part of a pipe to be coupled and fixed with an end cover of the coupler; the end cover of the coupler is fixedly connected with a seal gland; jaws are evenly distributed around the flange body; a jaw drive ring is arranged between the jaws and the seal gland; the pipe to be coupled is fixed with a round plate which is connected with an outer sleeve of a jaw connecting device; a drive hydraulic cylinder is arranged on the round plate; a rod of the drive hydraulic cylinder is connected with an annular plate; and a convex ring of the jaw drive ring is clamped in an annular groove of the annular plate. The jaw-type pipe coupler is used for fast automatic coupling of pipes in deep-water ocean, which causes the jaws to be located accurately, reduces impact on original jaws during moving, greatly simplifies the mechanism of the jaw-type coupler, realizes the possibility of production and serialization, requires no grasping force continuously provided by the outside when connecting the jaws, and realizes reliable grasping by the self-locking of the drive ring and the combination surface of the jaws.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com