Paper aligning device and working method thereof

A paper-aligning and front-aligning technology, which is applied in the field of paper-aligning devices, can solve the problems of slow movement, irregular paper-aligning, and poor paper-aligning effect, and achieves a smart structure, good paper-aligning effect, and convenient width adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

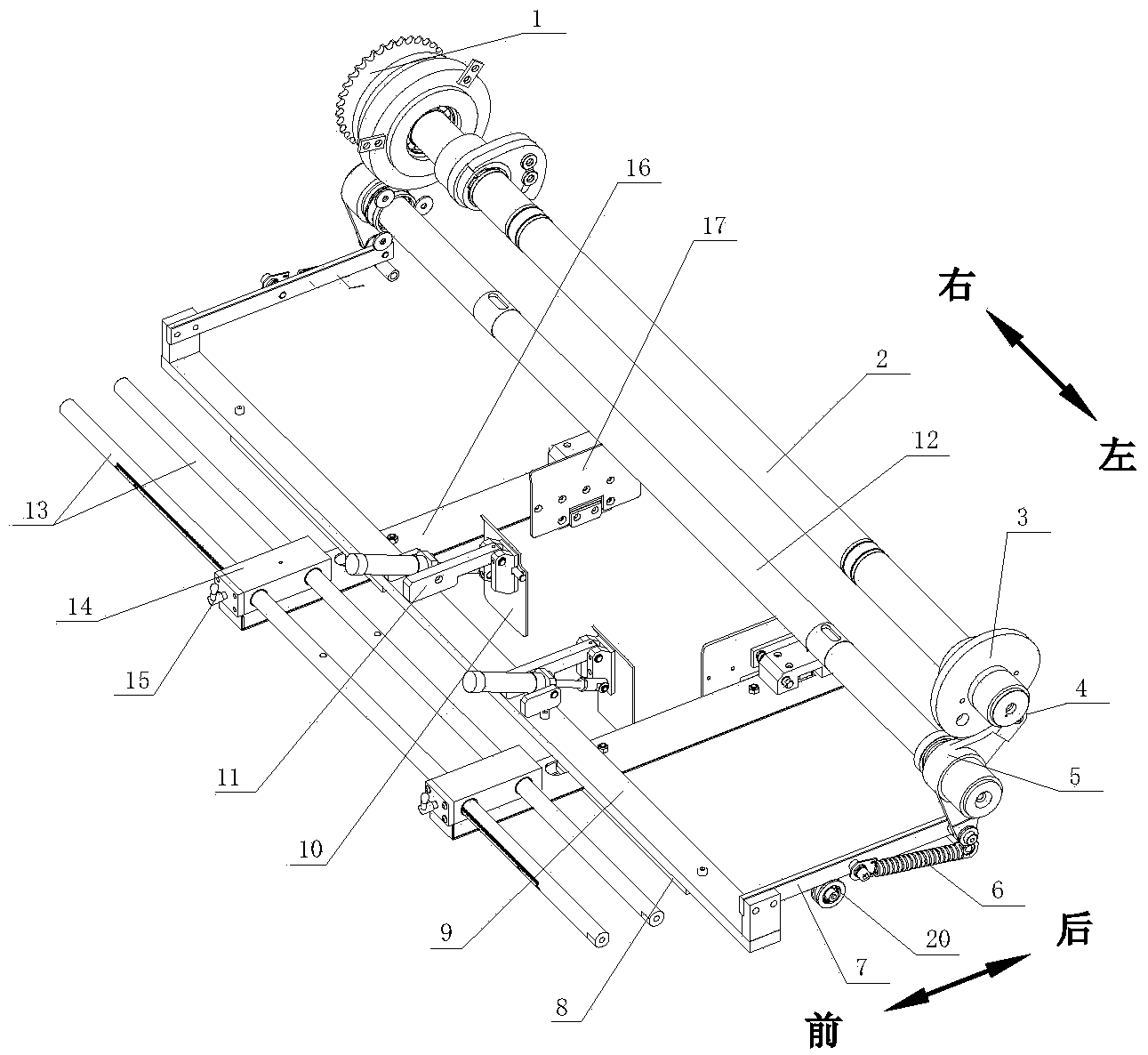

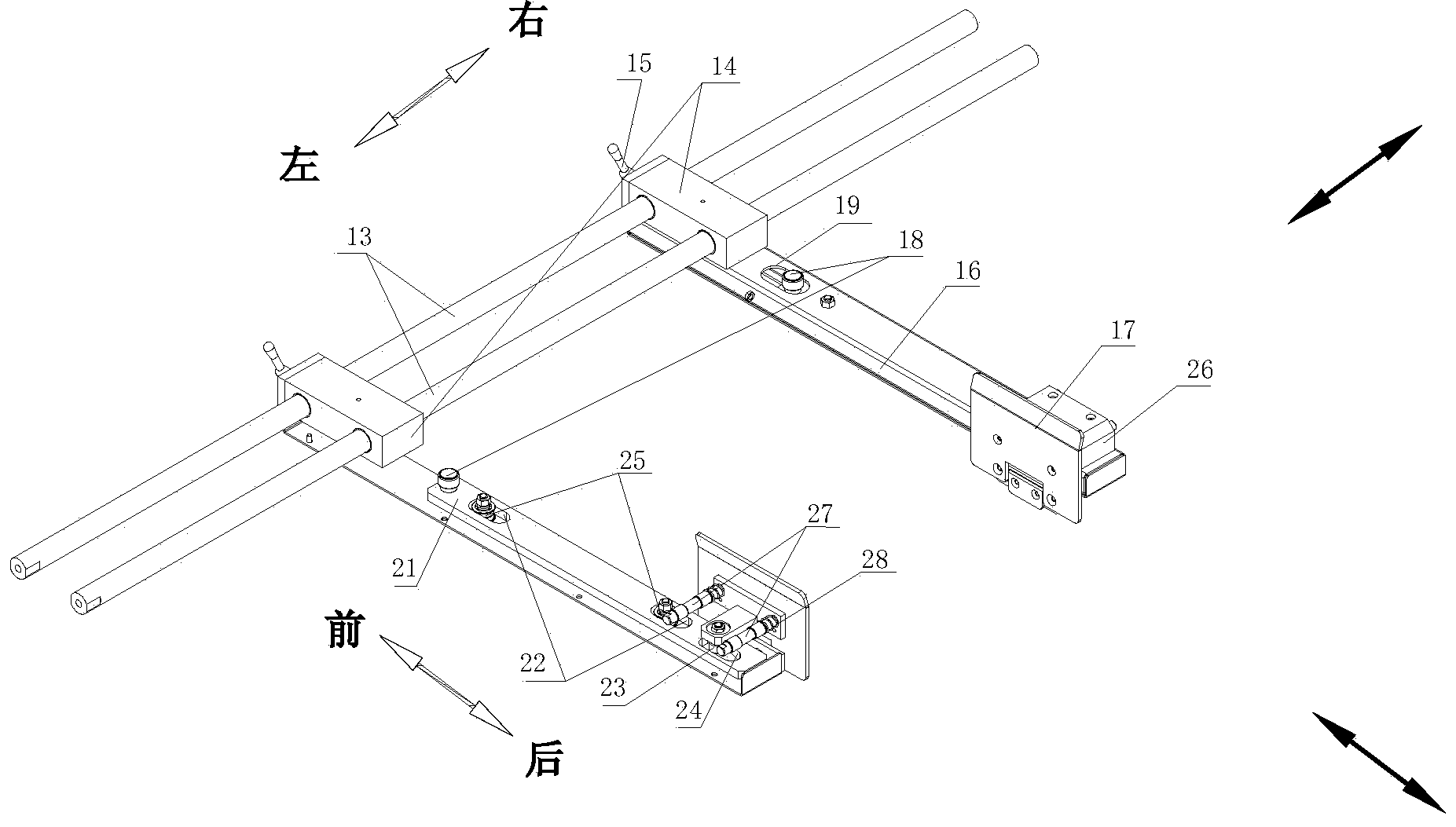

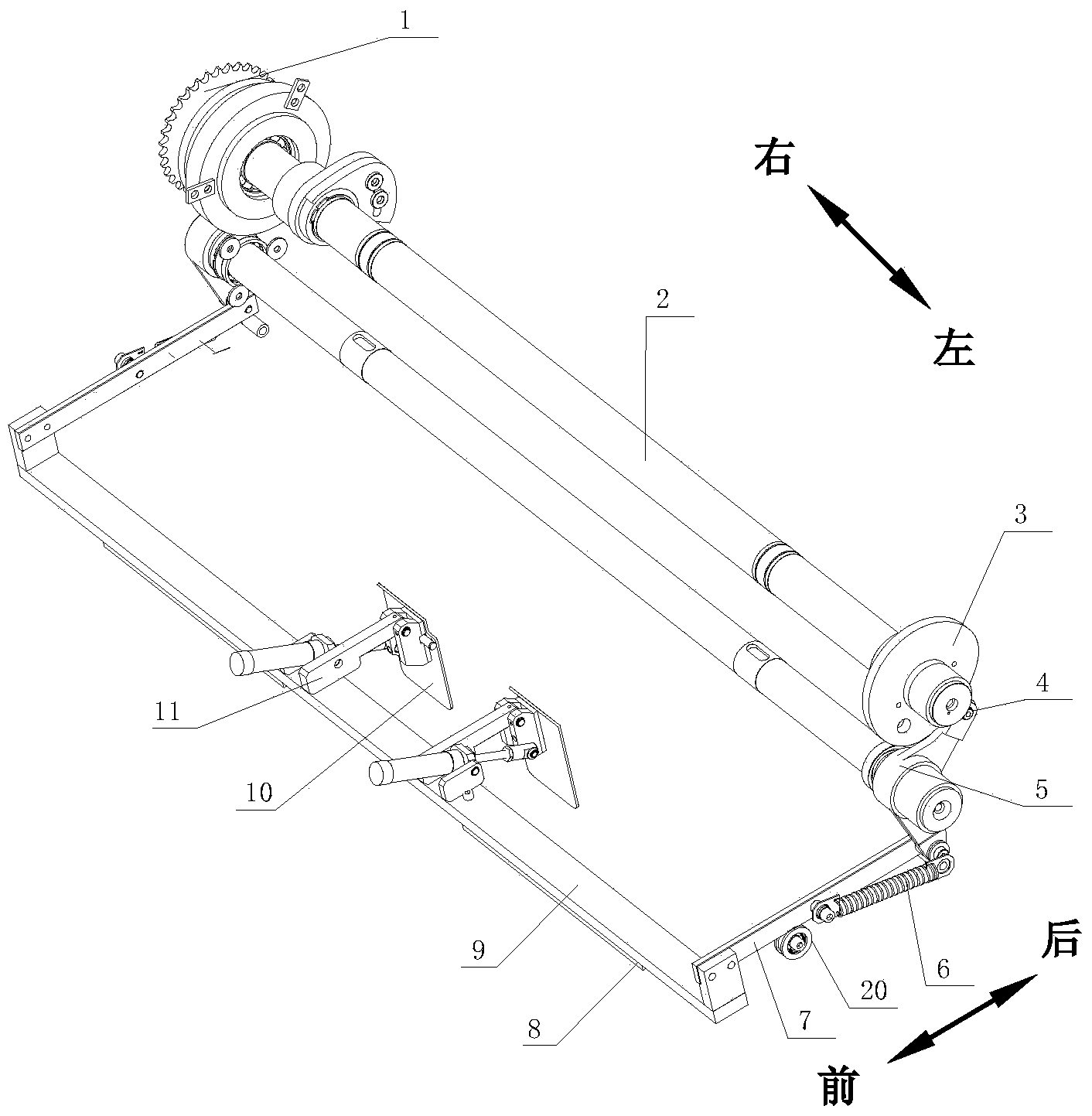

[0027] Embodiment: a kind of paper aligning device (see Figure 1 to Figure 4 ), which is characterized in that it includes a power source, a cam linkage mechanism, a direction conversion mechanism, a front paper jogging device, a side paper jogging device and a width adjustment device; the power source is connected to the power input end of the cam linkage mechanism; the cam The power output end of the link mechanism is connected to the direction conversion mechanism and the front paper jogging device; the side paper jogging device is connected to the direction conversion mechanism; Actions of paper and side jogging; the web adjusting device is connected with the side jogging device.

[0028] The cam link mechanism includes a cam 3, a swing rod 5, a connecting rod 7, a fixed cross bar 9 and a swing rod reset device, and the direction conversion mechanism includes a chute 8, a connecting square tube 16, a follower bearing I18, a long groove Ⅰ19, direction conversion lever 21,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com